3D (three-dimensional) printing adaptive slicing method capable of reserving model features

A 3D printing, self-adaptive technology, applied in the field of 3D printing, can solve the problems of increasing printing time, increasing the number of layers, and not being able to deal with the loss and offset of model features, so as to reduce the number of layers, reduce printing time, and reduce memory The effect of usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

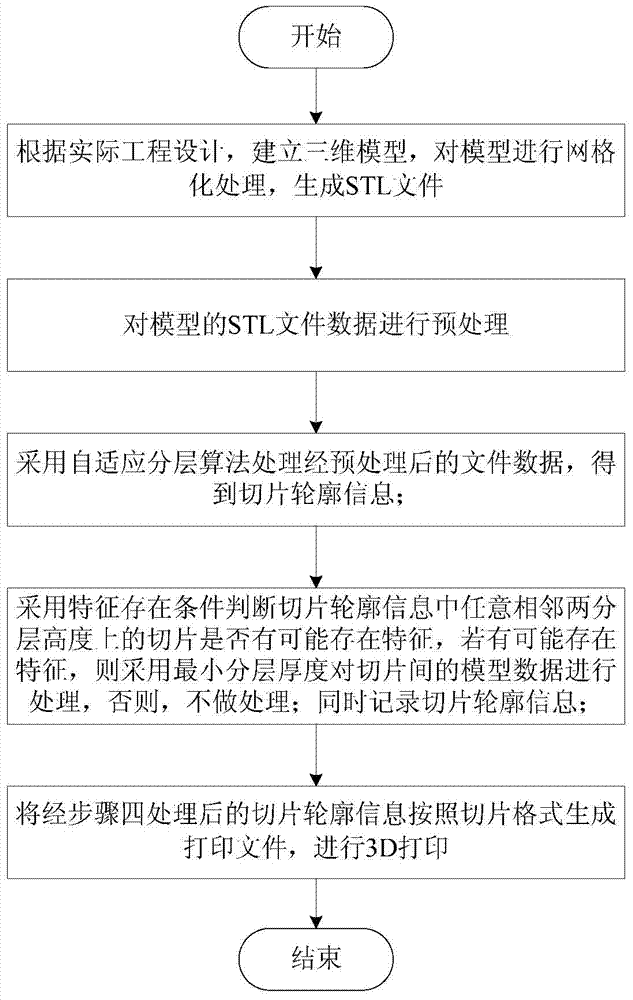

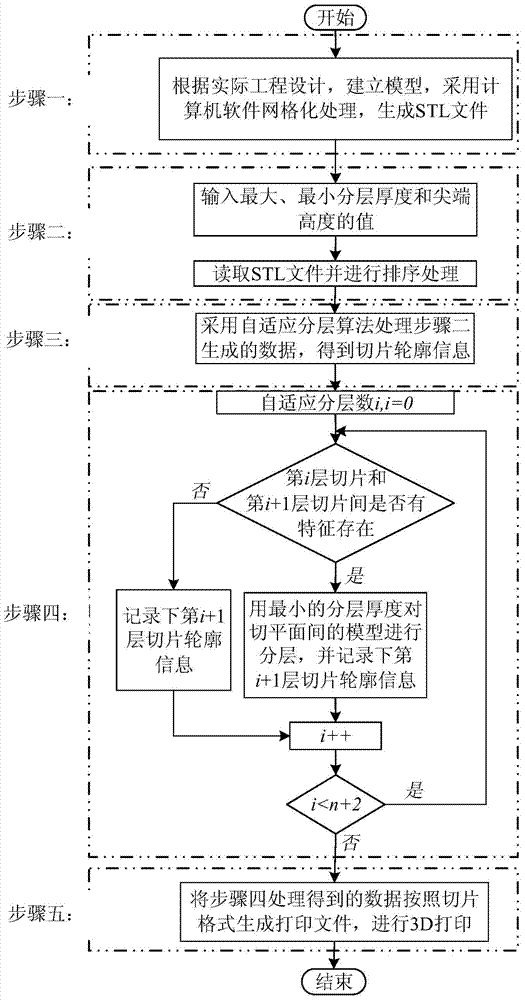

[0041]A 3D printing adaptive slicing method that retains model features provided by the present invention, such as figure 1 with figure 2 As shown, the party specifically includes the following steps:

[0042] Step 1: According to the actual engineering design, use computer software to establish a three-dimensional model, and perform grid processing on the model to generate STL file data;

[0043] The STL file data includes three-dimensional coordinates of three vertices and unit normal vector data of all triangular faces generated after meshing.

[0044] Step 2: Preprocessing the STL file data of the model; specifically, the following steps are included:

[0045] 1) The user specifies the maximum and minimum layer thickness (l max = 10mm, l min =1mm) and the value of tip height c, such as c=0.8mm;

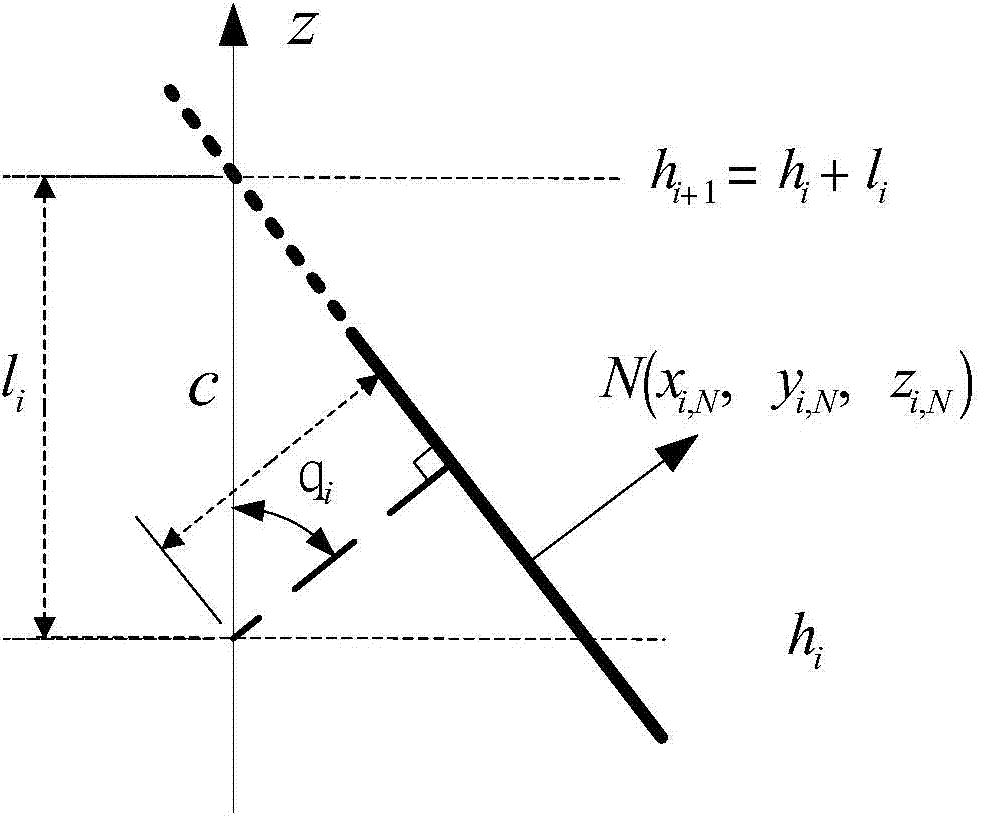

[0046] 2) Sorting and preprocessi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com