Patents

Literature

113results about How to "Reduce stuck phenomenon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

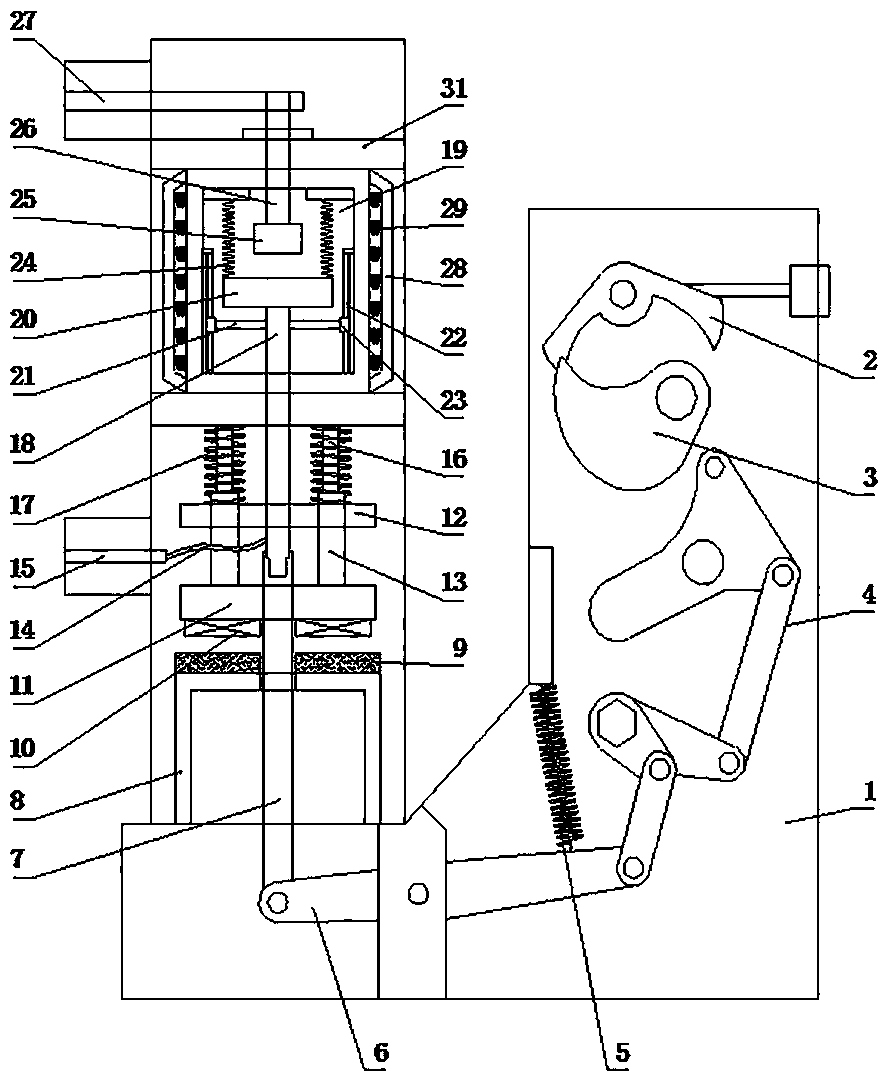

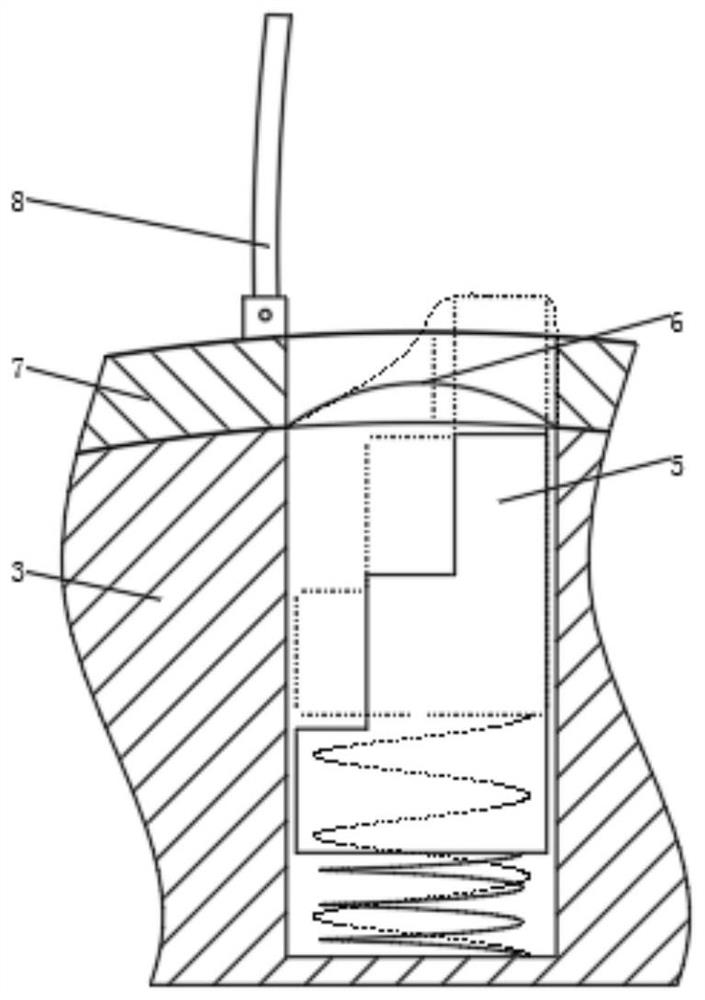

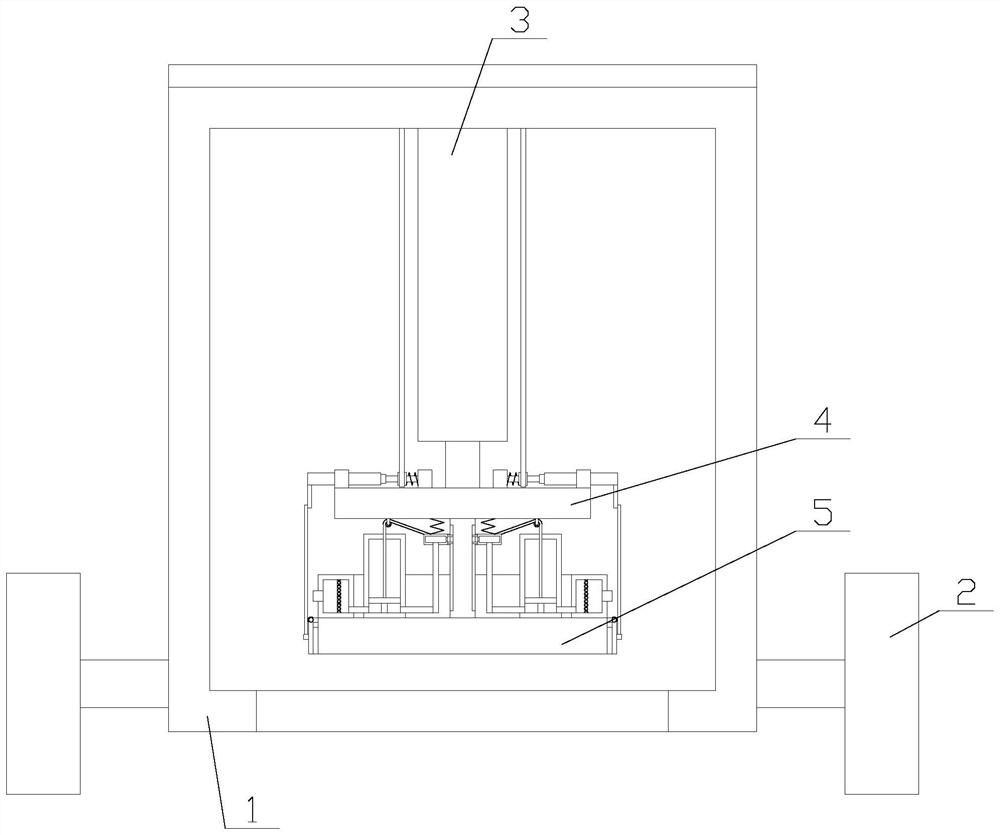

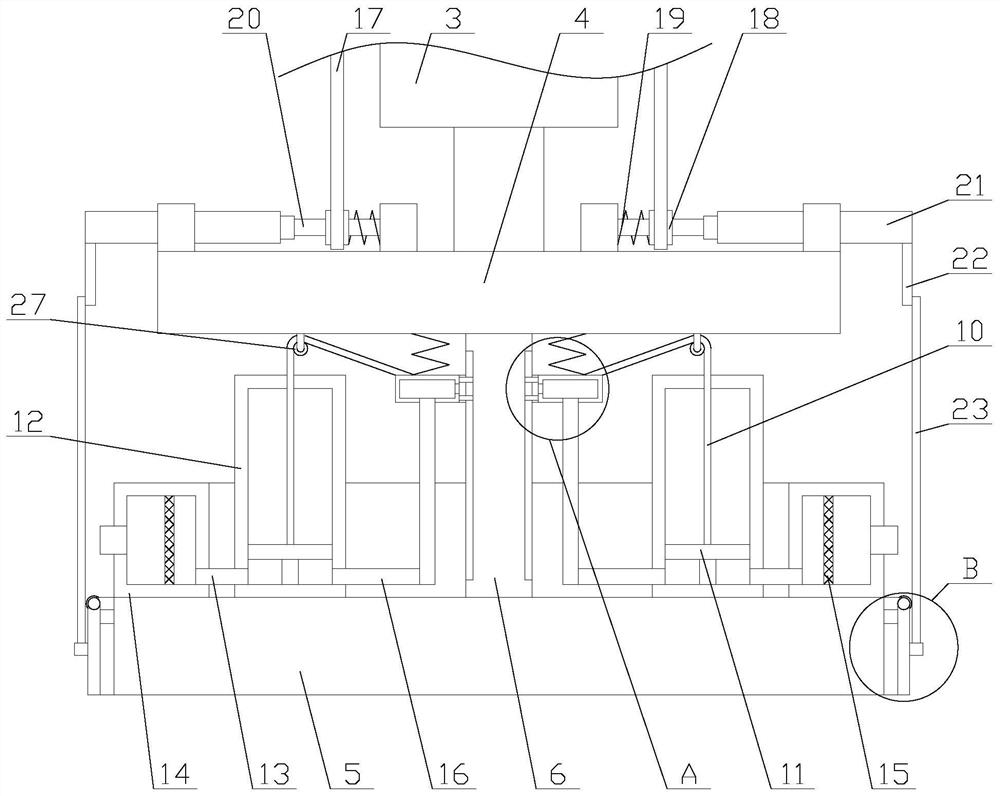

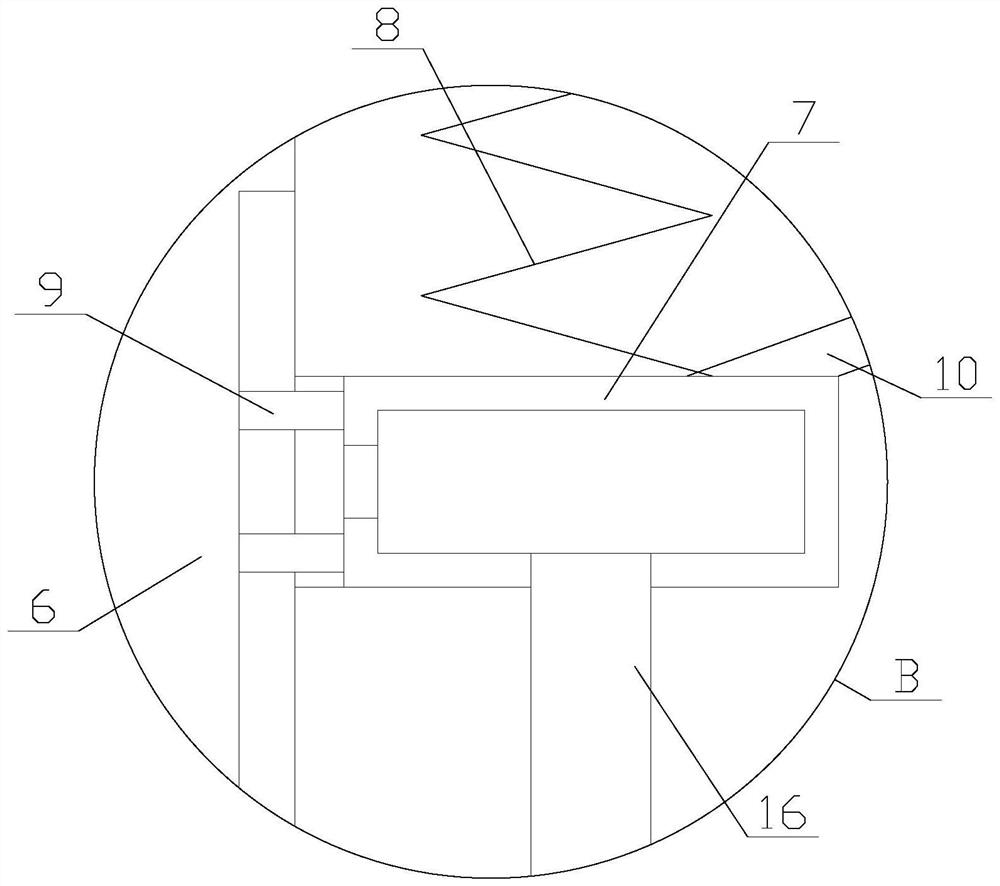

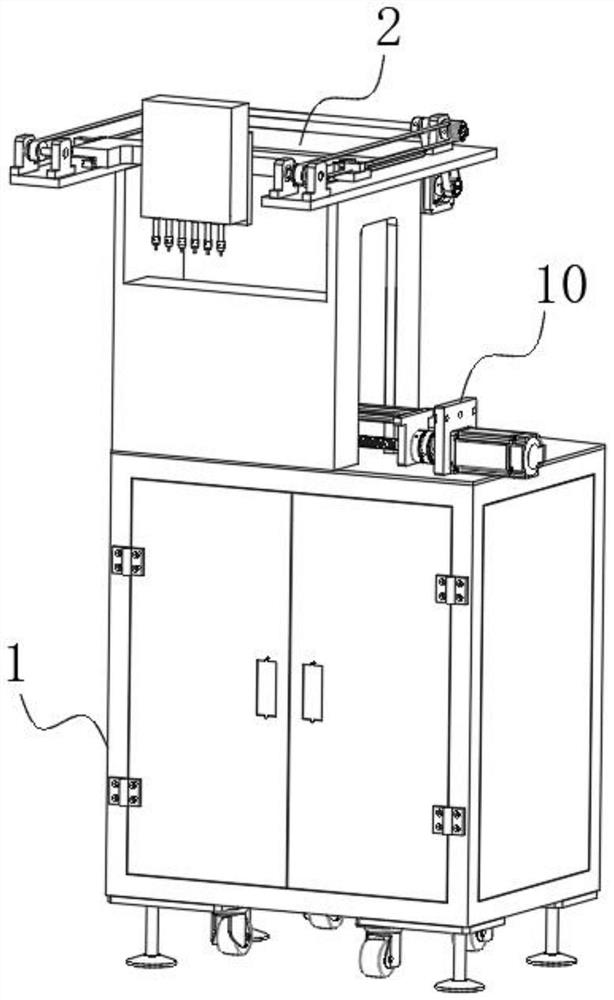

Vacuum direct-current fast circuit breaker

ActiveCN108428587ASafe and reliable workExtended service lifeHigh-tension/heavy-dress switchesAir-break switchesEngineeringVacuum arc

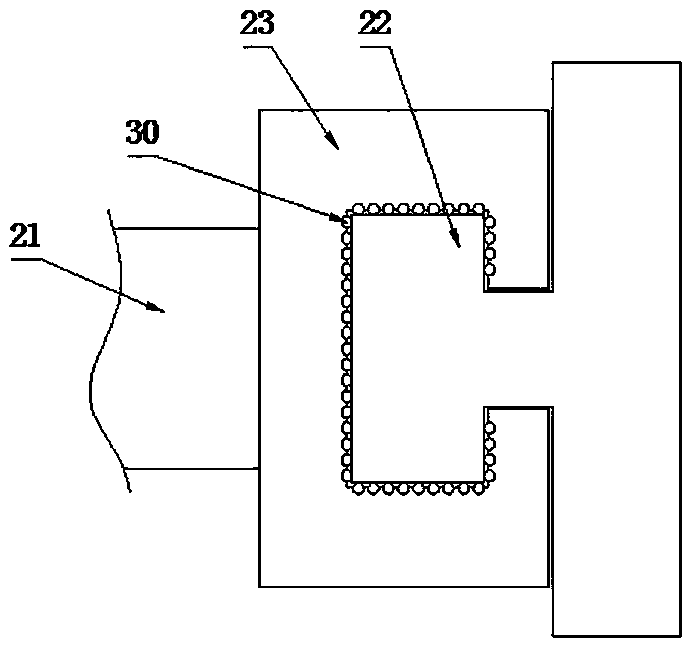

The invention discloses a vacuum direct-current fast circuit breaker which comprises a spring action mechanism box, an insulation pull rod, a permanent magnet, an electromagnet, a lower outgoing lineterminal, a vacuum arc-extinguishing chamber and an upper outgoing line terminal, the end, away from a transmission device, of a dual-arm pull rod is movably connected with the insulation pull rod, abreaking spring is fixedly connected to the end, close to the transmission device, of the dual-arm pull rod, the insulation pull rod penetrates through a fixing piece and a lower pressing plate to befixedly connected with a movable conductive rod, a plurality of contact springs are symmetrically arranged on the upper side of the upper pressing plate, the upper end of the movable conductive rod penetrates into the vacuum arc-extinguishing chamber and is fixedly connected with a moving contact, transverse rods are symmetrically arranged at the two sides of the upper end of the movable conductive rod, the tail ends of the transverse rods are each fixedly provided with a sliding block, the sliding blocks are slidably installed on guiding sliding rails, the guiding sliding rails are fixedly arranged on the two sides on the inner wall of the vacuum arc-extinguishing chamber, and a fixed contact is arranged above the middle of the moving contact; according to the vacuum direct-current fast circuit breaker, by arranging the transverse rods, the sliding blocks and the guiding sliding rails, the guiding effect on movement of the movable conductive rod is achieved, and the phenomenon of clamping of the movable conductive rod is reduced.

