Patents

Literature

345results about How to "Solve misalignment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-precision map data processing method and high-precision map data processing device

ActiveCN105260988AEliminate ghostingImprove clarityImage enhancementInstruments for road network navigationComputer scienceData processing

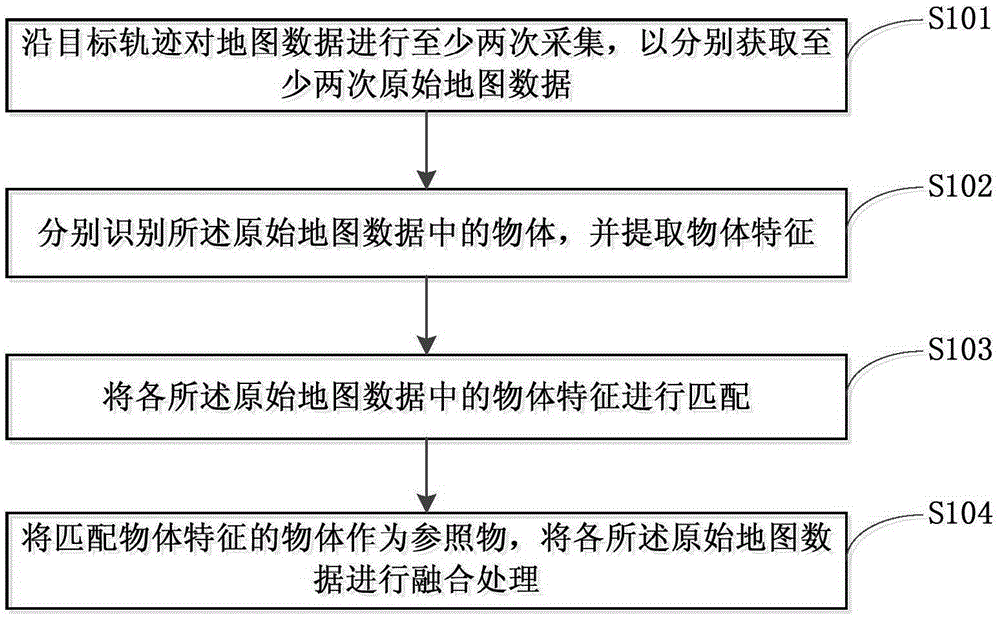

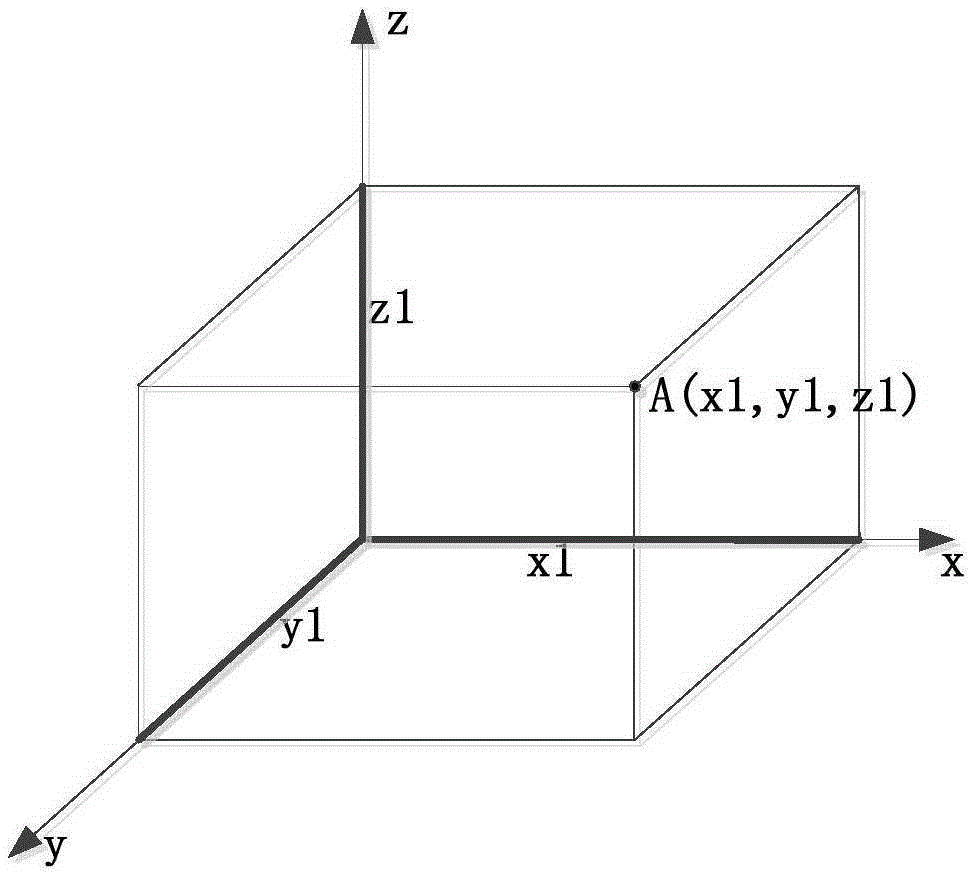

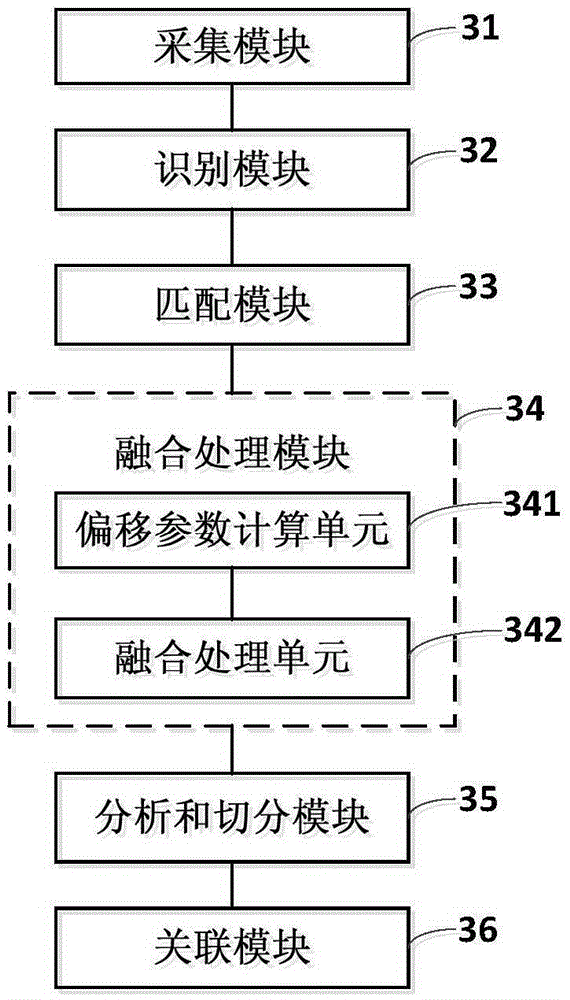

The embodiment of the invention discloses a high-precision map data processing method and a high-precision map data processing device. The method comprises the following steps of performing at least twice collection on map data along a target track so as to respectively obtain at least twice original map data; respectively recognizing objects in the original map data, and extracting object features; matching the object features in each original map datum; using an object with the matched object features as a reference substance; and performing fusion processing on each original map datum. The embodiment of the invention has the advantages that the objects in the original map data are recognized; the object features are extracted; the object features in each original map datum are further matched; the object obtained after the matching is used as the reference substance; and the reference substance is used for performing fusion processing on the original map data. The problem of offset of objects in a map image is solved; the ghost problem of the map image is solved; and the definition of the map image is improved.

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

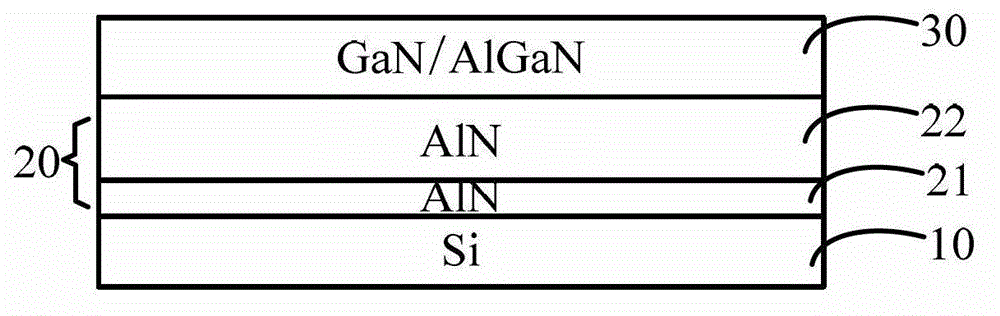

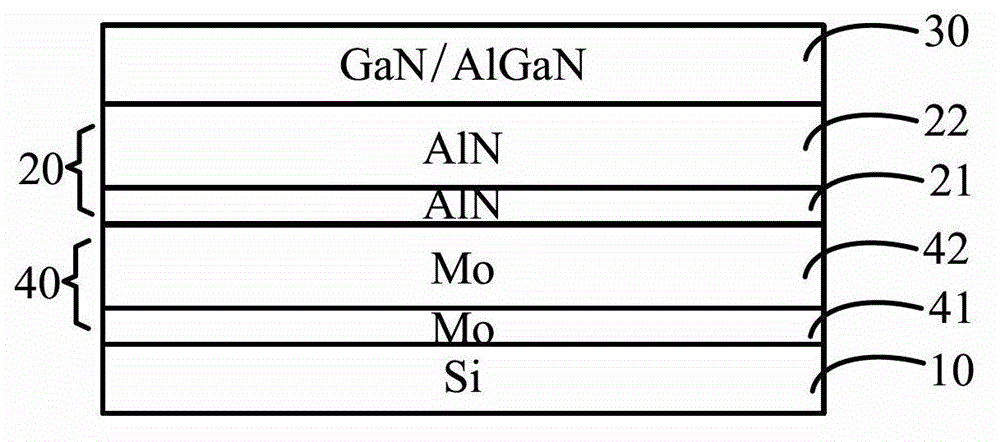

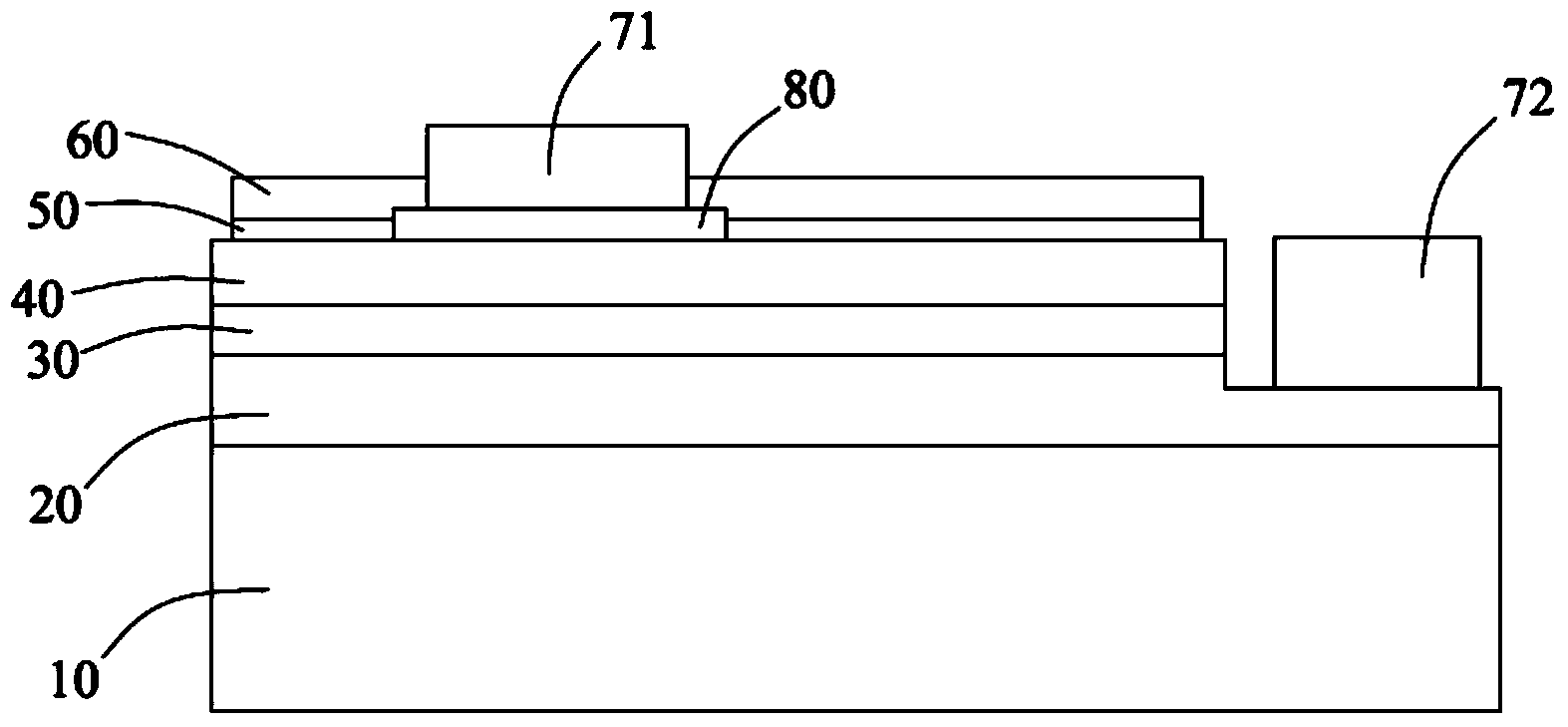

Growth method of compound semiconductor epitaxial layer on silicon substrate and device structure with epitaxial layer

ActiveCN103915537AImprove crystal qualityImprove performanceSemiconductor/solid-state device manufacturingSemiconductor devicesOrganometallic chemistryGas phase

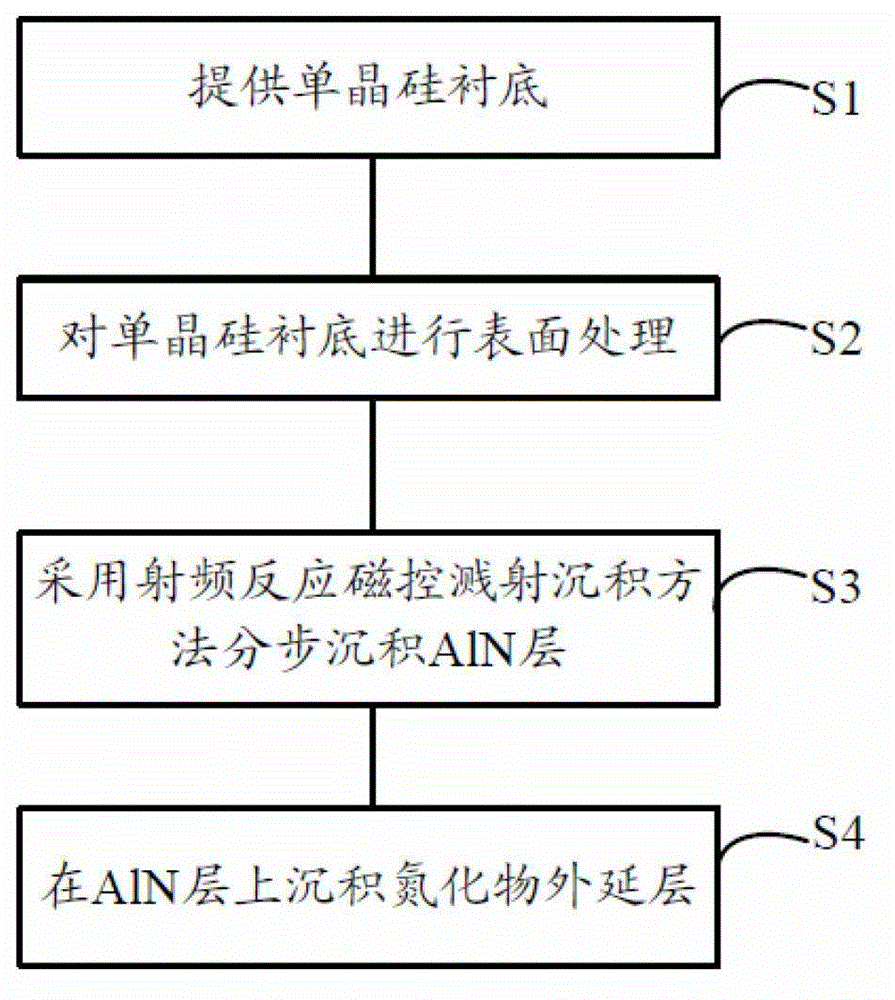

The invention discloses a growth method of a compound semiconductor epitaxial layer on a silicon substrate and a device structure with the epitaxial layer. The method comprises the steps of providing a single-crystal silicon substrate, carrying out surface processing on the single-crystal silicon substrate, depositing an AlN layer step by step through a radio frequency magnetron sputtering deposition method on the single-crystal silicon substrate, and depositing an AlN layer, or a GaN layer or an AlGaN layer on the AlN layer through an organometallic chemistry vapor deposition method or a hydride vapor phase epitaxy method. The AlN layer comprises an AlN nucleating layer used for controlling AlN crystal orientation and an AlN buffering layer used for controlling AlN crystal stress, and the AlN buffering layer is thicker than the AlN nucleating layer. The method effectively avoids the cracking and dislocation phenomenon caused by thermal mismatching and lattice mismatching, improves the crystal quality of the epitaxial layer, and enhances device performance.

