Main shaft axial dynamic stiffness test device

A testing device and dynamic stiffness technology, applied in the direction of machine gear/transmission mechanism testing, etc., can solve the problems of difficult control and testing, low testing accuracy, and narrow application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further explained below in conjunction with the drawings.

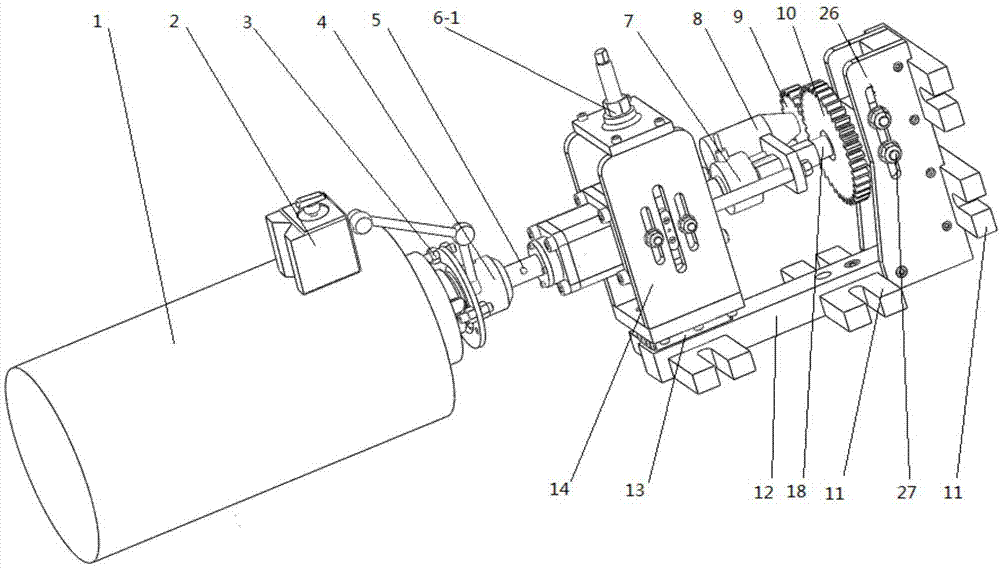

[0029] Reference figure 1 , A spindle axial dynamic stiffness test device, including a center height adjustment module, a force loading module, a displacement measurement module and a fixed support 12;