Owner:湖南斯德克智能科技有限公司

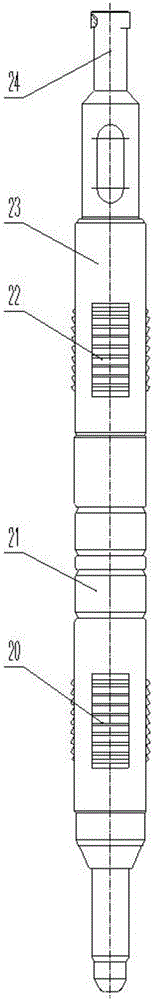

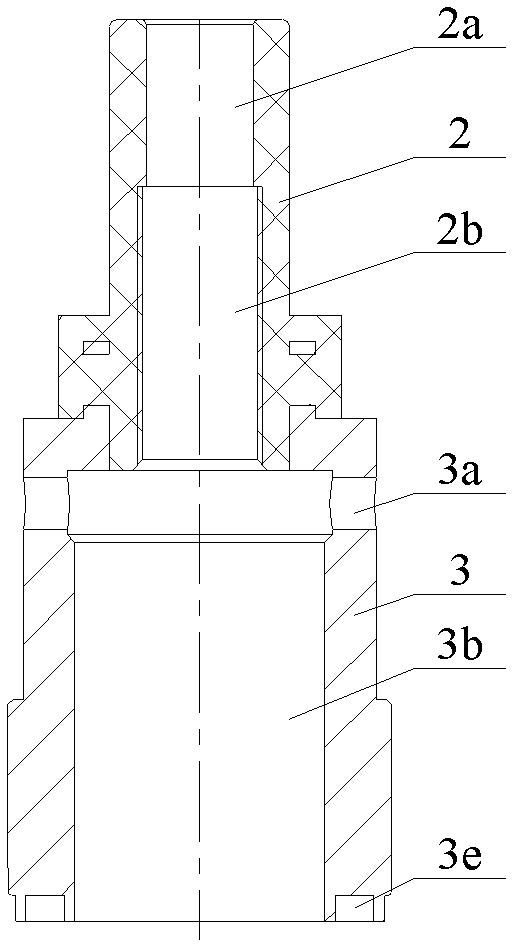

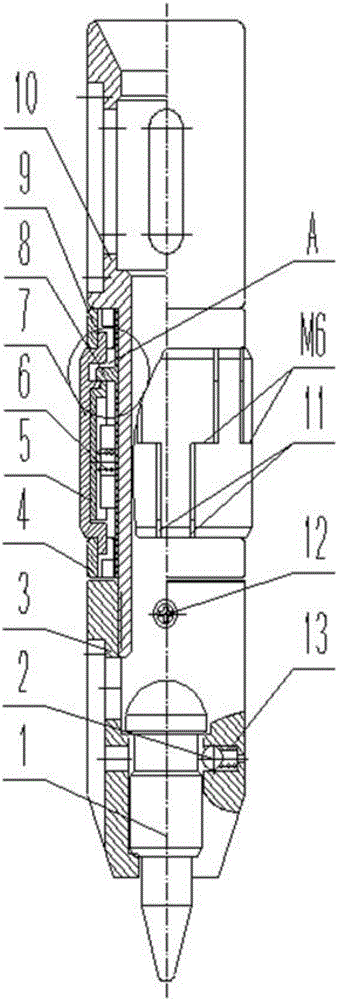

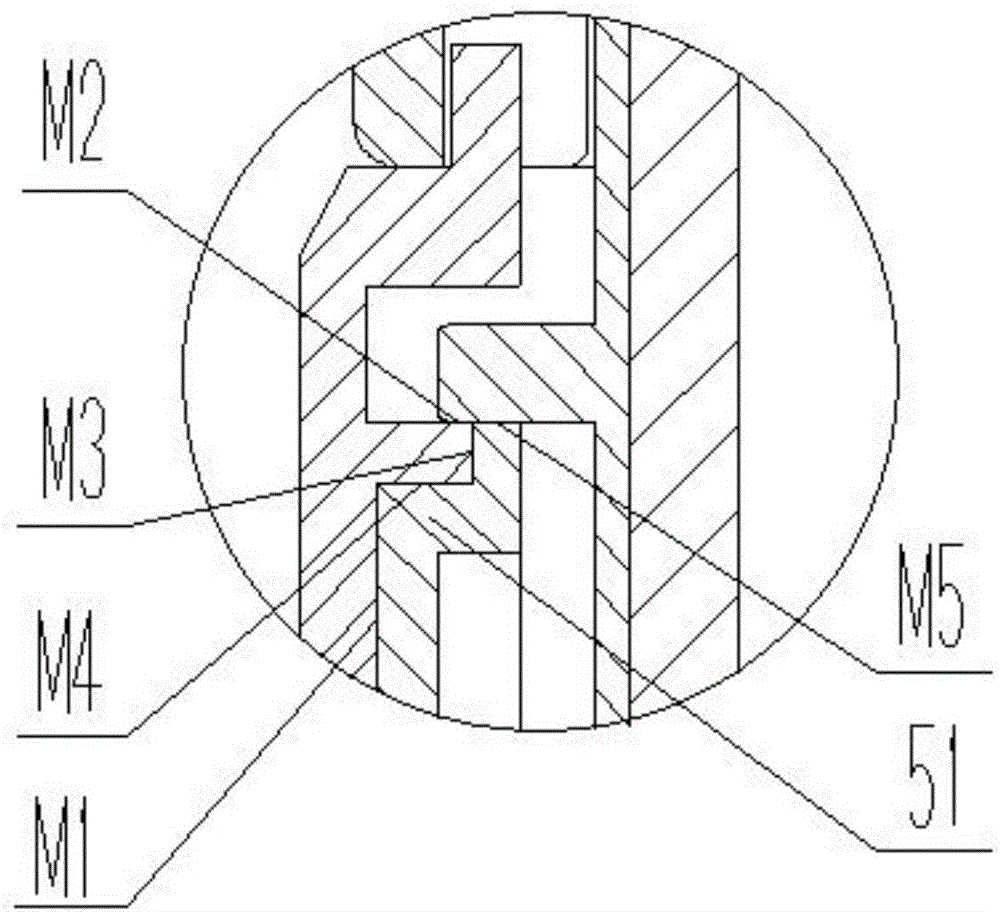

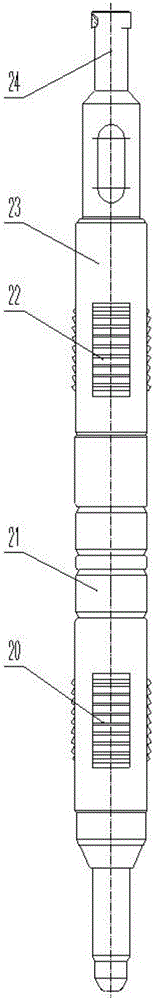

Diameter-variable assembly and diameter-variable sealing equipment

PendingCN106837234AGuaranteed sealing performanceImprove reliabilityFluid removalSealing/packingEngineeringMechanical engineering

The invention provides a diameter-variable assembly and diameter-variable sealing equipment comprising the diameter-variable assembly. The diameter-variable assembly comprises a sliding sleeve, a first limiting sleeve, a second limiting sleeve, a sealing sleeve and an inner fixing sleeve, wherein the first limiting sleeve and the second limiting sleeve are arranged at two ends of the inner fixing sleeve respectively; the sliding sleeve is spliced by at least two sliding branch sections, two ends of each sliding branch section are mounted in the first limiting sleeve and the second limiting sleeve respectively and are in radial sliding fit with the first limiting sleeve and the second limiting sleeve respectively; the outer wall of the sealing sleeve is in seal fit with the inner wall surface of the sliding sleeve, the sealing sleeve is spliced by at least two sealing branch sections, and each splicing gap of the sliding branch sections corresponds to one sealing branch section. When the outer diameter of the diameter-variable assembly is changed, the sealing performance of the diameter-variable assembly is guaranteed.