Owner:DEPOSITION EQUIP & APPL SHANGHAI LTD

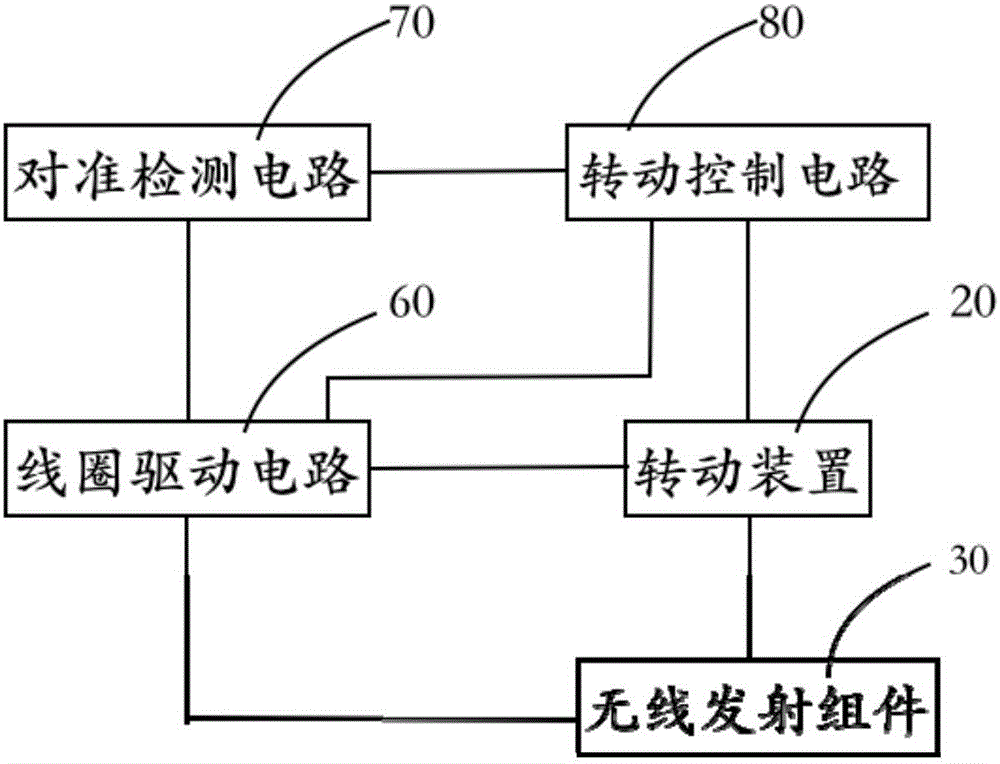

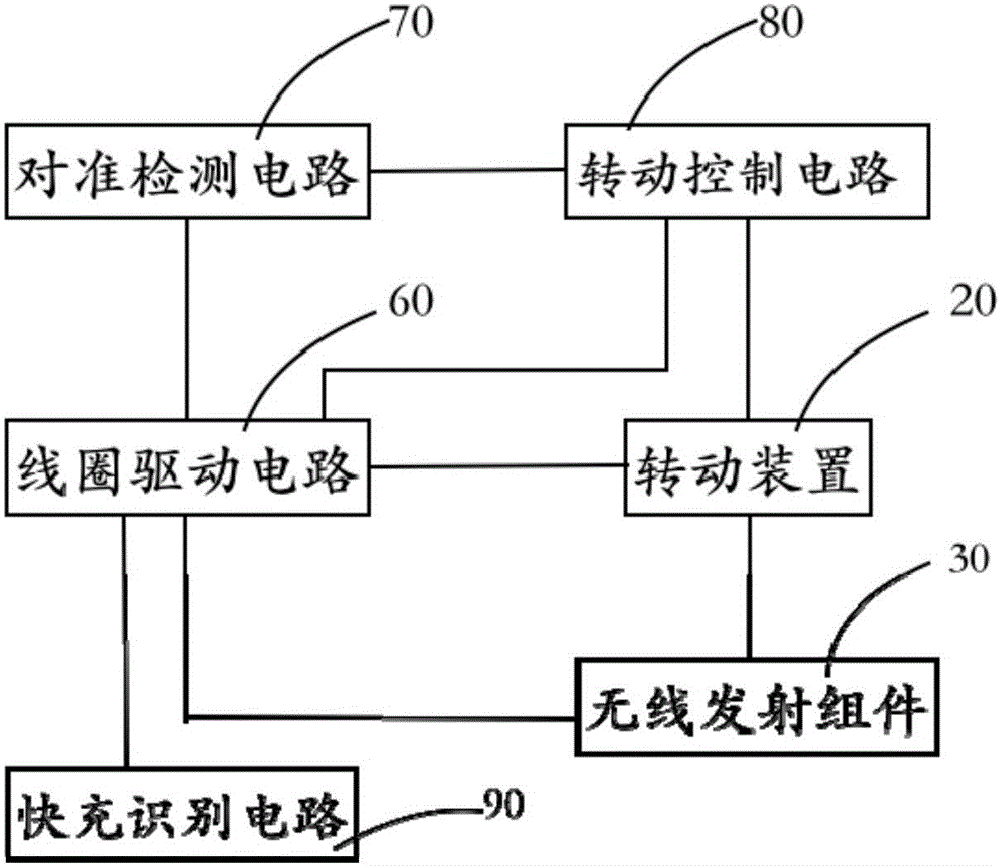

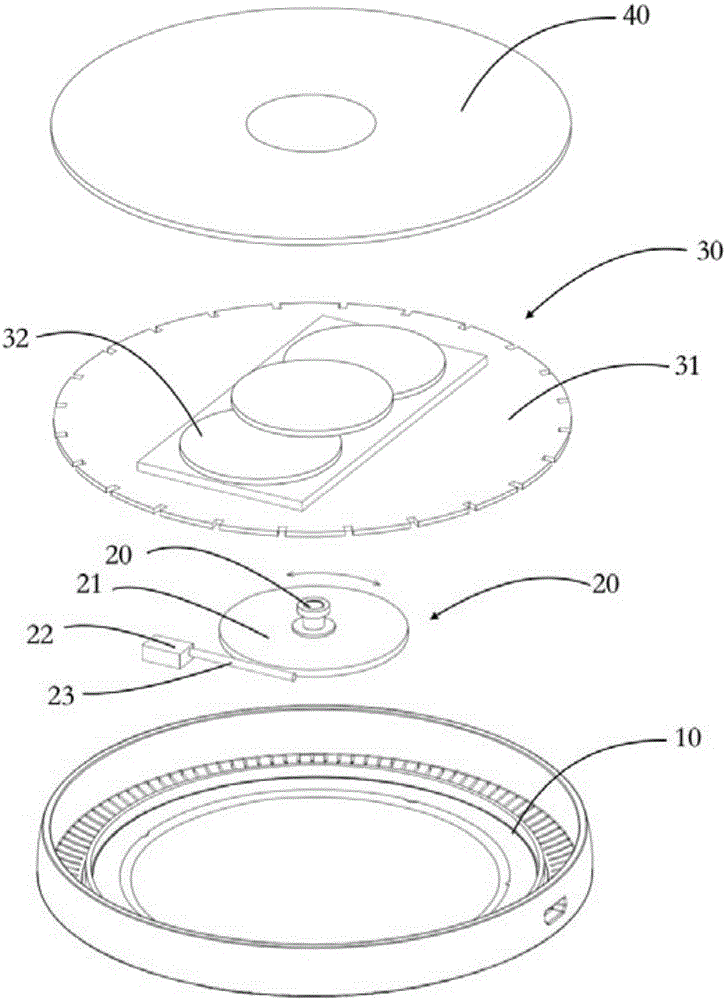

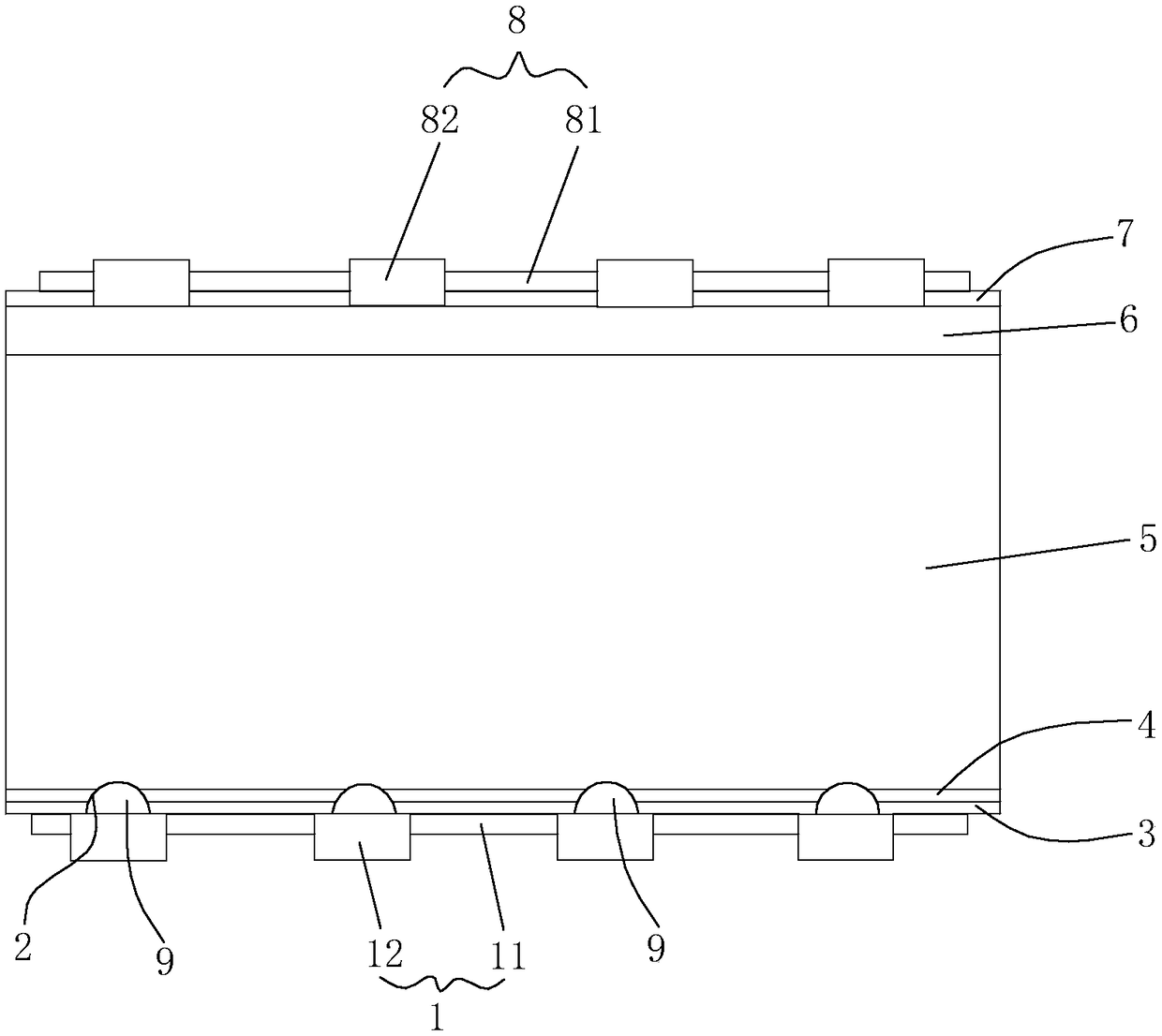

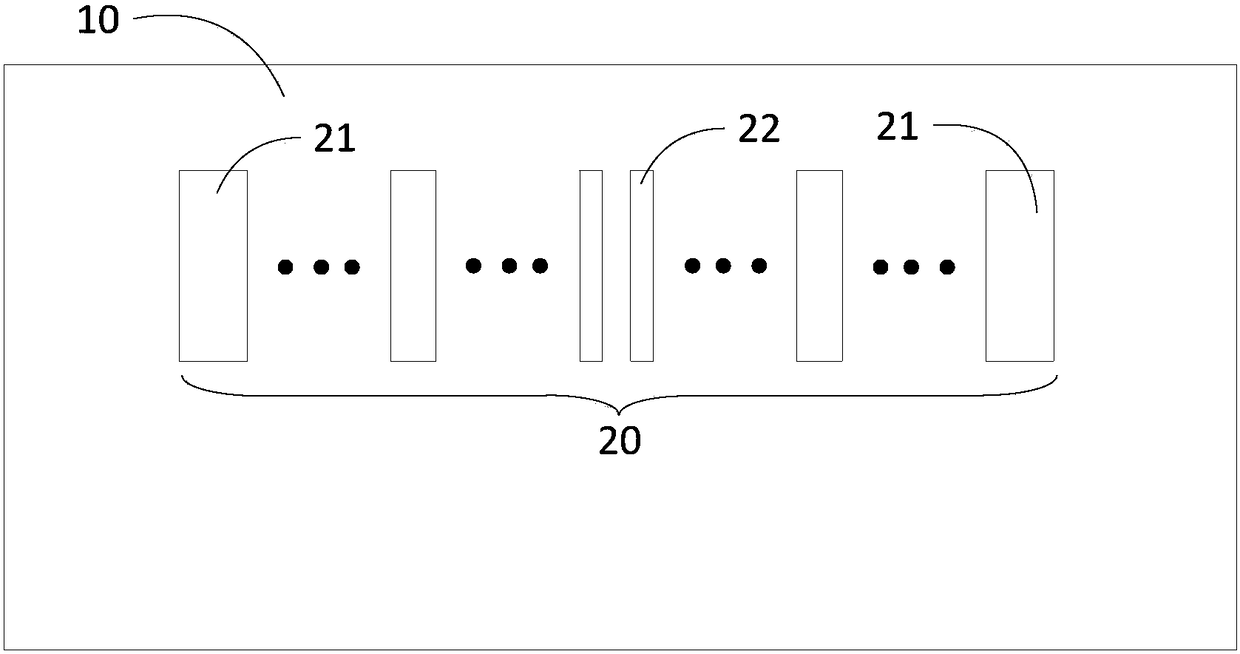

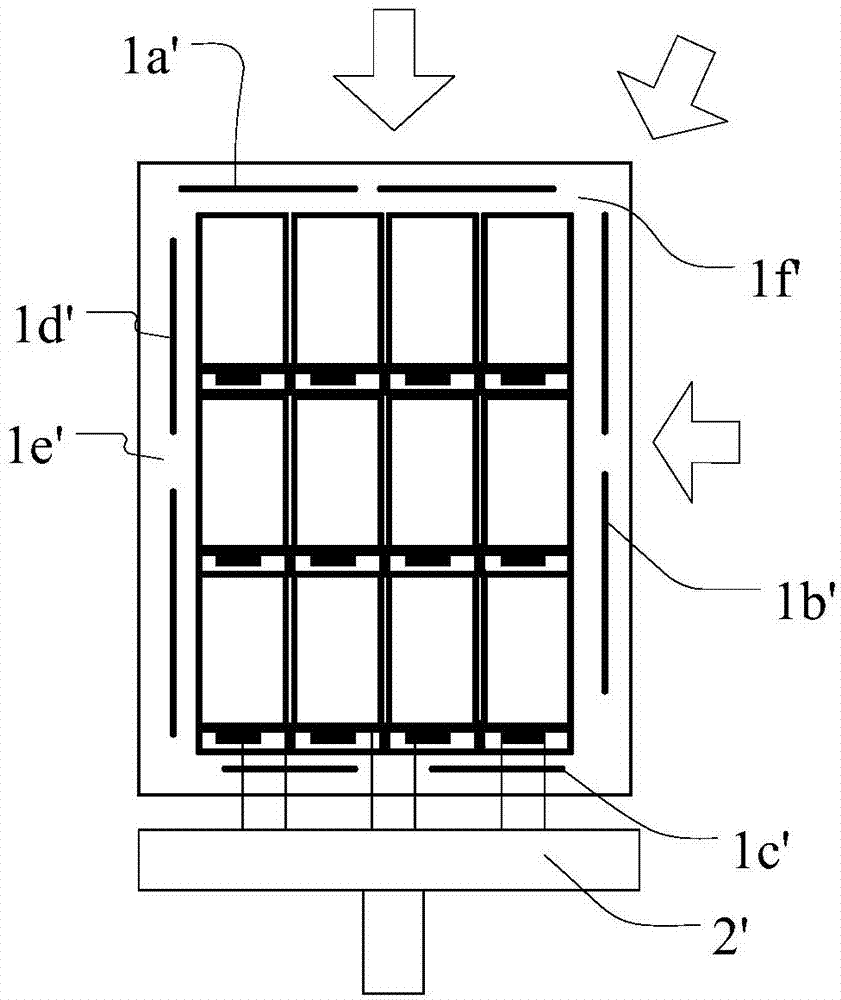

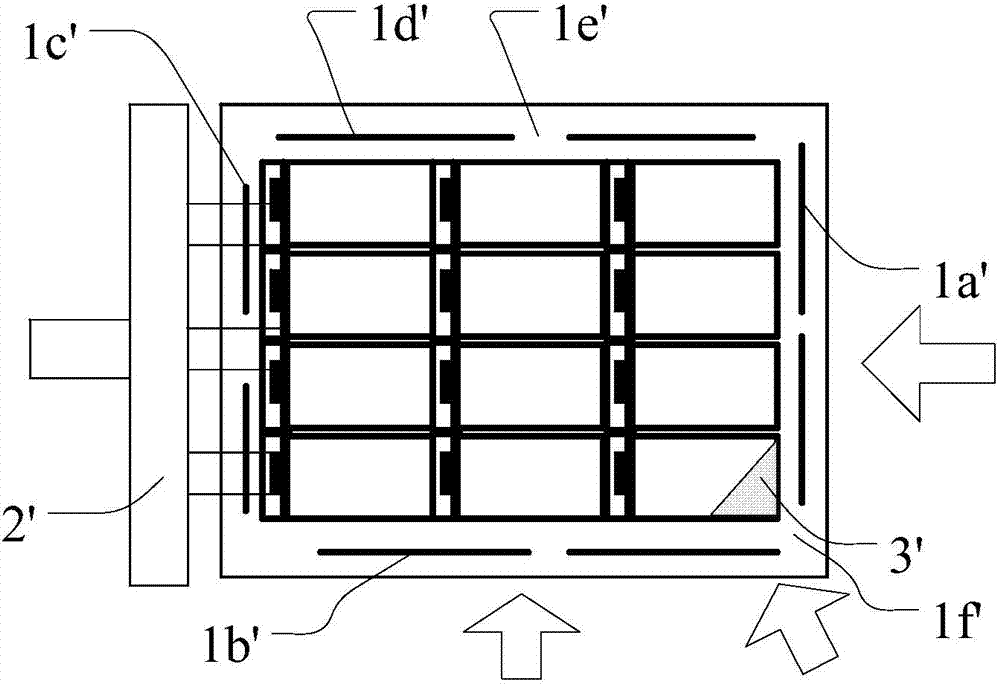

A wireless charging device and method

ActiveCN106230049ASolve misalignmentReduce lossBatteries circuit arrangementsElectric powerRotation controlEnergy loss

The invention relates to a wireless charging device and method. The wireless charging device comprises a coil drive circuit for driving a charging coil to operate; and an alignment detection circuit for detecting a charging parameter in the coil drive circuit, determining that the charging coil and a to-be-charged device to be aligned when a charging parameter matches a preset reference and keeping charging at the present position.When the charging parameter does not match the preset reference, a rotation control circuit is trigger to begin working. The wireless charging device also comprises a rotation control circuit used for controlling the rotation apparatus to rotate after being triggered by the alignment detection circuit; and a rotation apparatus used to rotate under driving of the rotation control circuit and triggering the coil drive circuit to begin working after the rotation is stopped. According to the embodiment of the present invention, the position of the charging coil is automatically adjusted by detecting the charging parameter of the charging coil, thereby solving the problem of misregistration between the wireless charging device and the to-be-charged device, improving the charging efficiency, reducing energy loss and shortening the charging time .

Owner:ANKER INNOVATIONS TECH CO LTD

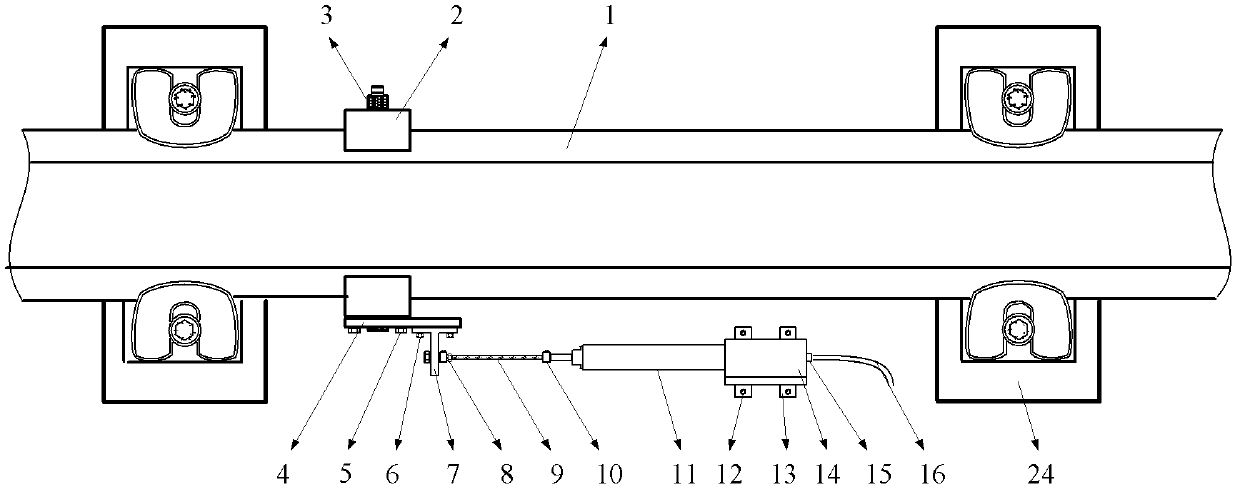

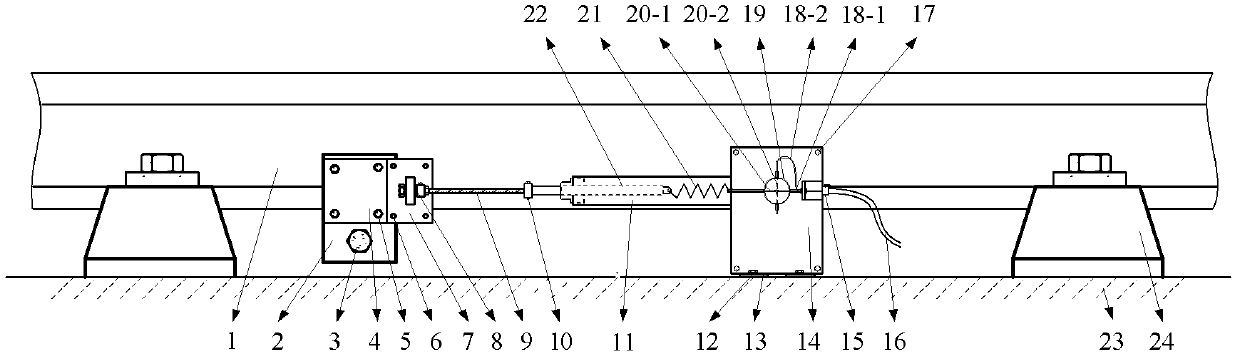

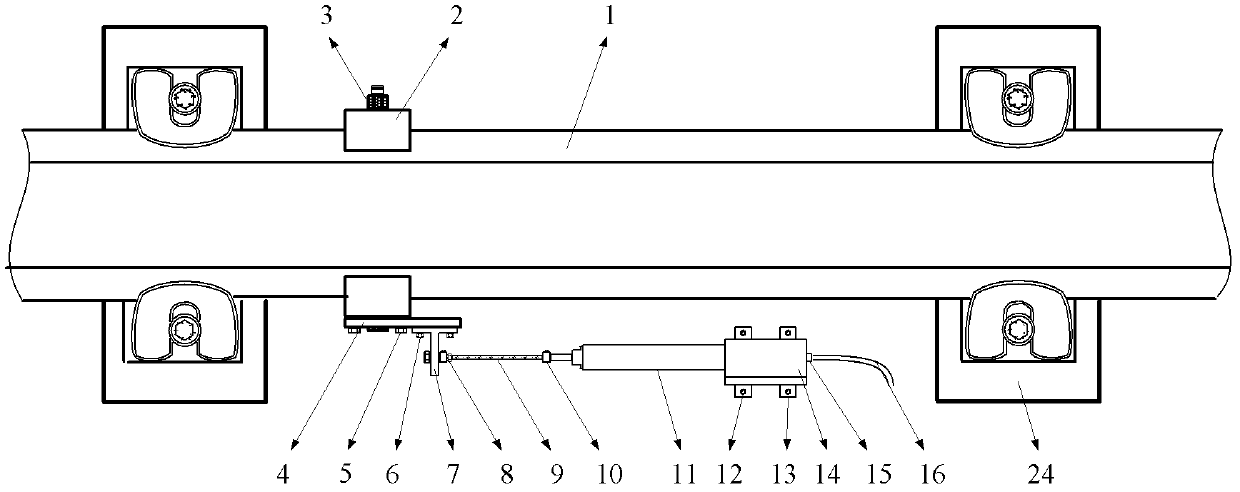

Steel rail or bridge displacement monitoring device for fiber Bragg grating transformation ring

The invention provides a steel rail or bridge displacement monitoring device for a fiber Bragg grating transformation ring. The steel rail or bridge displacement monitoring device consists of a fixing clamp assembly, a connection assembly, a fiber Bragg grating transformation ring assembly, a pull rod assembly and a sensor shell device. One part of the steel rail or bridge displacement monitoring device is fixedly arranged on a steel rail or a beam body to be measured of the bridge, and the other part of the steel rail or bridge displacement monitoring device is fixedly arranged on a ballastless rail bed or a bridge reference beam body. The two parts of the steel rail or bridge displacement monitoring device are connected through the connection assembly. Two fiber Bragg gratings with different wavelengths are vertically cured on a rigid round ring. Force generated by that a target to be measured is displaced is transmitted to the rigid round ring through a pull ring and a spring, so that the two fiber Bragg gratings are inversely stressed. A center wavelength is offset to an inverse direction, so as to obtain the displacement of the target to be measured by overlapping the wavelength offset values. Therefore, the optical signal aberration generated by directly sticking the gratings is avoided and the interference caused by an environment temperature is omitted. The steel rail or bridge displacement monitoring device is applicable to long-term online monitoring, and is sensitive, stable, reliable, compact in structure and convenient to repair and maintain.

Owner:WUHAN UNIV OF TECH

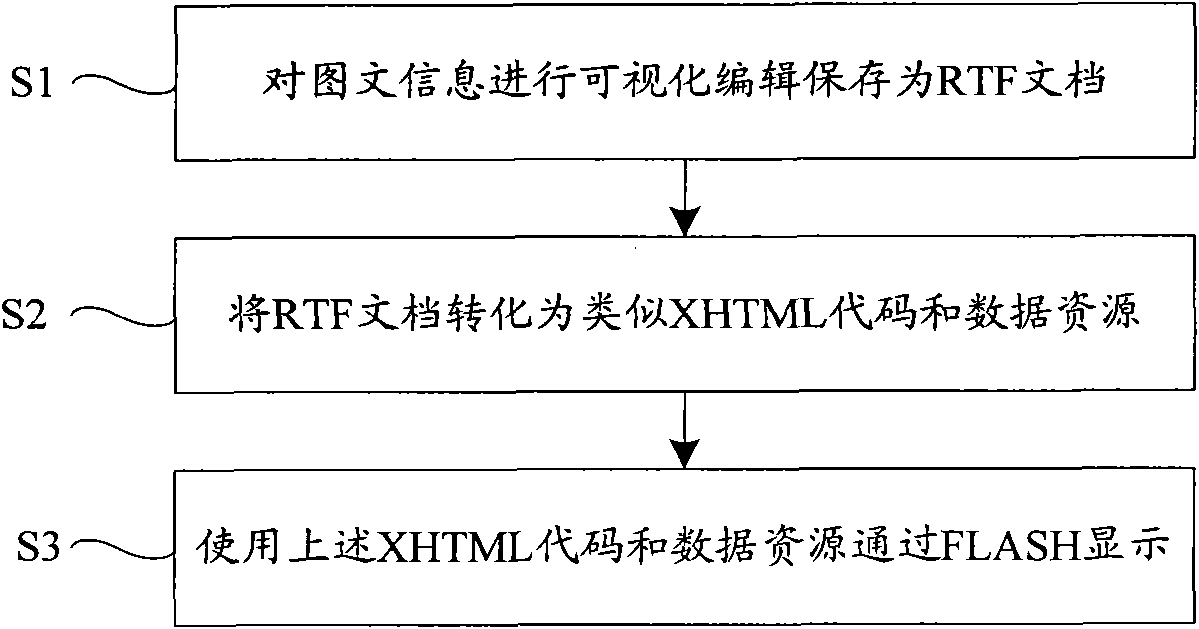

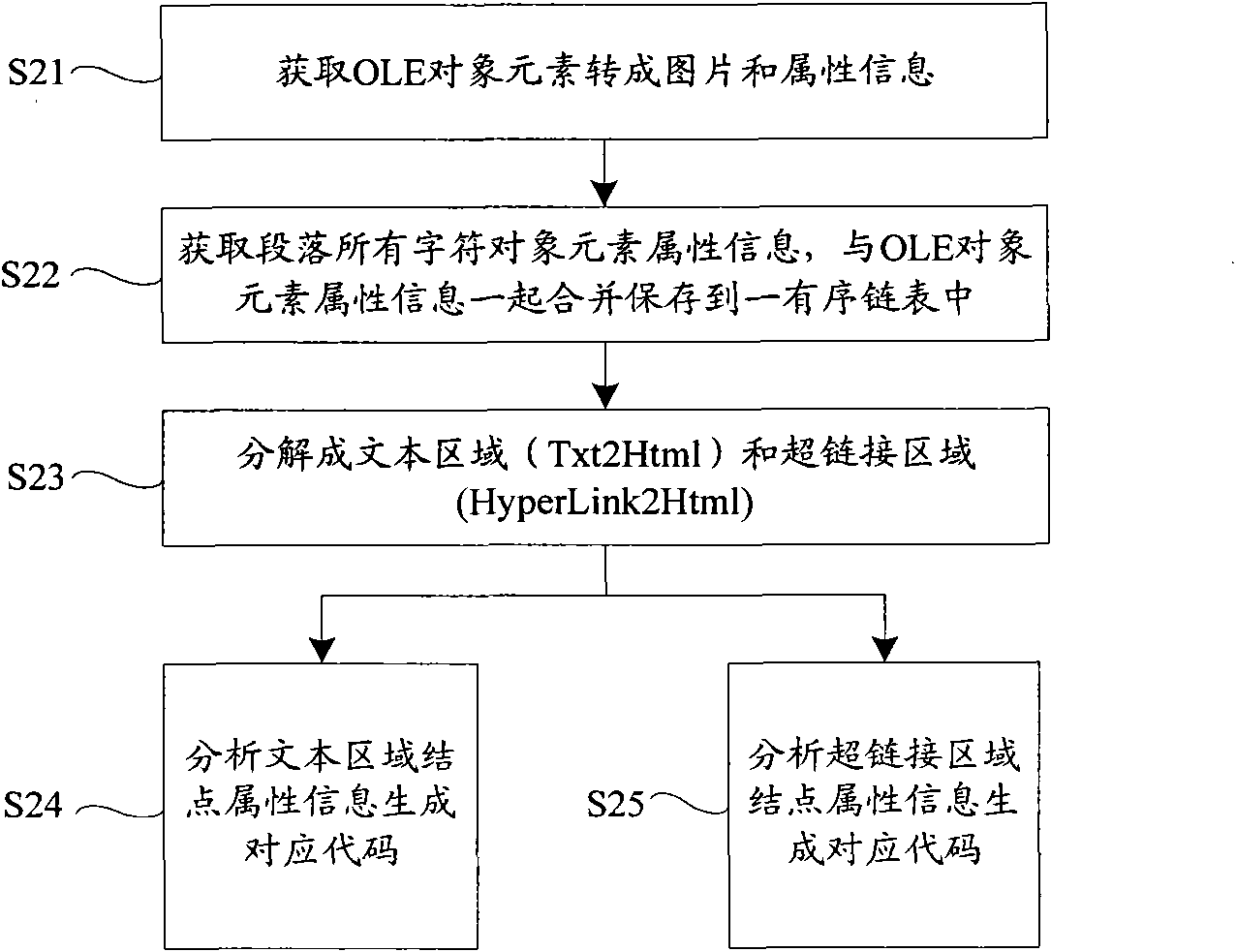

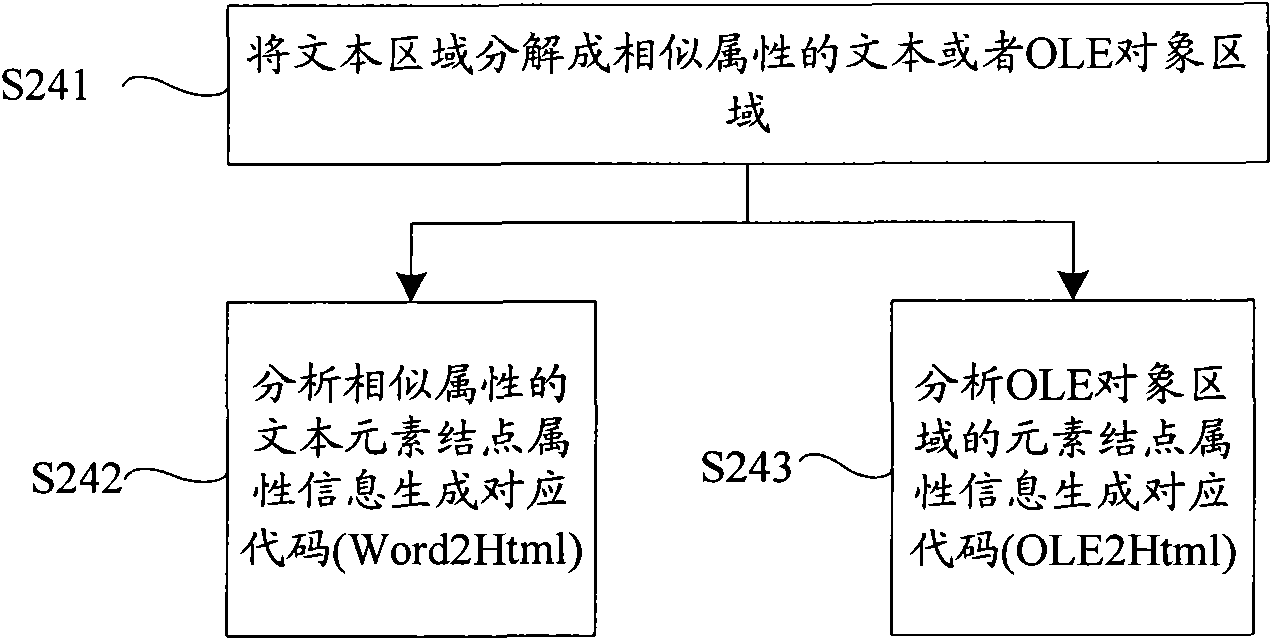

Method for editing rich text and for restoring and displaying rich text through FLASH

ActiveCN101882075ASimple and convenient visual editingSolve misalignmentSpecific program execution arrangementsEditing/combining figures or textComputer graphics (images)Data source

The invention relates to a method for editing rich text and for restoring and displaying the rich text through FLASH, which comprises the following steps that: S1. an editor is used for visually editing a picture and text message and for storing the picture and text message as an RTF document; S2. the RTF document is transformed to an HTML code and a data resource; S3. the HTML code and the data source are used for restoring the picture and text message in FLASH. The picture and text message can be simply, conveniently and visually edited through the editor, and the effect when editing the picture and text can be restored in FLASH, so completely-dislocated problem of the pictures when displaying the pictures and texts through the FLASH software can be solved.

Owner:WONDERSHARE TECH CO LTD

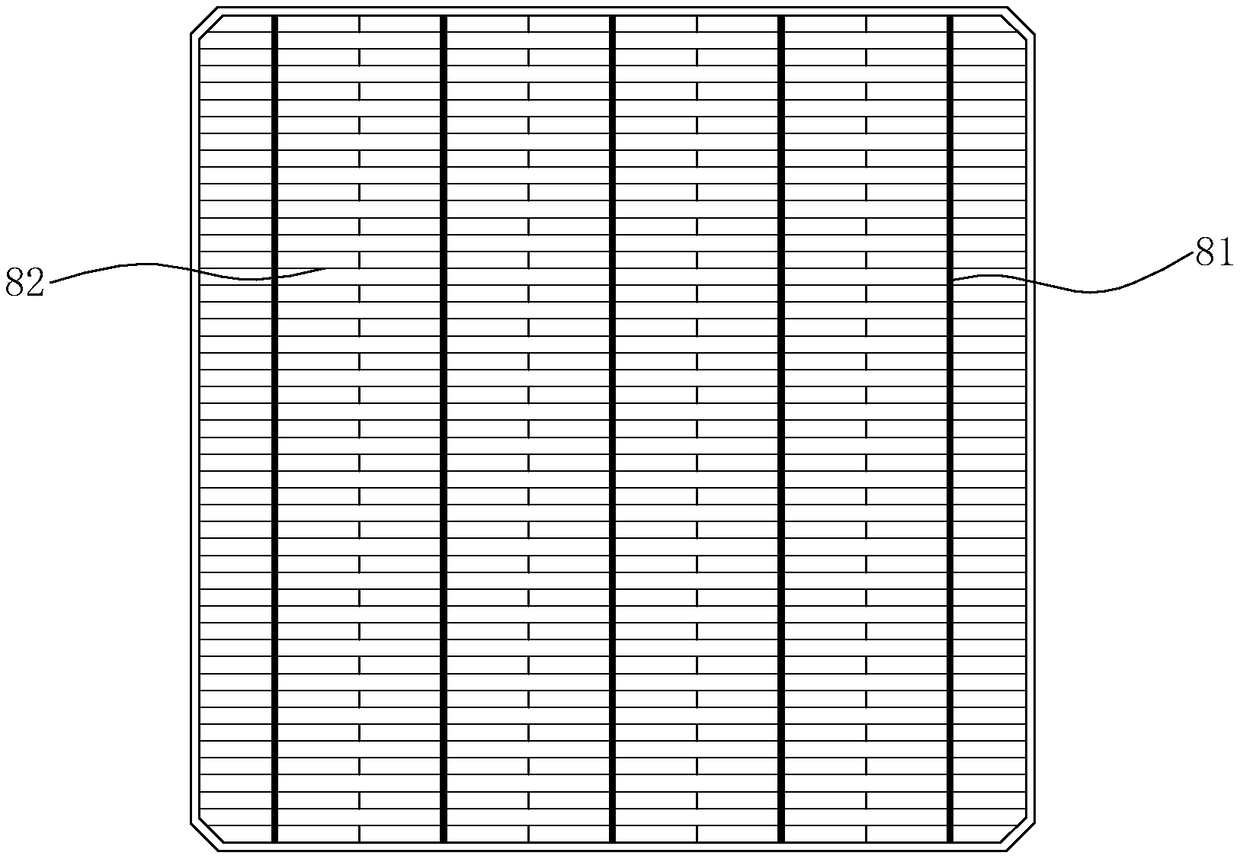

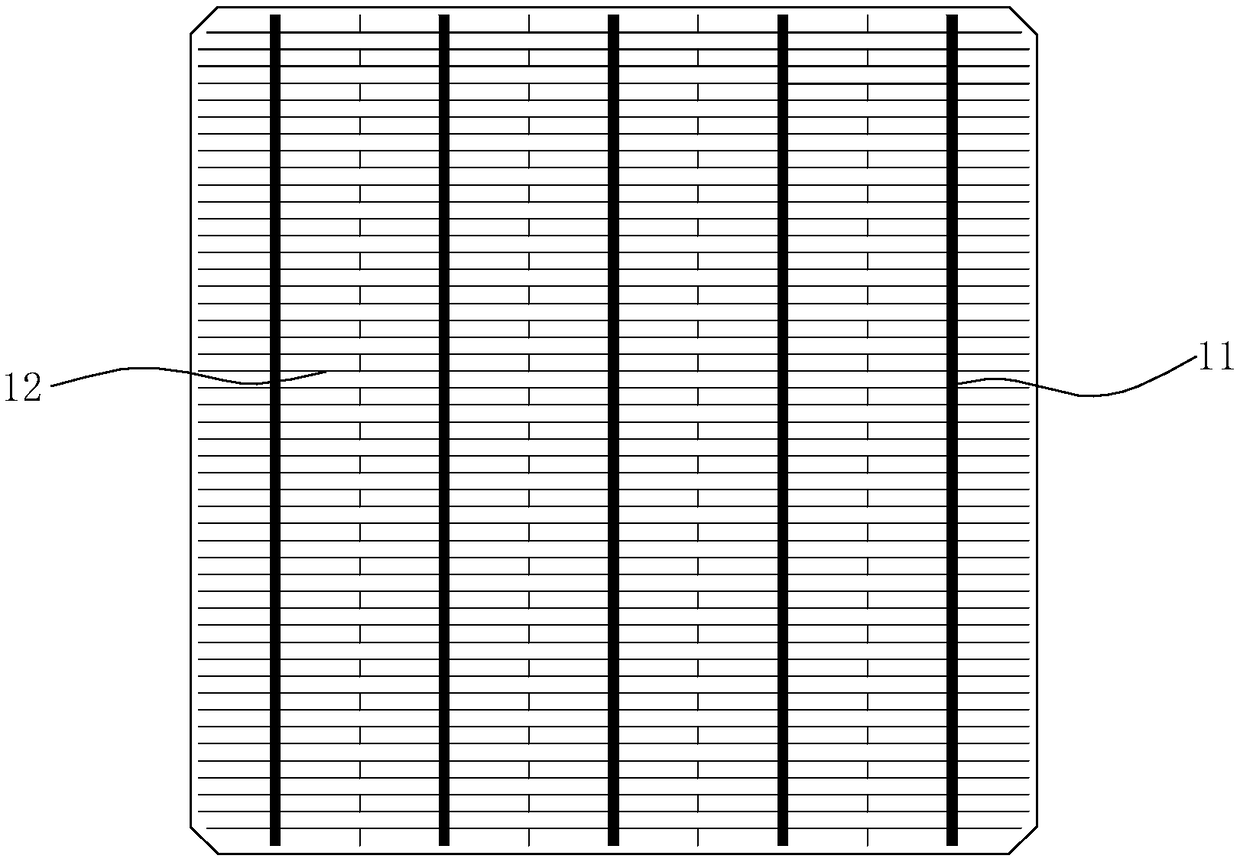

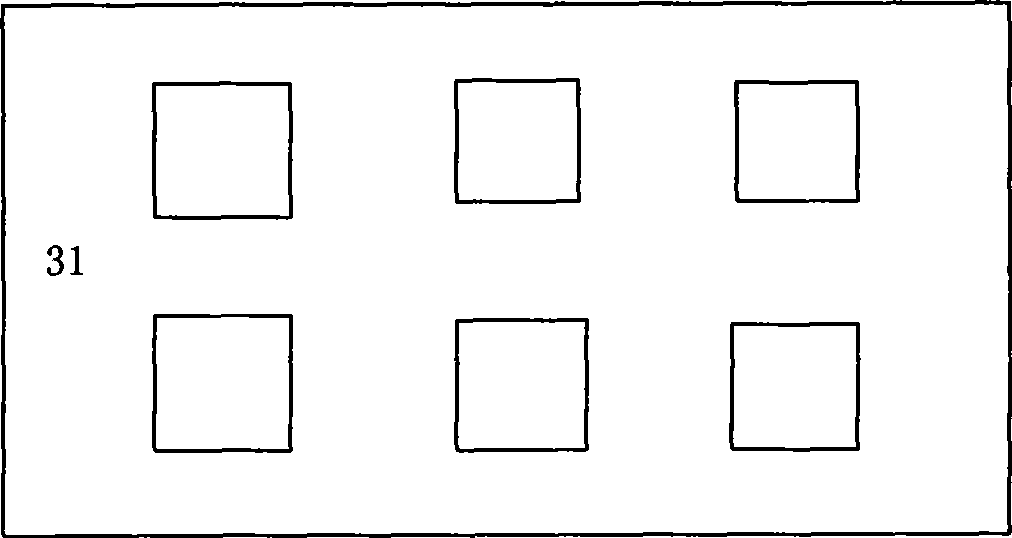

A P-type SE-PERC double-sided solar cell and a preparation method thereof

PendingCN109065658AImprove stabilitySolve misalignmentFinal product manufacturePhotovoltaic energy generationSilver electrodeSolar cell

The invention discloses a P-type SE-PERC double-sided solar cell and preparation method thereof, the solar cell includes back electrodes arranged sequentially from bottom to top, A back side silicon nitride film, back alumina film, P-type silicon, N-type silicon, A front silicon nitride film and a positive silver electrode, the front surface of the n-type silicon is formed with a plurality of laser grooves parallel to each other by laser doping after diffusion and before depositing the front surface silicon nitride film, the laser slots are designed with slotted areas with different spacing orwith different slotted areas with different width, the number of laser grooves is equal to the number of positive silver sub-gate electrodes, and one-to-one correspondence, when etching the positivesilver electrode with the positive silicon nitride film, the paste falls in the laser groove to form the positive silver sub-gate electrode, thereby solving the problem that the positive silver sub-gate electrode is not aligned with the laser doped region due to the deformation of the positive silver electrode screen plate in the printing process, and improving the stability of batch production ofthe battery. The invention also discloses a preparation method of the solar cell.

