Patents

Literature

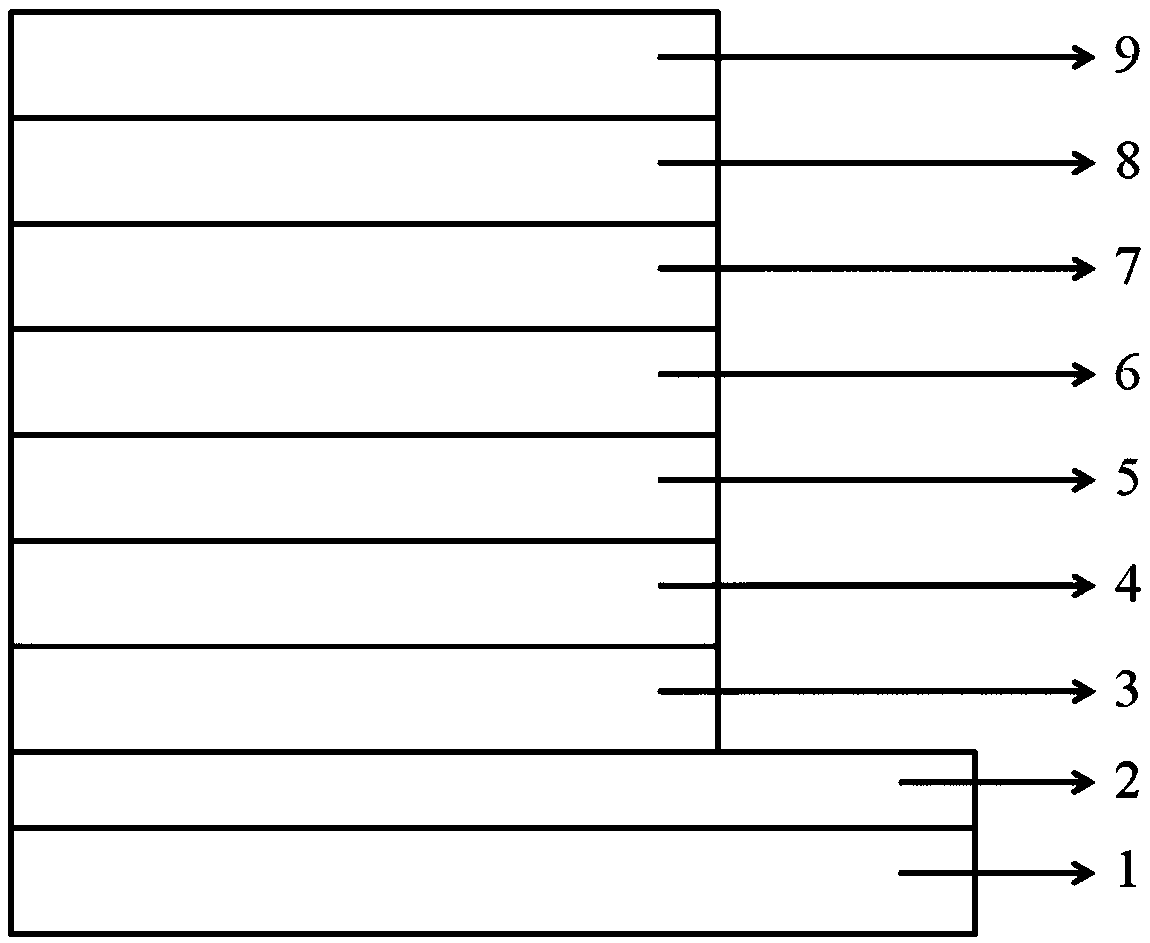

306results about How to "Resolve offset" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electroluminescence device based on boron-containing organic compound

ActiveCN110492006AImprove efficiencyExtend your lifeSolid-state devicesSemiconductor/solid-state device manufacturingOrganic light emitting deviceCharge carrier

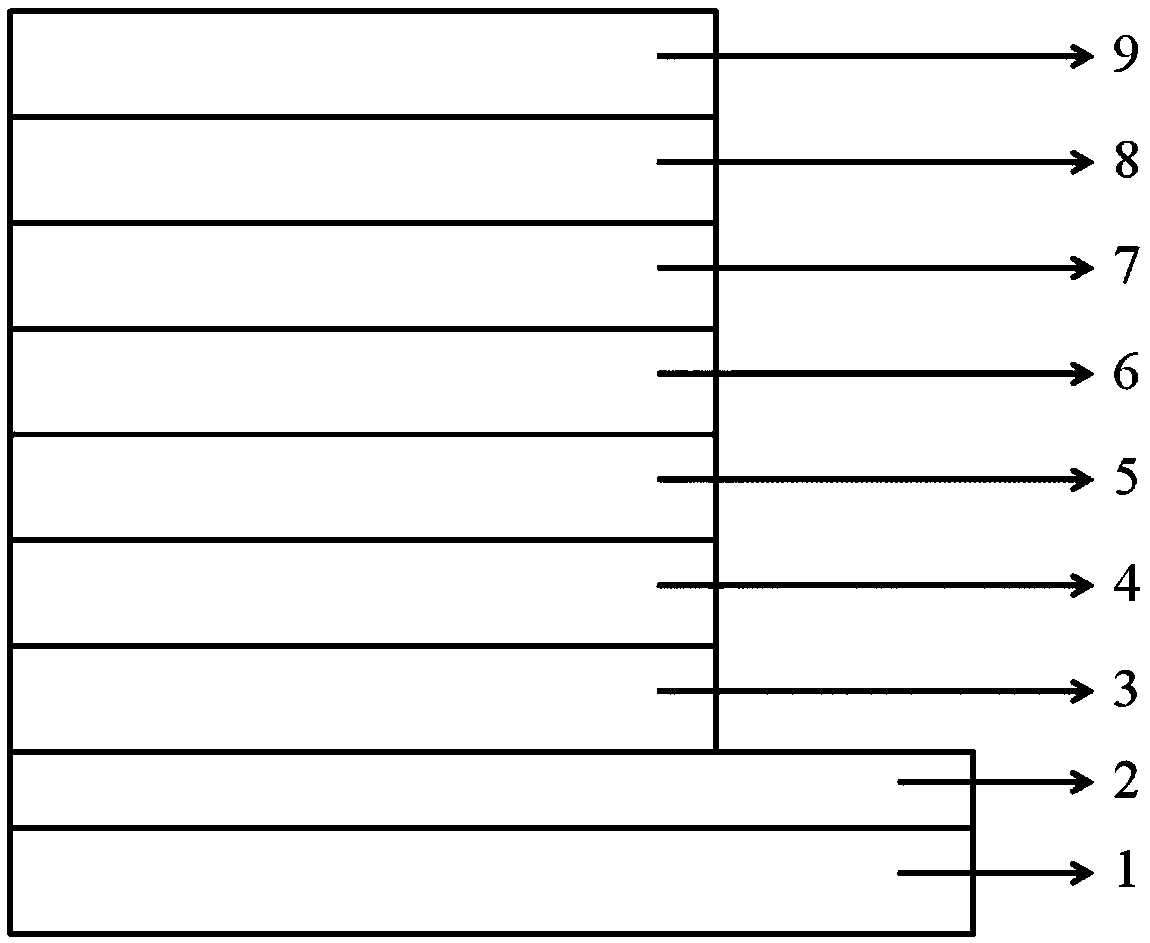

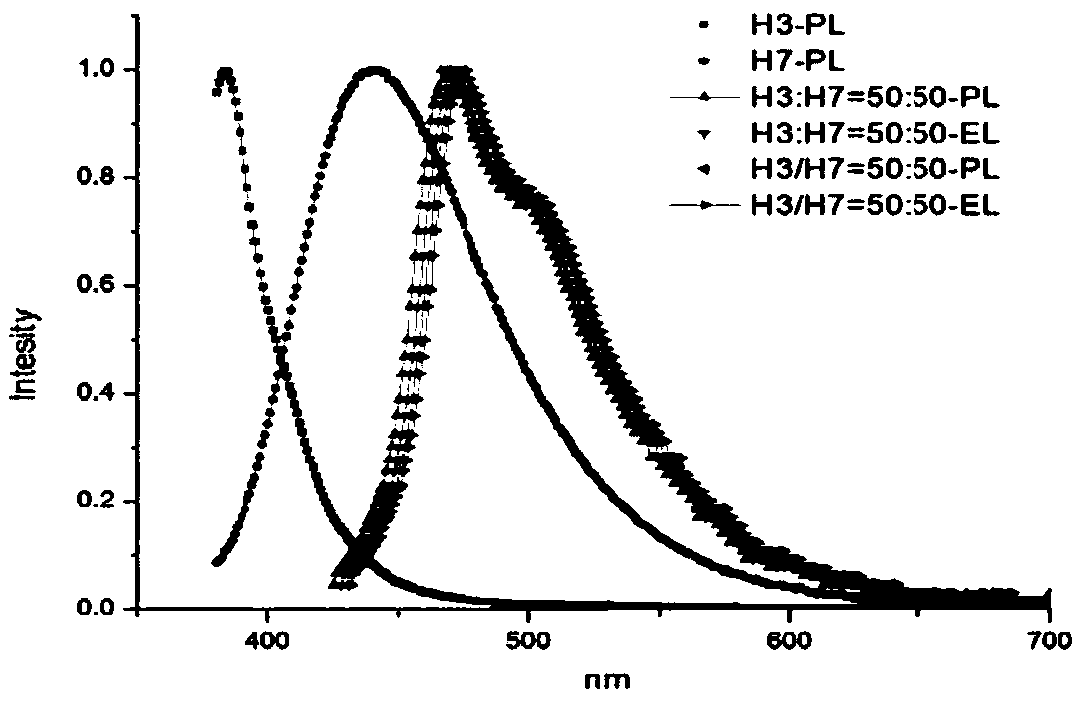

The present invention relates to an electroluminescence device based on a boron-containing organic compound, wherein a main body material comprises a first organic compound and a second organic compound, the difference between a singlet state energy level and a triplet state energy level of the first organic compound is not greater than 0.2 eV, the singlet energy level of the second organic compound is greater than the singlet energy level of the first organic compound by more than 0.1 eV, and the triplet energy level of the second organic compound is greater than the triplet energy level of the first organic compound by more than 0.1 eV; the first organic compound and the second organic compound have the different carrier transport characteristics, wherein an object material is the boron-containing organic compound, the singlet energy level of the object material is lower than that of the first organic compound, and the triplet energy level of the object material is lower than that ofthe first organic compound. An organic light-emitting device prepared by the method has the characteristics of high efficiency and long service life.

Owner:JIANGSU SUNERA TECH CO LTD

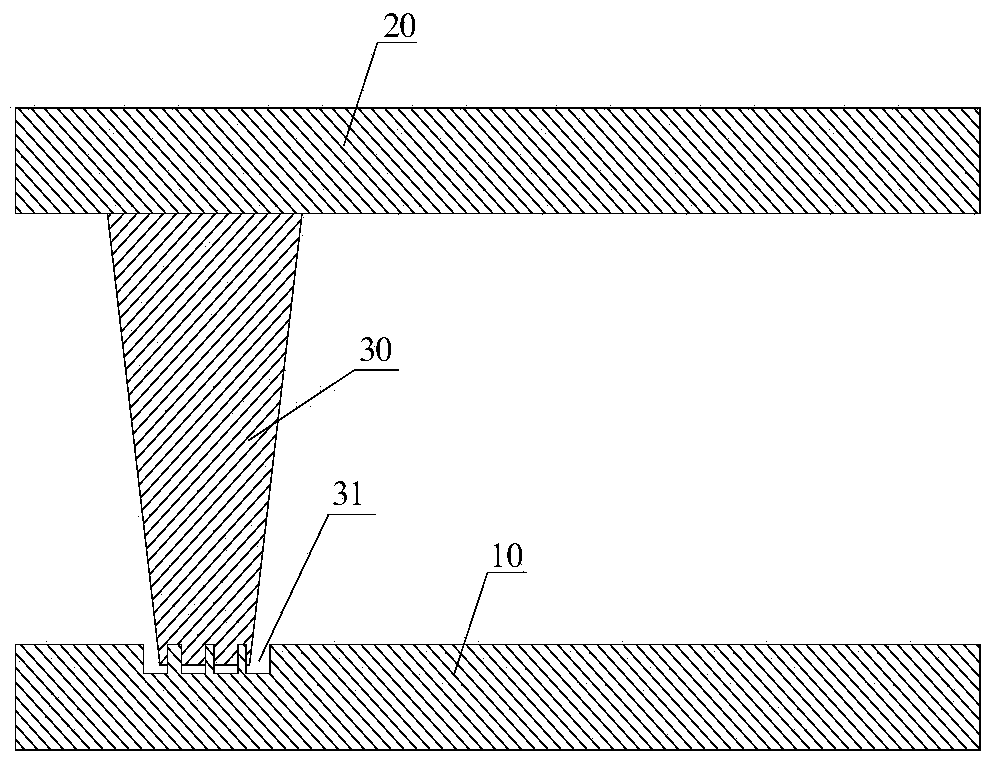

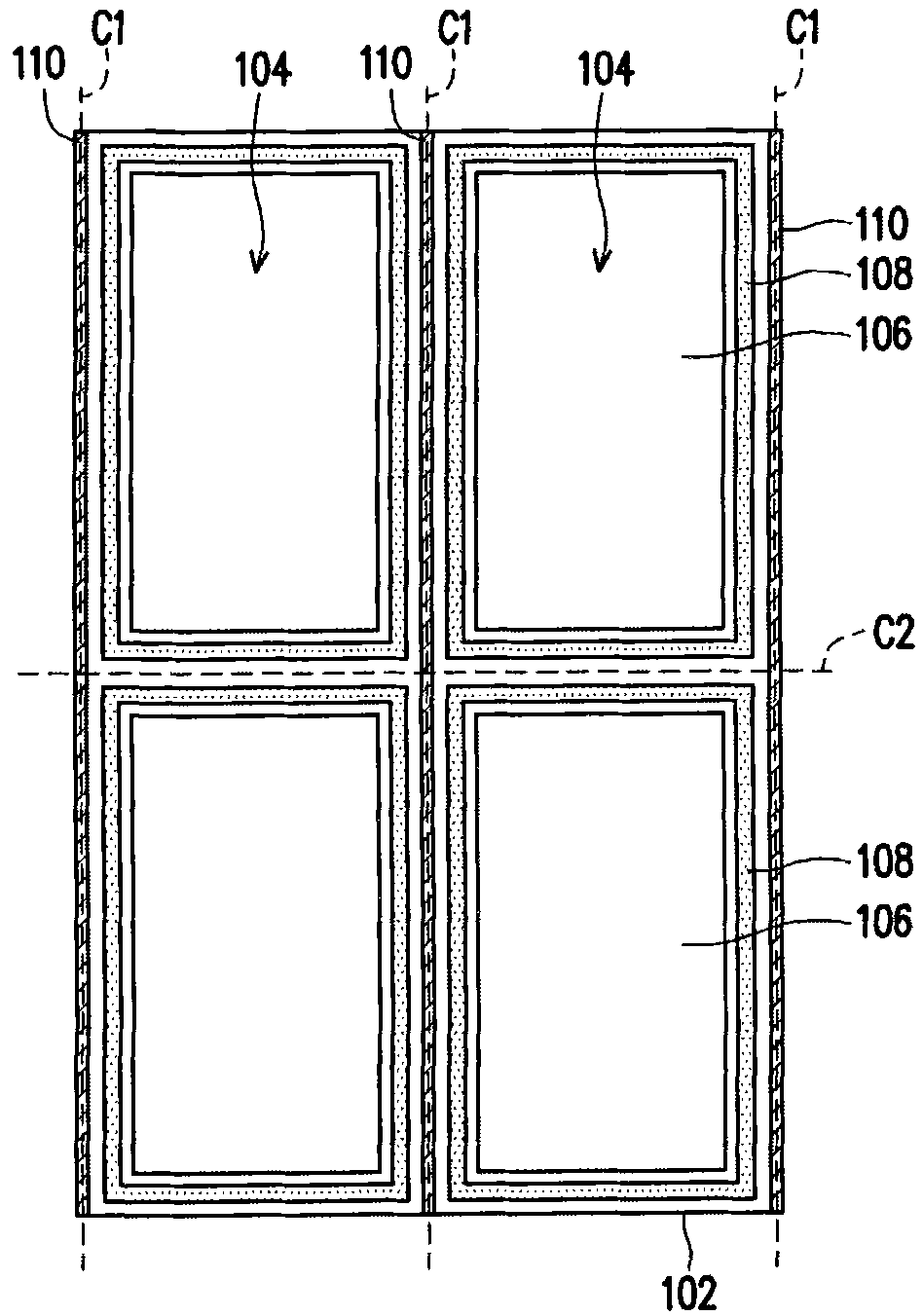

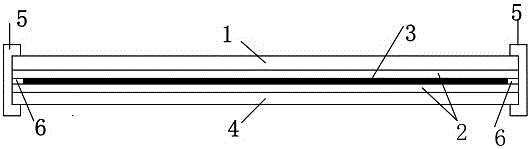

Display panel, manufacturing method thereof and display device

InactiveCN103885251AEasy to fixStable positionThin material handlingNon-linear opticsDisplay deviceEngineering

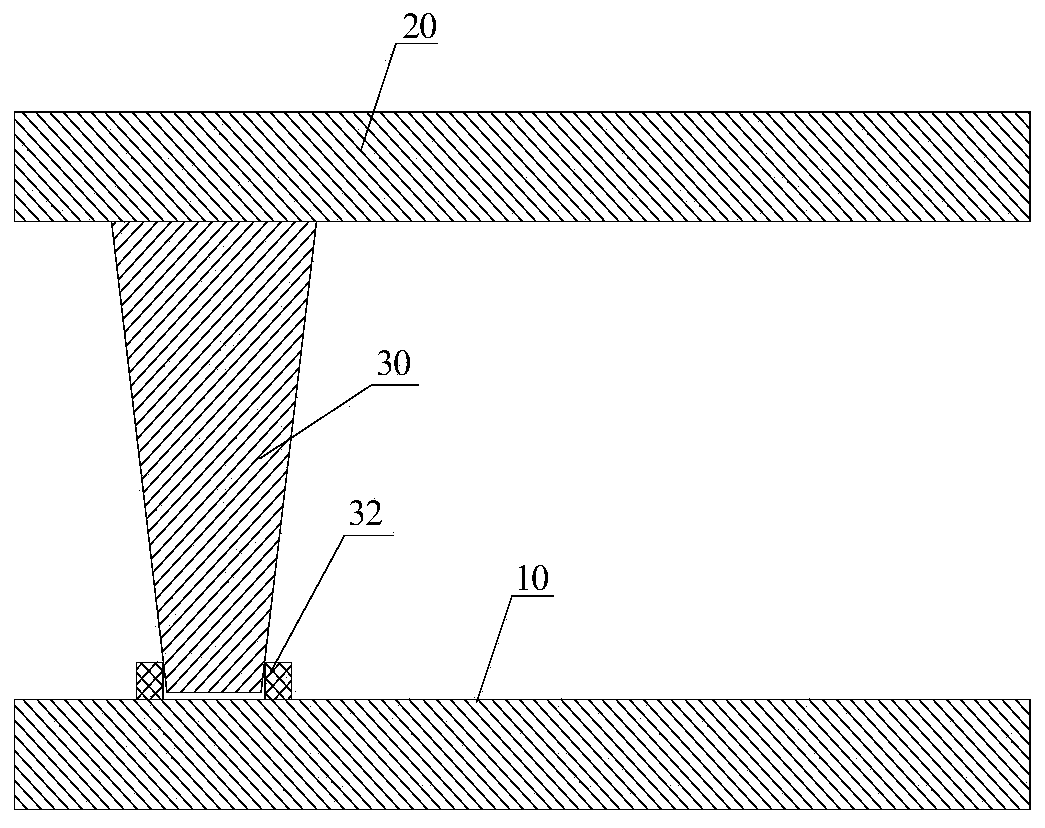

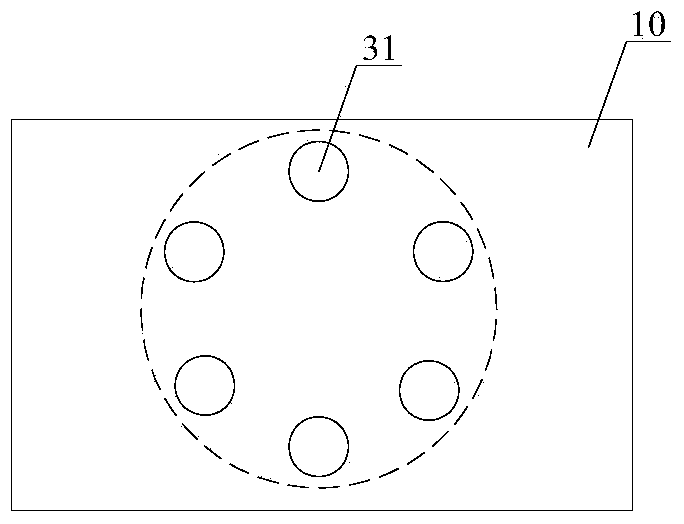

The invention provides a display panel. The display panel comprises an array substrate and a box aligning substrate, wherein the array substrate and the box aligning substrate are oppositely arranged. A spacer is arranged between the array substrate and the box aligning substrate, one end of the spacer is arranged on one of the array substrate and the box aligning substrate, a microstructure is arranged on the other of the array substrate and the box aligning substrate, and the other end of the spacer makes close contact with the microstructure. Correspondingly, the invention further provides a manufacturing method of the display panel and a display device. According to the display panel, the manufacturing method of the display panel and the display device, the problem that in the prior art, the array substrate and the box aligning substrate may deviate when the display panel is moved can be solved, the alignment accuracy of the array substrate and the box aligning substrate can be guaranteed, and the phenomenon of cross color when the display panel is used for displaying pictures is avoided.

Owner:BOE TECH GRP CO LTD +1

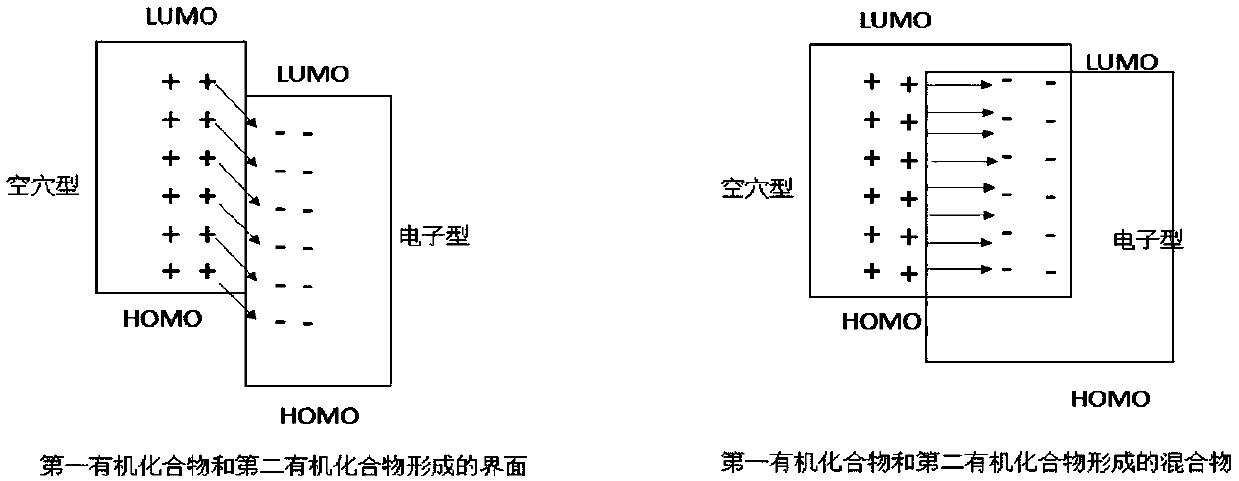

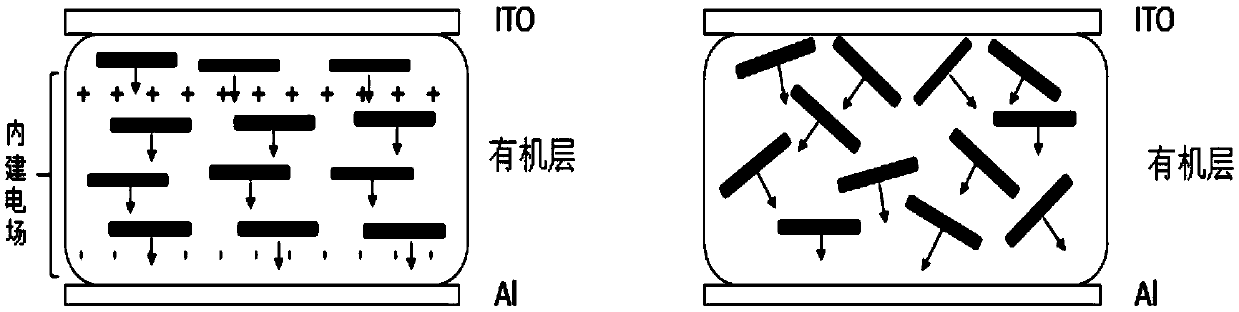

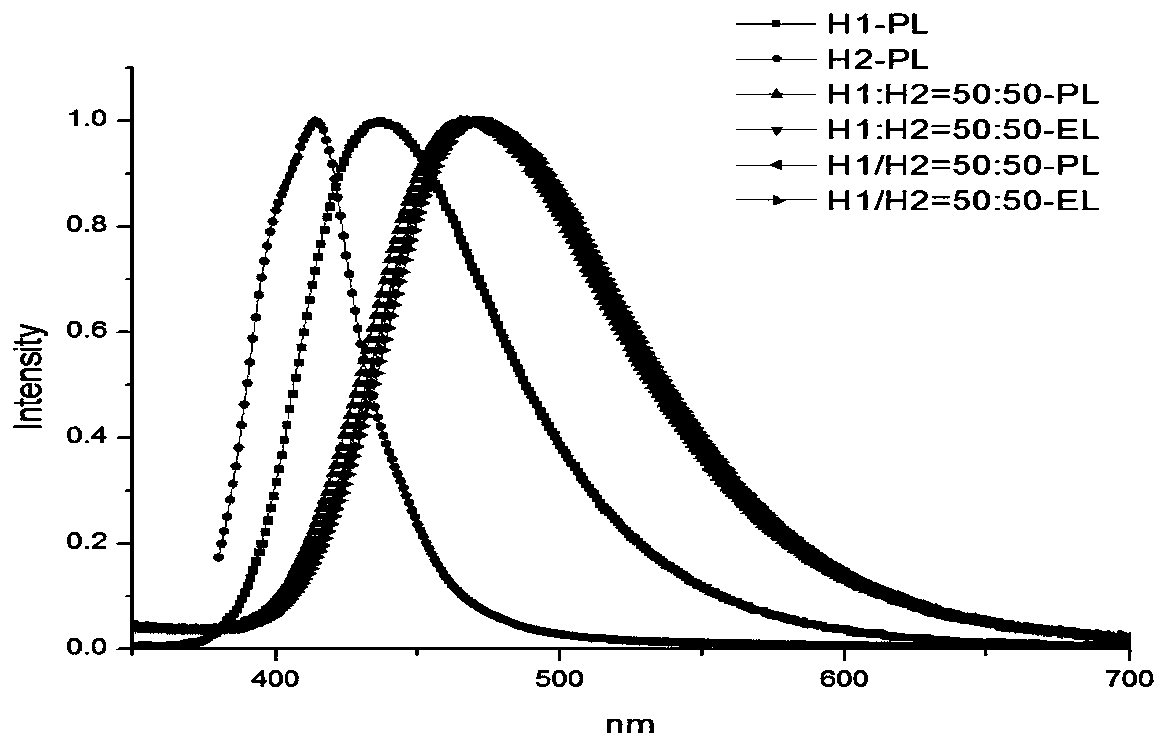

Organic light-emitting device taking exciplex as main body material

ActiveCN110492005AImprove stabilityReduce concentrationSolid-state devicesSemiconductor/solid-state device manufacturingSimple Organic CompoundsLight excitation

The invention relates to an organic light-emitting device taking an exciplex as a main body material, in particular to an organic light-emitting device containing the main body material and a fluorescent material, wherein the main body material comprises a first organic compound and a second organic compound, a mixture or an interface formed by the first organic compound and the second organic compound generates the exciplex under the condition of optical excitation or electric field excitation, and the emission spectrum of the formed exciplex and the absorption spectrum of the fluorescent doped material are effectively overlapped to form the effective energy transfer; the first organic compound and the second organic compound have the different carrier transport characteristics, wherein the fluorescent material is an organic compound containing the boron atoms. The organic light-emitting device prepared by the method has the characteristics of high efficiency and long service life.