Owner:BEIJING AOSAIQI PETROLEUM TECH DEV CO LTD

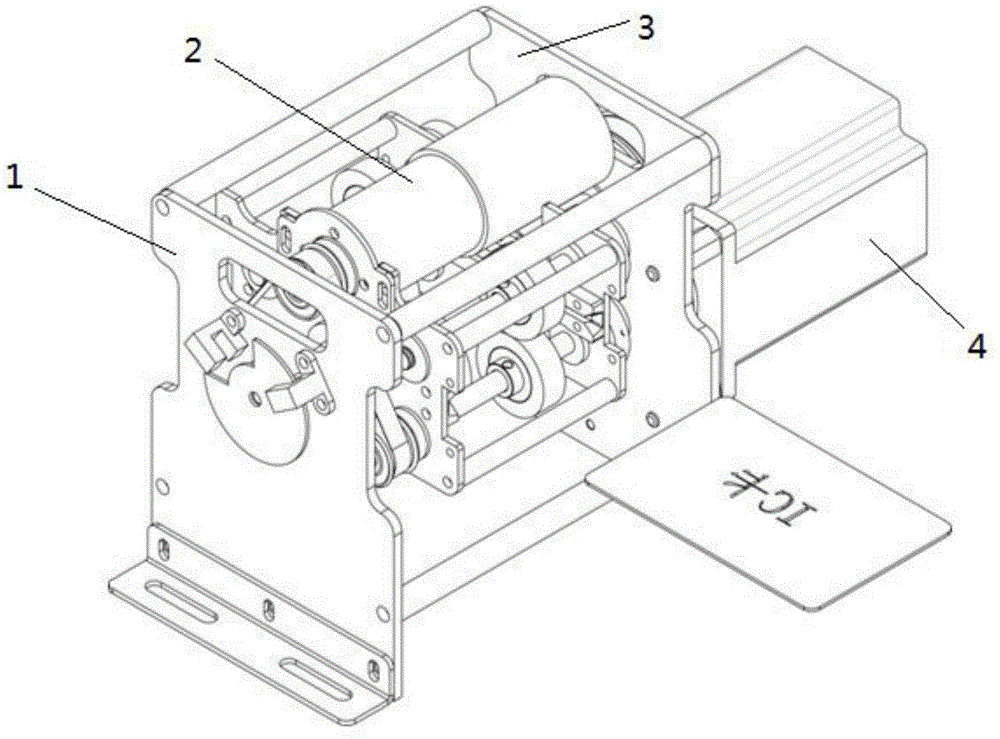

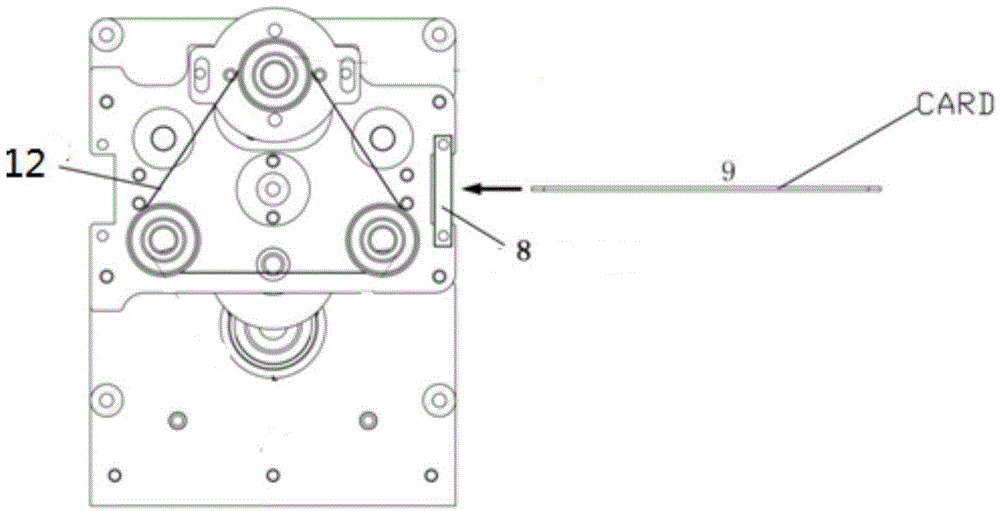

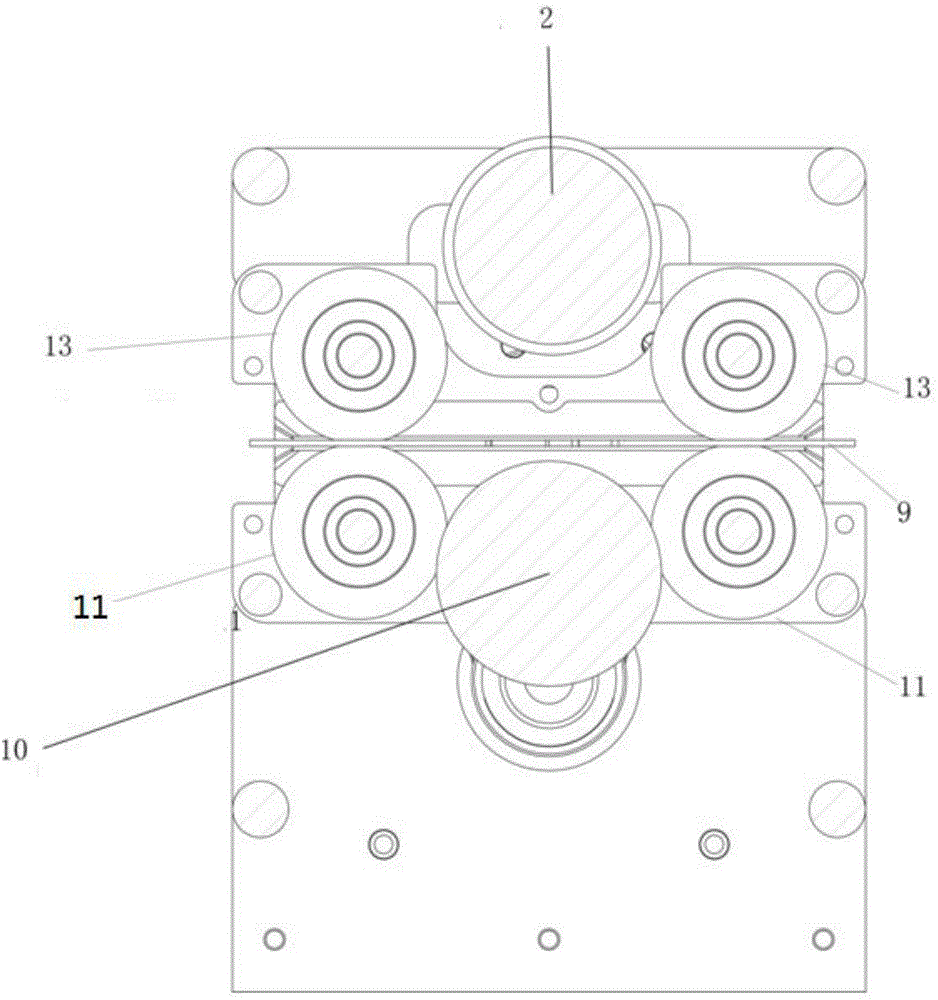

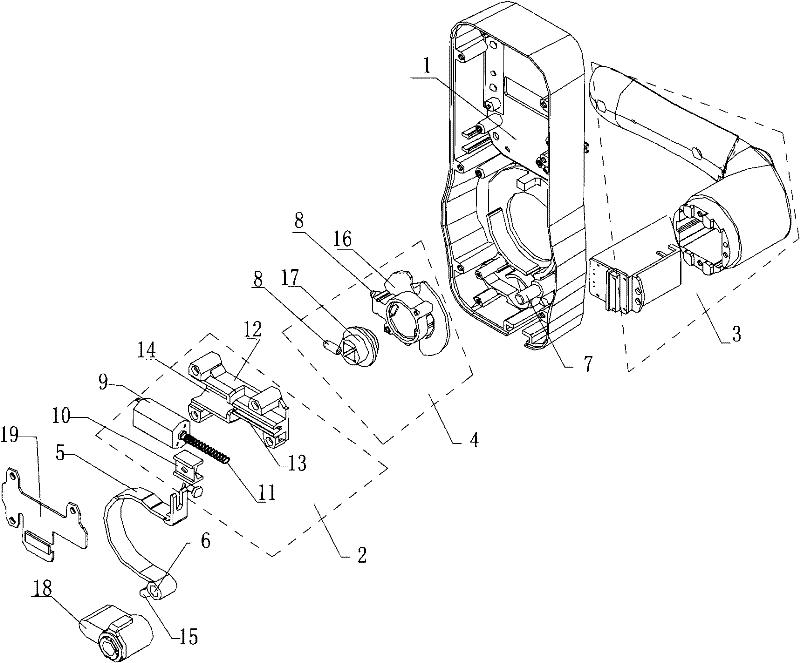

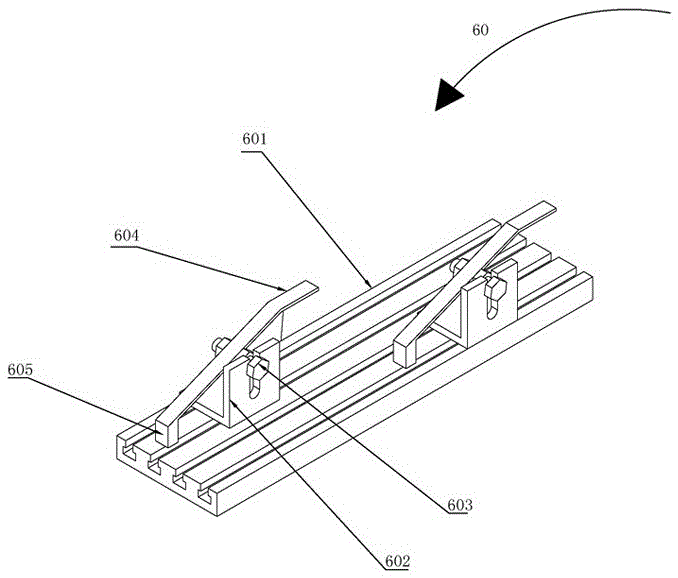

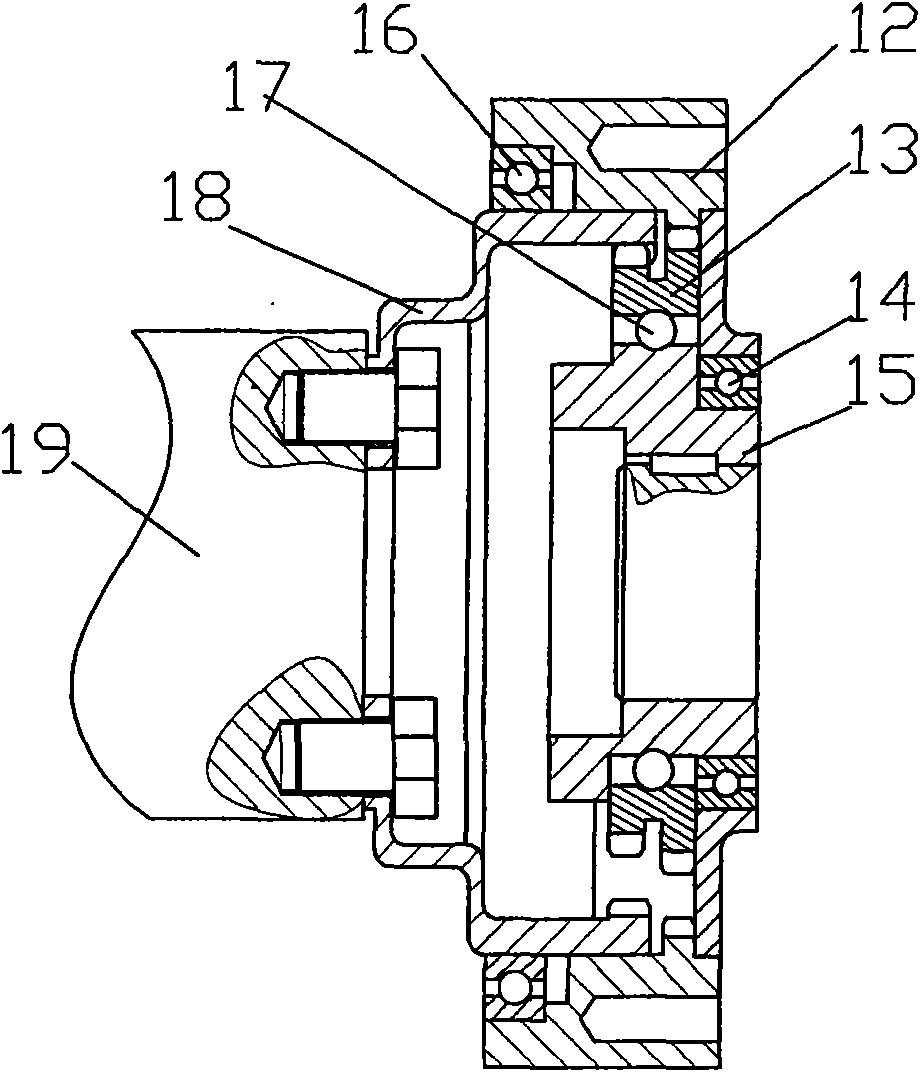

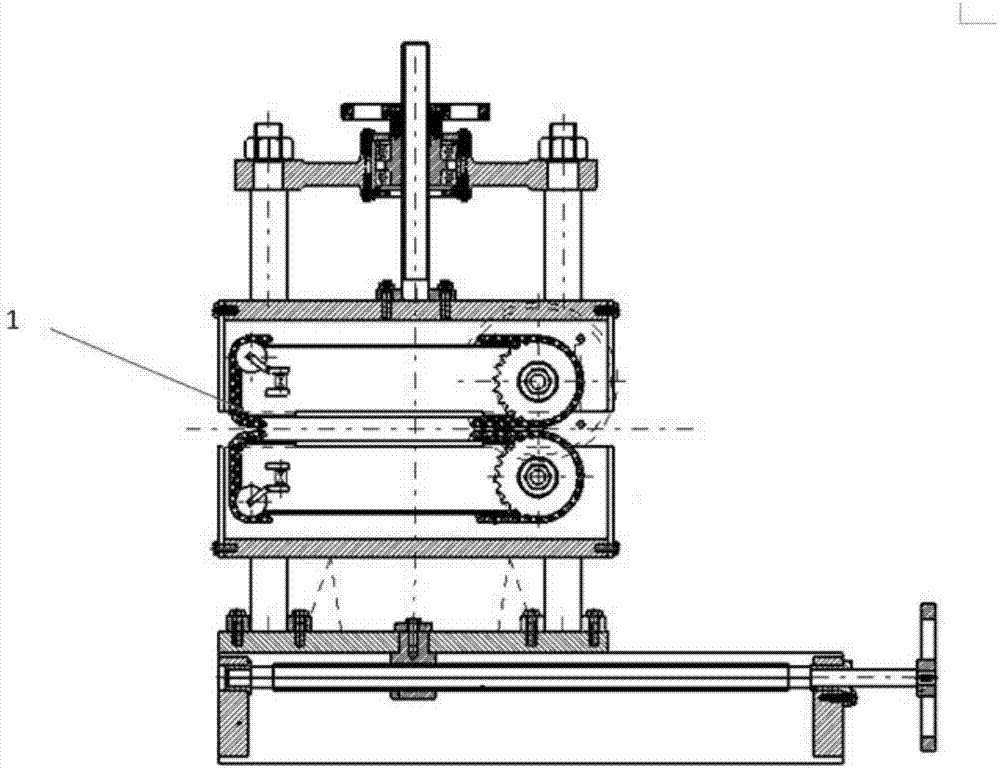

Smart card overturning module

The invention relates to a smart card overturning module comprising a card overturning rear supporting plate, a card moving motor, a card overturning front supporting plate, and a stepping motor. The output shaft of the card moving motor drives a pair of synchronizing wheels below to rotate synchronously by means of a synchronous belt. The top of each of the pair of synchronizing wheels is provided with a corresponding rubber wheel. A gap between each rubber wheel and the corresponding synchronizing wheel is less than the thickness of a smart card. A counterweight block is disposed on a position, corresponding to the card moving motor, between the pair of synchronizing wheels. After a card-in sensor detects that the card is fed in, the card moving motor starts to rotate after receiving a signal and drives a card passing synchronizing wheel rotate by means of a card passing synchronous belt. The card passing synchronizing wheel and the rubber wheels above clamp the card and inwardly feed the card into a card overturning module. According to a card manufacture requirement, the stepping motor rotates if the card is required to be overturned. A card overturning synchronizing wheel is driven by the synchronous belt to rotate by 180 degrees. Then the card overturning front supporting plate drives the card overturning rear supporting plate and a card overturning module between the card overturning front supporting plate and the card overturning rear supporting plate to integrally rotate by 180 degree. In the meantime, the card moving motor starts to rotate and feeds the card out of a card overturning structure from an opposite side.

Owner:江苏华桠融通智能科技有限公司 +1

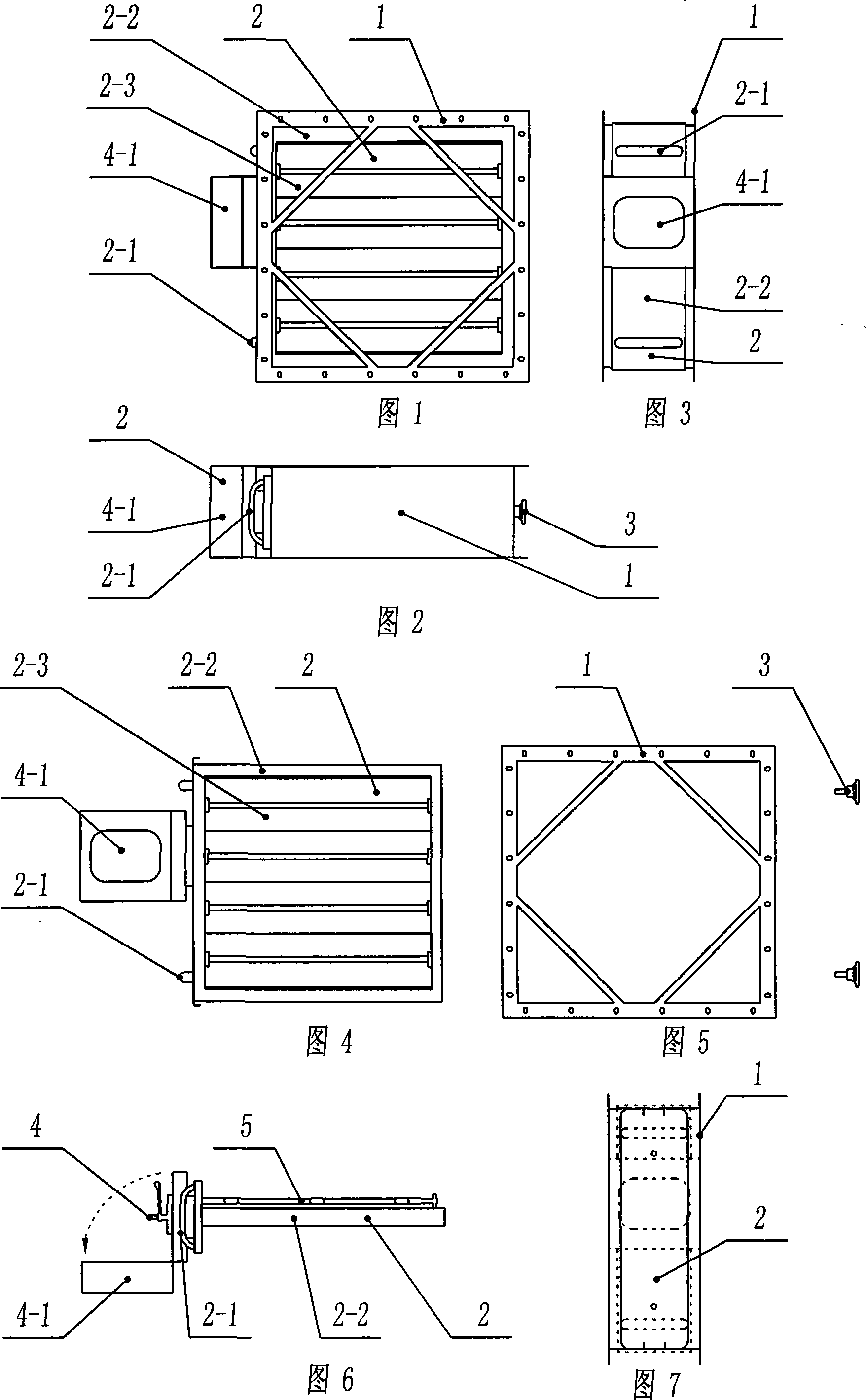

Draw-out type fire-fighting fire-proof valve

ActiveCN101225900AReduce weightWill not affect normal operationEqualizing valvesSafety valvesFire controlThermal expansion

The invention discloses a draw-out type fire control valve, which is capable of drawing a valve body, an actuator and a thermofusion device out together easily in order for maintenance and cleaning. Although a deformation happens to an outer frame, the normal work of vane groups cannot be influenced, an admission space for the thermal expansion is reserved and the detection range of the temperature of the gas in an air duct is enlarged. The draw-out type fire fighting fire resistance valve comprises a valve body, an actuator, a thermofusion device and a guide rail type outer frame; wherein, the valve body is positioned in the guide rail type outer frame; the guide rail type outer frame is slidingly connected with an upper side and a lower side of an outer frame of the valve body; the guide rail type outer frame is movably connected with the an outer back side of the outer frame of the valve body through a handwheel; the upper part and the lower part at the same side of the actuator are provided with a handle; the periphery of end faces at the left side and the right side of the guide rail type outer frame are respectively fastened with a left segment air duct and a right segment air duct through screws. The draw-out type fire control valve is mainly suitable for fire control and safety of the ventilating fire-resistant pipeline, in particular for the fire control and safety of the electrostatic fume purifying device.

Owner:KELAN TECHNICS ENVIRONMENTAL PROD CO LTD

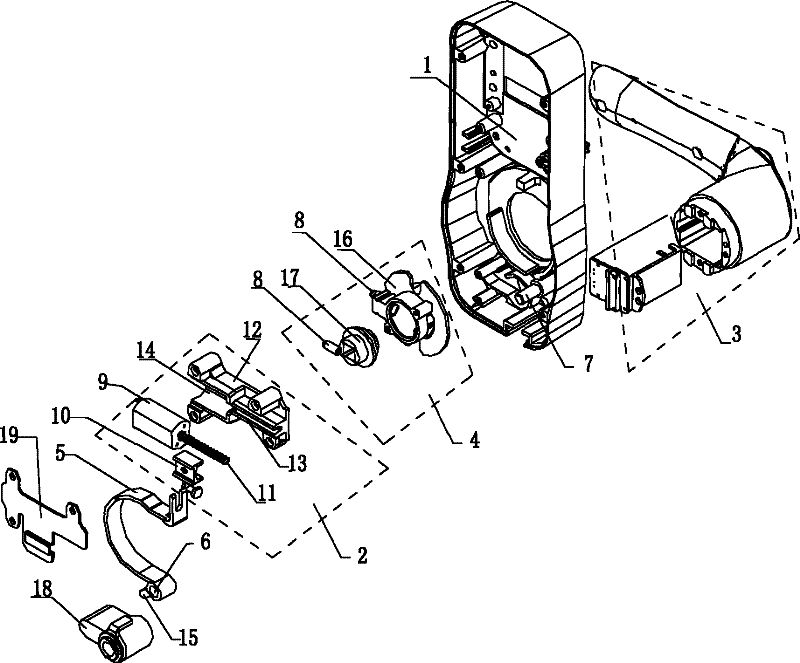

a fingerprint lock

ActiveCN102287090AImprove stabilityReduce parts stuckNon-mechanical controlsElectric permutation locksClutchFingerprint

The invention discloses a fingerprint lock, which comprises a lock case panel, a braking device, and a peach clutch for fingerprint identification handle, and is characterized in that: the lock case panel is provided with an arc-shaped pressing bar, and one end of the arc-shaped pressing bar It is connected with the braking device, and the other end is sleeved on the column of the lock housing panel through the reaming hole on it, and the arc part of the arc pressure rod is pressed on the marble in the peach clutch. The brake device is composed of a motor and a slide block, the output shaft of the motor is provided with a torsion spring, the slide block is sleeved on the torsion spring, and one end of the arc-shaped pressing rod is connected with the slide block. Since the motor controls the opening and closing of the peach clutch of the fingerprint recognition handle through the torsion spring to drive the arc-shaped pressure rod, the stability of unlocking the lock is greatly enhanced, and the phenomenon of parts being stuck during the opening process of the lock is reduced. The invention has the characteristics of simple structure, safe and reliable use, and durability.