Owner:ZHEJIANG AIKO SOLAR ENERGY TECH CO LTD +1

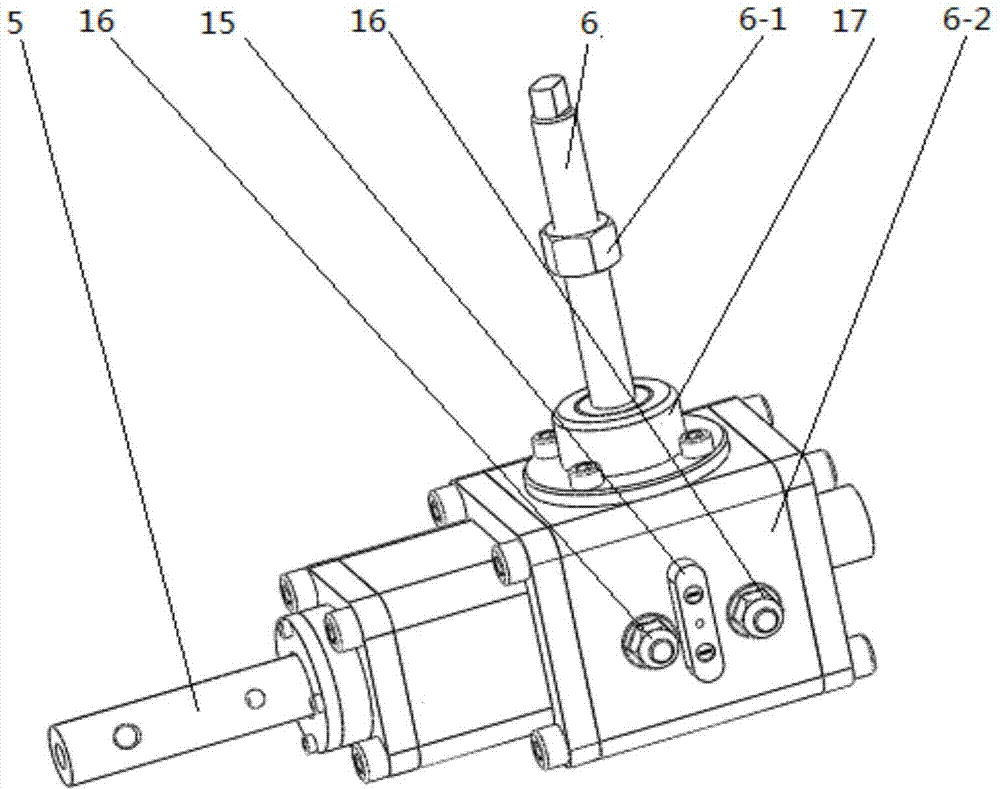

Main shaft axial dynamic stiffness test device

ActiveCN103712791AGuaranteed stabilityGuaranteed accuracyMachine gearing/transmission testingAxial displacementDynamic stiffness

The invention discloses a main shaft axial dynamic stiffness test device. A center height adjusting screw is arranged on a box body. A butterfly-shaped spring is arranged in the box body. The butterfly-shaped spring is connected with a force sensor. The force sensor is connected with a guide element of a force loading module. The guide element is connected with a feed screw. A displacement measurement module is arranged on a main shaft. A center height adjusting knob is adjusted. Through a connecting guide rod, the main shaft and test equipment are connected. After the displacement measurement module is arranged and adjusted, the displacement measurement module and a force measurement module access a computer, and test software is turned on. The main shaft is rotated, and the force loading module is started. The force loading module axially applies a corresponding pull pressure load on the main shaft. The test software synchronously acquires and records the applied pull pressure load and the corresponding axial displacement offset. After a procedure carries out data processing, a main shaft dynamic stiffness test result is output.

Owner:XI AN JIAOTONG UNIV

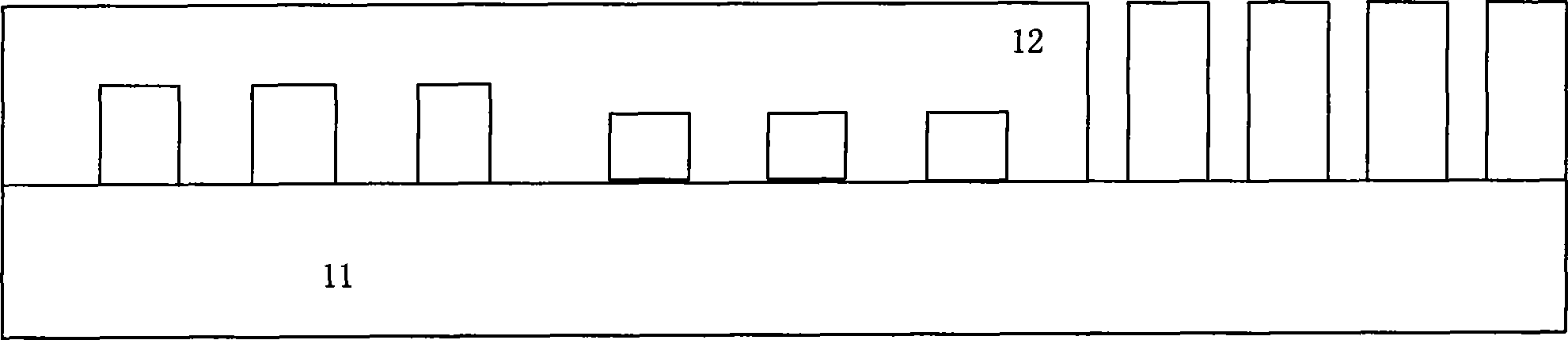

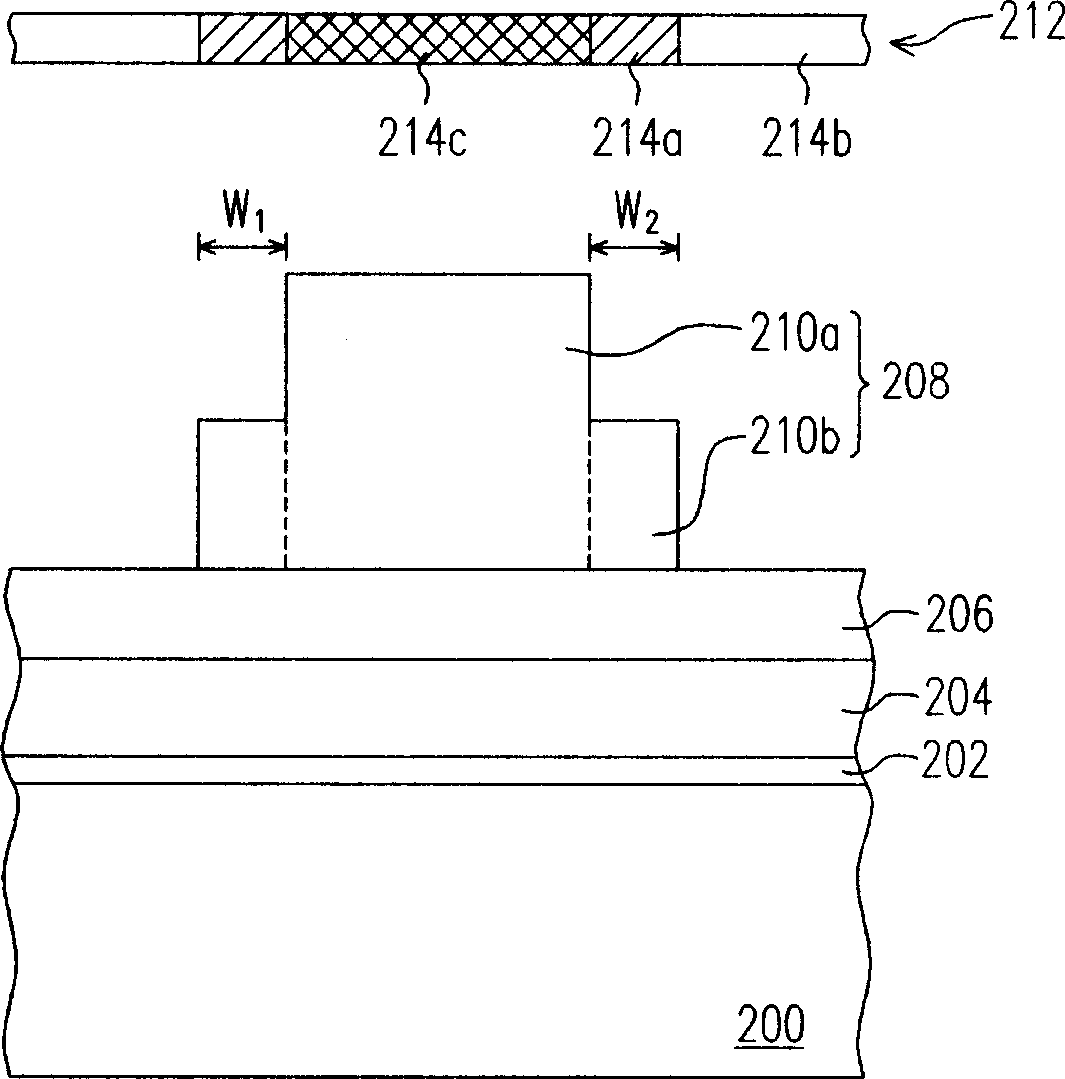

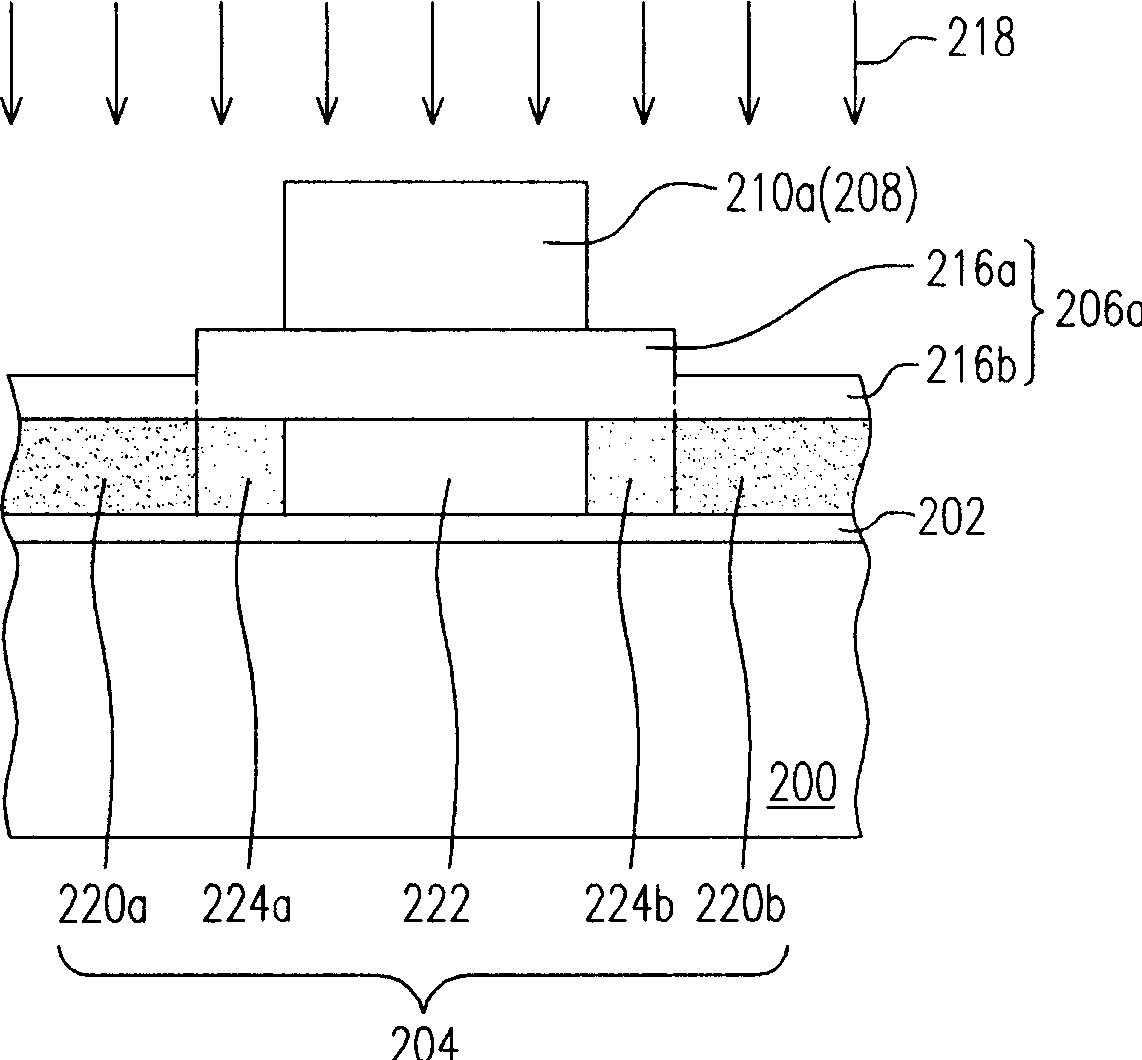

Mask target and method for forming the same

InactiveCN101373757AGroove depth deepenedOptical Signal EasySemiconductor/solid-state device detailsSolid-state devicesMaterials scienceField oxide

The invention provides an alignment mark and a forming method thereof. The method comprises the following steps: forming a field oxide layer, a grid polysilicon layer and a metal antemedium layer in sequence on a substrate; forming communicated trenches in sequence on the field oxide layer, the grid polysilicon layer and the metal antemedium layer; and taking the stacked multi-layer trenches as the alignment mark. The alignment mark and the forming method enable the trench depth of the alignment mark of the metal antemedium layer to be deepened, and enable the acquisition of optical signals of the alignment mark to be easier when photoetching is conducted, thereby solving the problem that the alignment precision is reduced or alignment can not be realized because the alignment mark is too shallow.

Owner:HEJIAN TECH SUZHOU

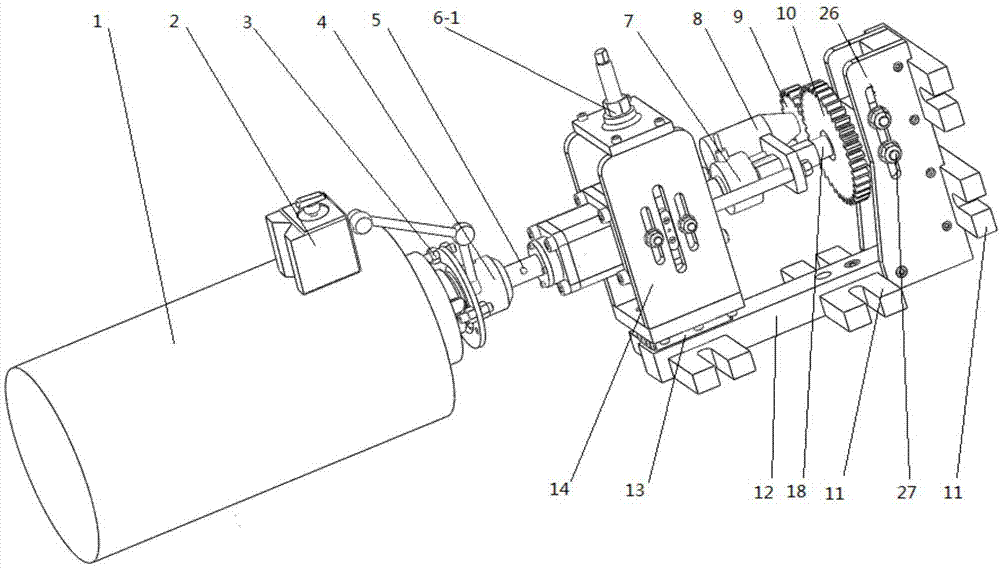

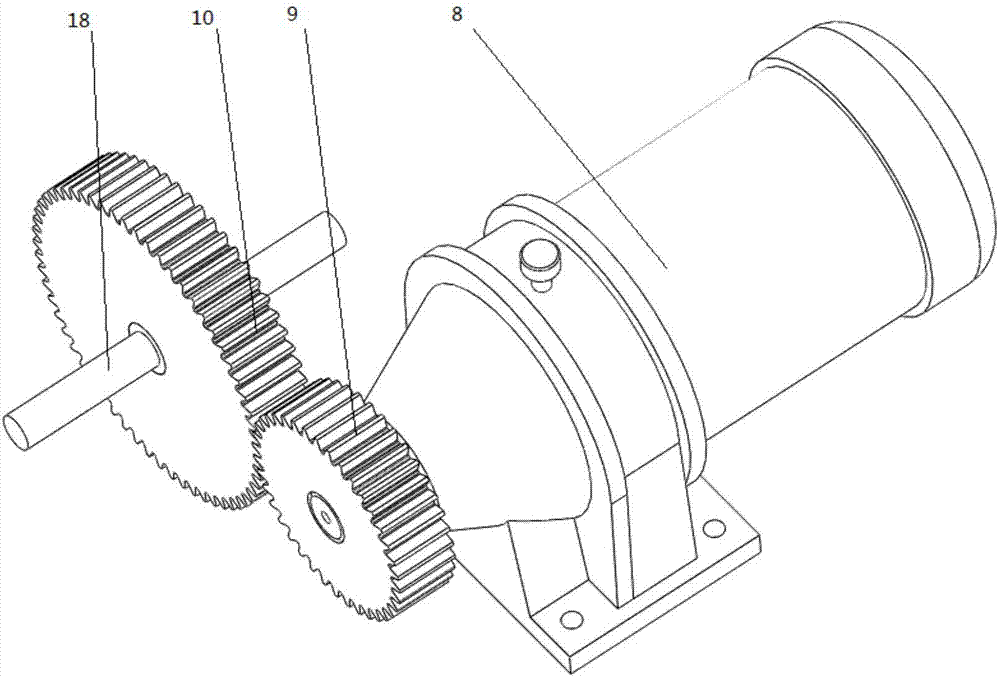

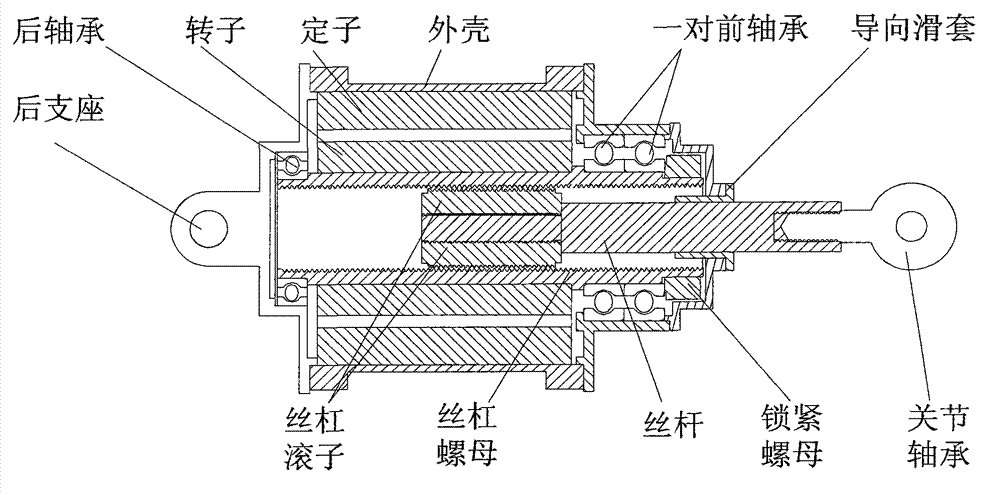

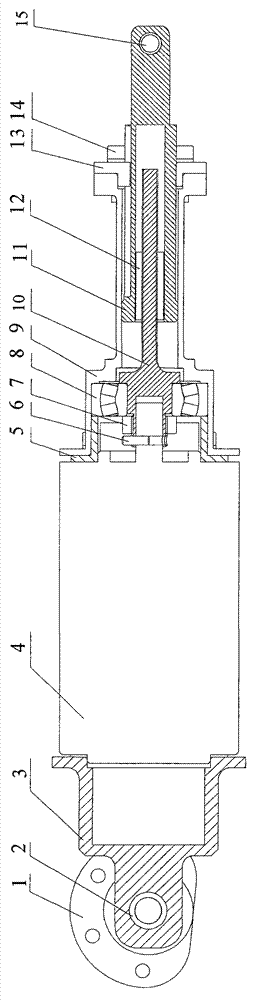

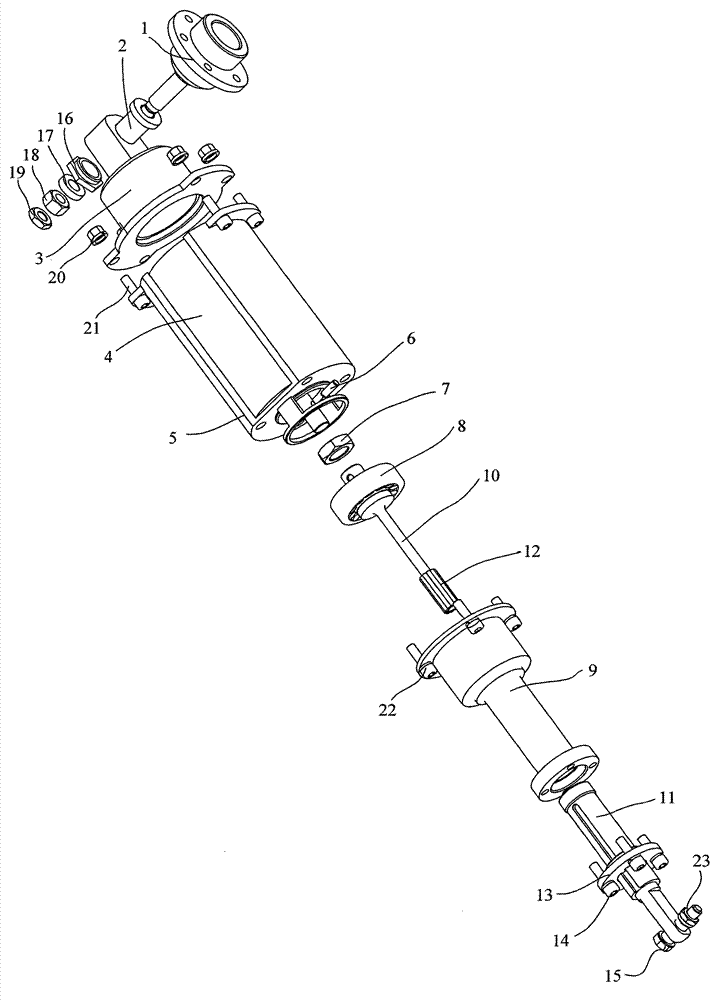

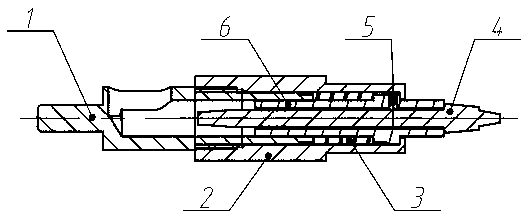

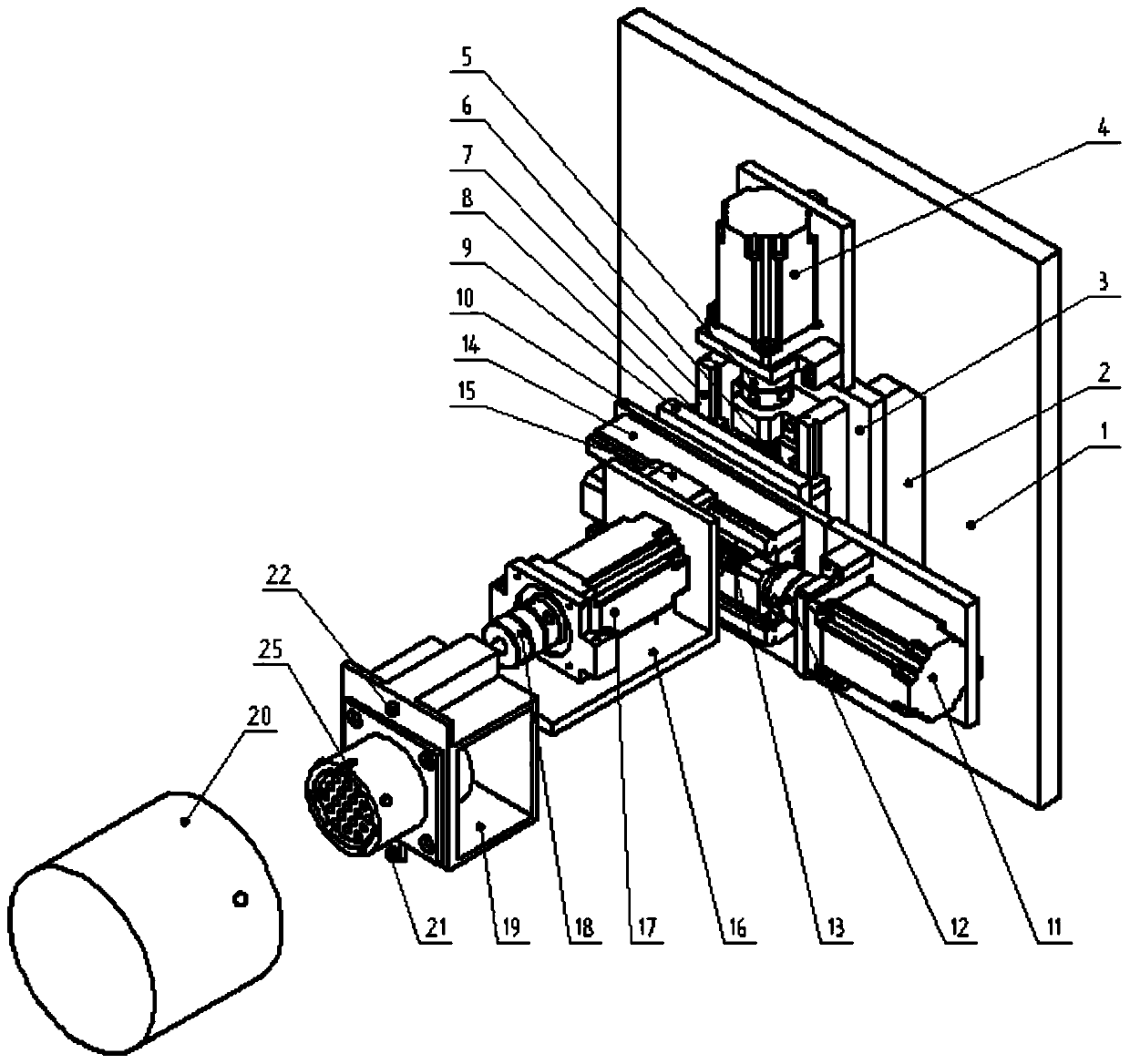

Compact electric servo mechanism for linear displacement

ActiveCN102931760AReduce design difficultyGuaranteed integrityGearingMechanical energy handlingBall screwElectric machine

The invention provides a compact electric servo mechanism for linear displacement. The compact electric servo mechanism comprises a support saddle, a sliding bearing, a motor connector, a motor, a motor shell, a self-aligning roller bearing, a screw support shell, a ball screw, a ball screw nut, a screw roller, a guide element, an output shaft and a sliding bearing end cover. According to the compact electric servo mechanism, the integrity of the motor structure is ensured by a combined design of the screw and the motor; the motor does not need to be independently designed; the design difficulty of the motor is reduced; the motor is directly connected with the ball screw to achieve direct drive, and the screw nut moves forwards and backwards when the motor rotates, so that the screw nut does not need to adopt the structure of a long thread hole, and a guide groove is designed on the screw nut to be used along with the guide element. Therefore, the accurate servo control of linear displacement is achieved, and the linear output of the mechanism does not need the assistance of an external structure.

