Auxiliary frame sealing glue structure, box-aligning substrate and display device

A technology for aligning cell substrates and display devices, applied in nonlinear optics, instruments, optics, etc., can solve problems such as poor alignment, different cell alignment pressure, and uneven cell thickness around a single liquid crystal panel, so as to improve quality and yield , Solve the alignment deviation and avoid the effect of uneven box thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

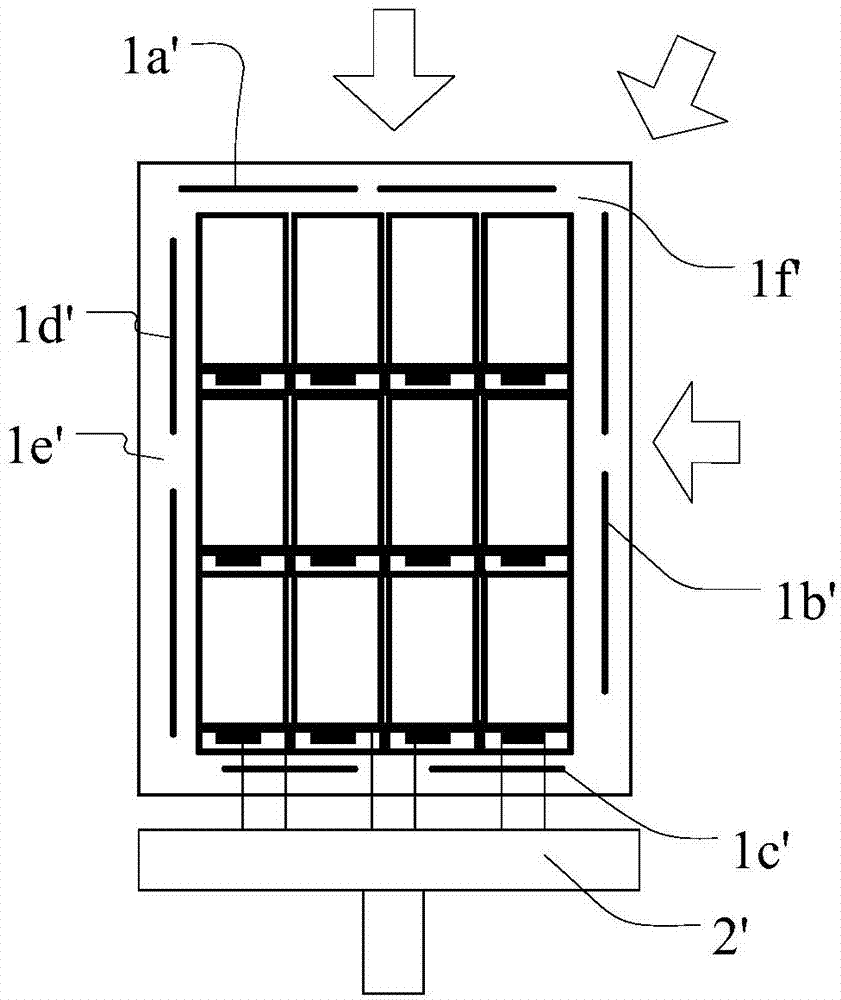

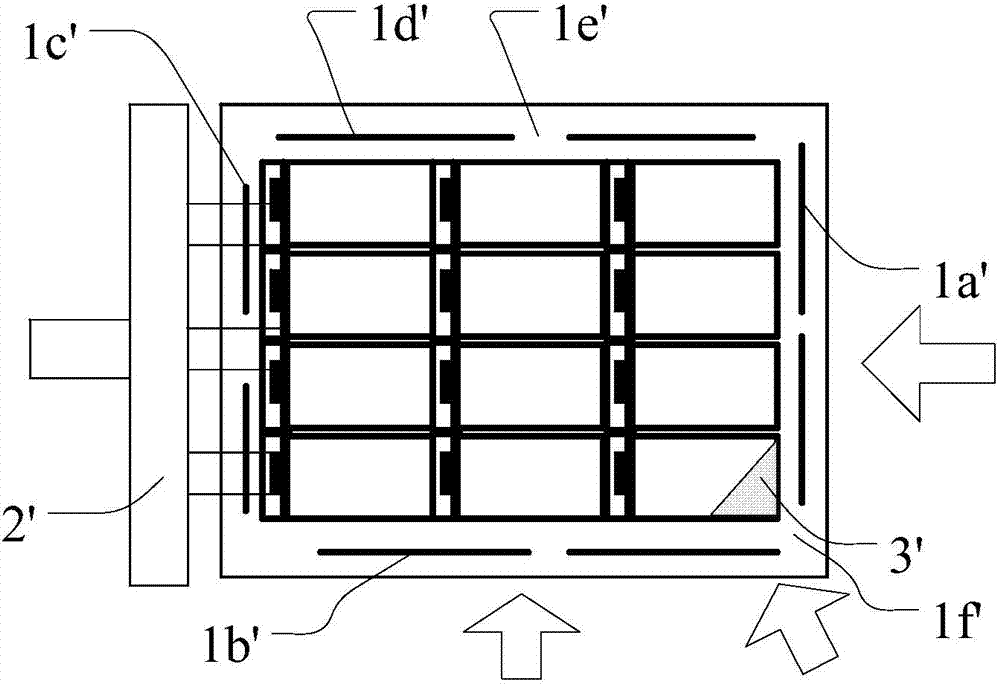

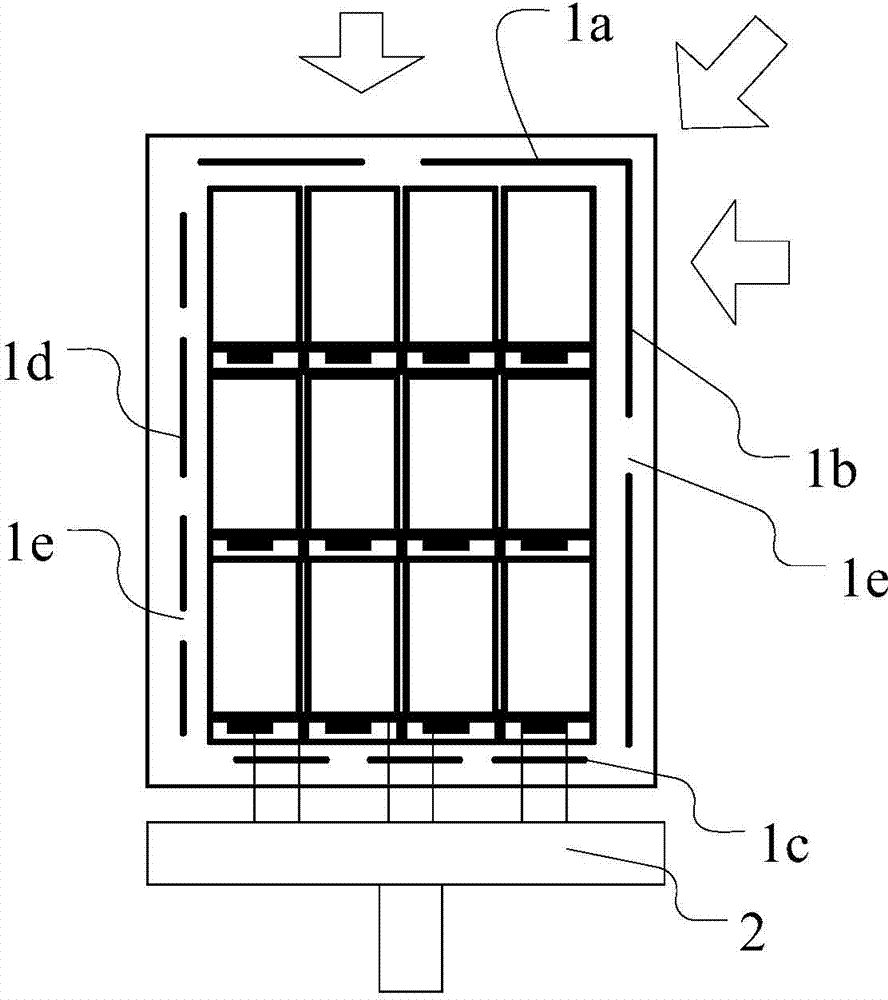

[0028] image 3 It is a schematic diagram of an auxiliary frame sealant structure provided in an embodiment of the present invention. The auxiliary frame sealant structure is arranged between the upper substrate and the lower substrate. The auxiliary frame sealant includes an opening structure 1e, a first frame 1a, and a One end of the first frame is connected to the second frame 1b, and the connection between the first frame 1a and the second frame 1b is in a closed state.

[0029] Since the auxiliary frame sealing structure in the non-closed state includes an opening structure, during the rotation of the substrate, the first frame and the second frame of the auxiliary f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com