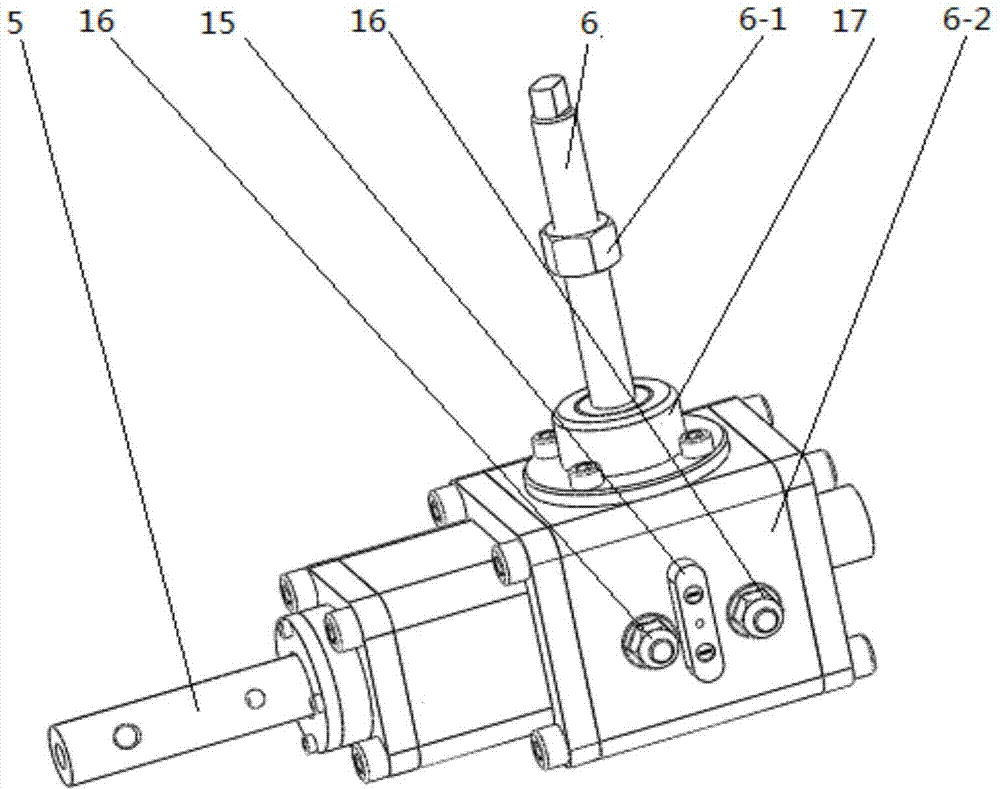

[0030] Reference figure 1 , figure 2 , Figure 4 The central height adjustment module includes a central height adjustment screw 6, a knob 6-1 is provided on the central height adjustment screw 6, and the central height adjustment screw 6 is mounted on the box 6-2 through a thrust ball bearing 17, and the box 6 -2 is connected with the first fixing plate 14 through the first lock nut 16, a butterfly spring 19 is arranged inside the box 6-2, and the butterfly spring 19 passes through the force sensor of the T-shaped force transmission part 7-1 and 7 connection, the force sensor 7 is connected to the guide element 7-2 of the force loading module;

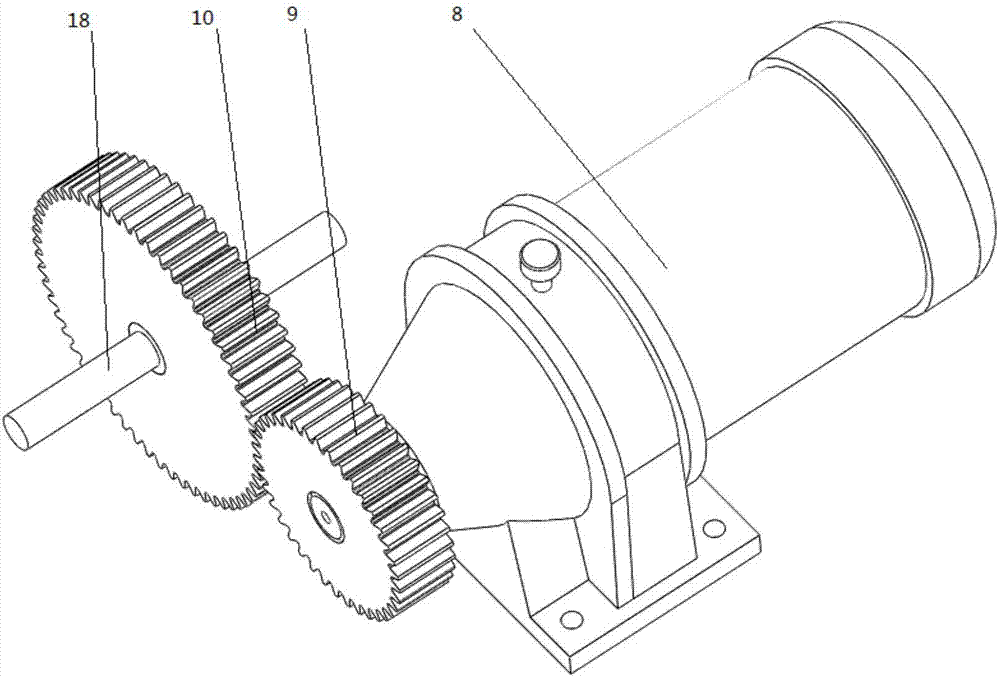

[0031] Reference image 3 , Figure 4 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com