Owner:JIANGSU SUNERA TECH CO LTD

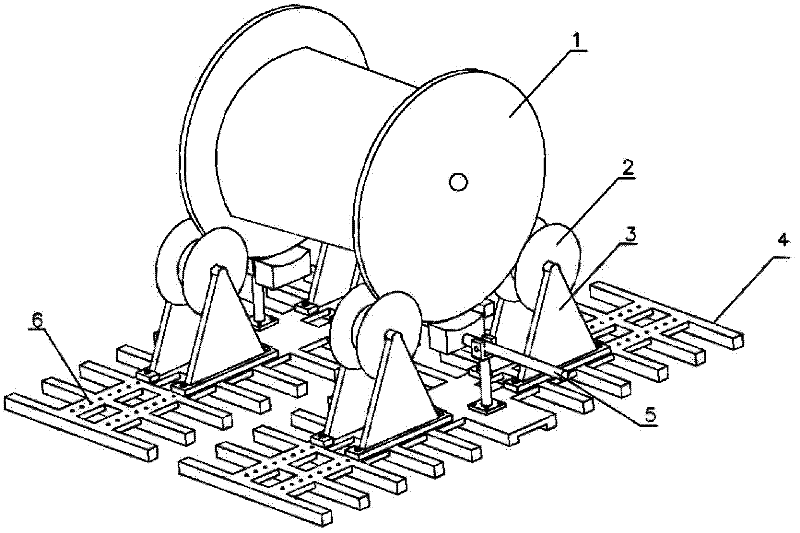

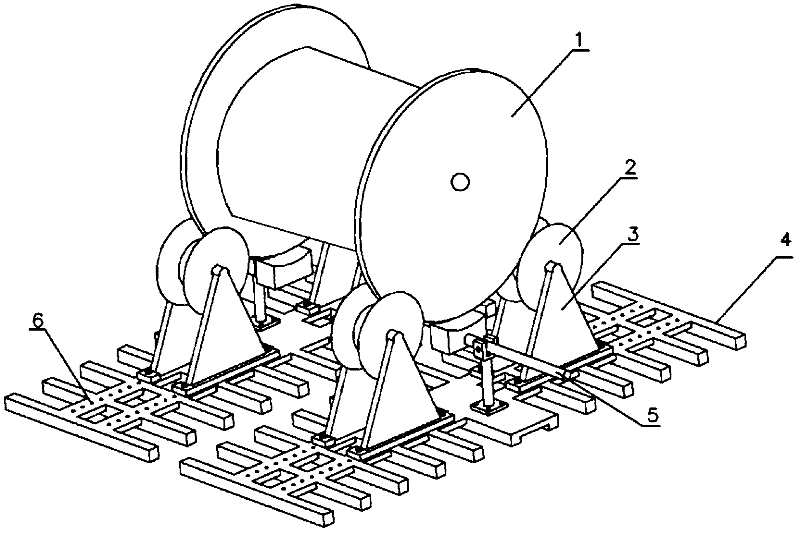

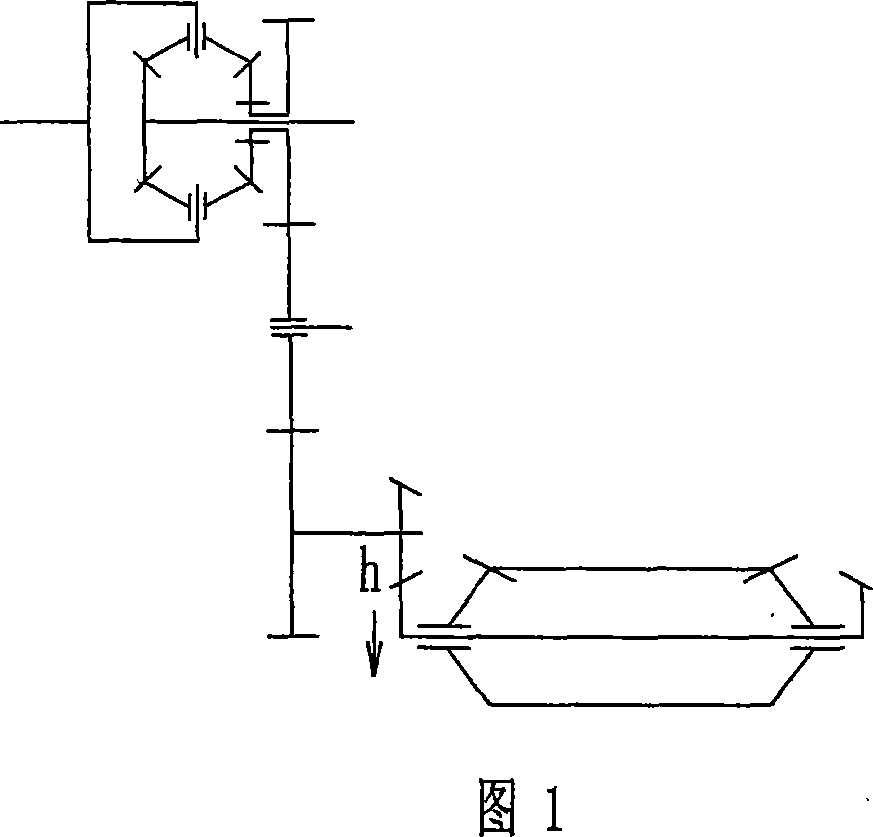

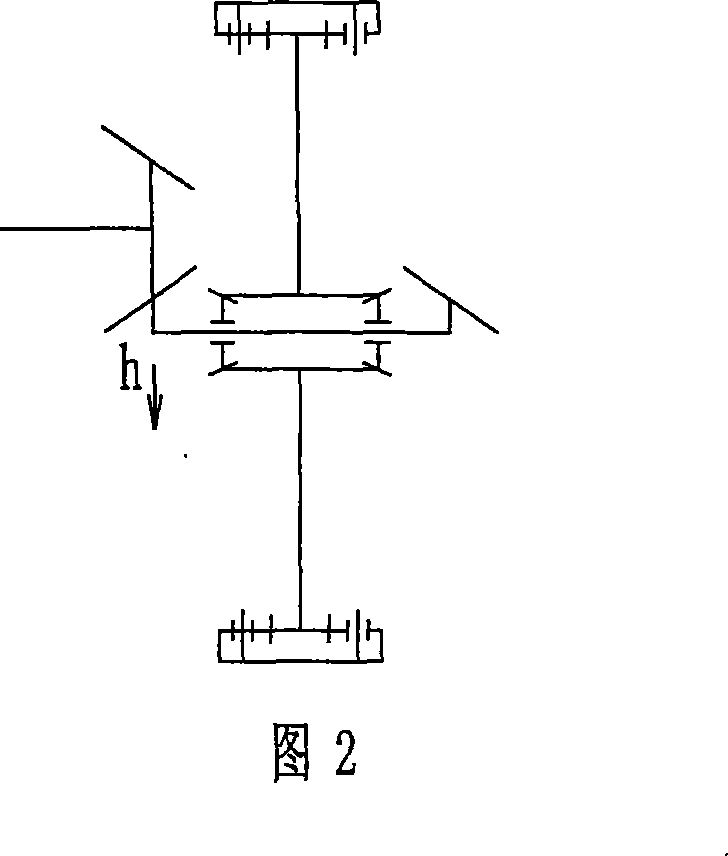

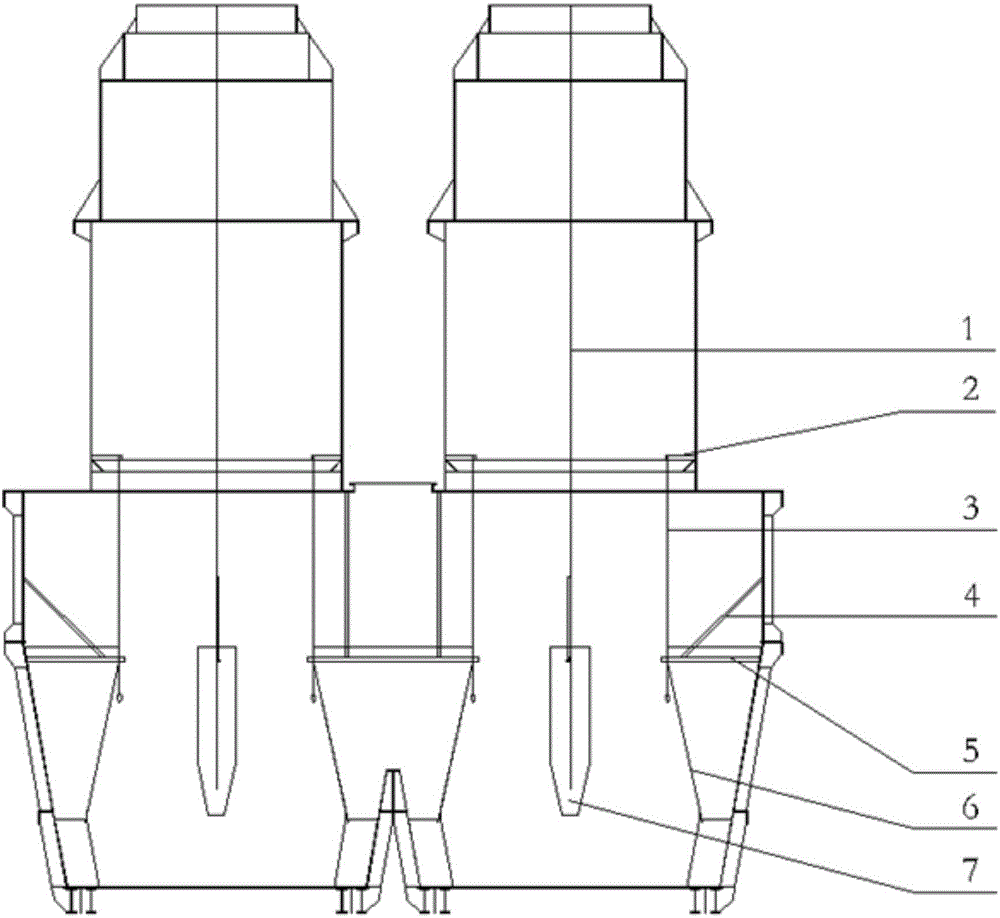

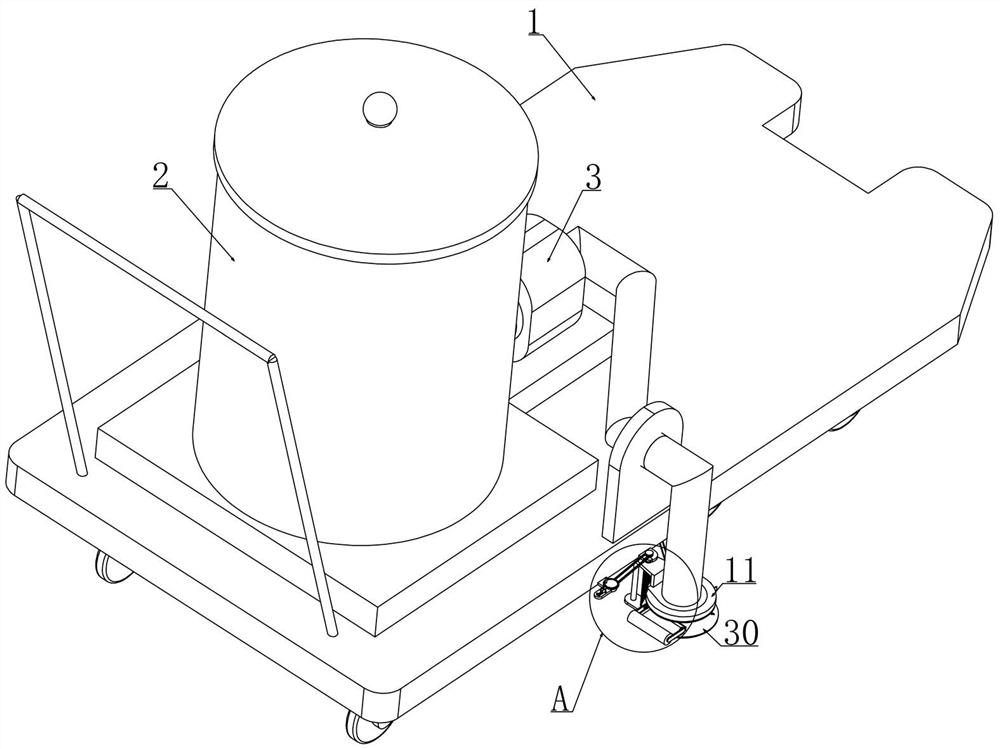

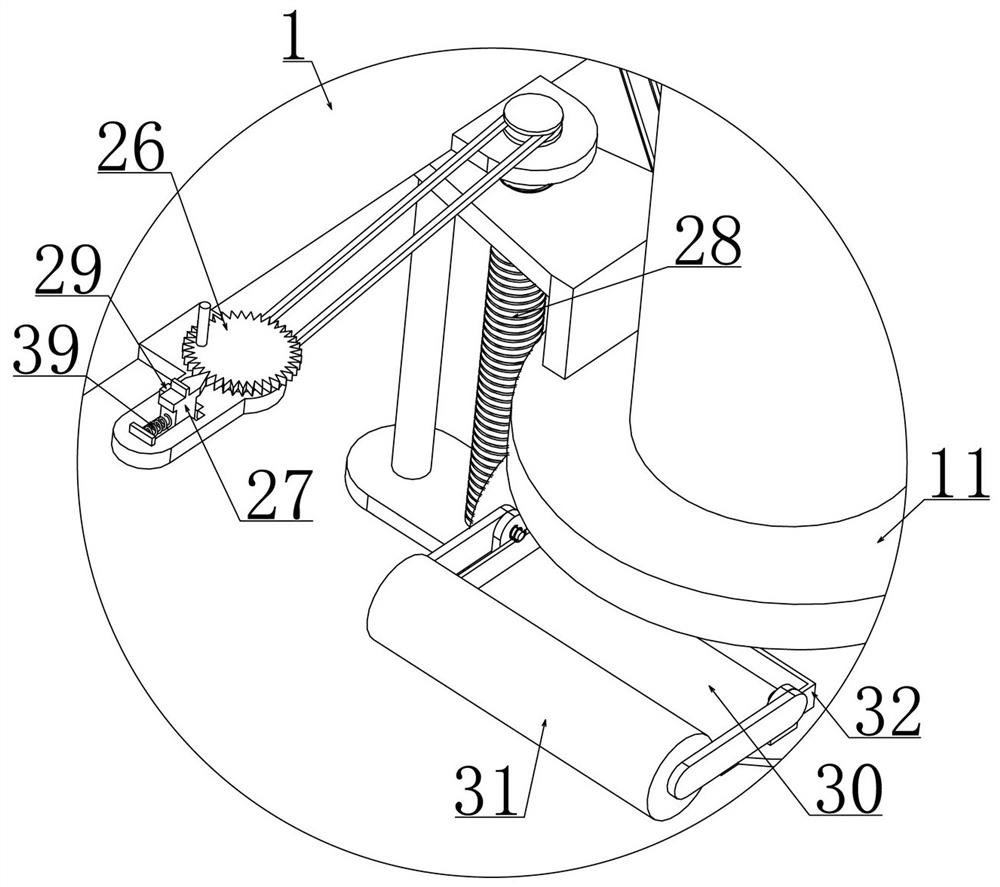

Conductor payoff rack

InactiveCN102403675AImprove securityImprove work efficiencyFilament handlingApparatus for overhead lines/cablesSafety coefficientEngineering

The invention discloses a conductor payoff rack for a power transmission line, which comprises a conductor wheel disc, rollers, four support frames, two rows of bases and two sets of brake devices, wherein the conductor wheel disc is supported on the rollers on which the four support frames are arranged respectively; every two support frames are respectively placed on the two rows of bases; and the brake devices are arranged at the middle of the two rows of bases transversely spanning below the conductor wheel disc. Each brake device is of a lever type structure and comprises a pressing rod, a brake pad arranged at the inner end of the pressing rod and a pressing rod supporting rod; and the two sets of brake devices are wholly seated between the two groups of support frames and are respectively installed on the two bases. The conductor payoff rack has the beneficial effects that the limit of a traditional operation method is basically solved, and the safety coefficient in the operation is greatly improved; and the space between every two rollers is correspondingly adjusted according to conductor wheel discs with different diameters, so that the payoff and use requirements of a conductor wheel with common mass are satisfied. As the rollers, the support frames, the bases, the brake devices and other parts on the conductor payoff rack are easy to process and assemble and are easy to popularize in the electric construction, the work efficiency is improved, and the safety is ensured during the use, and therefore, the economic and social effects are remarkable.

Owner:LUOHE POWER SUPPLY OF HENAN ELECTRIC POWER CORP

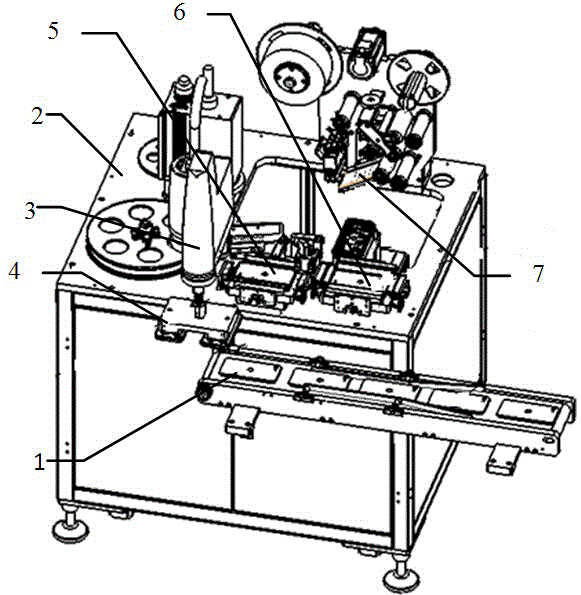

Double-station rotary material fetching and placing mechanism

InactiveCN104163336ASolve the problem of automatic loading and unloadingResolve offsetPackagingConveyor partsThin membraneEngineering

The invention relates to a double-station rotary material fetching and placing mechanism. The double-station rotary material fetching and placing mechanism comprises a feeding belt, a machine table, a mechanical arm, a double-station sucker, a locating platform, a laminating platform and a shaping platform. The double-station rotary material fetching and placing mechanism is characterized in that the mechanical arm, the locating platform and the shaping platform are arranged on the machine table, the feeding belt is located on one side of the machine table, the laminating platform is arranged on the other side of the machine table, and the double-station sucker is arranged on the mechanical arm and moves along with the mechanical arm. A four-axis mechanical arm body is adopted by the mechanical arm. The double-station sucker is a vacuum type sucker. The mechanical arm, the locating platform and the shaping platform are arranged on the machine table in sequence in the advancing direction of the feeding belt. By the adoption of the double-station rotary material fetching and placing mechanism, automatic product feeding and discharging of a laminator is achieved, the practicability of an automatic device is improved, and the problem of deviation of a film is solved. The double-station rotary material fetching and placing mechanism is low in cost, high in performance, high in locating accuracy and quite convenient to operate.