Owner:SHANGHAI ANVIZ TECH CO LTD

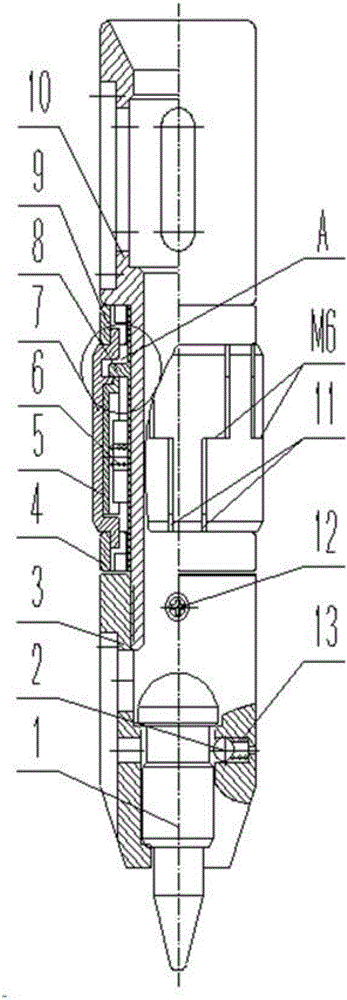

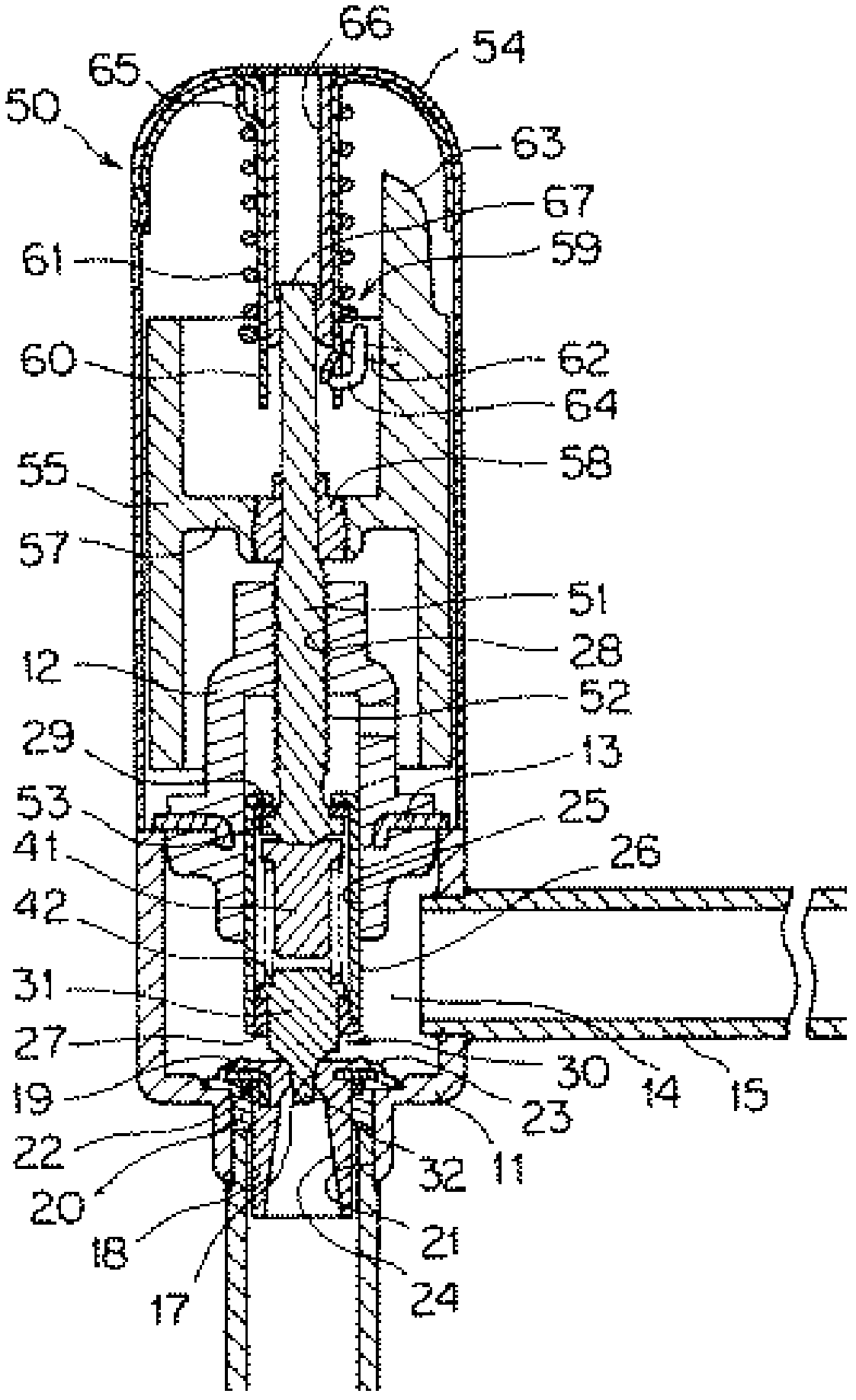

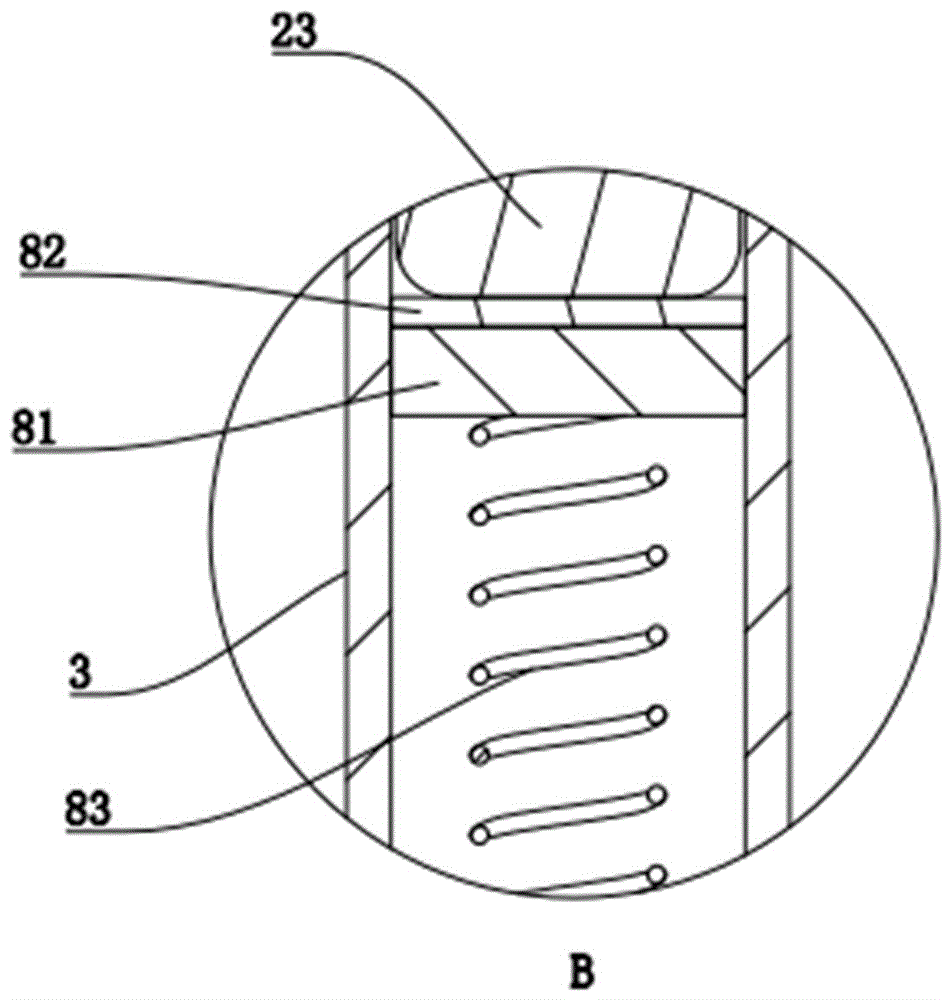

Electronic expansion valve and manufacturing method therefor

ActiveCN102829586AReduce usageGuarantee working reliabilityEfficient regulation technologiesFluid circulation arrangementPlastic materialsEngineering

The invention discloses an electronic expansion valve which is sequentially provided with a valve needle, a bearing block, a nut and a valve rod relative to an inlet shaft of a valve seat in the axial direction; the valve needle is internally arranged in the bearing block which is fixedly arranged on the valve seat; the valve rod and the nut are in screw thread fit and drive the valve needle to shift axially; and the nut adopts a plastic material and is integrally formed by means of injection molding with the bearing block. Based on the prior art, the self-structure and fit relationship of the nut are improved so as to increase the coaxiality between the nut and the valve seat and guarantee the work reliability of a complete machine. On the basis, the invention also provides a manufacturing method for the electronic expansion valve.

Owner:ZHEJIANG SANHUA INTELLIGENT CONTROLS CO LTD

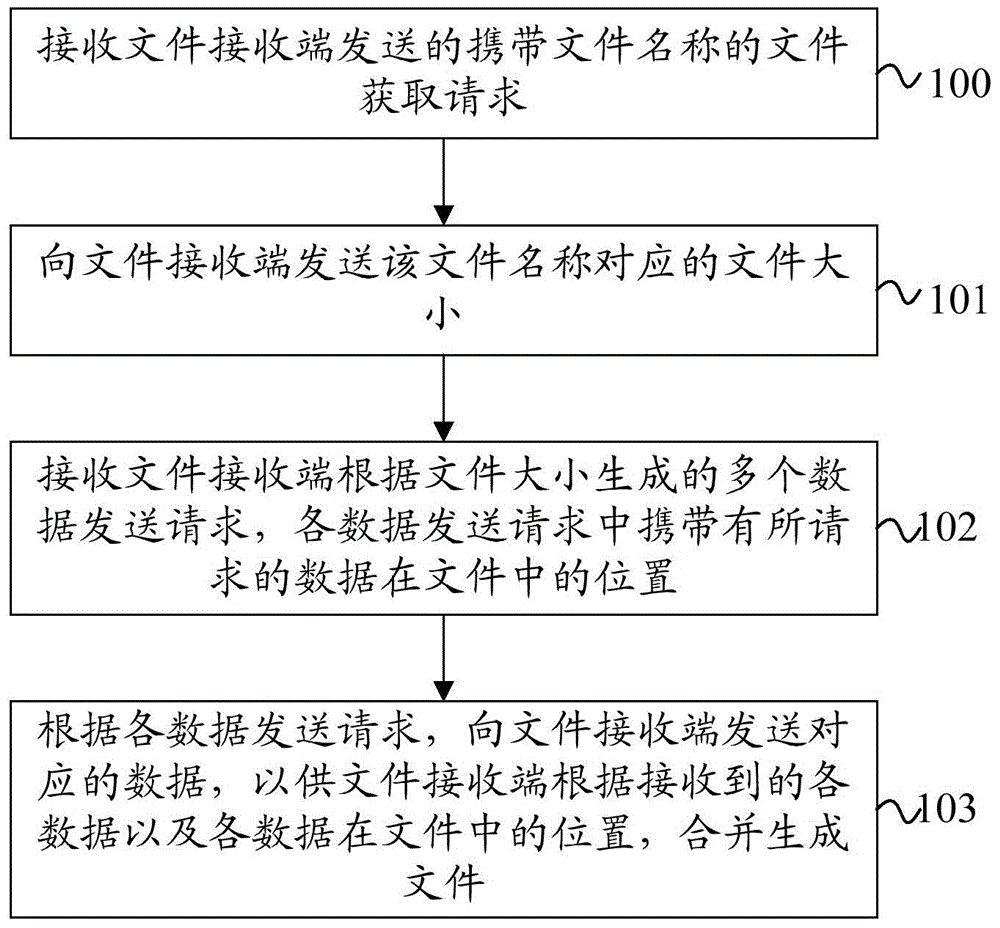

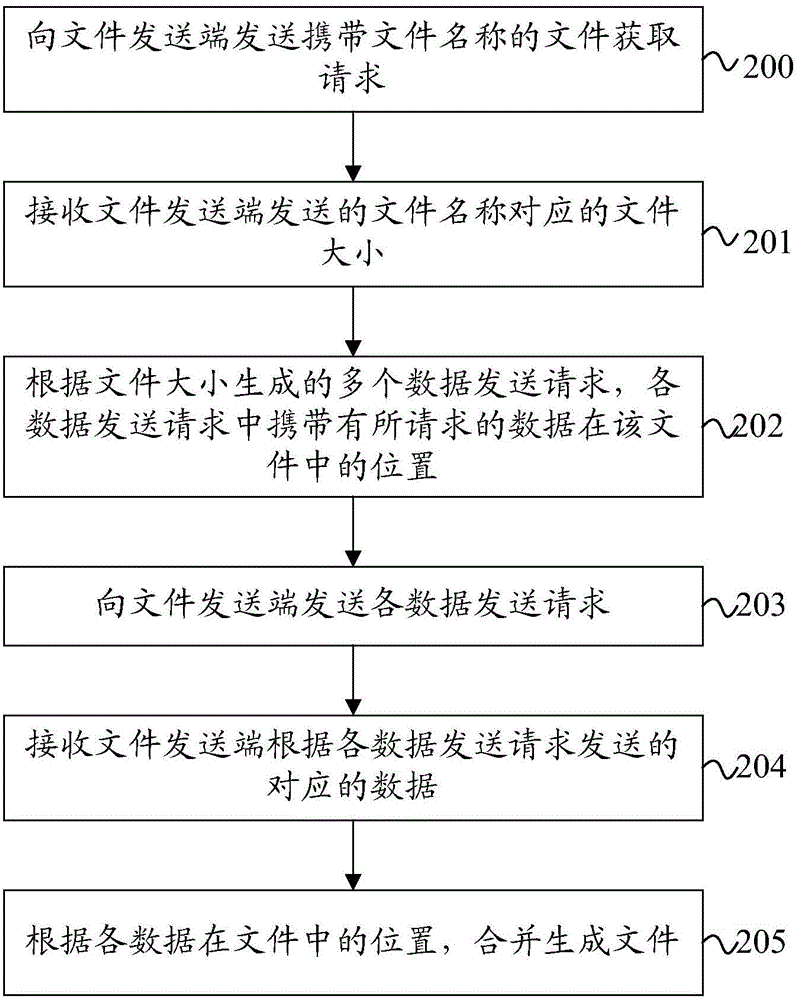

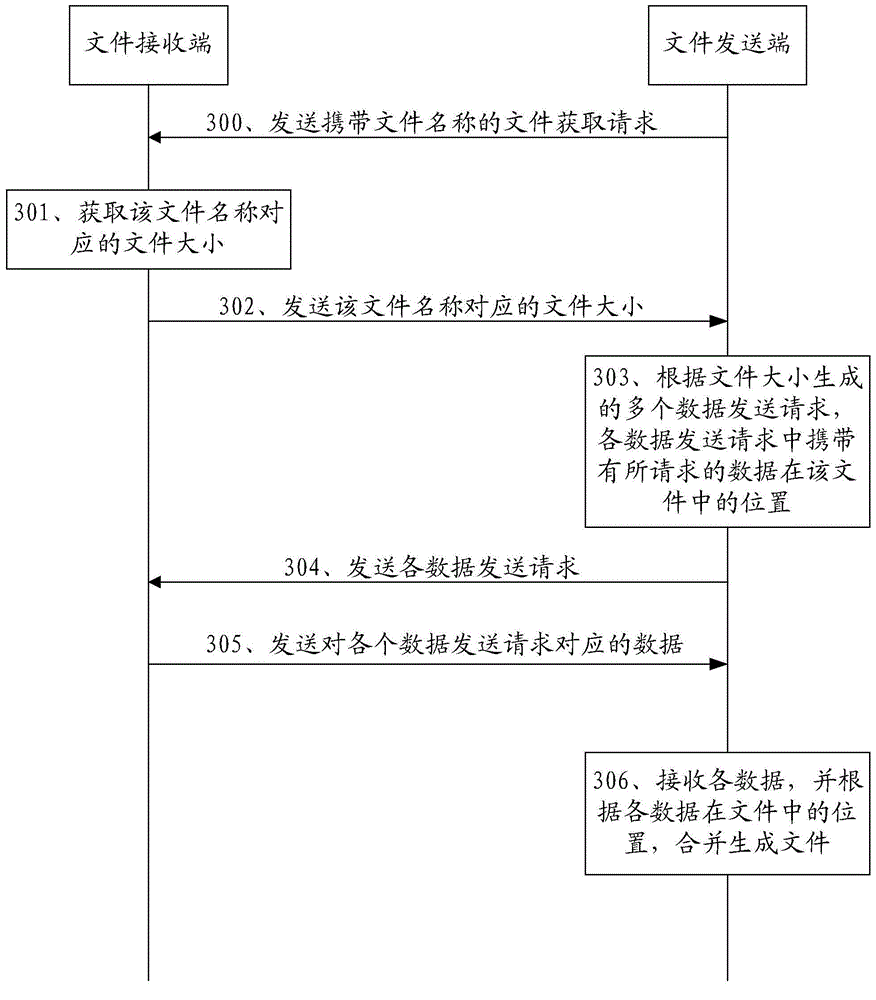

File transmission method and system, file sending device, and file receiving device

InactiveCN104967663AReduce transfer timeShorten the timeTransmissionFile transmissionComputer science

The invention discloses a file transmission method and system, a file sending device, and a file receiving device. The file transmission method comprises: receiving a file acquiring request carrying a file name and sent by a file receiving end; sending a file size corresponding to the file name to the file receiving end; receiving multiple data sending requests generated by the file receiving end according to the file size, wherein each data sending request carries the position of the requested data in a file; according to the data sending requests, sending corresponding data to the file receiving end in order that the file receiving end performs merging to generate the file according to the received data and the position of the data in the file. The invention also discloses another file transmission method and a device and system for implementing the same. According to the file transmission method, the file can be divided into multiple segments to be transmitted such that file transmission time is shortened and a probability of interruption and jamming in file transmission can be reduced. Therefore, file transmission efficiency is effectively improved.

