Patents

Literature

152results about How to "Avoid unbalanced load" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

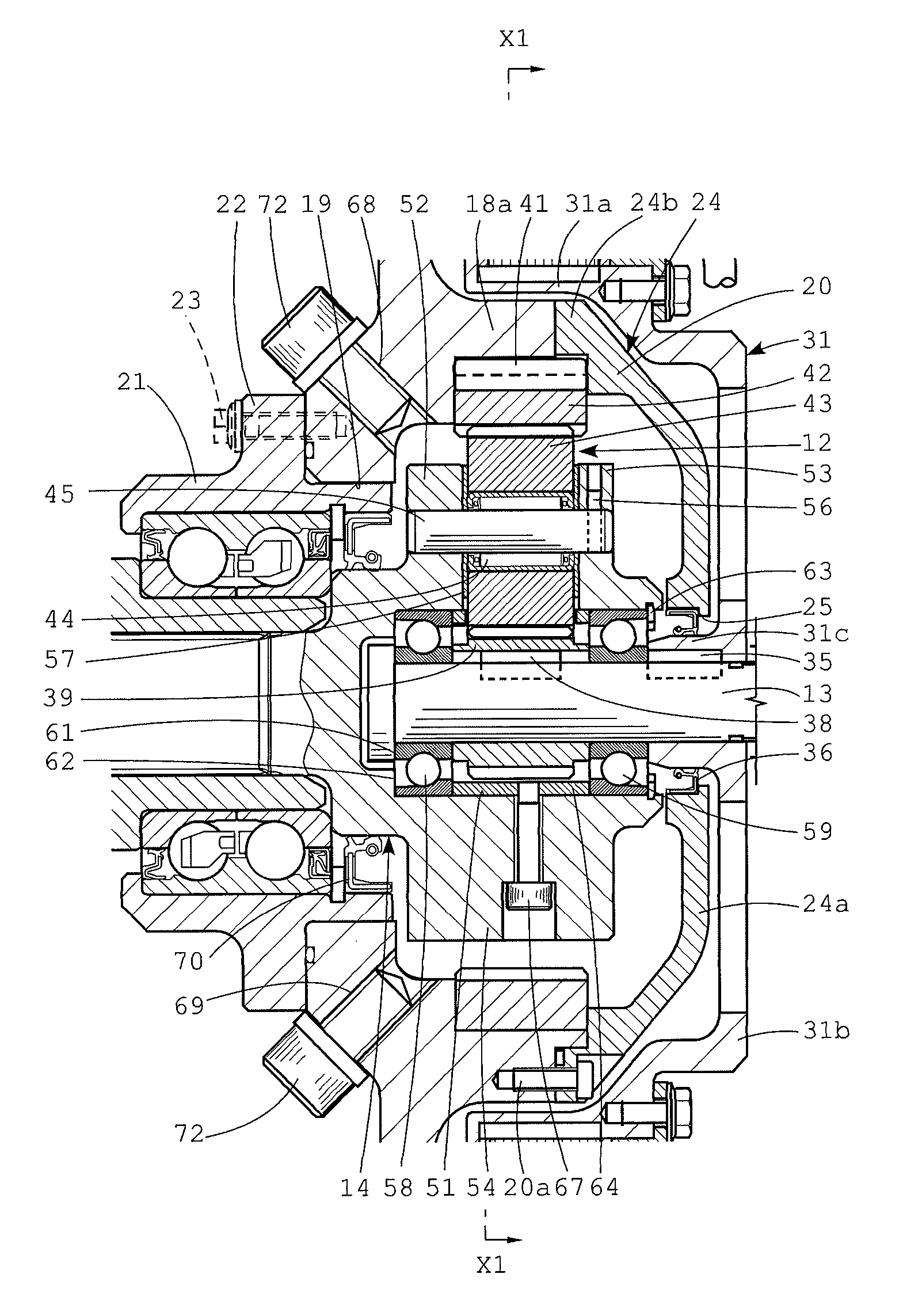

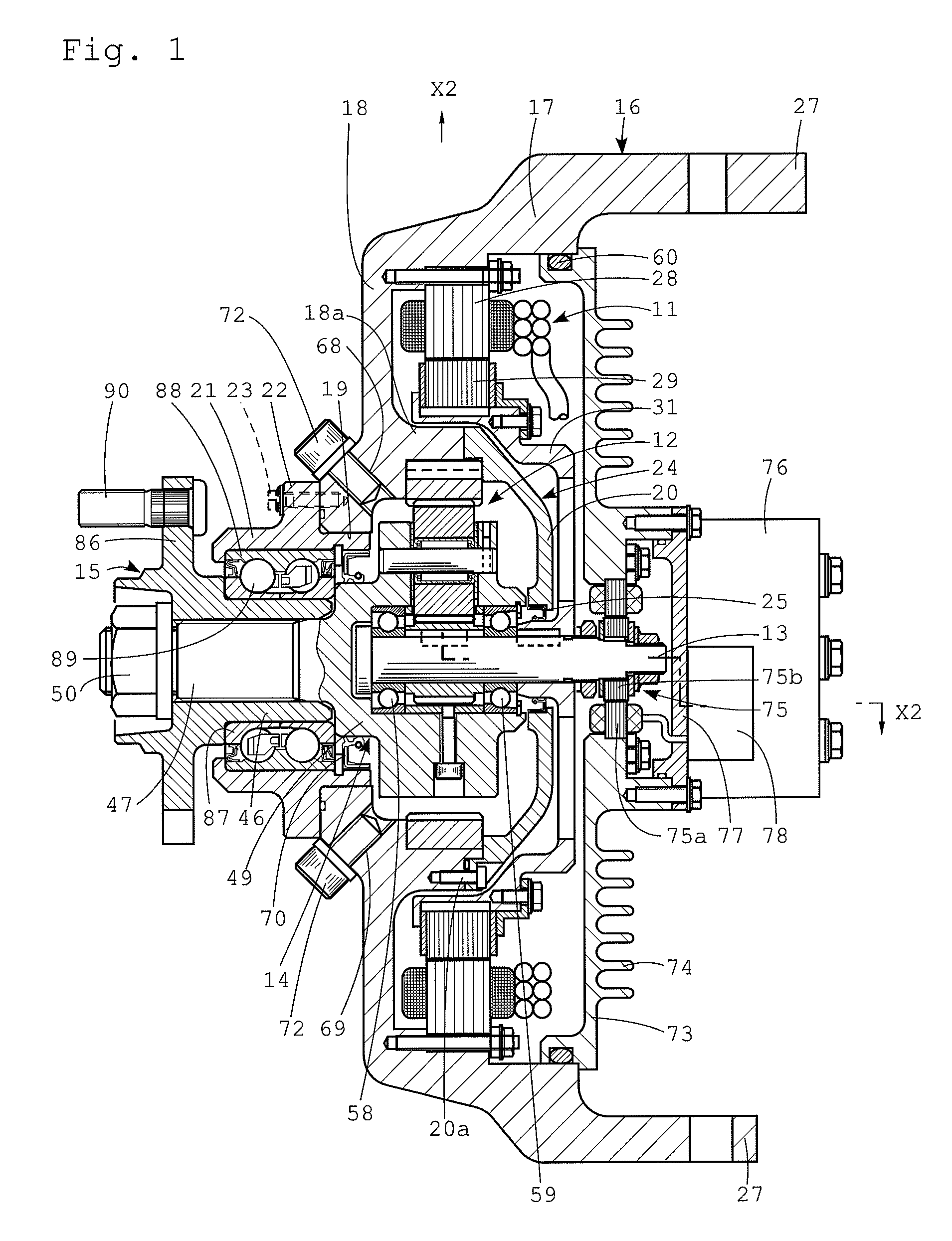

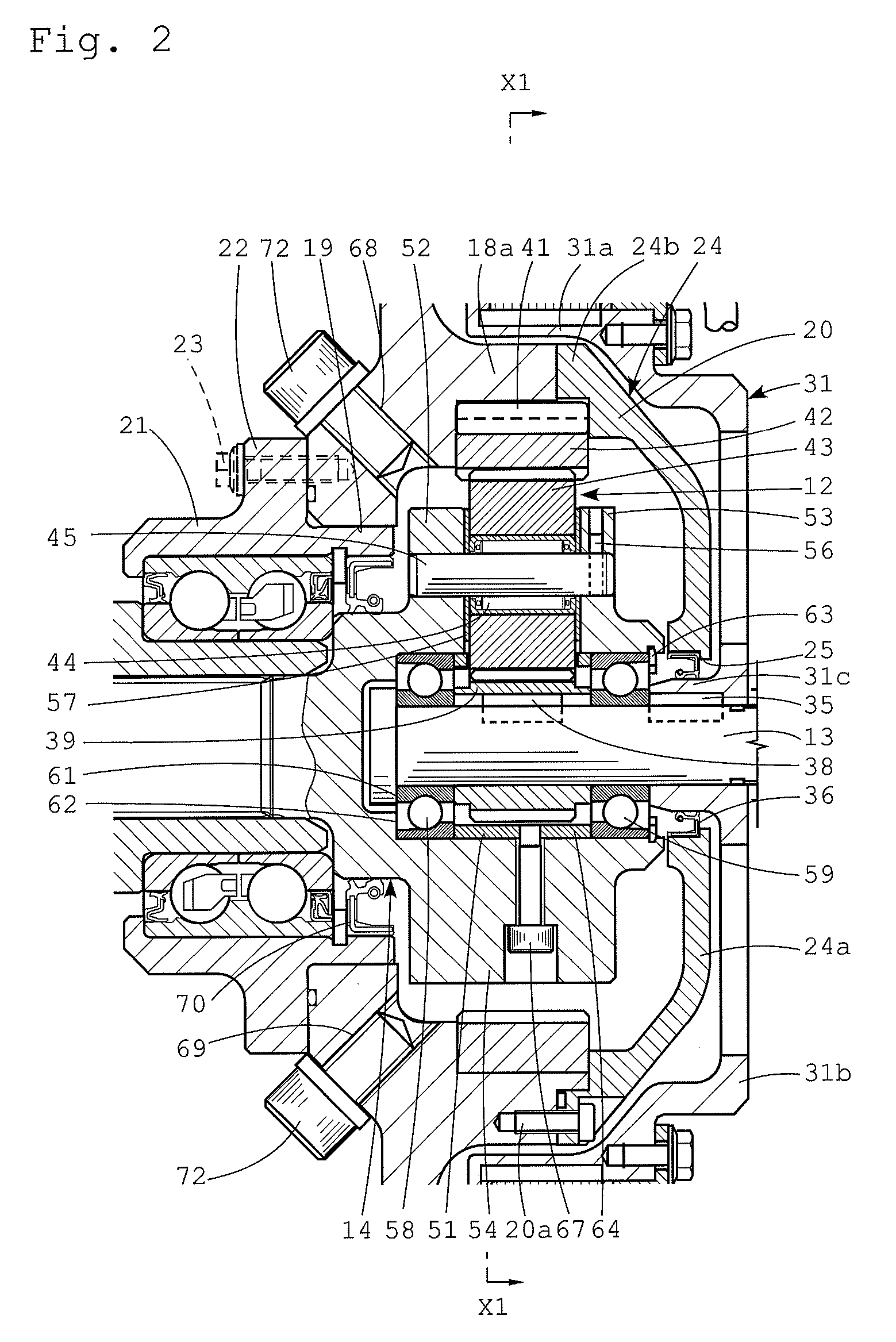

Recoil starter

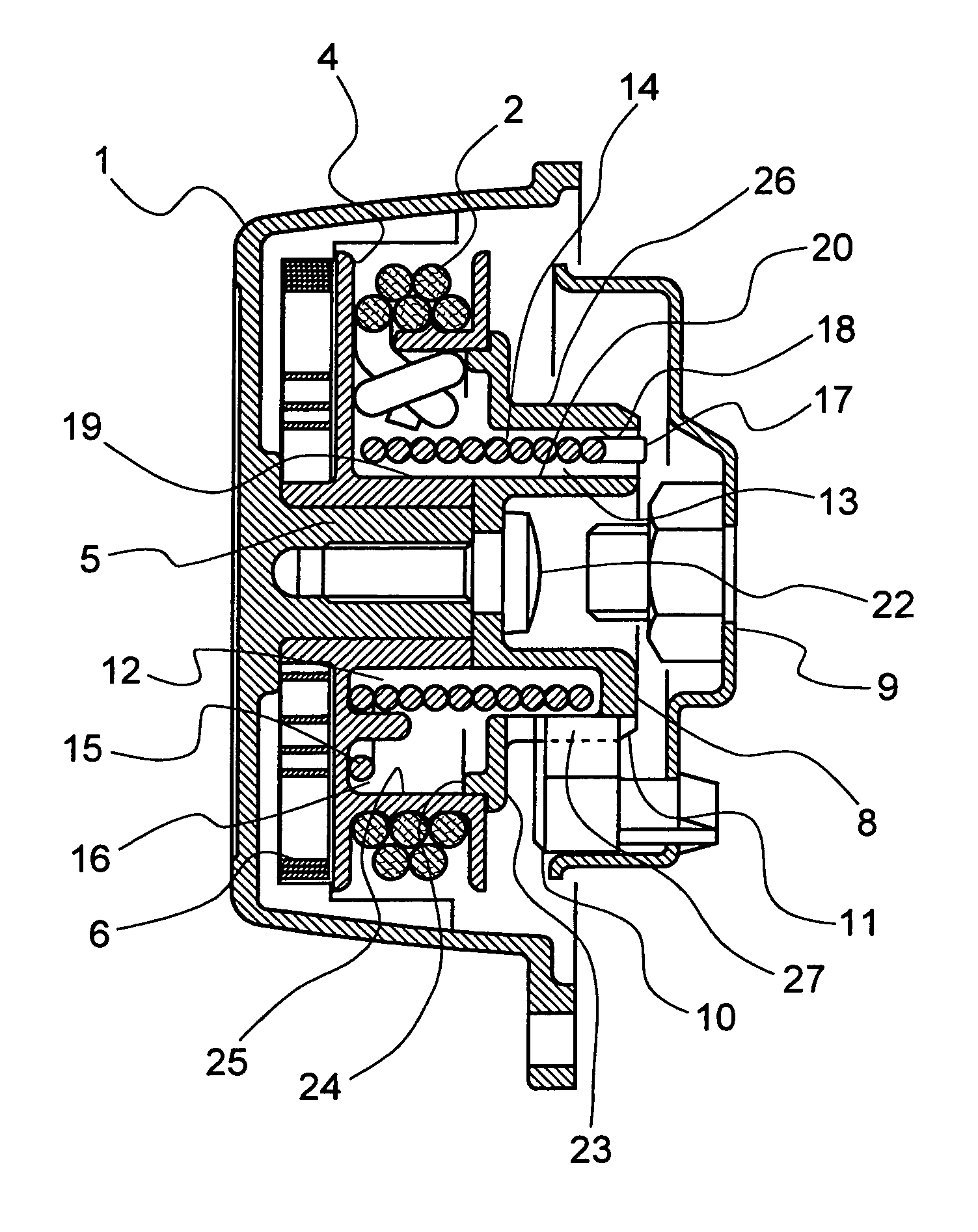

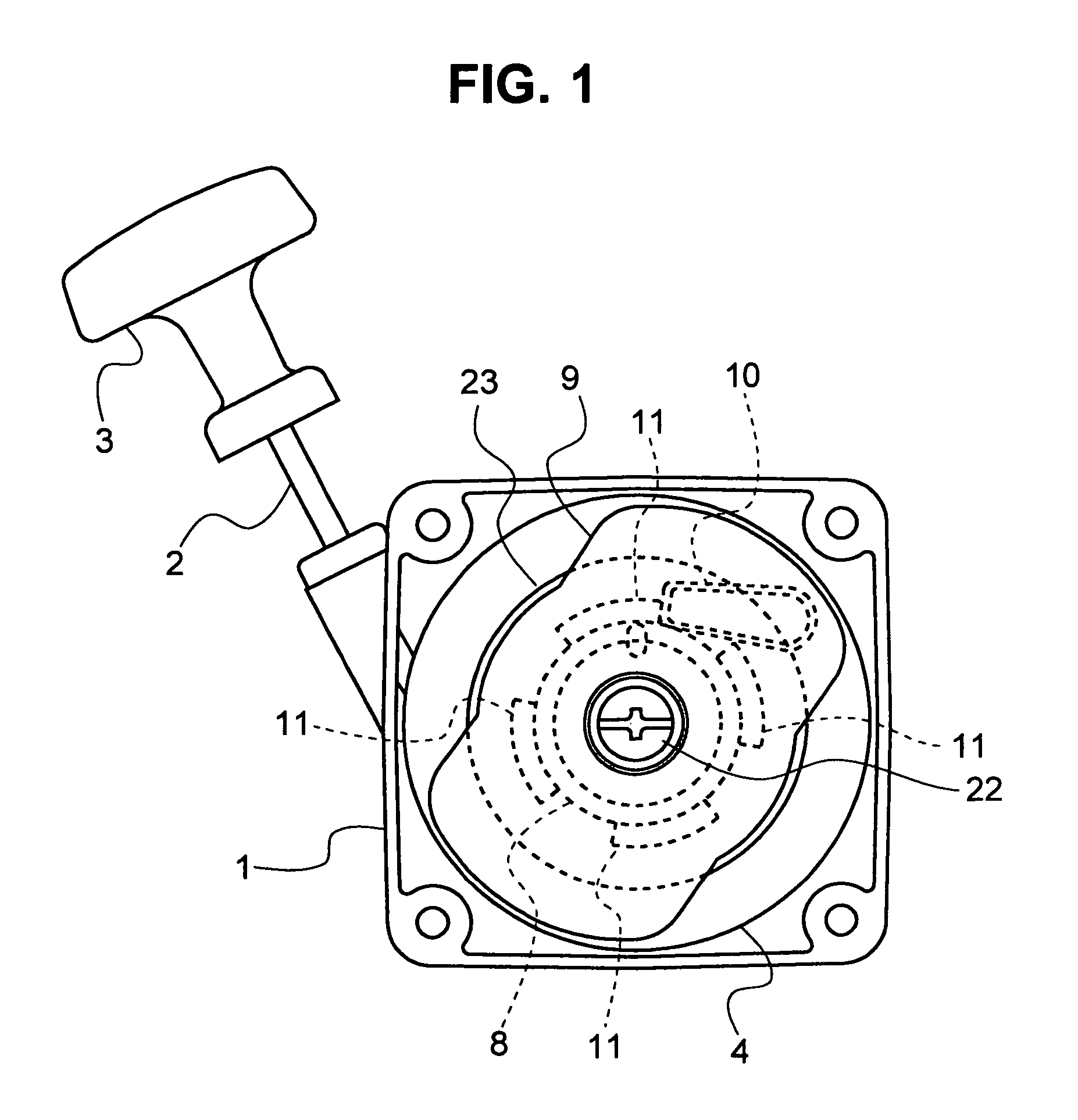

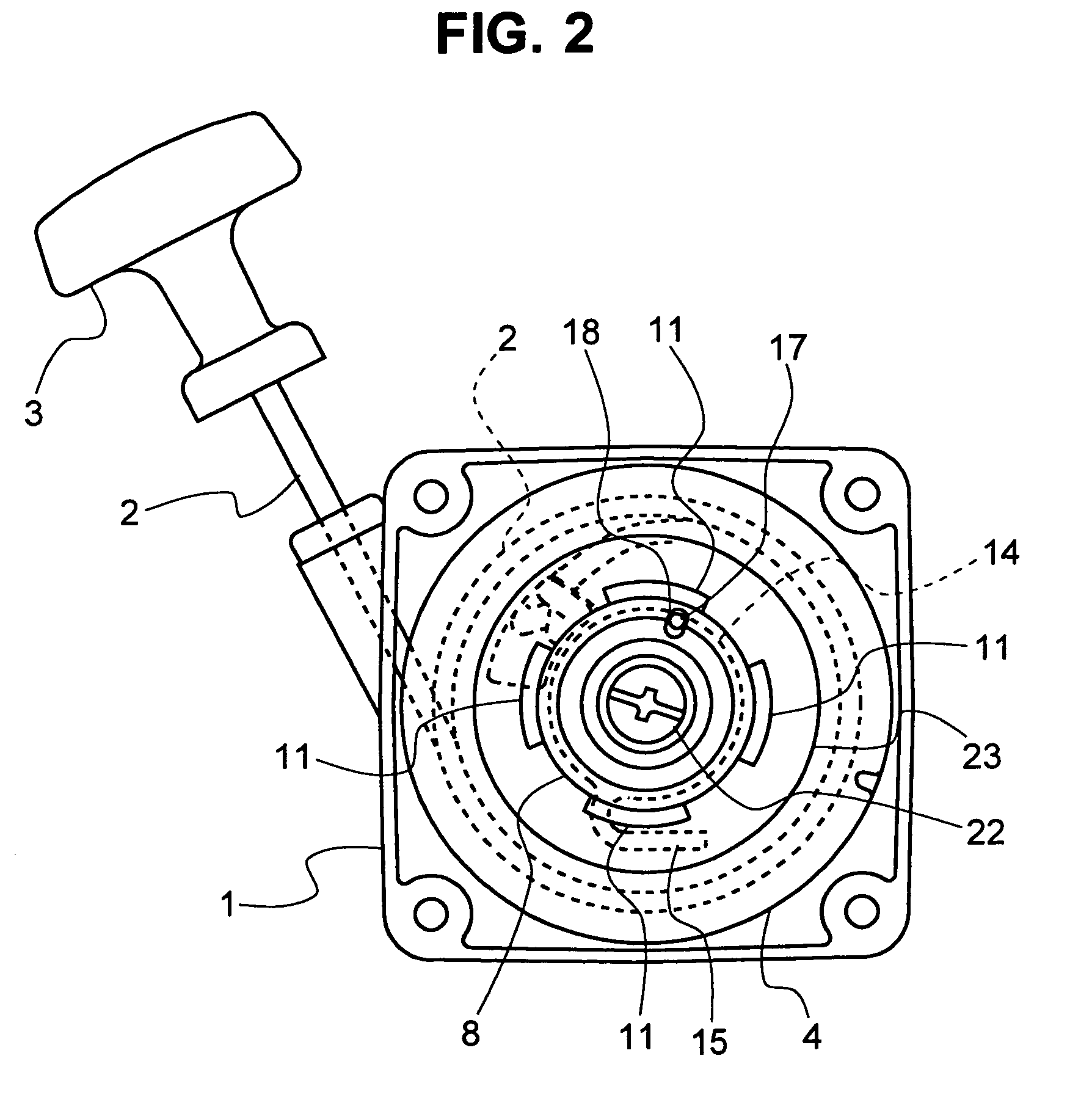

InactiveUS6981482B2Increased durabilityPrevent excessive deformationPower operated startersMuscle operated startersSnubberCam

A recoil starter having improved durability by inhibiting excessive deformation of a damper spring, and capable of receiving a damper spring with high shock-absorbing and force-storing capabilities. The recoil starter includes a rope reel and a cam which are rotated by pulling a recoil rope, so that a rotation of the cam is transmitted to an engine via a ratchet mechanism to start the engine. A damper spring which couples the rope reel and the cam to each other has, at opposite ends thereof, engaging portions radially movably supported by holding portions of the rope reel and the cam, respectively, so that substantially the overall length of the damper spring winds and tightens uniformly around outer peripheral surfaces of both bosses of the rope reel and the cam due to a startup resistance of the engine.