Owner:SUZHOU SECOTE PRECISION ELECTRONICS CO LTD

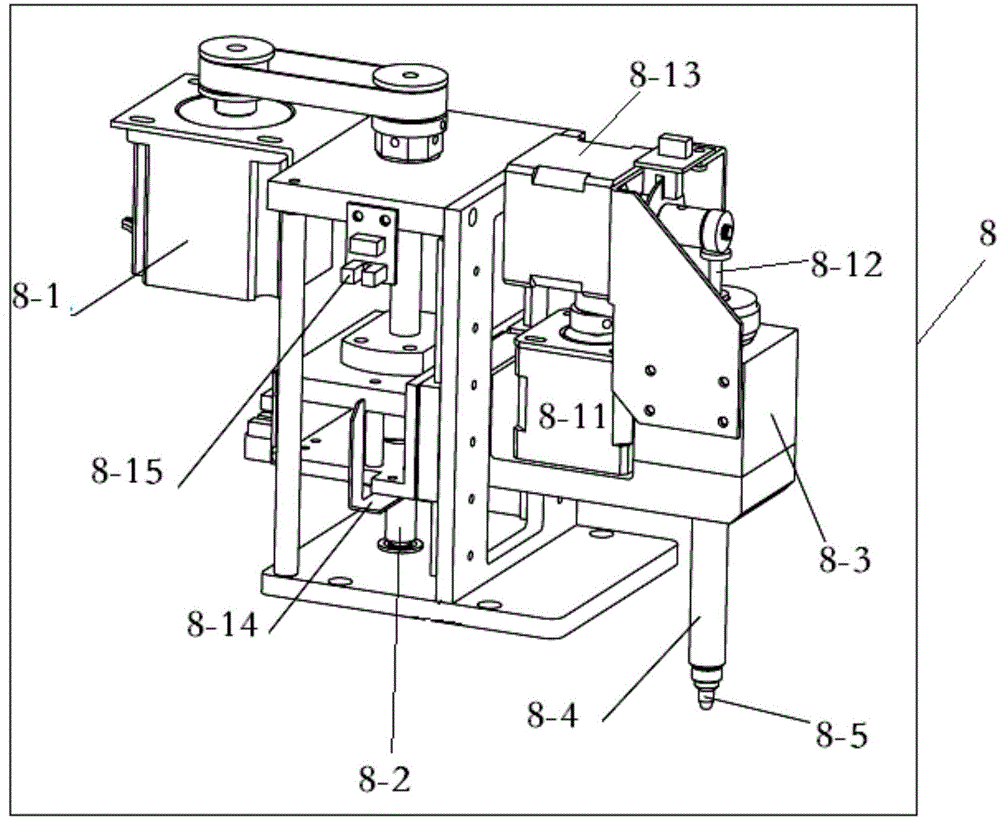

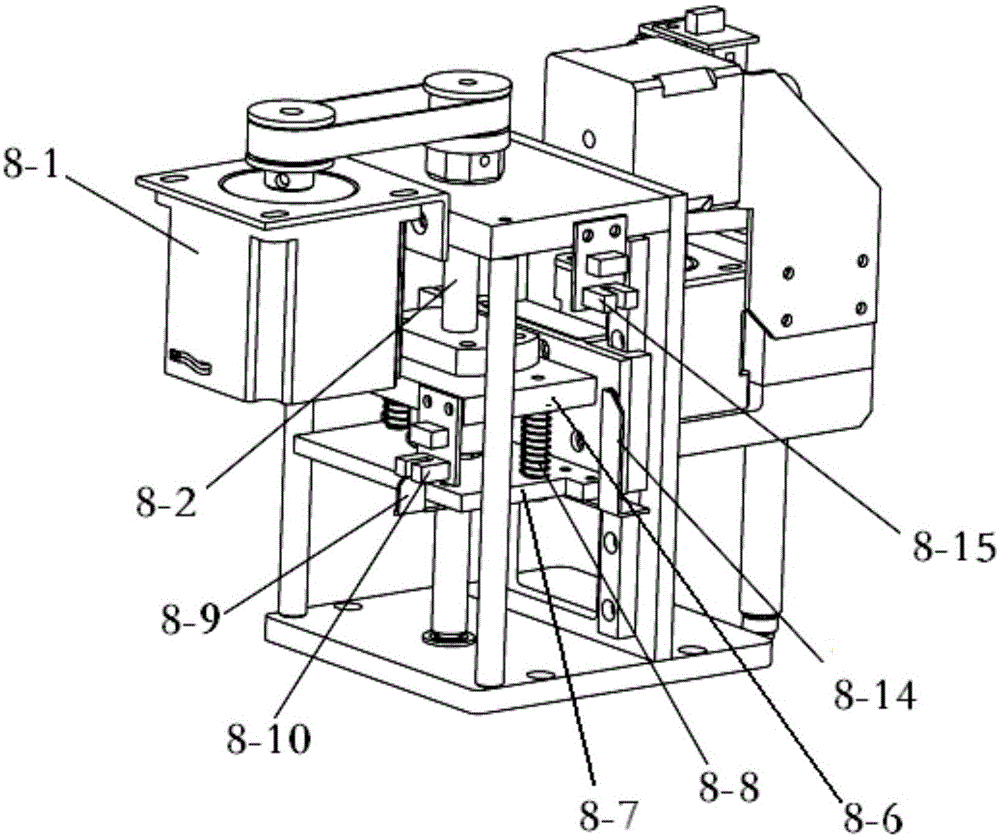

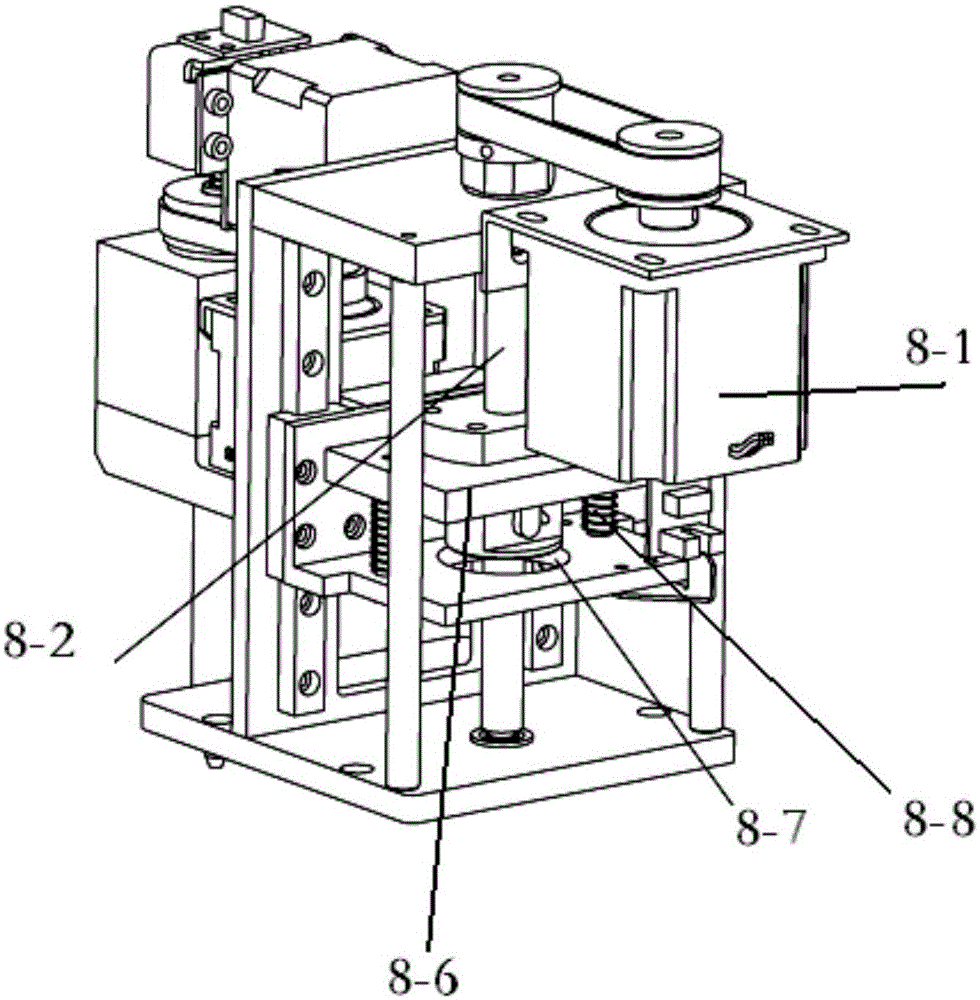

Automatic punch and automatic punching method

ActiveCN105108822ASimple structureHigh control precisionWithdrawing sample devicesMetal working apparatusPunchingEngineering

The invention provides an automatic punch and an automatic punching method. The automatic punch comprises an automatic punching device (8). The automatic punching device (8) comprises a first drive mechanism (8-1), a transmission piece (8-2), a first position detection mechanism, a lifting connection piece (8-3), a rotating arm (8-4) and a punching tool bit (8-5). The automatic punch further comprises a rotating plate system and a device movement system. The automatic punch and the automatic punching method have the advantages that the whole punching and sampling process can be controlled in a full-automated mode, and the advantages of being high in control accuracy in the automatic punching and sampling process is achieved while it is ensured that the structure is simple; the punching tool bit can be easily replaced with punching tool bits of different specifications, and therefore the automatic punch can be suitable for application occasions of different types; the punching tool bit can conduct punching and sampling on all areas of gaskets, and the service life of the gaskets is prolonged.

Owner:北京达博创新科技开发有限公司

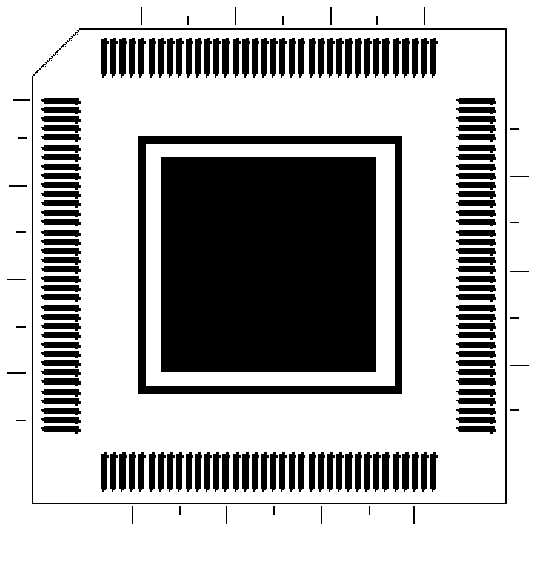

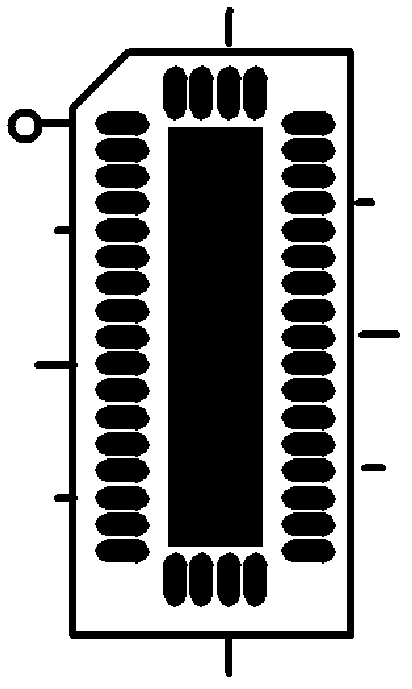

Method for designing bonding pad of surface mounted component, bonding pad structure and printing circuit board

ActiveCN102543765AResolve offsetSolve slidingSemiconductor/solid-state device detailsSolid-state devicesSolder maskSurface mounting

The invention provides a method for designing a bonding pad of a surface mounted component. The method comprises the following steps of: modifying a design structure of a radiating bonding pad in the center of the surface mounted component, and dividing a solder mask of the bonding pad into N equal parts according to the size of the radiating bonding pad of the surface mounted component, so that the lengths or widths of the divided solder masks of the bonding pad range from 2 to 3 millimeters; and arranging a through hole array at adjacent positions of the equal parts of the divided solder masks of the bonding pad. By the method, the problem of the offset or sliding caused in the process of processing the surface mounted component by a backflow welding process is solved, and the radiating requirement of chips is met.

Owner:MAIPU COMM TECH CO LTD

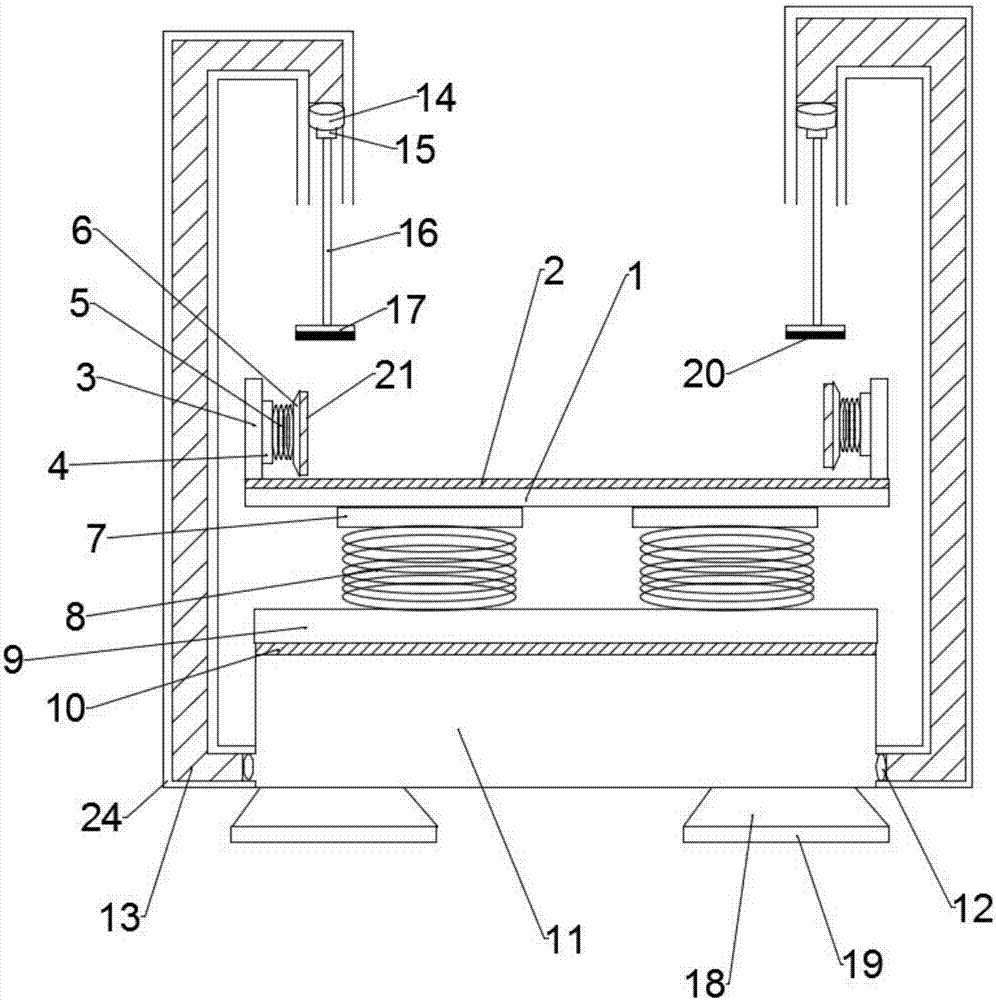

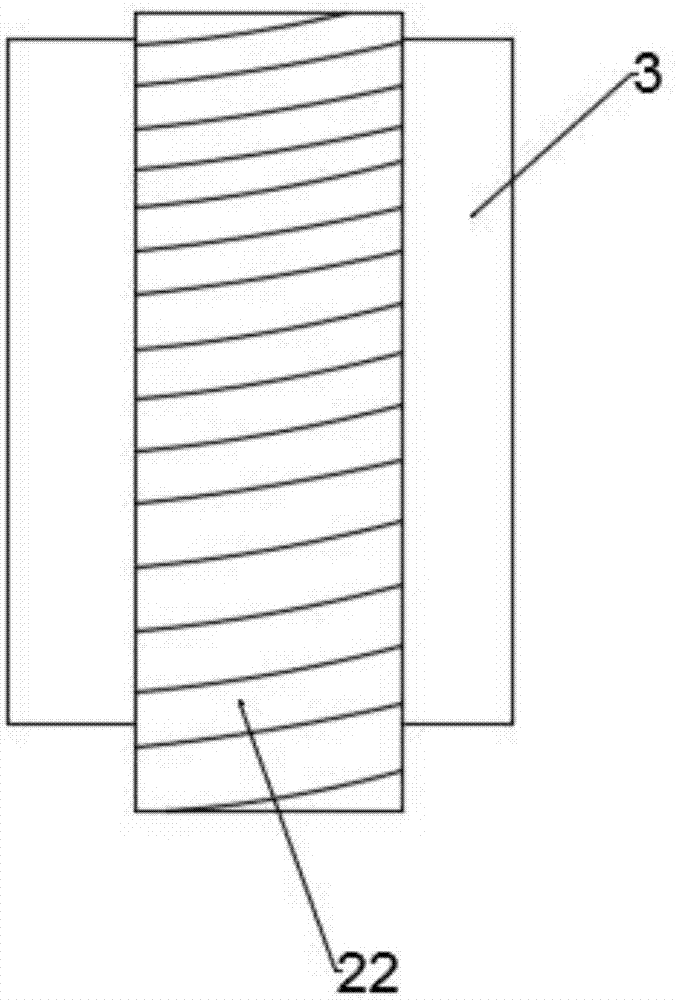

Positioning and fixing device for automobile part stamping die

InactiveCN107497936APlay a buffer roleResolve offsetShaping toolsMetal-working feeding devicesPistonMotor vehicle part

The invention discloses a positioning and fixing device for an automobile part stamping die. The positioning and fixing device comprises a plate surface, a movable groove is formed in the upper surface of the plate surface, and baffle plates are arranged at the two ends of the plate surface; a fixed body is arranged on the right side of each baffle plate, a spring is arranged on the right side of each fixed body, and a top body is arranged on the right side of each spring; fixed ends are arranged on the lower part of the plate surface, elastic support bodies are arranged on the lower parts of the fixed ends, a compression plate is arranged on the lower parts of the elastic support bodies, and an air bag cavity is formed in the lower part of the compression plate; piston floating bodies are arranged at the lower end openings of hydraulic cabins, and upper floating bodies are arranged at the upper end openings of the hydraulic cabins; connecting blocks are arranged on the lower end surfaces of the floating bodies, connecting rods are arranged at the lower ends of the connecting blocks, and pressing bodies are arranged at the bottom ends of the connecting rods; fixing feet are arranged at the bottom end of the air bag cavity; and protective shells are arranged on the outer sides of the surfaces of the hydraulic cabins. The positioning and fixing device solves the problems that the surface of a part is worn due to the traditional device and a fixed position is offset due to the traditional device, and further solves the problem that the pressure of the existing device needs to be adjusted by human power.

Owner:温州天和汽车部件有限公司

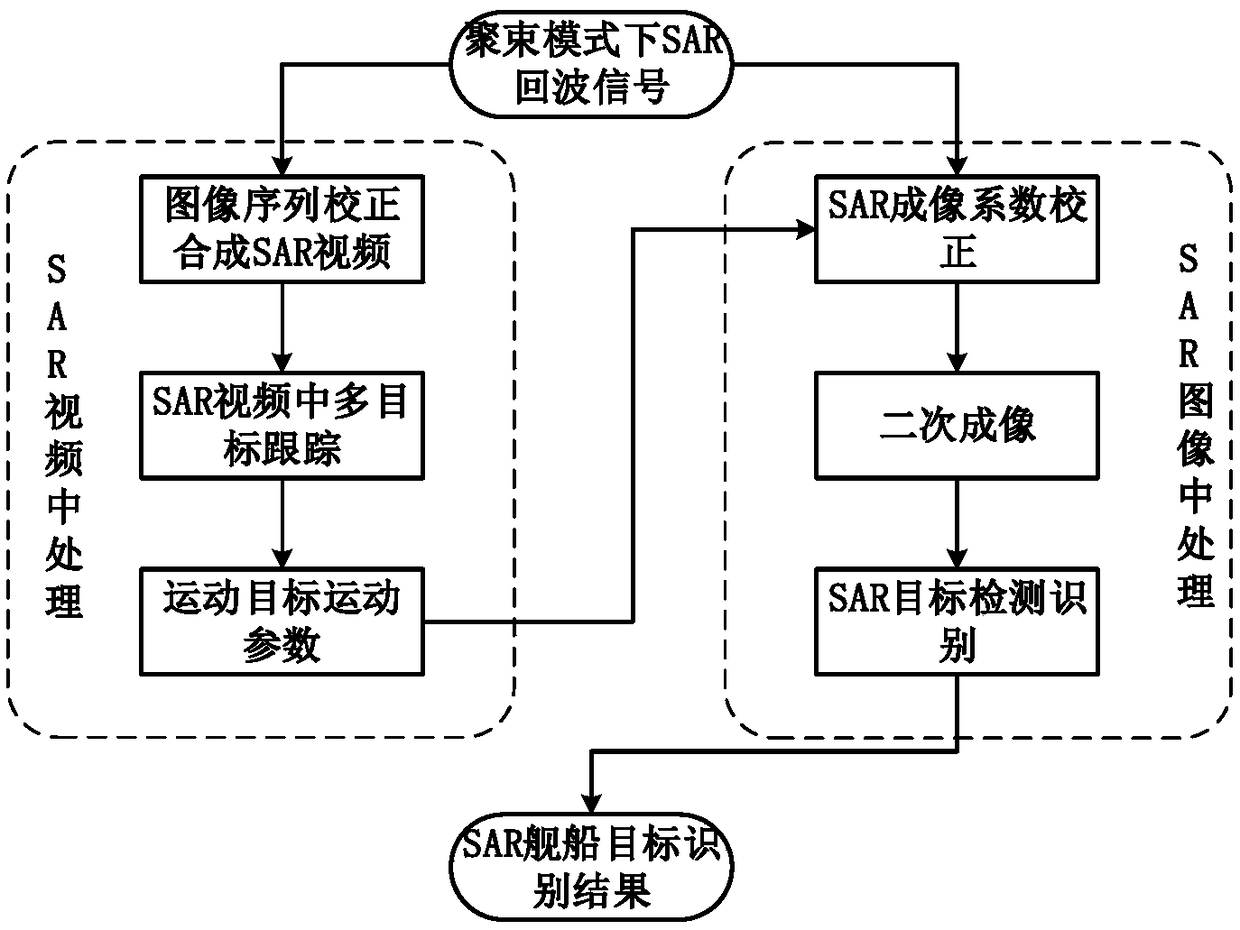

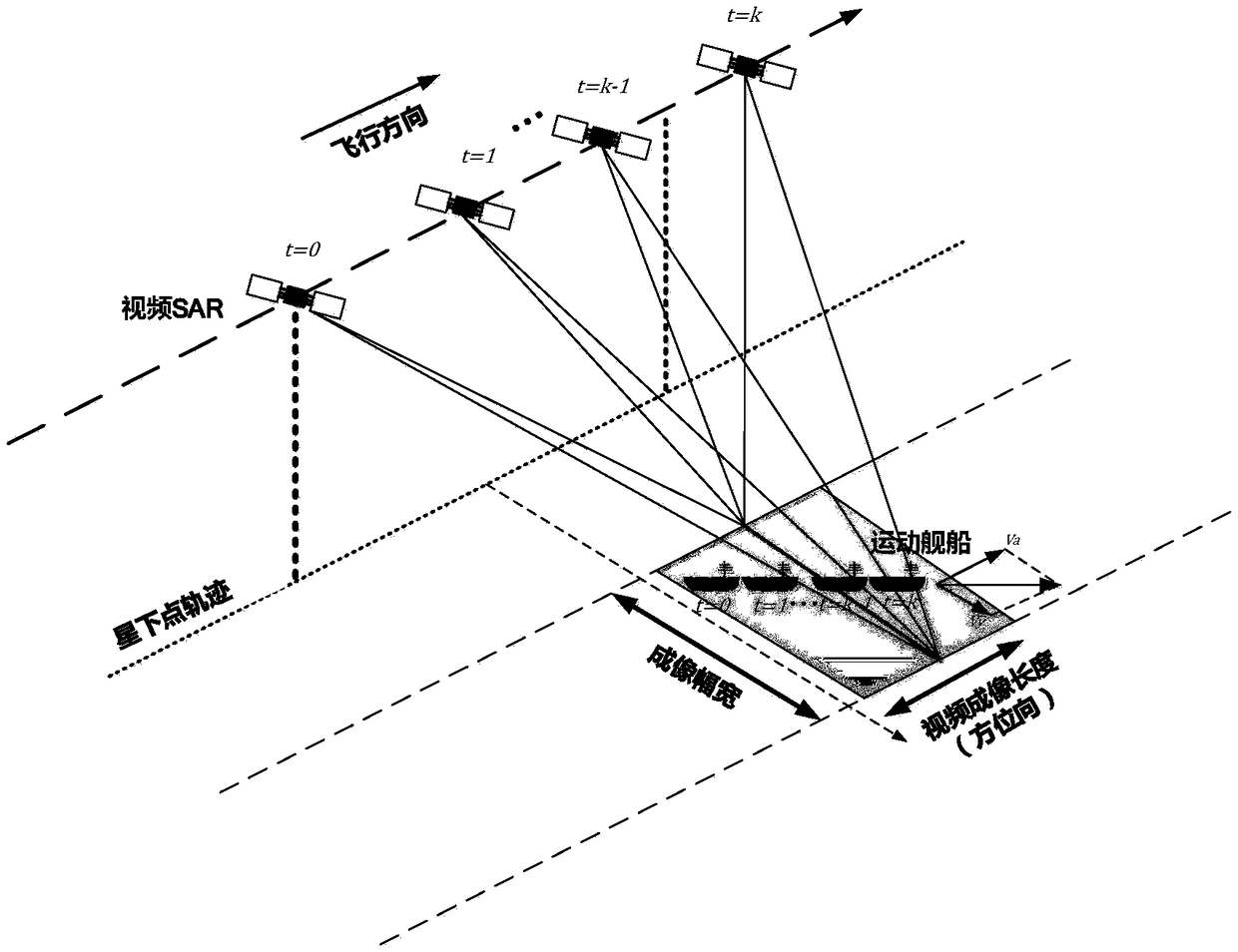

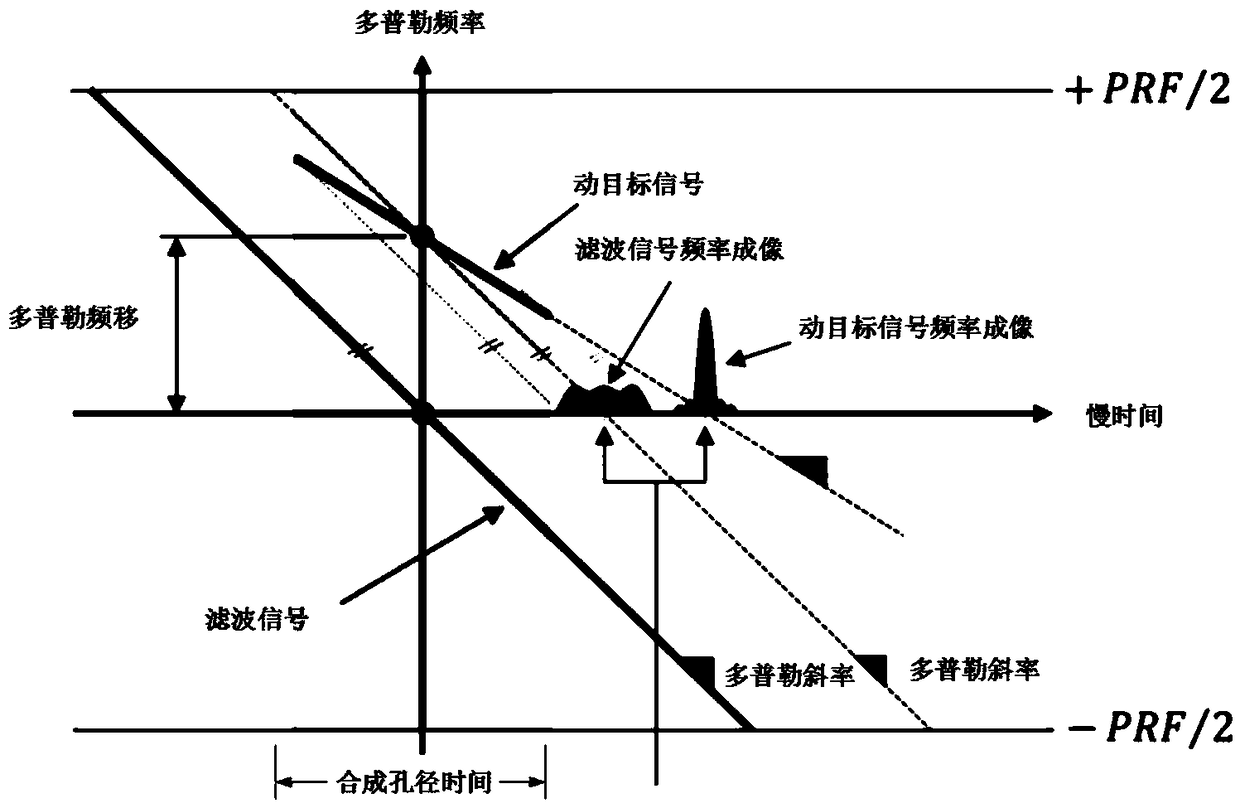

High-precision moving target imaging and recognition method based on multi-target tracking

ActiveCN108957453AResolve offsetRadio wave reradiation/reflectionMulti target trackingMotion parameter

The invention discloses a high-precision moving target imaging and recognition method based on target tracking. The method comprises the following steps: acquiring a SAR video by an SAR platform working in a bunching mode; using the Probability Hypothesis Density multi-target tracking method to perform tracking, and estimating motion parameters of moving targets; using the acquired motion parameters of the moving targets to correct a Doppler imaging coefficient, and acquiring SAR images that are accurately imaged after defocusing and displacement; and detecting and recognizing the moving targets in the acquired accurate SAR images. The technical effects of the method are that the motion parameters of the moving targets in the SAR video can be acquired through the multi-target tracking method in the video, the Doppler imaging coefficient and the problems of defocusing and offsetting in the images are corrected according to the acquired motion parameters of the moving targets so as to obtain high-precision images; and a support is provided for high-precision recognition.

