Twin-chamber limekiln masonry measuring and positioning method

A technology of double-chamber lime kiln and positioning method is applied in the directions of measuring devices, measuring instruments, surveying and mapping, and navigation, etc., which can solve the problems of shortening construction period and difficult positioning, and achieve the effects of convenient size control, simple production and accurate positioning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

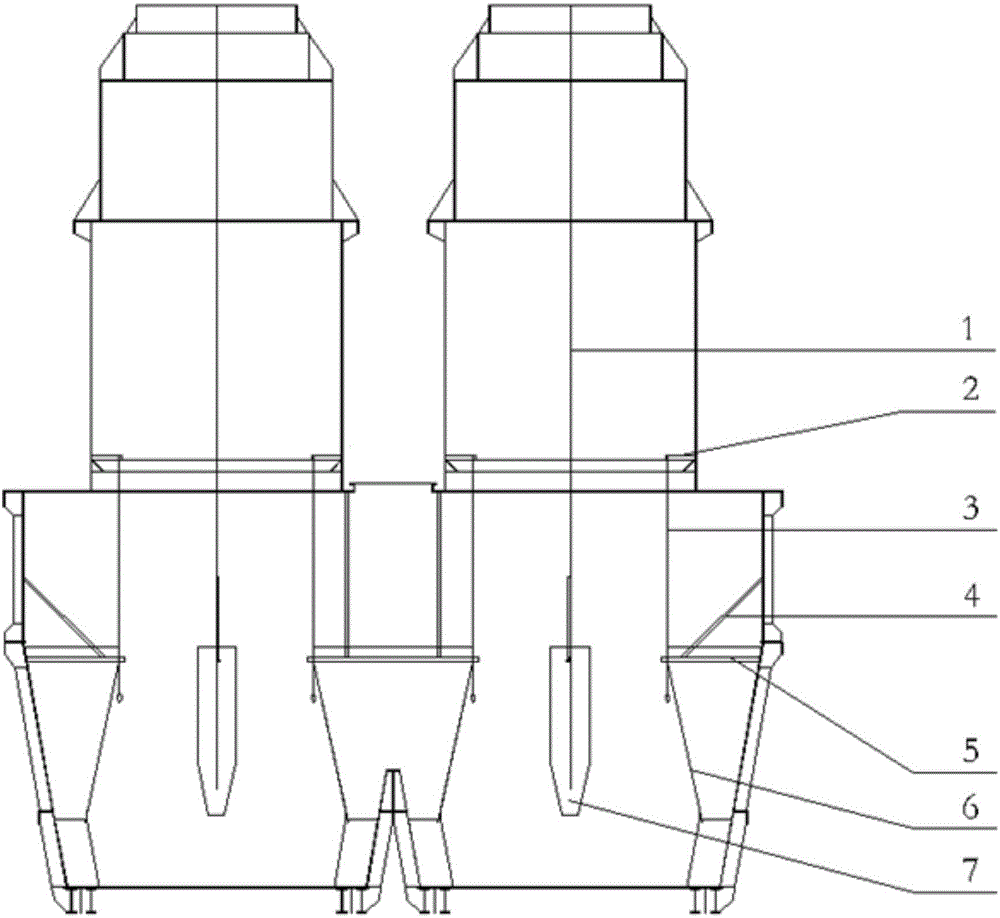

[0020] Below in conjunction with accompanying drawing, the present invention is further described:

[0021] like figure 1 As shown, a method for measuring and positioning the masonry of a double-chamber lime kiln includes the following steps:

[0022] (1) Select the hanging plate as the pay-off work platform;

[0023] (2) According to the size of the masonry, the pay-off stand and the line stand diagonal support 4 are made, and the pay-off stand and the line stand support 4 are both composed of angle steel with a model of L50, and are connected by welding;

[0024] (3) Lift the hanger to the designated position according to the design requirements, fix the pay-off stand and the diagonal brace 4 of the line stand, and hang the plumb bob 7 and the white wire; the plumb bob 7 is the center of the kiln chamber, so the rope for suspending the plumb bob 7 is The center line 1, wherein the white line and the rope for hanging the plumb weight are made of 22# iron wire, and the pay-o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com