Owner:STARTING IND CO LTD

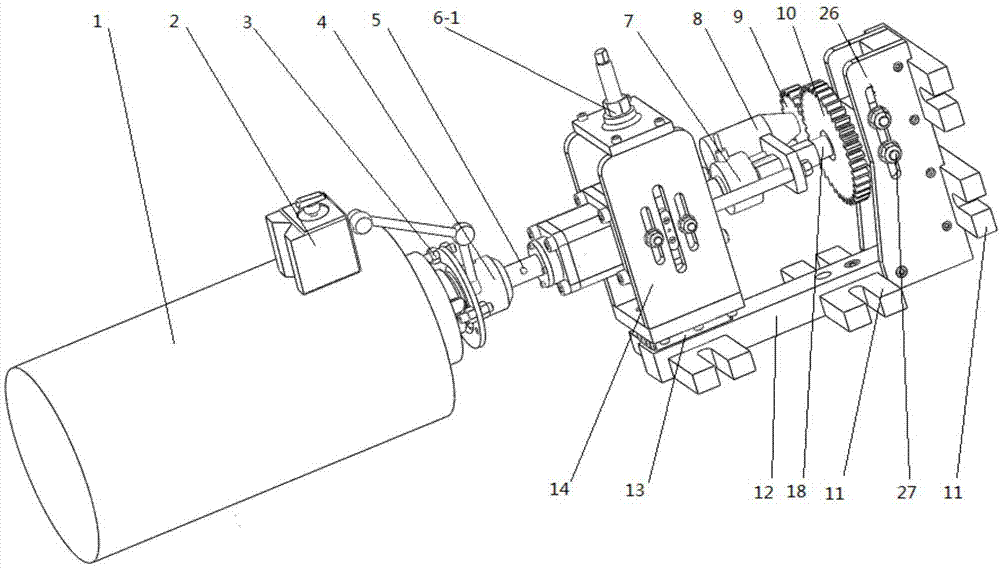

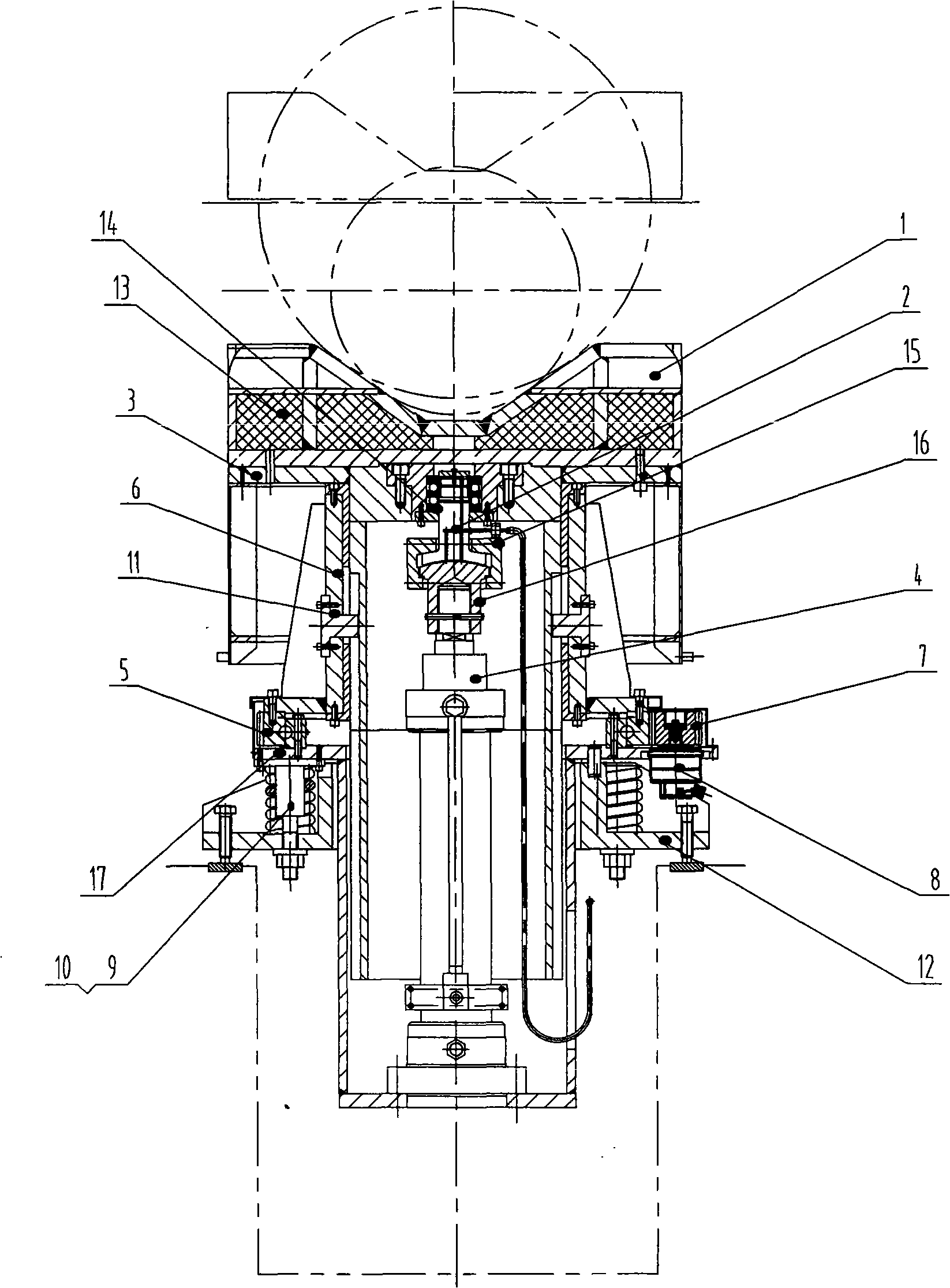

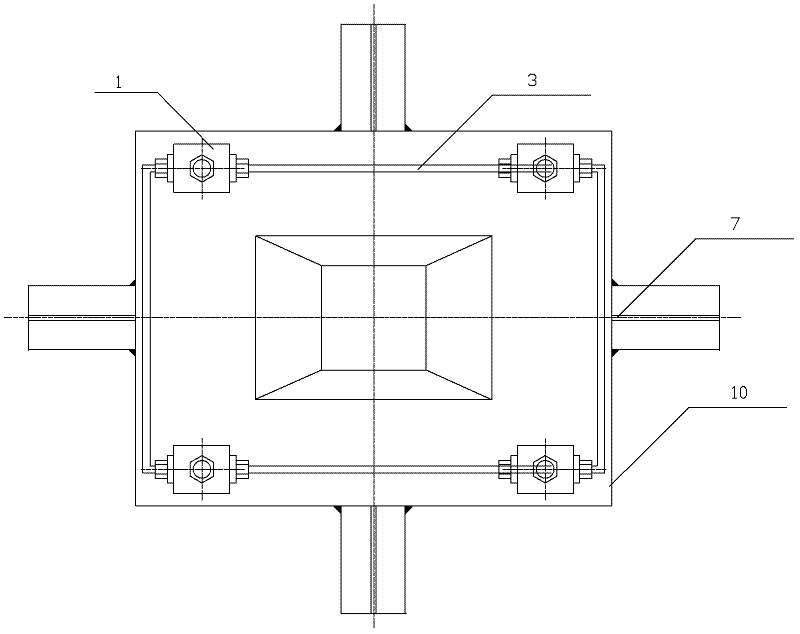

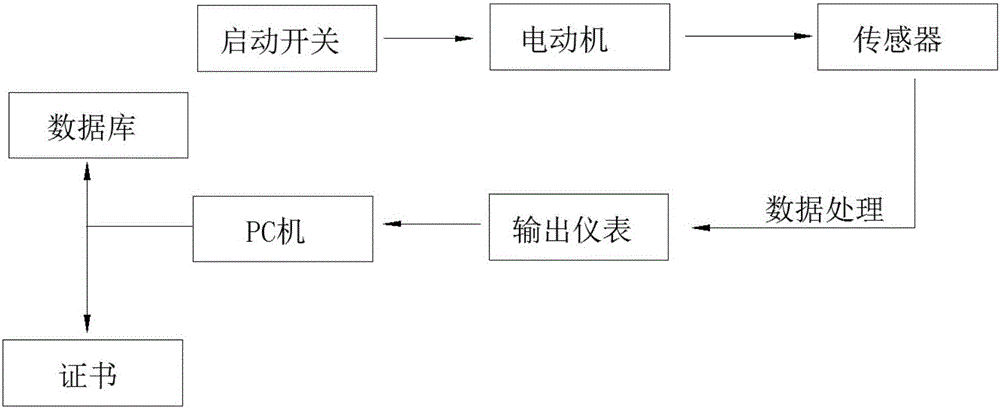

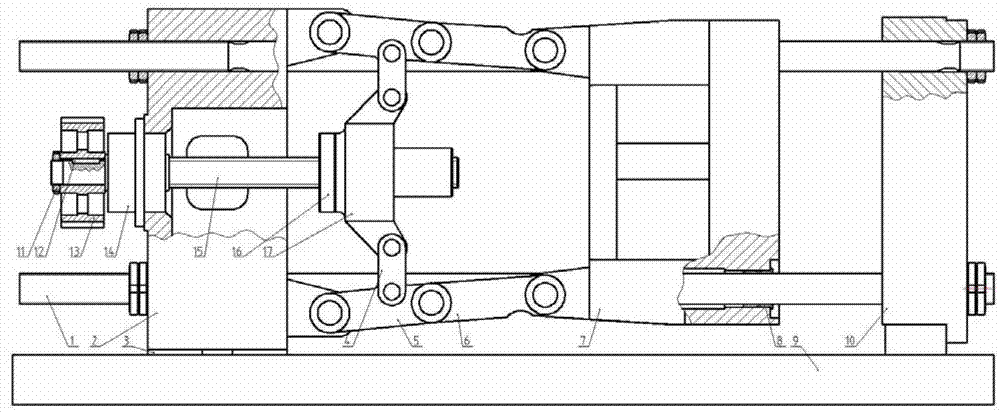

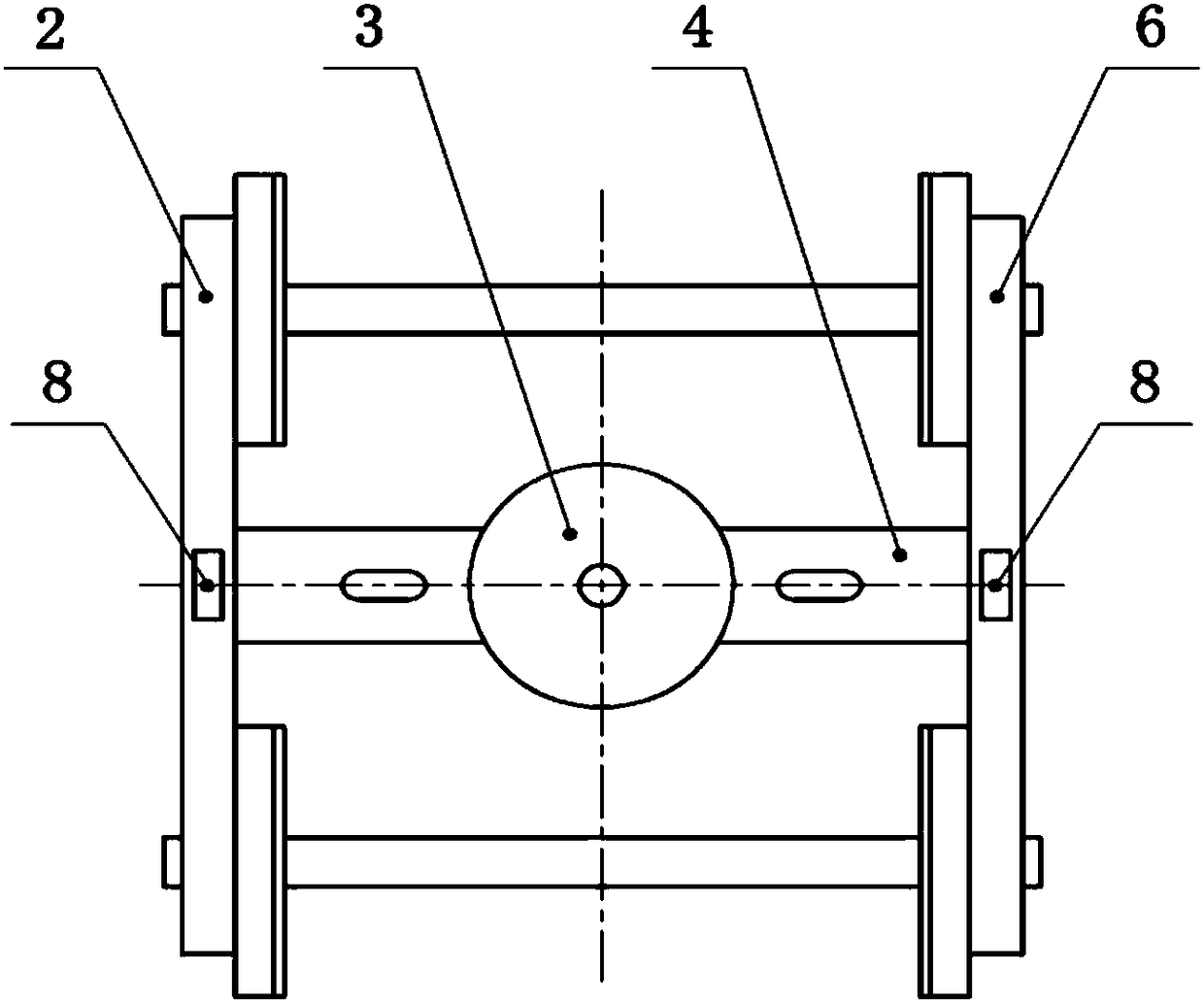

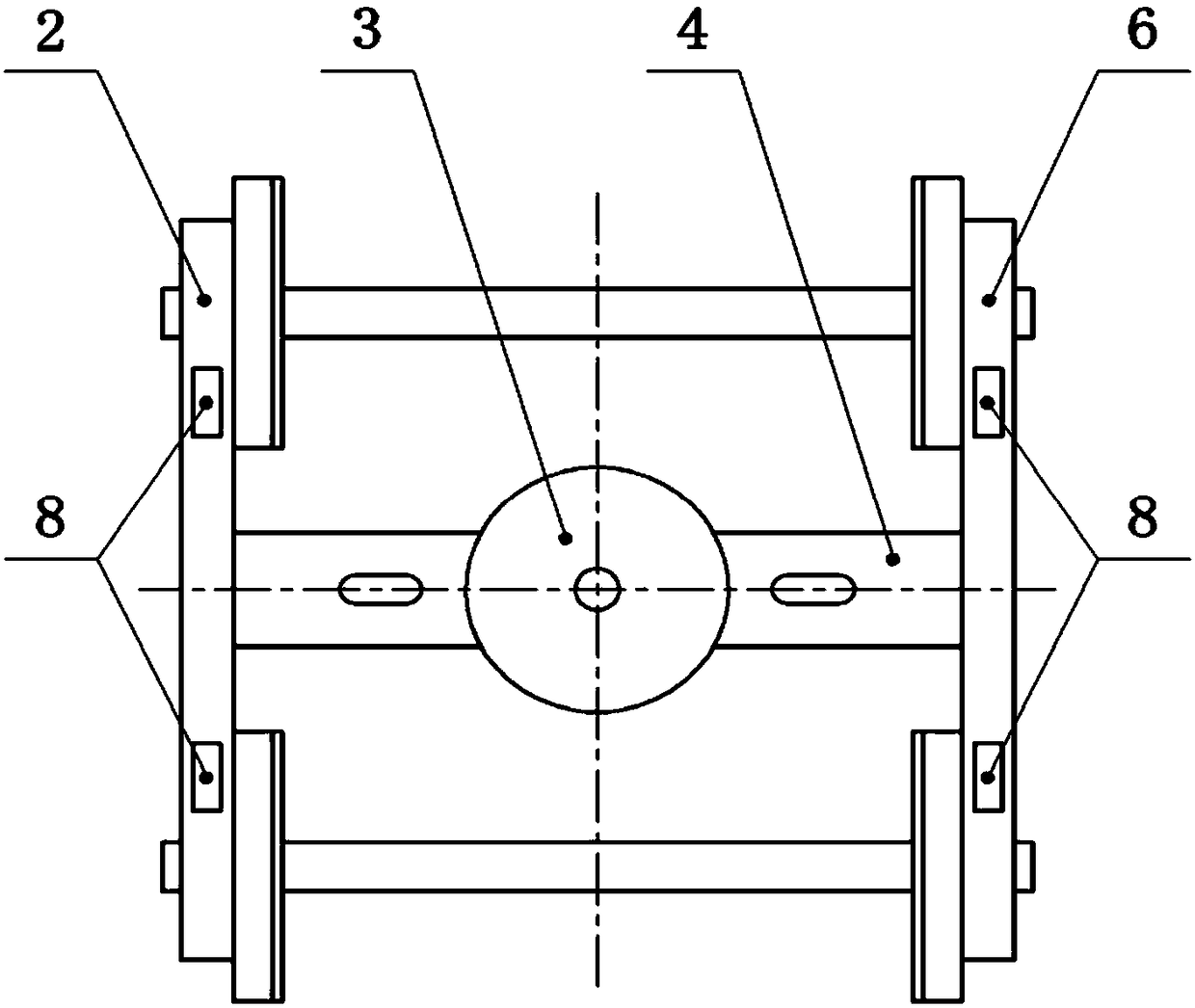

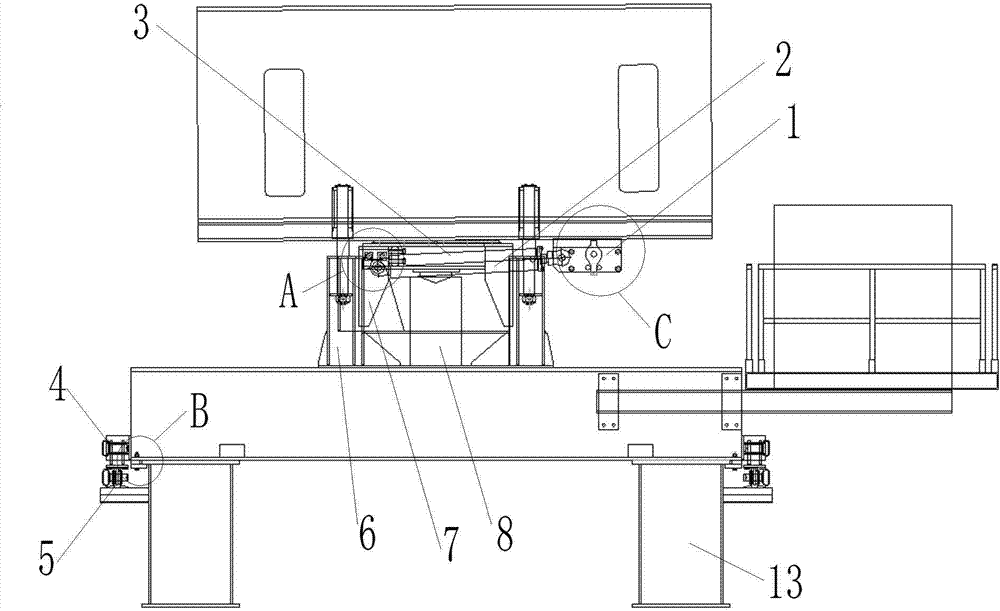

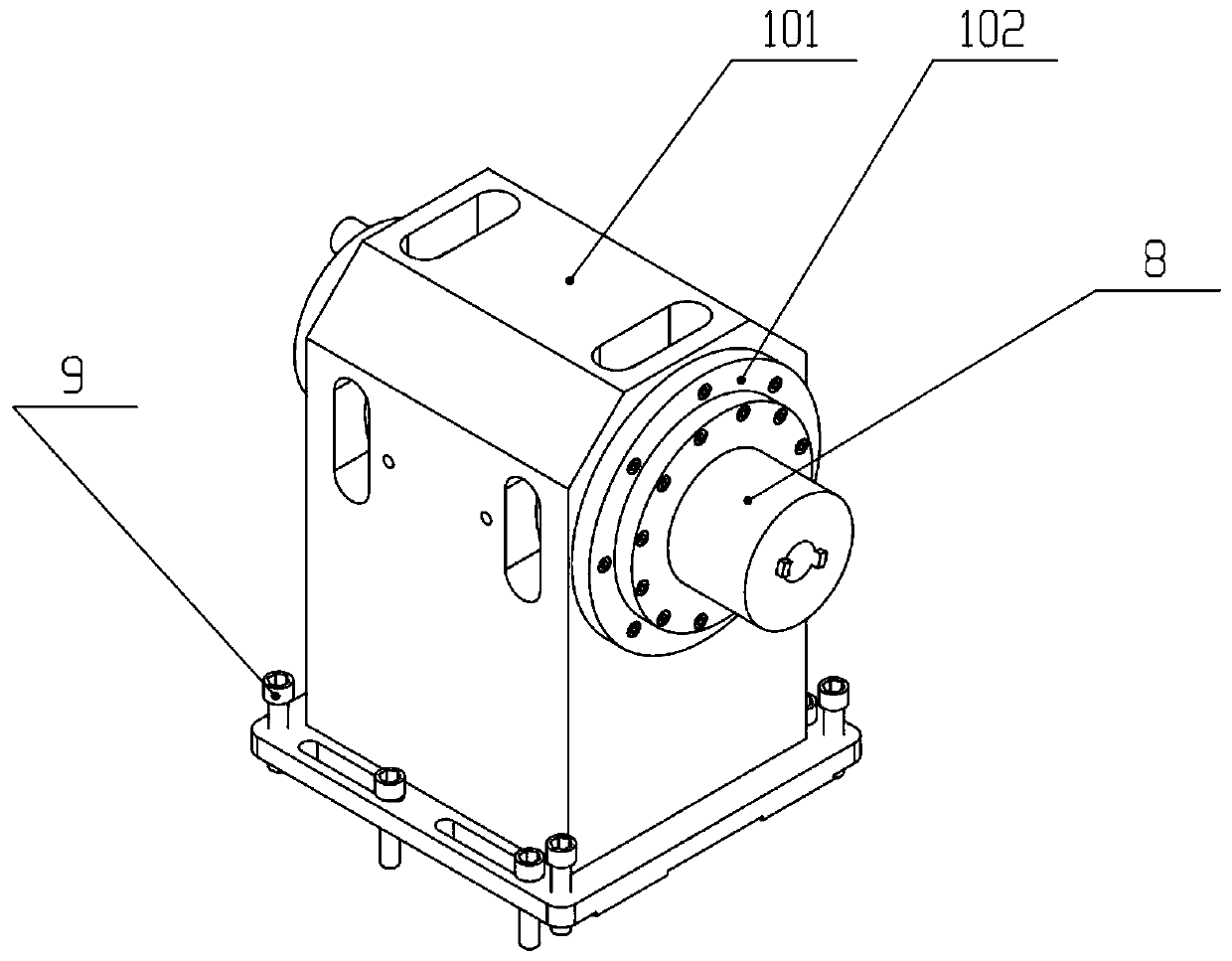

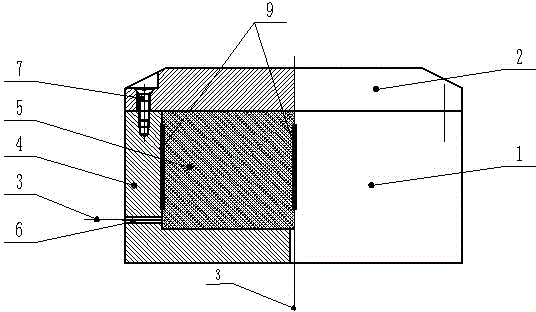

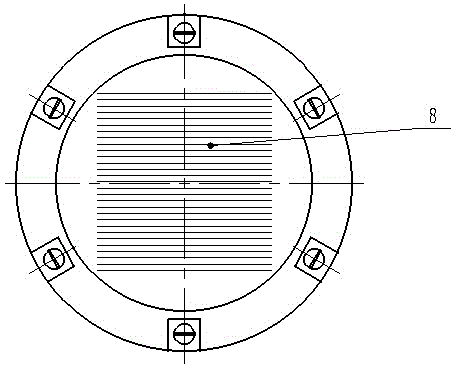

Main shaft axial dynamic stiffness test device

ActiveCN103712791AGuaranteed stabilityGuaranteed accuracyMachine gearing/transmission testingAxial displacementDynamic stiffness

The invention discloses a main shaft axial dynamic stiffness test device. A center height adjusting screw is arranged on a box body. A butterfly-shaped spring is arranged in the box body. The butterfly-shaped spring is connected with a force sensor. The force sensor is connected with a guide element of a force loading module. The guide element is connected with a feed screw. A displacement measurement module is arranged on a main shaft. A center height adjusting knob is adjusted. Through a connecting guide rod, the main shaft and test equipment are connected. After the displacement measurement module is arranged and adjusted, the displacement measurement module and a force measurement module access a computer, and test software is turned on. The main shaft is rotated, and the force loading module is started. The force loading module axially applies a corresponding pull pressure load on the main shaft. The test software synchronously acquires and records the applied pull pressure load and the corresponding axial displacement offset. After a procedure carries out data processing, a main shaft dynamic stiffness test result is output.

Owner:XI AN JIAOTONG UNIV

Up-down rotary display stand for forging steel ingot

InactiveCN101254520AOvercome eccentric loadAvoid Cylinder FailureForging/hammering/pressing machinesRotary stageMaterials science

A lift / rotation bench for forging steel ingots is provided, which belongs to the field of forging tools. The steel ingot-turning device in the prior art has the disadvantages such as offset load of the hoist cylinder during the placement of steel ingots and single V-shaped structure of the steel ingot supporter. In the invention, a reticulated V-shaped steel ingot supporter is connected with a frame of the lift / rotation bench and also supported against the top end surface of a thrust bearing; the thrust bearing is connected with a bearing block; the bearing block is connected with a spherical joint through a clamping block; the spherical joint is connected with a hoist cylinder; a rotary guide bracket is fixed thereon with a guide key; the guide key is in socket joint with a guide groove on the lift / rotation bench; the rotary guide bracket is fixed to the outer ring of a turntable bearing; the external teeth of the turntable bearing are engaged with a pinion gear; the pinion gear is driven by a variable motor, a supporter is fixed to the inner ring of the turntable bearing and positioned above a spring; and the supporter is arranged on a pedestal. The bench overcomes the problem of offset load of the hoist cylinder, avoids the failure of the oil cylinder, improves the work efficiency, and widens the range of forging specifications of steel ingots.

Owner:TAIYUAN HEAVY IND

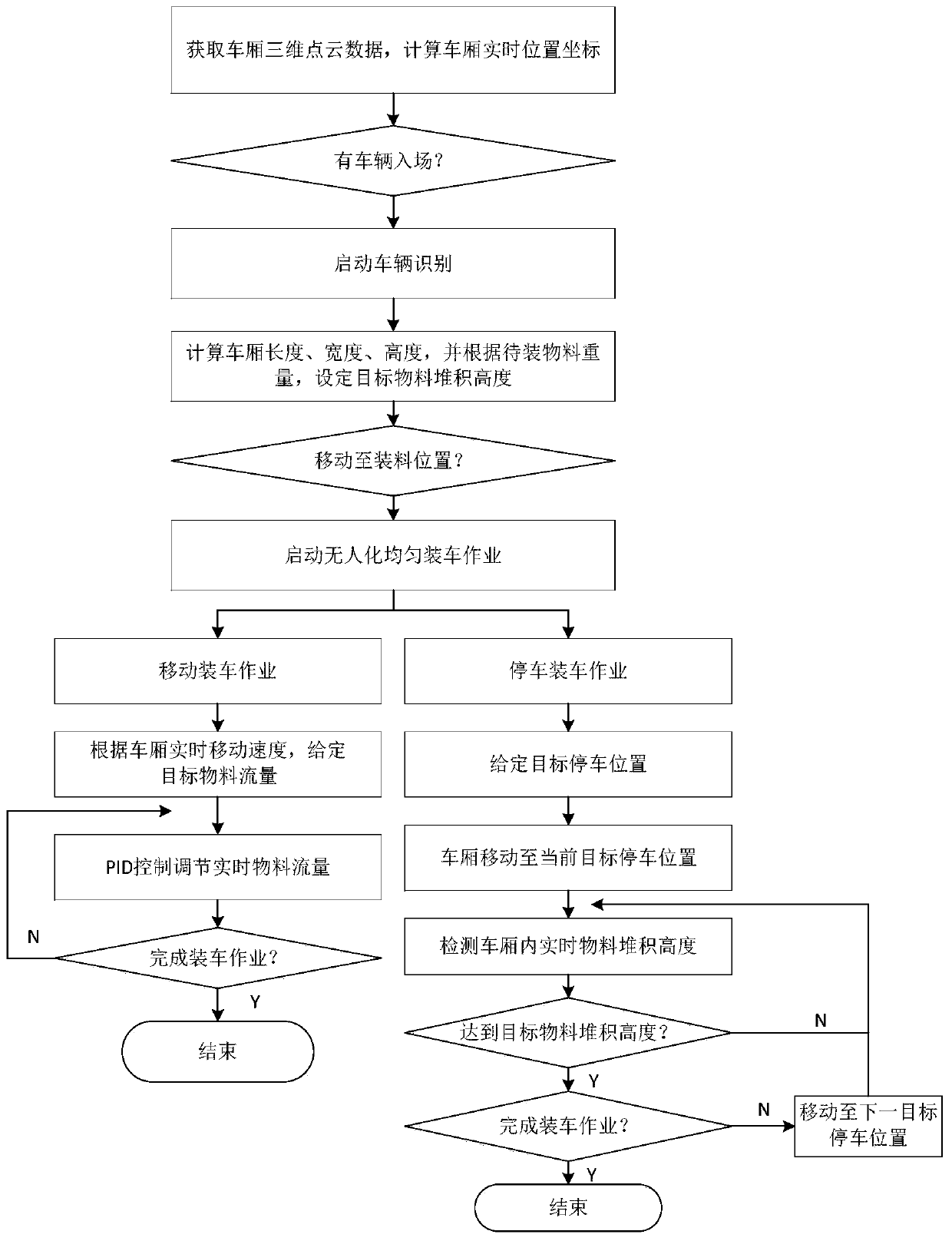

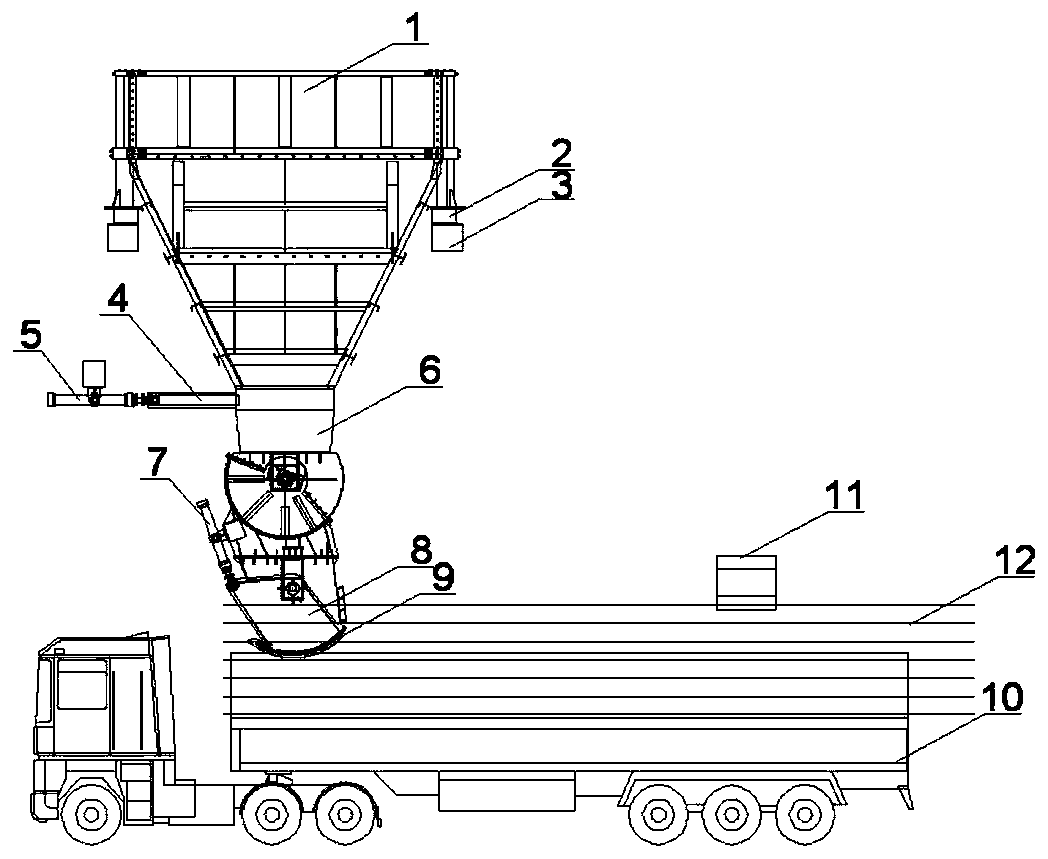

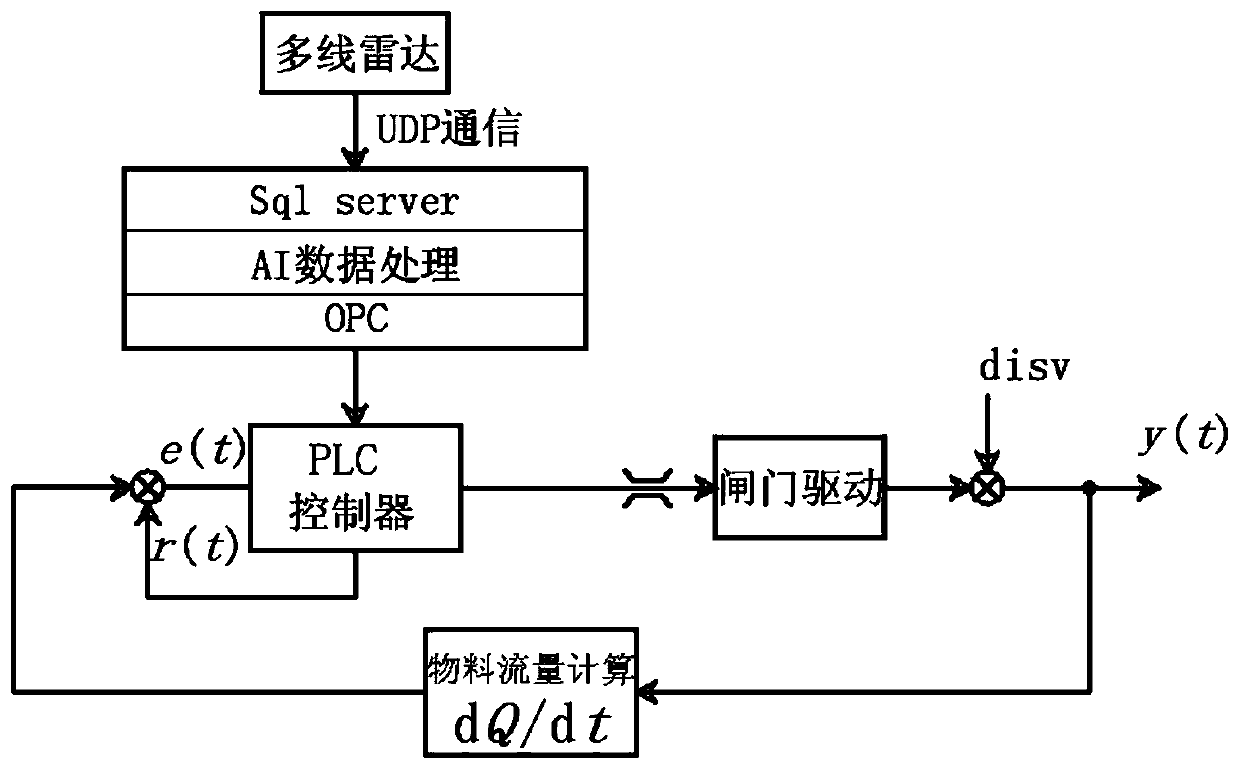

Bulk material unmanned loading control method, system and device based on multi-line laser radar

ActiveCN111487918ABreak through the bottleneck of intelligent loading technologyLower loading costsMeasurement devicesFlow control using electric meansRadarControl engineering

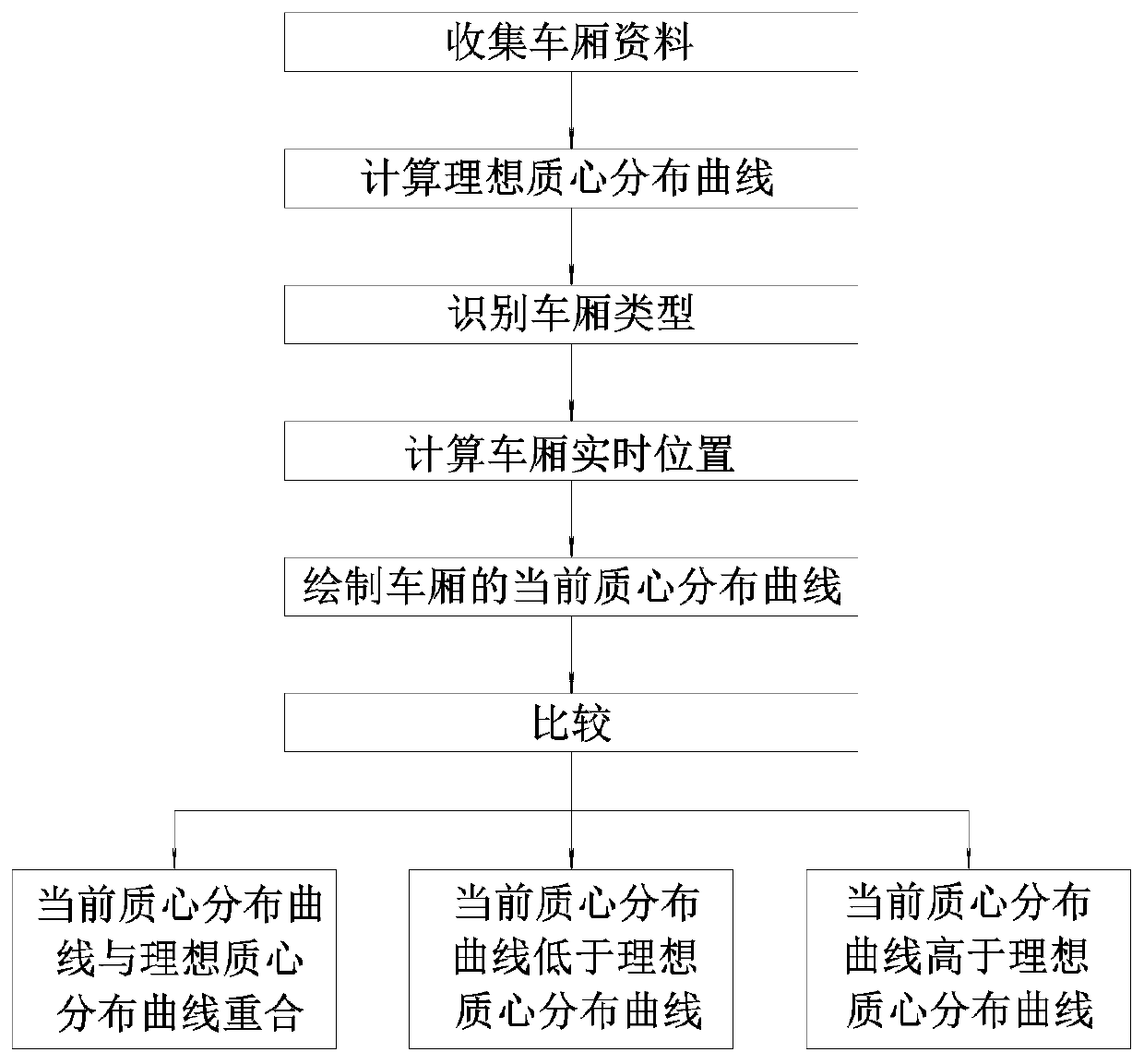

The invention relates to a bulk material unmanned loading control method, system and device based on a multi-line laser radar. The method comprises the steps: collecting three-dimensional point clouddata of a carriage through the multi-line laser radar; recognizing the size of the carriage, a real-time movement position of the carriage and a real-time movement speed; dynamically adjusting a loading process; and achieving unmanned automatic loading control. Different control parameters can be adopted for loading according to different carriage types, a technical bottleneck of loading intelligence is broken through, loading cost is reduced, and loading efficiency is improved. Problems that in the prior art, due to a fact that a manual loading mode is adopted, labor cost is increased, loading quality stability cannot be effectively guaranteed, conditions such as reciprocating loading or loading unbalance loading and the like often occur, and the loading efficiency is not high are solved.