Owner:SPACE STAR TECH CO LTD

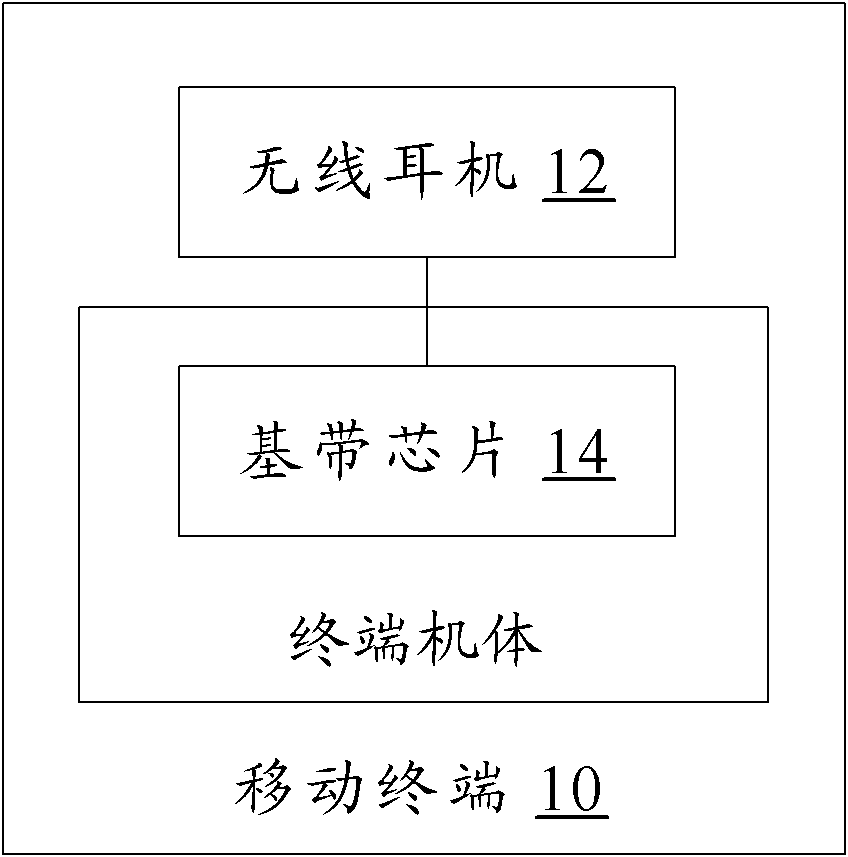

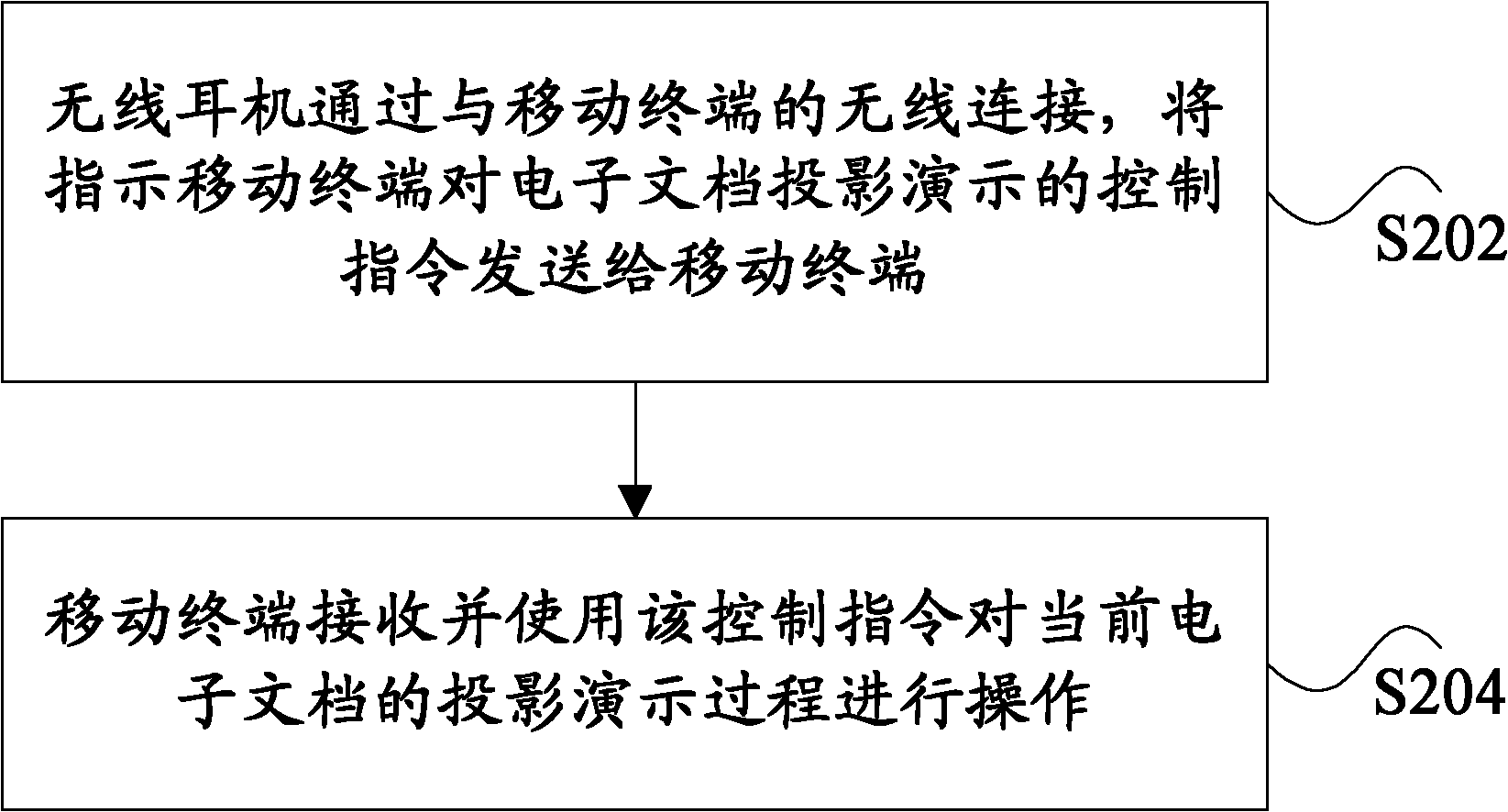

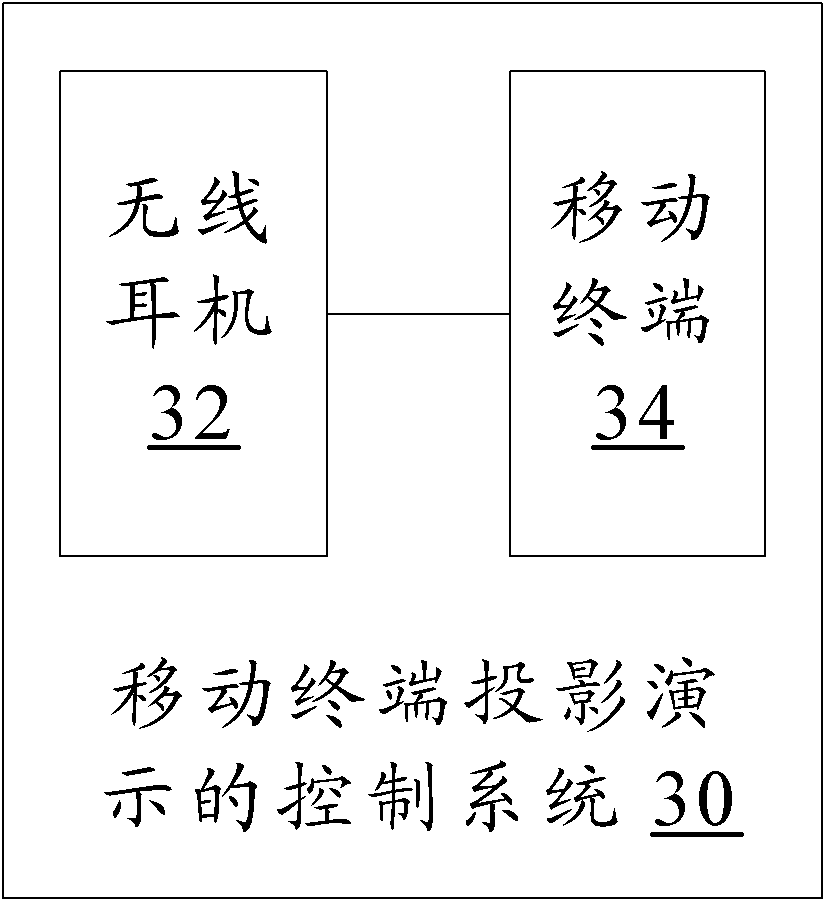

Control method and system for projection demonstration of mobile terminal, and mobile terminal

The invention discloses a control method and system for projection demonstration of a mobile terminal, and the mobile terminal. The mobile terminal comprises a wireless earphone, and a base-band chip located in a terminal machine body, wherein the wireless earphone is used for transmitting a control command, which instructs the terminal machine body to carry out projection demonstration on an electronic file, to the terminal machine body through the wireless connection with the terminal machine body; and the base-band chip is used for receiving and using the control command to operate the projection demonstration process of the current electronic file. According to the invention, the system has enhanced flexibility and can improve the user experience.

Owner:ZTE CORP

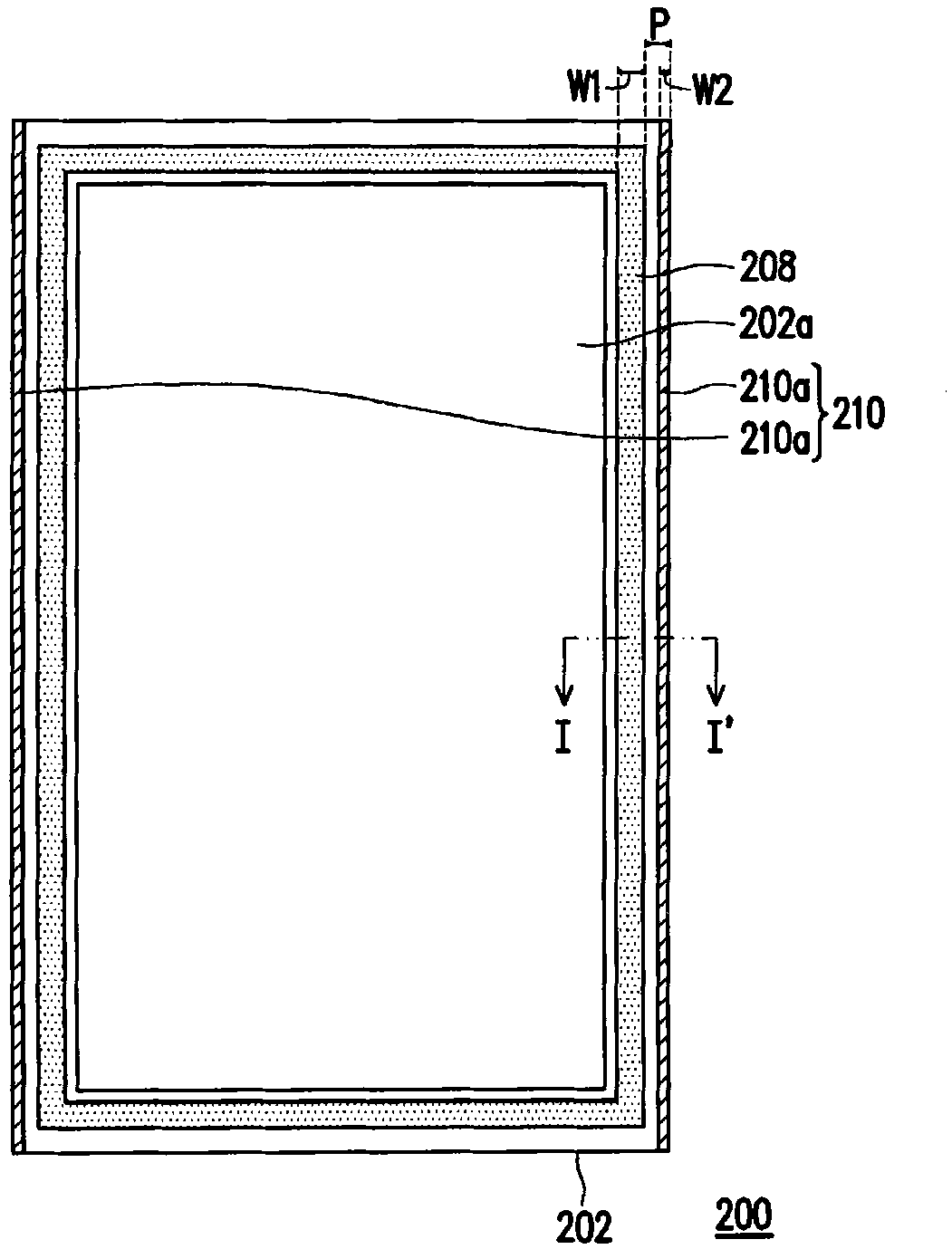

Liquid crystal display panel

InactiveCN101916007ASmooth breakingMeet the design requirementsNon-linear opticsLiquid-crystal displayEngineering

The invention discloses a liquid crystal display panel. The liquid crystal display panel comprises a first substrate, a second substrate, a liquid crystal layer, a photocured sealant and a first shading pattern, wherein the liquid crystal layer is arranged between the first substrate and the second substrate; the photocured sealant is arranged between the first substrate and the second substrate, and embraces and contacts the liquid crystal layer; the first shading pattern is arranged on the first substrate; a part of the side wall of the first shading pattern is basically flush with that of the first substrate; and the first shading pattern is only superposed with one external edge of the photocured sealant or not superposed with the photocured sealant.

Owner:AU OPTRONICS CORP

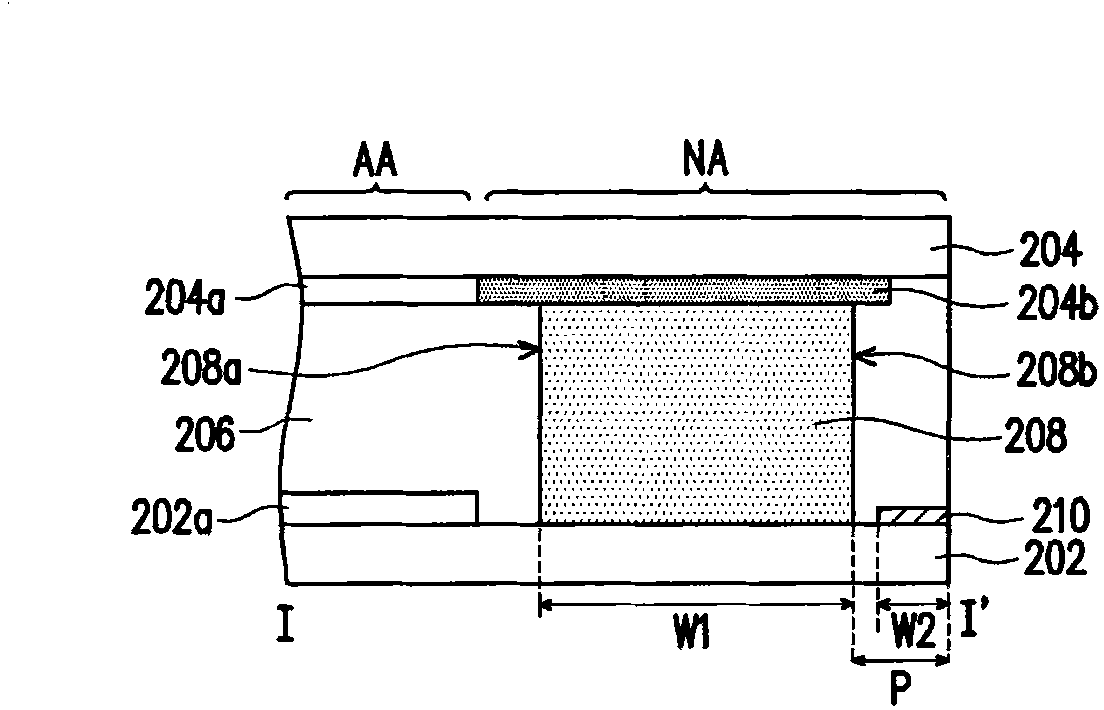

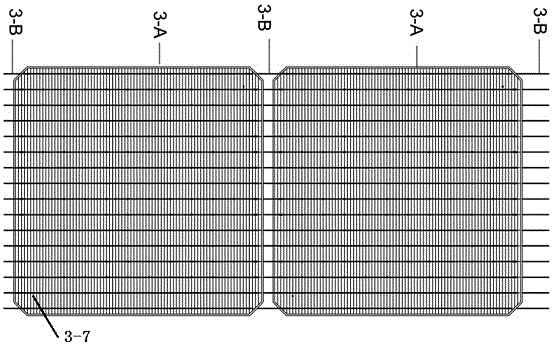

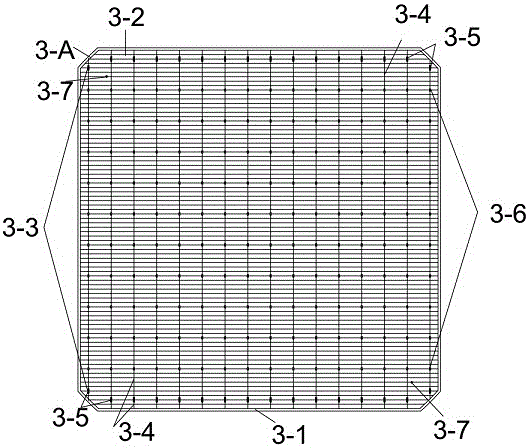

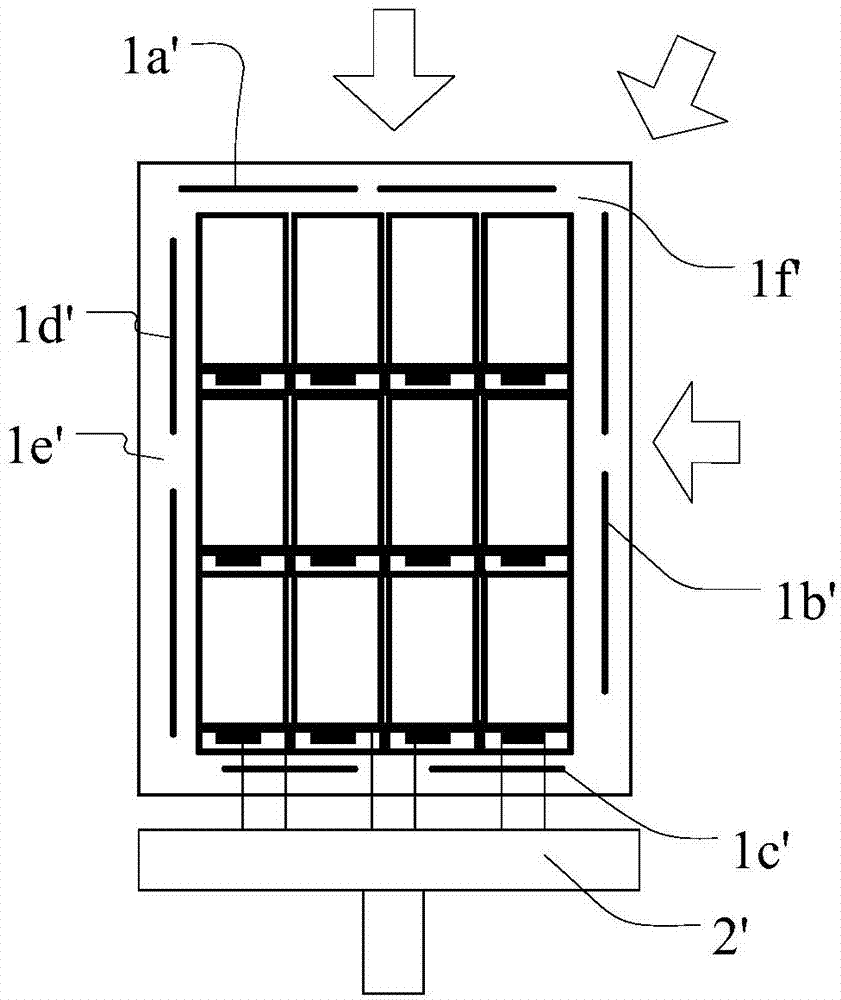

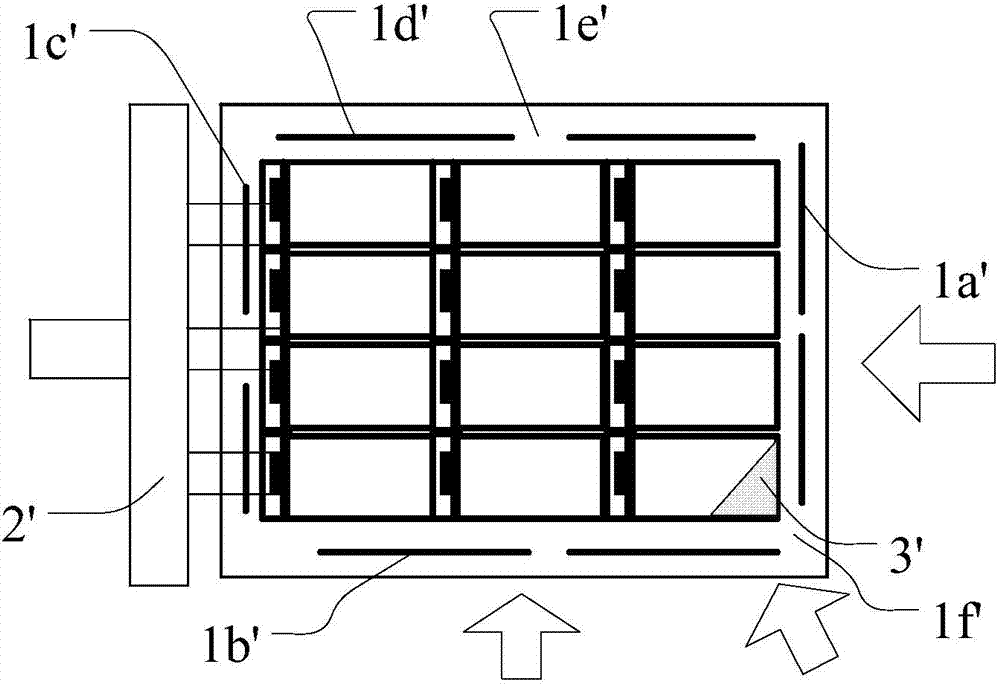

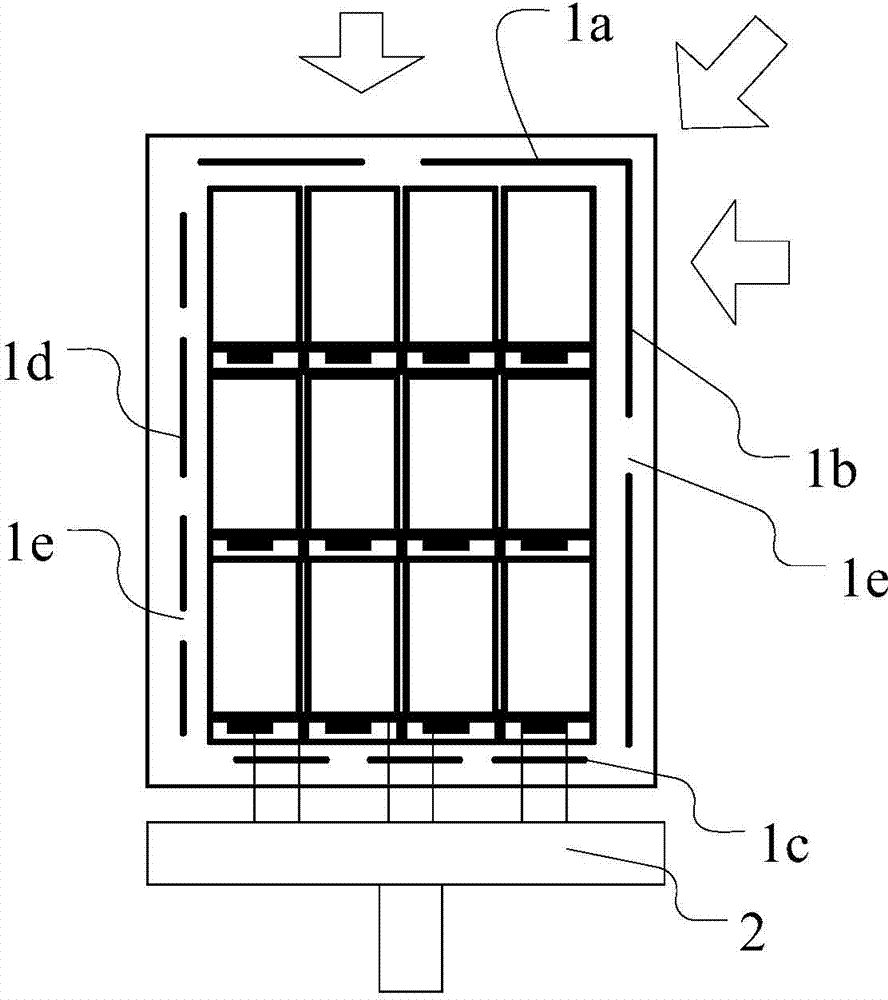

Multi-main grid double-sided solar battery assembly

InactiveCN106229356AImprove reliabilityImprove power generation efficiencyPhotovoltaic energy generationSemiconductor devicesElectricityElectrical resistance and conductance

The invention discloses a multi-main grid double-sided solar battery assembly, which comprises an assembly body which comprises a front film, a double-sided solar battery pack and a back film, wherein the double-sided solar battery pack is arranged between the front film and the back film; packaging adhesive films are arranged between the double-sided solar battery pack and the front film and between the double-sided solar battery pack and the back film; the double-sided solar battery pack comprises a plurality of multi-main grid double-sided solar battery pieces and metal wires; the metal wires extend between the adjacent battery pieces to achieve electric connection; a silicon substrate is arranged in the middle of each multi-main grid double-sided solar battery piece; 10-25 main grid lines and 70-500 secondary grid lines are arranged on the front surface and the reverse surface of each silicon substrate; the main grid lines are vertical to the secondary grid lines; welding spots are arranged on intersection points of the main grid lines and the secondary grid liens at intervals; and silver connection lines are arranged among the welding spots of the main grid lines. The contact resistance of the metal wires and the battery pieces can be reduced by optimizing the main grid line design of double-sided solar batteries; the offset problem in welding of a plurality of main grid lines is solved; the reliability and the power generation efficiency of the battery assembly are improved; and the production cost of the assembly is reduced.