Owner:BEIJING AUTOMATION CONTROL EQUIP INST

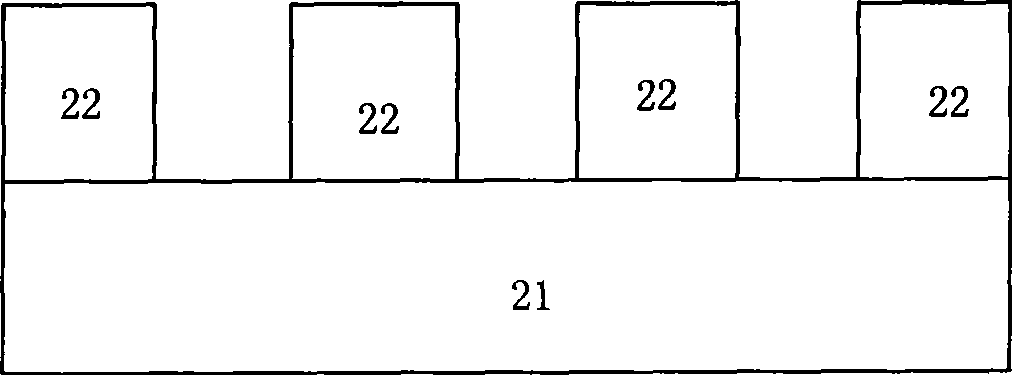

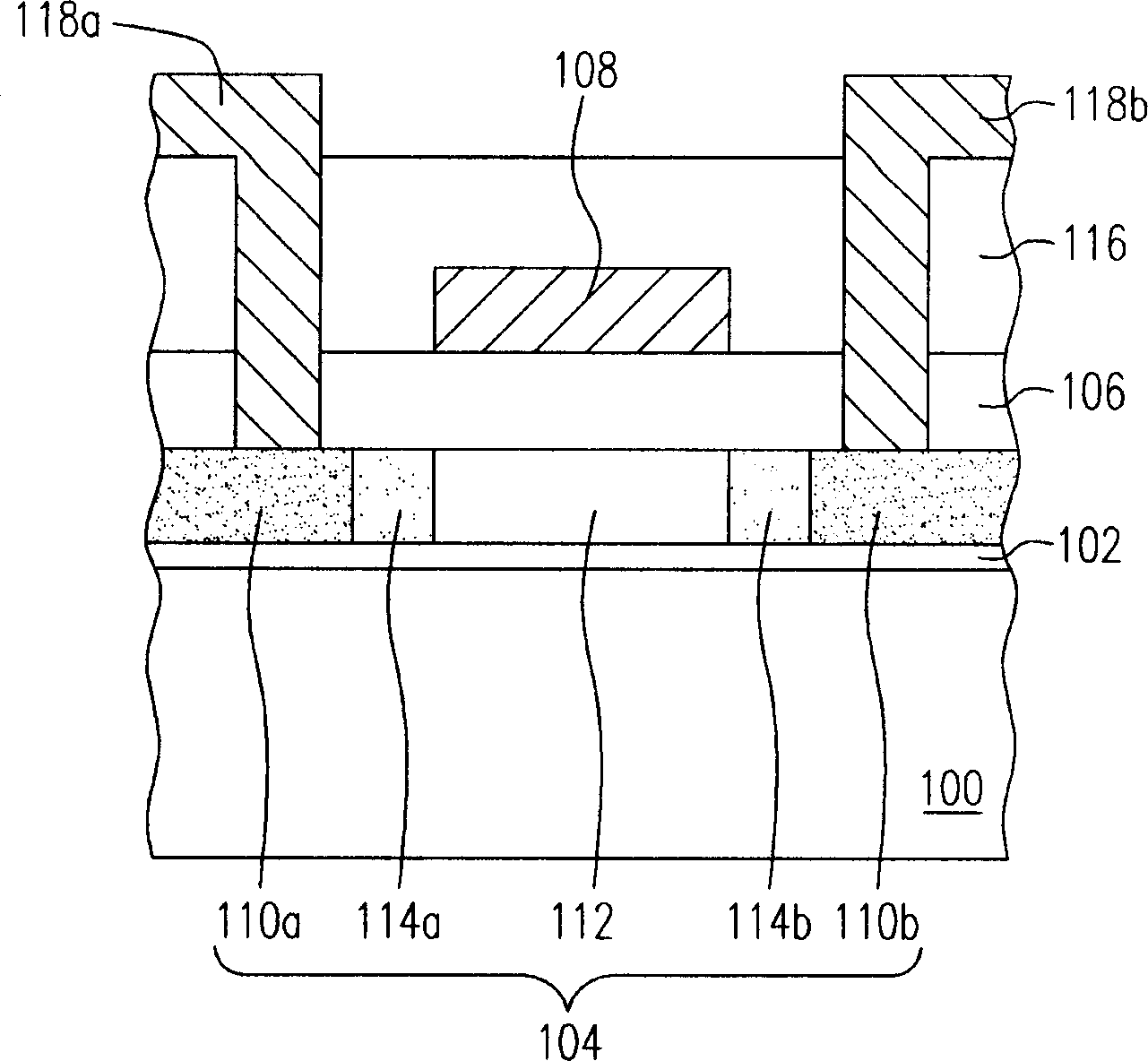

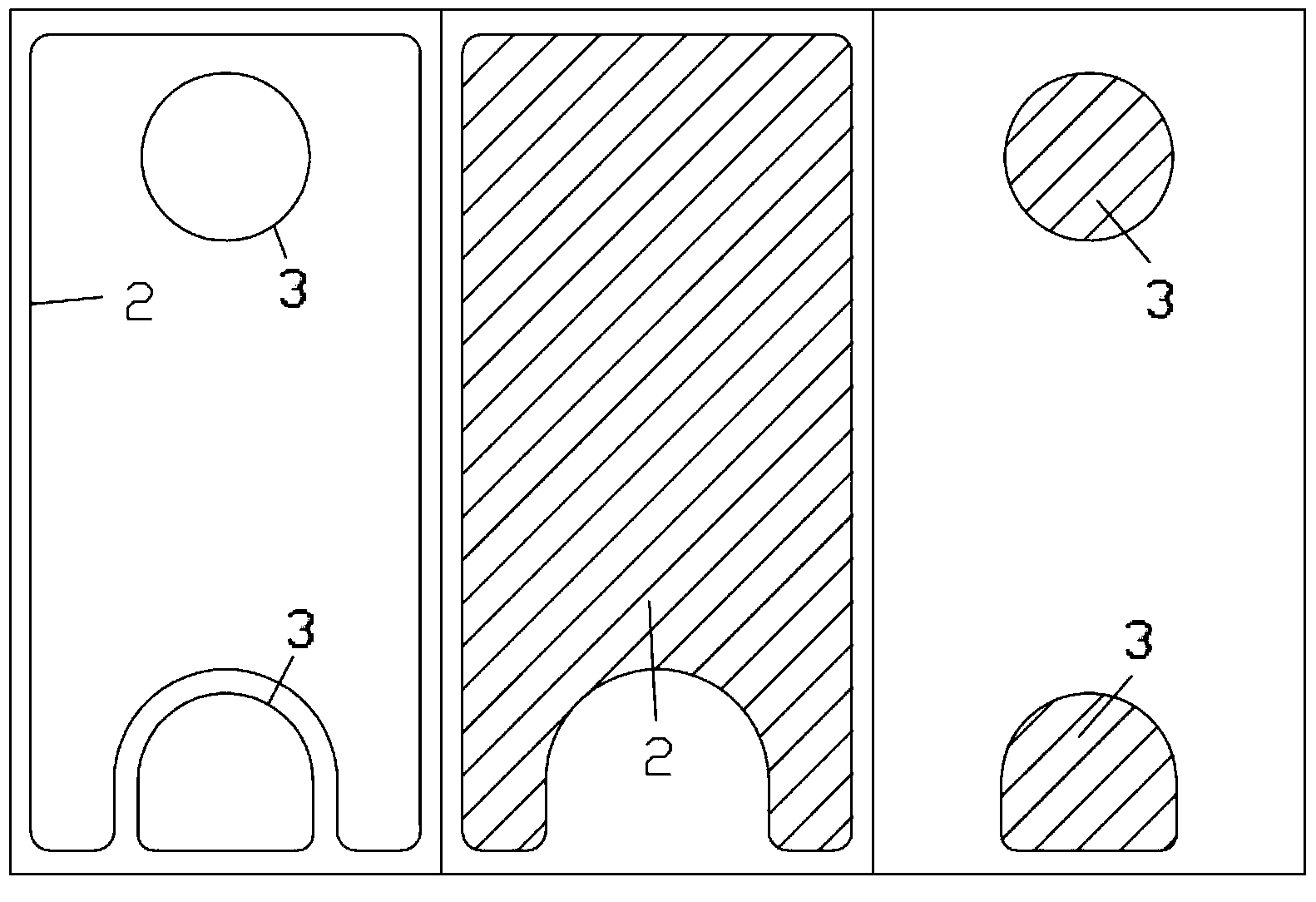

Thin film transistor and method for manufacturing the same

InactiveCN1790164ASolve misalignmentEasy to prepareTransistorSemiconductor/solid-state device manufacturingOptoelectronicsDielectric layer

The invention discloses a film crystal pipe, which comprises the following parts: base, polysilicon layer, patterning grate dielectric layer, grid layer, source polar region, drain region and light dope drain region, wherein the polysilicon layer is set on the base; the patterning grate dielectric layer is set on the polysilicon layer, which possesses the third and fourth parts with the thickness of the third part less than the thickness of the fourth part; the grid layer is set on part of the patterning grate dielectric layer; the source polar region and drain region are set in the polysilicon layer corresponding to the fourth part of patterning grate dielectric layer; the corresponding part of grid layer and polysilicon layer is channel region; the light dope drain region is set in the polysilicon layer corresponding to the third part of patterning grate dielectric layer.

Owner:CHUNGHWA PICTURE TUBES LTD

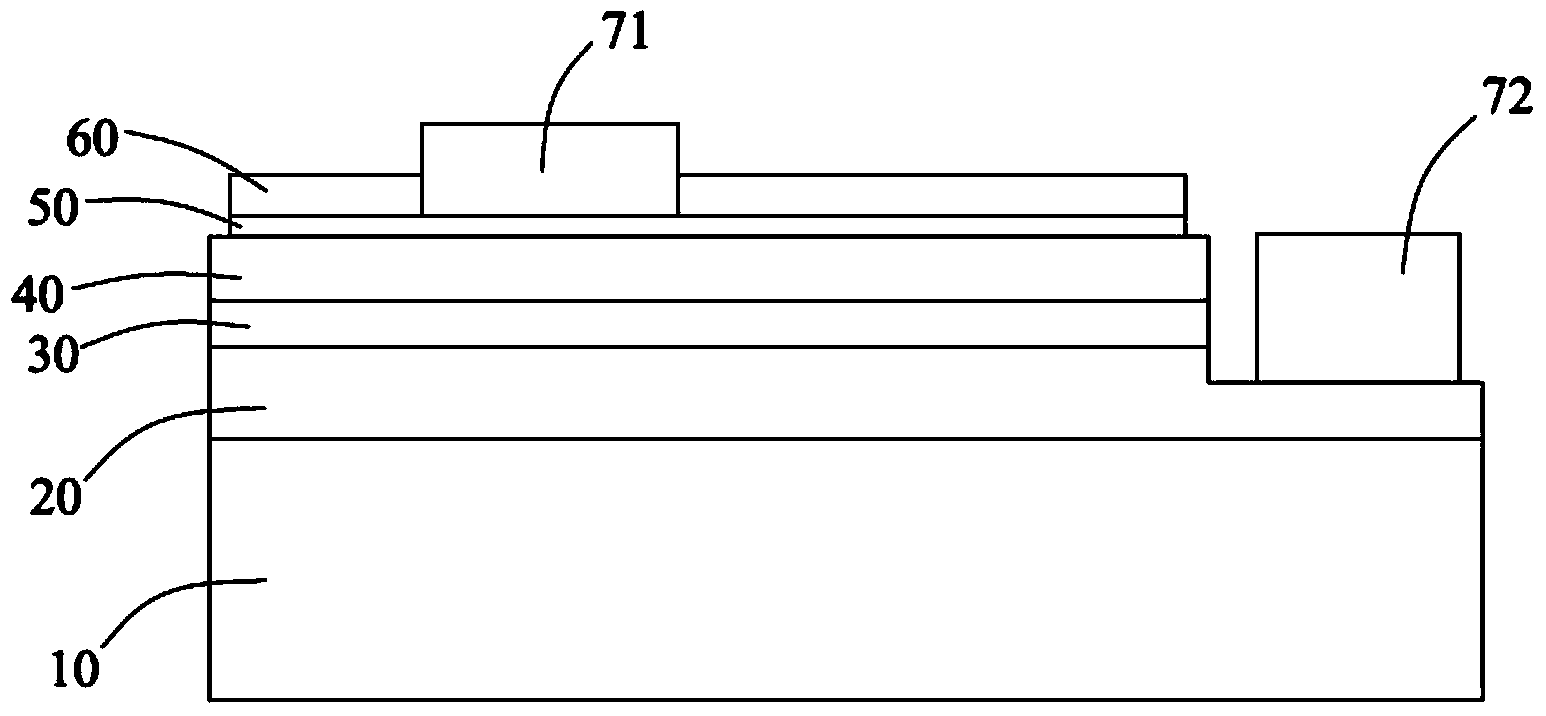

Production method of LED (light emitting diode) chip

InactiveCN103633205ASolve misalignmentRealize self-alignment functionSemiconductor/solid-state device manufacturingSemiconductor devicesPhotoresistIndium

The invention discloses a production method of an LED (light emitting diode) chip. The production method comprises the following steps of providing a substrate, and sequentially producing an N-type semiconductor layer, a luminescent layer and a P-type semiconductor layer on the substrate to form an LED wafer; depositing an ITO (indium oxide) transparent conductive layer on the LED wafer; performing the MESA photoetching on the ITO transparent conductive layer through photoetching glue to form an MESA layer; performing ITO etching on the ITO transparent conductive layer; performing the ICP etching on the LED wafer to form an N-type semiconductor table-board; removing the photoetching glue remained after the MESA photoetching; depositing a passivation layer on the ITO transparent conductive layer and the N-type semiconductor table-board; performing the PAD photoetching on the passivation layer through the photoetching glue to form a PAD layer; performing the passivation etching on the PAD layer, and removing the passivation layer in the area of the PAD layer; producing a P electrode and an N electrode on the etched passivation layer; and removing the photoetching glue remained after the PAD photoetching. By adopting the method, a self-aligning function of the photoetching can be realized, the machining flow of the chip can be shortened, and the machining cost of the chip can be reduced, the ITO light emitting area is increased, and the brightness of the chip is improved.

Owner:FOCUS LIGHTINGS SCI & TECH

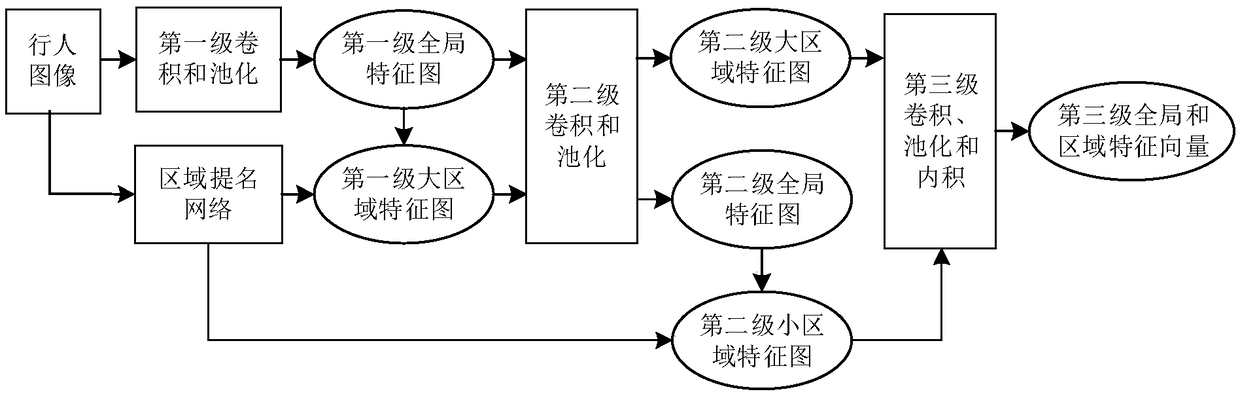

A pedestrian re-identification system and method

ActiveCN109740541AEliminate distractionsImprove re-identification accuracyCharacter and pattern recognitionReference imageMulti stream

The pedestrian re-identification system comprises a multi-stream feature distance fusion system used for calculating the image similarity between an image p to be detected and each reference image inan initial reference image set G, a sorting system used for sorting the reference images according to the image similarity, and a re-sorting system based on k neighborhood distribution scores. And thereordering system is used for reordering the reference images in the initial ordering list according to the k neighborhood distribution score on the basis of the initial ordering list. The inventionfurther discloses a pedestrian re-identification method, and the pedestrian re-identification system is adopted by the pedestrian re-identification method. The pedestrian re-identification method aimsat two main factors influencing pedestrian re-identification, namely image similarity calculation and image sorting, improvement is carried out respectively, and compared with the prior art, the improvement of any one aspect can improve the accuracy of pedestrian re-identification. And an optimal pedestrian re-identification effect can be obtained through the combination of the improvement of thetwo aspects.

Owner:CHONGQING UNIV

Circuit substrate and display device

ActiveCN108391373ASolve misalignmentIncrease contact areaElectrical connection printed elementsDisplay deviceEngineering

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

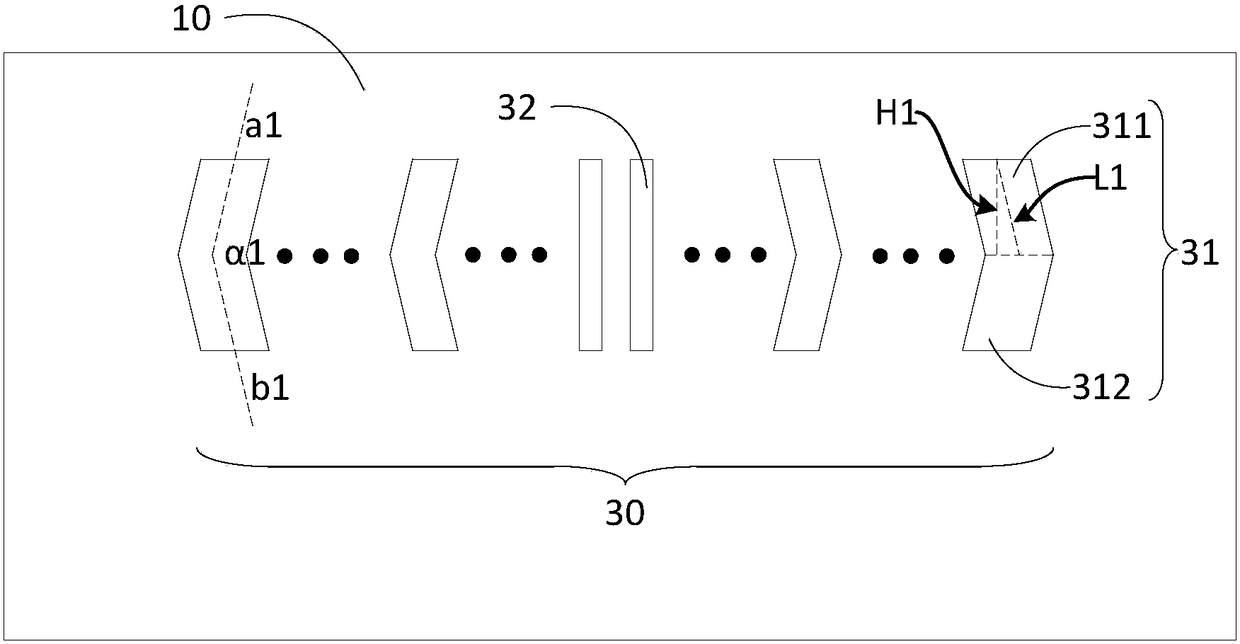

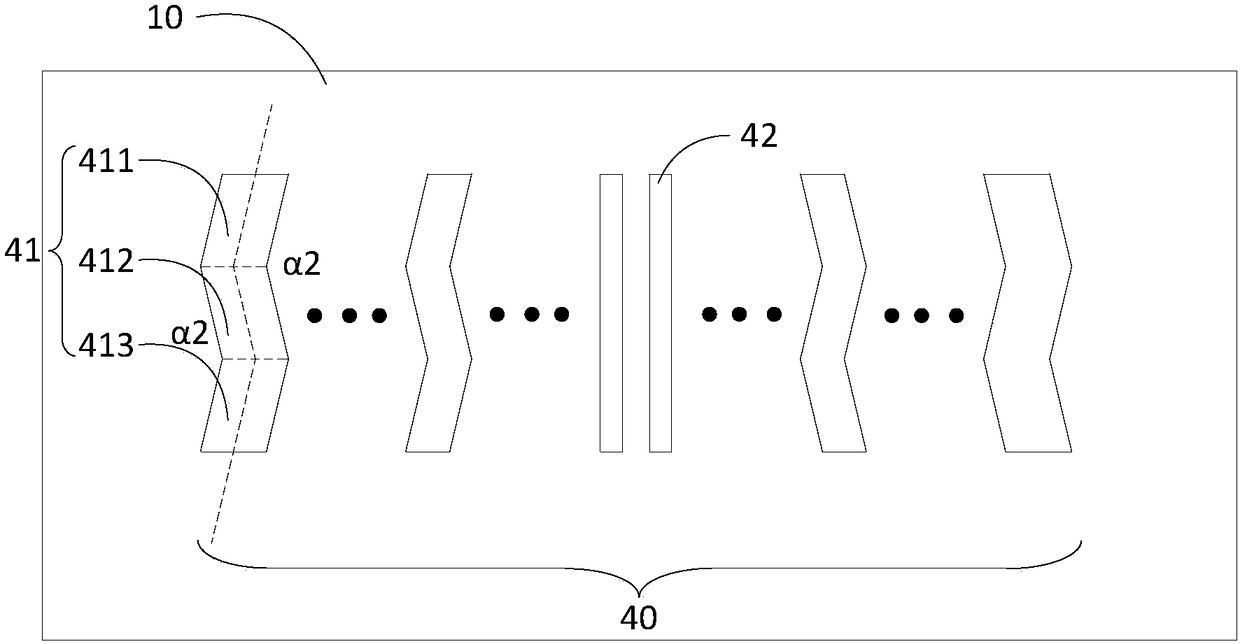

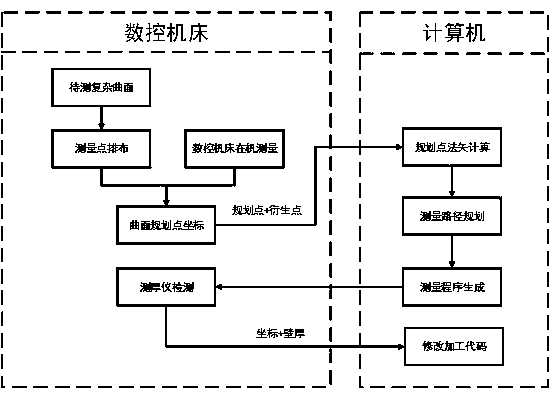

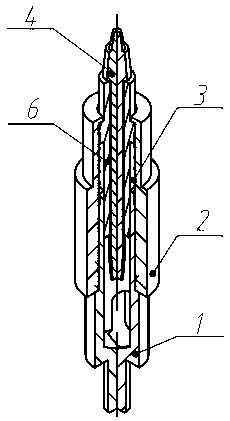

On-machine measuring method for wall thickness of complex thin-wall structure part

ActiveCN110076631AImprove measurement efficiencyImprove real-time performanceMeasurement/indication equipmentsNumerical controlUltrasonic sensor

The invention discloses an on-machine measuring method for a wall thickness of a complex thin-wall structure part; after a numerical control milling machine is roughly processed and installed on the complex thin-wall structure part on a rotary table, a contact probe is called and installed to a main shaft of a machine tool, and a plurality of planning points are arranged on the curve surface of the tested area of the complex thin-wall structure part; the actual measurement value of coordinates of the planning points is detected by the contact probe; and then the actual normal vector of each planning point on the curve surface of the tested aera of the complex thin-wall structure part is drawn by the actual measurement value of the coordinate. A transfer device provided with a ultrasonic sensor is continuously replaced and called to the maine shaft of the machine tool; through the posture control of the main shaft of the machine tool and the rotary table, an ultrasonic thickness gauge can calculate the wall thickness value of the tested point automatically when the ultrasonic sensor touches the curve surface planning point of the complex thin wall structure part; and the wall thickness value is transmitted to a computer through a signal cable in real time; and then the computer processes, analyzes, and stores the wall thickness measuring data of all planning points of the complex thin wall structure part.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

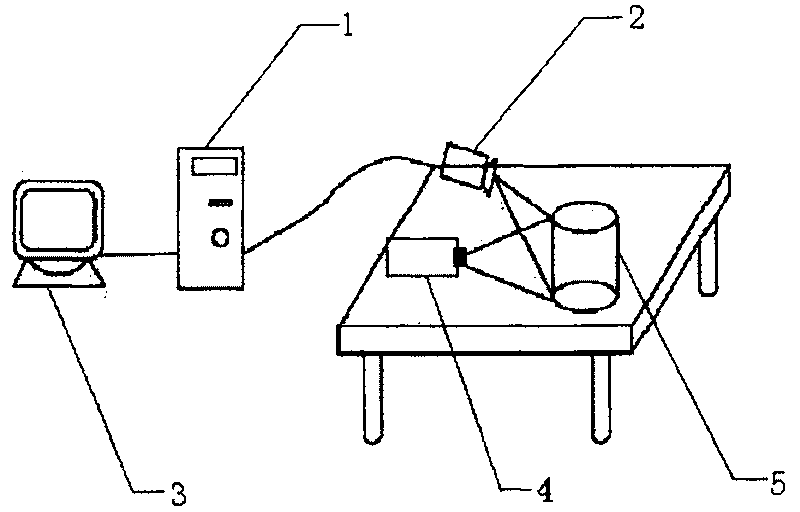

Feather point matching method based on colored false random coding projection

InactiveCN101763654AOvercome isolationOvercome the shortcomings that all connections will hinder decodingImage coding3D modellingShift registerTheoretical computer science

The invention belongs to the filed of image matching of coding structured light active visual sense in machine visual sense, in particular to a feather point matching method based on the colored false random coding projection. The invention is based on a false random coding principle, and designs a novel colored coding projection template by using a point and line combined method. The method comprises the following concrete steps: 1. generating a false random sequence from a0, a1 to an by a feedback network n-displacement bit register specified by a primitive polynomial h(x)=xm+hm-1xm-1+...+h1x+h0; 2. filling the false random sequence from a0, a1 to an into a matrix with the size of n=n1*n2 for generating a false random array b; and 3. using the generated array values as the discrete feather points, connecting the feather points by a feather line, and establishing a coding template. The invention introduces a morphological algorithm, and provides the extraction algorithm of the relevant feather points. In the decoding process, the invention provides the thought of mutual verification of adjacent windows, can realize the automatic extraction and matching of the feature points, and can perfectly solve the problem of shadow generation during the projection of the structural light on the surface of the complicated three-dimensional scenes and the problem of mistake feather point matching caused by that parts of coding patterns are covered because the shooting angles of a video camera are different.