Owner:WUXI TVMINING MEDIA SCI & TECH

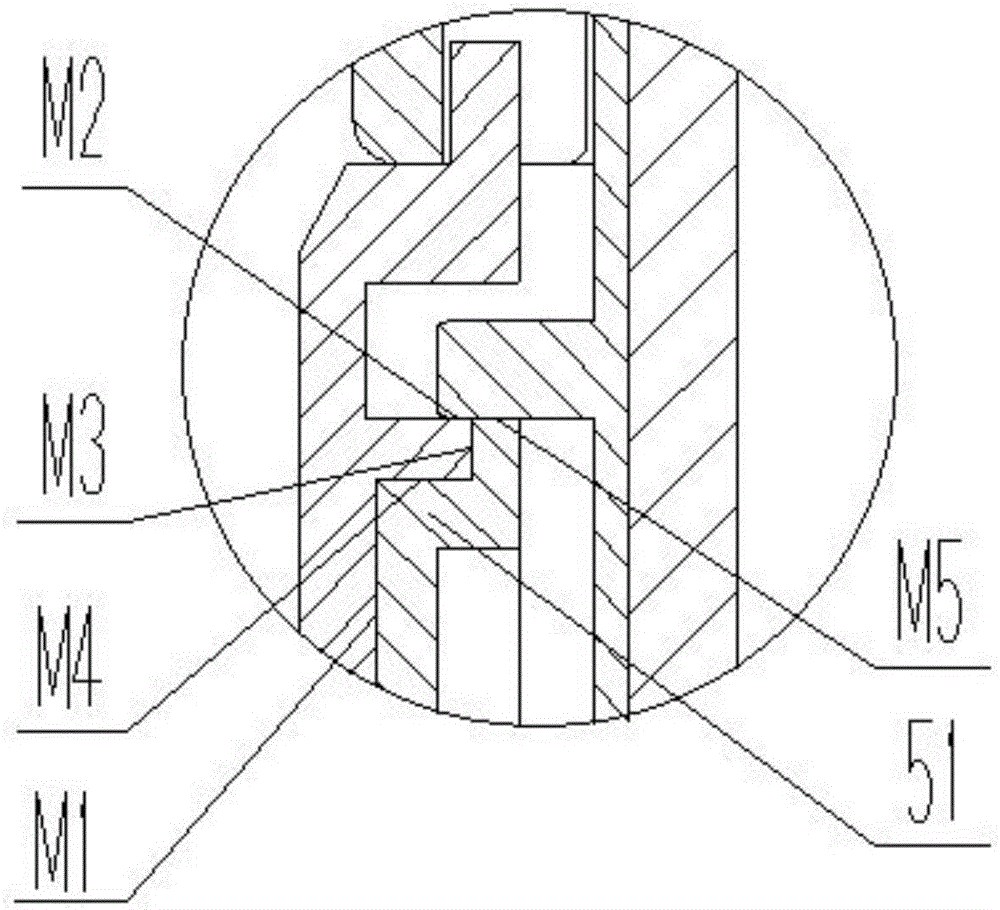

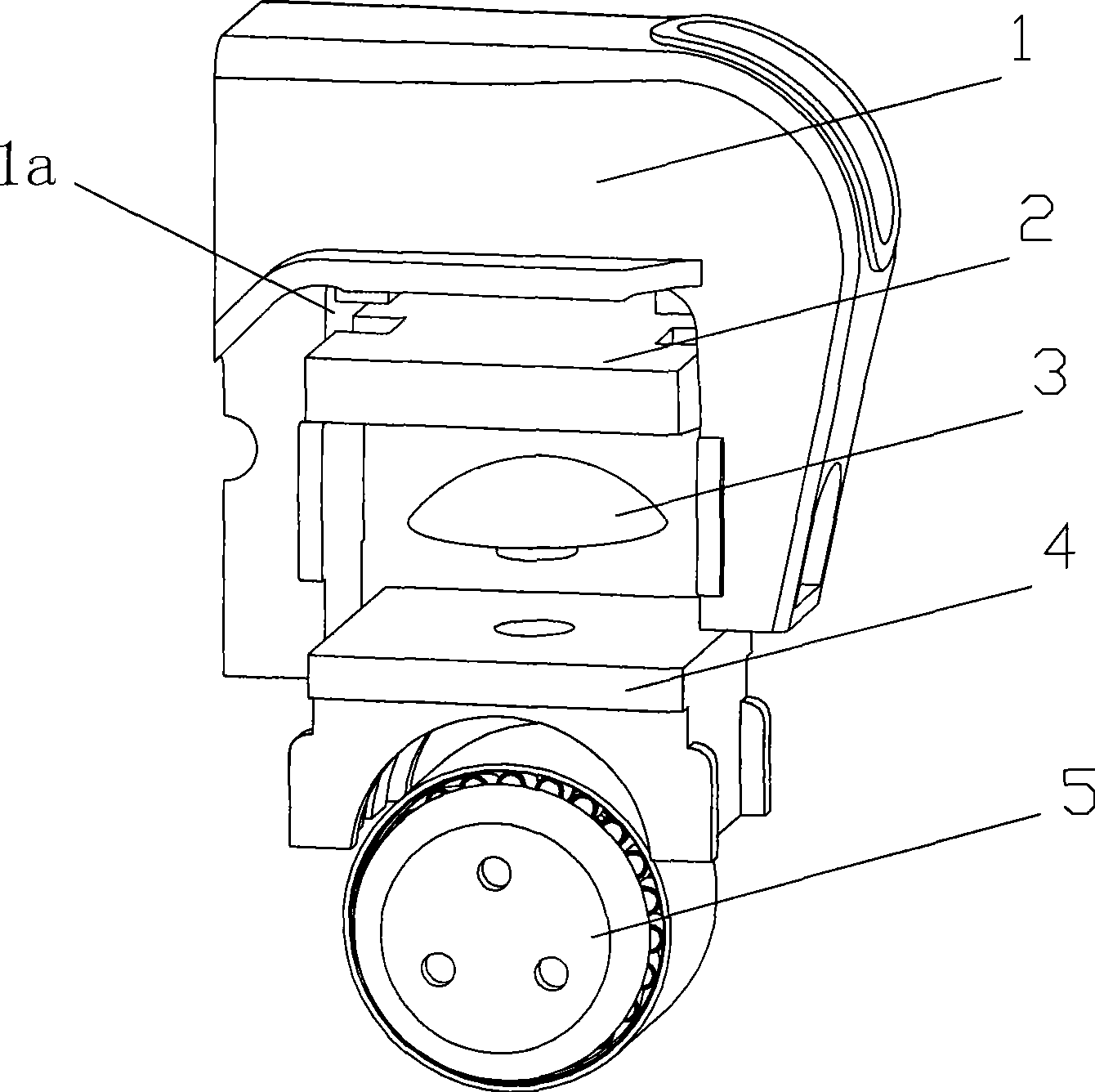

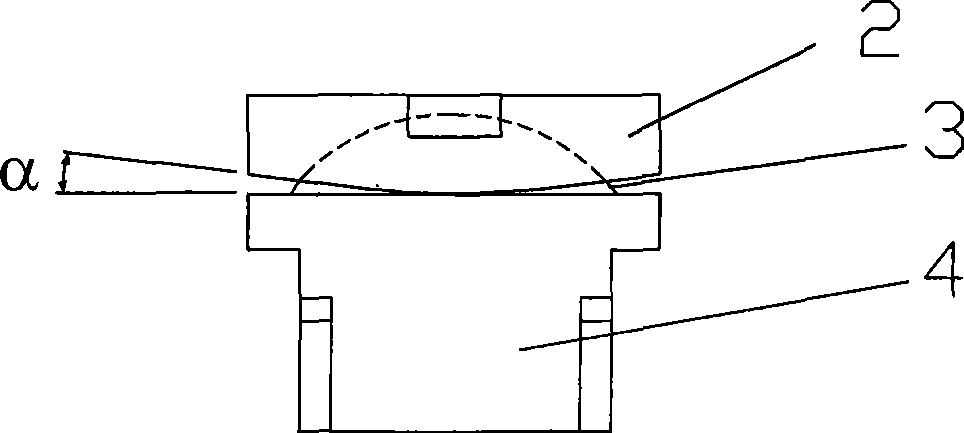

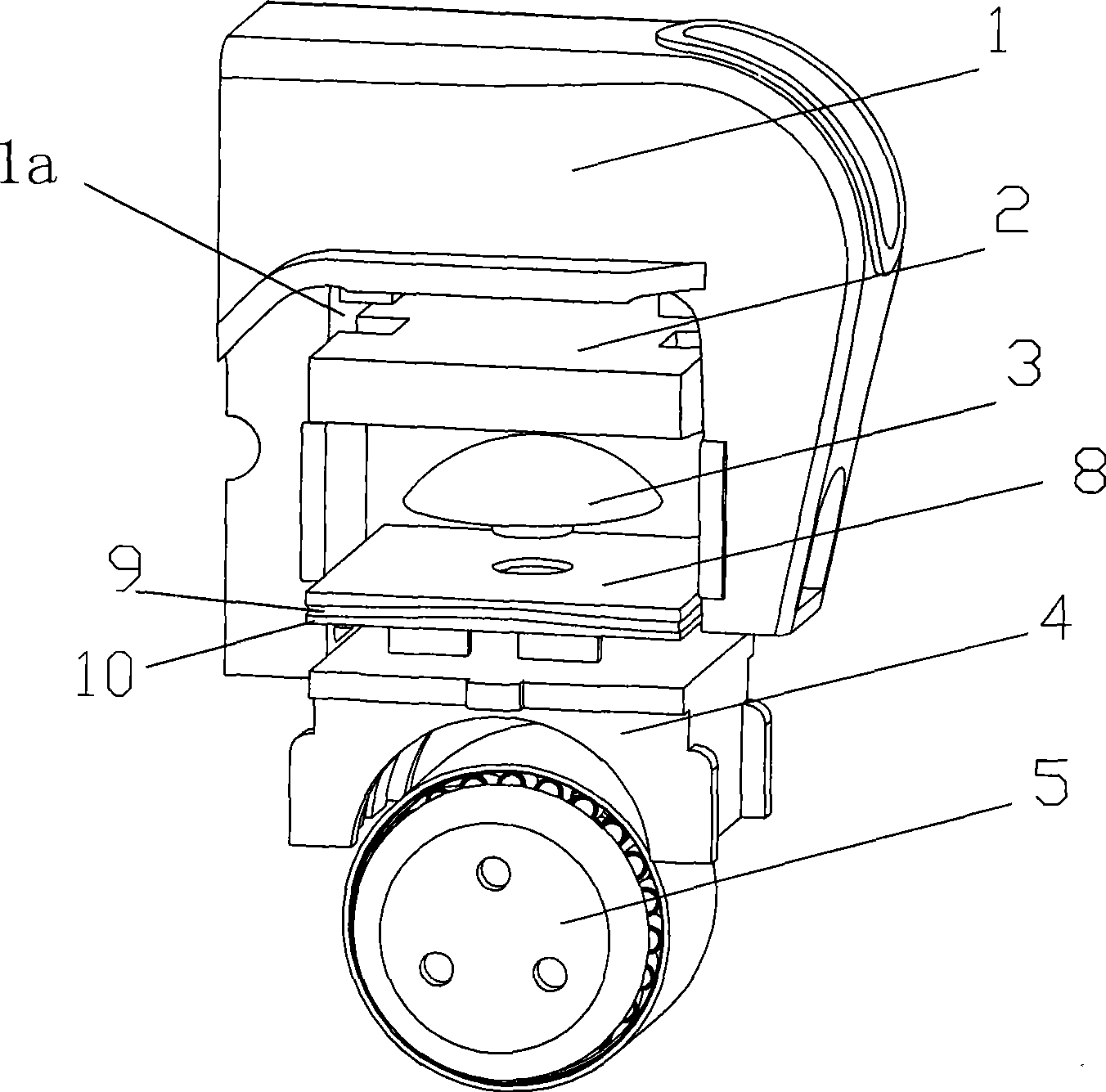

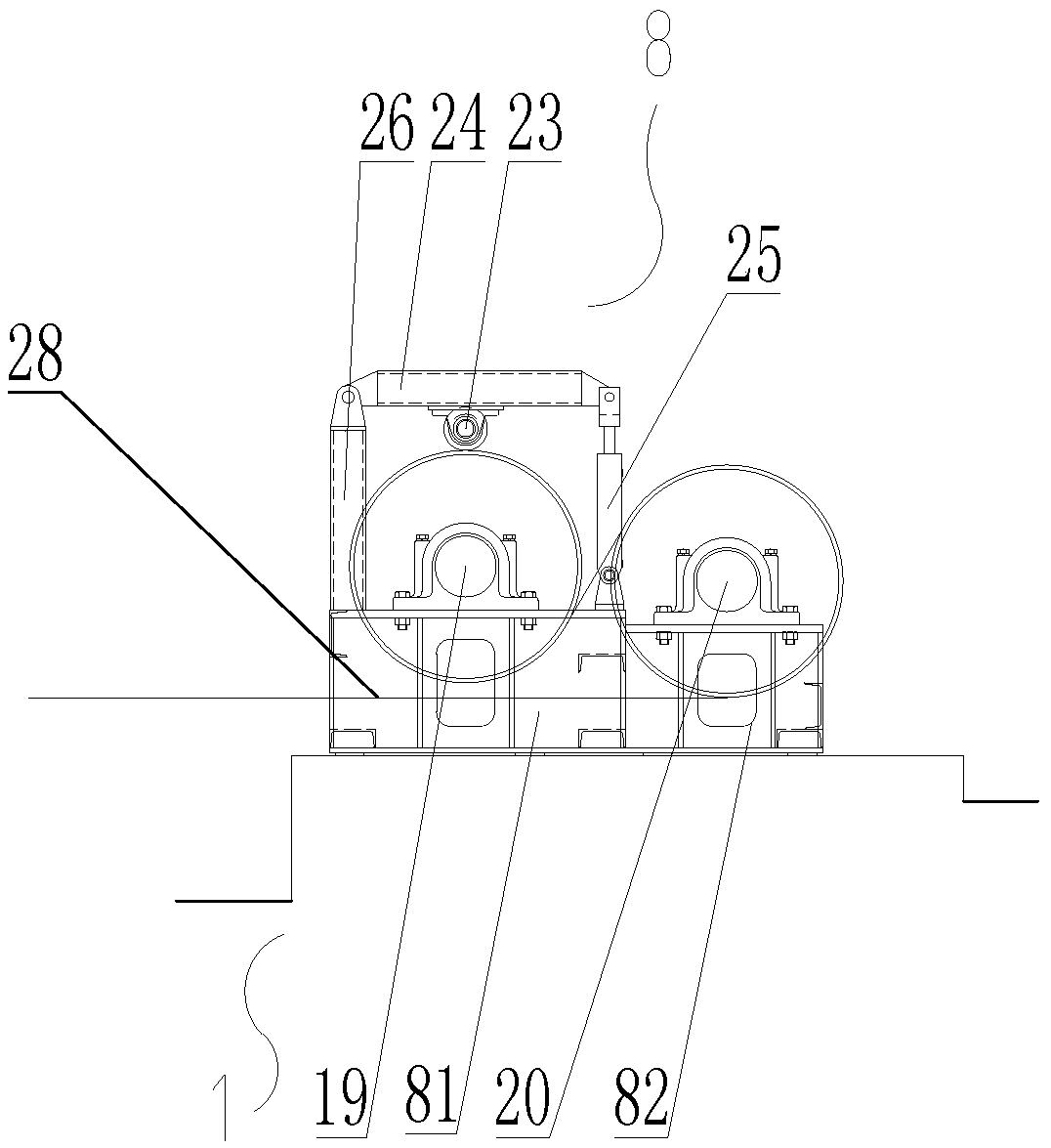

Auxiliary bearing saddle assembly for spherical cap of pendulum goods train

InactiveCN101428628ASmall swing resistanceReduce stuck phenomenonBogie-underframe connectionsEngineeringTruck

The invention discloses a spherical crown pair adapter component used for a pendulum railway freight car, which comprises a shaking seat (2) inside of the guide basket (1a) of a side frame (1) and an adapter (4) under the shaking seat (2), wherein, the lower part of the adapter (4) is matched with the outer ring of a bearing (5). The spherical crown pair adapter component is characterized in that the two ends of the upper surface of the shaking seat (2) are embedded on the two edges at the upper part of the guide basket (1a) of the side frame (1), the lower surface of the shaking seat (2) is a concave spherical surface, the concave spherical surface is matched with a convex spherical crown (3), and the lower part of the convex spherical crown (3) is connected with the adapter (4). The invention has the advantages that surface force transmission is adopted, the crown pair adapter component is free from unbalanced or inclined loadings, the adapter and the convex spherical crown (3) are under even load, the fatigue life is long, the back swing resistance of the side frame is small, and the work is reliable.