Owner:LIANYUNGANG SHENZHOU NEW ENERGY

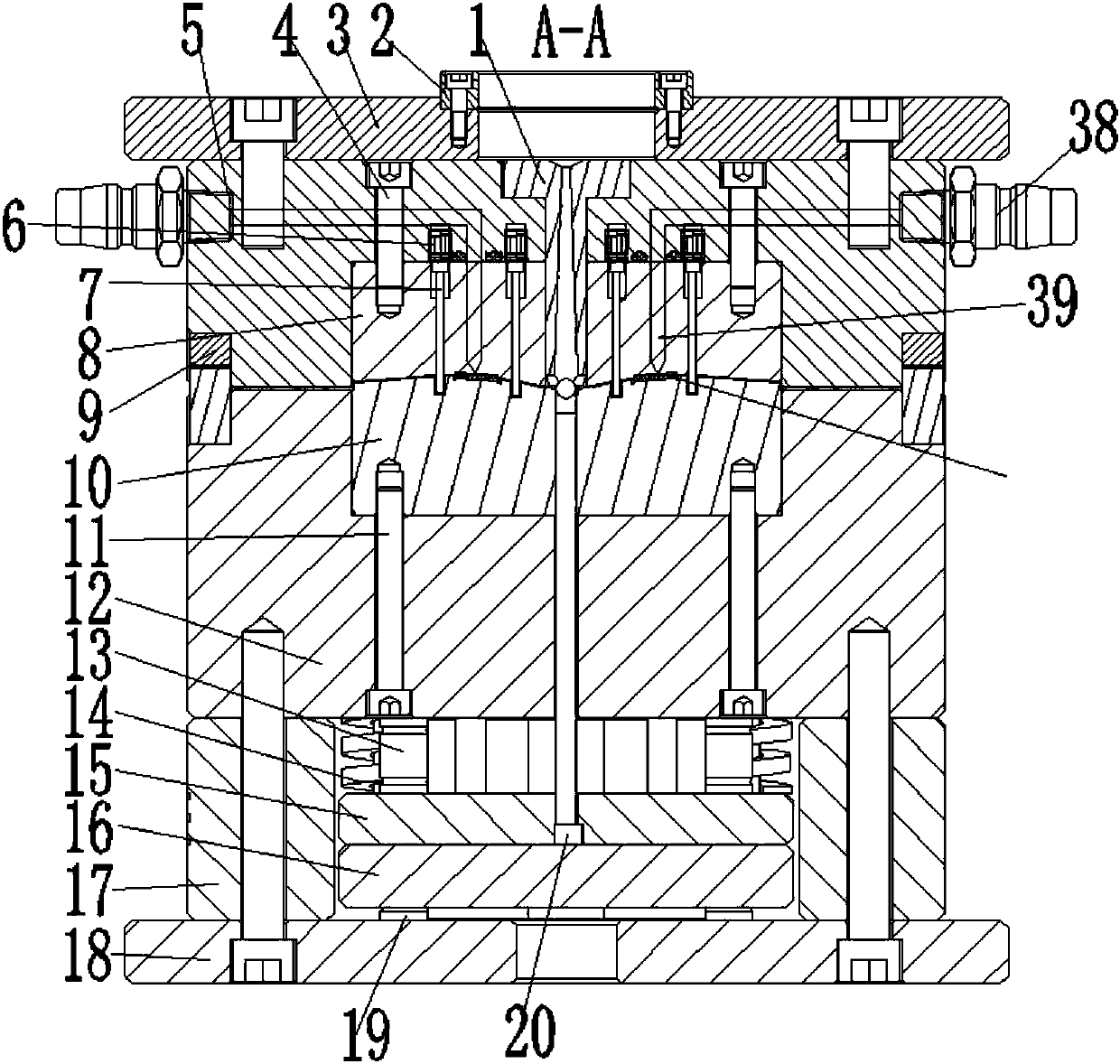

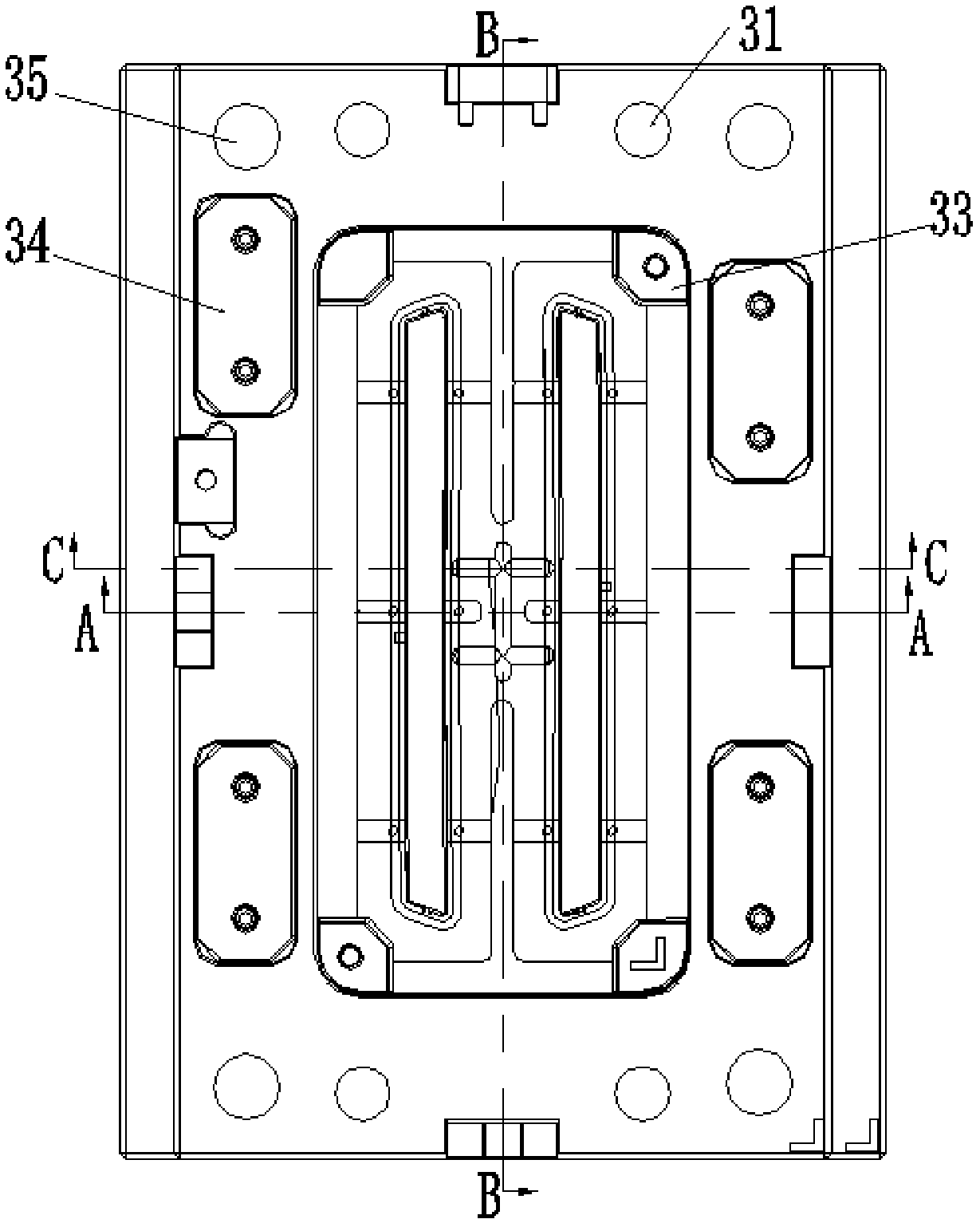

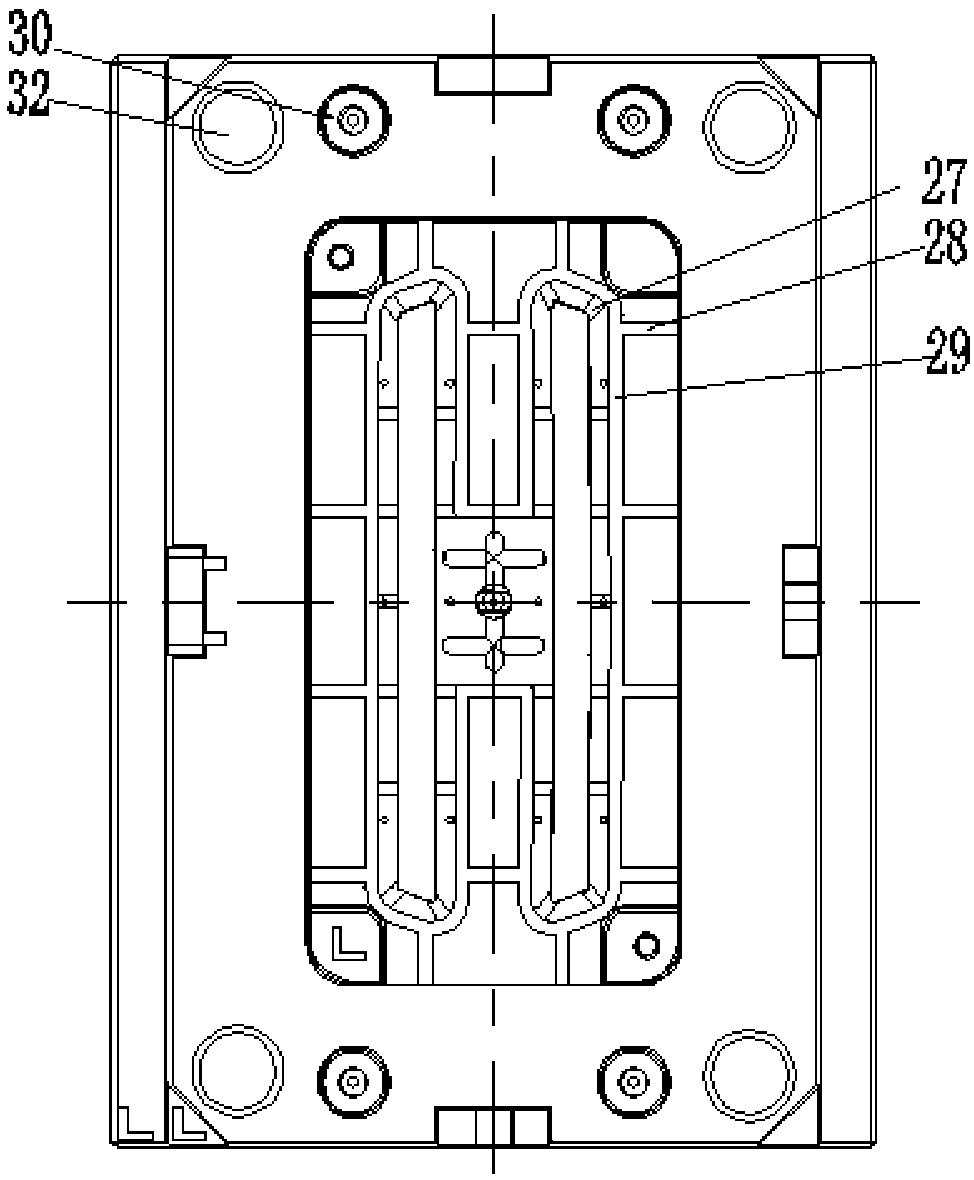

Injection mold adopting IMR process and application method for injection mold

The invention provides an injection mold adopting an IMR process and an application method for the injection mold. The novel injection mold and the application method thereof aim to meet the requirements that products needs to adopt the IMR process for molding. The novel injection mold is designed and has the advantages that a diaphragm positioning mechanism, a mold cavity exhaust mechanism and novel injection molding sprues capable of preventing a diaphragm from being burnt out are structurally and additionally arranged so that the problems of edge curl, uneven shrinkage and deformation in the thin film injection molding process in the IMR process can be solved, the zero-defect and automatic molding production of the products can be realized, and therefore the product forming quality canbe effectively guaranteed, the mold structure and mechanism are novel in design, and the automatic injection molding production of the products can be realized.

Owner:乌鲁木齐九品芝麻信息科技有限公司

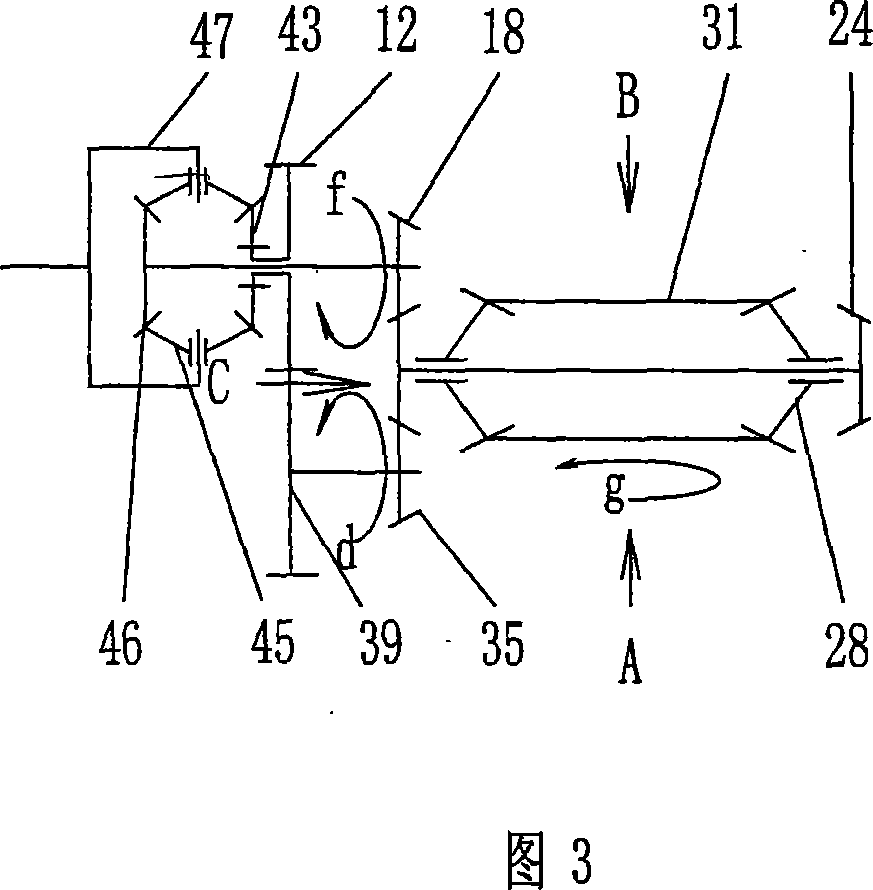

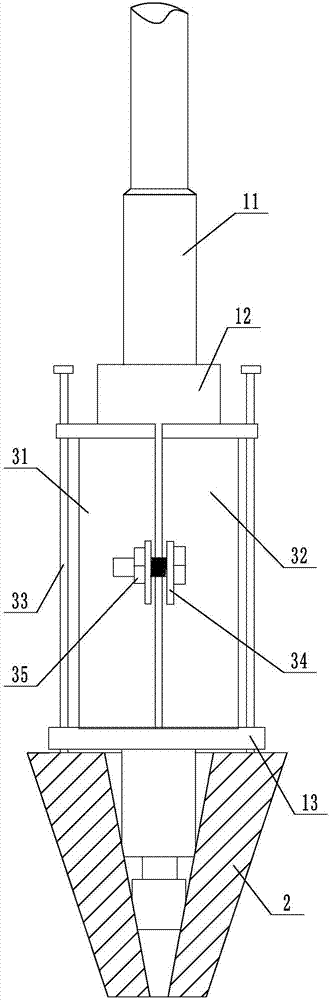

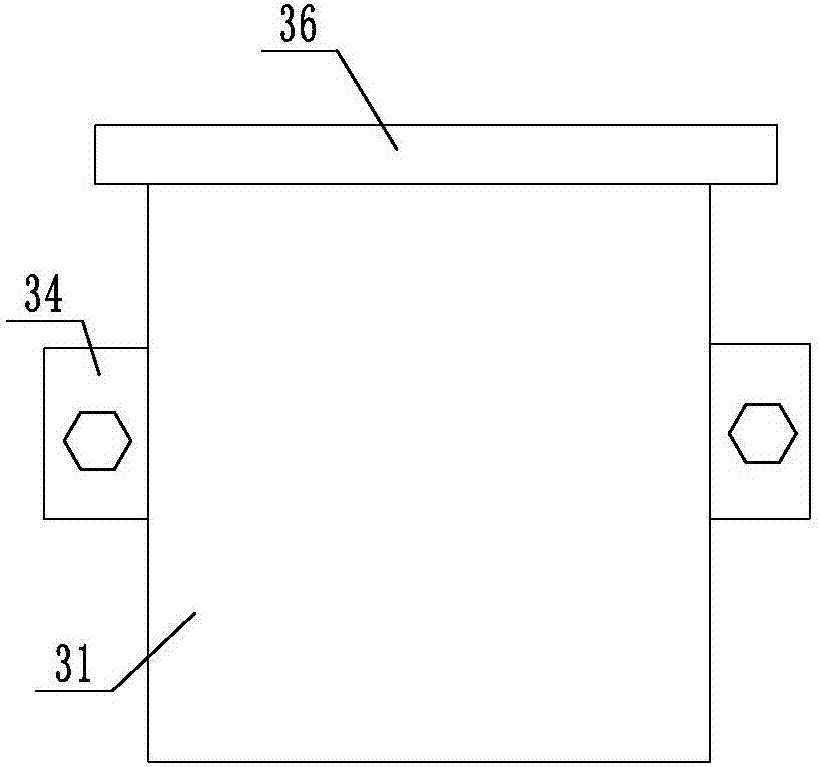

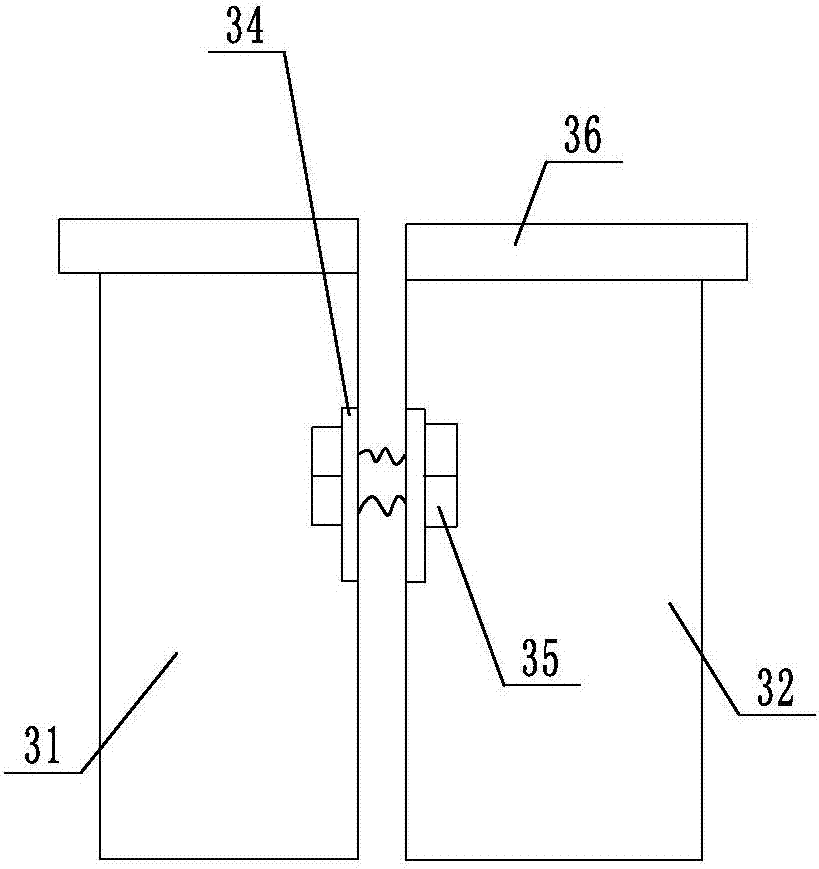

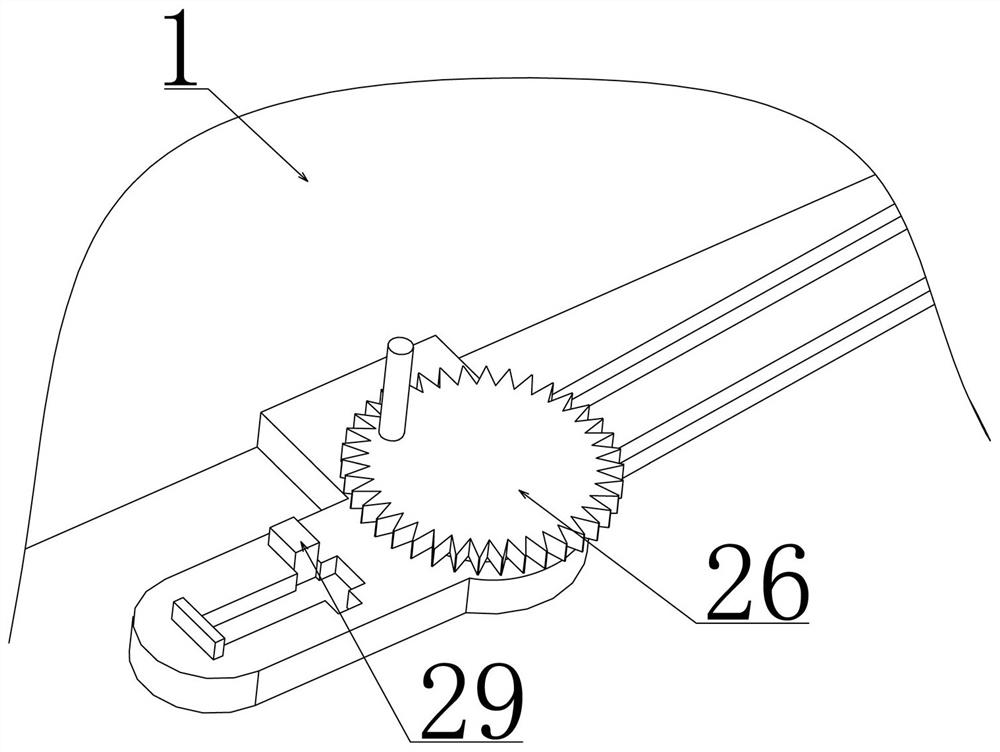

Main gear down device

InactiveCN101055018ASimple structureImprove support rigidityToothed gearingsDifferential gearingsGear wheelEngineering

The present invention provides a main decelerate device which includes a planet gear load-uniformed mechanism, a driver gear and a initiative bevel gear driven by the device, a driven bevel gear engaged with the initiative bevel gear and a speed differientiator connected to the driven bevel gear. It is characterized in that one of the sun gear in the planet gear load-uniformed mechanism is connected to the initiative bevel gear, another sun gear is connected to one of two engaged intermediate drive gears by an axle sleeve, another intermediate drive gear is connected to a secondary initiative bevel gear, the initiative bevel gear and the secondary initiative bevel gear are both connected to a driven bevel gear with double cog. The device divides the power into two parallel path powers with reverse rotate direction and equal torsion, and then combines the two powers into one power by making the main, secondary initiative bevel gears engage with the driven bevel gear with double cog, and passes the power to the speed differientiator by the driven bevel gear and output the power by an axle shaft gear, thereby complete the power output between interleaving shafts, conquers the axial direction offset of the driven bevel gear and increases the drive ability by times.