Owner:JIANGSU UNIV

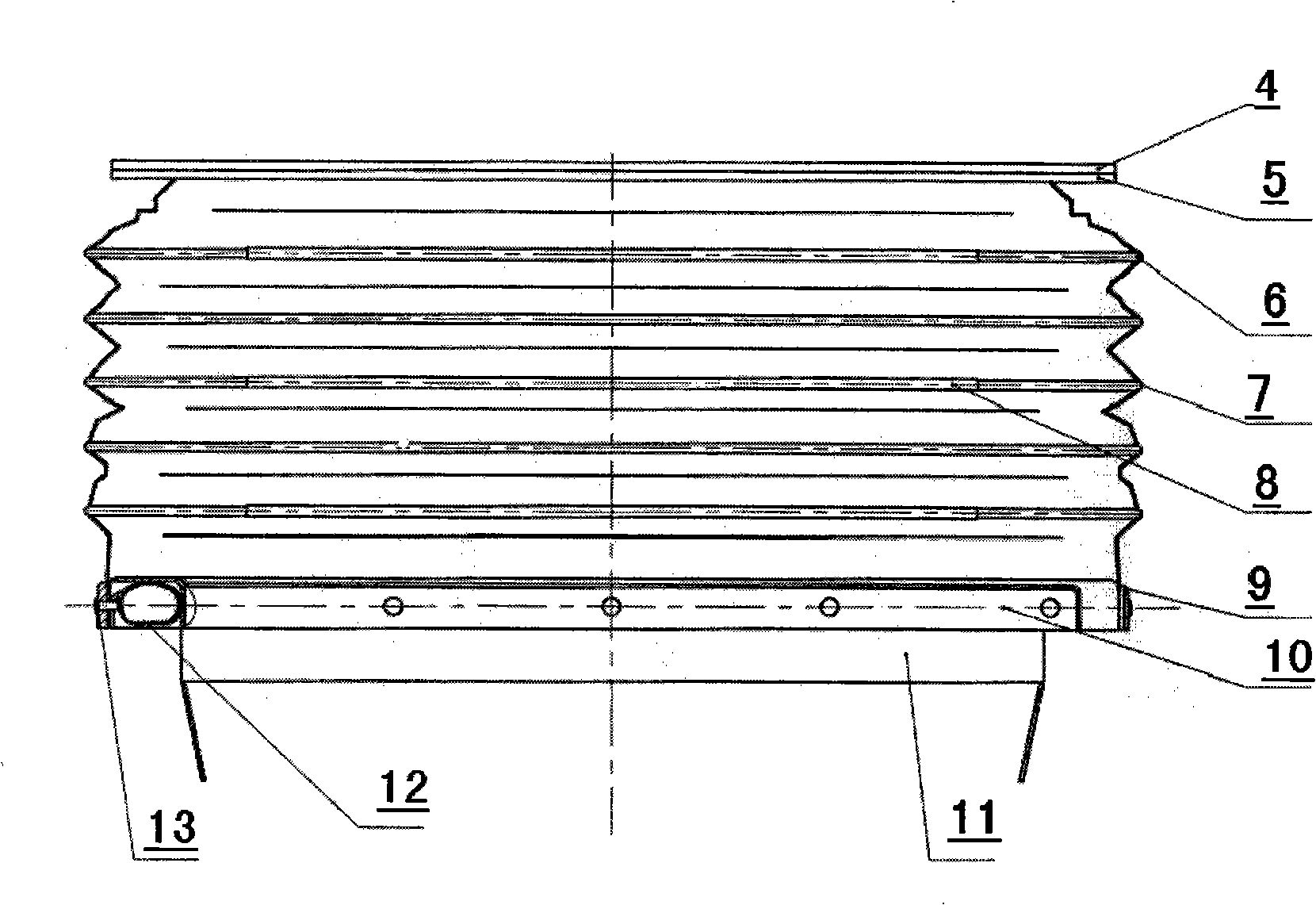

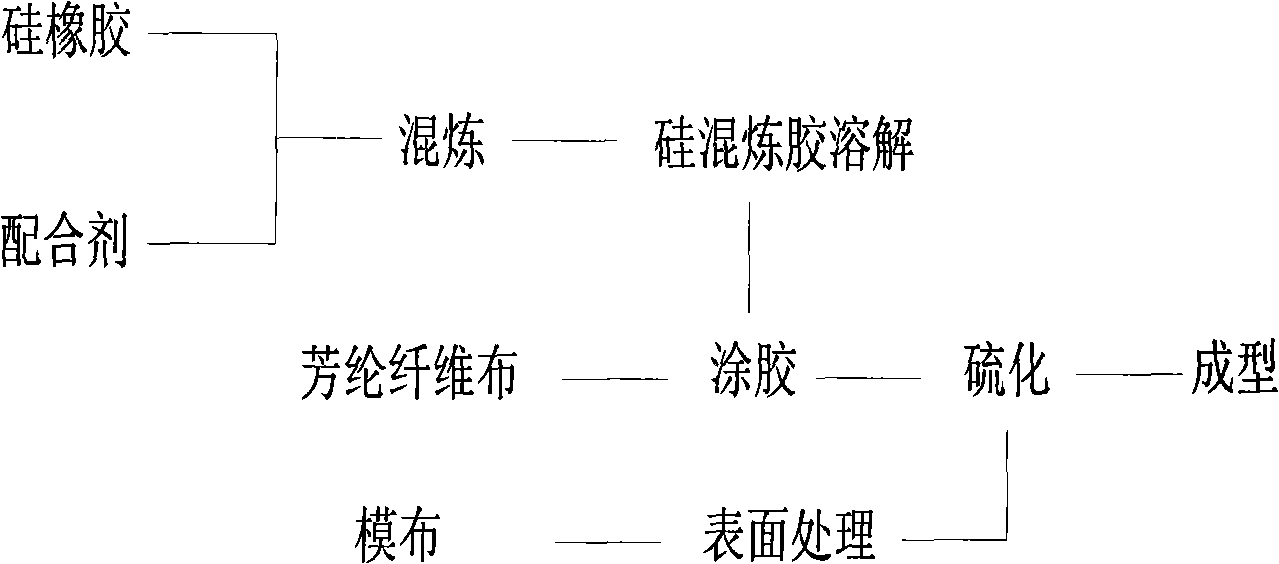

Aramid fiber fibre-silastic fabric, production method thereof and use in soft pipeline

InactiveCN101328650AEnables direct bondingImprove adhesionFibre typesLiquid/gas/vapor textile treatmentRubber materialPolymer science

The invention relates to an aromatic polyamide fiber-silicone rubber cloth, a method for producing the same and an application thereof in the aspect of manufacturing a hose. The production method comprises the following steps that: silicone rubber virgin rubber is added with an auxiliary agent to be mixed into silicone gross rubber through a rubber refining machine; the silicone gross rubber is added with the auxiliary agent and a coupling agent to be stirred and prepared into silicone gross rubber paste; the silicone gross rubber paste is applied on the surface of an aromatic polyamide fiber cloth; sulfur treatment is performed; etc. The production method realizes direct adherence of the rubber and the surface of the aromatic polyamide fiber cloth by adoption of the method of adding the coupling agent in the silicone gross rubber. The product of the aromatic polyamide fiber-silicone rubber cloth produced by the method can meet the following performance indexes: the tensile strength of rubber materials is more than or equal to 6 MPa; the tear strength of the rubber materials is more than or equal to 30 N.mm<-1>; the adhesive strength between Ib rubber with flame-retardant property and a base-cloth layer is more than or equal to 3 N.mm<-1>; the service temperature is between 60 DEG C below zero and 200 DEG C; and the folding fatigue resistant time is more than or equal to 2 million times. The aromatic polyamide fiber-silicone rubber cloth is used for manufacturing various flexibly connected pipes and is a superior cloth for manufacturing a transition air channel hose of a pulling motor of a locomotive.

Owner:株洲市华丰复合材料有限公司

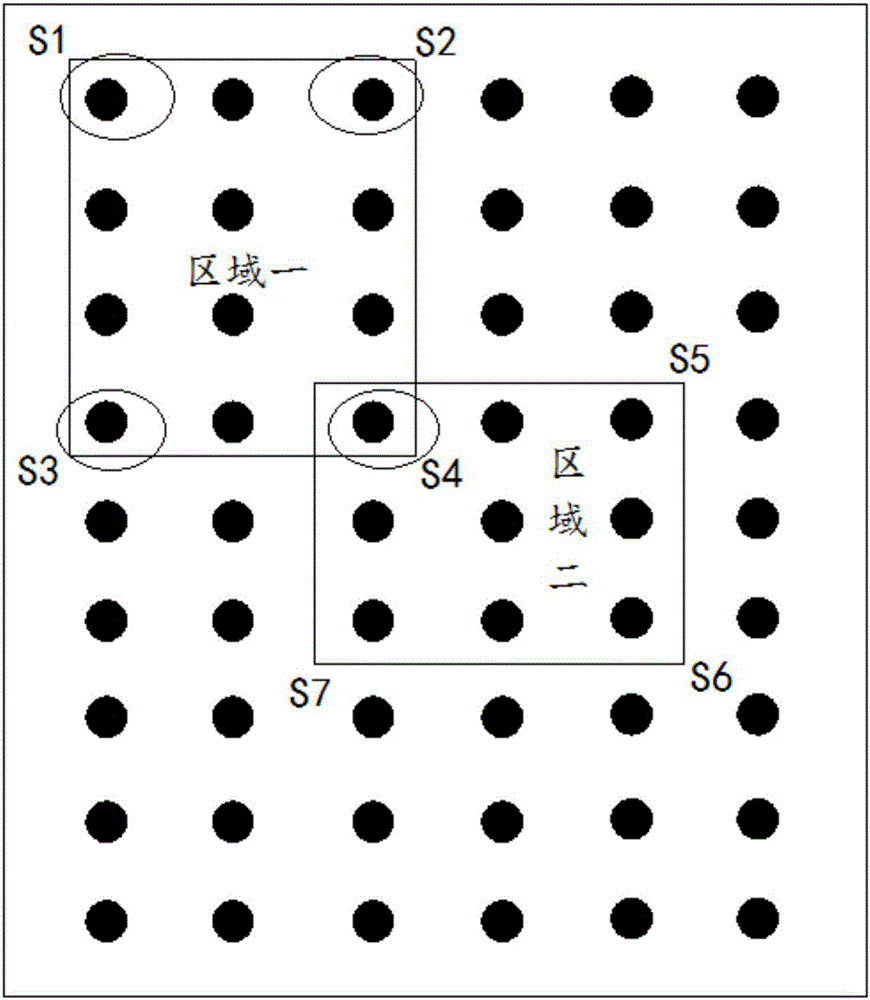

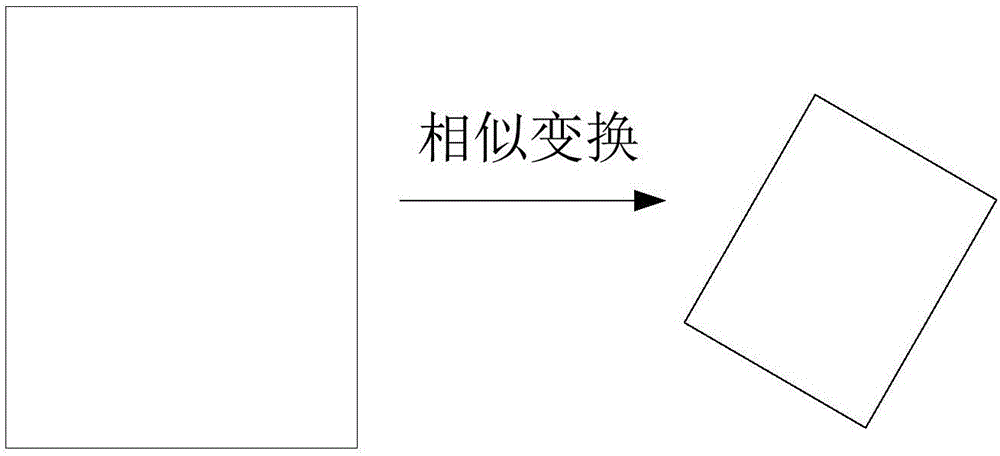

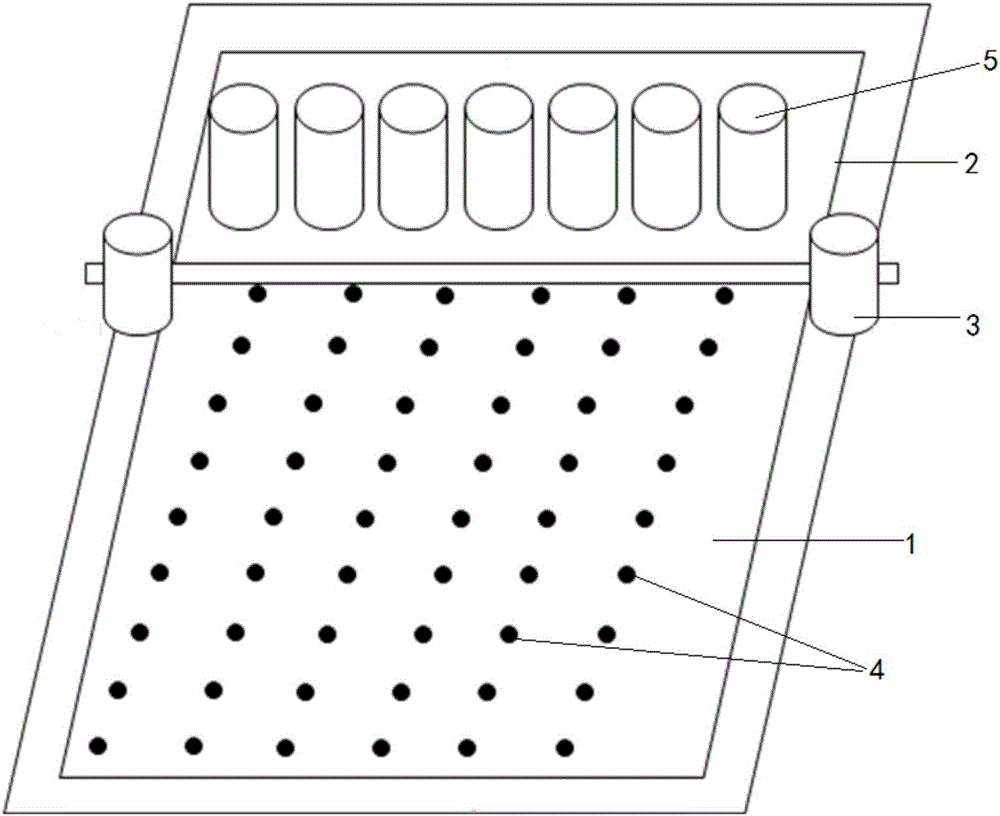

Error correction and compensation method and device based on calibration board in direct-writing exposure machine

ActiveCN106647180ASave film programEfficient processPhotomechanical exposure apparatusMicrolithography exposure apparatusGraphicsAlgorithm

The invention discloses an error correction and compensation method and device based on a calibration board in a direct-writing exposure machine. The method includes the steps: firstly, acquiring vertex coordinate values of at least one arbitrary area on the calibration board; secondly, determining size expanding and shrinking variation quantity of the area corresponding to the vertex coordinate values according to a graph similarity transformation model and the vertex coordinate values; finally, performing error correction and compensation for a direct-writing exposure machine system according to the size expanding and shrinking variation quantity. According to the method, deformation of graphs of different areas is measured and corrected by the aid of the calibration board, correction and compensation of an exposure device system are achieved, so that the quality exposing imaging results of different areas are improved.

Owner:ADVANCED MICRO LITHO INSTR INC

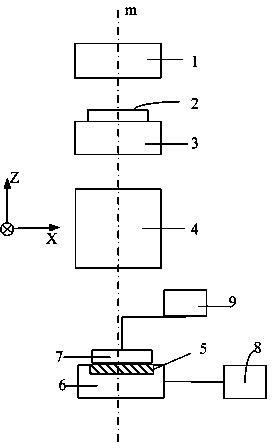

Method for improving positioning precision of workpiece bench of lithography machine

ActiveCN103792792APrecise positioningSolve misalignmentUsing optical meansPhotomechanical exposure apparatusLithographic artistEngineering

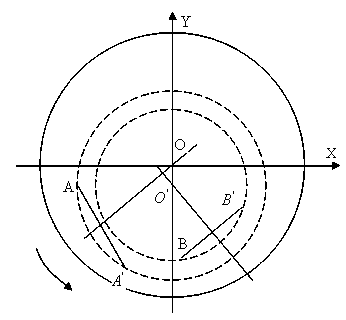

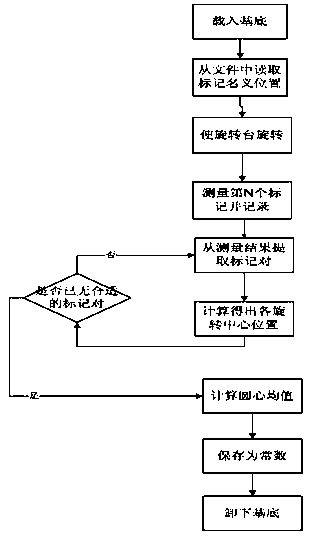

The invention provides a method for improving a positioning precision of a workpiece bench of a lithography machine. According to the method, through a base with an aligning mark pair, acquired data is tested and an actual rotation center of a rotation platform is calculated. Multiple mark pairs are measured so that a circle center position is obtained, an average value is calculated and is used as a final circle center position value of the rotation platform, and in workpiece bench motion, a compensation process is carried out. The method for determination of a rotation center of the rotation platform of the workpiece bench well solves the problem of installation mechanical error-caused misalignment of an actual rotation center of the rotation platform and a geometrical center of the base and the problem of translation interference caused by workpiece bench rotation because of the misalignment. Through compensation of the measured actual rotation center of the rotation platform, a workpiece can be positioned accurately so that exposure quality is greatly improved.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

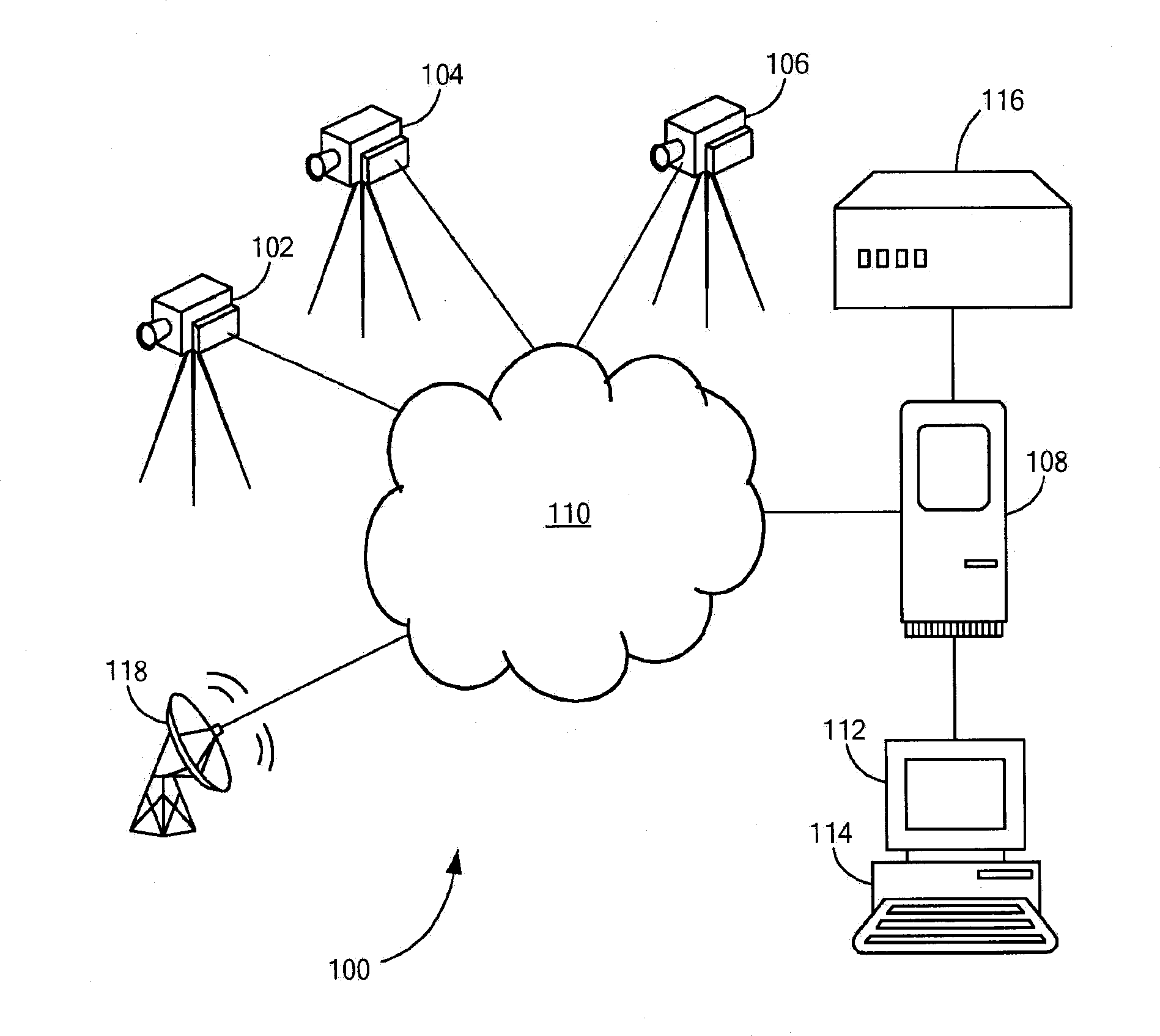

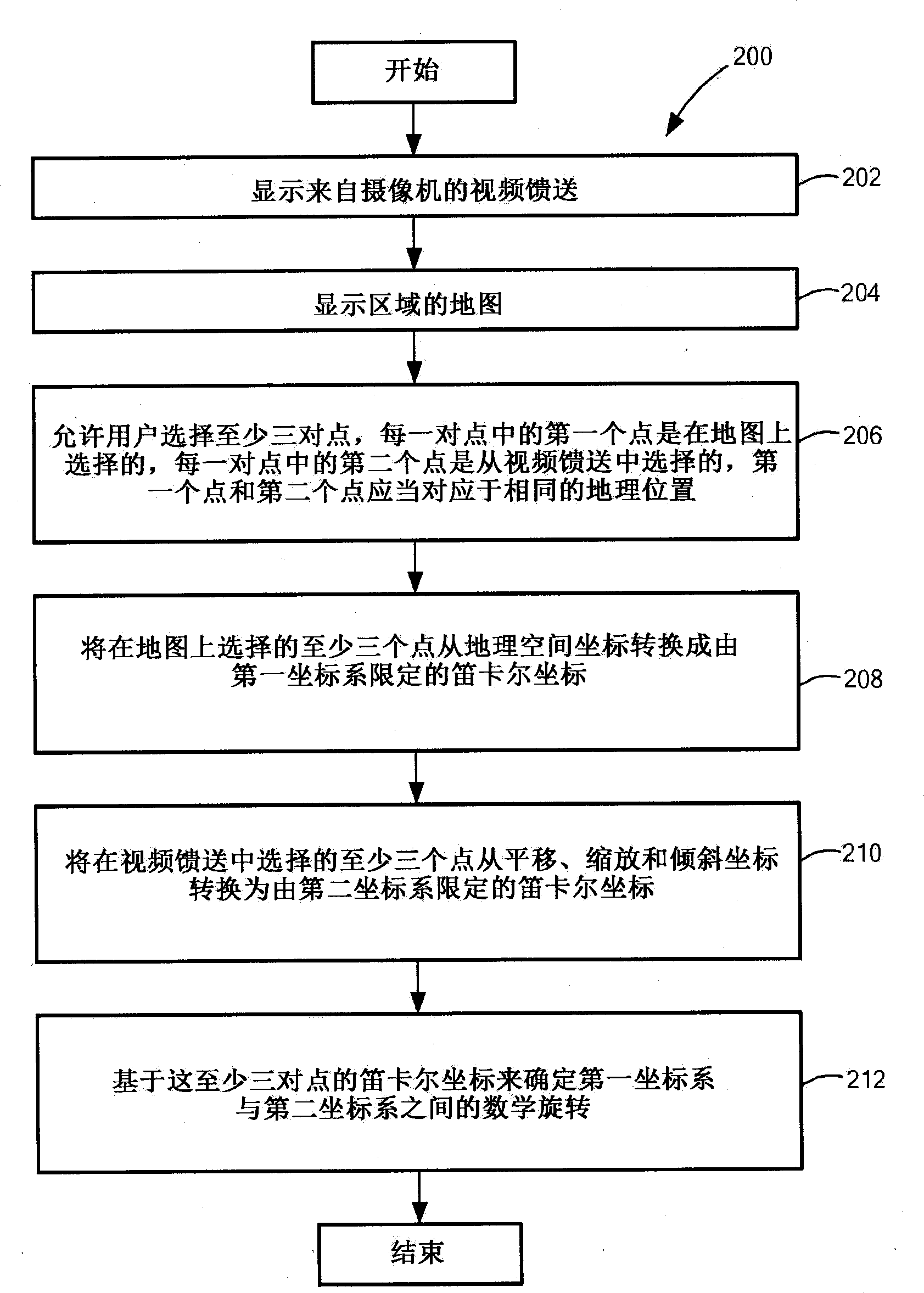

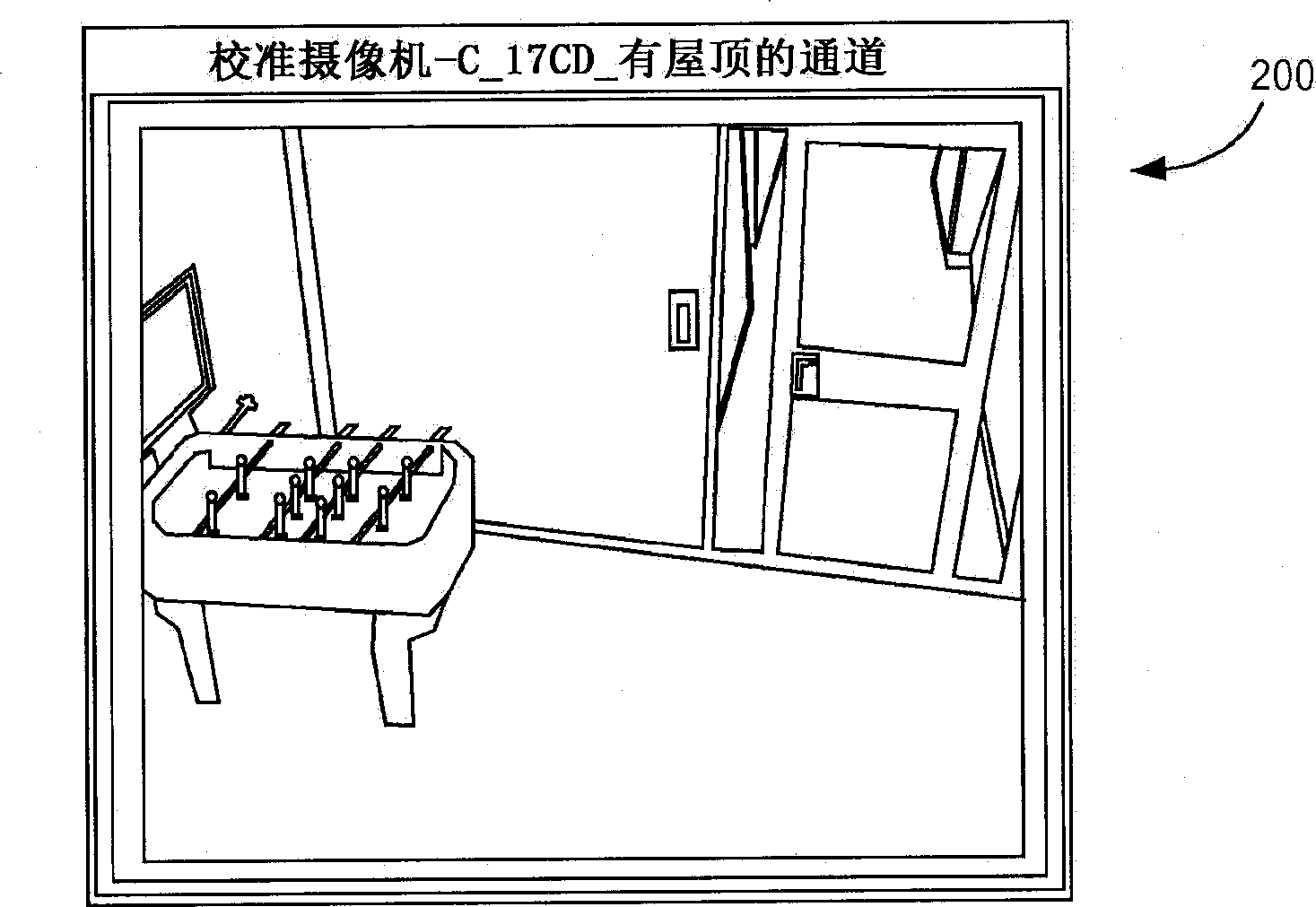

System and method for camera control in a surveillance system

ActiveCN103380618ASolve misalignmentTelevision system detailsClosed circuit television systemsCamera controlMonitoring system

A method and a system for calibrating a camera in a surveillance system. The method and system use a mathematical rotation between a first coordinate system and a second coordinate system in order to calibrate a camera with a map of an area. In some embodiments, the calibration can be used to control the camera and / or to display a view cone on the map.