Owner:TIANDI SCI & TECH CO LTD

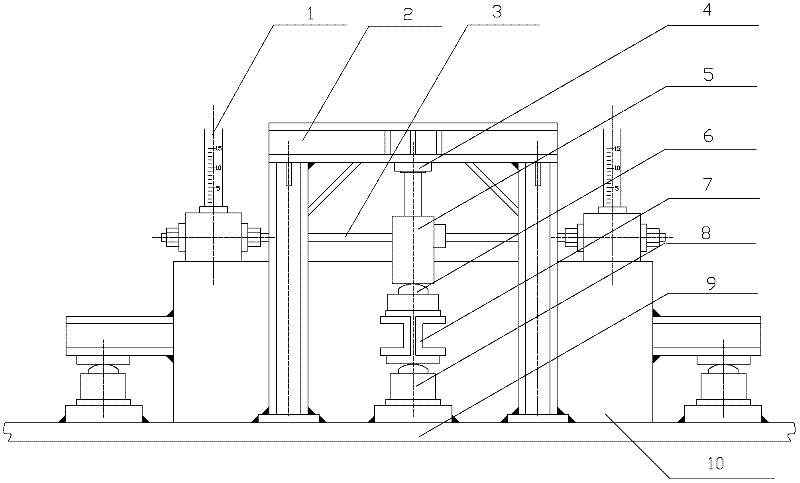

Scale calibrating device and scale calibrating method for hopper scale with hopper or hopper bin horizontal detection

ActiveCN102353438AImprove pass rateReduce labor intensityWeighing apparatus testing/calibrationMechanical forcePortal frame

The invention relates to a scale calibrating device and a scale calibrating method for a hopper scale with hopper or hopper bin horizontal detection. The device mainly comprises a jack, a portal frame, a magnetic level instrument, a magnetic level instrument connection hose, a pressure applying platform, a standard weighing sensor and a weighing display instrument, wherein the lower end of the central position of a horizontal transverse beam of the portal frame is provided with the jack; the jack is vertically arranged on the upper surface of the standard weighing sensor for scale calibrating; the pressure applying platform is arranged below the standard weighing sensor for scale calibrating; and the magnetic level instrument mainly comprises a magnetic base and a plastic pipe with graduations. The jack is used for converting a standard weight needed by electronic scale calibration into mechanical force instead of a weight, the magnitude of applied force is controllable, and the loading is at a uniform speed and is reliable; the magnitude of the applied force is accurately displayed through the standard weighing sensor and the weighing display instrument, so that the accurate metering of mechanical force is realized; and the scale calibrating device has a simple structure and a low price, is suitable for narrow fields, can be used repeatedly, is flexible and convenient for applying, and is convenient to install and use on site.

Owner:CHINA FIRST METALLURGICAL GROUP

Dynamic torque detection system

PendingCN106768621AHigh measurement accuracyPrevent sideways movementForce/torque/work measurement apparatus calibration/testingAerodynamic torqueElectricity

The invention discloses a dynamic torque detection system, comprising a bench and a torque sensor; an electrical-pneumatic torque wrench is fixedly mounted on the bench; one end of the torque sensor is connected with an output shaft of the electrical-pneumatic torque wrench; the other end of the torque sensor is connected with a sleeve through a coupling; the sleeve is rotationally fixed on the bench and is connected with a torque brake device that may provide continuous braking for torque. By providing the torque brake device that may provide continuous braking for torque to detect a torque peak, measurement precision is improved; the torque brake device is arranged as a bolt, continuous braking is achieved by tightening the bolt; compared with simulated bolts, the dynamic torque detection system as a calibrator allows an actually used bolt to be sued in the detection process, and the actual condition can be simulated to maximum extent.

Owner:SICHUAN DONG TAI MACHINERY MFG CO LTD

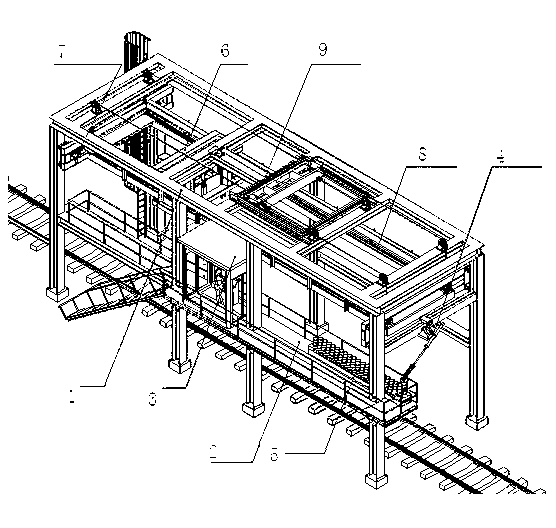

Trolley for concrete construction on multiple sections by employing mining method and construction method thereof

ActiveCN103470272ASimple and fast operationImprove work efficiencyUnderground chambersTunnel liningVehicle frameArchitectural engineering

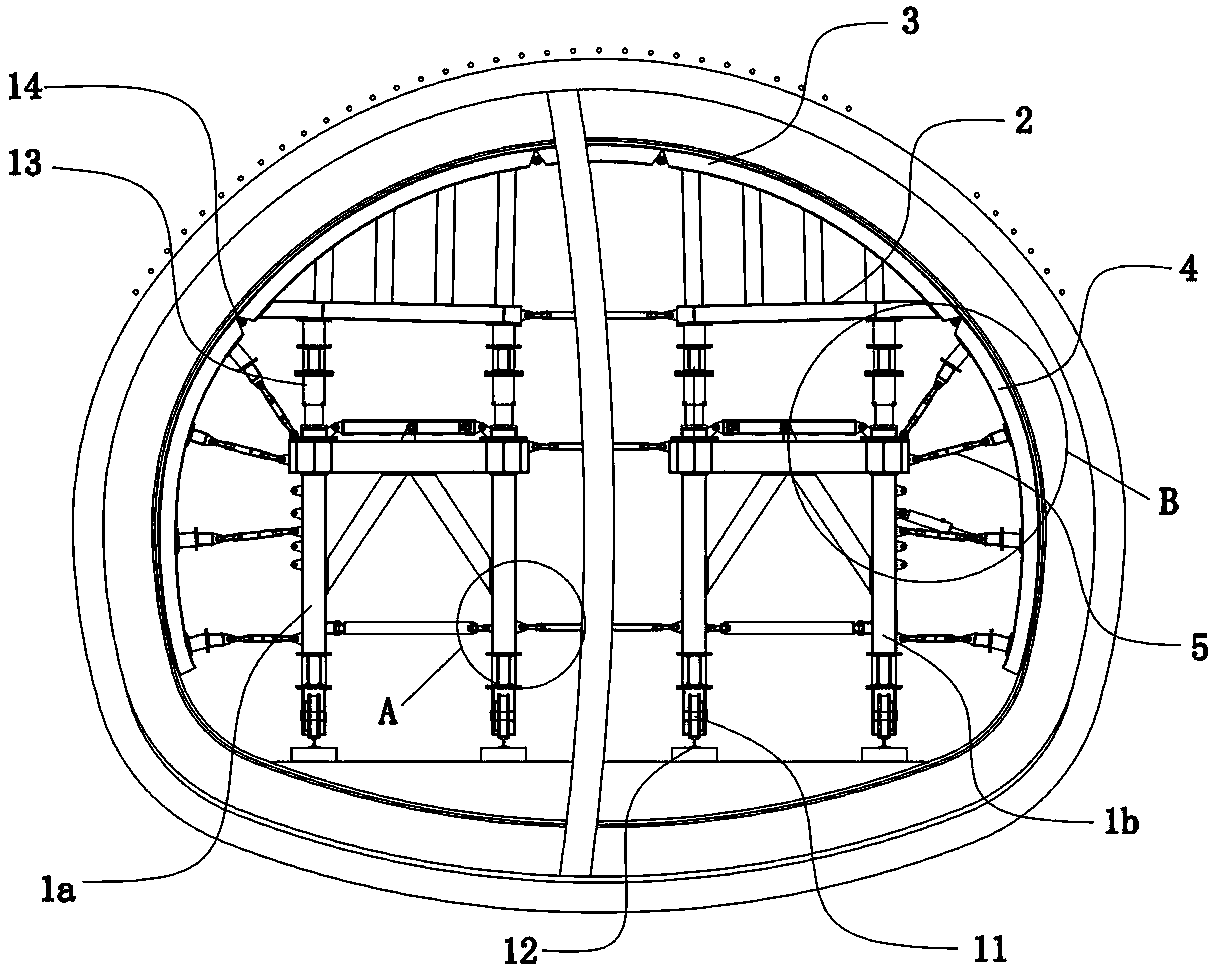

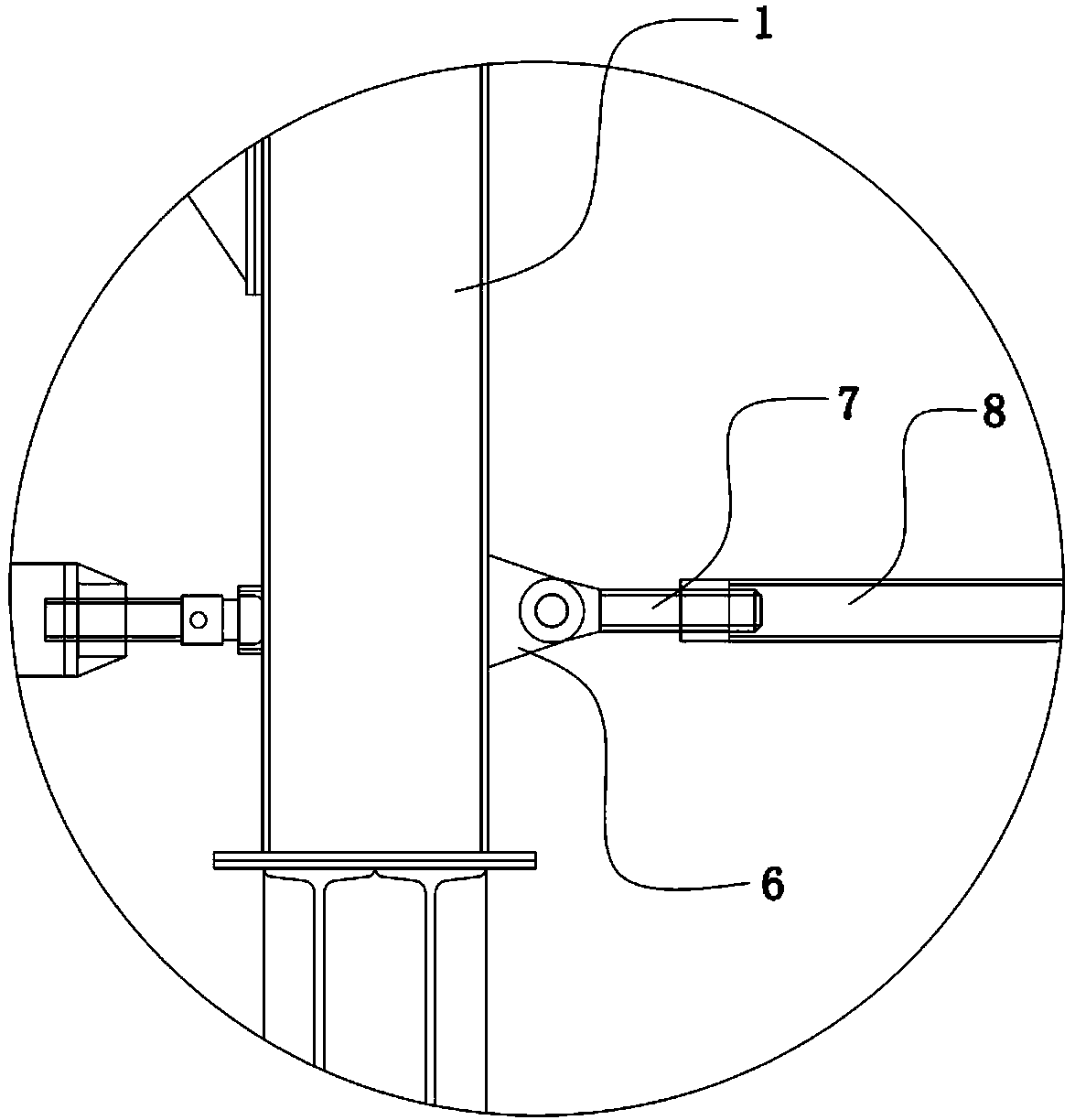

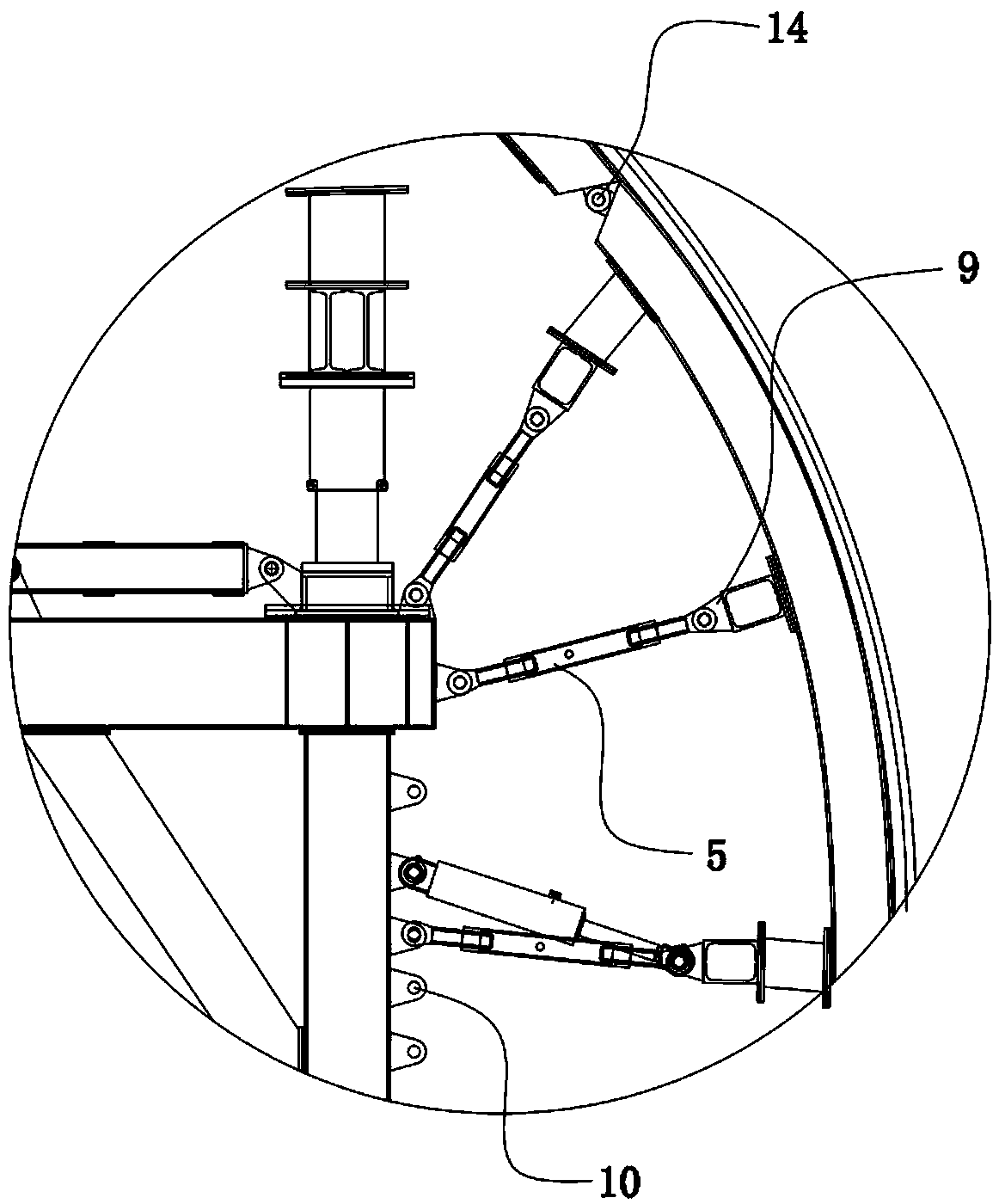

The invention discloses a trolley for concrete pouring construction on multiple sections by employing a mining method. The trolley comprises a frame, wherein the frame is connected with a template, and comprises a portal and a top arch rack, wherein the top arch rack is arranged above the portal; a top template is arranged above the top arch rack; lateral templates are arranged on two sides of the portal; a lateral cylinder is arranged between the lateral templates and the portal; two ends of the lateral cylinder are respectively hinged with the lateral templates and the portal. Firstly, the trolley can be applicable to different sizes of sections, can adjust the posture and the radian of the template in construction of changing sections, adapts to the dimensional requirements of different sections, and can achieve the beneficial effects of changing the sections without changing the trolley; secondly, the trolley adopts a separated alternative bay construction method; the trolley respectively enters a flow construction period from two sides of the tunnel, and then connecting, merging and assembling on the scene are achieved by separating the overall portal into two small portals when a transverse temporary arc is dismantled in primary support of the tunnel.

Owner:北京住总集团有限责任公司

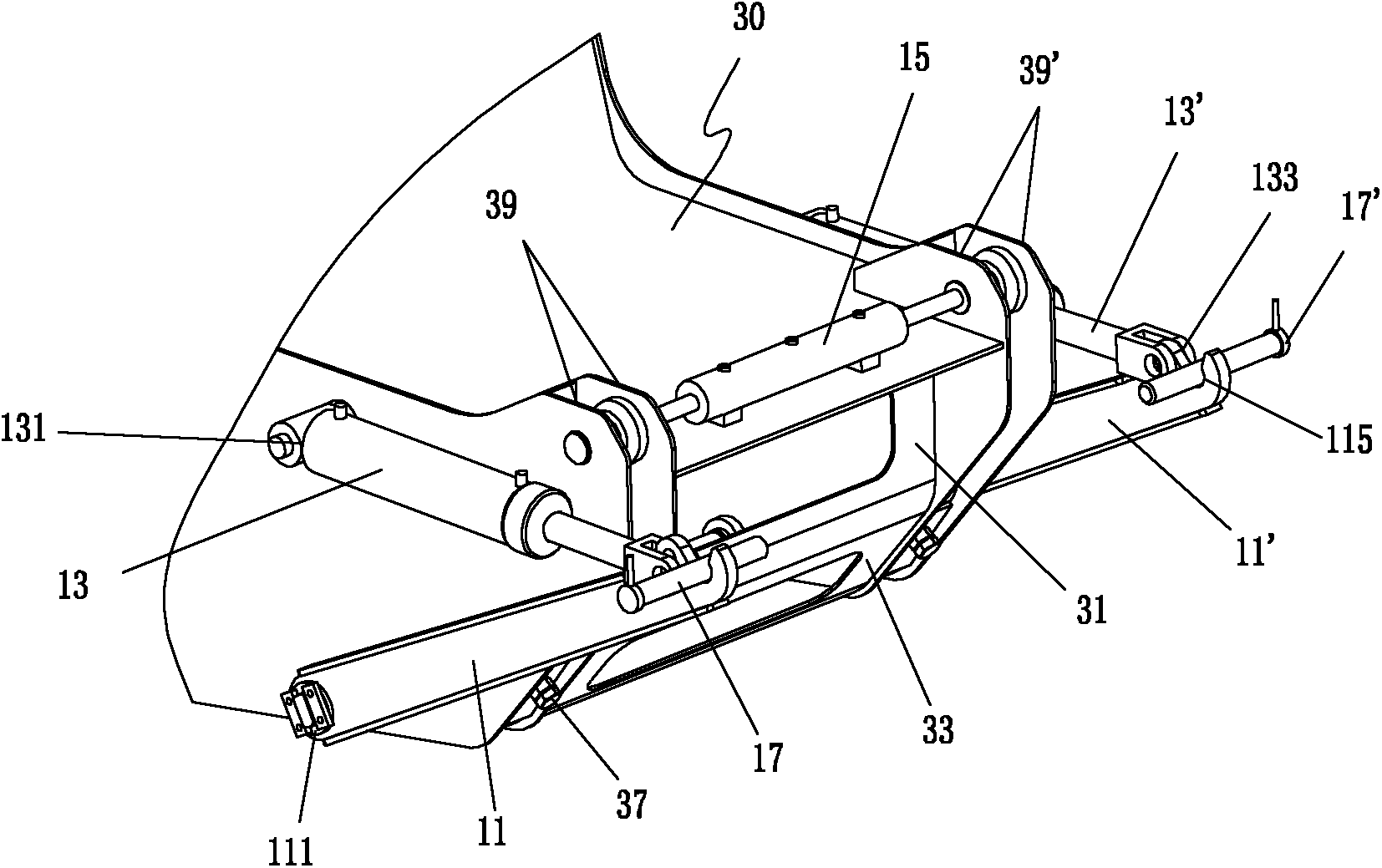

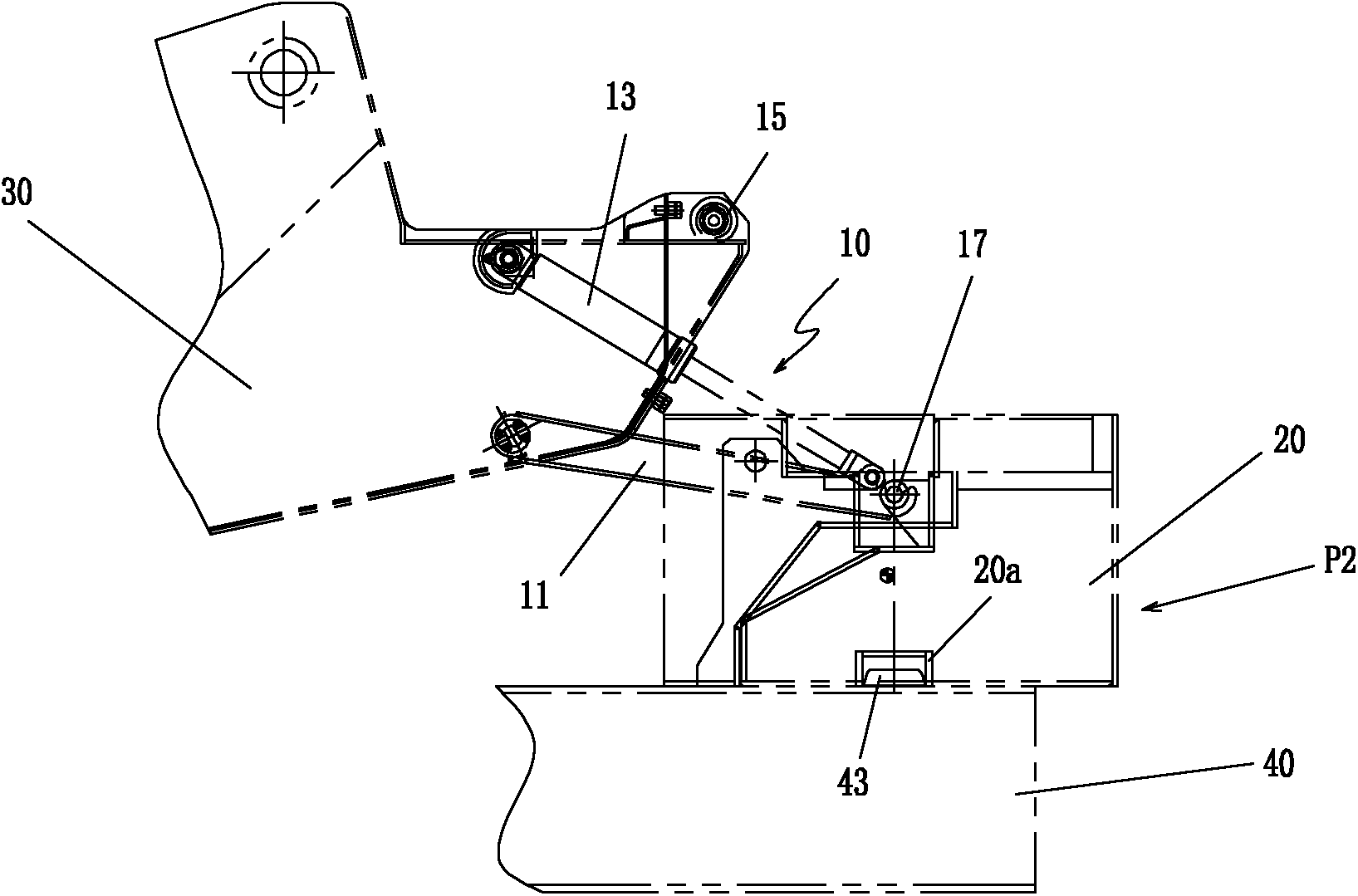

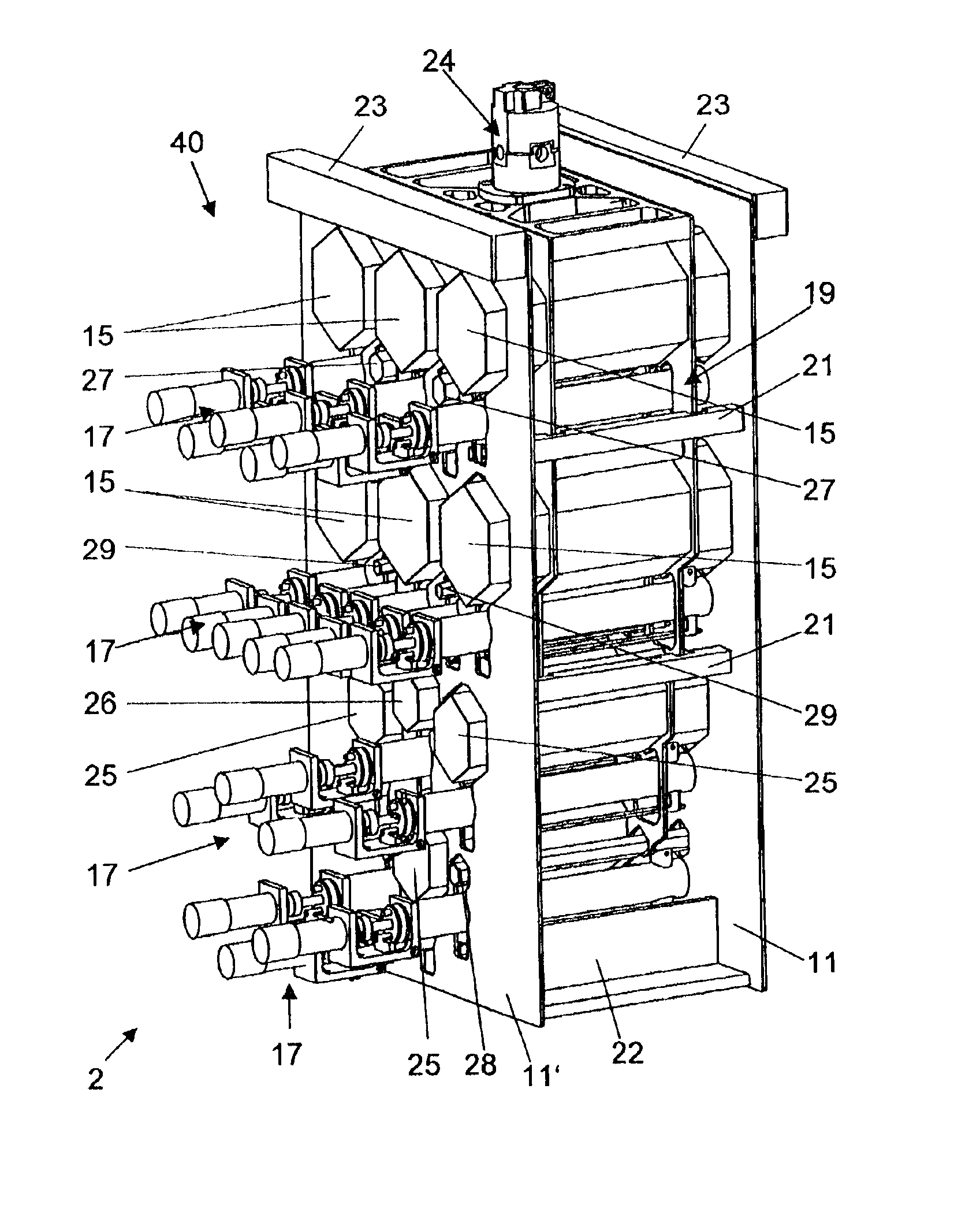

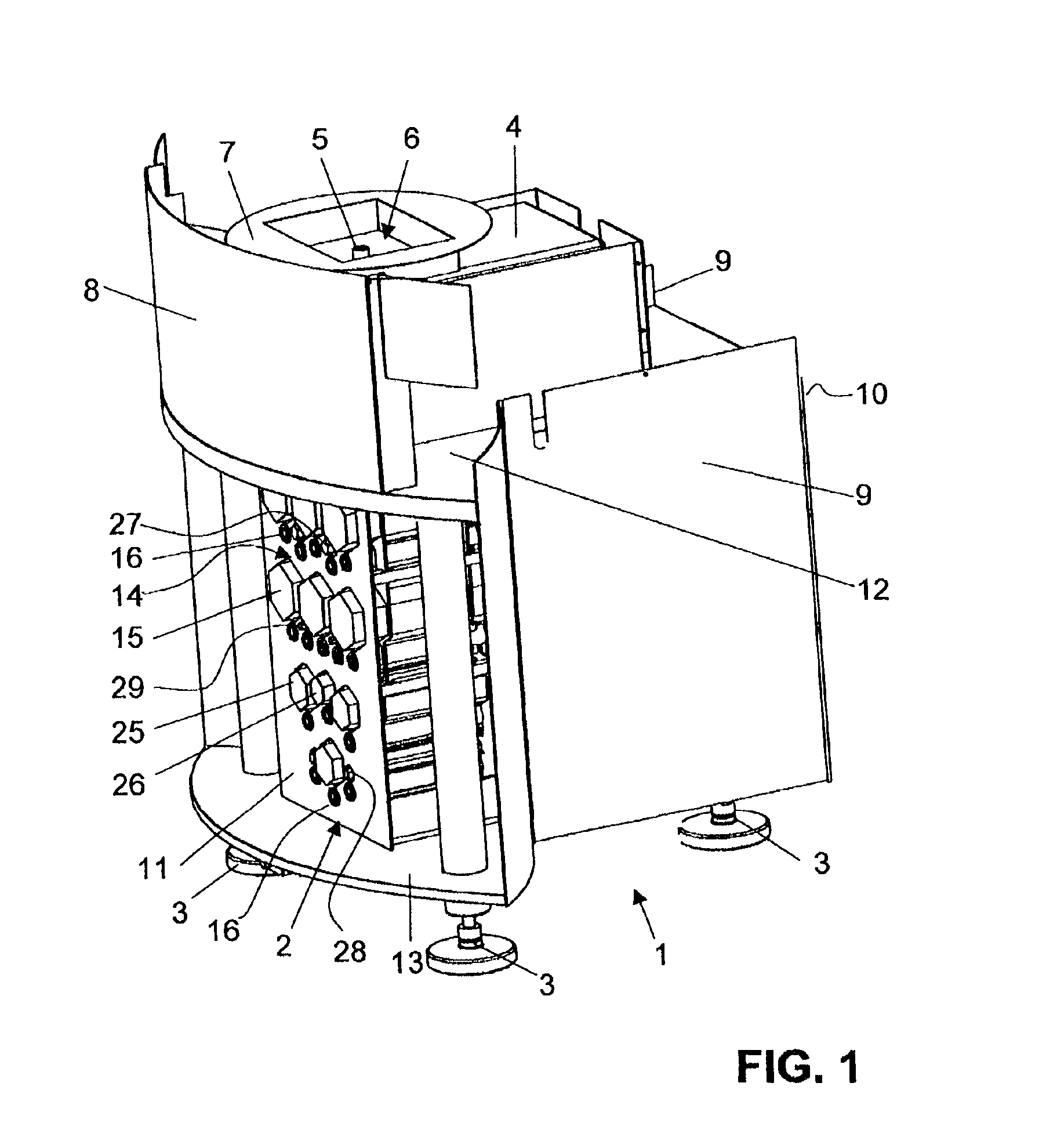

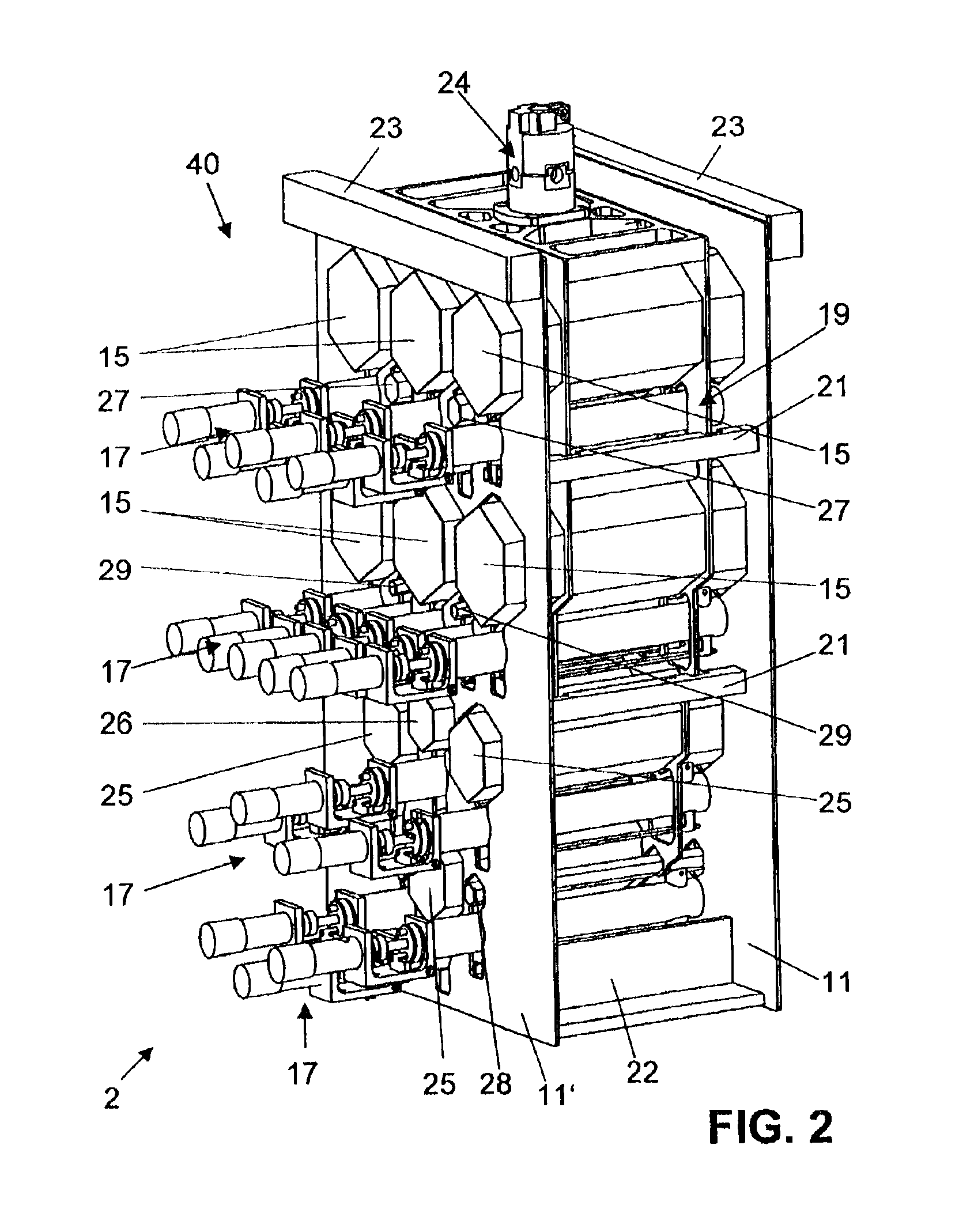

Cranes and crane counterweight handling mechanisms, counterweights

InactiveCN102275836AEasy horizontal posture adjustmentAvoid unbalanced loadCranesMechanical engineeringPiston rod