Owner:SOUTHWEST JIAOTONG UNIV

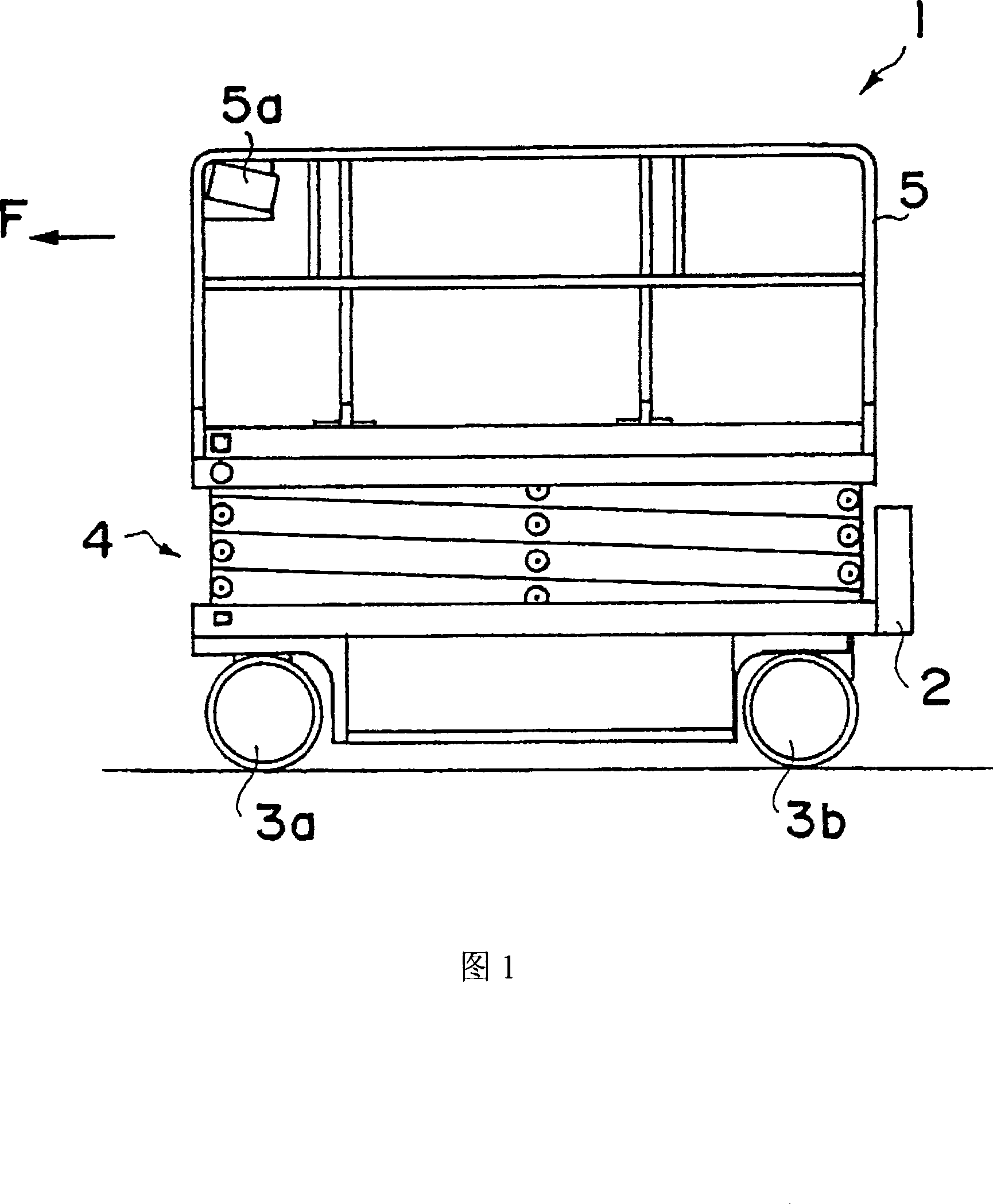

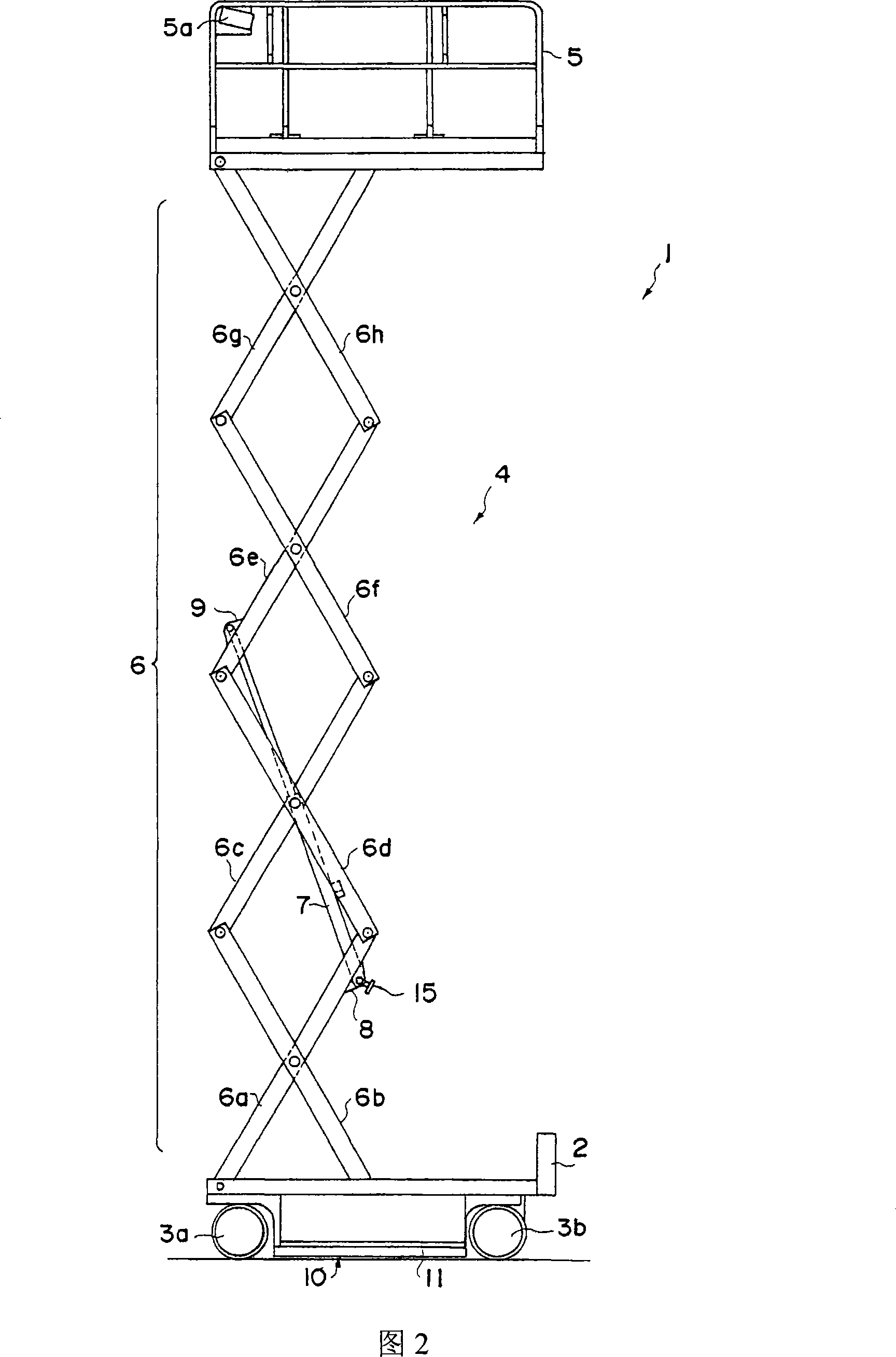

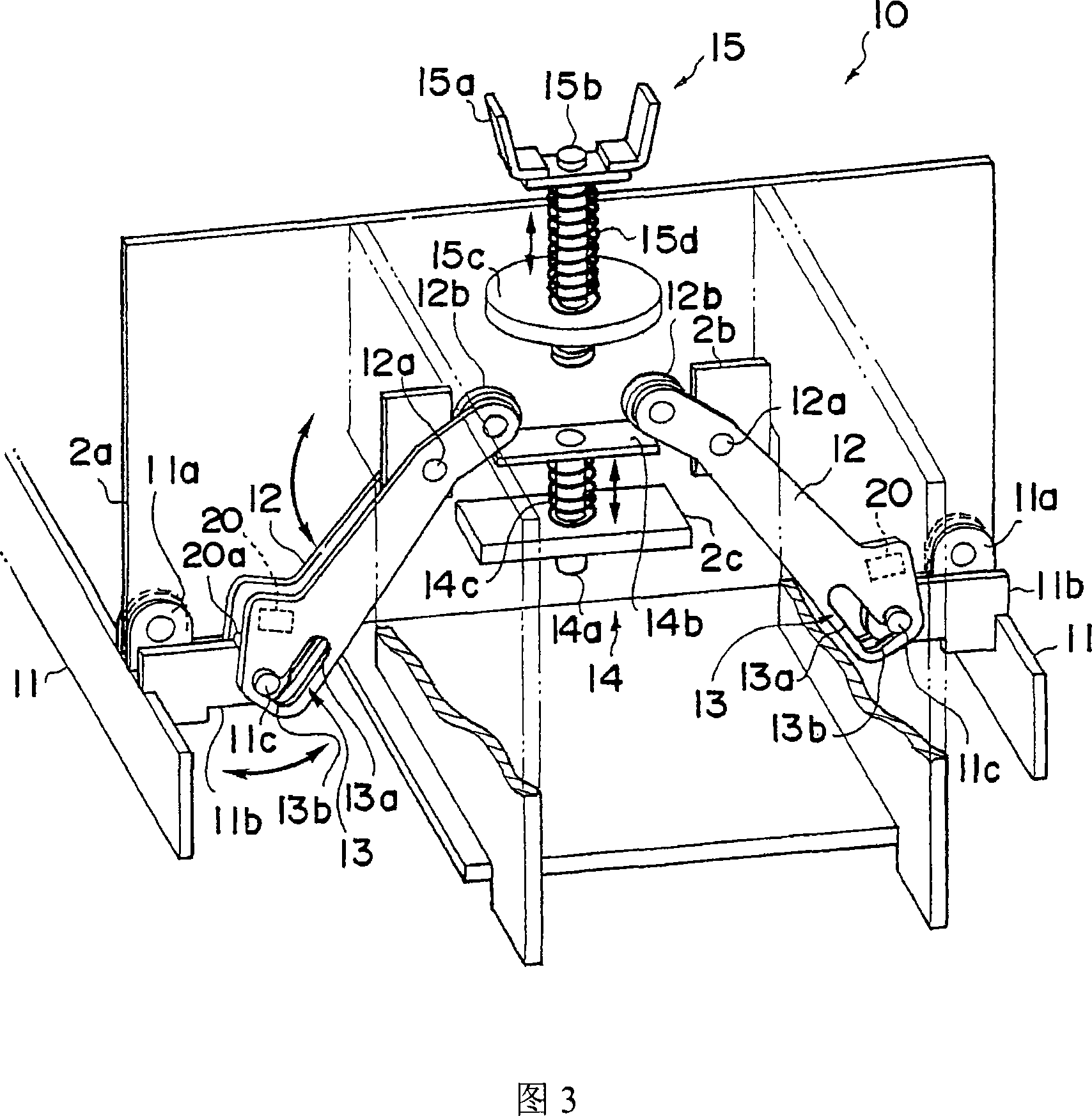

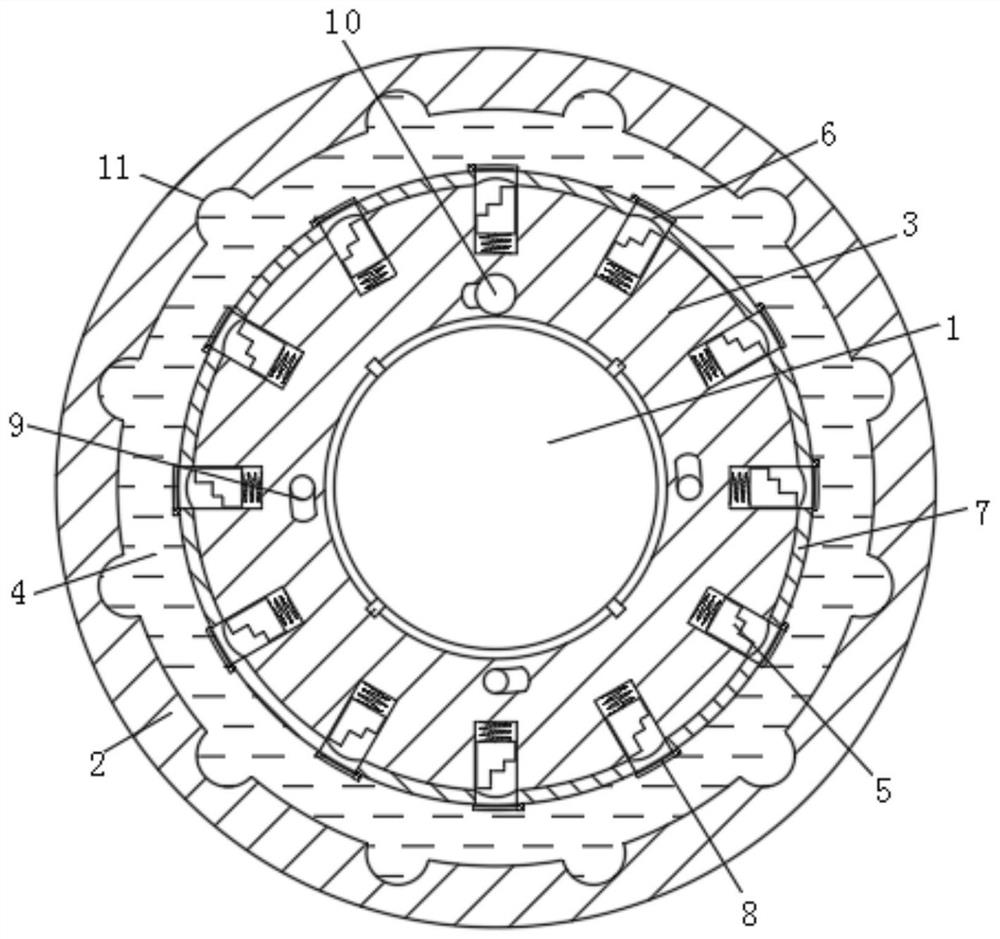

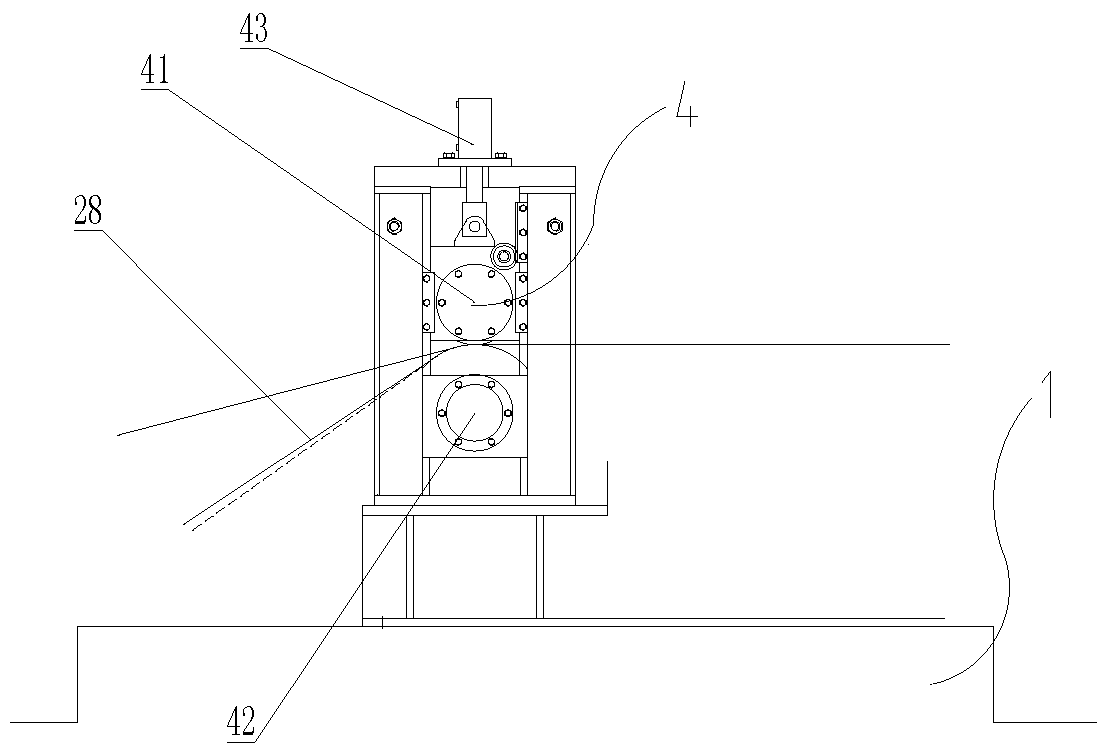

Reversal preventing equipment

ActiveCN101200270AReduce in quantityReduce stuck phenomenonSafety devices for lifting equipmentsEngineeringTruck

The invention relates to an anti-perversion device (10) used for an overhead working truck (1). The overhead working truck comprises a truck body which is provided with a front wheel and a rear wheel (3a and 3b) and walks forwards, and a fork-type lifting device (4) arranged on the truck body and used for lifting a working table (5). The invention comprises an anti-perversion board (11) arranged inside a vertical panel extending leftwards and rightwards below the truck body between the front wheel and the rear wheel in a free swing way and moved to a folding position and an unfolding position; a driving arm (12) whose external side part is connected with the anti-perversion board; an unfolding operation part (14) arranged on the truck body and used for pushing upwards the head (12b) of the driving arm so as to swing downwards to the external side part of the driving arm and swing the anti-perversion board towards to the unfolding position; and a folding operation part (15) arranged onthe lifting device and used for pressing downwards the head of the driving arm when the lifting device lifts downwards and swing upwards the external side part of the driving arm so as to swing the anti-perversion board to the folding position.