Owner:张春

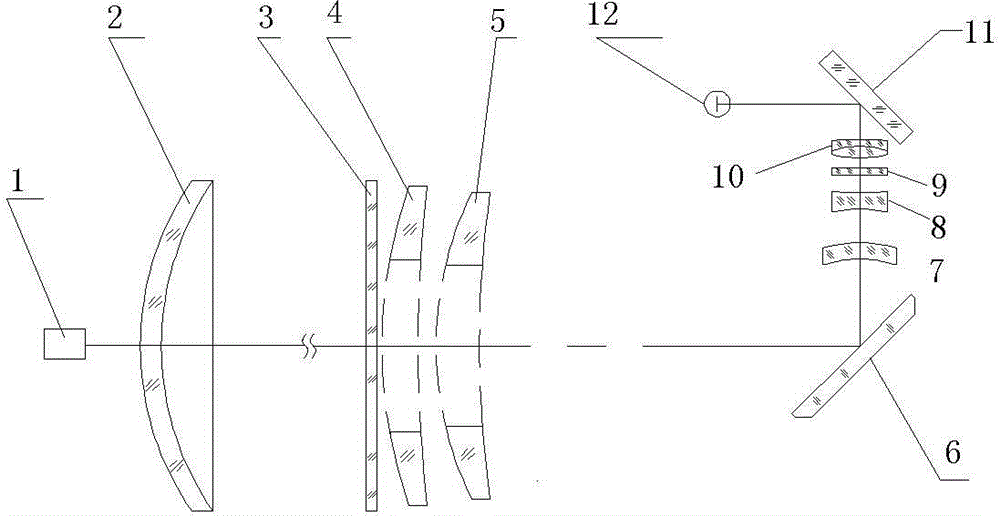

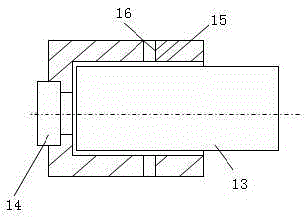

Laser reception debugging method and apparatus

ActiveCN105301578AEasy to operateLow skill level and experience requirements for workersWave based measurement systemsOptical pathLaser ranging

The invention relates to the optical adjusting field of a laser range finding machine, and specifically relates to a laser reception debugging method and apparatus. The laser reception debugging method comprises adjusting a reception light path; performing convergence and at least two-level replication for a laser echo signal generated after reflection of the signal emitted from the laser range finding machine through a detection object, and converging the laser echo signal at the photosensitive surface position of the detector eventually; setting an endoscope which can convert the invisible light into visible light, at the position of the photosensitive surface of the detector; and then adjusting the detector. The laser reception debugging method and apparatus can utilize the endoscope to display the invisible light as the visible light so that visual adjusting of a laser optical axis can be realized and accurate adjusting of the light path can be realized. The laser reception debugging method and apparatus can solve the problem about offset of the optical axis because of blind adjusting of laser optical axis, optical component machining error and adjusting error of an assembling staff, and has the advantages of being simple in operation, having no requirement for the skill level and the experience of workers, reducing the adjusting time, effectively improving the adjusting accuracy, and being able to realize accurate and effective adjusting of the laser optical axis.

Owner:LUOYANG INST OF ELECTRO OPTICAL EQUIP OF AVIC

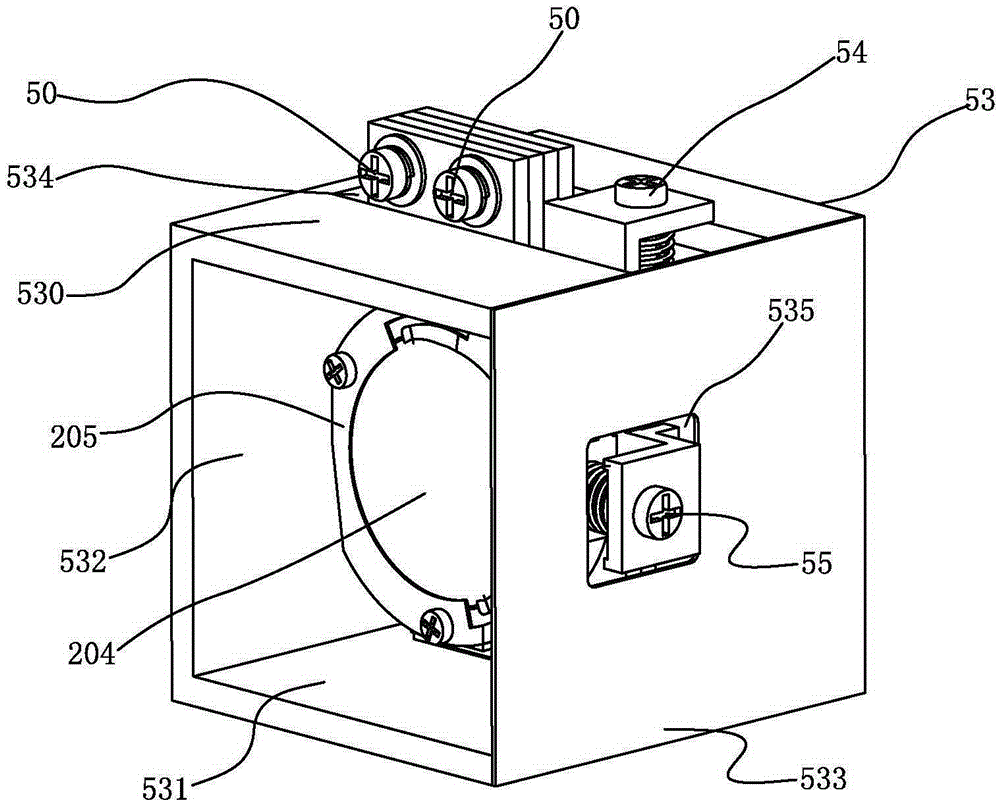

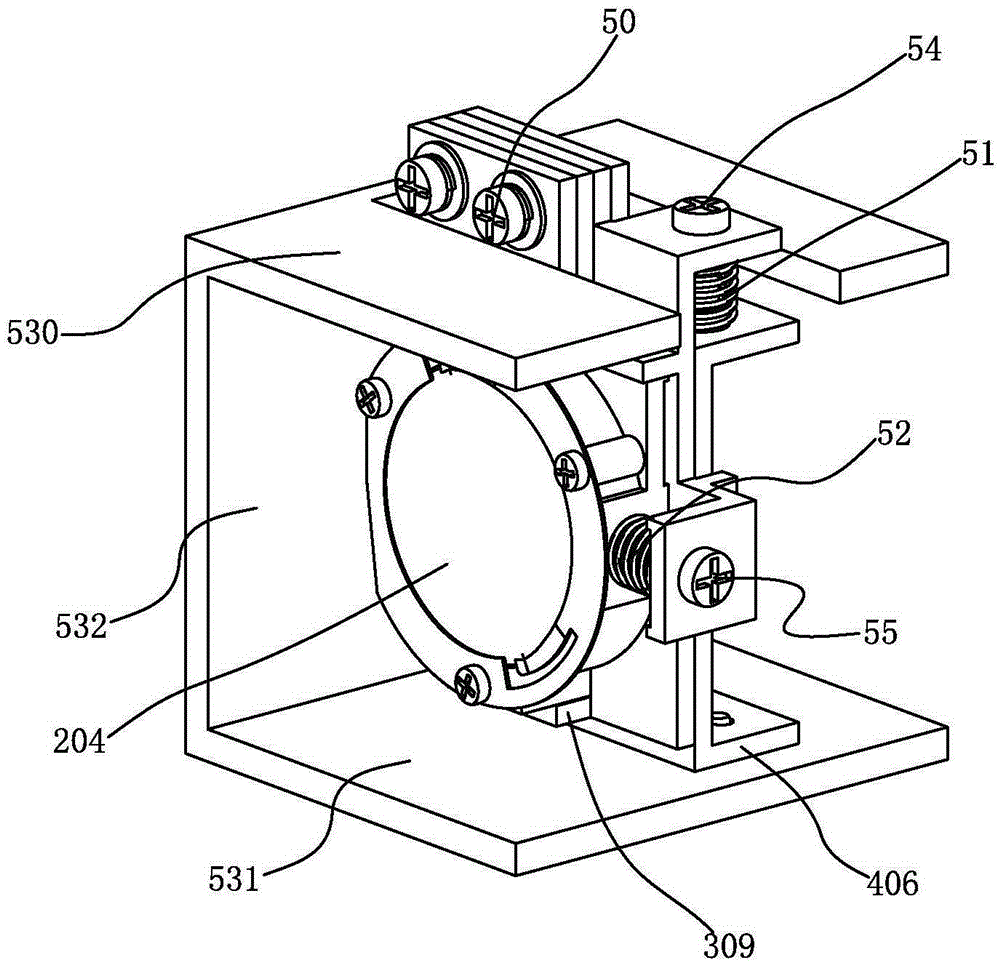

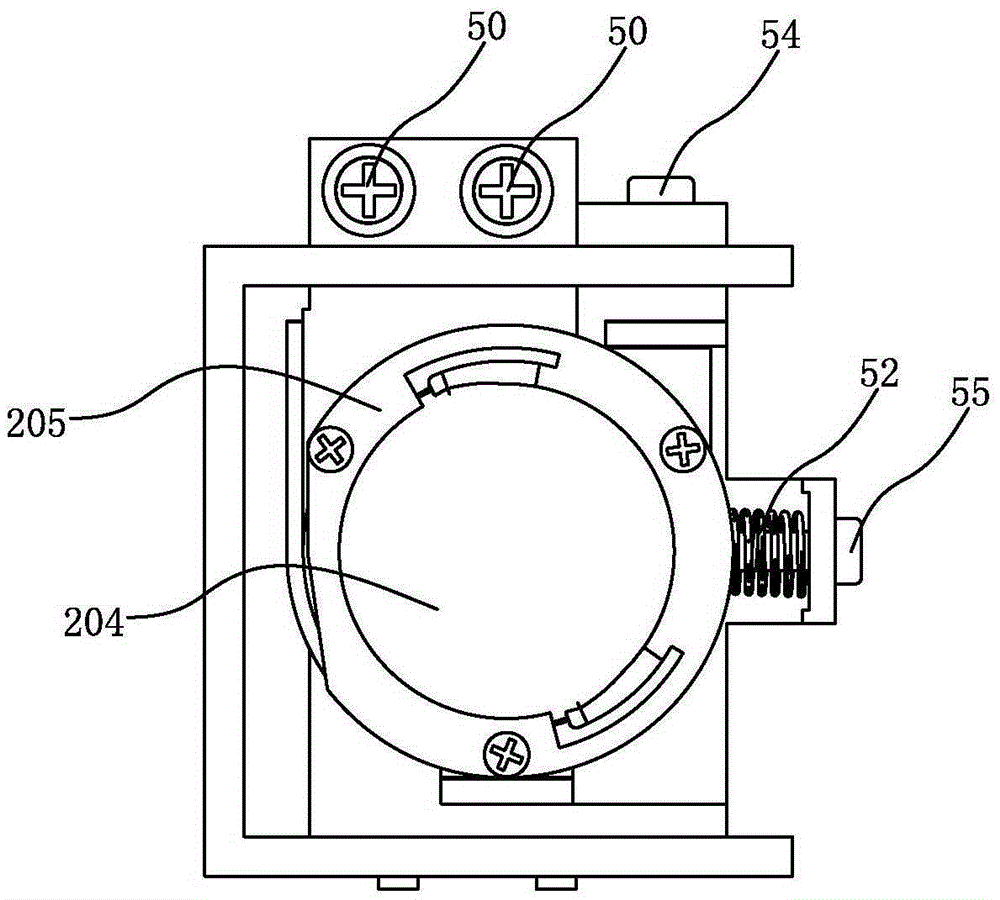

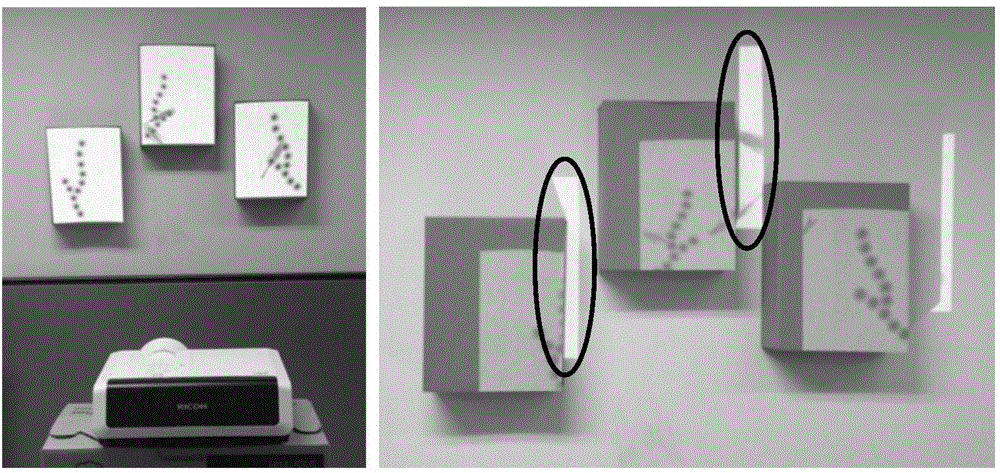

Lens adjusting device and projection optical system

ActiveCN105403975AGood optical axis consistencyResolve offsetProjectorsMountingsOptical axisEngineering

The invention discloses a lens adjusting device and a projection optical system. The lens adjusting apparatus includes a first adjustment base, a second adjustment base and a third adjustment base which are arranged sequentially; the first adjustment base is provided with a first hollow part, a first positioning component arranged at the side wall of the first adjustment base, and first positioning datum holes located at the upper part of the first adjustment base; the second adjustment base is provided with a second hollow part, a first bending component arranged at the side wall of the second adjustment base, a second bending component arranged at the upper part of the second adjustment base, and second positioning datum holes located at the upper part of the second adjustment base; and the third adjustment base is provided with a third hollow part, a third bending component arranged at the upper part of the third adjustment base, and second positioning datum holes located at the upper part of the third adjustment base. With the lens adjusting device of the invention adopted, the consistency of the optical axis of the optical system can be ensured greatly.

Owner:CHINA HUALU GRP

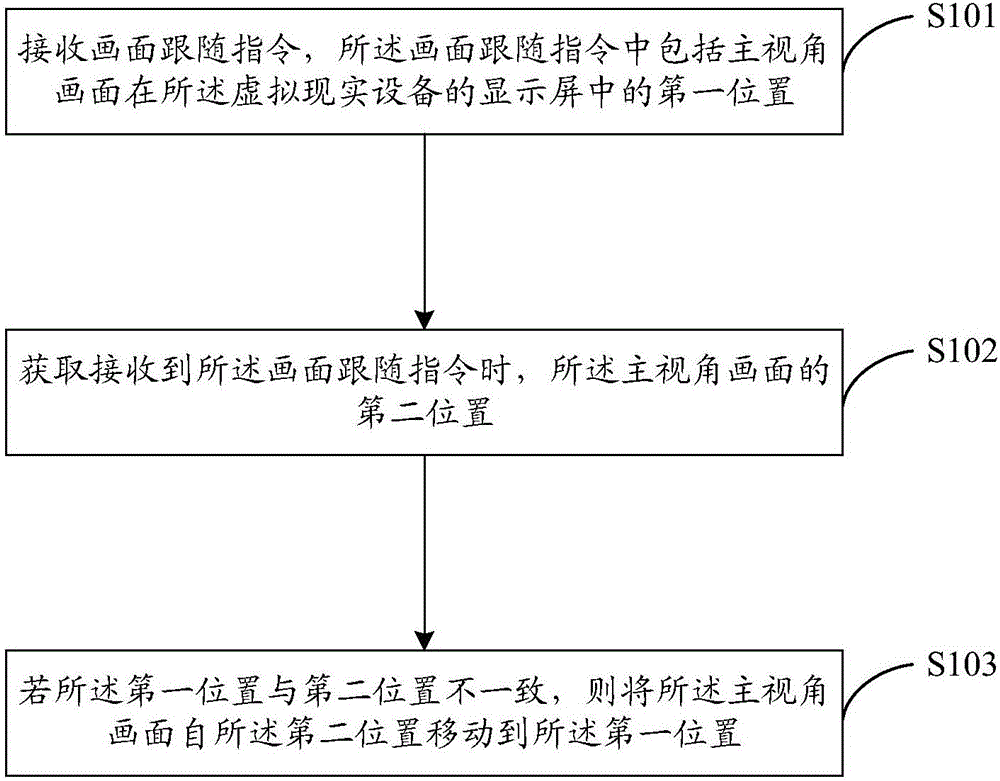

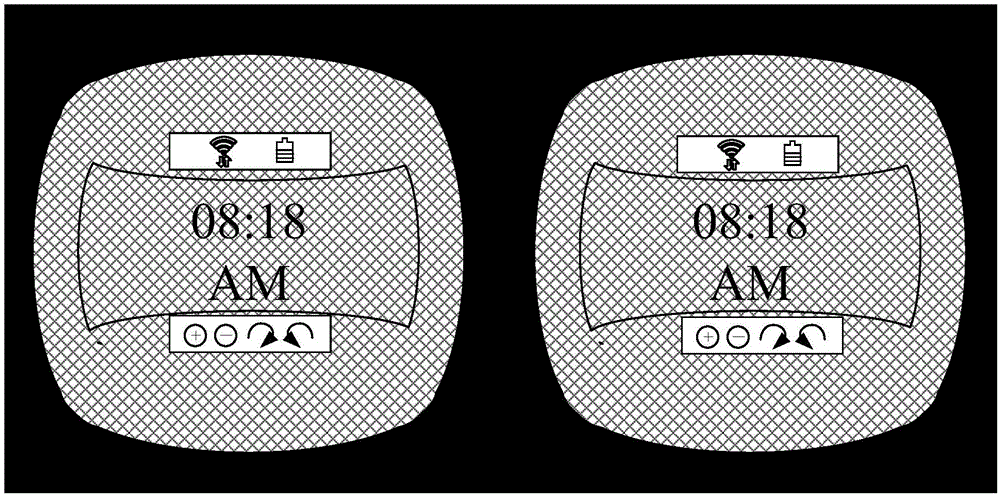

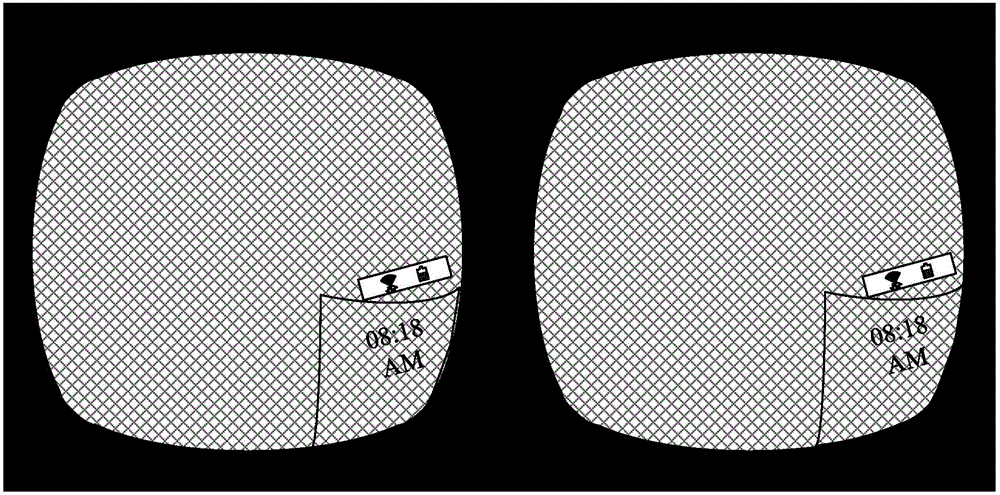

Image display method and device of virtual reality equipment

ActiveCN106354258AResolve offsetInput/output for user-computer interactionGraph readingComputer scienceVirtual reality

The invention relates to the technical field of virtual reality and discloses an image display method and device of virtual reality equipment. The method includes: receiving an image following instruction which includes the first position of a main-viewing-angle image in the display screen of the virtual reality equipment; acquiring the second position of the main-viewing-angle image when the image following instruction is received; moving the main-viewing-angle image from the second position to the first position if the first position and the second position are inconsistent. By the method, the problem of main-viewing-angle image deviation can be solved.