Owner:INTERGRAPH

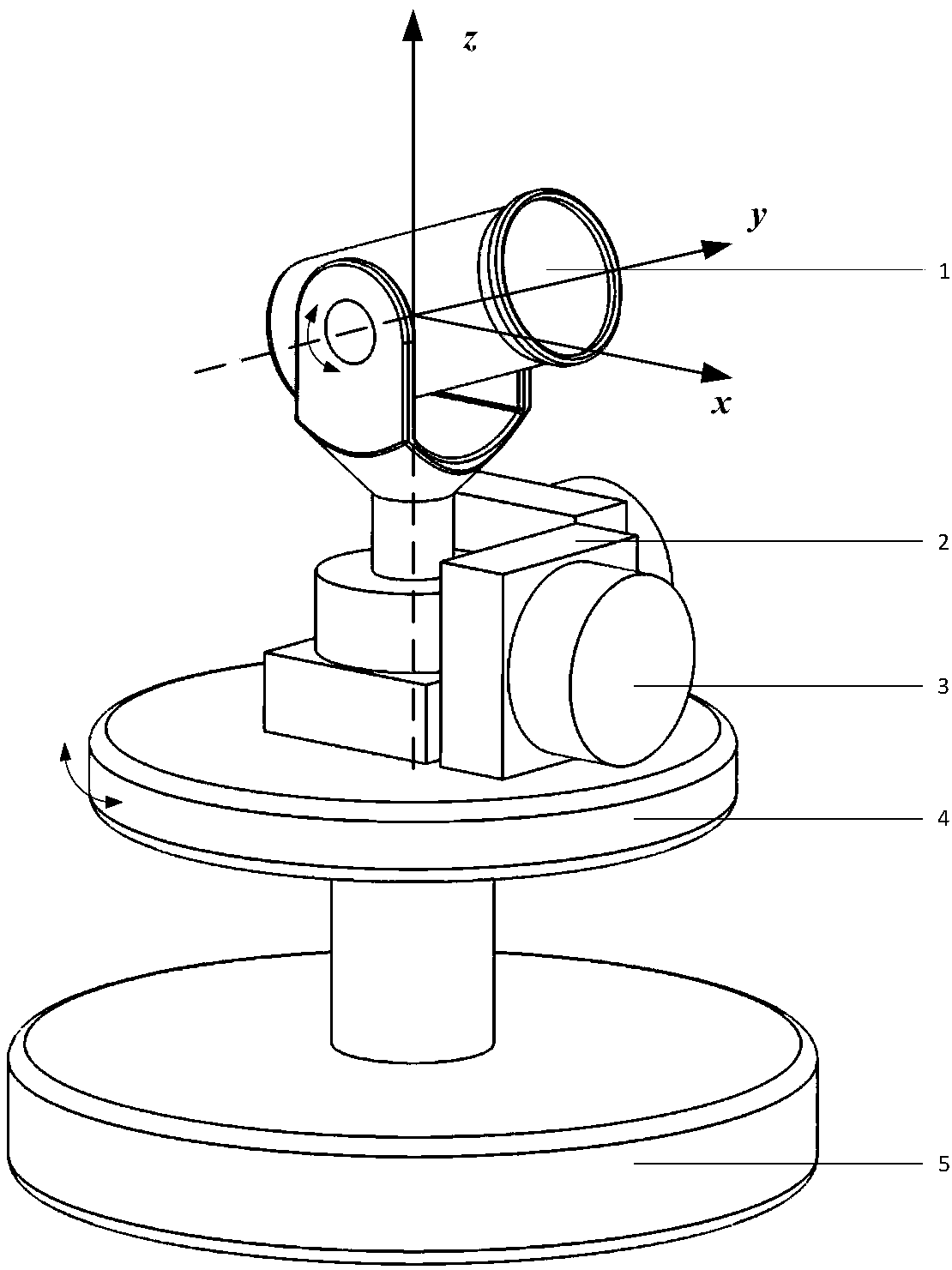

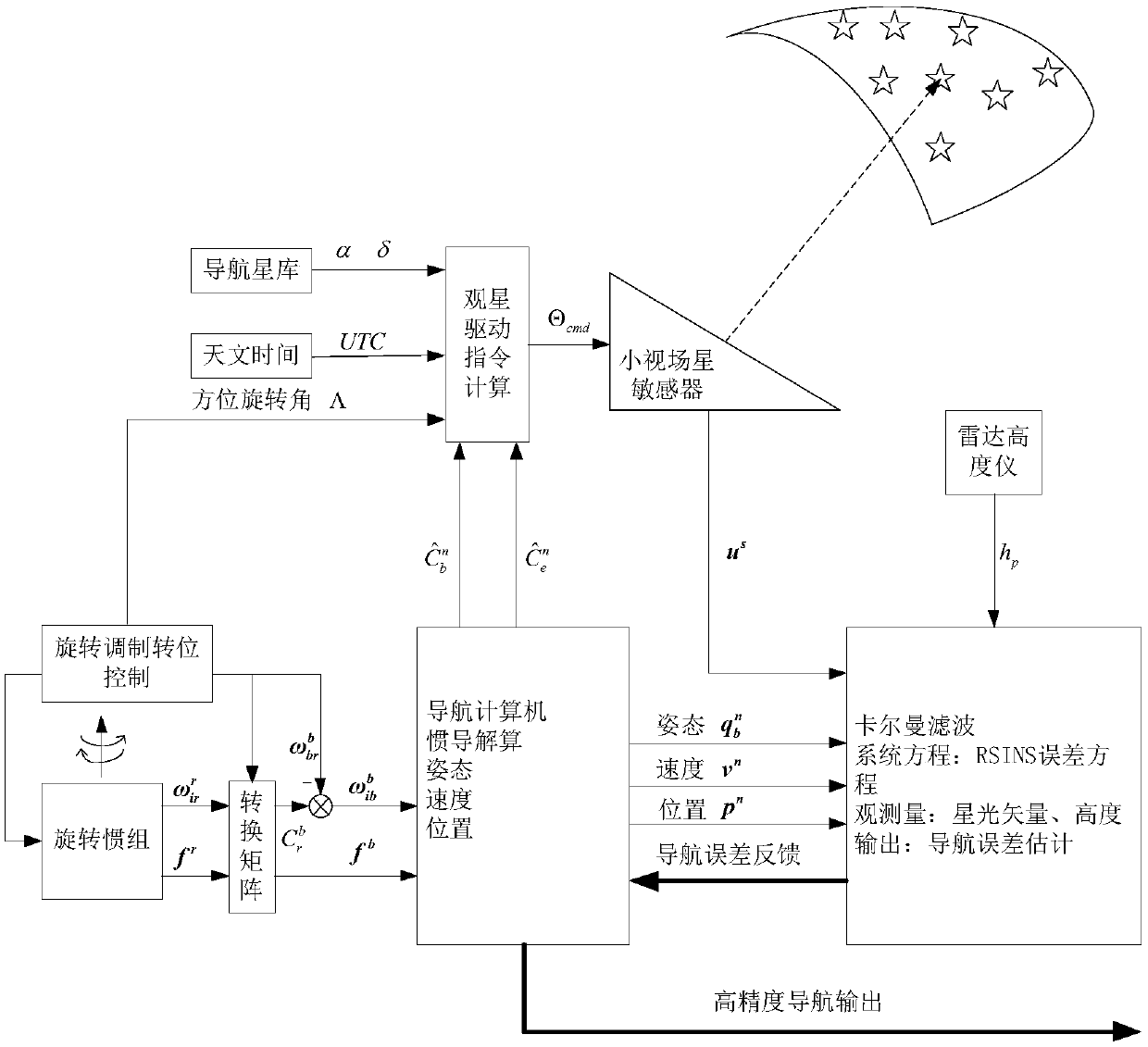

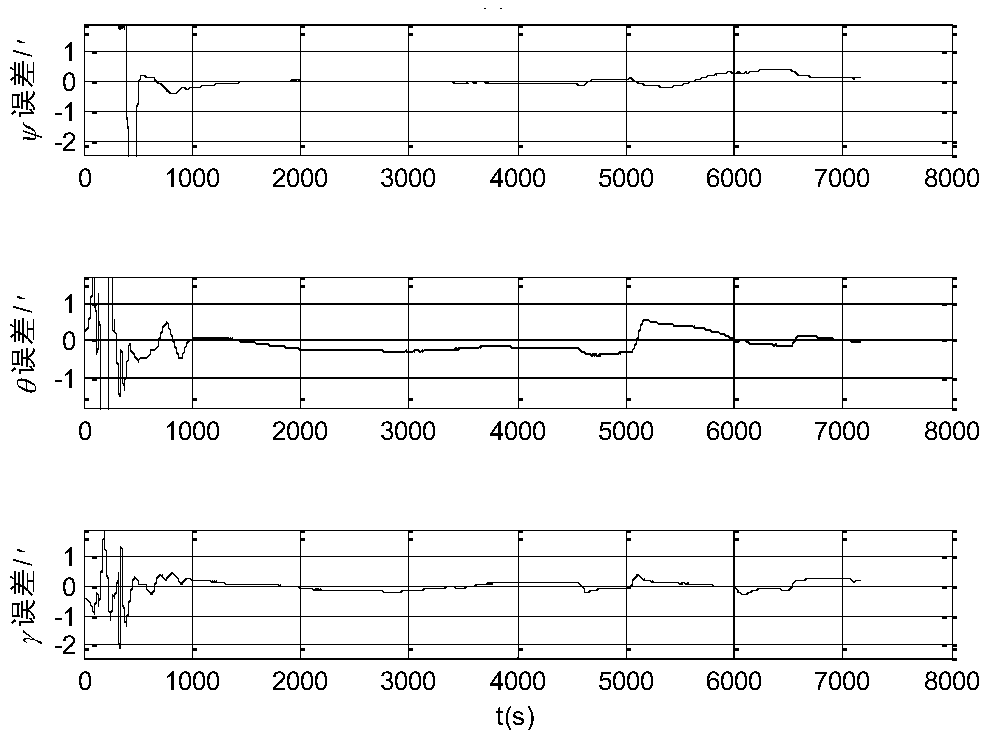

Uniaxial rotational modulation based inertial and celestial combined navigation system and calculation method

ActiveCN108731674AReduce divergenceSolve misalignmentNavigational calculation instrumentsNavigation by speed/acceleration measurementsIntegral actionCelestial navigation

The invention discloses a uniaxial rotational modulation based inertial and celestial combined navigation system and a calculation method. The system comprises a uniaxial rotational modulation strap-down inertial navigation system, a celestial navigation system and a horizontal rotating table. A rotational modulation shaft of the uniaxial rotational modulation strap-down inertial navigation systemis coincided with a shaft, perpendicular to the horizontal rotating table, of the celestial navigation system so as to realize rotational modulation along with rotation of the rotational modulation shaft. By selection of a reasonable rotating mode, inertial device biases form periodic signals under a navigation coordinate system, and caused navigation errors are eliminated through the integral action. By combination of the uniaxial rotational modulation based inertial and celestial combined navigation system and the calculation method based on the same, high-precision high-reliability navigation information output is realized, and demands of current navigation users are met.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

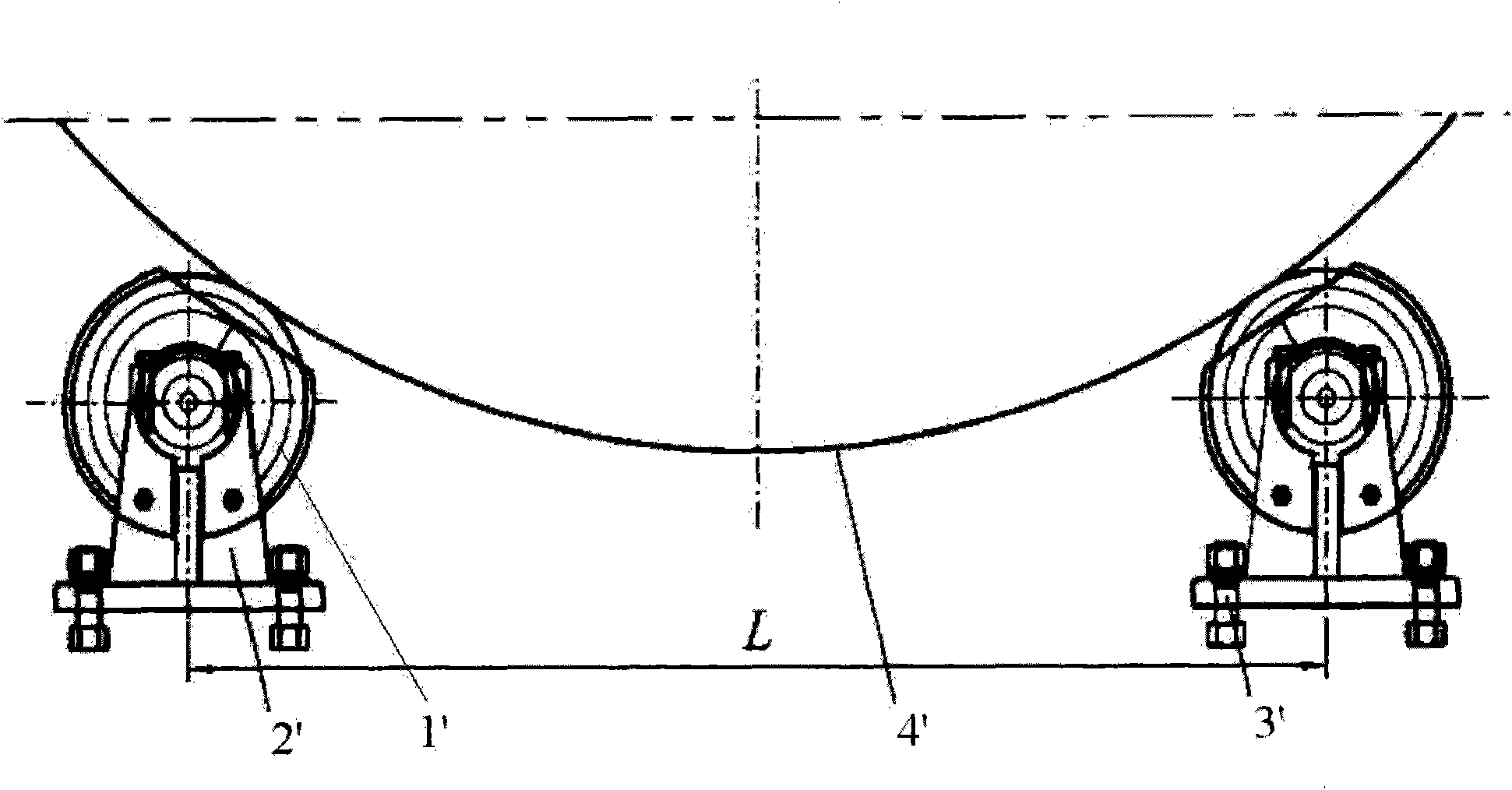

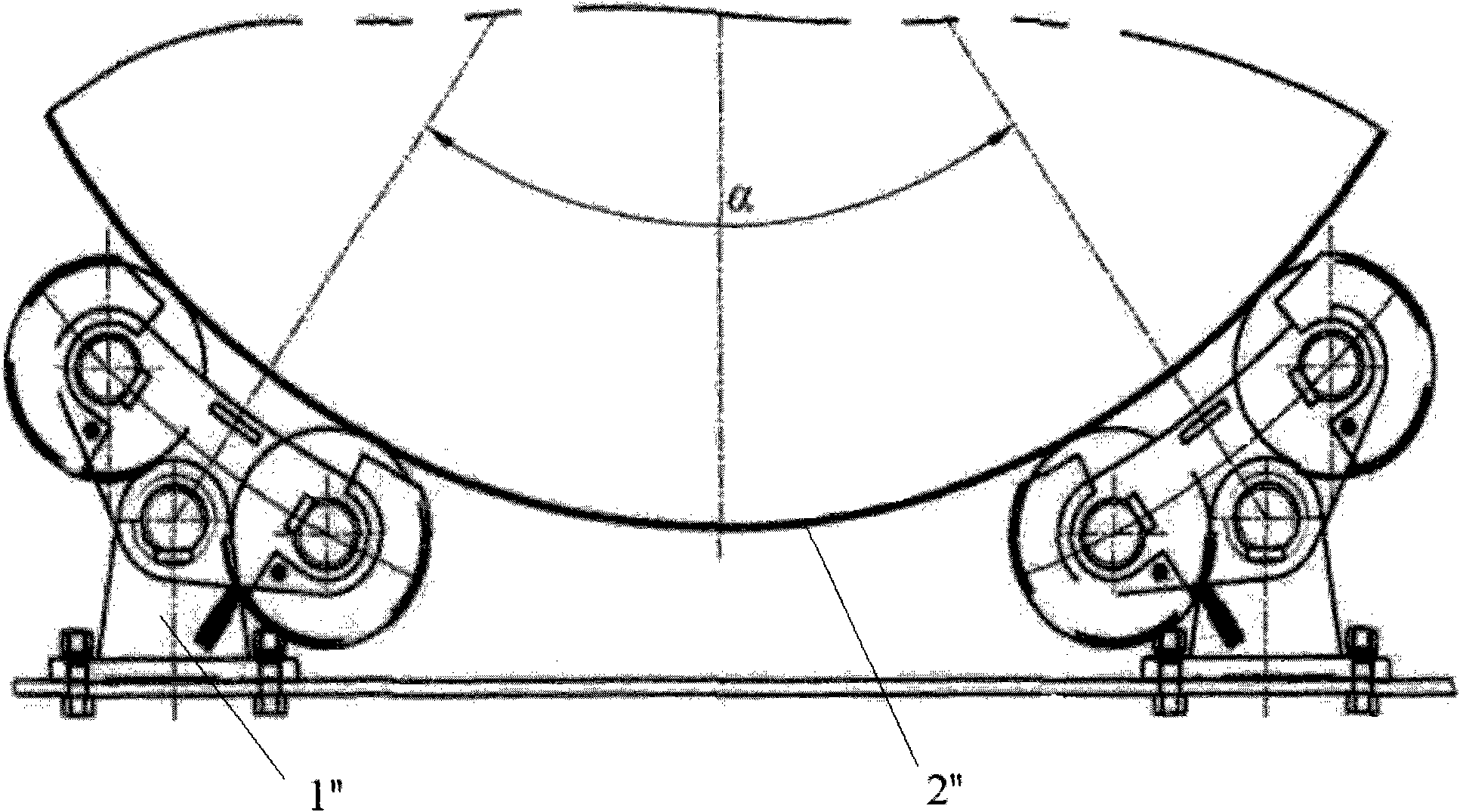

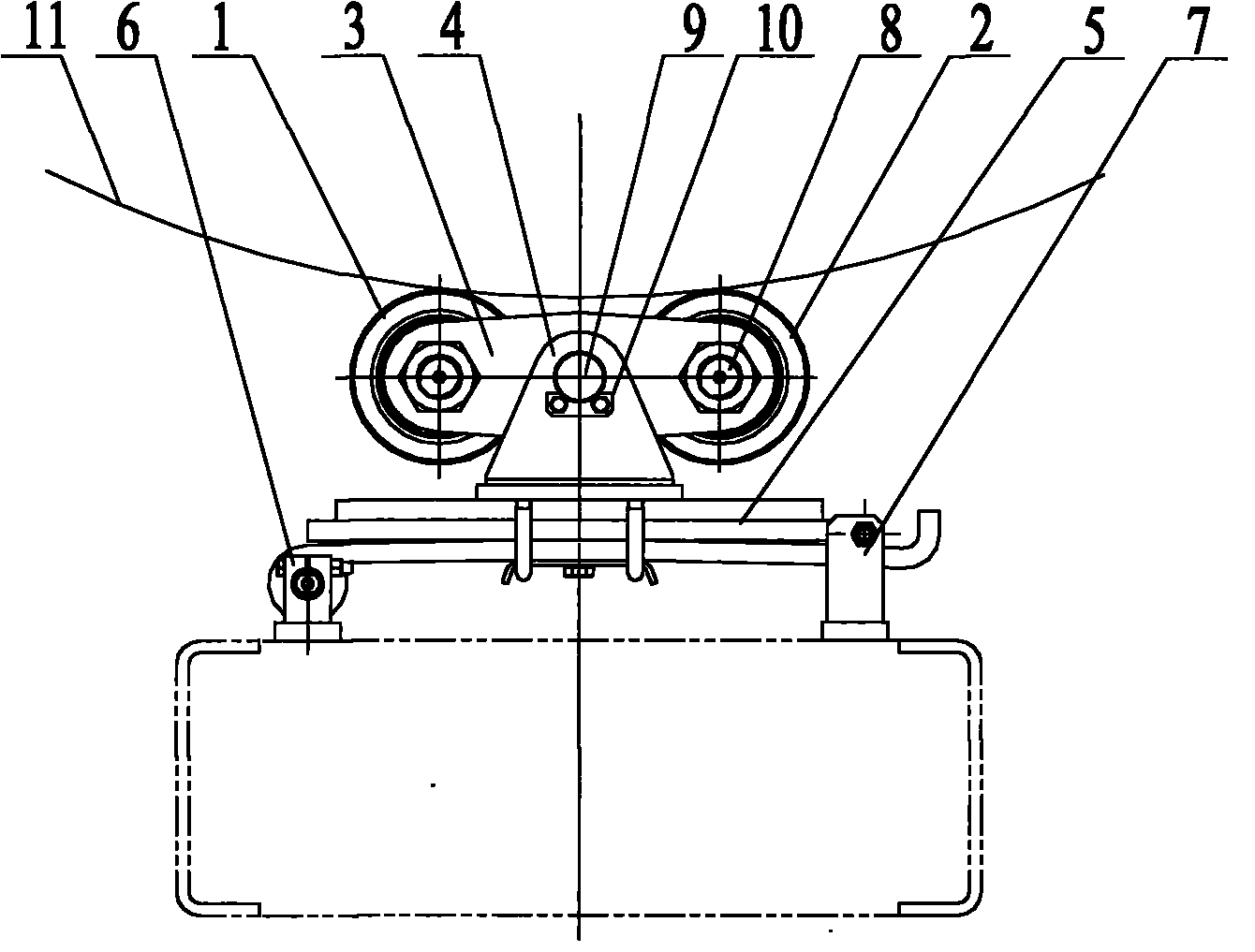

Support device and agitating lorry

InactiveCN101844372AReduce shockSolve misalignmentCement mixing apparatusRoad surfaceMechanical engineering

The invention relates to the technical field of agitating lorries, and discloses a support device, which is used for supporting an agitator drum of an agitating lorry. The support device comprises a riding wheel assembly, wherein the bottom end of the riding wheel assembly is fixed to a lorry body of the agitating lorry through an elastic device. The bottom end of the riding wheel assembly of the support device is fixed to the lorry body of the agitating lorry through the elastic device; and when the agitating lorry runs on bumpy and uneven roads quickly, the impact generated by the upward jumping of the agitator drum can be absorbed by the elastic device, so that the impact generated by the upward jumping of the agitator drum can be reduced, and the agitator drum and the riding wheel assembly are protected effectively. The invention also discloses the agitating lorry.

Owner:SANY HEAVY IND CO LTD (CN)

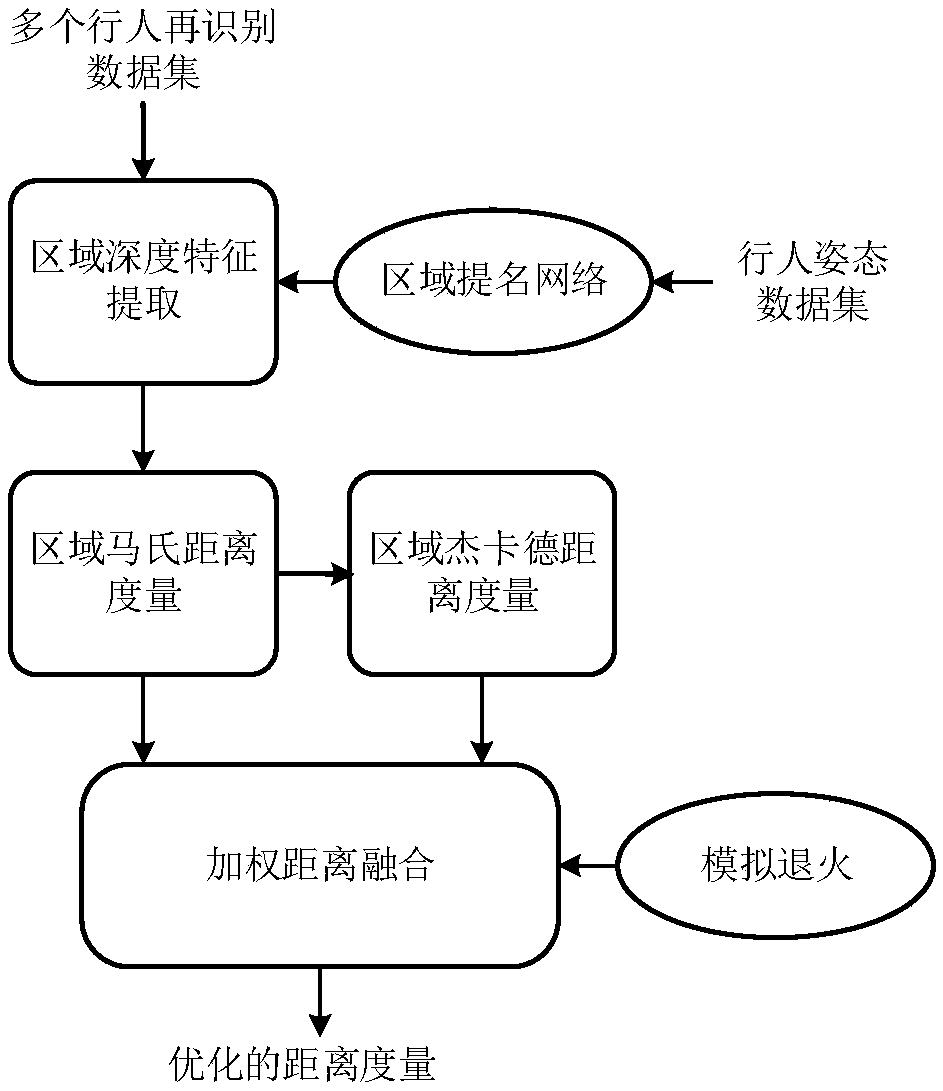

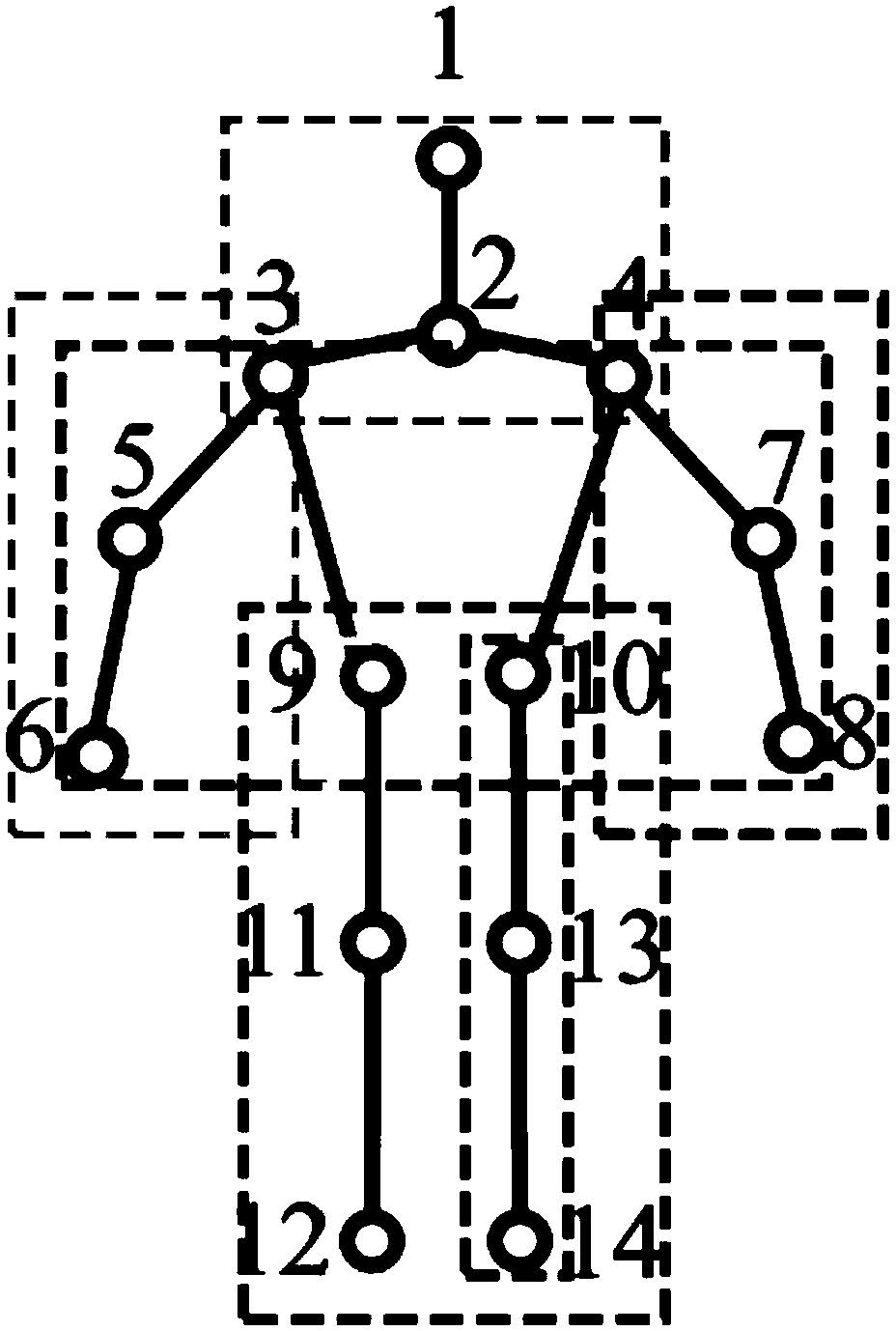

A pedestrian re-identification method combining deep learning and metric learning

InactiveCN109447175AFix misalignmentSolve misalignmentCharacter and pattern recognitionNeural architecturesRe identificationMahalanobis distance

The invention discloses a pedestrian re-identification method combining deep learning and metric learning. The pedestrian re-identification method comprises the following steps of extracting pedestrian image deformation area deep convolution features; calculating a pedestrian image deformation area Mahalanobis distance measure and a Jackalide distance measure; and optimizing the distance metric across the camera pedestrian. According to the invention, a region naming network is used; a local deformation area of the pedestrian image is obtained, and the deep convolution characteristic of the local deformation area of the pedestrian appearance is fully applied. The pedestrian recognition method based on the simulated annealing algorithm is used for representing multiple pieces of detail information of the pedestrian image, the simulated annealing algorithm is applied to learn the optimal distance function of the cross-camera pedestrian by combining the Mahalanobis distance and the Jackddistance of the deformation area of the pedestrian image, and the optimal distance measurement of the cross-camera pedestrian is realized, so that the pedestrian re-recognition ability and robustnessare improved.