Owner:AICHI

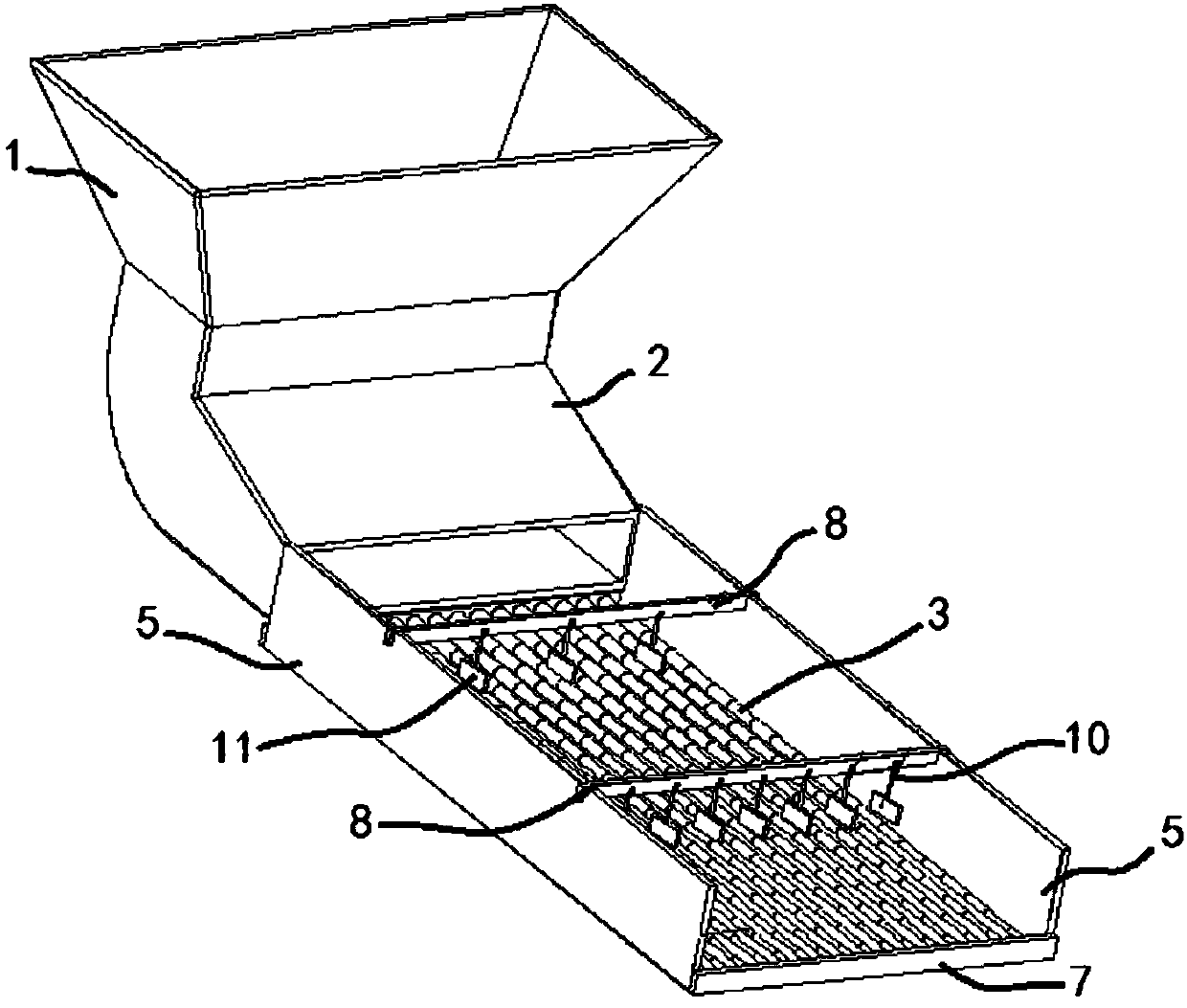

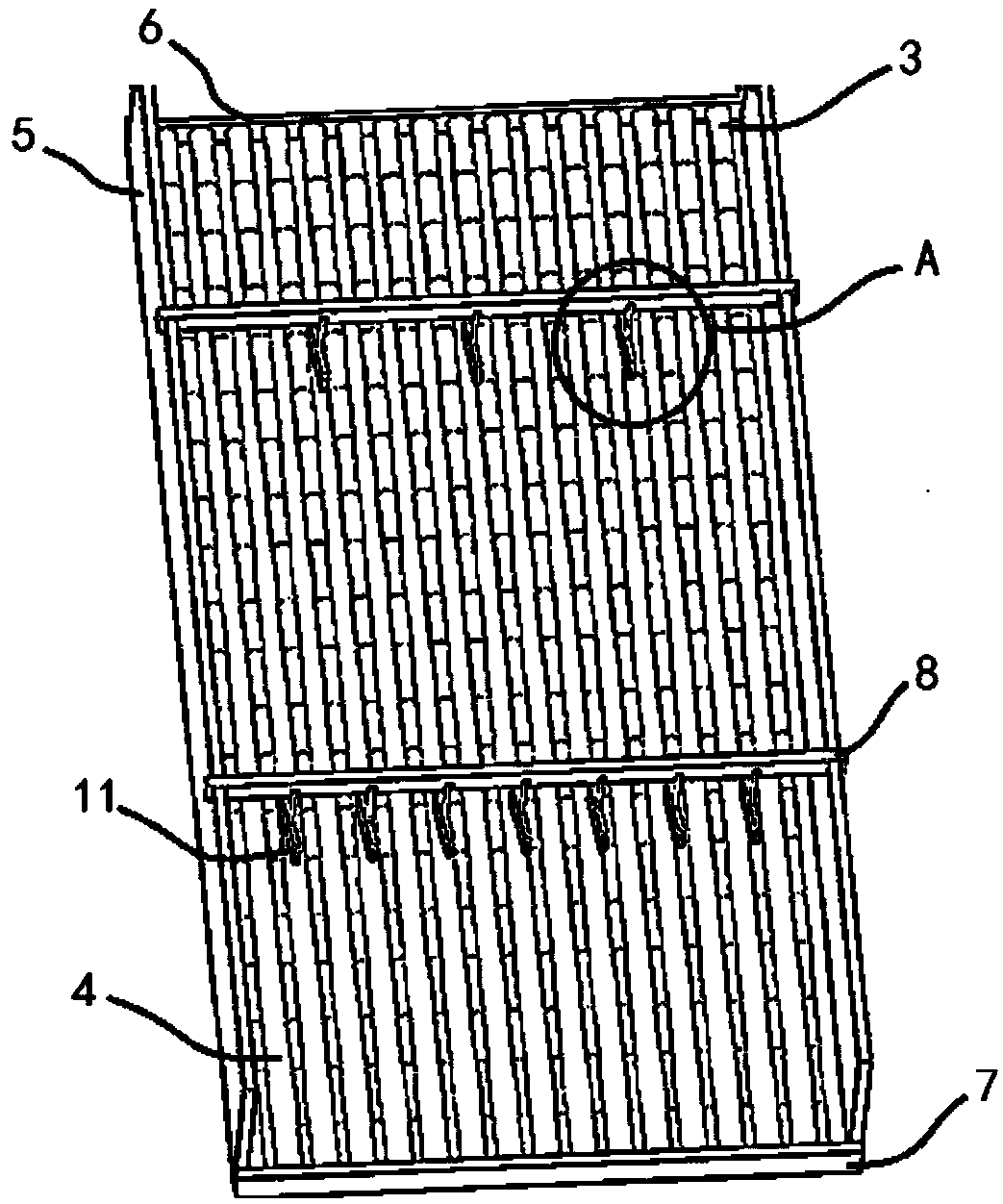

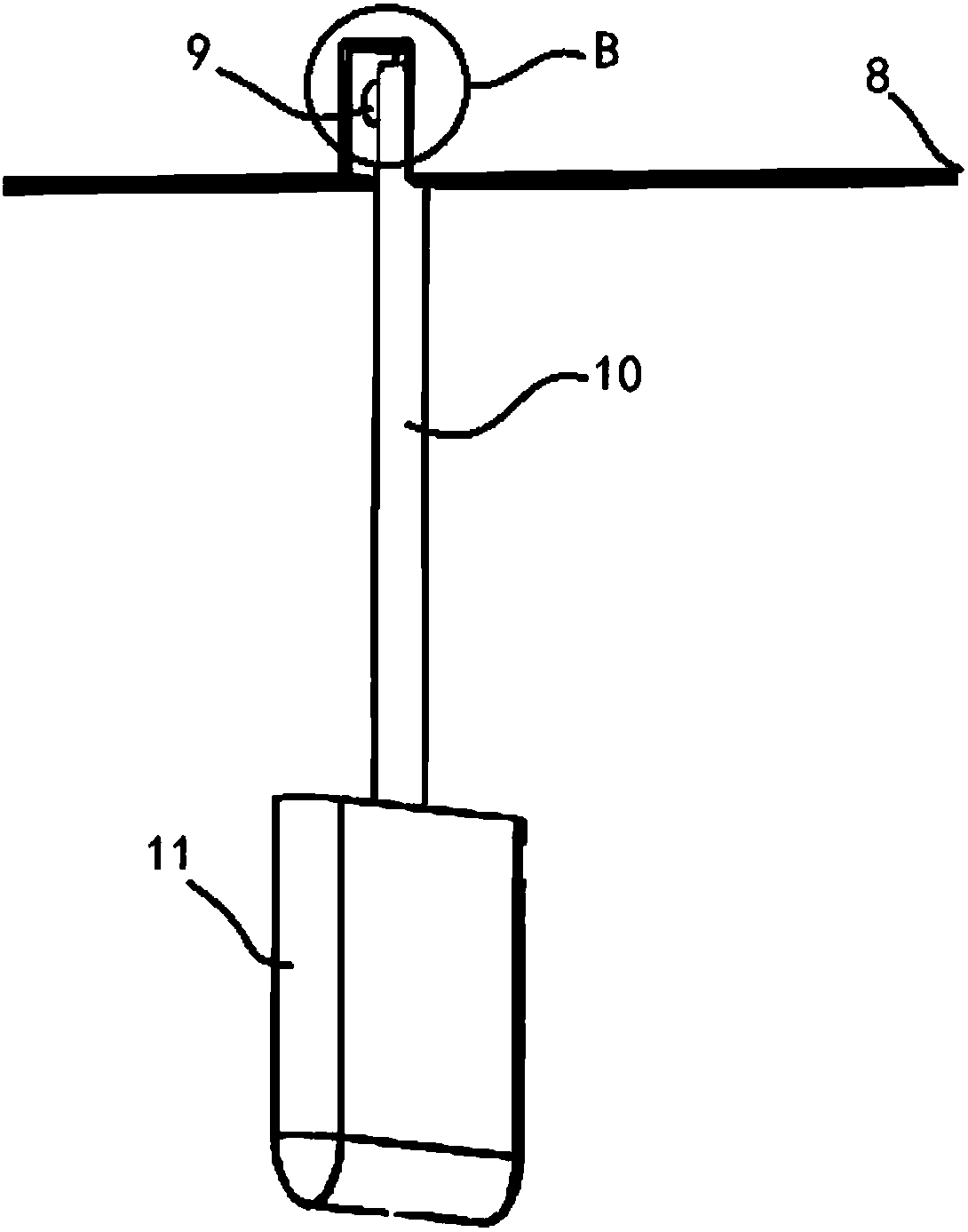

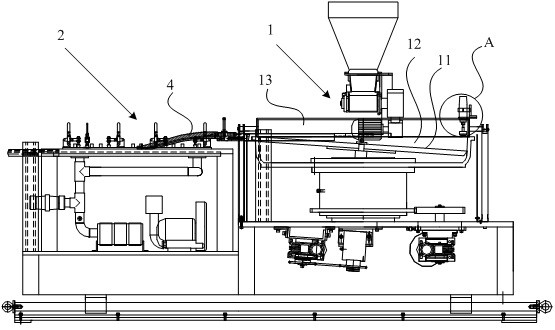

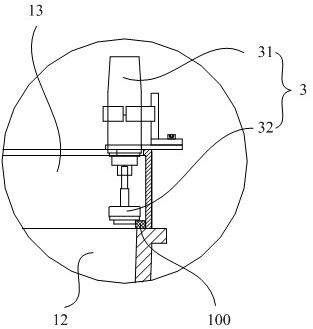

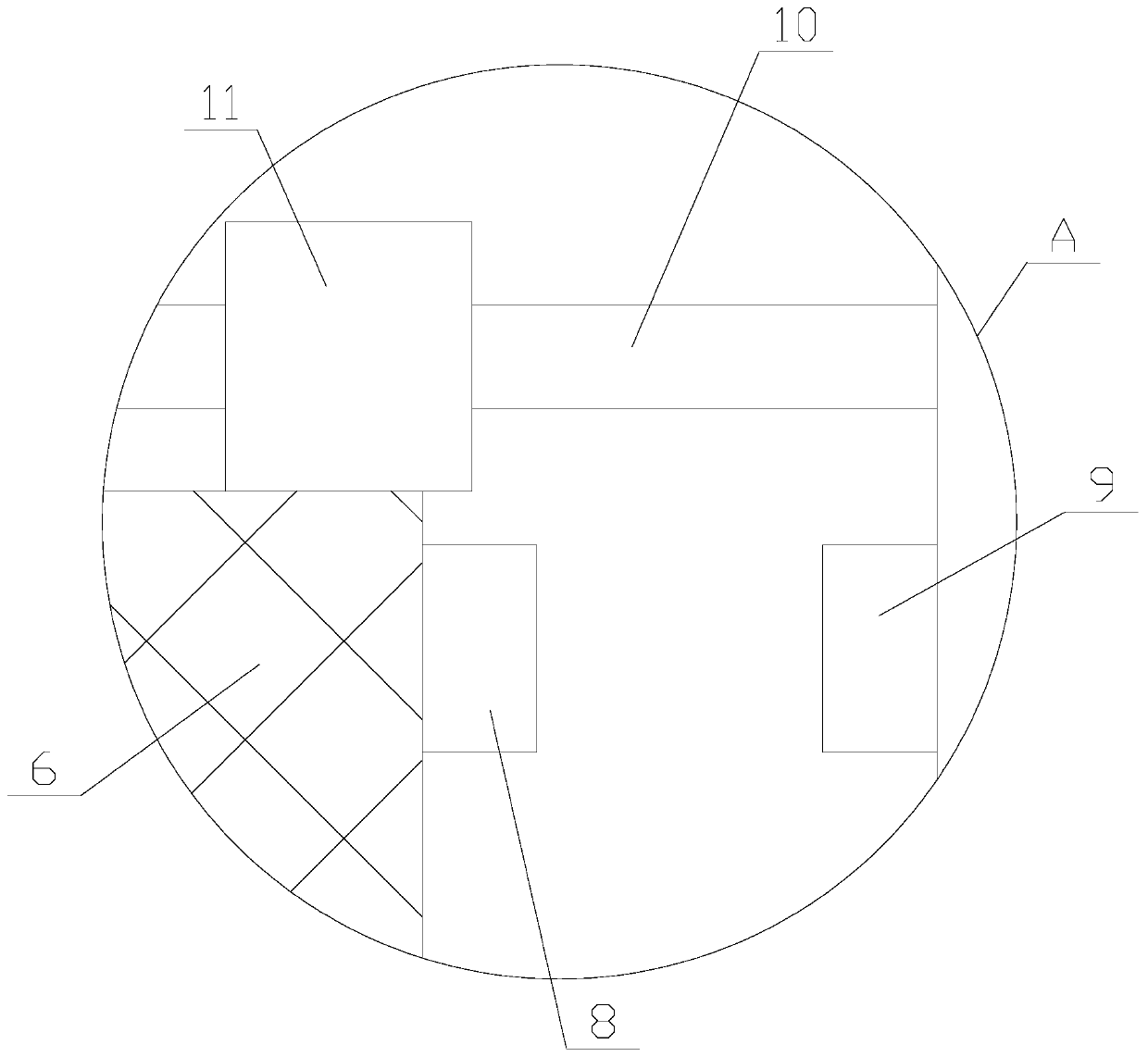

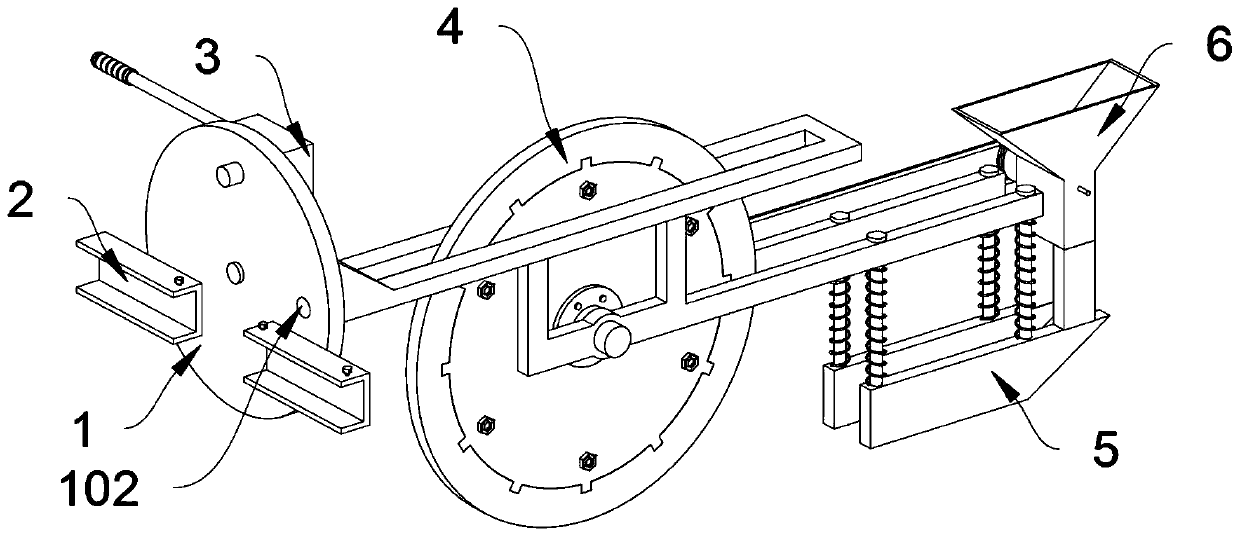

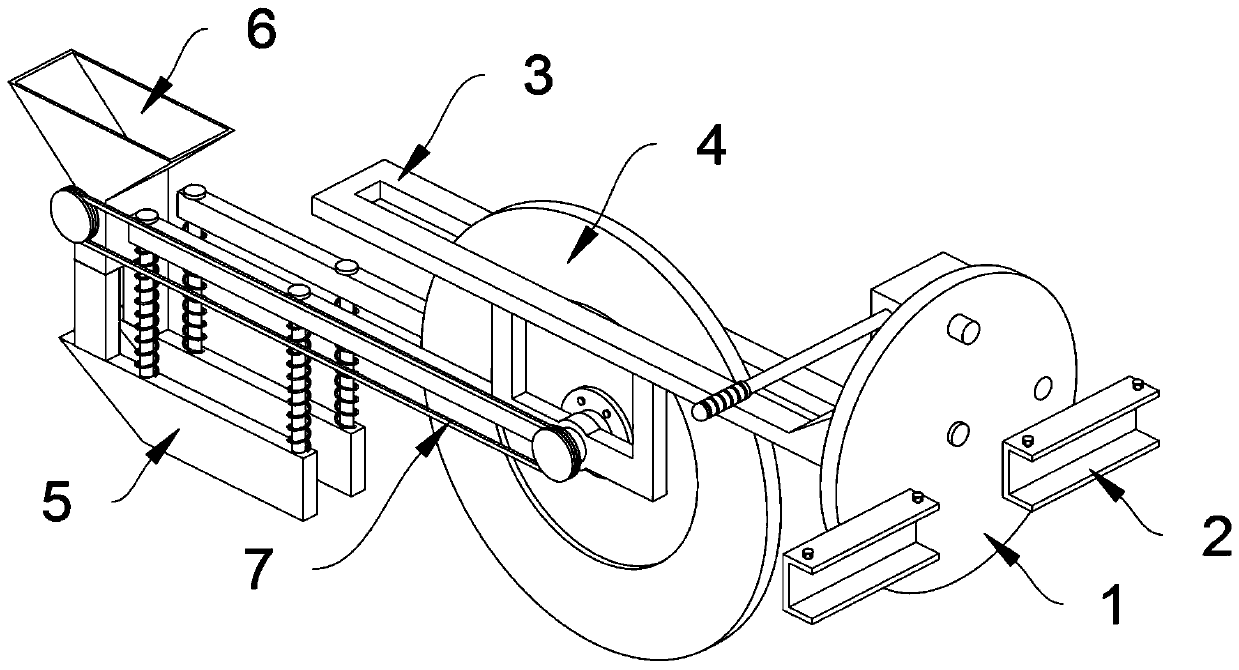

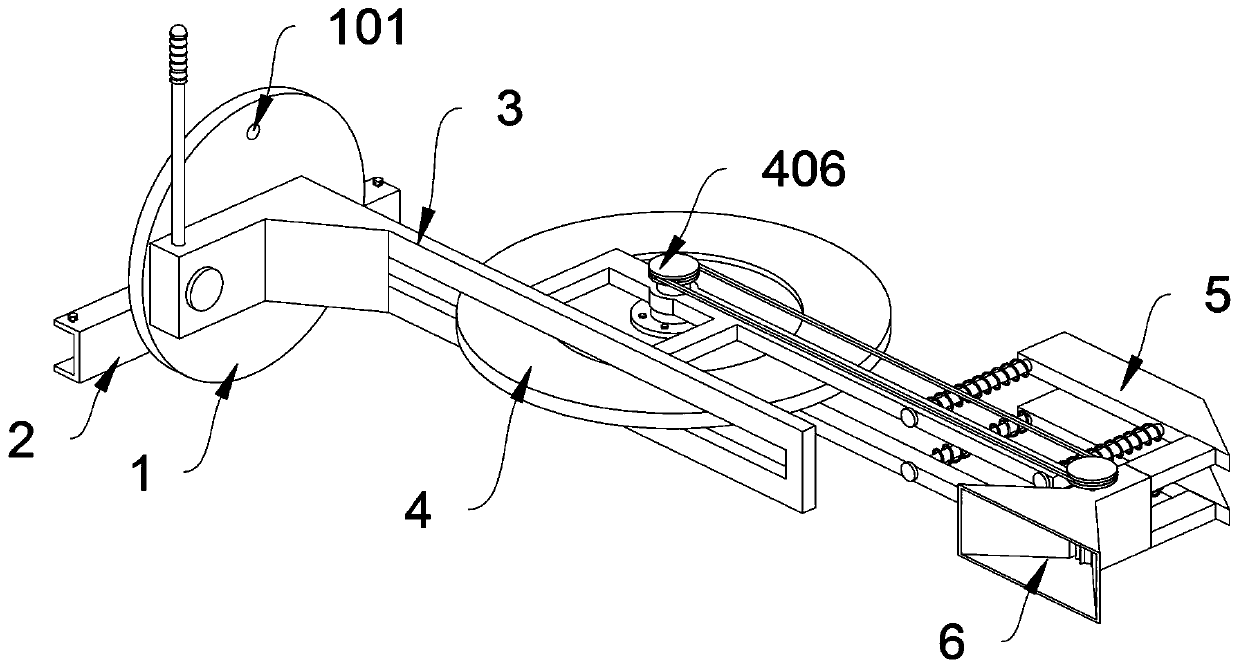

Fish classification device of interrupted bamboo-joint type nonlinear structure

PendingCN107593561ASatisfy precision processingMeet the surface roughness processing requirementsPisciculture and aquariaNonlinear structureJoints types

Provided is a fish classification device of an interrupted bamboo-joint type nonlinear structure. The device includes a feeding mechanism, a discharging mechanism and a classification aligning mechanism; a discharging end of the feeding mechanism is connected with a feeding end of the discharging mechanism, the classification aligning mechanism is positioned above the discharging mechanism, the feeding mechanism comprises a feeding hopper and a feeding pipe, and an outlet end of the feeding hopper is connected with an inlet end of the feeding pipe; the discharging mechanism comprises a guide rail rod, a discharging plate, a side baffle, a guide rail front-end plate and a guide rail rear-end plate; the side baffle is positioned at the lateral side of the discharging plate; the guide rail front-end plate is positioned at the inlet end of the discharging plate; the guide rail rear-end plate is positioned at an outlet end of the discharging plate; the guide rail rod is arranged above the discharging plate; one end of the guide rail rod is connected with the guide rail front-end plate, and the other end of the guide rail rod is connected with the guide rail rear-end plate; the classification aligning mechanism comprises a cross beam, a cross beam rod, a connecting rod and a baffle, the cross beam is arranged on the side baffle, the cross beam rod is located in a groove of the crossbeam, the connecting rod is matched with the cross beam rod, and the baffle is matched with the connecting rod.