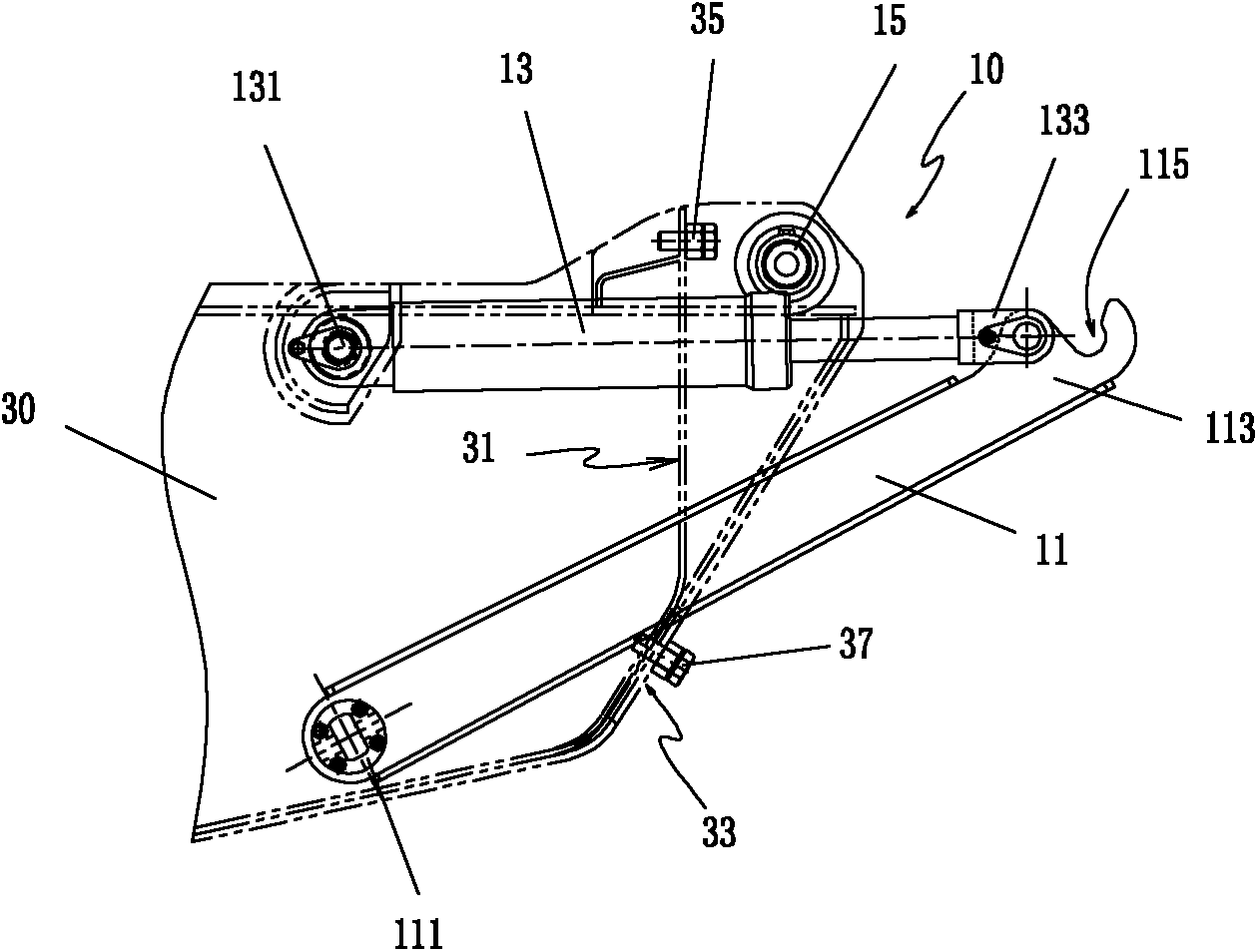

Disclosed is a counterweight loading and unloading mechanism for a crane. The counterweight loading and unloading mechanism (10) comprises: two jibs (11, 11'), symmetrically disposed at two sides of a slewing platform (30) of the crane, a first end (111) of each jib being pivotably connected on the slewing platform of the crane, a second end (113) extending outwardly at the tail of the slewing platform and having a latch hook (115); two counterweight cylinders (13, 13'), symmetrically disposed at two sides of the slewing platform of the crane, and driving the jibs to rotate between the installation position (P1) and a placement position (P2) of a counterweight block; and a locking device, disposed at the tail of the slewing platform of the crane and along the width direction of the slewing platform of the crane, the latch hook and the counterweight block being connected detachably through a latch bar, and the latch bar locking and fitting the counterweight block when the counterweight block is at the installation position. Further disclosed are a crane having the counterweight loading and unloading mechanism and a counterweight block fitting the counterweight loading and unloading mechanism. The counterweight loading and unloading mechanism is capable of avoiding offset loading of the cylinder piston rod incurred when the two cylinders are asynchronous, which is very suitable for horizontal arrangement of counterweight cylinders and facilitates the adjustment of horizontal posture of the counterweight block.

Owner:HUNAN ZOOMLION SPECIAL VEHICLE

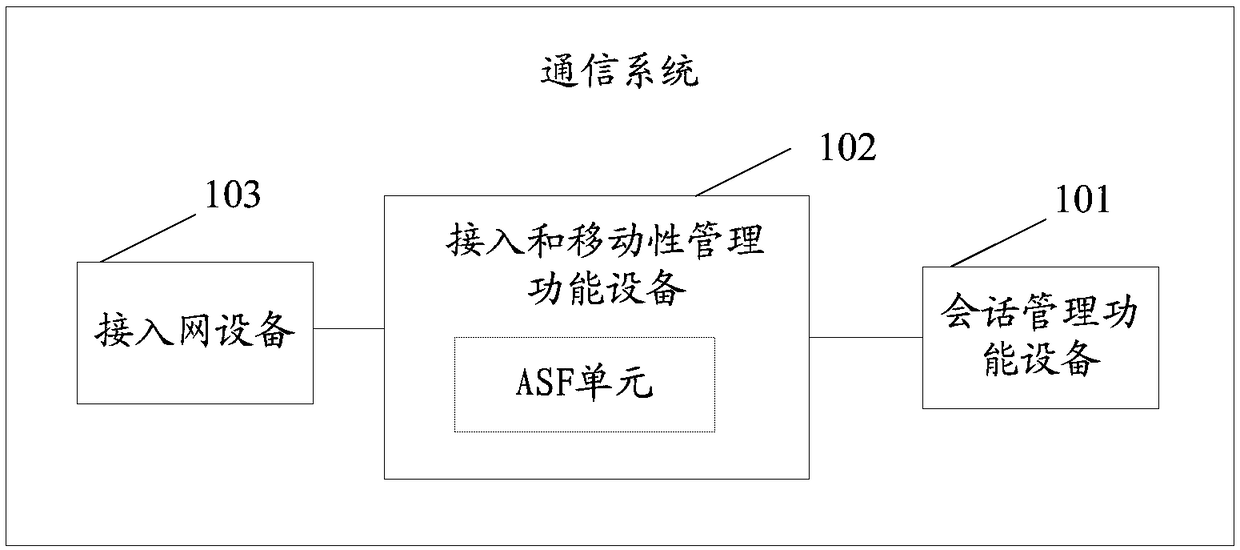

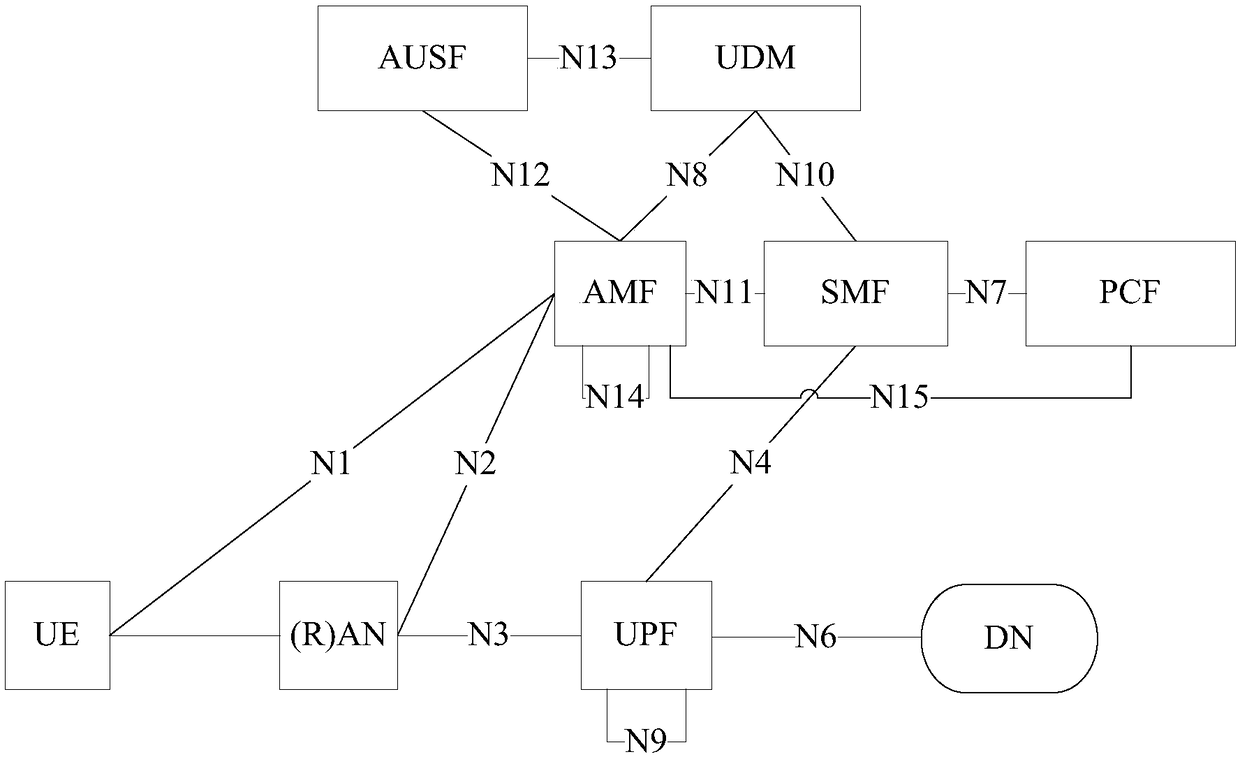

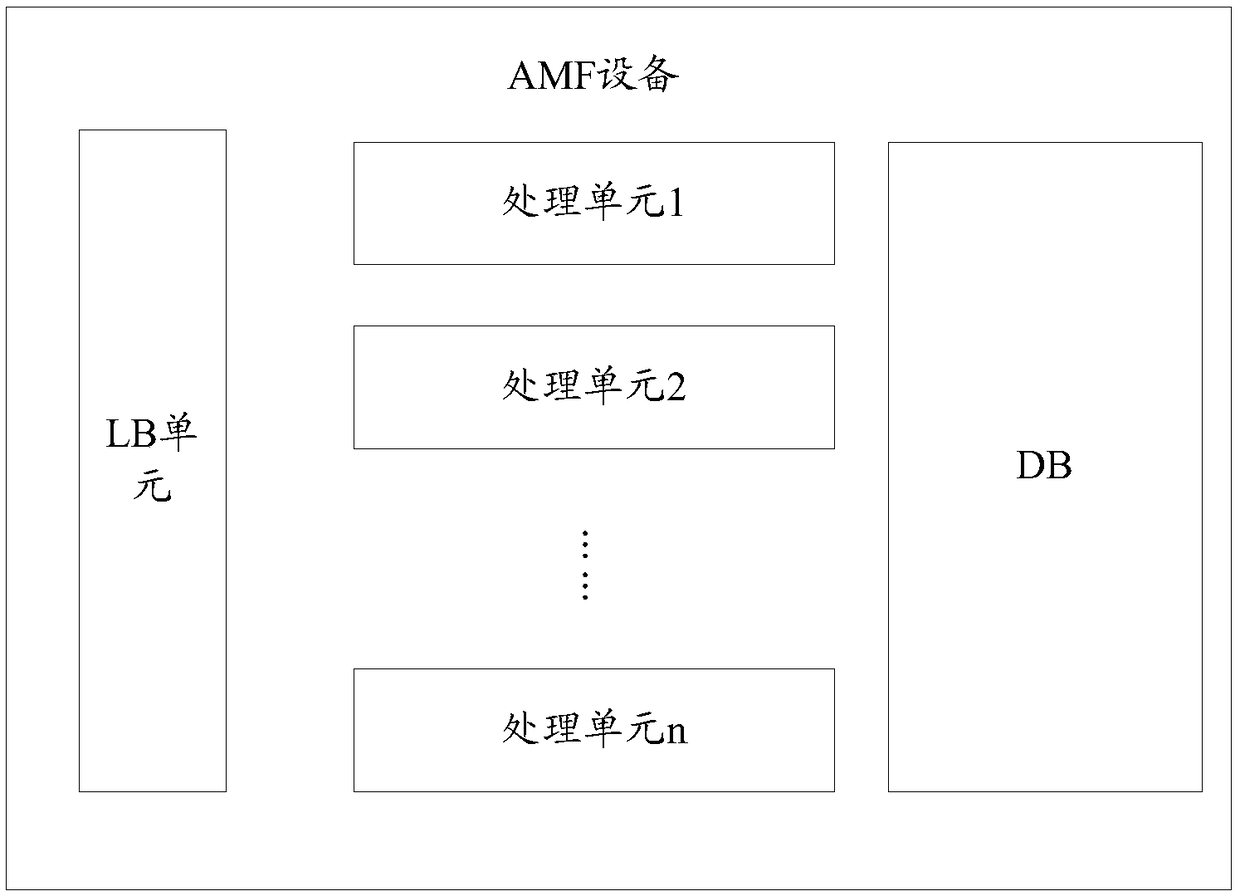

Message transmission method and device

ActiveCN108810988AImprove business qualityAvoid unbalanced loadNetwork traffic/resource managementSession managementComputer engineering

The application discloses a message transmission method and a message transmission device, relating to the technical field of communications and capable of solving the problem of unbalanced load between equipment serving UE. The method provided by the application comprises: the session management function equipment receives a deletion indication from the first equipment and the indication information of the group to which the first equipment belongs, and deletes the second interface information in the UE session context according to the deletion indication in the case that the session management function equipment receives the first interface release message from the first equipment; then, when a downlink message needs to be sent, the session management function equipment sends the downlink message to the second equipment, wherein the second equipment is determined according to the indication information of the group for serving the UE. This application is applicable to the process ofmessage transmission.

Owner:HUAWEI TECH CO LTD

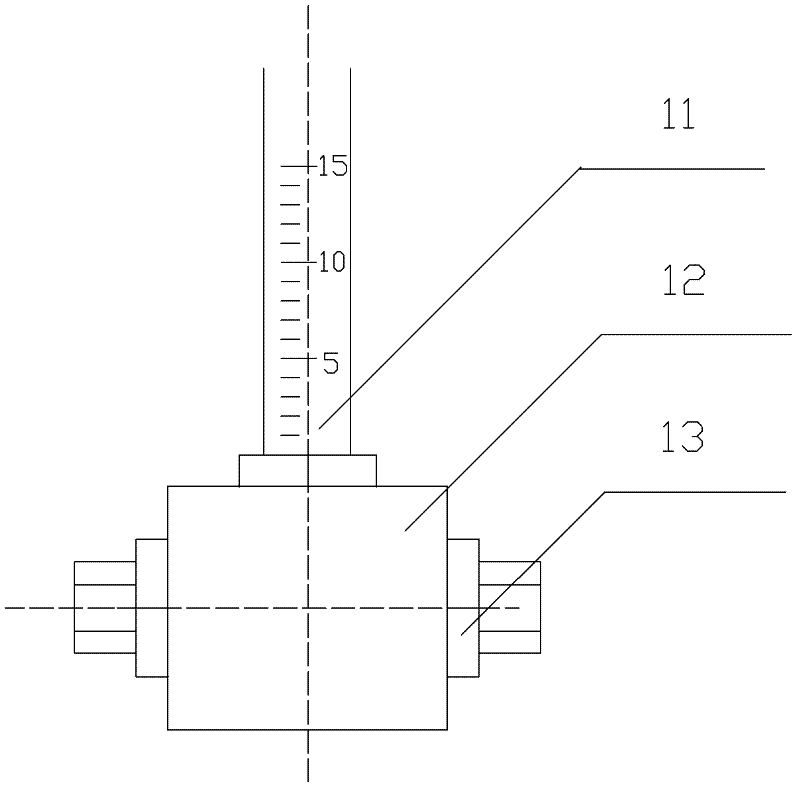

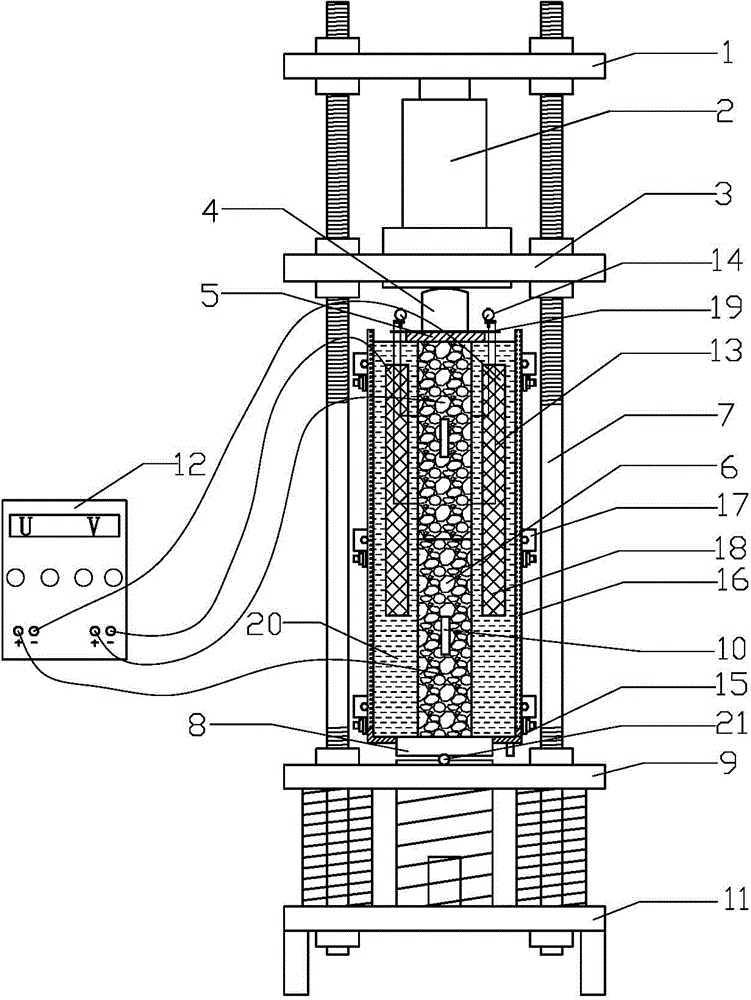

Testing mechanism for concrete creep under corrosion action, application and creep testing method

ActiveCN105890969AReduce volumeEasy to operateWeather/light/corrosion resistanceStrength propertiesCouplingRebar

The invention discloses a testing mechanism for concrete creep under the corrosion and load coupling action. The testing mechanism comprises a stress steel plate and a pressure sensor, wherein the stress steel plate is installed on the upper portion of a testing sample. The testing mechanism is characterized in that the testing sample is installed in the center of an open container containing a corrosion solution; a conductive metal net is arranged in the corrosion solution, a steel bar in the testing sample is connected with the positive electrode of a constant-voltage direct-current power source, the conductive metal net is connected with the negative electrode of the constant-voltage direct-current power source, and an electrochemical corrosion circuit is formed by the corrosion solution, the constant-voltage direct-current power source, the conductive metal net and the testing sample; a dial indicator is installed on the testing sample. The creep testing method of the testing mechanism comprises the first step of manufacturing of the testing sample, the second step of installation, the third step of loading and the like. The creep characteristics of concrete under the corrosion and load coupling action are taken into consideration and better conform to the environment state of practical engineering structures, tests have higher engineering value, and significant engineering application value and wide market application prospects are achieved.

Owner:HUNAN CITY UNIV

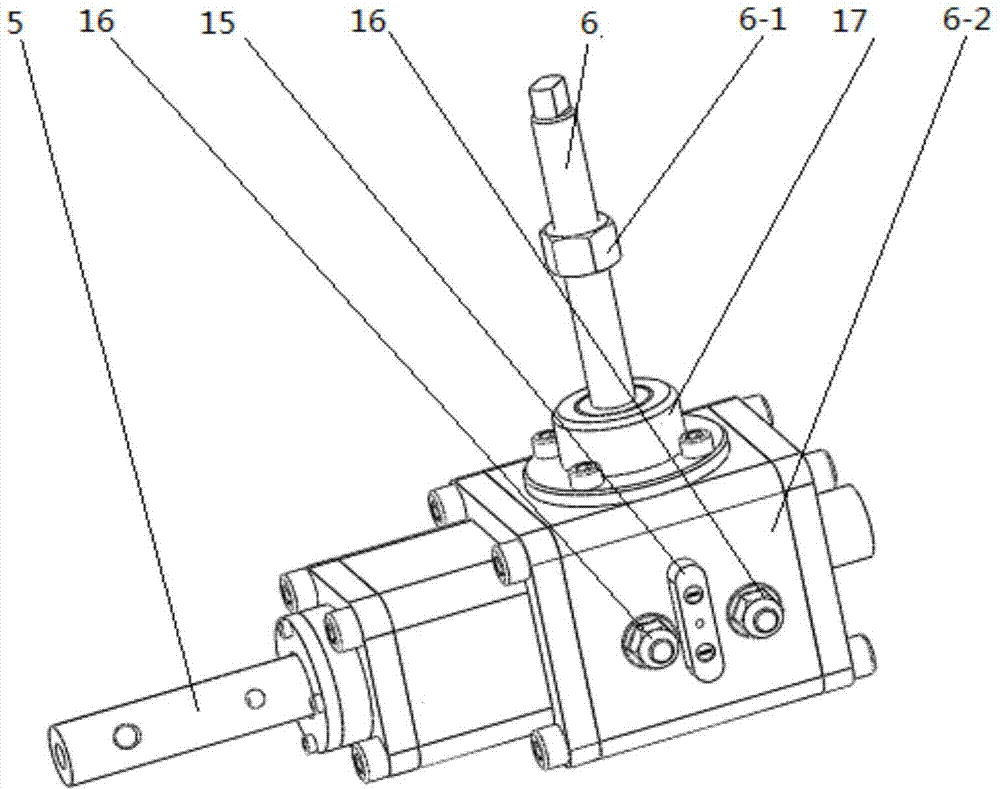

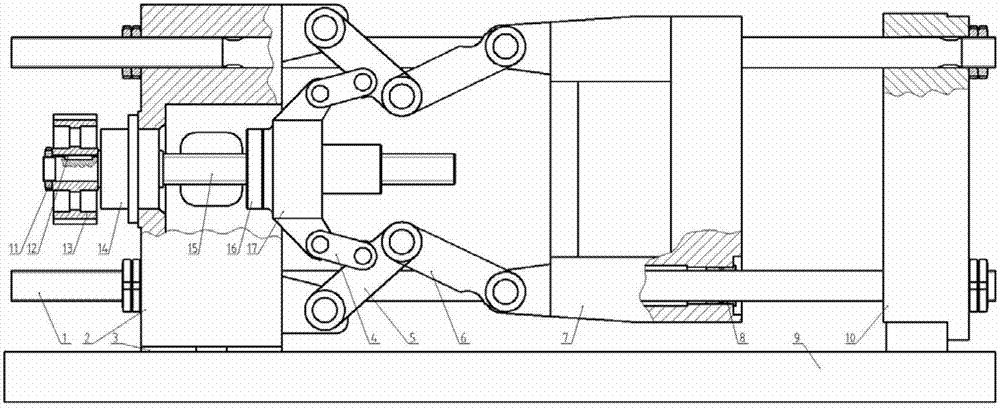

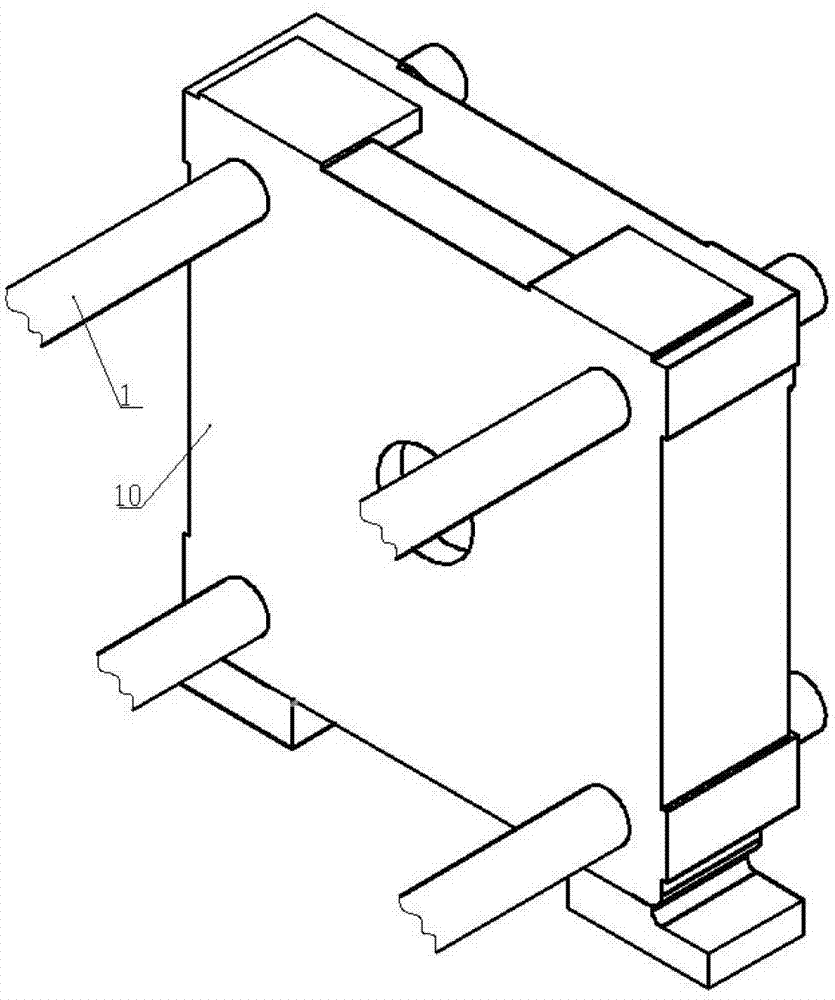

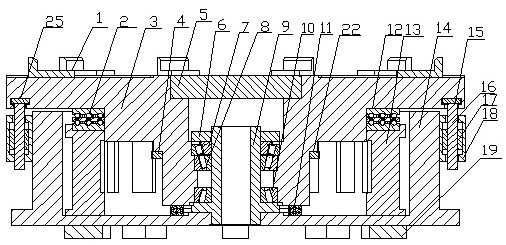

Ball screw pair-driven clamping mechanism

The invention discloses a ball screw pair-driven clamping mechanism. The ball screw pair-driven clamping mechanism comprises four pull rods, a tail plate, two toggle mechanisms, a movable mould plate, a head plate, a synchronous pulley, a screw bearing base, a ball screw, a ball nut and a thrust block, wherein the four pull rods fix the distance between the head plate and the tail plate and are used for guiding movement of the movable mould plate. The ball screw pair-driven clamping mechanism is driven by a servo motor; and through a toothed synchronous belt and a ball screw pair, rotation of the motor is converted into back-and-front movement of the thrust block to drive a toggle link mechanism so as to open and close the movable mould plate.