Owner:HUANGSHAN UNIV

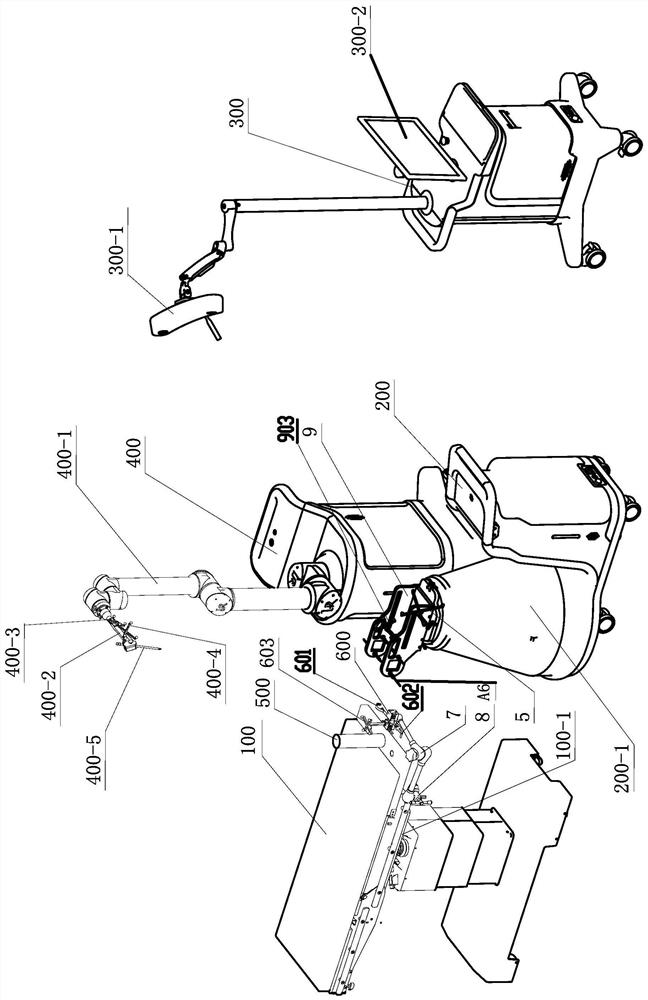

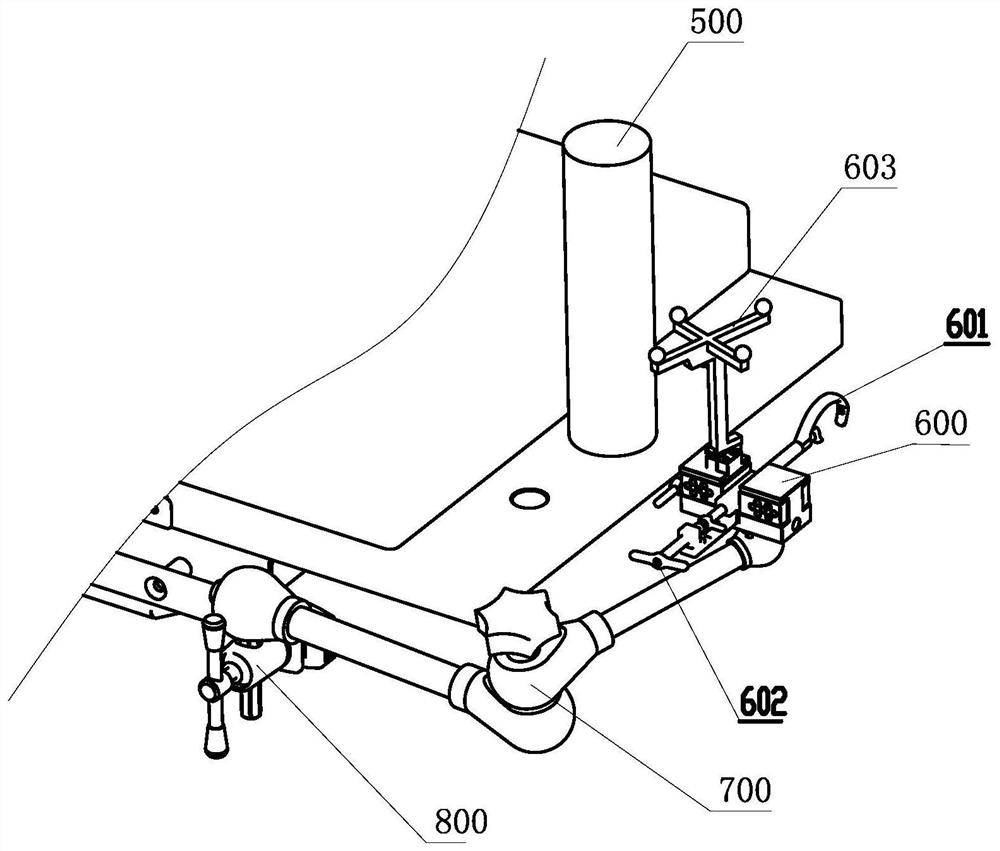

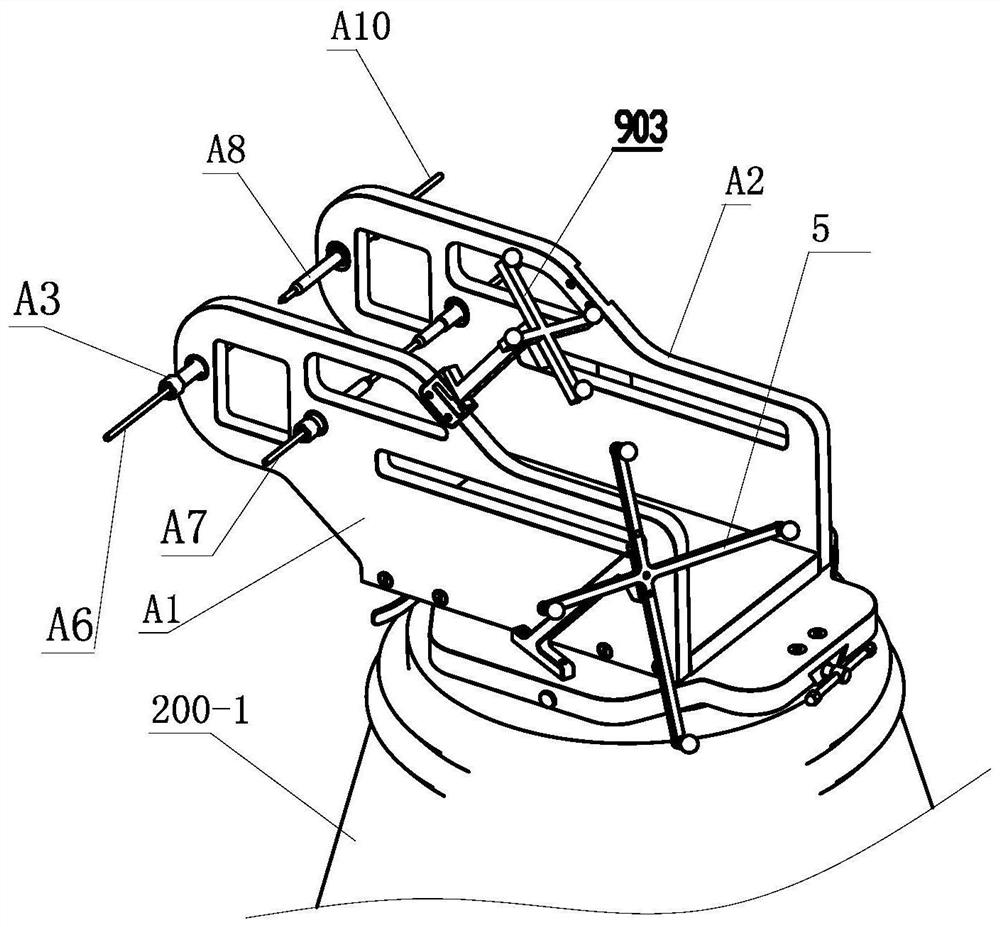

Orthopedic department reset positioning robot

ActiveCN112716603AAchieve positioningRealize resetInternal osteosythesisSurgical navigation systemsOrthopedics surgeryPhysical medicine and rehabilitation

The invention relates to an orthopedics department reset positioning robot, which solves the technical problem that an existing orthopedics department operation robot is low in reset precision during an operation and comprises a reset robot body, a navigation robot and a positioning robot body, the reset robot body comprises a reset platform, a far-end fixator and a far-end reference frame, and the far-end reference frame is fixed to the far-end fixator; the far-end fixator comprises a connecting base plate, a movable connecting plate, a first locking device, a reference frame, a first connecting side plate, a second connecting side plate, a first fixed sleeve, a second fixed sleeve, a fixing plate, a first fixed needle, a second fixed needle, a third fixed sleeve, a fourth fixed sleeve, a third fixed needle and a fourth fixed needle. The invention is widely applied to orthopedic surgery.

Owner:WEIHAI WEIGAO ORTHOPEDIC SURGICAL ROBOT CO LTD

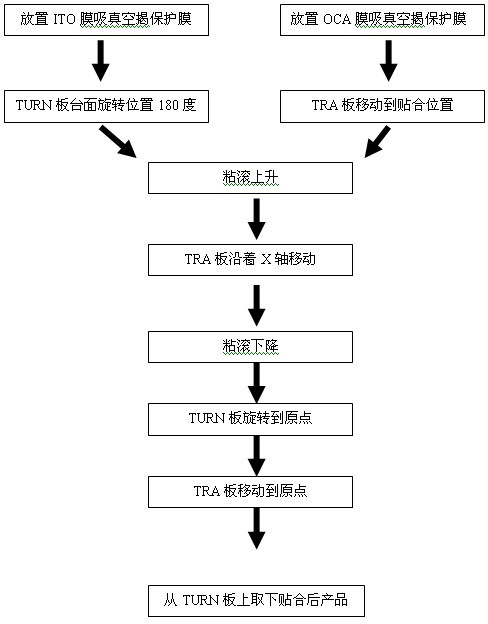

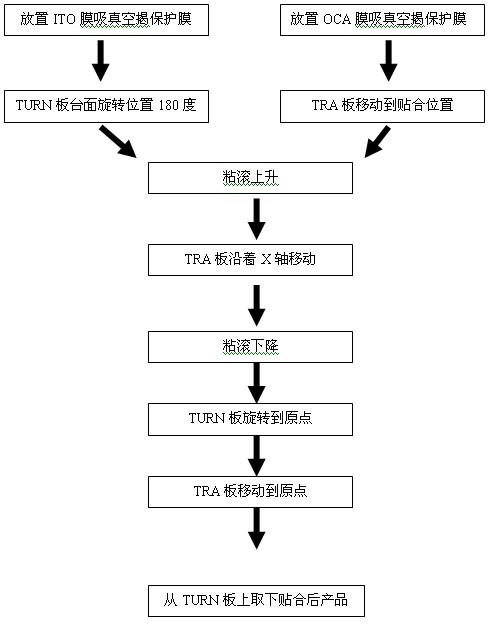

Capacitive touch screen laminating process

InactiveCN102303449ASolve misalignmentSolve the bubblesLaminationLamination apparatusForeign matterVacuum extraction

The invention relates to a capacitive touch screen laminating process. The process comprises the following steps: 1. selecting a lamination program according to the product model; 2. setting lamination parameters and vacuumizing the table board, wherein the pressure is -40 to -85 Kpa, the rolling shaft pressure is 400-600 g, and the shift-out speed is 30-50 cm / min; 3. clicking an original point and resetting a turning plate and a transfer plate; 4. clicking a locating needle button so that the locating needle pops up; 5. placing an optical clear adhesive (OCA) punched with locating holes on the transfer plate so as to carry out vacuum extraction; 6. placing a sheet needing to be laminated on the turning plate so as to carry out vacuum extraction; 7. removing the sheet needing to be laminated and a protective film on the OCA; 8. starting a start button so that equipment works; and 9. after the lamination, taking down the laminated sheet from the turning plate. Through the process, the problems of inaccurate alignment and bubble generation in the lamination process of the touch screen are solved, the lamination alignment precision is improved, the generation of foreign matters and bubbles is reduced, and the requirements on the product appearance are met. The lamination process is simple and fast and suitable for mass production.

Owner:TIANJIN ZHONGHUAN HI TECH

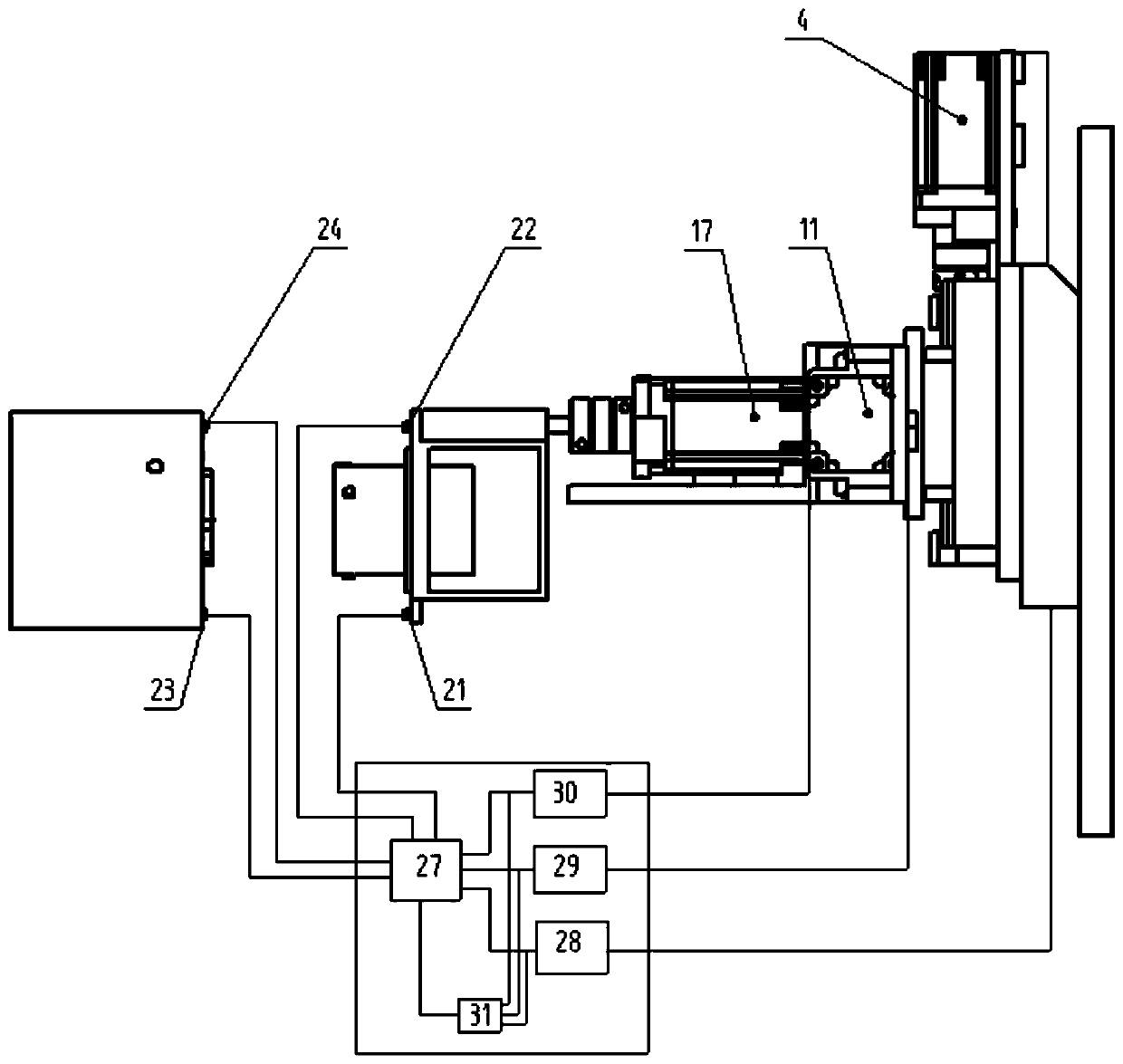

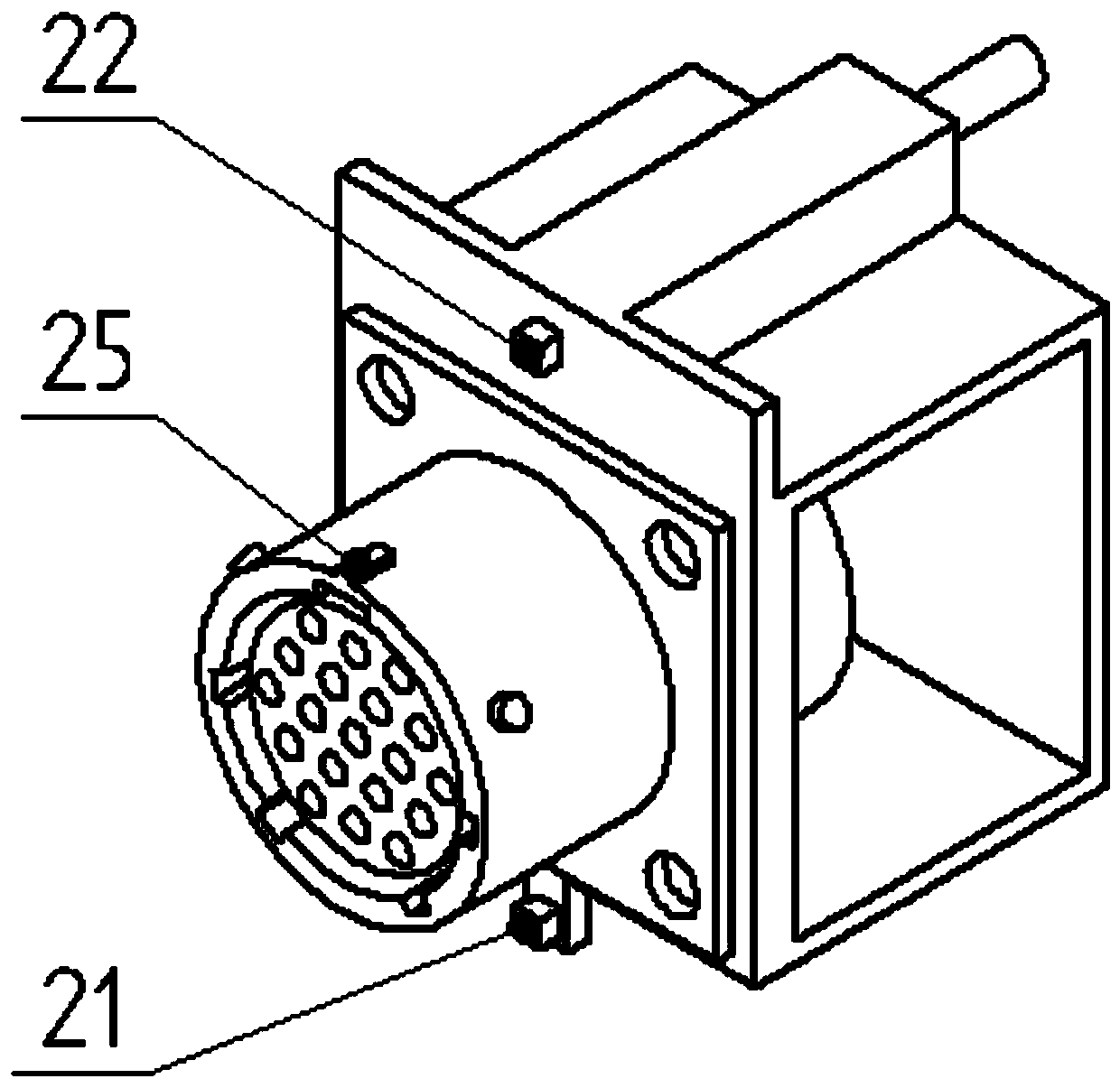

Automatic centering plugging method for electric connector

ActiveCN111431013ASolve the misalignmentSolve misalignmentCoupling device engaging/disengagingUsing optical meansServoElectrical connection

The invention discloses an automatic centering plugging method for an electric connector. After an existing electric connector plugging device is abraded, the coaxiality of a socket and a plug of theelectric connector is reduced. The method comprises the steps that the transmitting ends of two photoelectric sensors are both fixed on an electric connector socket clamp, the receiving ends of the two photoelectric sensors are both fixed on an electric connector plug clamp, and the translation in two directions and rotation in one direction of the electric connector socket clamp are realized through the driving of an XZ-axis two-dimensional sliding table and a rotary servo motor; a master controller judges that the receiving ends of the two photoelectric sensors receive the infrared light emitted by the emitting ends of the photoelectric sensors, the positioning protrusions of the electric connector socket, the positioning grooves of the electric connector plug and the central axes of theelectric connector socket and the electric connector plug are judged to be aligned, and then an electric connector plugging and unplugging device carries out plugging and unplugging tests on the electric connector. According to the invention, the problem that the socket and the plug of the electric connector cannot be centered after the electric connector plugging device is plugged for multiple times, is effectively solved.

Owner:ZHEJIANG SCI-TECH UNIV

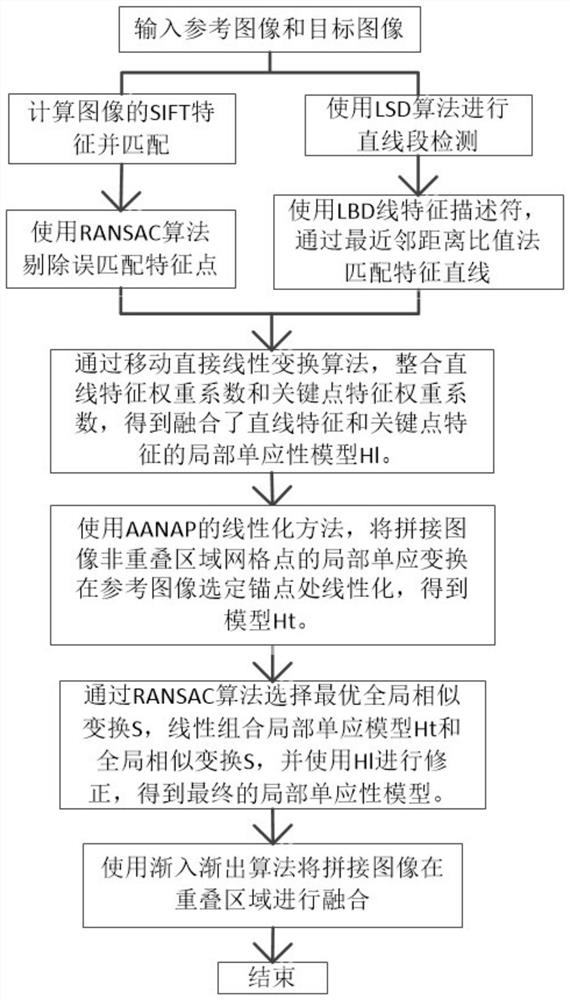

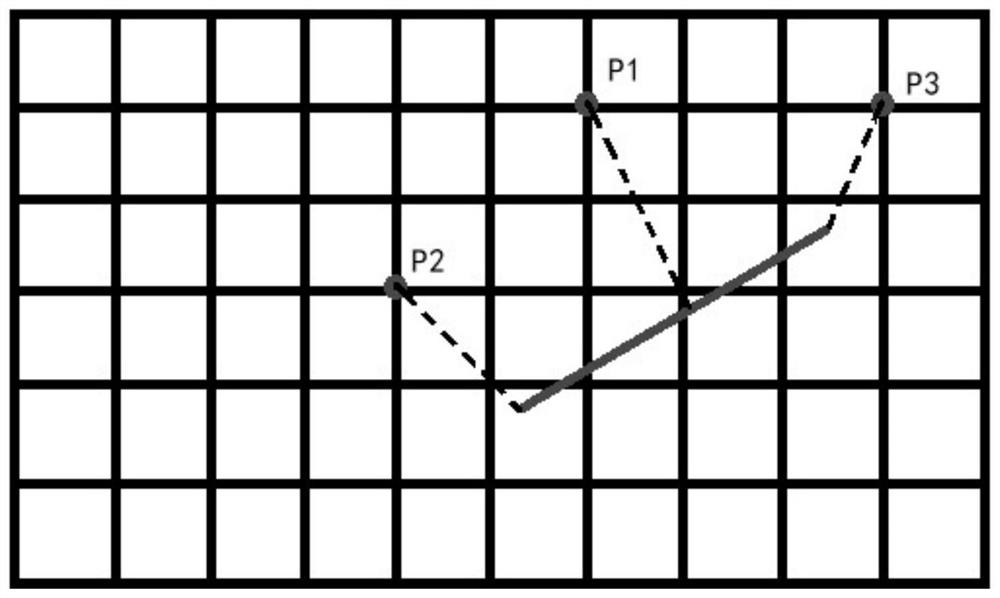

Image splicing method and system based on straight line feature and key point feature fusion

PendingCN112529019AImprove accuracyImprove follow-up registration accuracyImage enhancementImage analysisRadiologyImage alignment

The invention discloses an image splicing method and system based on straight line feature and key point feature fusion, and relates to the technical field of image splicing and pattern recognition. In order to extract more features on a low-texture image as much as possible, linear features are introduced, that is, the linear features and key point features on the image are detected at the same time, feature extraction of the to-be-spliced image is enriched, and a moving direct linear transformation algorithm combining the linear features and the key point features is introduced. Linear features and key point features are used for jointly guiding local homography transformation of each grid, in order to prevent the linear features from weakening the alignment capacity of the key point features, the fusion degree of the linear features is balanced through lambda constant coefficients, and it is verified that the moving direct linear transformation algorithm with the balance factor hasbetter low texture image alignment capacity, and the problem of misalignment caused by insufficient SIFT feature points of a low-texture image is effectively solved.