Owner:上海乐相信息科技有限公司

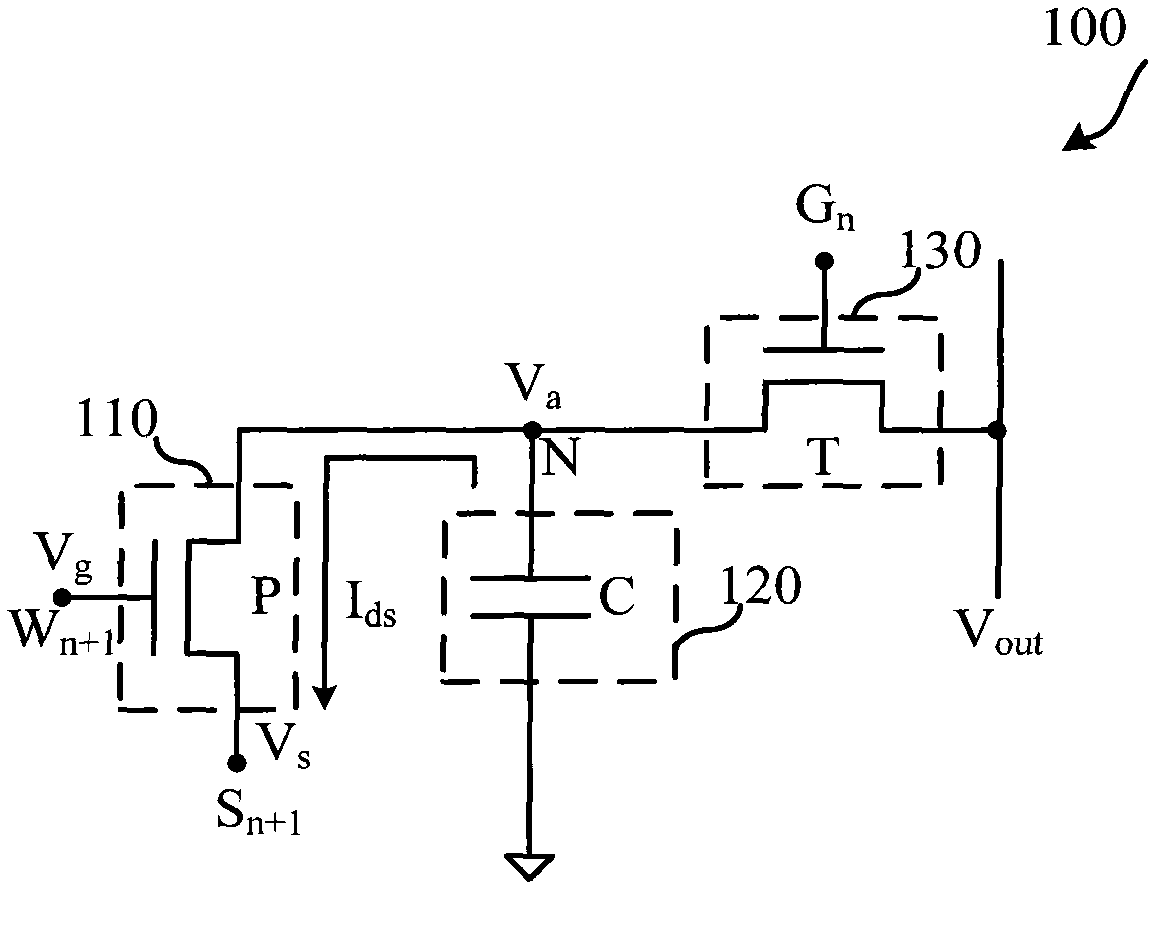

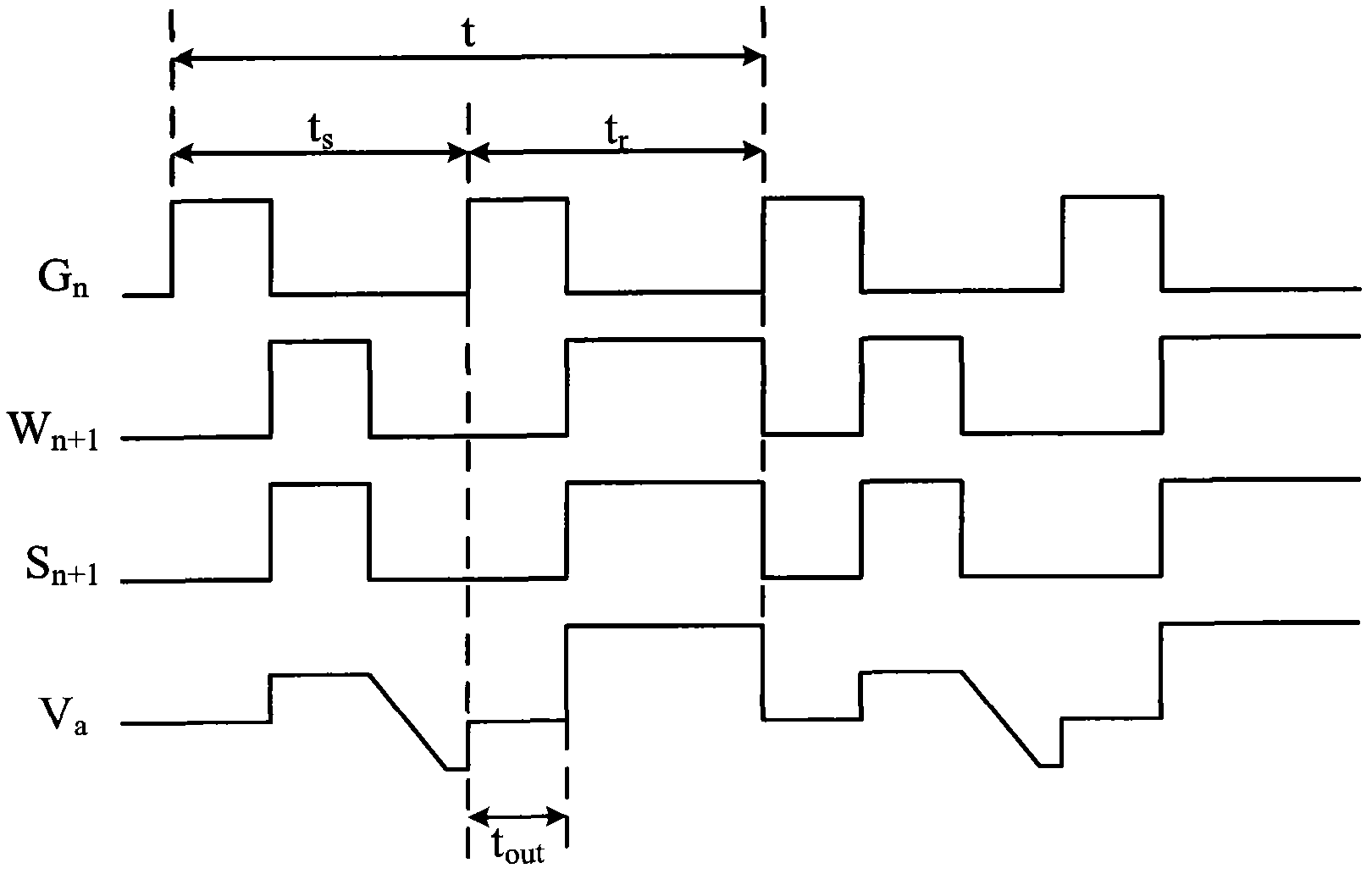

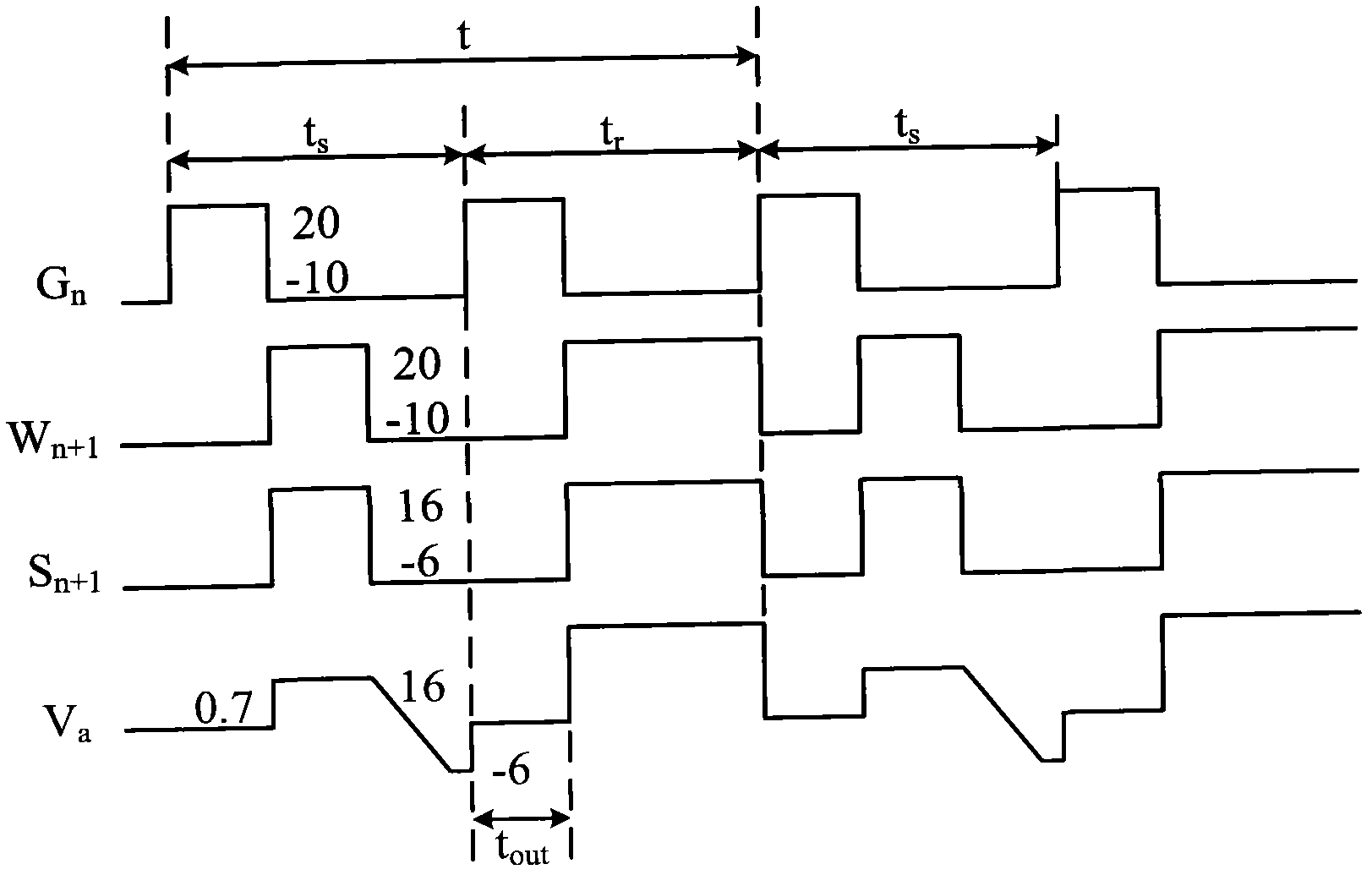

Light sensation type touch device and drive method thereof

InactiveCN102360257APrecise touchResolve offsetInput/output processes for data processingEngineeringDrain current

The invention provides a light sensation type touch device and a drive method thereof. The drive method comprises the step of: defining a scheduled period, wherein the scheduled period comprises a sensation period and an updating period, a first drive voltage is provided to the light sensation type touch device in the sensation period, and a second drive voltage is provided to the light sensation touch type touch device in the updating period. The light sensation type touch device and the drive method provided by the invention are used for correction deviation of a light sensation type film crystal in the updating period, thereby overcoming the problem of deviation of a leakage current-bias voltage curve and further ensuring that whether the light sensation type touch device is more accurately touched.

Owner:AU OPTRONICS CORP

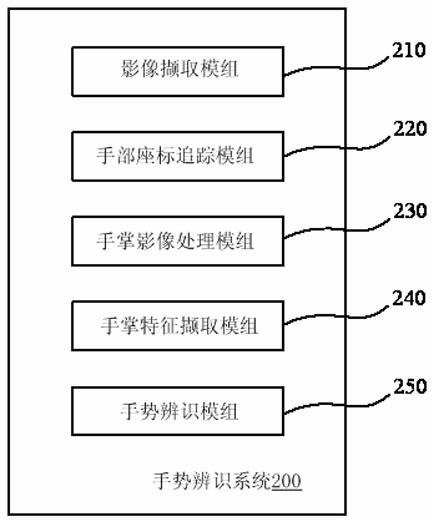

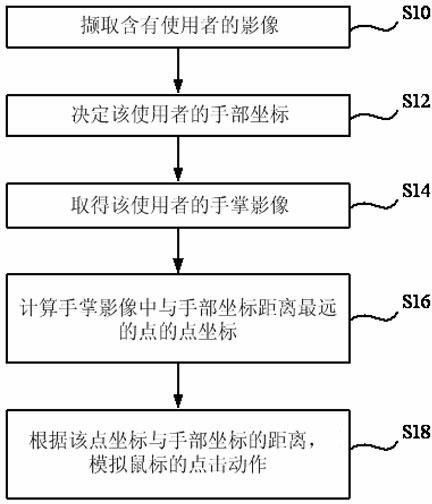

Gesture recognition system and method

ActiveCN102520794AResolve offsetInput/output for user-computer interactionGraph readingSimulationGesture recognition

The invention provides a gesture recognition system and a gesture recognition method. The pressing operation and loosening operation of a mouse are simulated by using hand opening and closing gestures of a user. During simulation of key clicking, particularly key double-clicking, of the mouse, the coordinates of the hand cannot be offset. By the invention, the problem that the coordinates of the hand are offset in the conventional mode of simulating the key clicking motion of the mouse can be solved.

Owner:苏州盛泽科技创业园发展有限公司

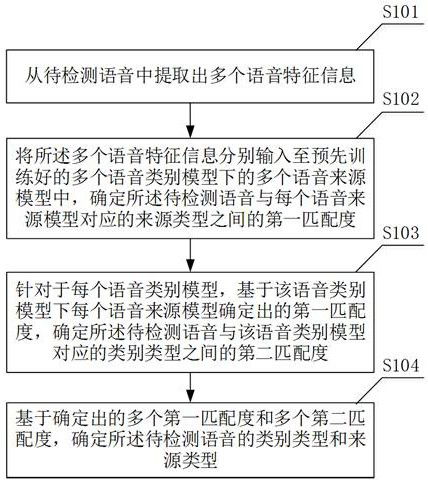

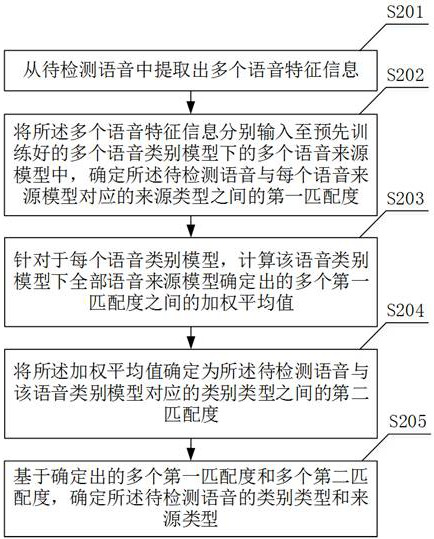

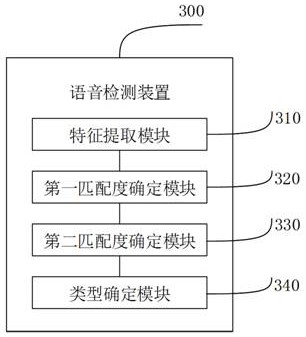

Voice detection method and device, electronic equipment and storage medium

ActiveCN112712809ASolve the problem of deviation of detection resultsResolve offsetSpeech analysisEngineeringSpeech sound

The invention provides a voice detection method and device, electronic equipment and a storage medium. The method comprises the steps: extracting multiple pieces of voice feature information from the to-be-detected voice; respectively inputting the voice feature information into a plurality of pre-trained voice source models, and determining a first matching degree between the to-be-detected voice and the source type of each voice source model; for each voice category model, determining a second matching degree between the to-be-detected voice and the category type corresponding to the voice category model based on the determined first matching degree; and based on the determined plurality of first matching degrees and the determined plurality of second matching degrees, determining a category type and a source type of the to-be-detected voice. Thus, voice detection is carried out by adopting the voice category model and the voice source model under the voice category model, voice authenticity and voice source detection is completed, the problem of detection result offset of an existing voice detection technology is solved, and the accuracy of the voice detection method is improved.

Owner:北京远鉴信息技术有限公司

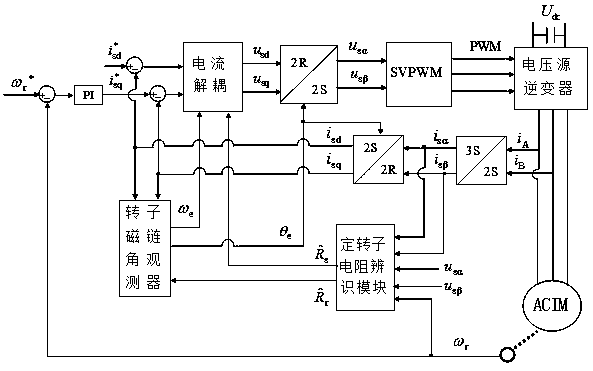

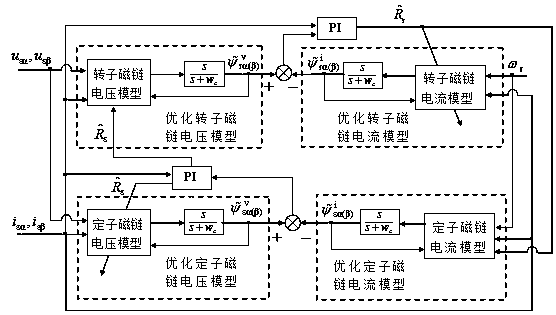

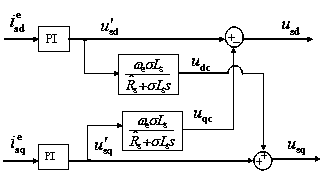

Rotor resistance and stator resistance online identification method for induction motor used for low speed electric vehicles

InactiveCN108631677AResolve offsetSmall amount of calculationElectronic commutation motor controlVector control systemsLow speedElectric vehicle

The invention provides a rotor resistance and stator resistance online identification method for an induction motor used for low speed electric vehicles. The identification for rotor resistance and the identification for stator resistance are realized based on an improved rotor flux linkage model and an improved stator flux linkage model respectively, and the identification precision is improved through interactive updating of the rotor resistance and the stator resistance. The rotor flux linkage voltage model is optimized by using a high-pass filter with variable cut-off frequency on the basis of the advantages of the rotor flux linkage model, so that the problems of direct current bias and integral saturation caused by a pure integral link are effectively avoided. Moreover, based on theonline identification of the improved stator flux linkage model for stator resistance, the identified stator resistance is fed back to the rotor flux linkage voltage model, so that the problem that the identification precision of rotor resistance is reduced by the change of the stator resistance is avoided. The method is applied to rotor flux linkage oriented vector control systems, so that the rotor flux linkage orientation is more accurate, efficient operation of a control system for the induction motor used for vehicles is guaranteed, and the dynamic property and reliability of the whole vehicle are improved.

Owner:SHANDONG UNIV OF TECH

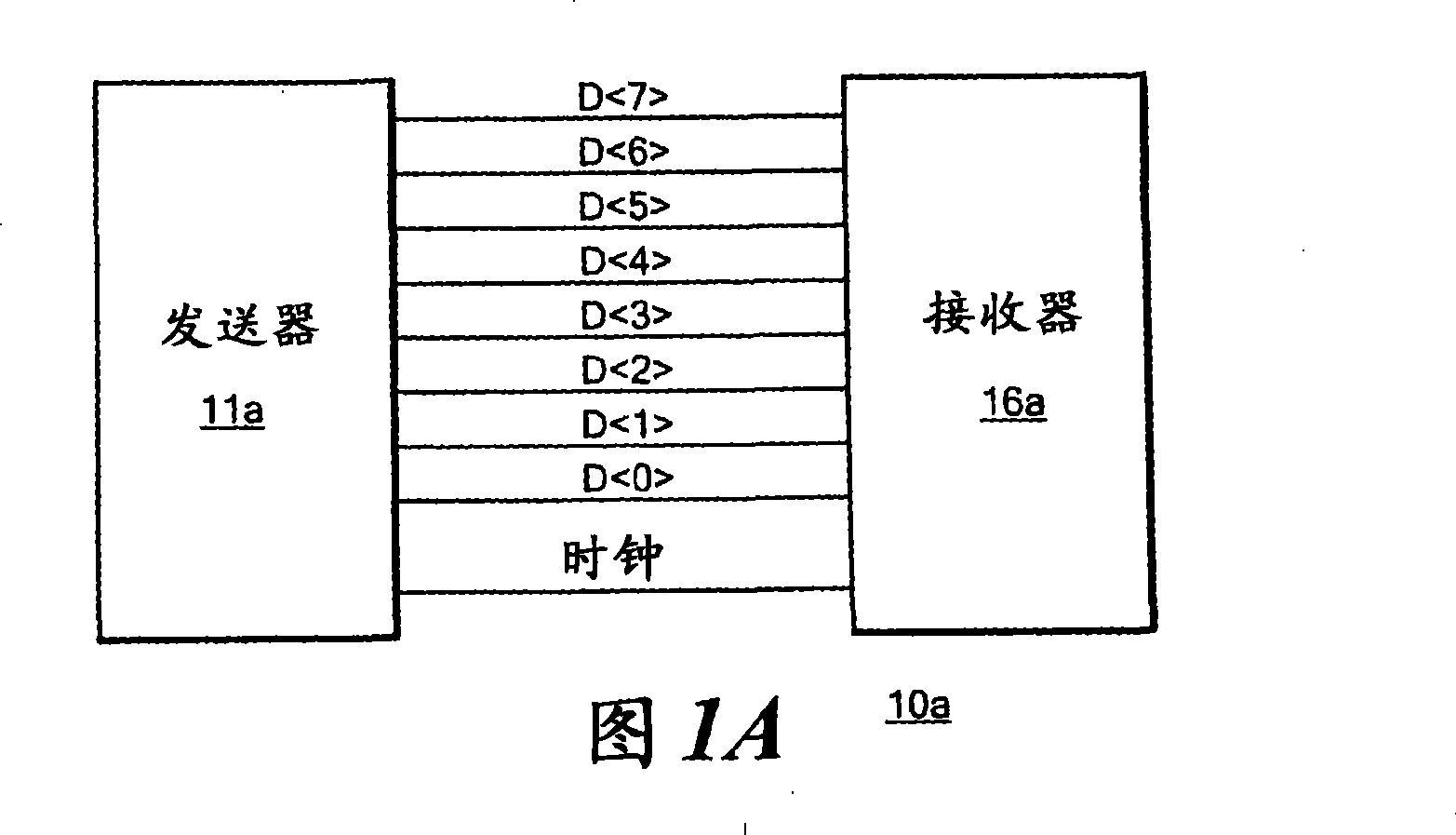

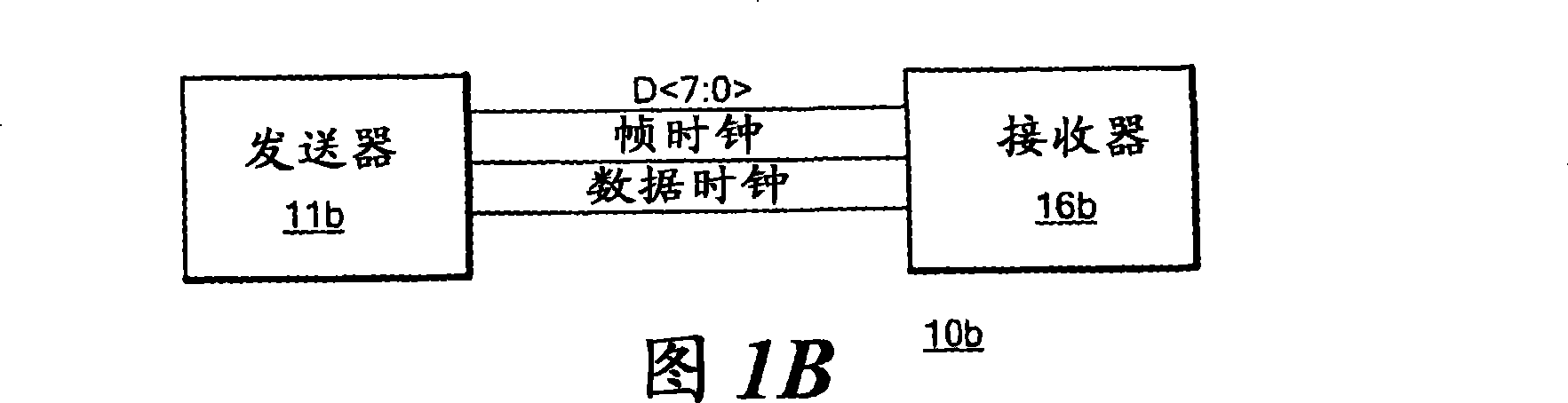

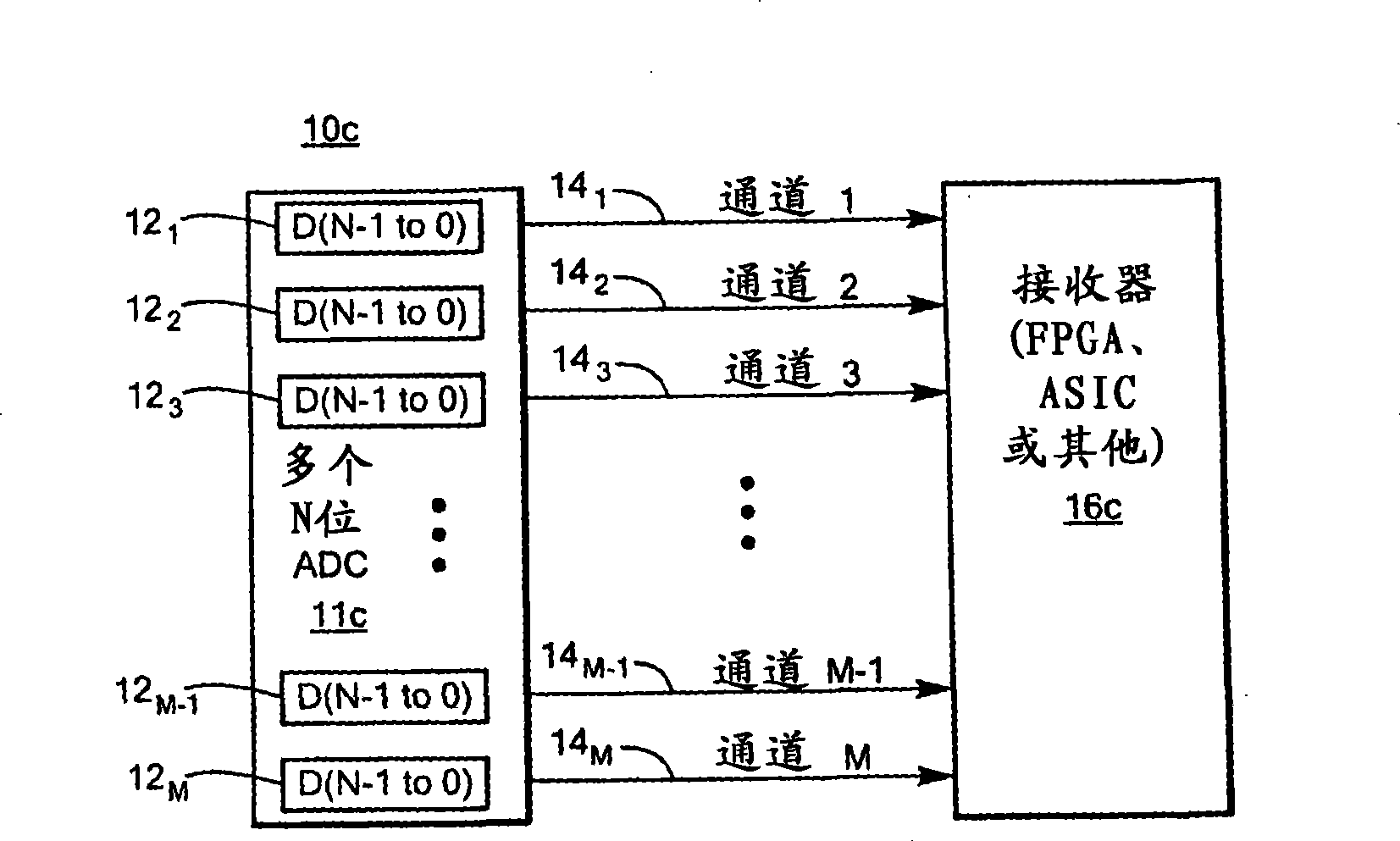

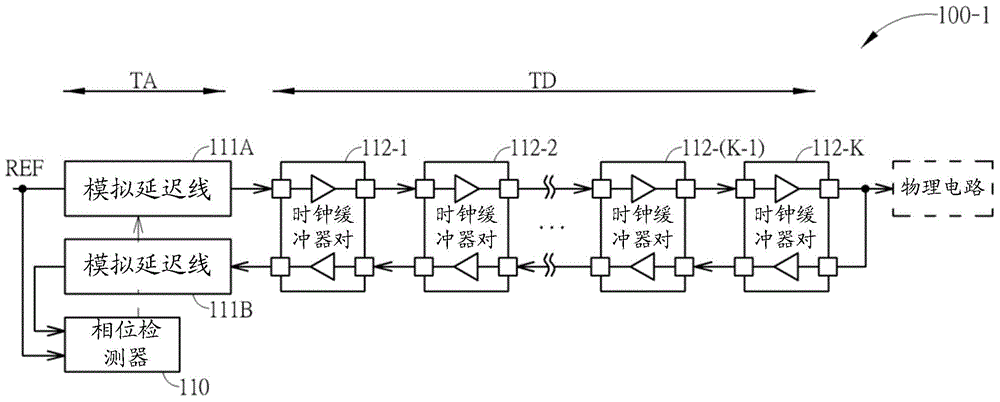

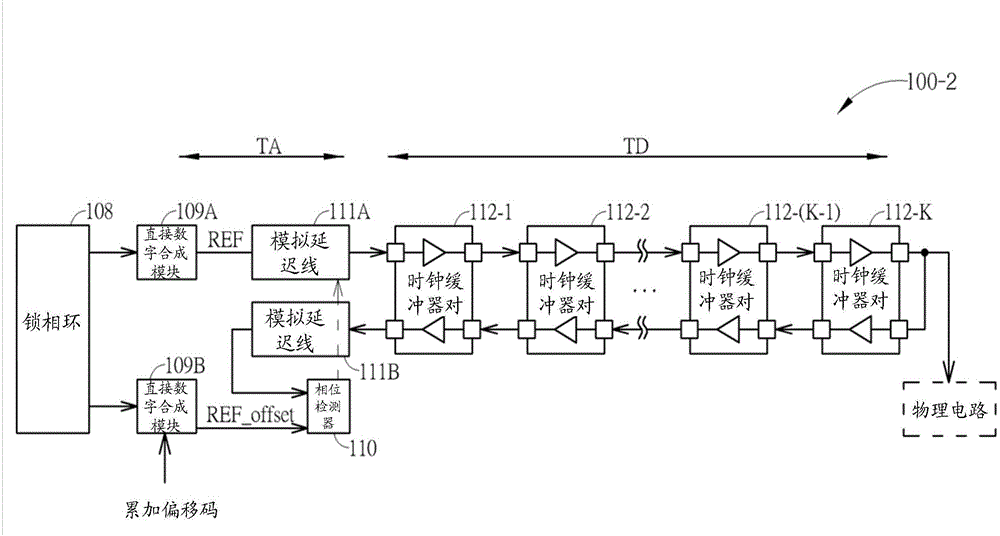

High speed transmission system

ActiveCN101366181AResolve offsetEliminates the need to adjust clocksAnalogue/digital conversionElectric signal transmission systemsNetwork packetTransmitter