Owner:ZHEJIANG UNIV

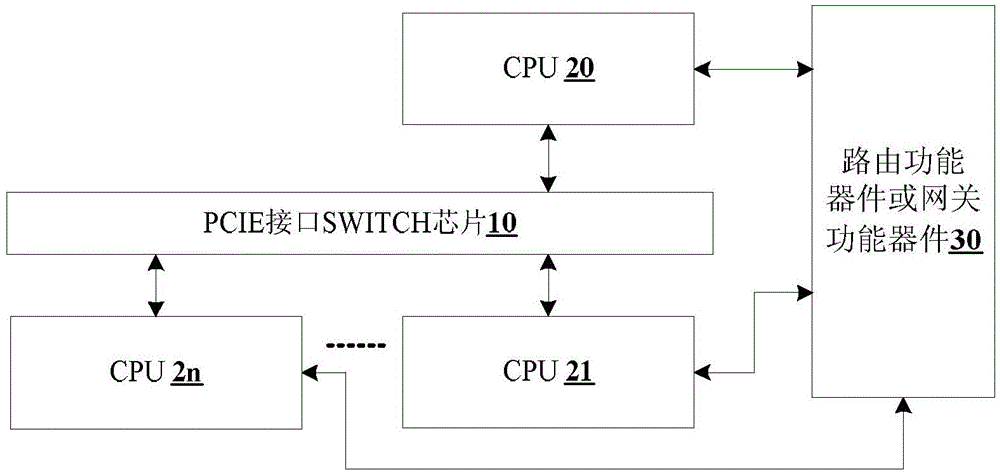

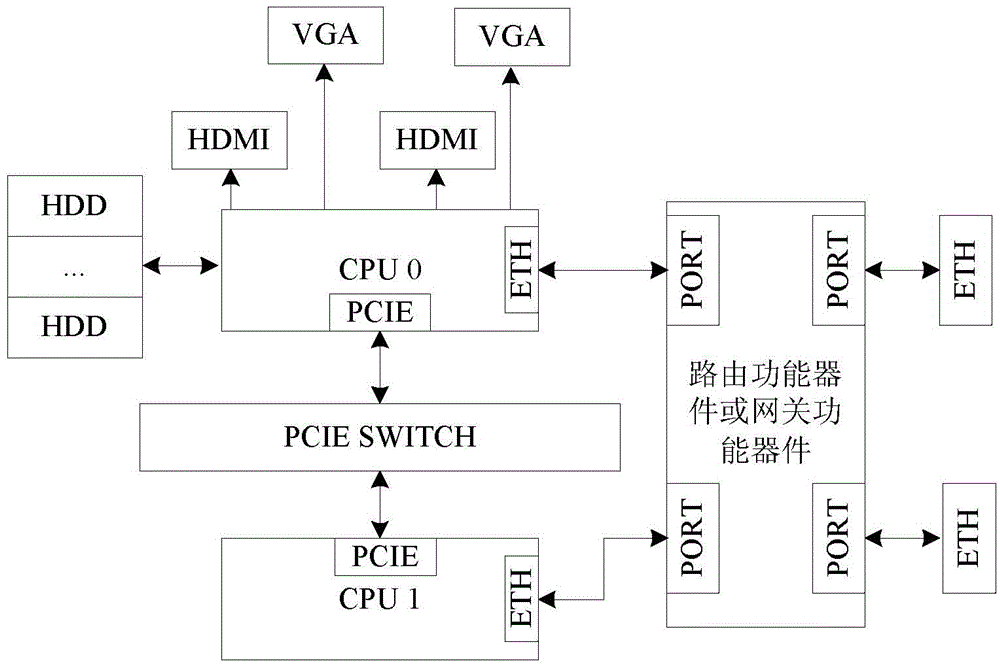

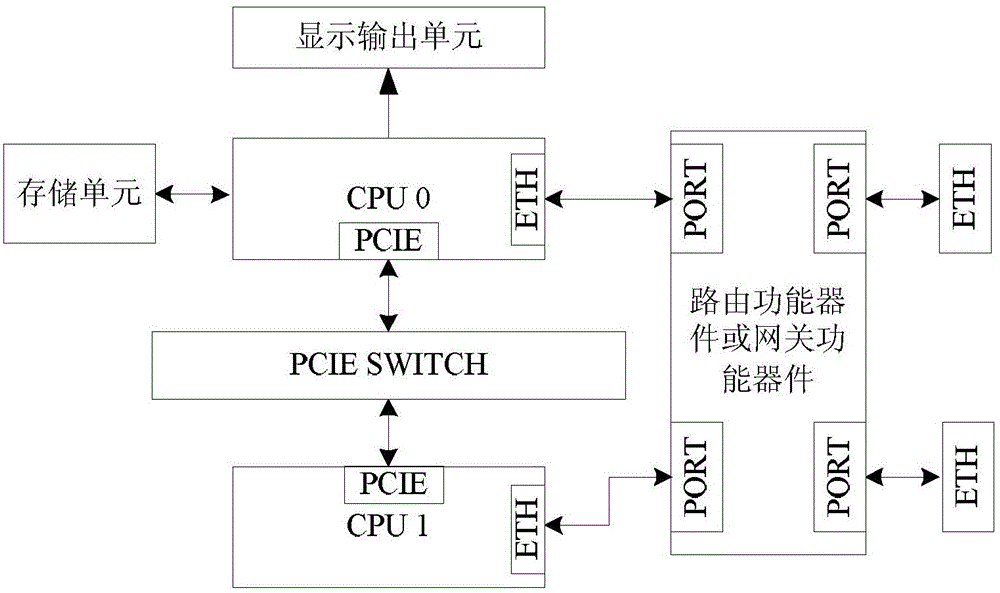

Digital video recorder with multiprocessor cluster and realization method of digital video recorder

ActiveCN105472291AAvoid unbalanced loadAvoid wastingTelevision system detailsResource allocationDigital videoComputer network

The invention discloses a digital video recorder with a multiprocessor cluster and a realization method of the digital video recorder. Data communication and exchange are carried out among multiple CPUs via a PCIE interface switch chip; each CPU is connected with the PCIE interface switch chip and a route or gateway function device to obtain a multimedia data code stream according to the network bandwidth and the IPC access way distributed by the route or gateway function device and process the multimedia data code stream, and processing of the multimedia data code stream includes at least one selected from decoding, storing, sending, display and output, replay, preview and intelligent analysis; and the route or gateway function device is connected with the multiple CPUs to distribute the network bandwidth and the IPC access way for the CPUs. According to the technical scheme provided by the invention, the CPUs are prevented from load imbalance and resource waste, the power consumption is reduced, the cost is reduced, and the using performance of products is improved.

Owner:HANGZHOU HIKVISION DIGITAL TECH

Vehicle-mounted weighing system of freight train as well as weighing method

InactiveCN108225513AAchieve full dynamic weighingWeighing at any timeTransmission systemsSatellite radio beaconingBogieFreight trains

The invention discloses a vehicle-mounted weighing system of a freight train as well as a weighing method. The weighing system comprises a weighing sensor, a connecting cable and a vehicle-mounted intelligent terminal, wherein the vehicle-mounted intelligent terminal consists of an ARM embedded controller unit, a power supply unit, a positioning unit, a wireless data transmission unit, a digital I / O interface unit, a weighing signal amplifying and conditioning circuit, an analog-digital conversion circuit and a data storage unit. A bogie strain-based indirect type weighing method is adopted bycombining the own structure of a rail wagon. For the safe working characteristic of railway freight, the weight of the wagon is monitored in real time in the loading, transportation and unloading processes of the freight train, and whole-course dynamic weighing of the whole wagon and the whole route is realized. The vehicle-mounted weighing system has remote monitoring and failure diagnosis functions, is high in measuring result precision and stability, has the characteristics of reliable performance, low cost of monitoring equipment and low requirements on mounting and use conditions, and iseasy to popularize and use.

Owner:西安航天三沃机电设备有限责任公司

Weight set for an electronic balance

InactiveUS6864437B2Promote exchangeSmall amount of spaceWeighing apparatus testing/calibrationForce/torque/work measurement apparatus calibration/testingEngineeringMechanical engineering

Owner:METTLER TOLEDO GMBH

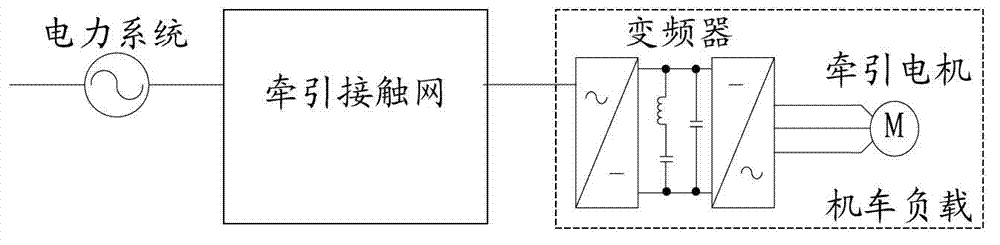

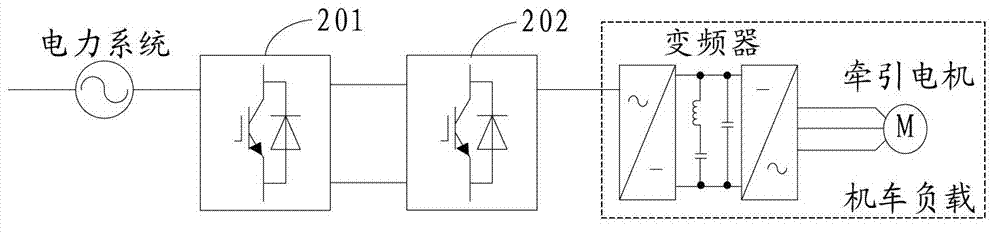

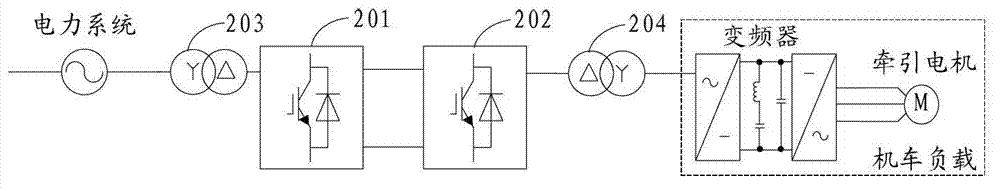

Traction contact system

ActiveCN102904271AThree-phase power load balance and stabilityAvoid unbalanced loadAC motor controlElectric power transfer ac networkSingle phaseThree-phase

The application discloses a traction contact system applied to a locomotive load; the locomotive load at least comprises a frequency converter and a traction motor; the traction contact system comprises a first receiving end convertor station and a first sending end convertor station, wherein the first receiving end convertor station is connected with a power system, rectifies a three-phase alternating current output by the power system to obtain a direct current and outputs the direct current; and the first sending end convertor station receives the direct current output by the first receiving end convertor station, inverts the direct current to obtain a single-phase alternating current, conveys the single-phase alternating current to a frequency changer, triggers the frequency changer to rectify and invert the single-phase alternating current to generate the three-phase alternating current, and sends the three-phase alternating current to the traction motor. According to the traction contact system disclosed by the embodiment of the invention, the three-phase power load of the power system for providing the three-phase alternating current can be balanced and stabilized, thereby avoiding the shortage of unbalanced load of the power system, reducing the loss of electric energy and improving the utilization rate of the electric energy.

Owner:ZHUZHOU NAT ENG RES CENT OF CONVERTERS

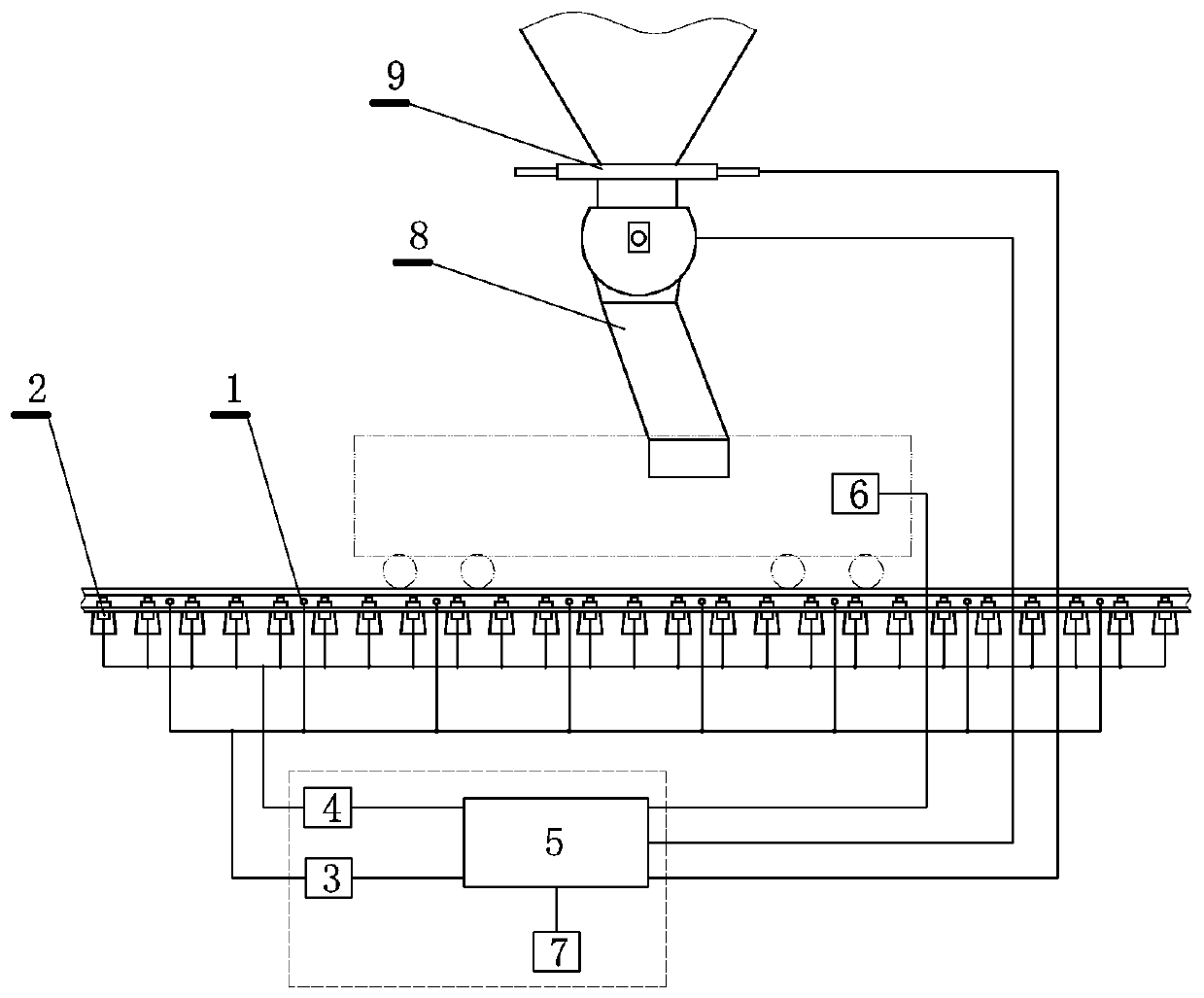

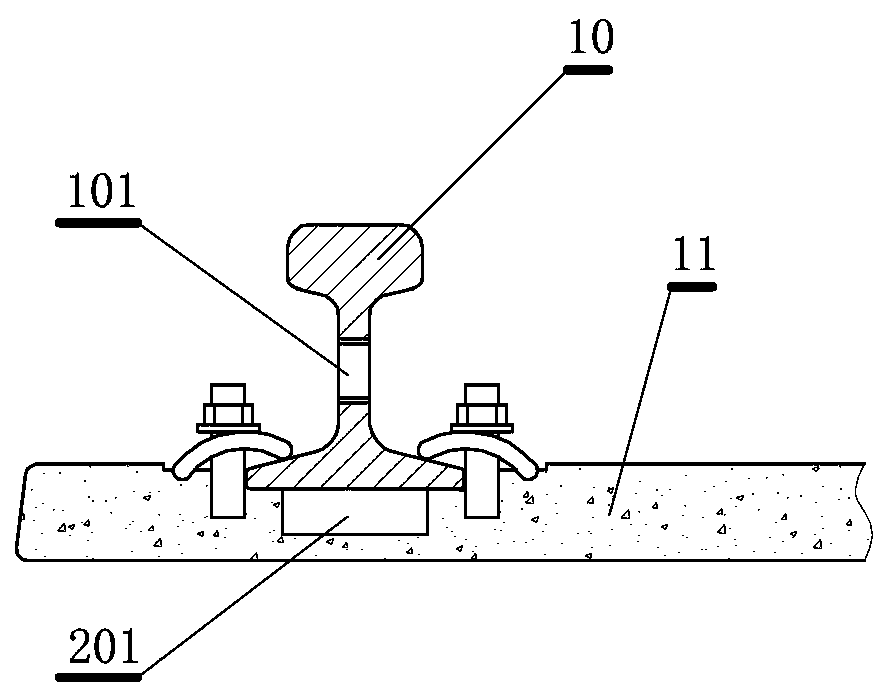

Train loading station real-time unbalance loading prevention system and method

The invention relates to a train loading station real-time unbalance loading prevention system and method. The system comprises a plurality of position sensors and centroid sensors distributed on or around loading stations of a loading station, each position sensor is connected with a carriage position calculating device, each centroid sensor is connected with a carriage centroid calculating device, the carriage position calculating device and the carriage centroid calculating device are connected with a gate chute controller, and the gate chute controller is connected with a carriage type identifier, a carriage information storage, an unloading chute and an unloading gate. According to the train loading station real-time unbalance loading prevention system and method, the dense sensors are arranged on a track passing through the loading station, the weight and the position of loaded carriages in the loading process are detected in real time, the centroid of goods entering the carriages is calculated in real time, the loading state of a balanced vehicle is compared according to the centroid, so that the balance of the current loading is estimated, the loading amount is adjusted inreal time according to the long-term condition, and the effect of automatically balancing and preventing unbalance loading is achieved.

Owner:中煤科工智能储装技术有限公司 +1

Multi-cast broadcasting business realizing method

ActiveCN1852249AImprove transmission efficiencyAvoid unbalanced loadPulse modulation television signal transmissionError preventionThe InternetBroadcasting

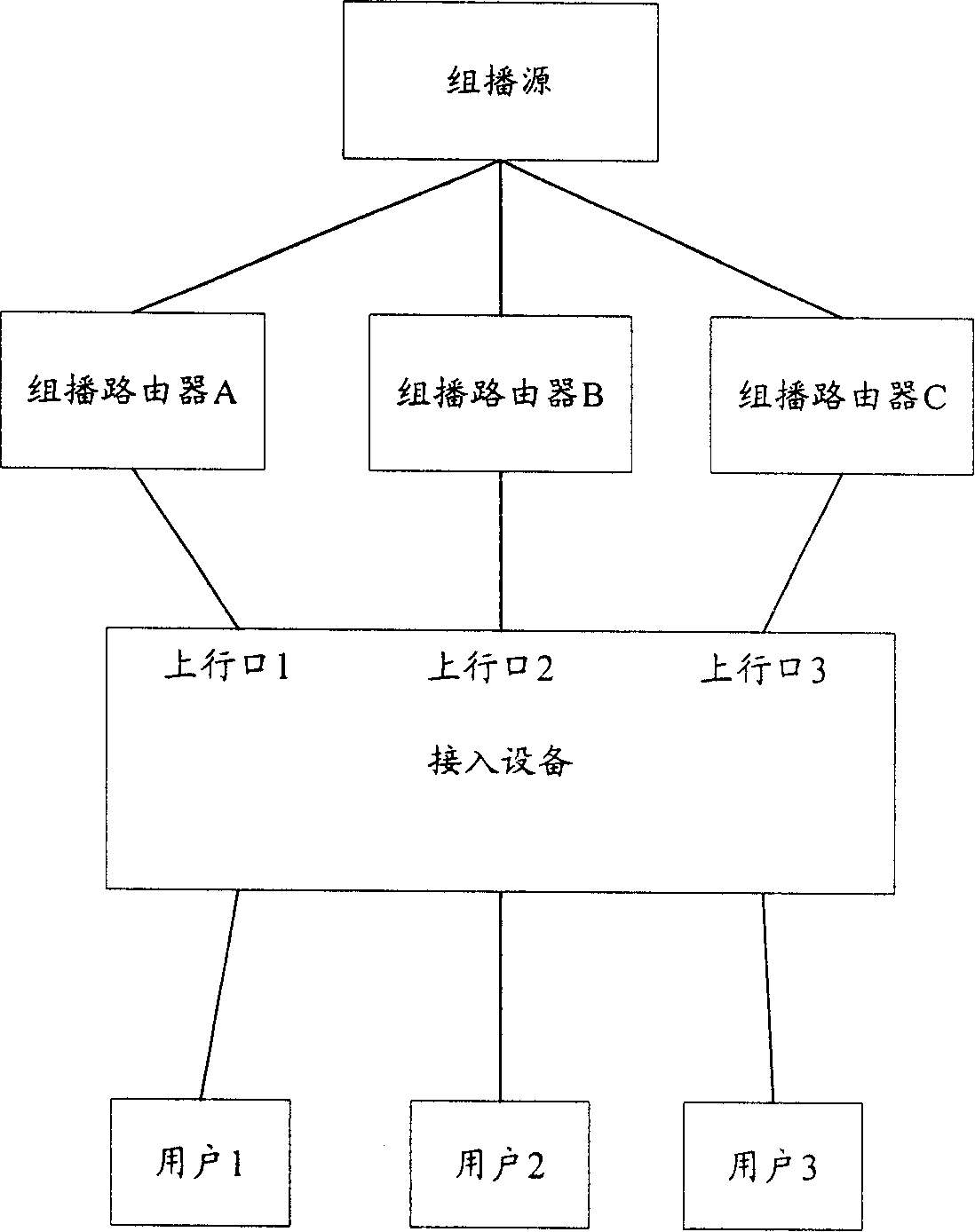

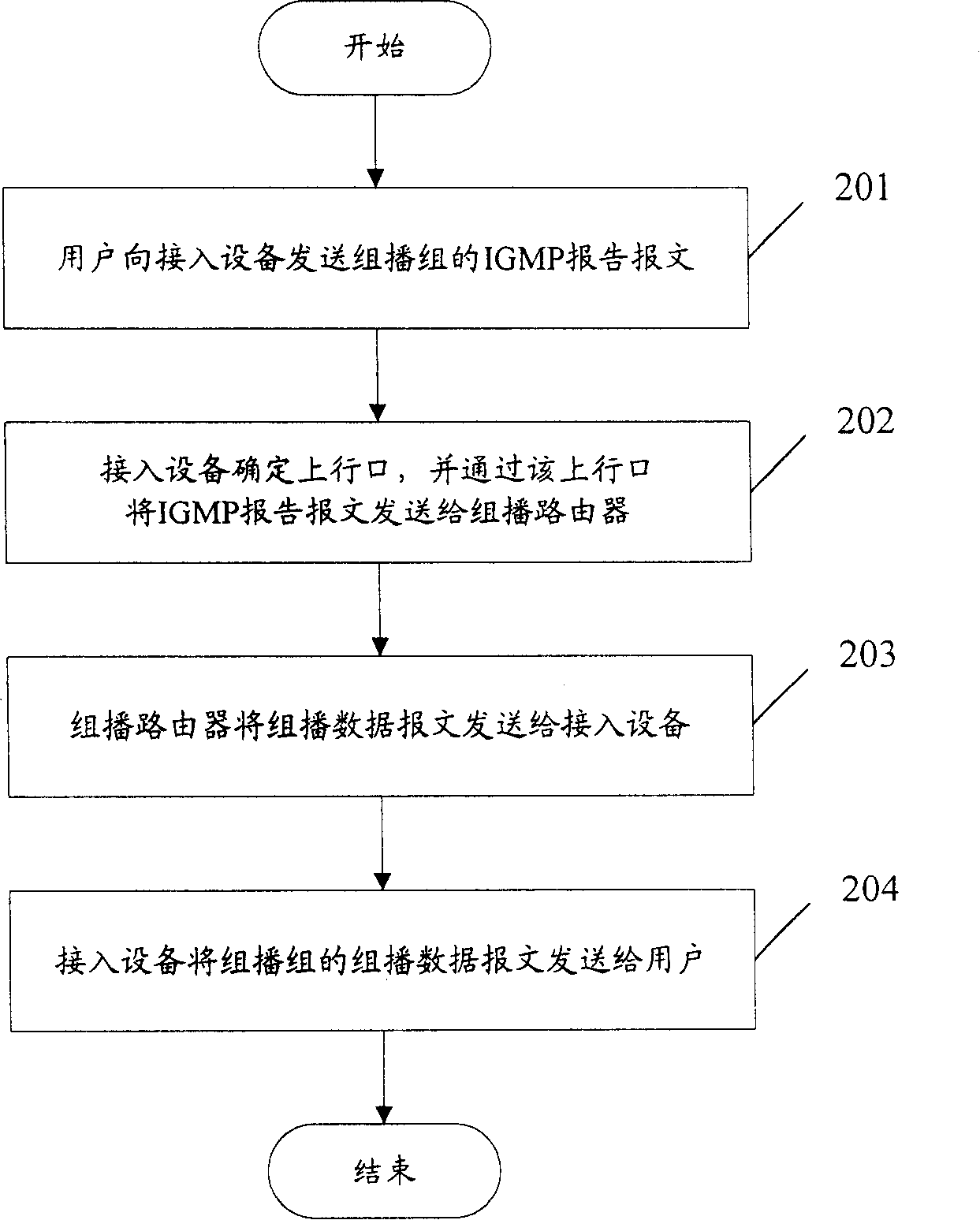

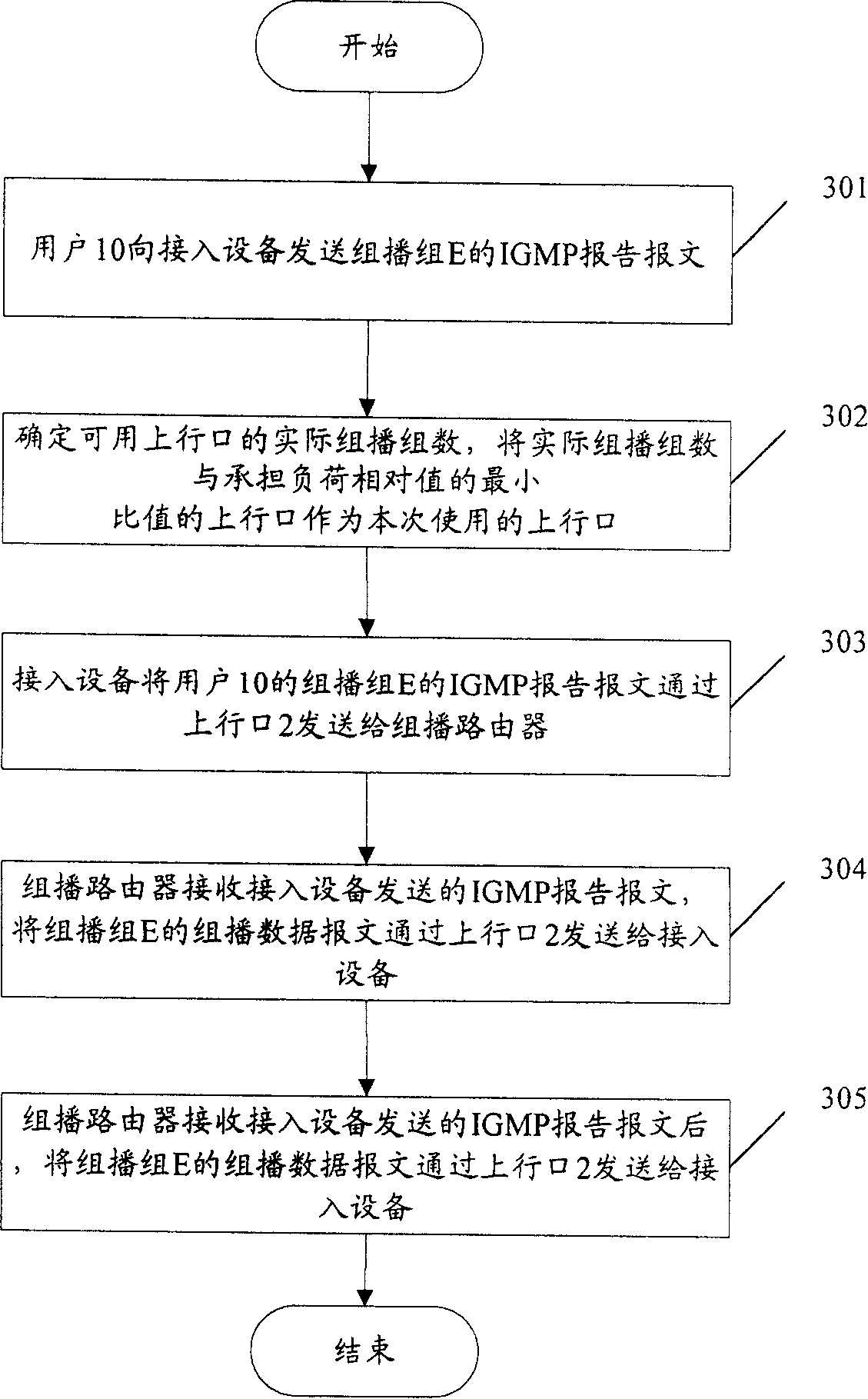

When asking for joining a multicast group, user sends report message in Internet group management protocol (IGMP) of the multicast group to access equipment; based on value of actual load of each available up going port, and load value setup in advance, the access equipment determines a up going port going to transfer multicast data of the multicast group; and through the determined up going port, the received report message in IGMP is sent to multicast route; after multicast route receiving the report message in IGMP from the access equipment, multicast route sends the multicast data of the multicast group through the determined up going port in the access equipment to the access equipment; then, the access equipment sends the multicast data to the user. The invention avoids unbalanced load of multicast service carried by up going port in access equipment so as to raise transmission efficiency.

Owner:HUAWEI TECH CO LTD

Drive device for electric vehicle

InactiveUS8932166B2Rotational accuracyImprove support stiffnessElectric propulsion mountingElectric machinesElectric vehicleControl theory

An object of the present invention is to achieve improvements in the rotational accuracy of the input shaft and the durability of the bearings, and suppression of rotational noise, by improving the support structure of the input shaft of the speed reduction unit. Provided is a drive device for an electric vehicle, including: an electric motor; a speed reduction unit including an input shaft driven by output of the electric motor; and a hub unit rotationally driven by an output member of the speed reduction unit, wherein the input shaft of the speed reduction unit is supported by bearings provided at two locations in an axial direction, the drive device for an electric vehicle being configured such that the bearings at the two locations are attached together to the output member.

Owner:NTN CORP

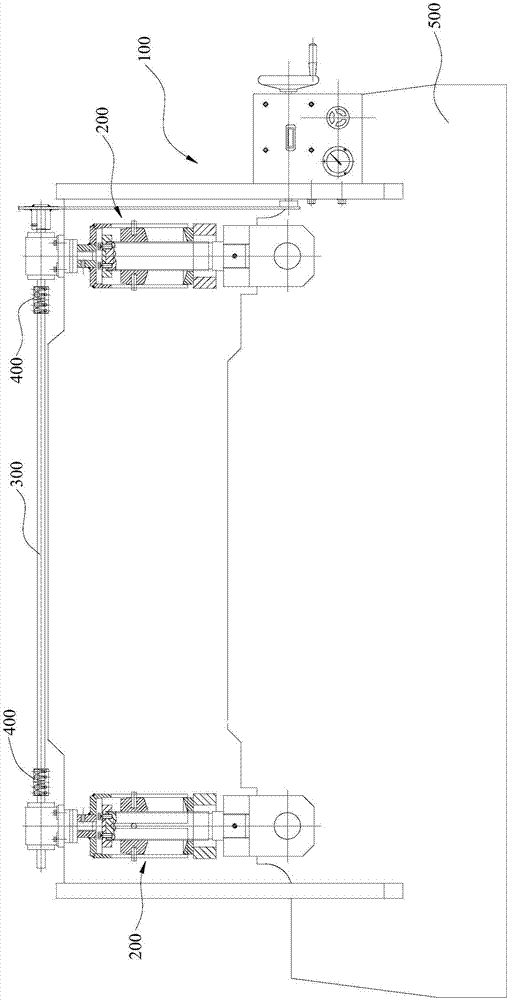

Propelling trolley

ActiveCN102953340AAvoid unbalanced loadAchieve liftingBridge erection/assemblyEngineeringStatically indeterminate

The invention relates to a propelling trolley, which comprises a trolley base, a plurality of connection bracket bodies, a hydraulic control system, adjusting brackets, an oil cylinder A, a transverse shifting device, a slope adjusting device and a longitudinal shifting device, wherein the connection bracket bodies and the hydraulic control system are arranged above the trolley base, the adjusting brackets are arranged on the connection bracket bodies in an up-to-down sliding manner, the oil cylinder A is vertically arranged on the trolley base, the transverse shifting device can enable the trolley base to transversally shift relative to bracket beams, the slope adjusting device is arranged on the adjusting brackets, the longitudinal shifting device is arranged on the trolley base, and can enable a main beam to longitudinally shift, and the oil cylinder A is connected with the hydraulic control system. According to the invention, under the action of the transverse shifting device and the longitudinal shifting device, the propelling trolley can drive the main beam to transversally or longitudinally shift, and the oil cylinder A can push upwards the adjusting brackets to lift the main bream; as the slope adjusting device is arranged on the adjusting brackets, the slope adjusting device can enable the slope of the front and the back of the propelling trolley to be constant, further, the condition that a bracket bearing system of a movable formwork bridge fabrication machine has unbalance loading can be avoided, and in the longitudinal traveling process, the disadvantageous hyperstatic working condition can be avoided.