Owner:HUAZHONG UNIV OF SCI & TECH

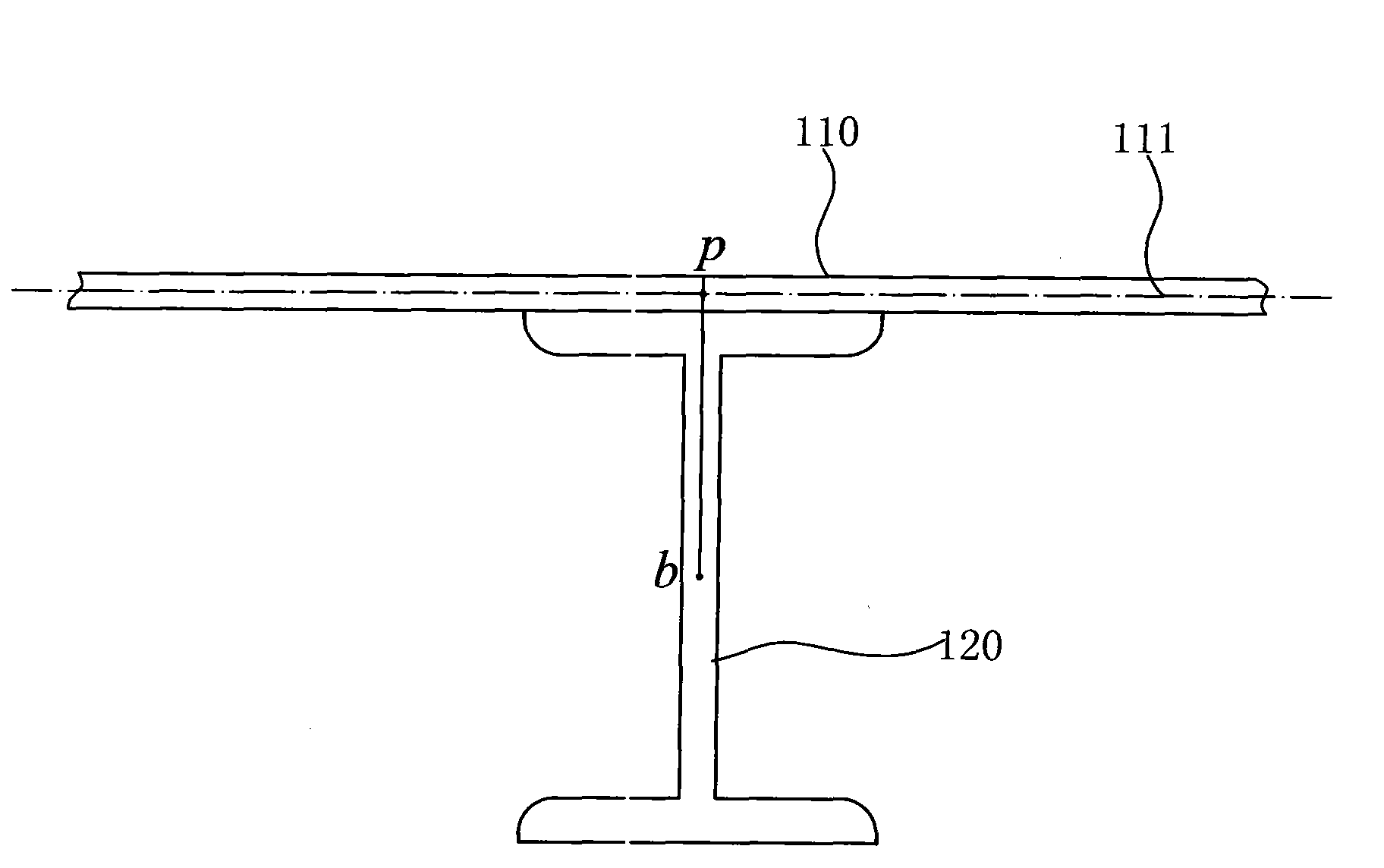

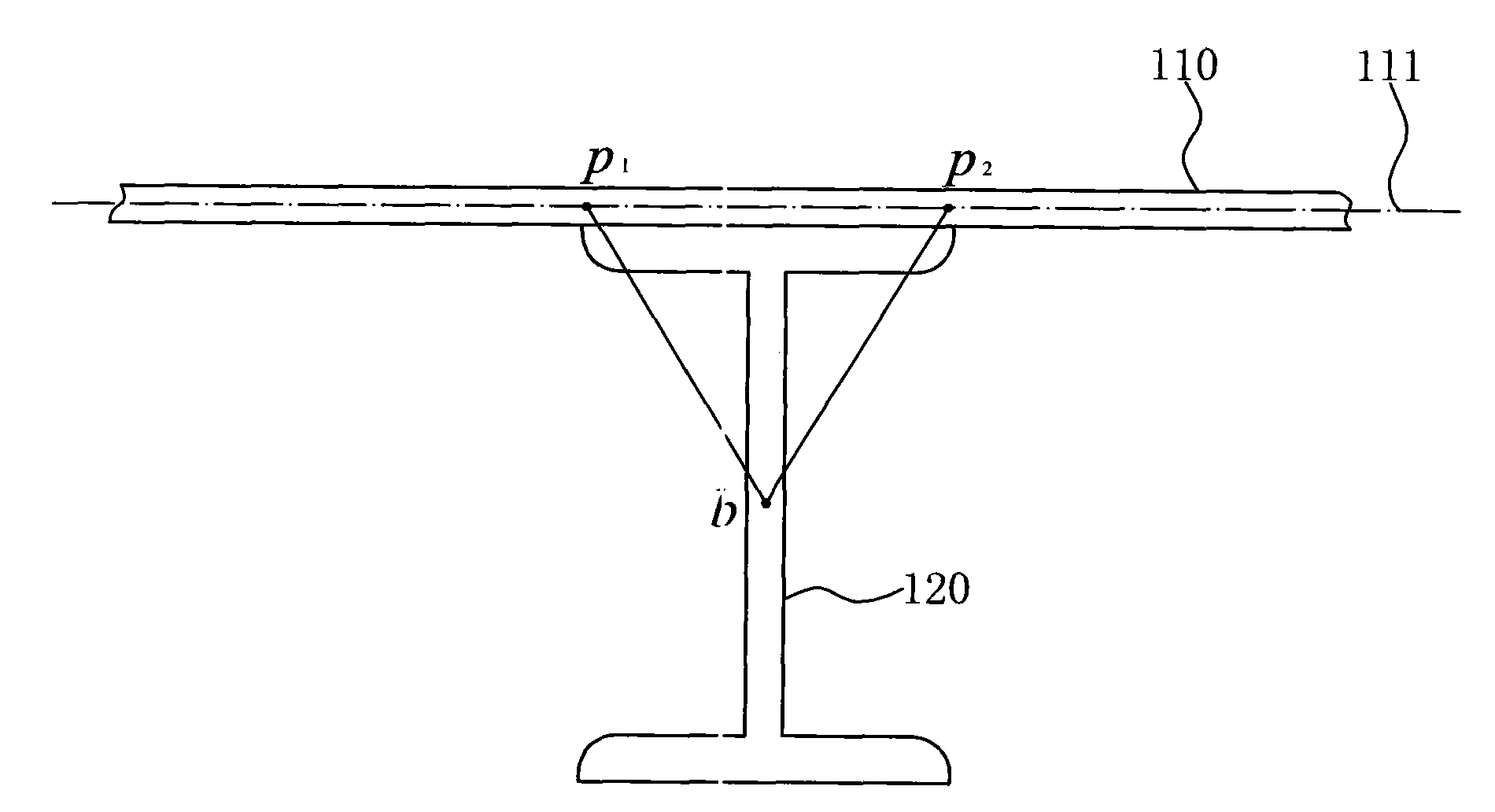

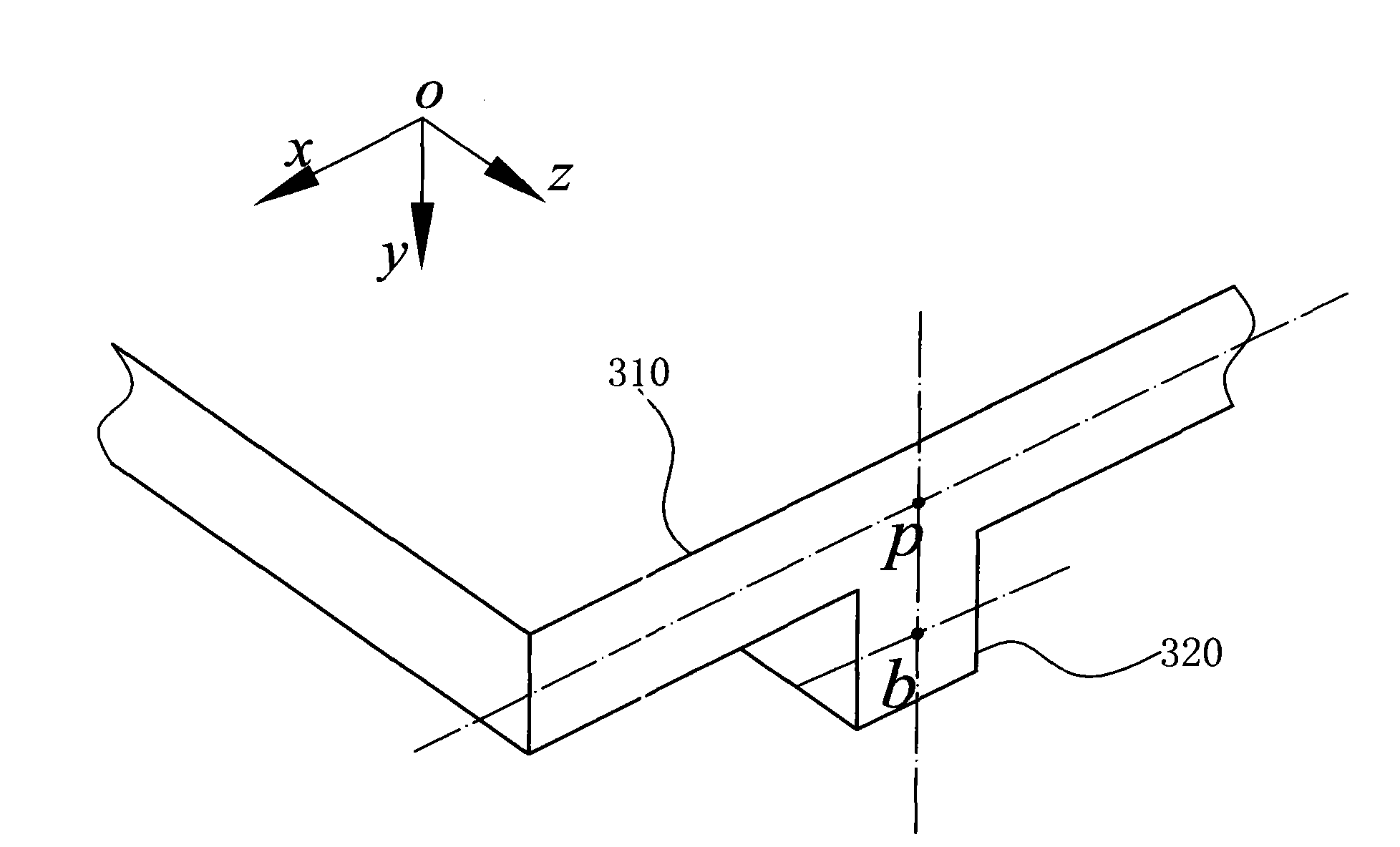

Method for constructing slab- girder structure of train body in analysis of train structure

InactiveCN101650758ASolve the problem of eccentric connectionSolve misalignmentAxle-box lubricationSpecial data processing applicationsStructure analysisEngineering

The invention relates to a method for constructing a slab-girder structure of a train body in the analysis of a train structure, which is used for solving the static force problem of a slab- girder combined structure in a train body steel structure. The method is characterized by comprising the following steps: constructing the slab-girder combined structure at a connection part of a girder unit and a slab unit, constructing an eccentric displacement relation of eccentric nodes when the slab unit is eccentrically connected with the girder unit; then formulating finite element programs constructing the slab-girder combined structure based on a penalty element method and a Lagrange multiplicator method respectively, wherein the finite element programs are respectively used for solving the static force problem of the slab- girder combined structure and the static force problem when the slab unit or the girder unit independently exists. The method can solve the contribution problem of theslab unit to the combined structure total rigidity matrix because of eccentric connection, has less total elements and nodes of the slab-girder combined structure, little occupation machine time of computation, low computation cost and results more accordant with practical situation, and is an effective method for constructing the slab-girder structure of the train.

Owner:CENT SOUTH UNIV

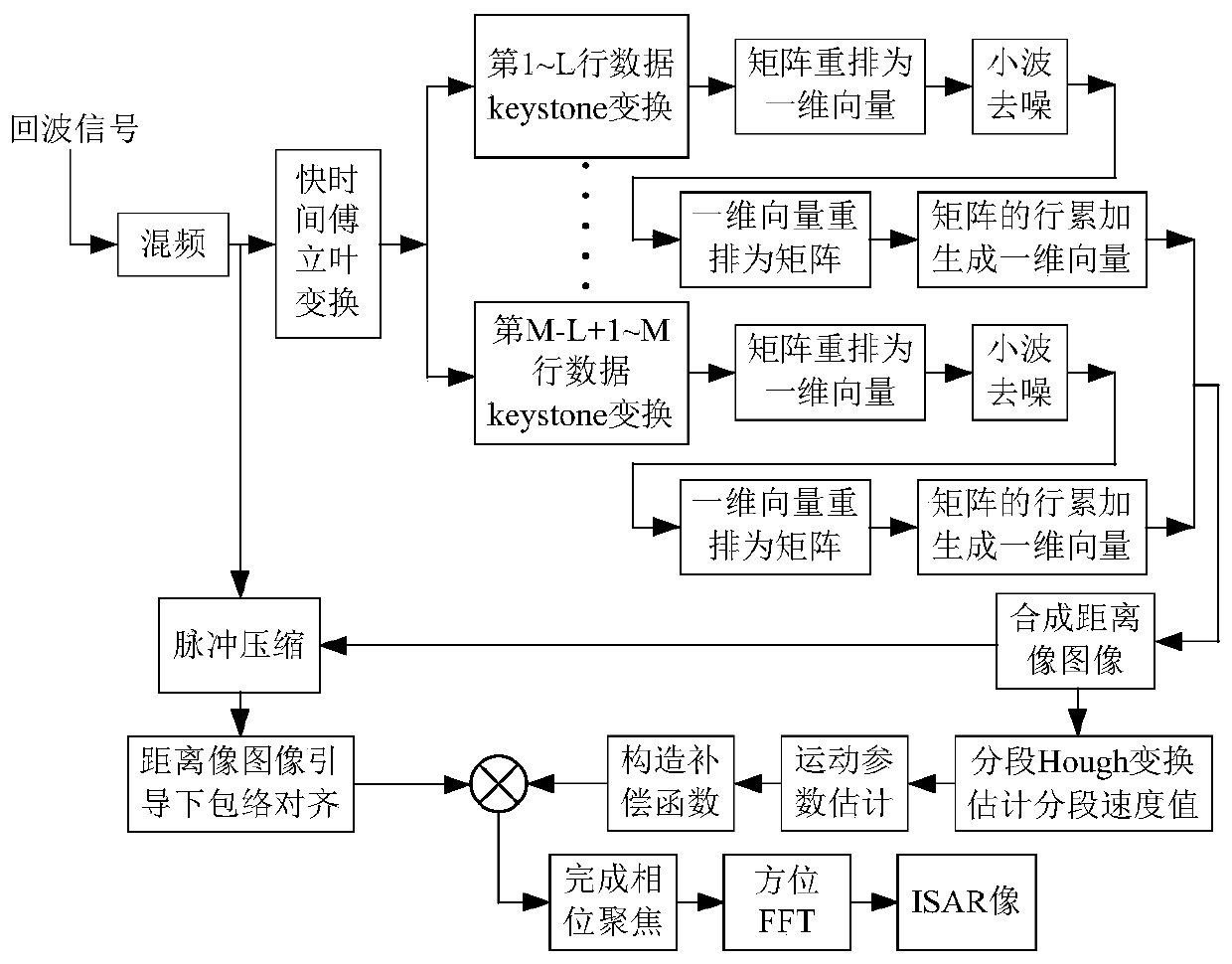

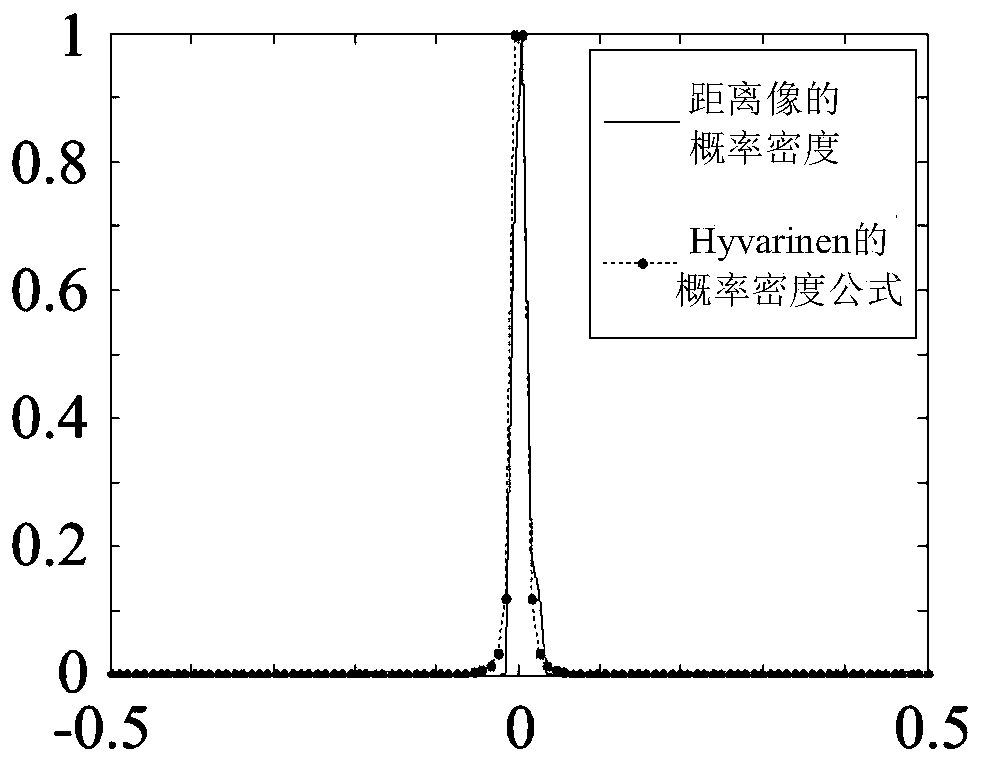

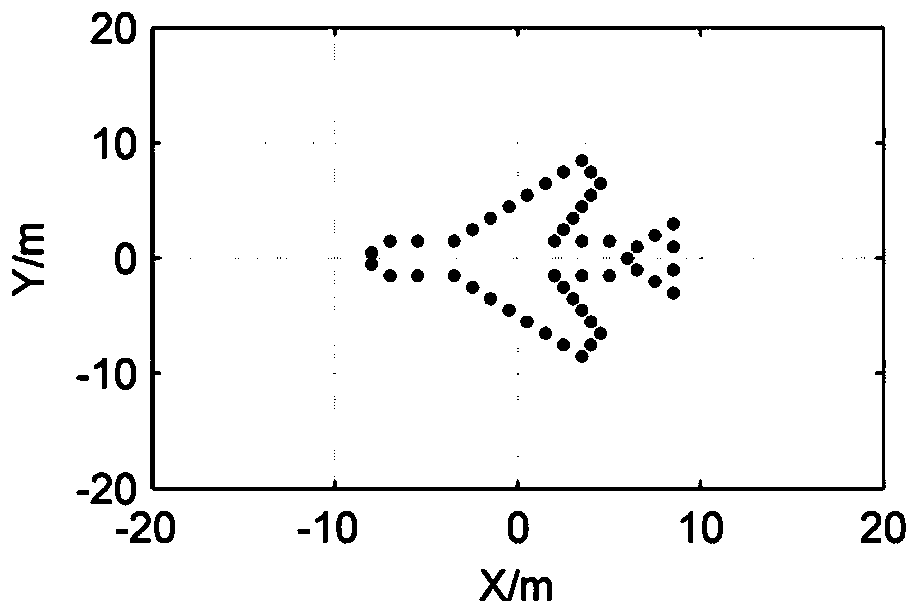

Low signal-to-noise ratio ISAR imaging motion compensation method

ActiveCN109709552AAccurate estimateGood motion compensationRadio wave reradiation/reflectionInterferometric synthetic aperture radarSignal-to-noise ratio (imaging)

The invention provides a low signal-to-noise ratio ISAR imaging motion compensation method, and belongs to the field of radar signal processing. For an inverse synthetic aperture radar (ISAR), key problems such as envelope alignment, phase focusing and target motion parameter estimation cannot be solved under a condition of low signal-to-noise ratio. The method converts and uses keystone for signal coherent accumulation, and adopts maximum likelihood wavelet threshold denoising to perform denoising on radar distance images, so that accurate target motion parameter estimation can be achieved, and better motion compensation results can be obtained, and therefore, effective imaging under low signal-to-noise ratio can be realized, and the method has popularization and application values.

Owner:NANJING COLLEGE OF INFORMATION TECH

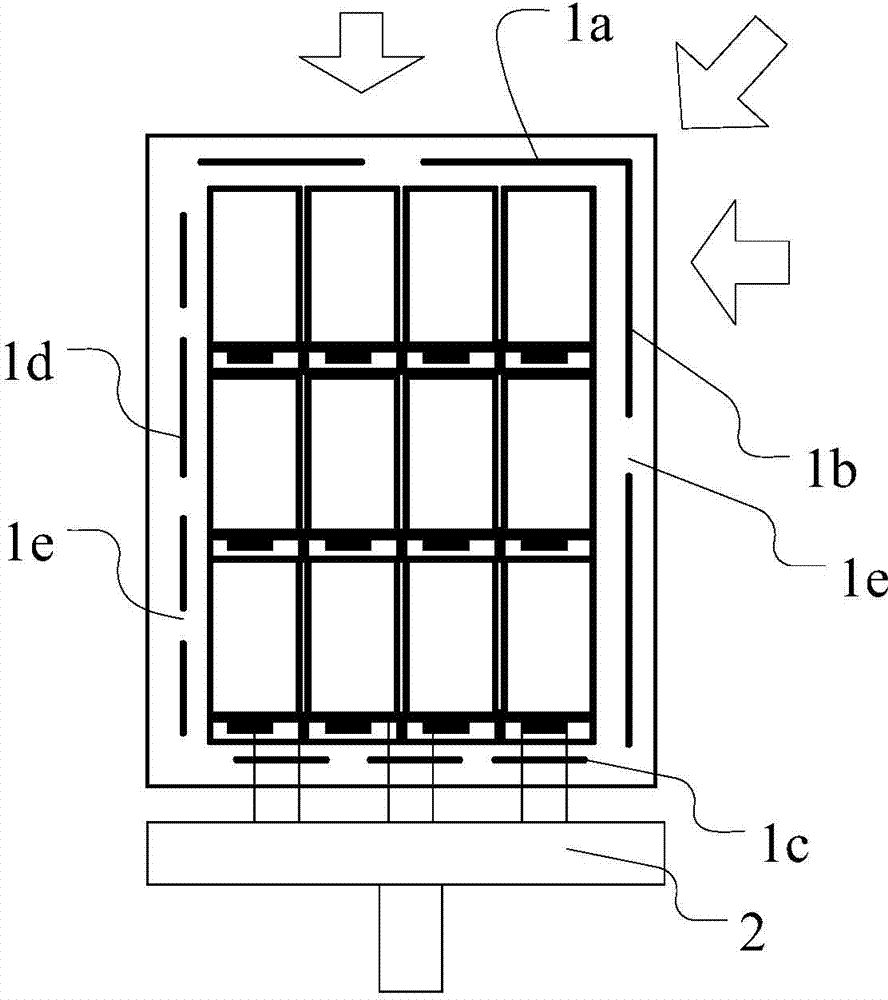

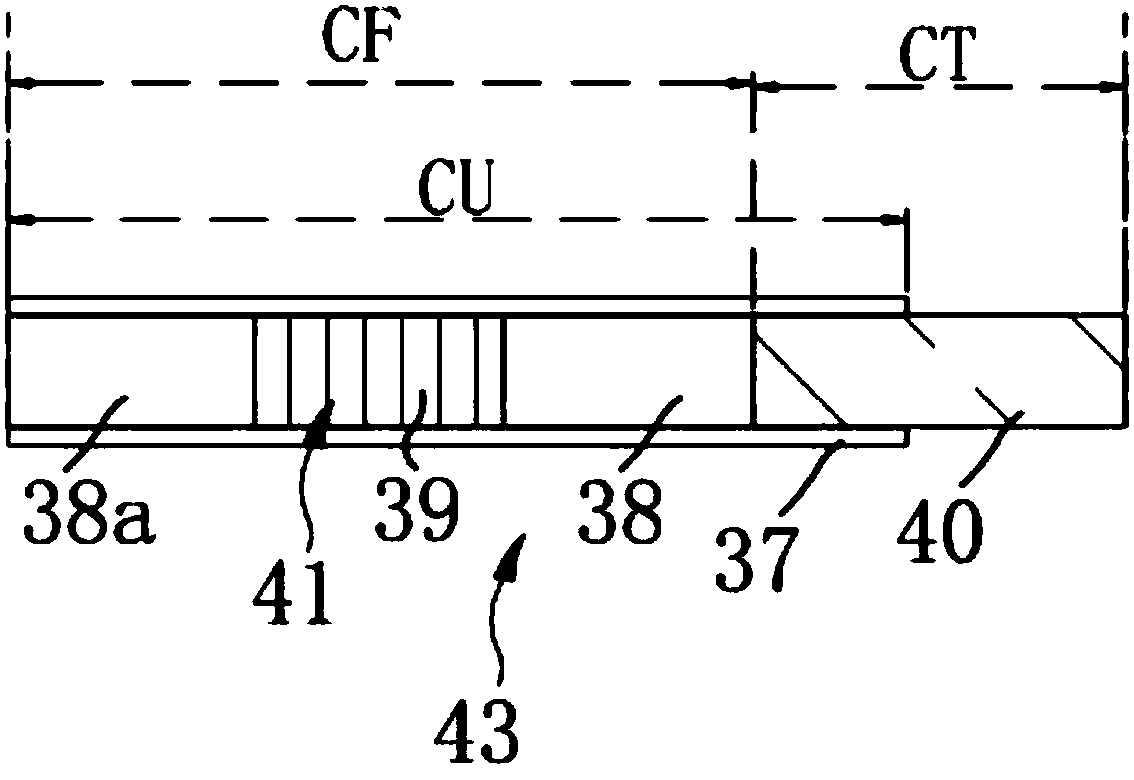

Auxiliary frame sealing glue structure, box-aligning substrate and display device

ActiveCN103499903ASolve for misalignmentAvoid uneven box thicknessNon-linear opticsLiquid crystalSurface plate

The invention provides an auxiliary frame sealing glue structure, a box-aligning substrate and a display device. The auxiliary frame sealing glue structure is arranged between an upper substrate and a lower substrate and comprises an opening structure, a first frame and a second frame connected with one end of the first frame, wherein the connecting position of the first frame and the second frame is in a sealed state. According to the auxiliary frame sealing glue structure, the junction position of the two frames on a windward surface in the rotation process is set to be in the sealed state, the opening structure is arranged in another position, the substrate is prevented from being affected by air resistance caused by rotation, the problem of deviation of a glass substrate in the rotation process is resolved, and further aligning deviation problem is effectively resolved. In addition, the uneven thickness of a box at the peripheral edge of a signal liquid crystal panel caused by uneven external atmospheric pressure acting on the inside and the outside of the substrate is avoided, and therefore the quality and yield of products are largely improved.

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD

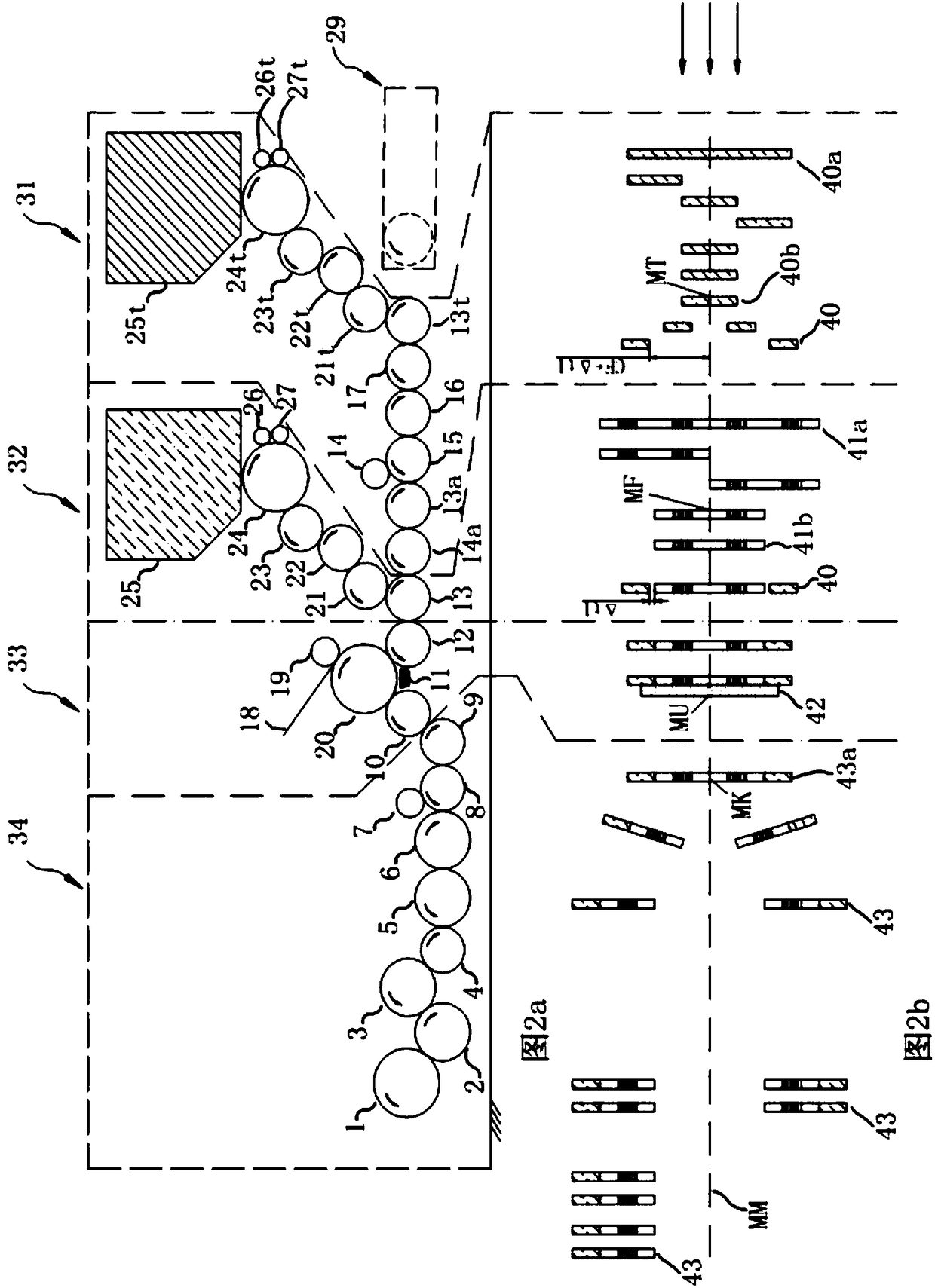

Nontraditional cut tobacco type cigarette production equipment

PendingCN108142989AAvoid quality risksIncrease production rateCigarette manufactureComposite filterPaper sheet

The invention discloses nontraditional cut tobacco type cigarette production equipment, which comprises multiple drum wheels, wherein a nontraditional cut tobacco stick section and a composite filtertip section are delivered to a wrapping region through the drum wheels, tipping paper is supplied along a dual-wide tipping paper centrosymmetric surface MU to wrap and form the nontraditional cut tobacco stick section and the composite filter tip section, and the distance between each of the dual-wide tipping paper centrosymmetric surface MU, a double-length composite filter tip section centrosymmetric surface MF and a double cigarette final cutter centrosymmetric surface MK and a center surface MM of the machine is 0. According to the equipment, the distance between each of the dual-wide tipping paper centrosymmetric surface MU, the double-length composite filter tip section centrosymmetric surface MF and the double cigarette final cutter centrosymmetric surface MK and the center surfaceMM of the machine is ensured to be 0, so that the problems of substandard cigarette appearance quality and scrap consumption caused by such a requirement that the tipping paper is aligned with a filter tip on one side during high-speed operation of the equipment are solved, the aim of controlling the quality and the aesthetics of cigarettes is fulfilled, and in addition, the production efficiencyis improved.

Owner:HONGTA TOBACCO GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com