Quick generation method of three-dimensional printing slice contour of triply periodic minimal surface

A technology of extremely small curved surface and three-dimensional printing, which is applied in manufacturing auxiliary devices, processing data acquisition/processing, additive processing, etc., can solve the problems of low slicing efficiency, large memory consumption, etc., achieve efficient generation, stable and reliable methods, and save Effect of processing time and memory consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

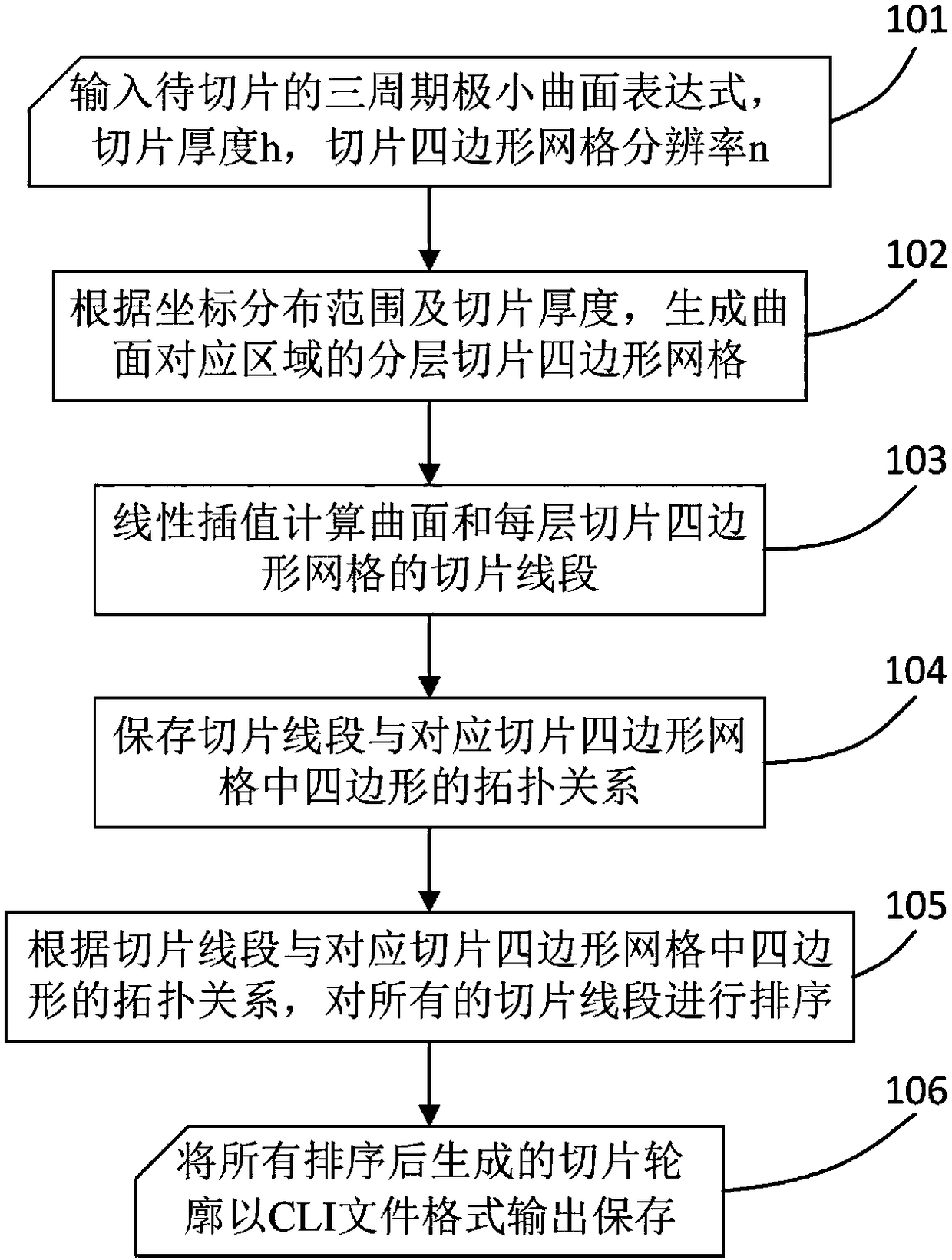

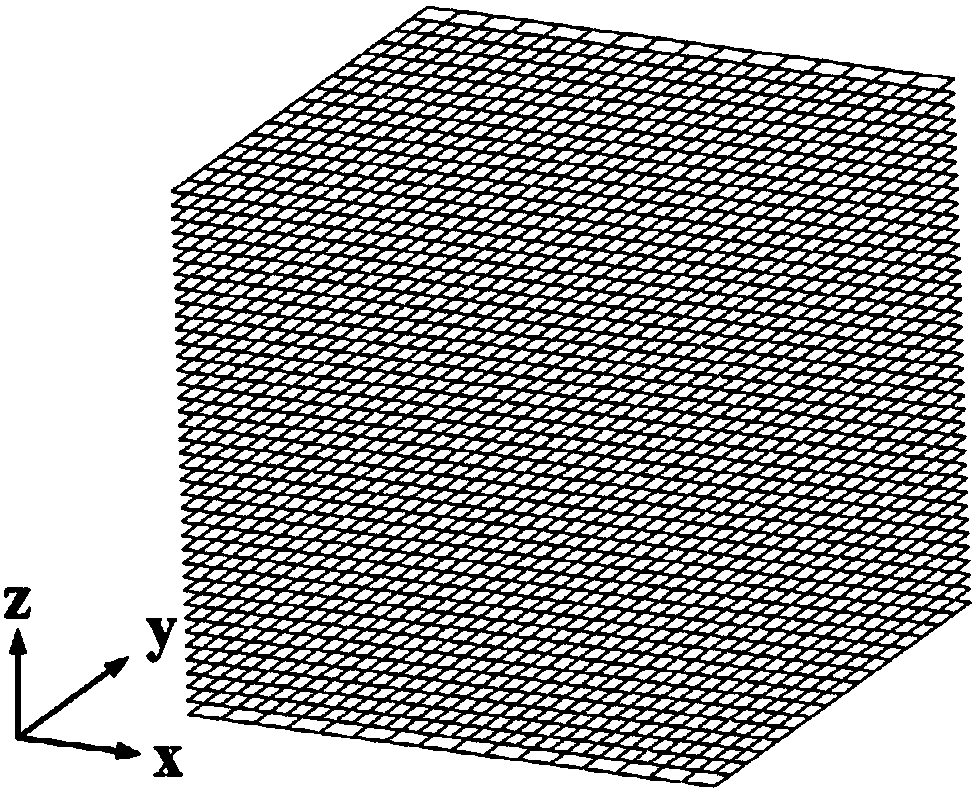

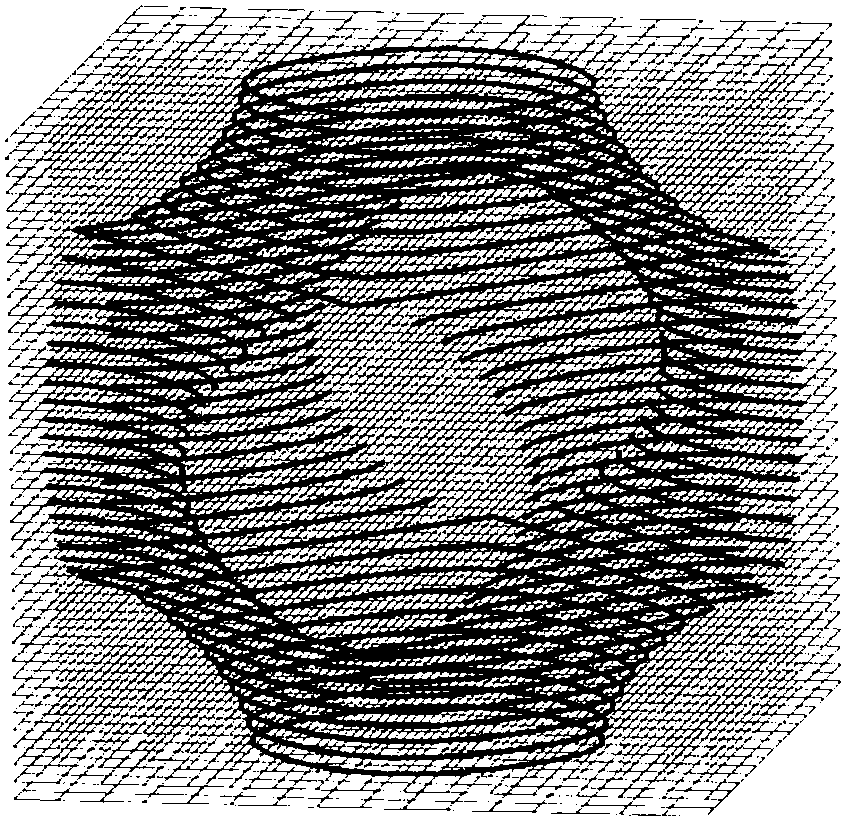

[0063] Typical implementation examples of the present invention are as follows:

[0064] Input the three-period minimal surface P surface function expression to be sliced as f(x,y,z)=cos(0.25πx)+cos(0.25πy)+cos(0.25πz)=0, x∈[0,8 ], y∈[0,8], z∈[0,8], slice thickness h=0.2mm, set different grid resolutions n to get different numbers of slice line segments, and get slice contours with different precision after sorting the slice line segments , to generate a slice CLI file and save it.

[0065] Test the slicing time difference between the fast slicing method and the traditional slicing method on a computer with an Intel Xeon CPU@3.40GHz and 8GB of memory. Such as Figure 4 As shown, fast slicing is obviously more efficient than the traditional method of first generating a three-period minimal surface STL model and then slicing, and it also saves the memory consumption of saving STL files.

[0066] In addition, in terms of slice line sorting, as shown in Figure 5(a), the quick...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com