Owner:SHANDONG LUQIAO GROUP

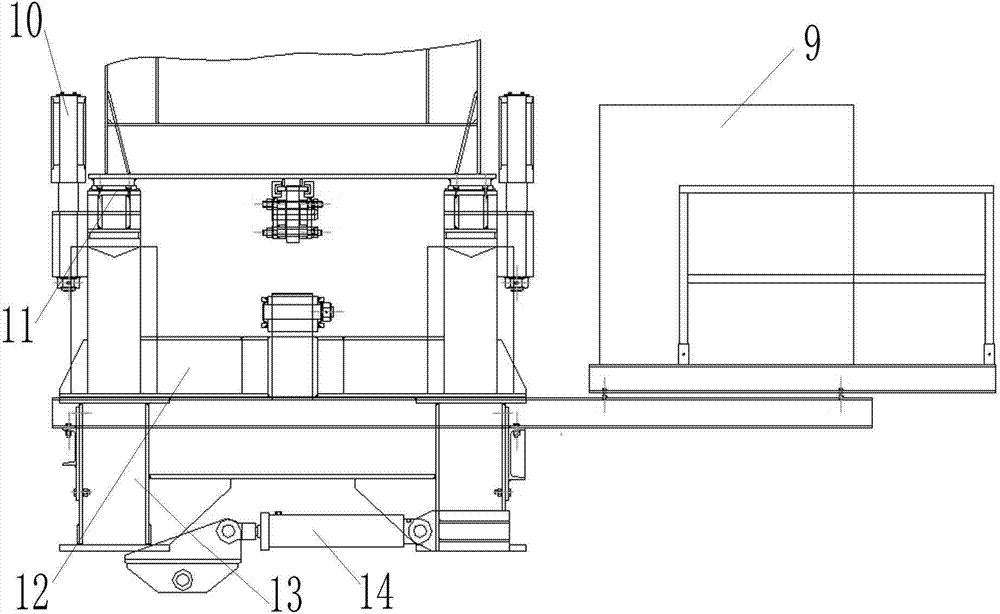

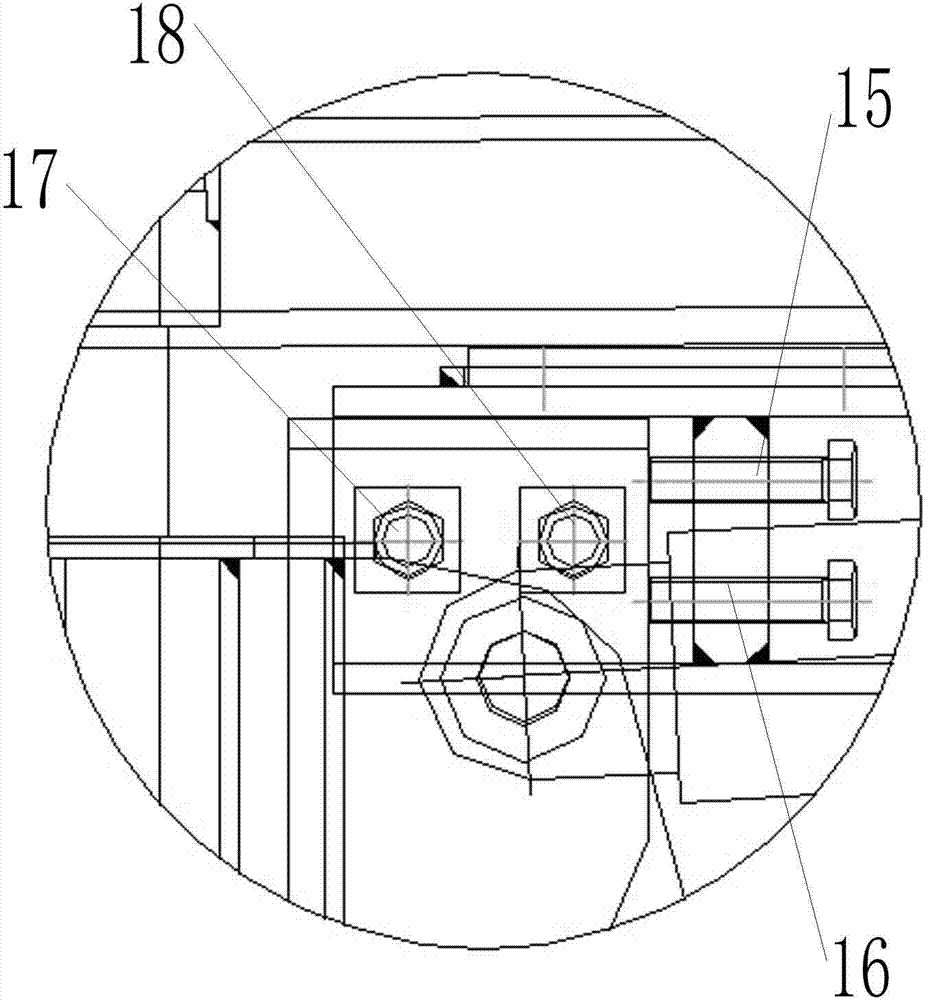

Automatic coal leveling sampling loading station

InactiveCN102992050AAvoid unbalanced loadSampling scienceLoading/unloadingAutomatic controlProcess engineering

The invention discloses an automatic coal leveling sampling loading station. The automatic coal leveling sampling loading station comprises a base frame, an operation platform, an operation room, a sampling manipulator, a reserved sample coal separator, a coal scraping vehicle, a coal scraping vehicle hydraulic driving device, a lifting track beam, a hydraulic lifter, a hydraulic power system and an automatic control system, wherein the operation platform is installed on the base frame; the operation room is arranged in the base frame; the sampling manipulator is fixedly arranged on the upper part of one end of the base frame; the reserved sample coal separator is arranged under the sampling manipulator; the coal scraping vehicle is installed on the lifting track beam; a coal scraping plate capable of being controlled by an oil cylinder to vertically move is arranged on the coal scraping vehicle; the coal scraping vehicle and the coal scraping vehicle hydraulic driving device are connected; and the lifting track beam is installed on the base frame and is connected with the hydraulic lifter. The automatic coal leveling sampling loading station is flat in coal vehicle, scientific in sampling, accurate in data, efficient and quick, and puts an end to unbalance loading; and coals are flat once the coals are loaded, and the coals can be loaded and unloaded at any time.

Owner:YANGZHOU LANXIANG ELECTROMECHANICAL ENG CO LTD

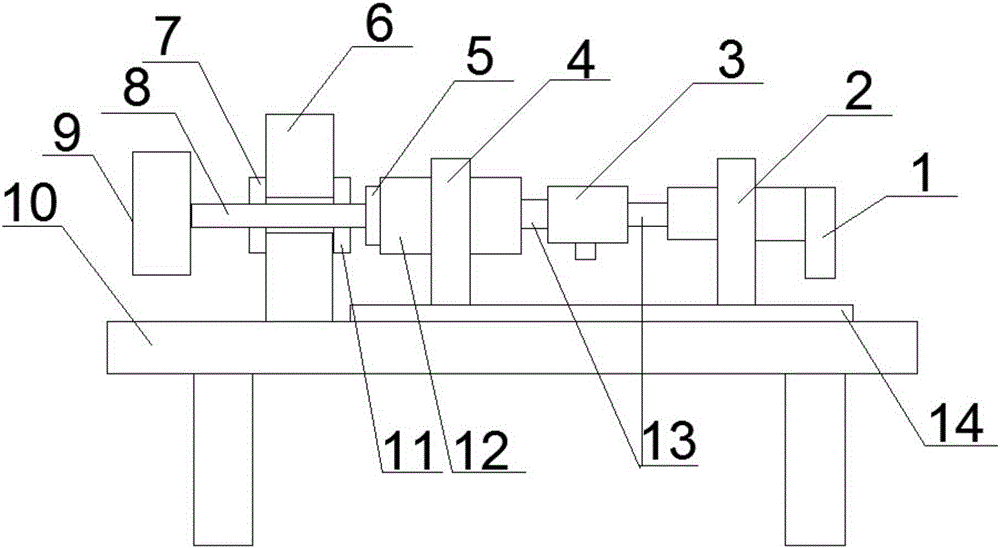

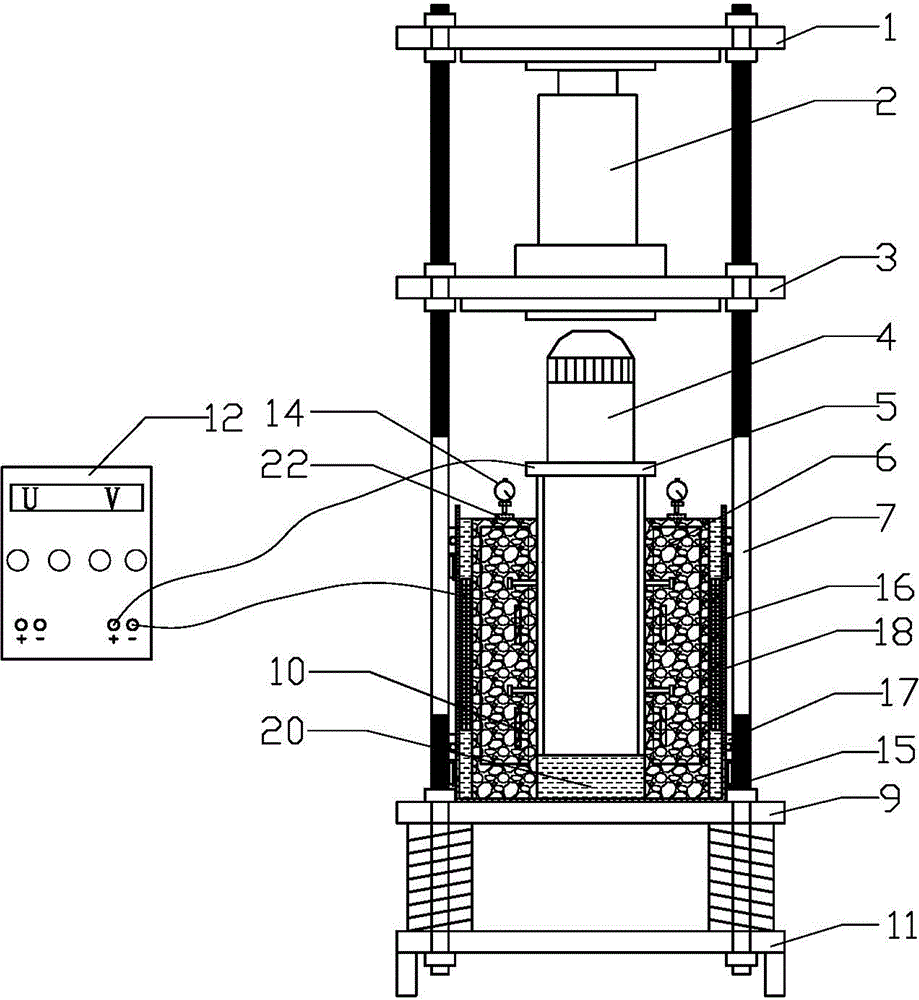

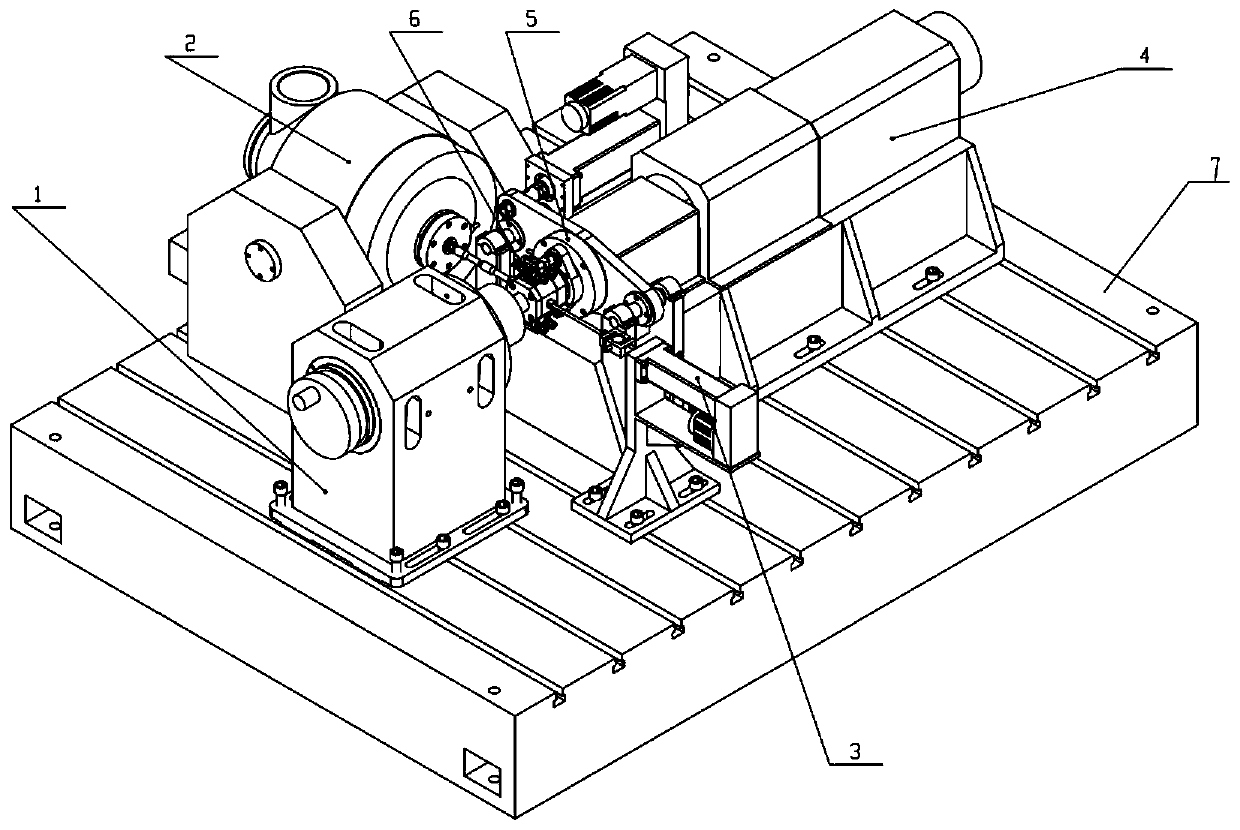

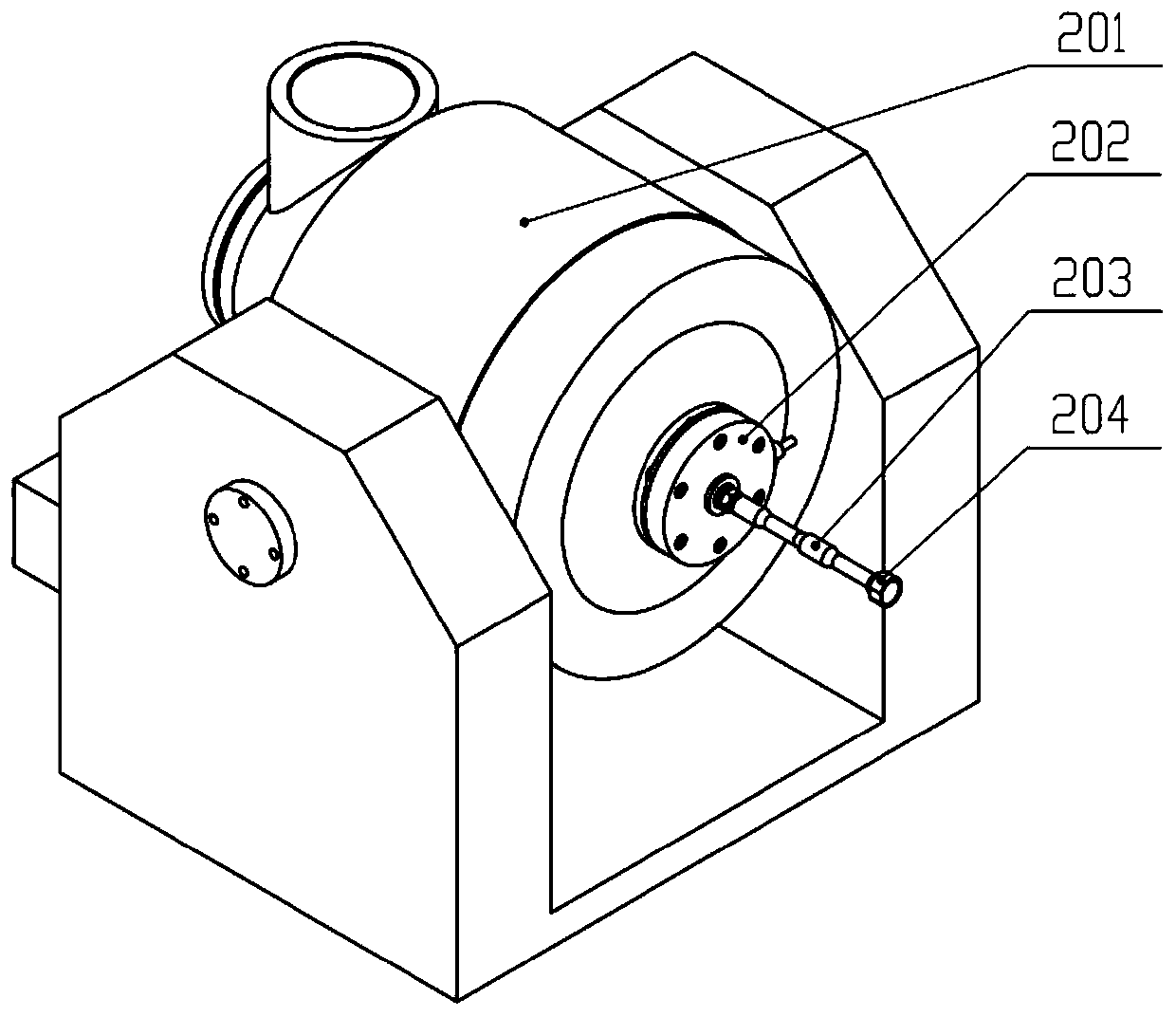

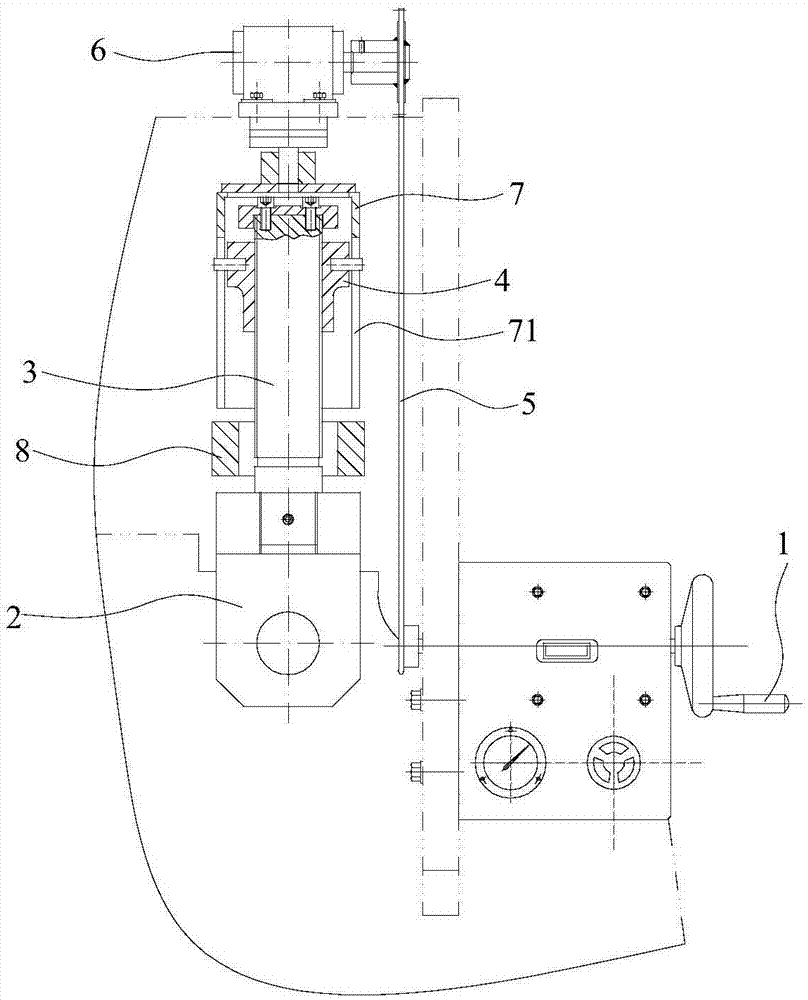

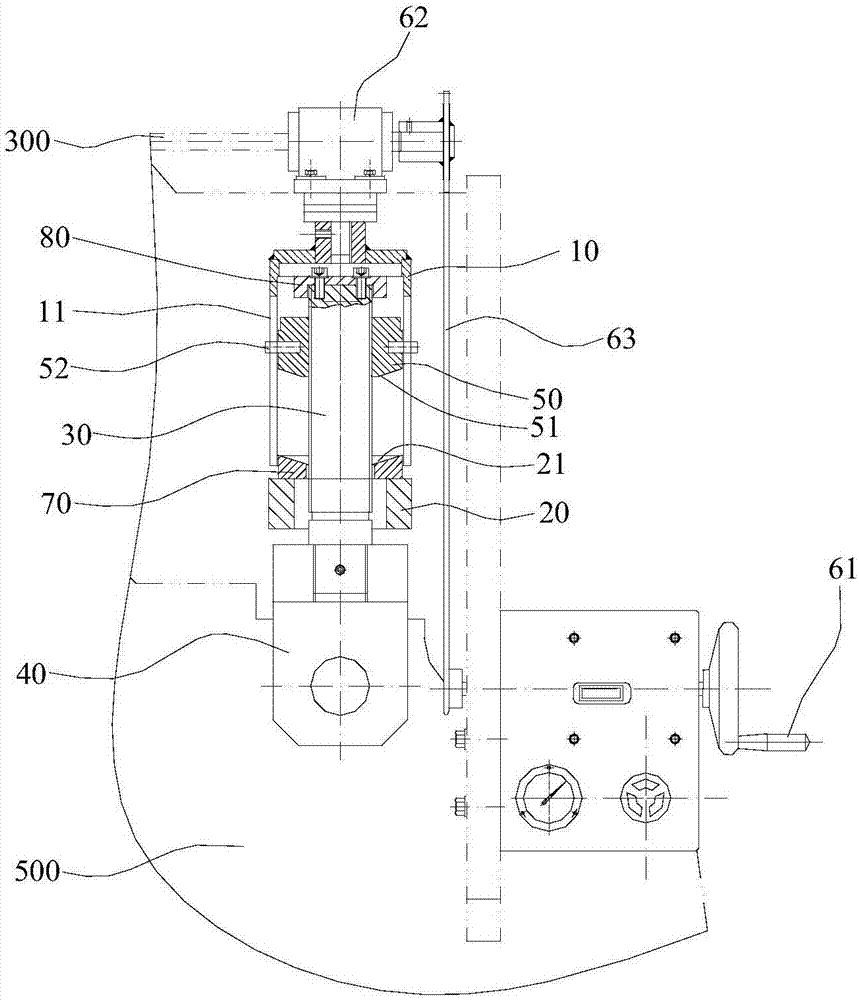

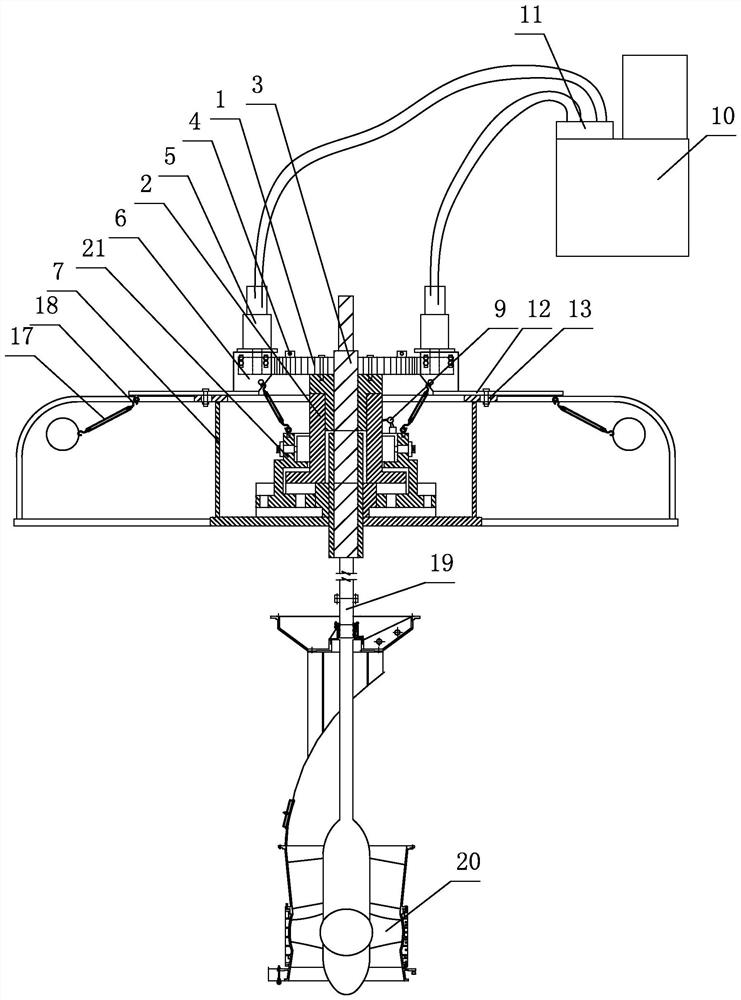

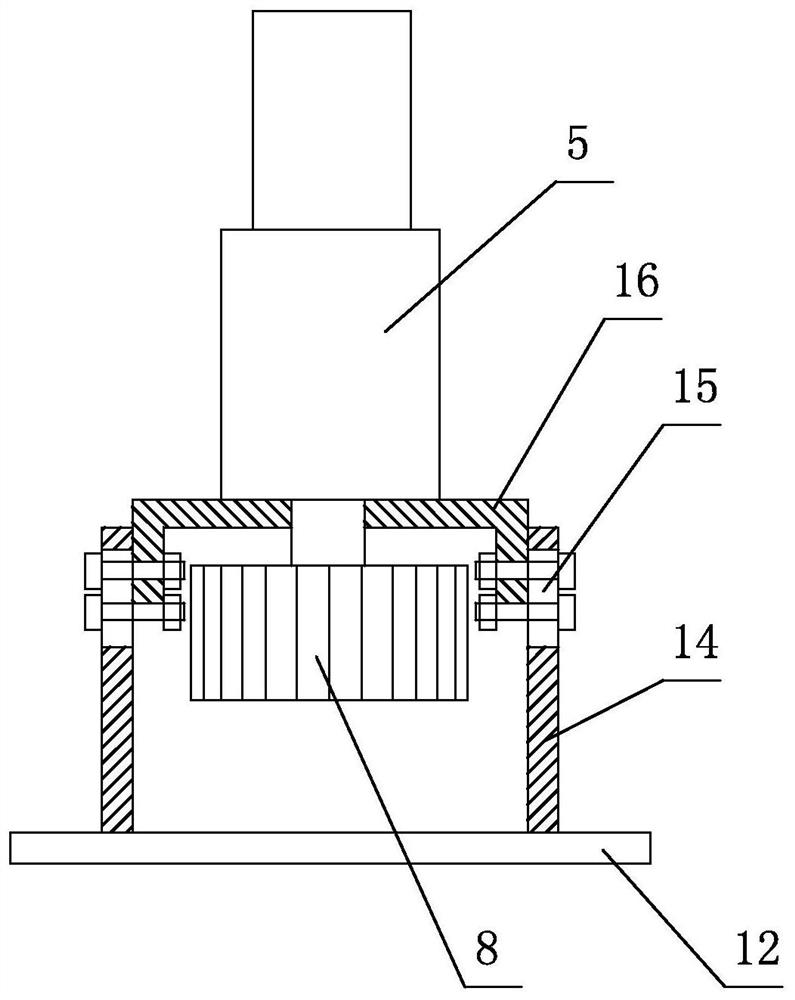

Electric main shaft reliability loading testbed for load comprehensive decoupling

PendingCN110542550AIncrease loading frequencyTwo-way loading implementationMachine part testingElectricityCoupling

The invention belongs to the technical field of the test of mechanical test equipment, and relates to an electric main shaft reliability loading testbed for load comprehensive decoupling. The testbedcomprises an electric main shaft clamping module, a radial force amplitude loading module, a radial force mean loading module, a cutting torque loading module, an axial force loading module and a loading unit module; the electric main shaft clamping module, the radial force amplitude loading module, the radial force mean loading module and the cutting torque loading module are fixed on horizontaliron; one end of a simulated handle in the loading unit module is connected with a bellows coupling in the cutting torque loading module, and the other end is matched with a main shaft conical surfacethrough a simulated real handle conical surface; the axial force loading module are connected with two sides of a front end of a dynamometer base in the cutting torque loading module through bracketsat two ends. The loaded state under a main shaft real working status is simulated by adopting the collaborative loading of an electrodynamics vibration generator and an electric cylinder, the load comprehensive decoupling is realized by adopting the flexible loading structure, and the loading accuracy is improved.