Owner:ANALOG DEVICES INC

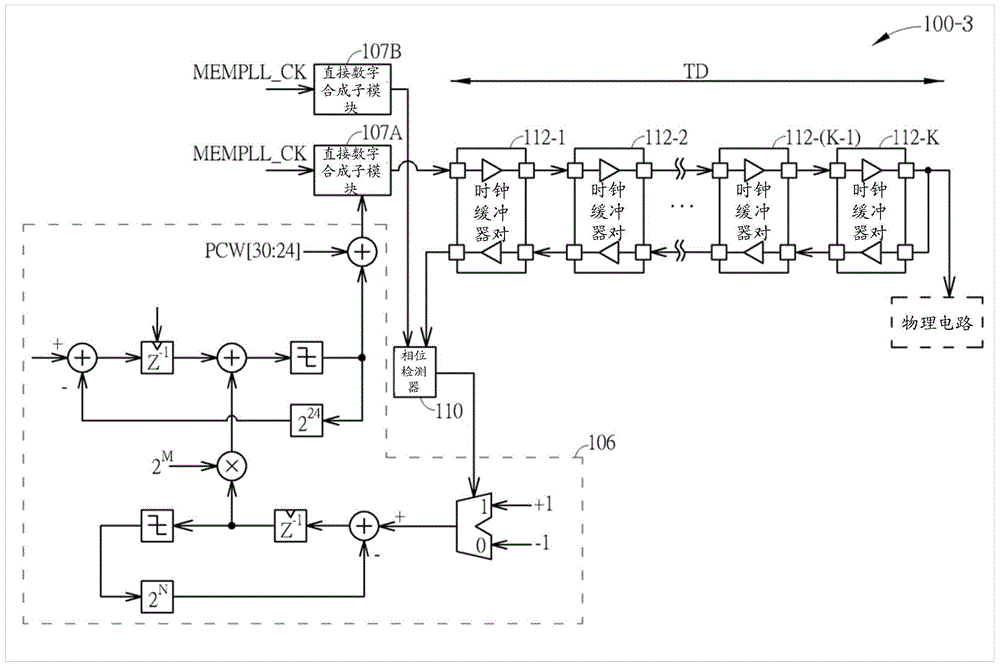

Method for performing memory interface control of an electronic device, and associated apparatus

InactiveCN104899165AGuaranteed performanceResolve offsetPulse automatic controlDigital storagePhase shiftedMemory interface

A method for performing memory interface control of an electronic device and an associated apparatus are provided, where the method includes the steps of: when it is detected that a phase difference between a data signal and a clock signal reaches a predetermined value, controlling the clock signal to switch from a first frequency to a second frequency, wherein both of the clock signal and the data signal are signals of a memory interface circuit of the electronic device, and the memory interface circuit is arranged for controlling a random access memory (RAM) of the electronic device; applying at least one phase shift to the data signal until a condition is satisfied; and controlling the clock signal to switch from the second frequency to the first frequency; wherein the memory interface circuit is calibrated with aid of the at least one phase shift.

Owner:MEDIATEK INC

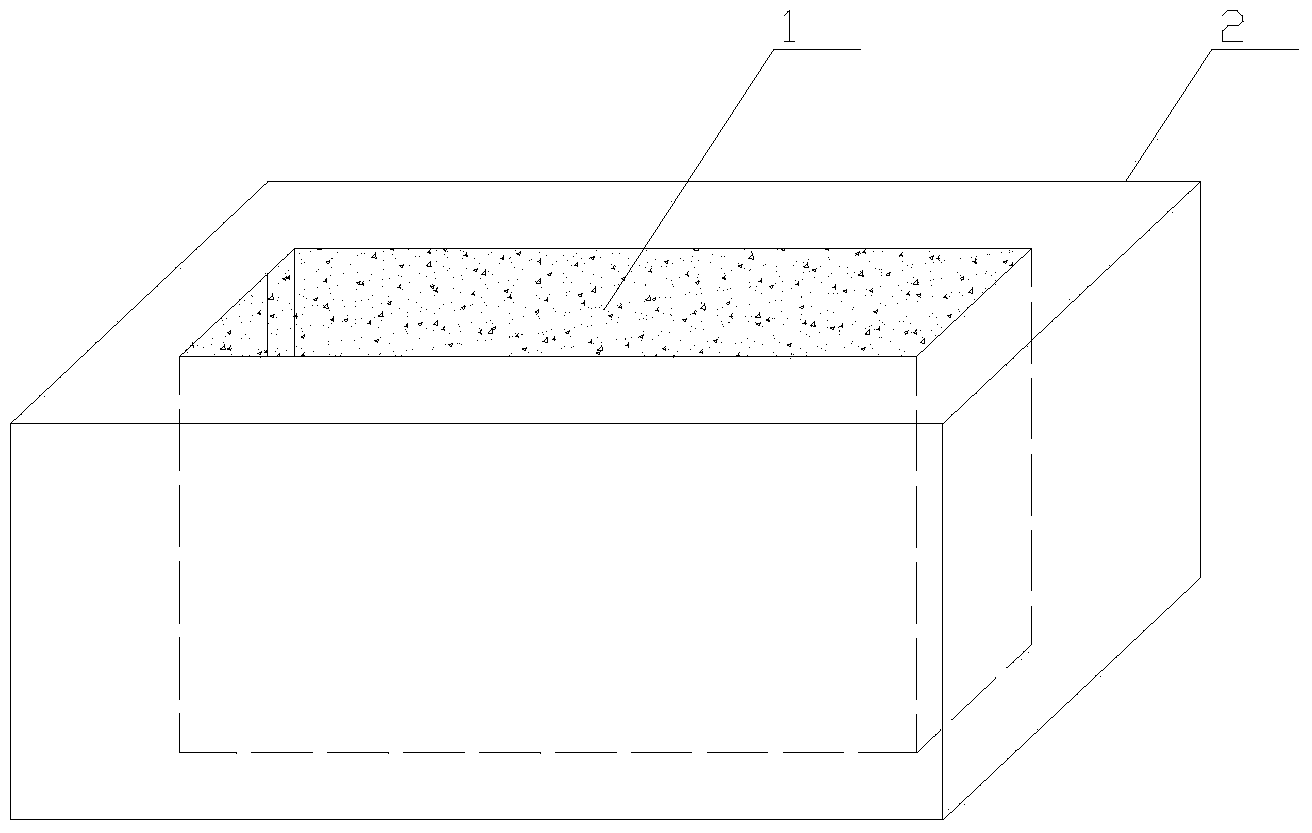

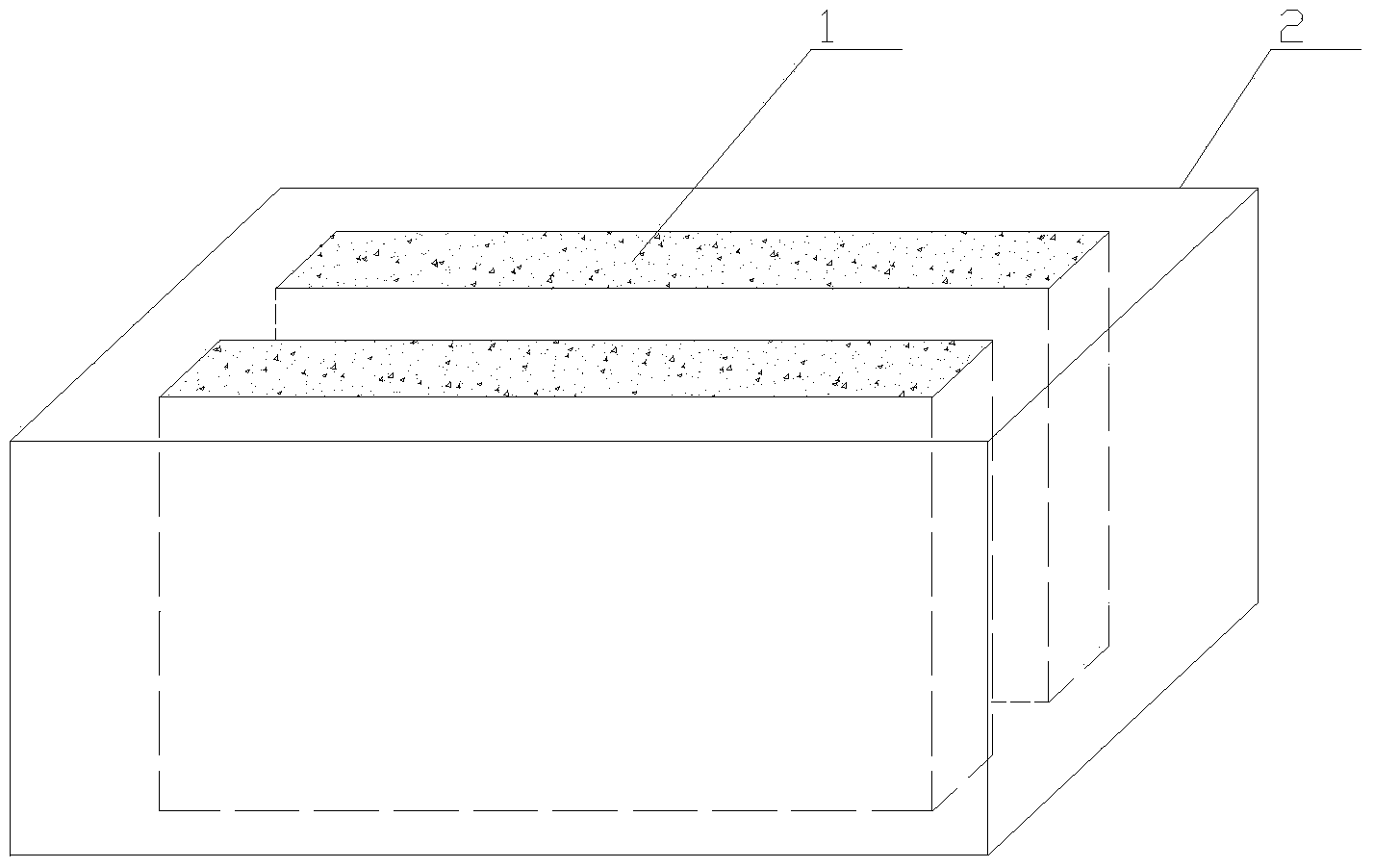

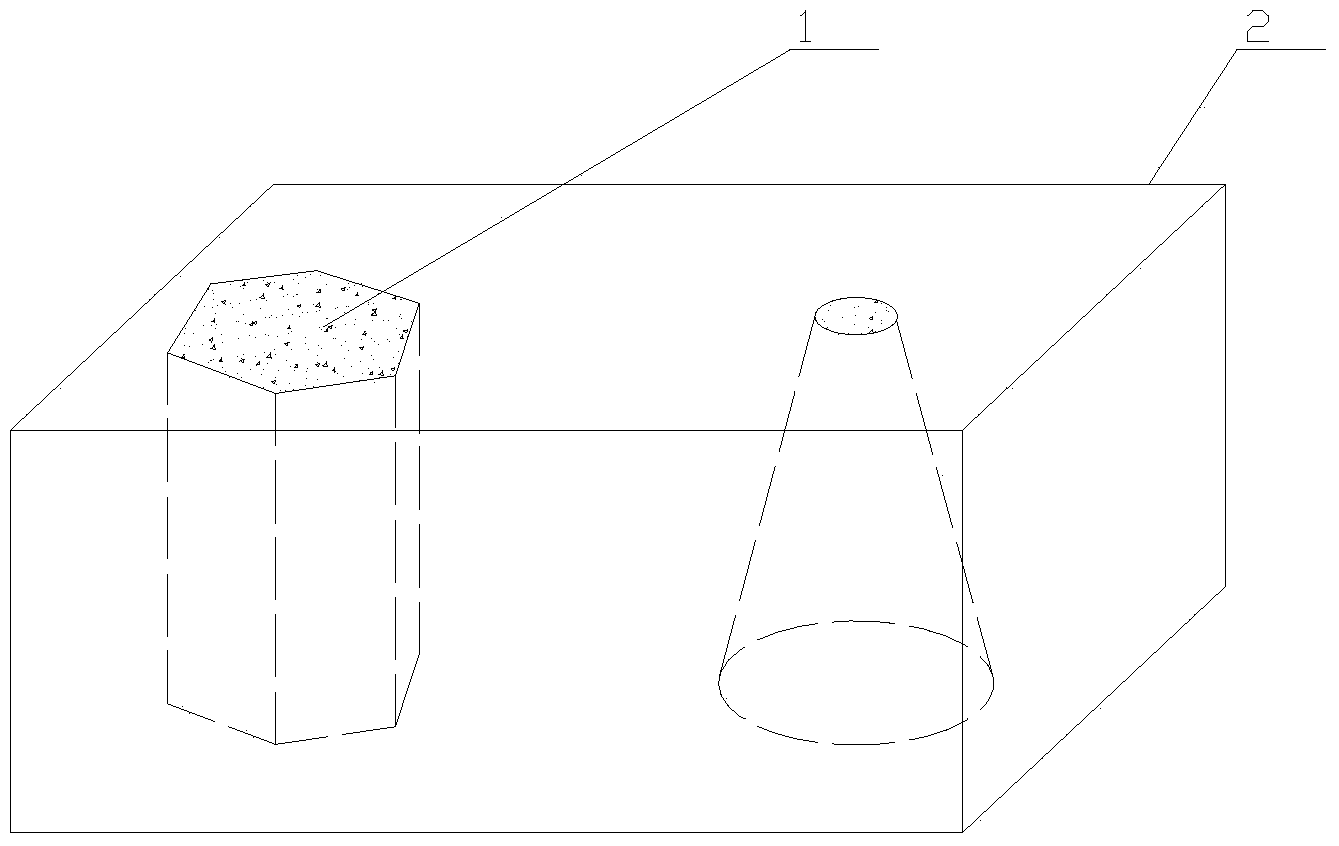

Composite building block as well as production mold and production method thereof

ActiveCN103833281ASolve floatingResolve offsetConstruction materialSolid waste managementCombustionUltimate tensile strength

The invention discloses a composite building block as well as a production mold and a production method thereof. The invention provides the composite building block which is stable in structure, high in specific strength, low in water absorption, good in size stability, high in combustion grade, good in heat preservation property and low in cost, and the production mold and the production method of the composite building block. The composite building block comprises a bearing base body and at least one heat preservation body, wherein the heat preservation body is prepared from the following components in percentage by weight: 40-60% of cement, 8-15% of silica fume, 3-5% of hydrogen peroxide, 0.5-1% of a modifying agent and 31-38% of water; the bearing base body is prepared from the following components in percentage by weight: 20-40% of cement, 0-40% of tailing sand, 25-65% of a construction waste raw material, 10-40% of coal ash, 3-5% of a fiber bar-shaped material, 0.10-0.40% of hydrogen peroxide, 0.7-1.6% of an additive and 20-36% of water; at least one accommodation hole is formed in the bearing base body; the heat preservation body is arranged inside the accommodation hole and is combined with the inner wall of the accommodation hole. The invention provides the composite building block which is stable in structure, high in specific strength, low in water absorption, good in size stability, high in combustion grade, good in heat preservation property and low in cost on the whole.

Owner:CHINA BUILDING MATERIALS ACAD

Plug-in type cable head disassembling tool

ActiveCN106936094AAvoid disadvantagesImprove the installation processApparatus for joining/termination cablesSwitchgearLeft halfEngineering

The invention provides a plug-in type cable head disassembling tool and relates to the technical field of power equipment, which comprising an upper clamping table. The upper clamping table is provided with a leading screw assembly. The leading screw assembly comprises a left half ring, a right half ring, a leading screw, a locking plate, a bolt and a leading screw pressing plate. The left half ring and the right half ring are provided with the locking plate. The left half ring and the right half ring are connected together through the bolt and a nut. The upper side of the left half ring and the upper side of the right half ring are provided with the leading screw pressing plate. The leading screw pressing plate is provided with a threaded hole. The leading screw spirally penetrates through the threaded hole and is inserted into a mounting hole in a lower clamping table. The leading screw is connected with an inner cone arranged below a cable plug-in type head. According to the technical scheme of the invention, the problem in the prior that the stress is not uniformly applied onto a cable terminal head can be effectively solved. Meanwhile, the offset and tilt problems of the cable terminal head of a metal armored cabinet can also be effectively solved. Moreover, the inconvenient installation problem due to the insufficient space of a cable cabin can be effectively solved.

Owner:HAIXI POWER SUPPLY COMPANY OF STATE GRID QINGHAI ELECTRIC POWER +2

Auxiliary frame sealing glue structure, box-aligning substrate and display device

ActiveCN103499903ASolve for misalignmentAvoid uneven box thicknessNon-linear opticsLiquid crystalSurface plate

The invention provides an auxiliary frame sealing glue structure, a box-aligning substrate and a display device. The auxiliary frame sealing glue structure is arranged between an upper substrate and a lower substrate and comprises an opening structure, a first frame and a second frame connected with one end of the first frame, wherein the connecting position of the first frame and the second frame is in a sealed state. According to the auxiliary frame sealing glue structure, the junction position of the two frames on a windward surface in the rotation process is set to be in the sealed state, the opening structure is arranged in another position, the substrate is prevented from being affected by air resistance caused by rotation, the problem of deviation of a glass substrate in the rotation process is resolved, and further aligning deviation problem is effectively resolved. In addition, the uneven thickness of a box at the peripheral edge of a signal liquid crystal panel caused by uneven external atmospheric pressure acting on the inside and the outside of the substrate is avoided, and therefore the quality and yield of products are largely improved.

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD

Twin-chamber limekiln masonry measuring and positioning method

The invention discloses a twin-chamber limekiln masonry measuring and positioning method which comprises the following steps: (1) a hanging scaffold is selected as a line laying work platform; (2) a line laying coil holder and a coil holder inclined strut are manufactured according to masonry size; (3) the hanging scaffold is lifted to an assigned position according to design requirements, the line laying coil holder and the coil holder inclined strut are fixed and a plumb bob and a white line are suspended; (4) the bracket pillar positioning white line is used as a border line to lay bracket pillars upwards step by step, and the bracket pillar control coil holder is used as a border line to control masonry height of the bracket pillars; and (5) an annular channel control white line is used as a border line to lay the internal wall upwards step by step, the distance between the internal wall and the center is measured during laying of 3-4 layers, and masonry radius is controlled. By the method, the positioning difficulty in masonry process is solved, construction quality is guaranteed, masonry efficiency is guaranteed, and construction cycle is shortened.

Owner:TIANJIN 20 CONSTR

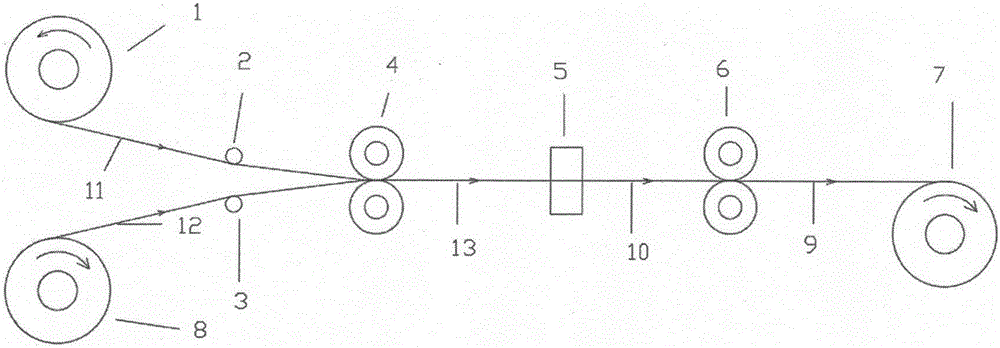

Method for molding micro-profiled composite joint strips

ActiveCN106807750AEfficient productionStable productionRollsMetal rolling arrangementsStress pointRoll forming

The invention discloses a method for molding micro-profiled composite joint strips. The method is characterized by comprising the following steps: performing wire drawing or roller drawing on square composite wires for pre-forming the needed double-peak appearance wires; and performing final forming on the pre-formed composite wires through a precision-rolling mill with a welding rib limited concave-convex molding roller, thereby obtaining the needed product with a special profile shape. The stress point of the composite strip in the rolling process is changed in a manner of pre-forming the double-peak appearance, so that the interface of the micro-profiled composite wire can be straightened, the precious metal cladding phenomenon is reduced, the utilization rate of precious metals is greatly improved, and the needed micro-profiled composite product is easily formed; and moreover, rolling forming is performed by utilizing the welding rib limited roller, the welding rib position does not need to be adjusted in the production process, the process wastes can be reduced, the production efficiency is improved, and the production cost of the whole product is reduced.

Owner:SHANGHAI TOUCH METALS TECH

Asphalt pavement crack filling device

InactiveCN113026514AResolve offsetPrevent overflowRoads maintainenceStructural engineeringRoad construction

The invention relates to the technical field of road construction, in particular to an asphalt pavement crack filling device, which is characterized in that the deflection direction of a wheel is controlled through the relative movement of a probe, so that a spray head always faces the position of a notch; additionally, the nozzle is provided with a flow control device; along with the change of the groove width, the flow change is controlled in real time, and the crack pouring glue is prevented from overflowing or being not filled.

Owner:霍延敏

Method, equipment and system for generating lightscribe projection content

ActiveCN106034213APromote rapid formationPromote formationTelevision system detailsPicture reproducers using projection devicesProjection mappingMask layer

The invention provides a method, equipment and system for generating a lightscribe projection content. The method comprises: after a position change of lightscribe projection equipment is obtained, the lightscribe projection equipment is used for shooting an image of a projected material object; all profile points, corresponding to the profile of the projected material object, in a mask layer of an original lightscribe projection content before the position change are determined; on the basis of stereoscopic vision matching, corresponding points of all profile points in the obtained image of the projected material object are determined, and a new mask layer is formed based on the set of the corresponding points; and with the new mask layer, a new lightscribe projection content after the position change of the lightscribe projection equipment is generated. On the basis of the lightscribe projection content generation technology, the new mask layer can be formed automatically by using the stereoscopic vision technology when the position of the projection equipment changes, so that the new lightscribe projection content can be generated rapidly and conveniently. Therefore, problems of lightscribe projection content offset and light leak can be solved.

Owner:RICOH KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com