Owner:JILIN UNIV

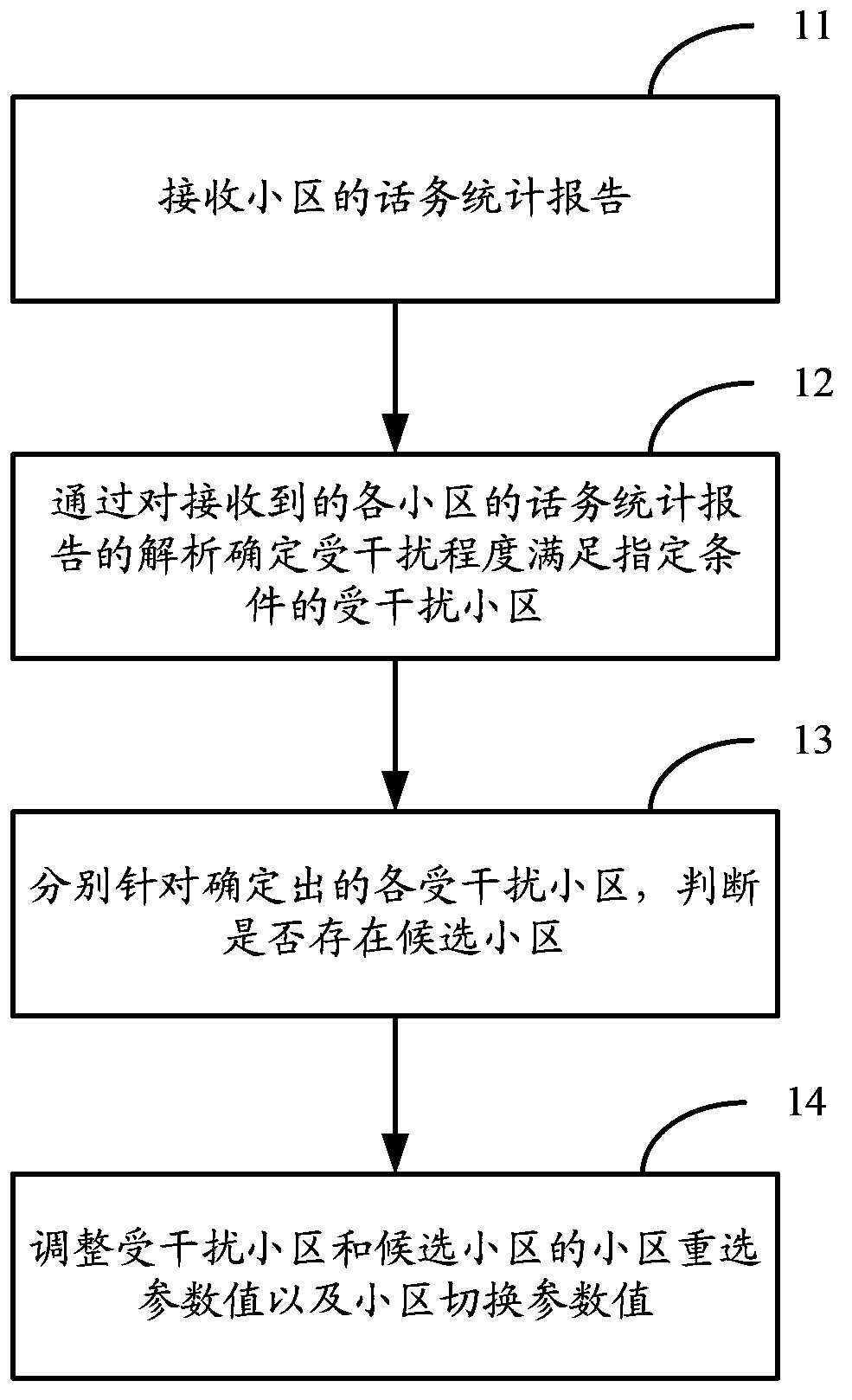

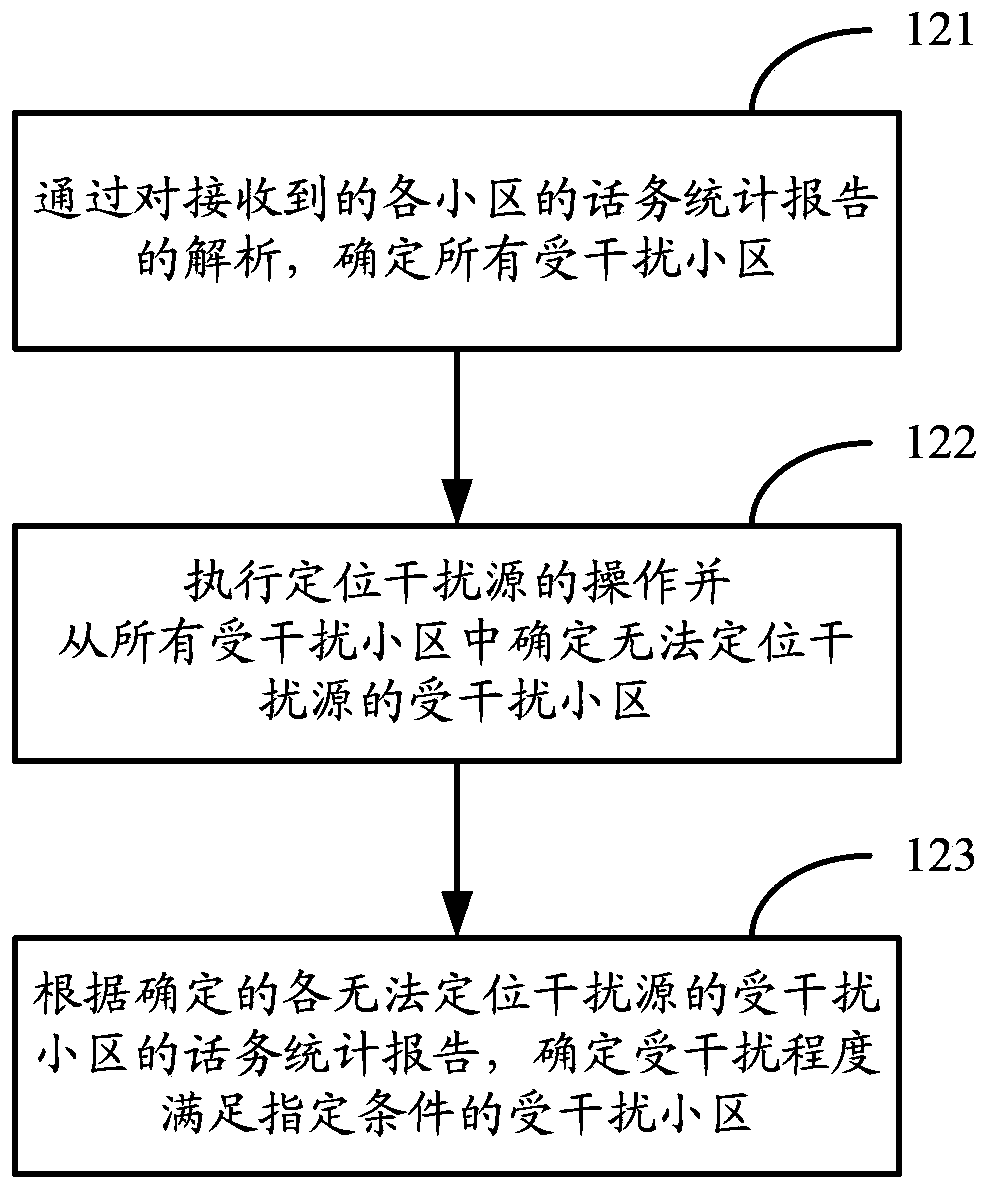

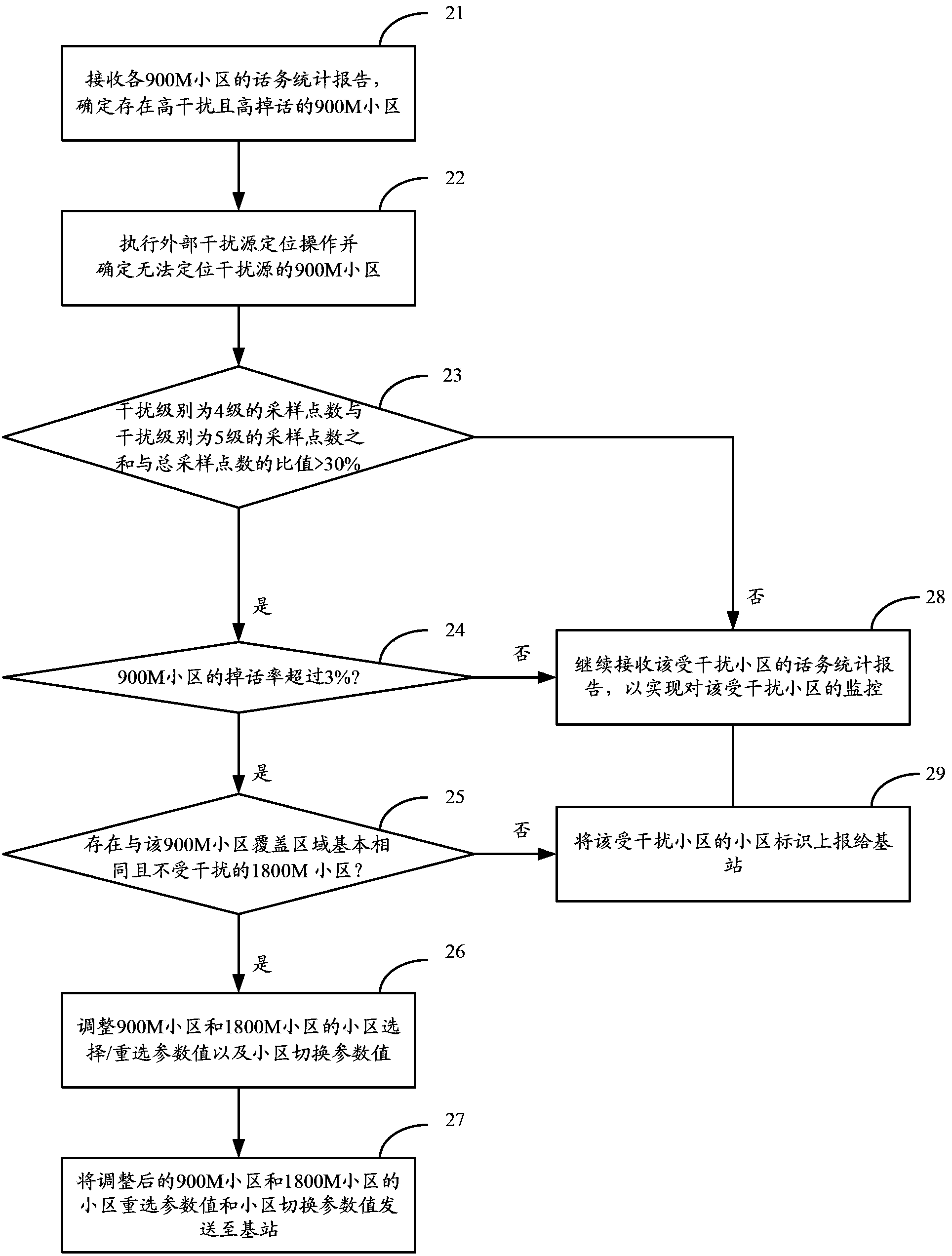

Method and device for handling cell disturbance

ActiveCN103906114AAvoid load capacity dropAvoid unbalanced loadNetwork traffic/resource managementDouble frequencyTraffic load

The invention discloses a method and device for handling cell disturbance. The method and device are used for solving the problems that in the prior art, when cell disturbance under the coverage of a double-frequency network is handled, traffic loads of cells under the coverage of the double-frequency network are unbalanced, and the overall traffic bearing capacity is lowered. The method for handling cell disturbance comprises the steps that by analyzing received traffic statistic reports of all the cells, the disturbed cells with the disturbed degree meeting specified conditions are determined; after undisturbed candidate cells with the same coverage area as the disturbed cells are determined, according to the interference signal level determined for the disturbed cells, reselection parameter values of the disturbed cells and the candidate cells and cell switching parameter values are adjusted respectively so that the disturbed cells can absorb high level traffic with the level higher than the interference signal level and the candidate cells can absorb relatively low level traffic.

Owner:CHINA MOBILE GROUP SHAIHAI

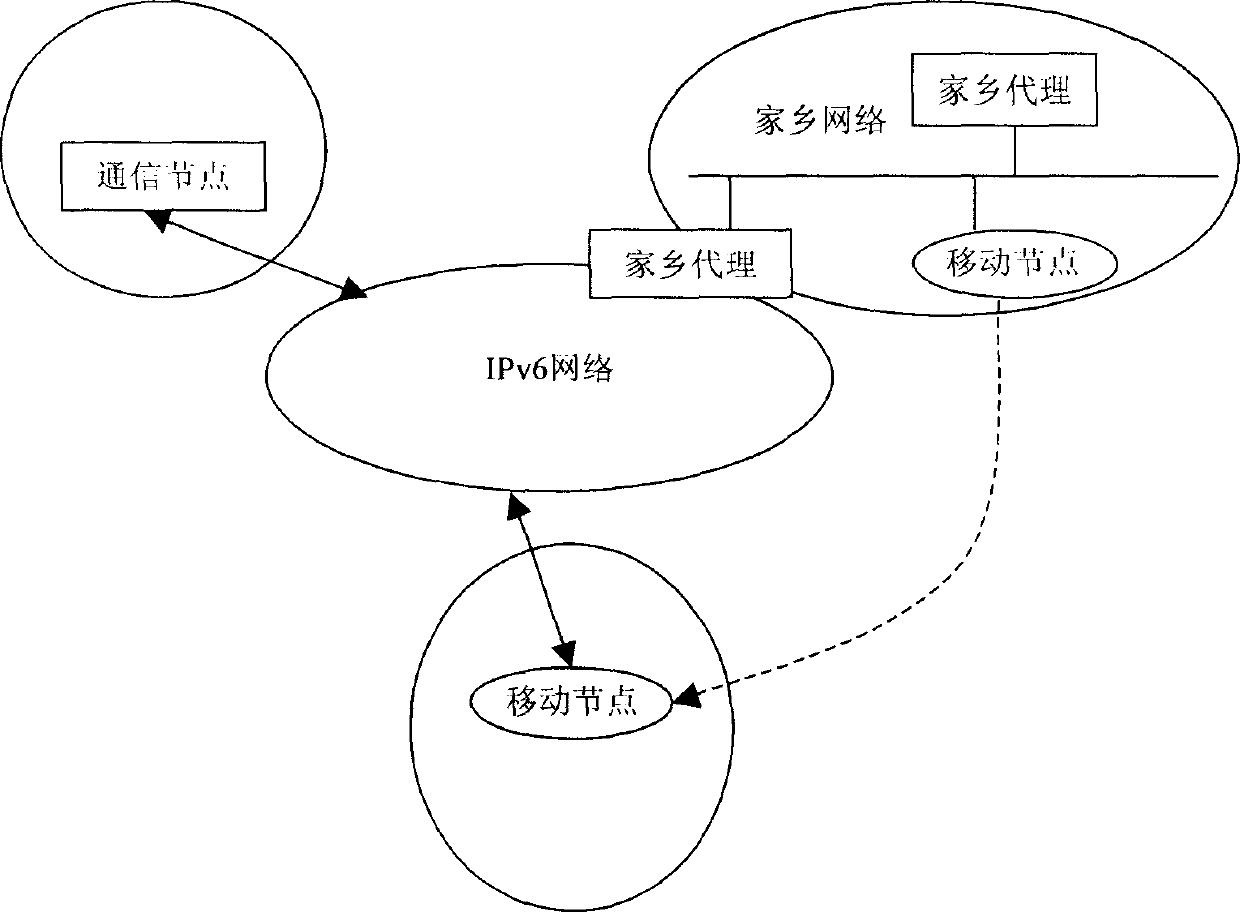

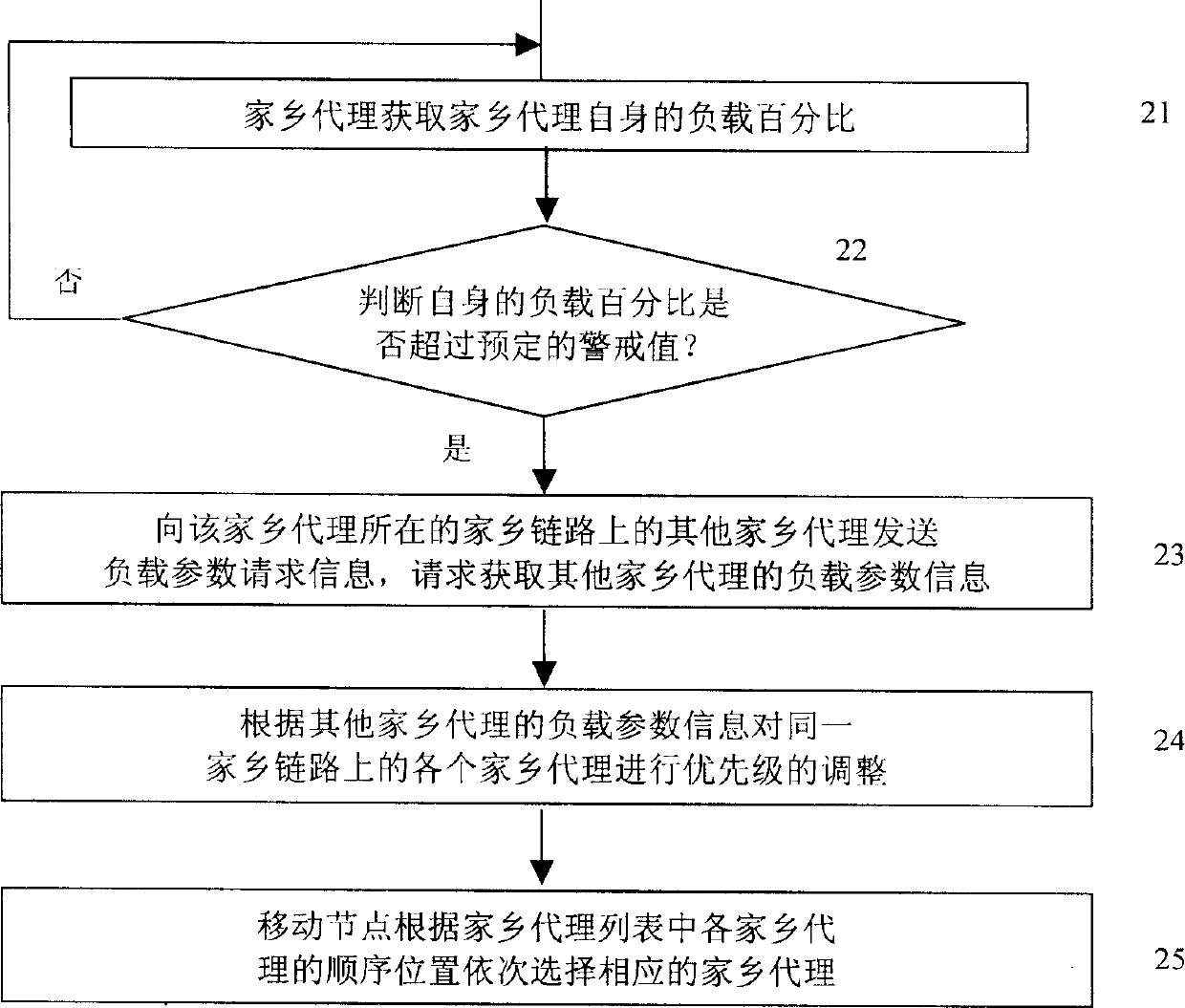

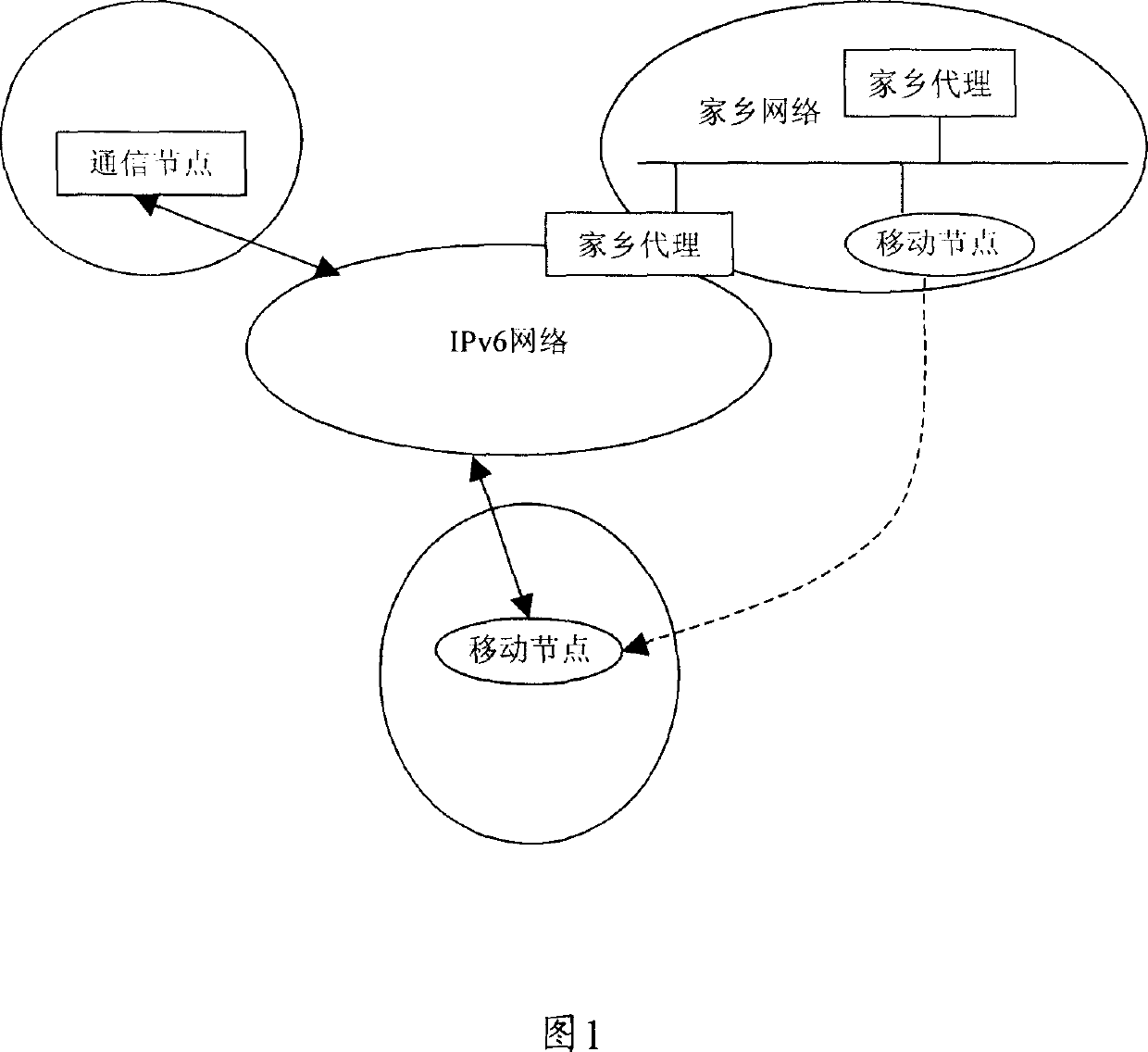

Method for equalizing hometown agent load in mobile network

InactiveCN1816203AAvoid unbalanced loadGood choiceWireless network protocolsRadio/inductive link selection arrangementsCurrent loadMobile Web

Based on current load parameter of home proxy in same link, the method adjusts priority of home proxy dynamically in mobile communication network. Based on adjustment of priority, sequence of home proxy in list of home proxy is changed so as to influence on mobile node to select home proxy. Thus, each home proxy bears a balanced share in load can be realized. The invention effectively prevents issue of unbalanced loads among home proxies from occurring caused by too many mobile nodes to select same home proxy. The invention adjusts loads on each home proxy without need of network manager to carry out fussy operation of configuration and maintenance.

Owner:晋宁宁

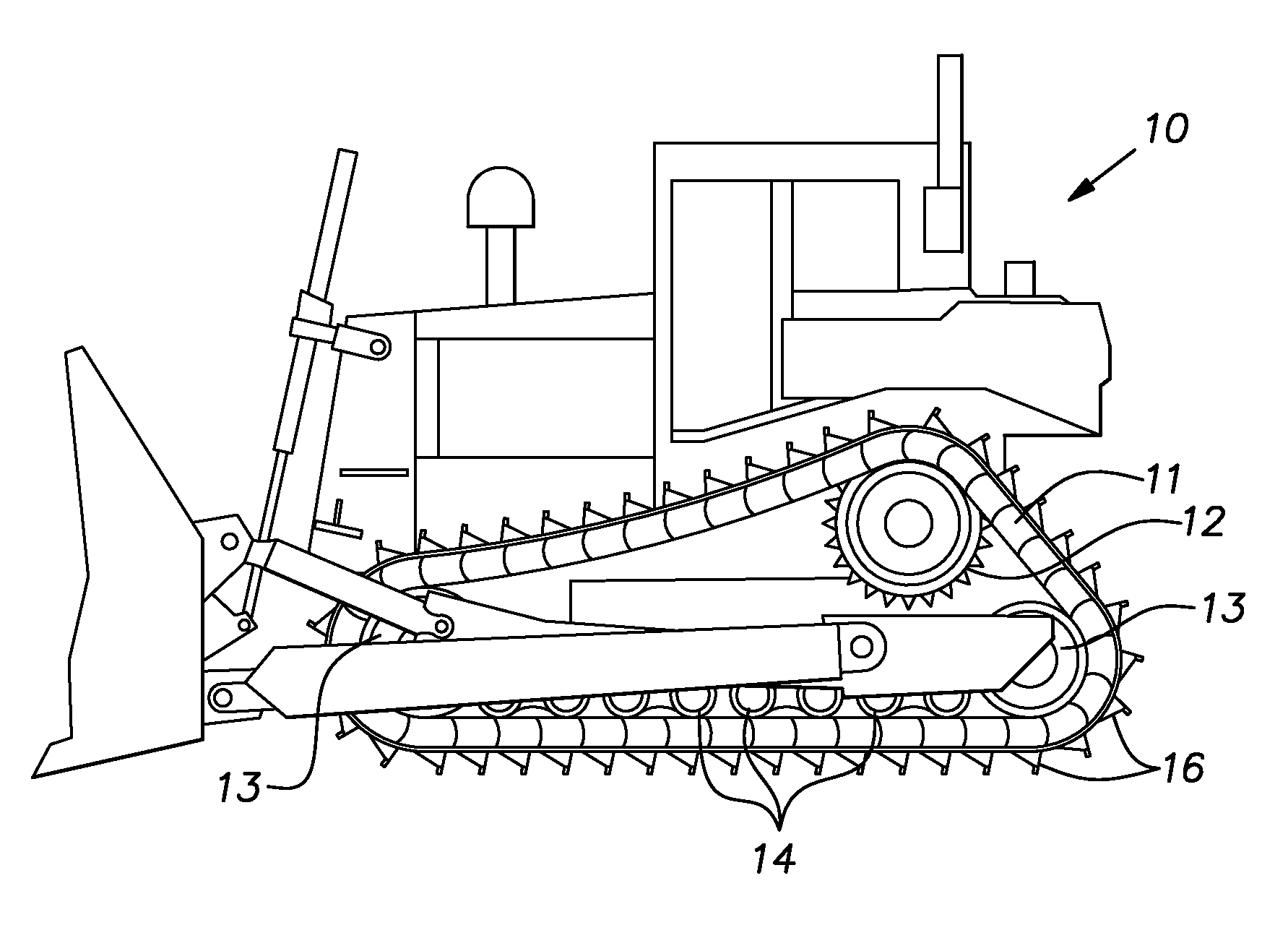

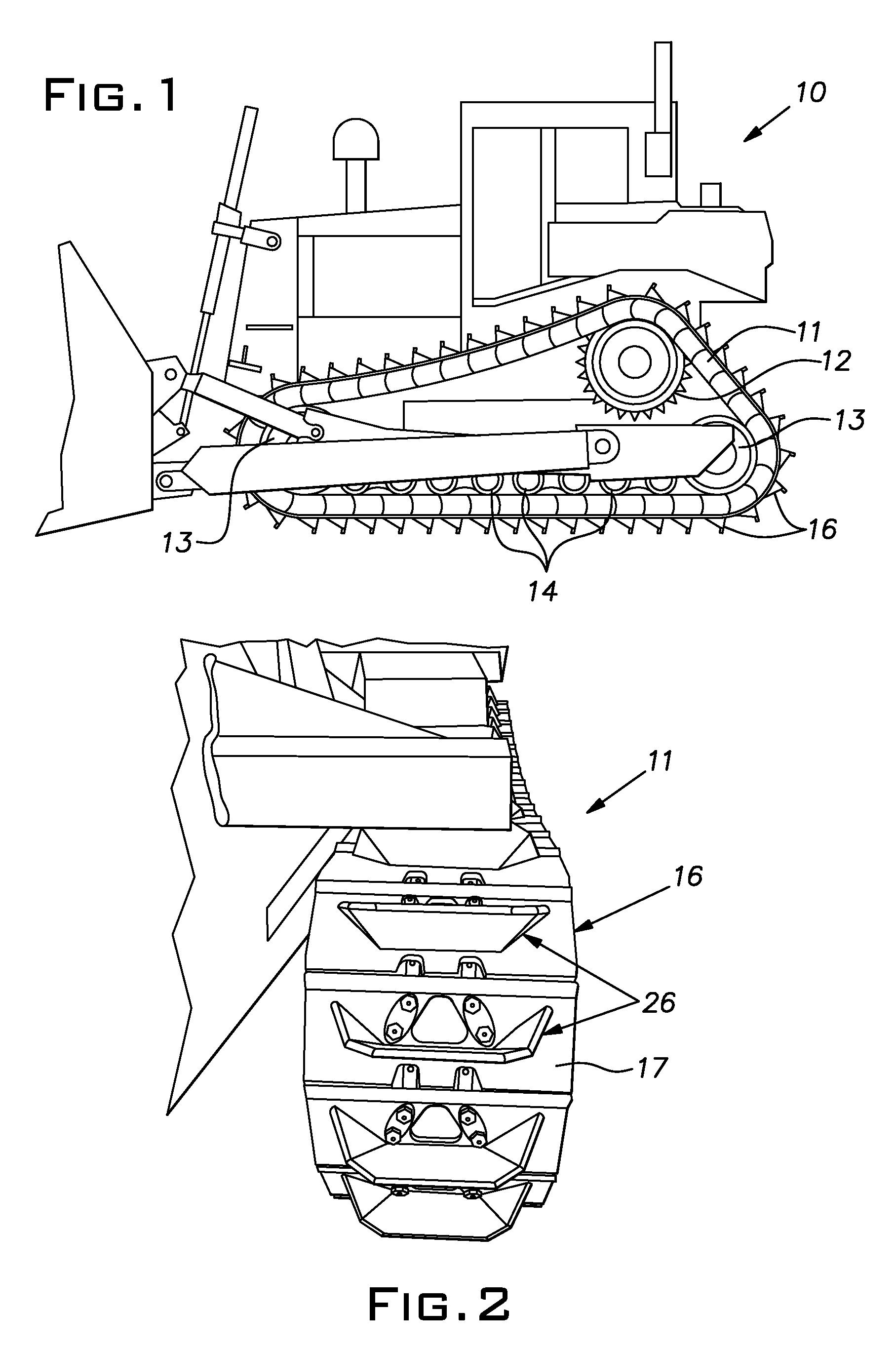

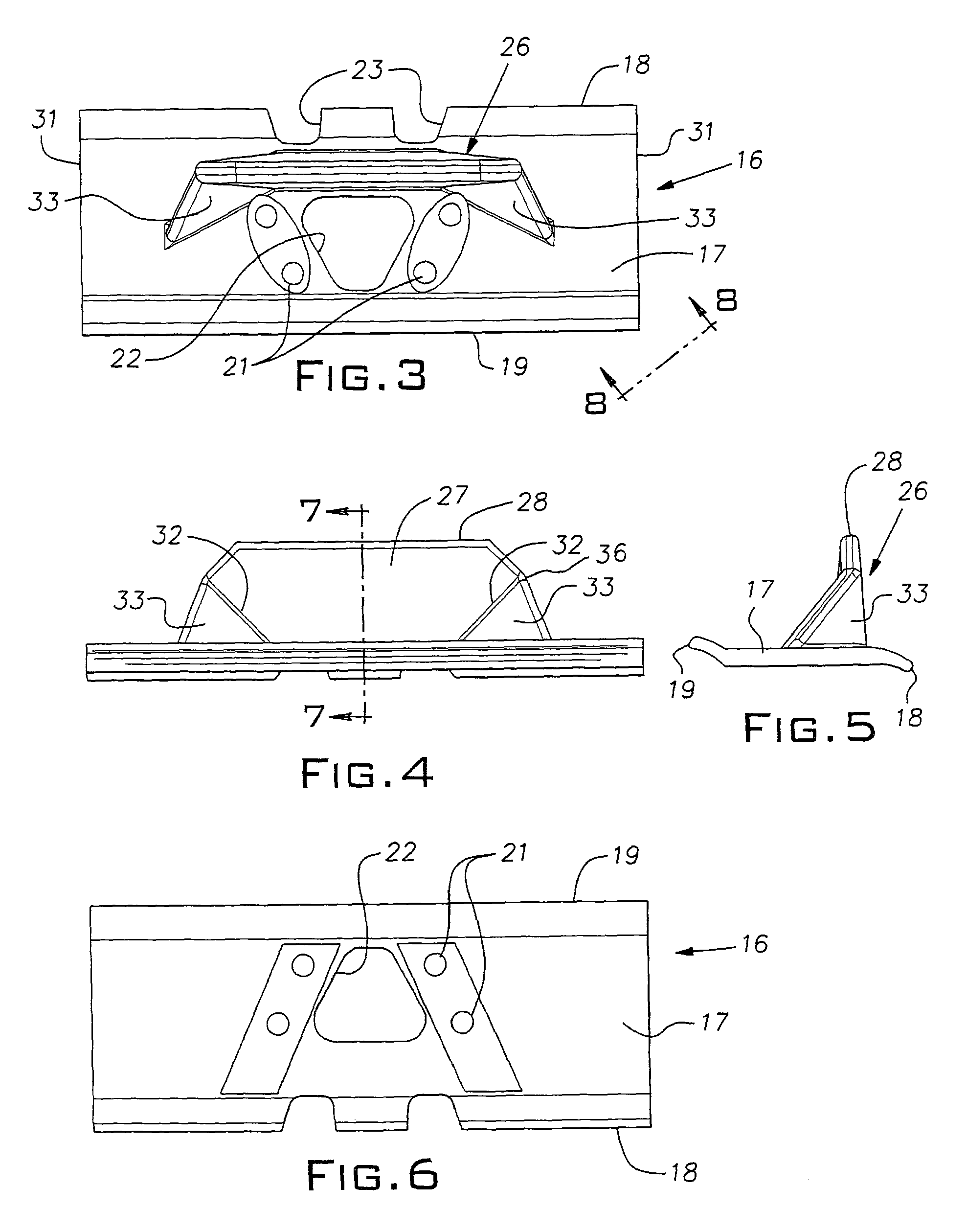

Track pad

ActiveUS9102370B2Reduces and delay destructive build-upImproves traction and compaction and lateral stability and gripEndless track vehiclesHigh riseMechanical engineering

Owner:FREEMAN ERNIE

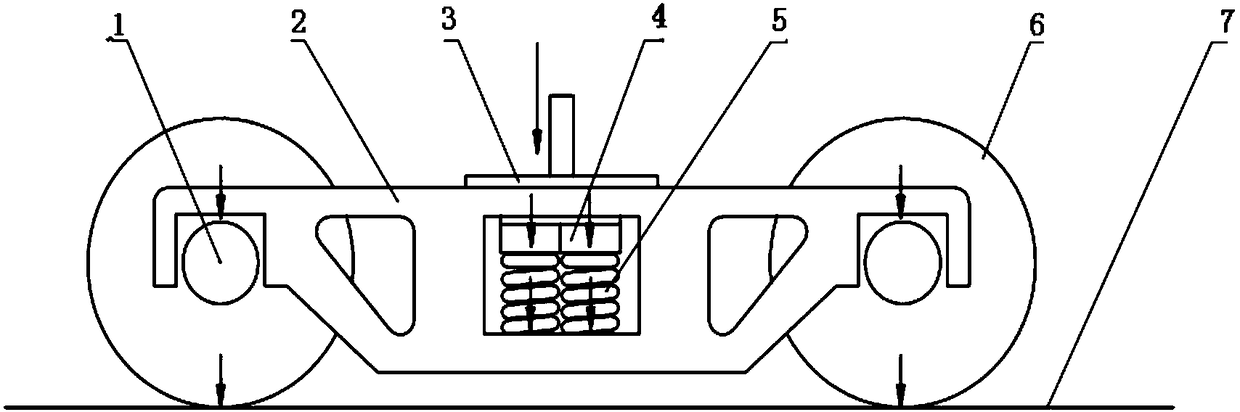

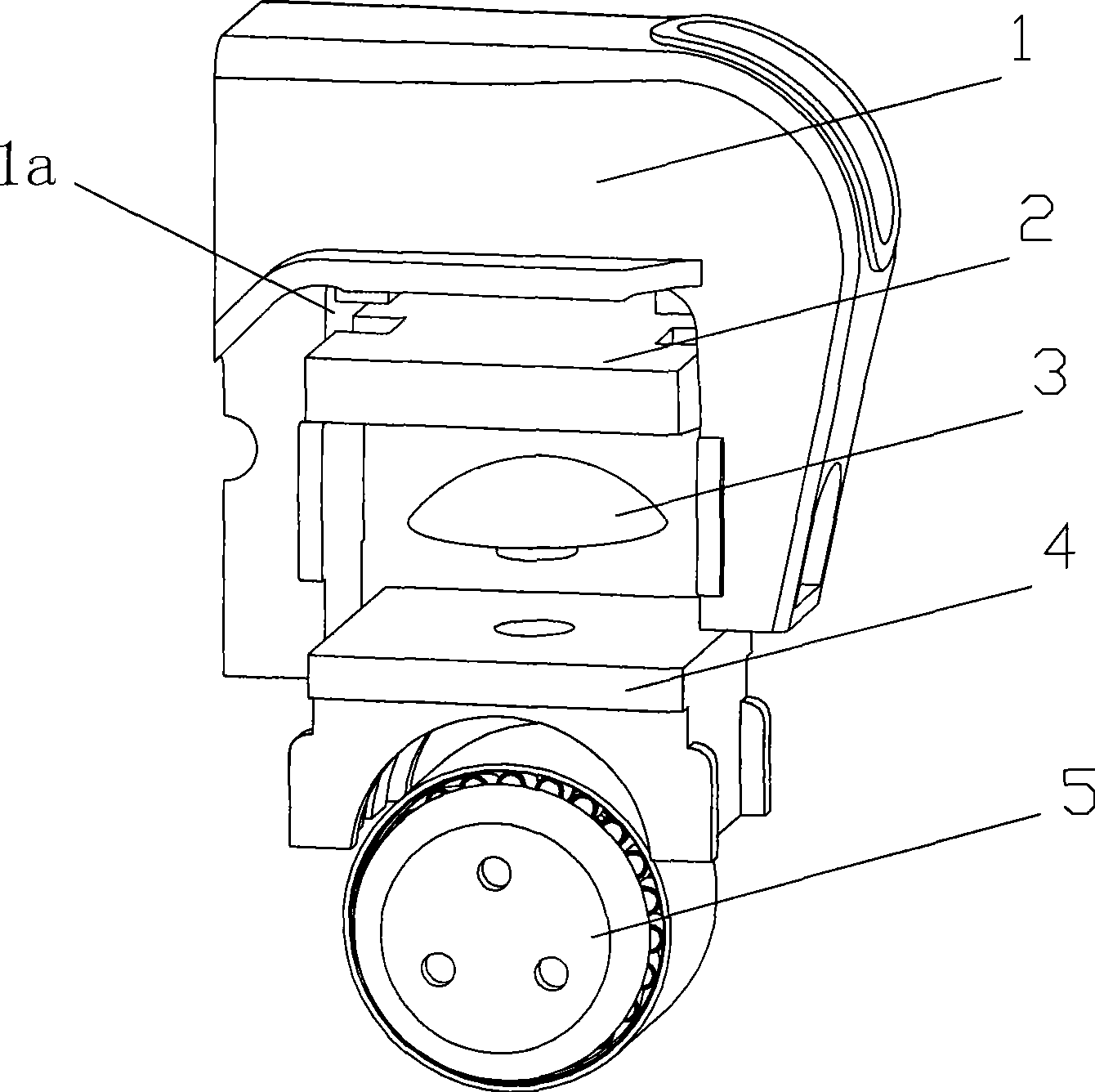

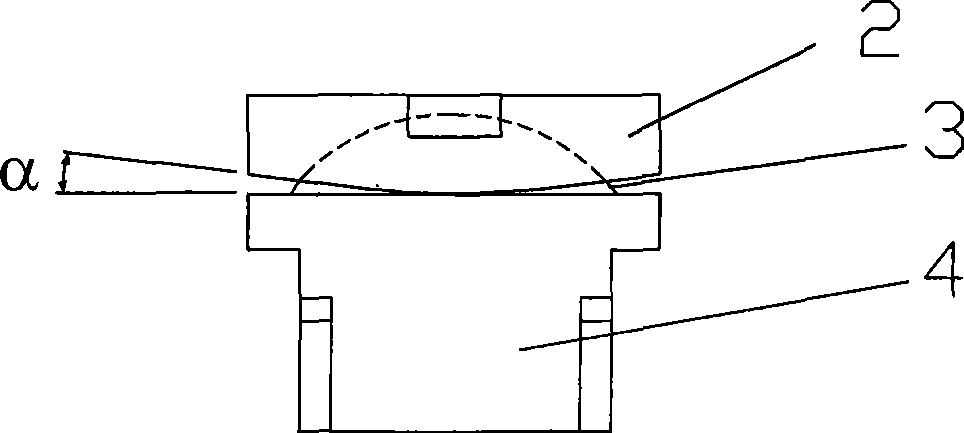

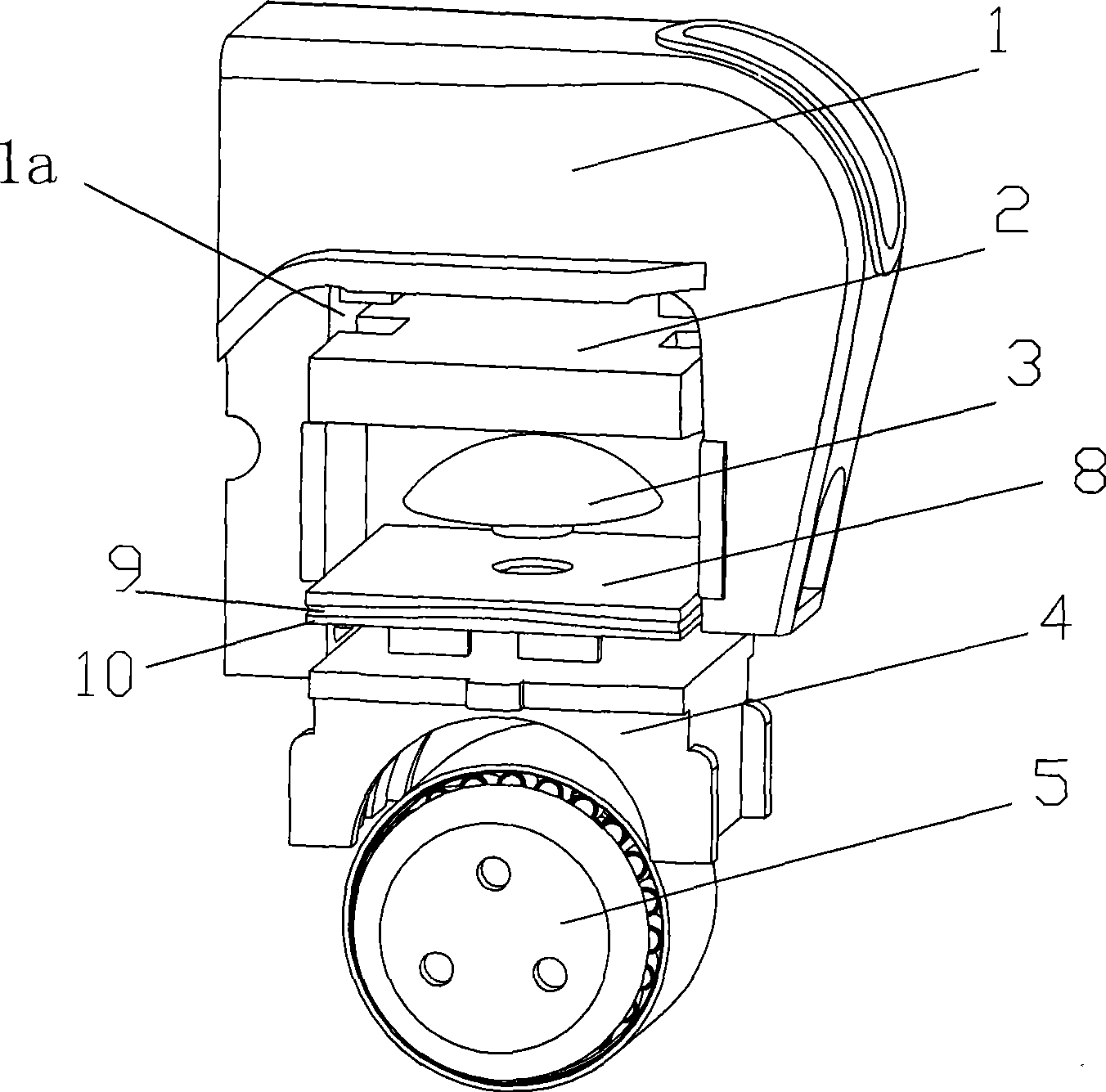

Auxiliary bearing saddle assembly for spherical cap of pendulum goods train

InactiveCN101428628ASmall swing resistanceReduce stuck phenomenonBogie-underframe connectionsEngineeringTruck

The invention discloses a spherical crown pair adapter component used for a pendulum railway freight car, which comprises a shaking seat (2) inside of the guide basket (1a) of a side frame (1) and an adapter (4) under the shaking seat (2), wherein, the lower part of the adapter (4) is matched with the outer ring of a bearing (5). The spherical crown pair adapter component is characterized in that the two ends of the upper surface of the shaking seat (2) are embedded on the two edges at the upper part of the guide basket (1a) of the side frame (1), the lower surface of the shaking seat (2) is a concave spherical surface, the concave spherical surface is matched with a convex spherical crown (3), and the lower part of the convex spherical crown (3) is connected with the adapter (4). The invention has the advantages that surface force transmission is adopted, the crown pair adapter component is free from unbalanced or inclined loadings, the adapter and the convex spherical crown (3) are under even load, the fatigue life is long, the back swing resistance of the side frame is small, and the work is reliable.

Owner:SOUTHWEST JIAOTONG UNIV

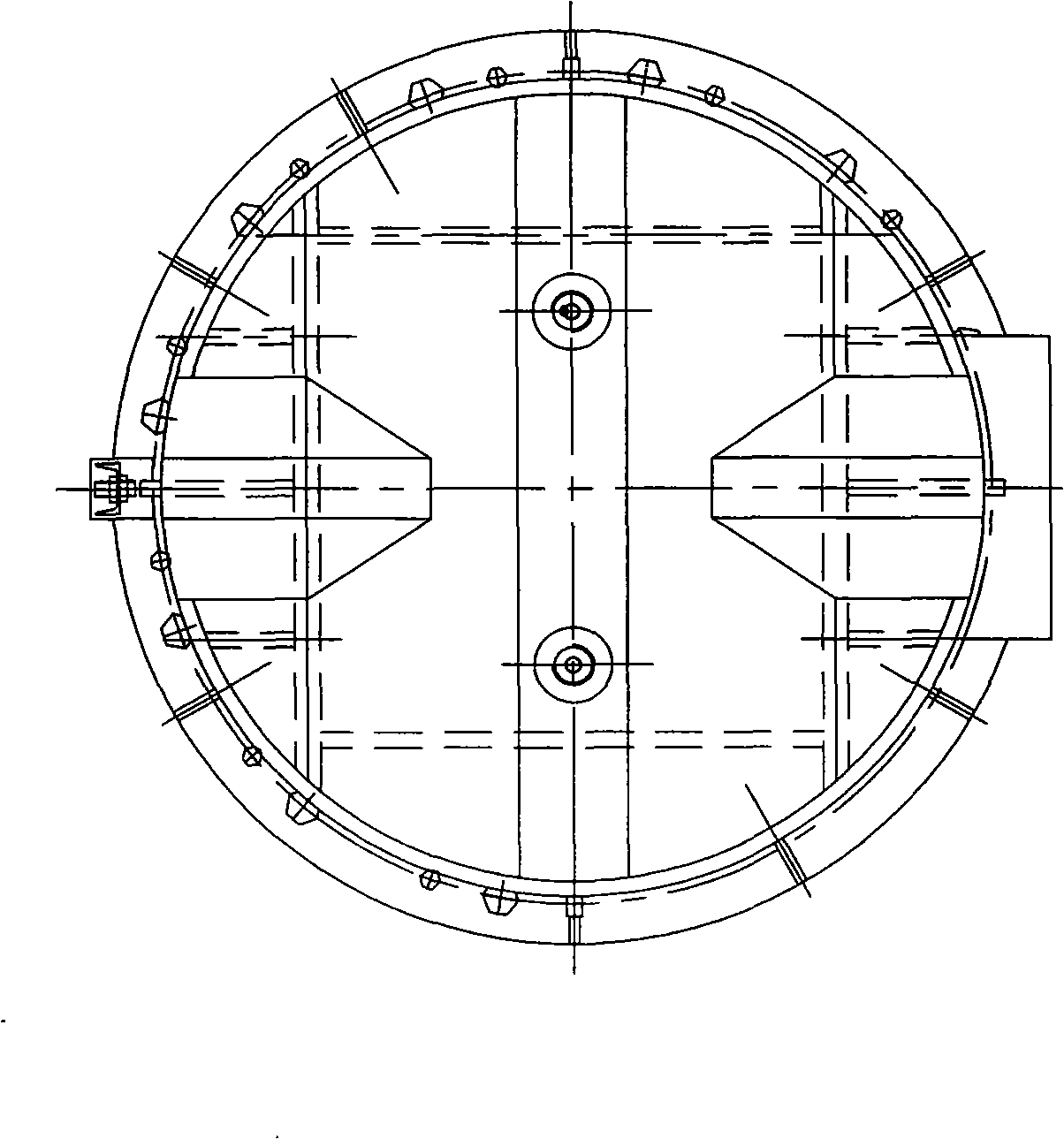

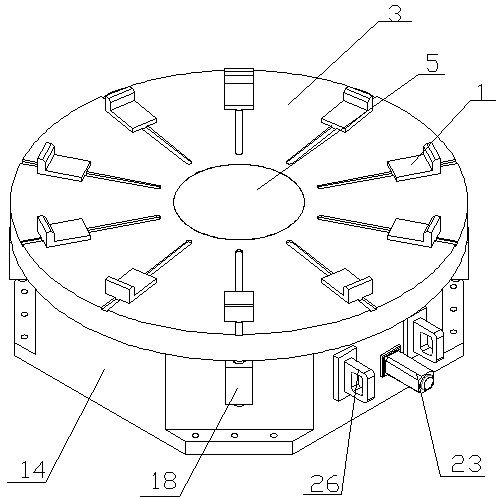

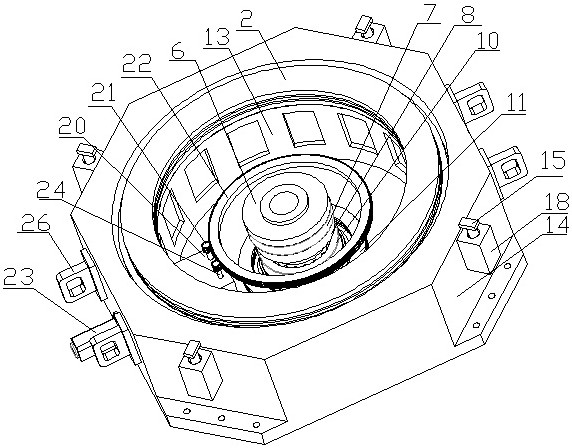

Turntable

PendingCN111922997ALow turning resistanceReduce overturning momentWork benchesMechanical energy handlingSupporting systemRotary stage

The invention relates to a turntable. The center of a rotary table of the turntable is provided with a through hole as a seat hole, a base is connected to the rotary table through a main shaft and a bearing set that are arranged in the seat hole, the main shaft is assembled in the central hole of the base, and the base at the outer side of the main shaft is arranged with a secondary plane thrust bearing; in the end surfaces of both ends of the rotary table, the end surface of one end is a working plane, and the end surface of the other end is supported by the secondary plane thrust bearing; afirst cylindrical step is also provided between the end surfaces of both ends of the rotary table, a main support body is arranged around the secondary plane thrust bearing on the base, a main plane thrust bearing is assembled between the main support body and the first cylindrical step, and three or more speed reduction slots are symmetrically arranged in the center on the big end ring surface ofthe first cylindrical step. A dual-rotary support system of the turntable is strong in loading capability, simple in structure, easy to manufacture and process, transport and install, and is specifically suitable for application under large-diameter fully loaded transportation condition.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

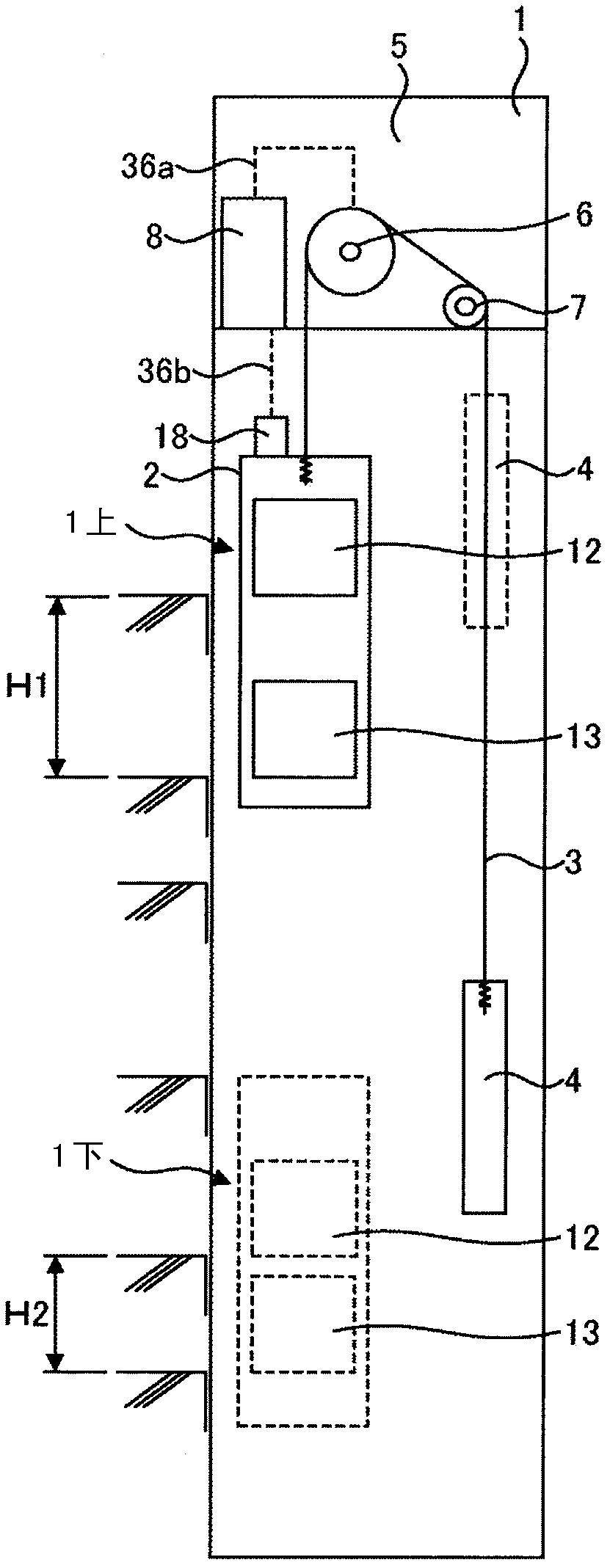

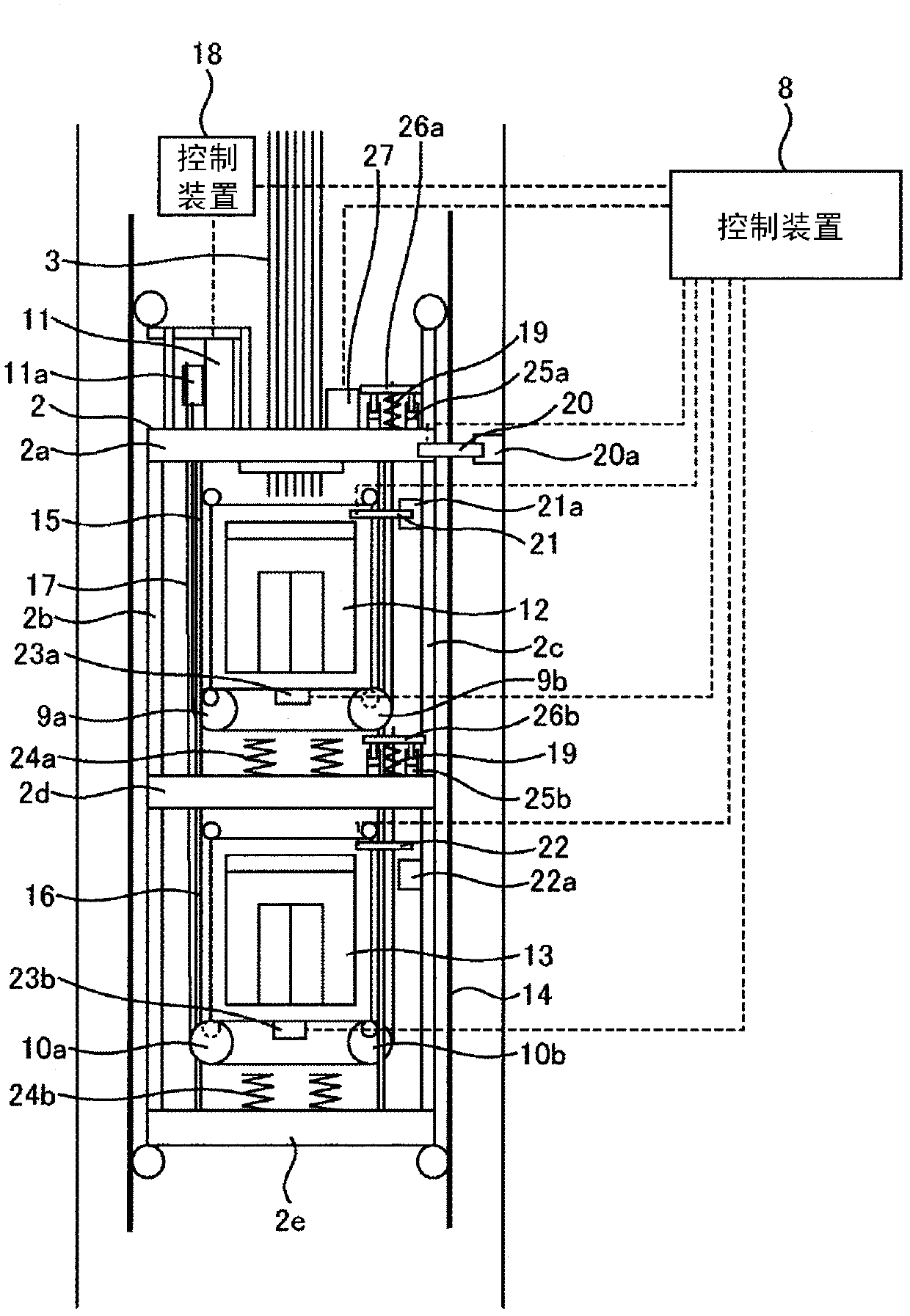

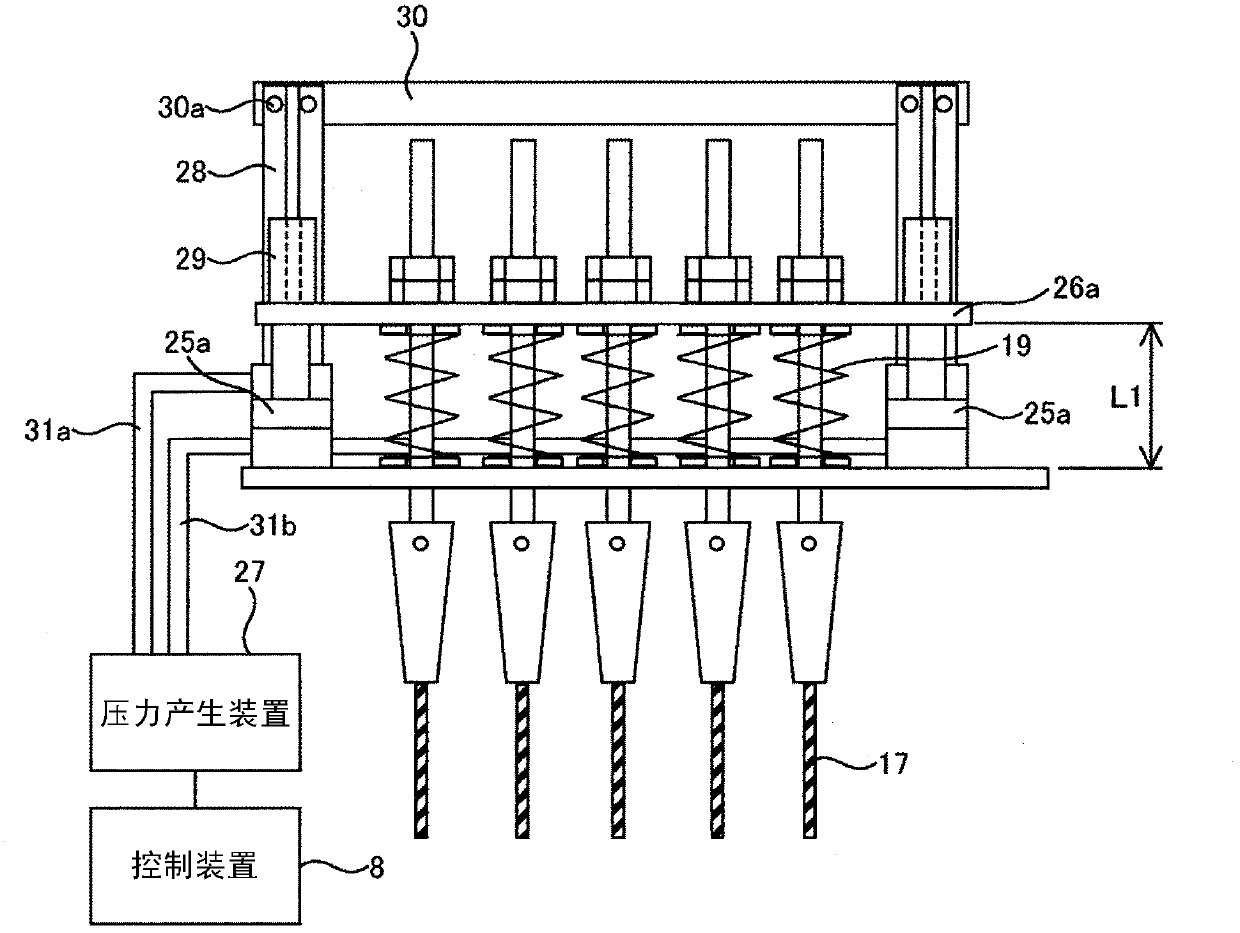

Double-deck elevator

Provided is a double-deck elevator. In the double-deck elevator, elevator cars are arranged in an elevator car frame in the vertical direction and are suspended via end portions of ropes. The double-deck elevator can prevent the occurrence of unbalance loading when fixing members for fixing the end portions of the ropes are moved. The double-deck elevator comprises an elevator car frame (2), an upper car (12), a lower car (13), a driving device (11) for adjusting the car position and a rope-shaped body (17). In the double-deck elevator, one end or two ends of the rope-shaped body (17) are suspended down from the fixing members (26a, 26b) and are mounted on the elevator car frame (2) via fixing member moving units (25a, 25b) which allow movement of the fixing members (26a, 26b). In addition, the double-deck elevator has guide mechanisms (28, 29). When the fixing members (26a, 26b) are driven to move by the fixing member moving units (25a, 25b), the guide mechanisms (28, 29) guide the movement of the fixing members.

Owner:HITACHI LTD

Pressure heavy load sensor of concrete filled steel tube

InactiveCN104155050ASimple structureEasy to processFluid pressure measurement using ohmic-resistance variationElectrical resistance and conductanceEngineering

Disclosed is a one-dimensional heavy load sensor which is high in accuracy, high in rigidity, large in load and low in cost. The concrete filled steel tube structure is adopted as a bearing body, the outer portion of the concrete filled steel tube structure is of a cylindrical structure, two sets of resistance strain sheets are arranged in the bearing body, the first set comprises four resistance strain sheets vertically and evenly distributed on the contact surface of concrete and the steel tube, the other set comprises one resistance strain sheet which is arranged in the center of the concrete filled steel tube, the two ends of the resistance strain sheets are connected with wires, and the wires on the resistance strain sheets are connected to external equipment through through holes in the wall and the bottom end of the sensor. The concrete filled steel tube is adopted as the bearing body, the load bearing capacity is largely increased, and the size of the bearing body can be largely reduced. The sensor is provided with the two sets of resistance strain sheets which are five in number, so that the sensitivity and accuracy of the sensor are improved. The pressure heavy load sensor of the concrete filled steel tube has the advantages of being simple in structure, convenient to machine, reliable in performance, good in load bearing capacity, high in measurement accuracy, small in size, high in rigidity, stable in performance and the like.

Owner:UNIV OF JINAN

Feed depth adjustment mechanism of bending machine and bending machine

The invention discloses a feed depth adjustment mechanism of a bending machine and the bending machine. The feed depth adjustment mechanism of the bending machine comprises a rotary cover, a stop block, a screw, an adjustment nut and a driving assembly. The rotary cover is provided with a sealed end and an open end. The stop block is fixed to a machine frame of the bending machine. One end of the screw is inserted into the rotary cover, and the other end of the screw extends out of the rotary cover through the opening end of the rotary cover. The screw penetrates through the stop block to be connected with a sliding block of the bending machine. The adjustment nut is mounted in the rotary cover and connected with the screw in a threaded mode. The rotary cover can drive the adjustment nut to rotate around the screw and enables the adjustment nut to move up and down along the screw. The driving assembly is connected with the sealed end of the rotary cover. A limiting convex part is arranged at the end, close to the stop block, of the adjustment nut. A limiting groove matched with the limiting convex part in size is formed in the end, close to the adjustment nut, of the stop block. Compared with the prior art, by adoption of the feed depth adjustment mechanism, unbalance loading between the adjustment nut and the stop block can be avoided, and the situation that the service life of the screw is affected due to the fact that non-axial force is borne by the screw is avoided.

Owner:GUANGZHOU SHIPYARD INTERNATIONAL LTD

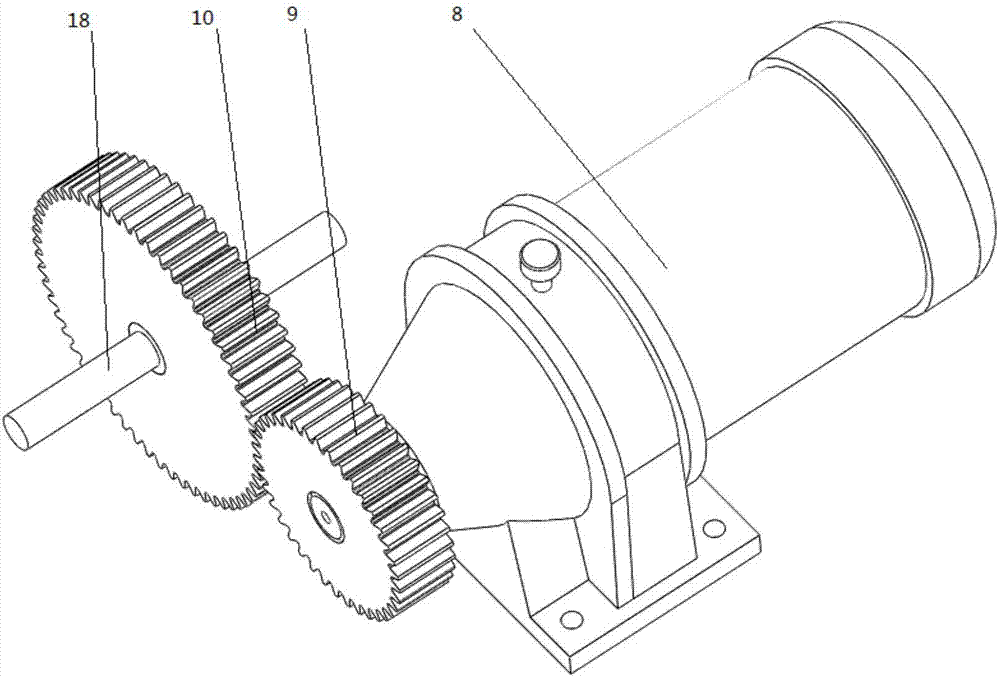

Hydraulic turning overhauling device and method for large vertical axial-flow pump unit

PendingCN111810434AForce balanceEven by forcePump componentsElectric/magnetic position measurementsHydraulic motorAxial-flow pump

The invention discloses a hydraulic turning overhauling device and method for a large vertical axial-flow pump unit. The device comprises a gear disk, two hydraulic motors and a detecting instrument;the gear disk is mounted on a thrust bearing through bolts; a motor spindle penetrates through the center of the gear disk; lifting rings are arranged on the upper surface of the gear disk; the two hydraulic motors are arranged symmetrically with the motor spindle used as the center; the two hydraulic motors work synchronously; the hydraulic motors are mounted on a motor casing through adjustablesupporting seats; the adjustable supporting seats are used for adjusting the horizontal positions, the vertical positions and the inclination angles of the hydraulic motors; pinions driven by the hydraulic motors are in meshing connection with the gear disk; and the detecting instrument is used for detecting the motor spindle or a pump shaft. The power is sufficient, the stress balance of the geardisk can be guaranteed, the horizontal positions, the vertical positions and the inclination angles of the hydraulic motors are adjusted through the adjustable supporting seats, the meshing precisionof the pinions and the gear disk is guaranteed, and safe and stable operation of a water pump is guaranteed.

Owner:南水北调东线山东干线有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com