Owner:SHANGHAI OCEAN UNIV

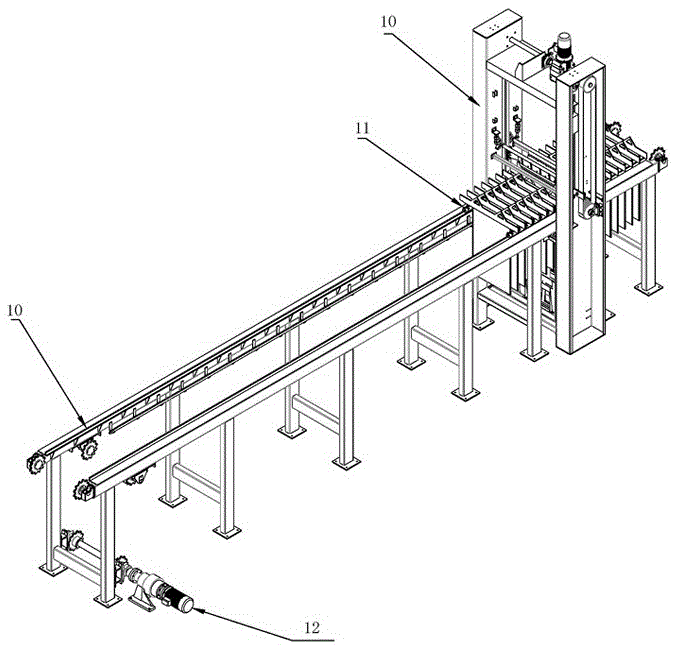

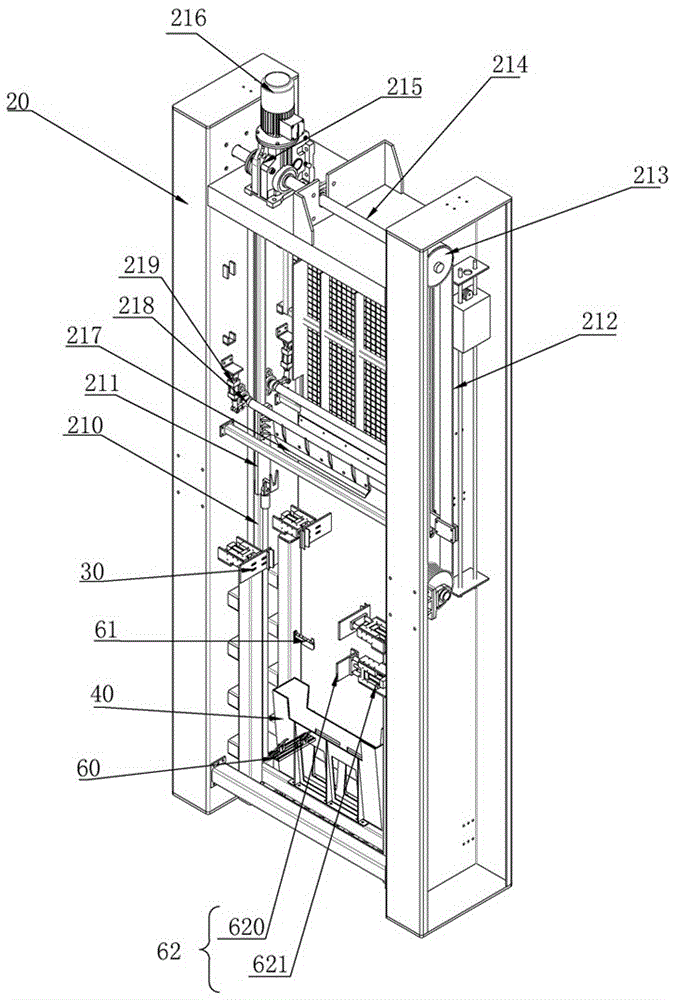

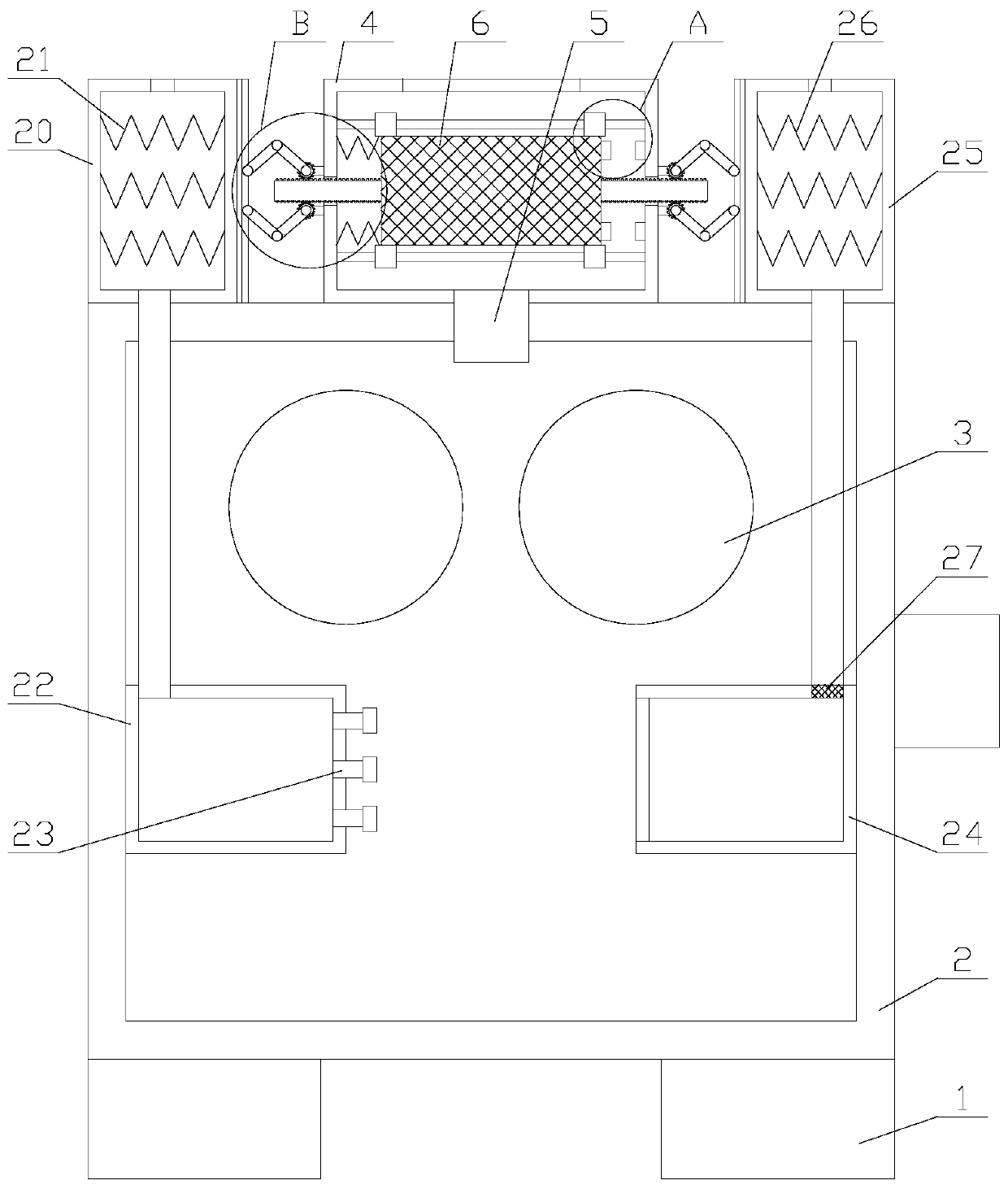

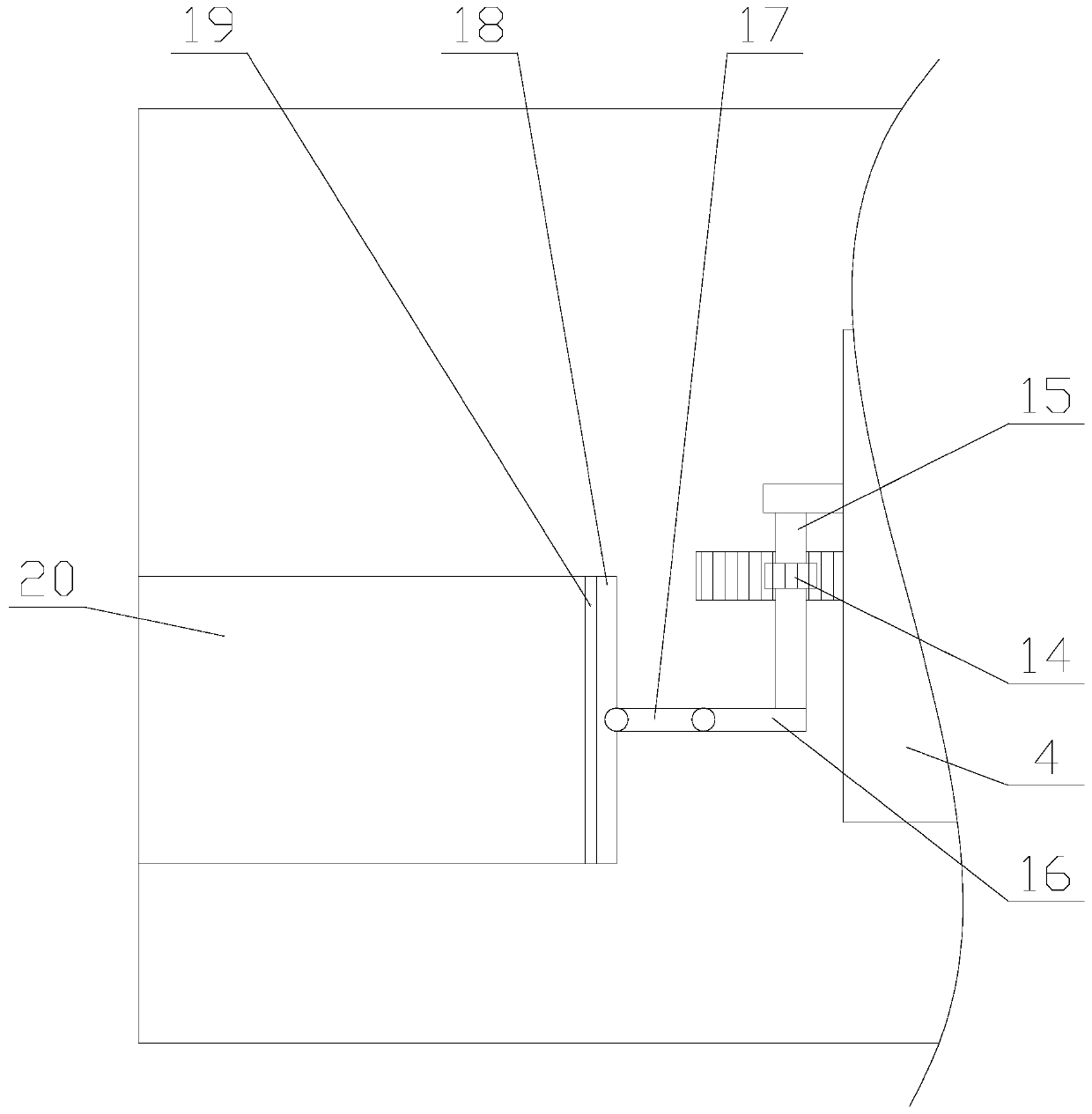

Automatic zinc sheet cathode plate stripping machine

The invention relates to an automatic zinc sheet cathode plate stripping machine. The machine comprises a conveying device and a stripping device connected with the conveying device, and further comprises an aligning and clamping device, buffer introducing devices and a cathode plate swing retarding device. The aligning and clamping device comprises two pairs of clamping plates which are arranged on a rack and driven by cylinders. The two pairs of clamping plates are located on the front side and the rear side of a lifting track correspondingly. Each pair of clamping plates is oppositely fixed to the left side and the right side of the rack. Each buffer introducing device is a V-shaped trough fixedly connected with a lifting mechanism and moves synchronously with the lifting mechanism. The cathode plate swing retarding device comprises a first one-way passing unit, a safety unit and a second one-way passing unit. The full-automatic cathode plate stripping machine adopting the devices has the advantages of being capable of effectively reducing the plate stuck phenomenon and achieving automatic operation in the whole process, high in production efficiency and capable of effectively reducing accidents.

Owner:HENAN YUGUANG METALLURGICAL MACHINERY MFG CO LTD

Adjustable shared bicycle lock

InactiveCN112224313AShort strokeImprove structural strengthAnti-theft cycle devicesMagnetorheological fluidMagneto rheological

The invention relates to the technical field of anti-theft equipment, and discloses an adjustable shared bicycle lock which comprises an axle, a rotating disc is assembled on the side wall of the axle, a fixed disc is arranged outside the rotating disc in a sleeving mode, and a filling cavity filled with magnetorheological fluid is formed between the rotating disc and the fixed disc. According tothe adjustable shared bicycle lock, the viscosity of magnetorheological fluid is controlled through the size of the outlet of the magnetic block, then riding resistance is controlled, when a user onlynormally commences, the user selects a state with small resistance and normally cleans the bicycle to reach a destination, and when the user needs to do fitness, riding resistance is improved, and riding exercise intensity is increased; when the resistance is adjusted to the maximum, the shared bicycle can hardly be ridden, so that the purpose of limiting the use of the shared bicycle is achievedby replacing a traditional bicycle lock, and secondly, main parts are all located in the axle and the fixed disc, are slightly influenced by the external severe environment and reduce the failure rate.

Owner:陈丽敏

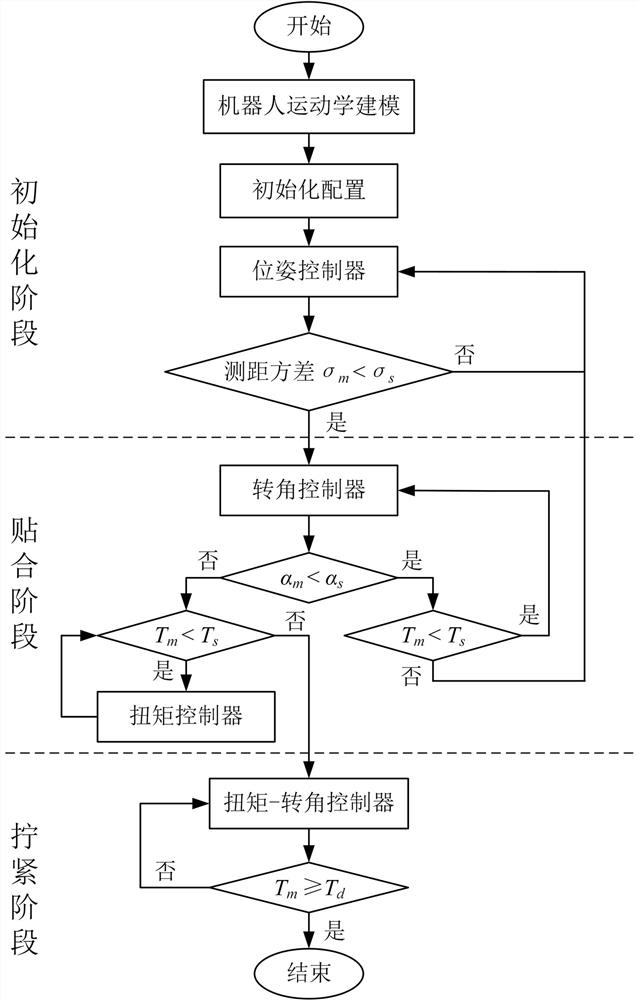

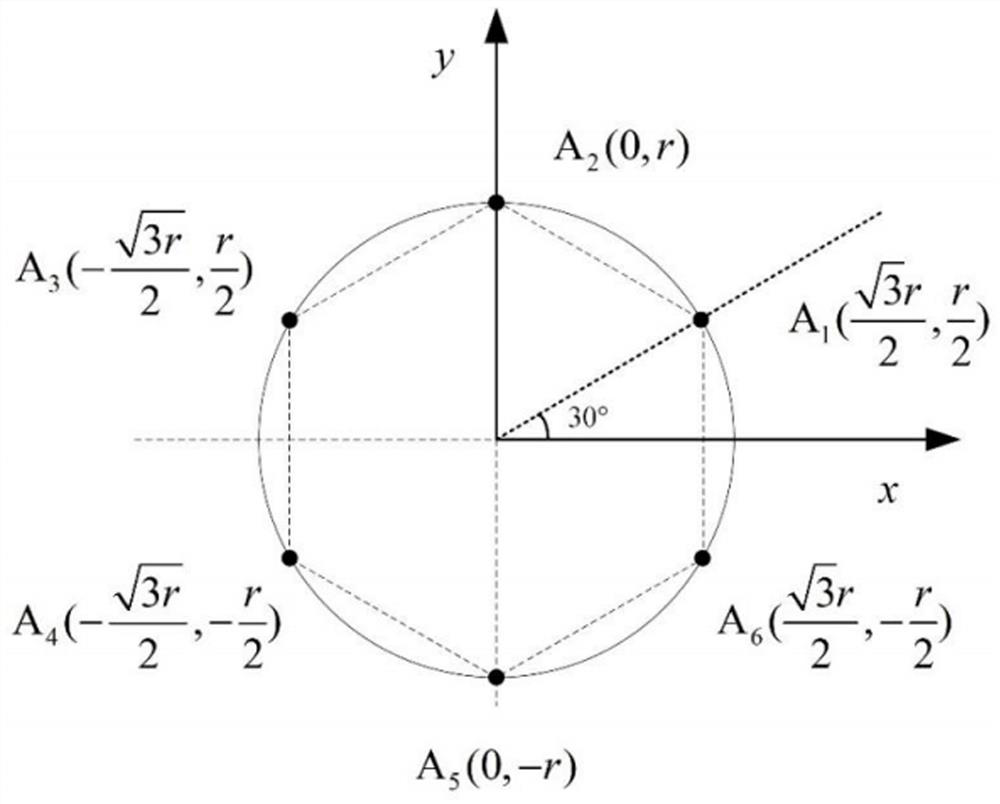

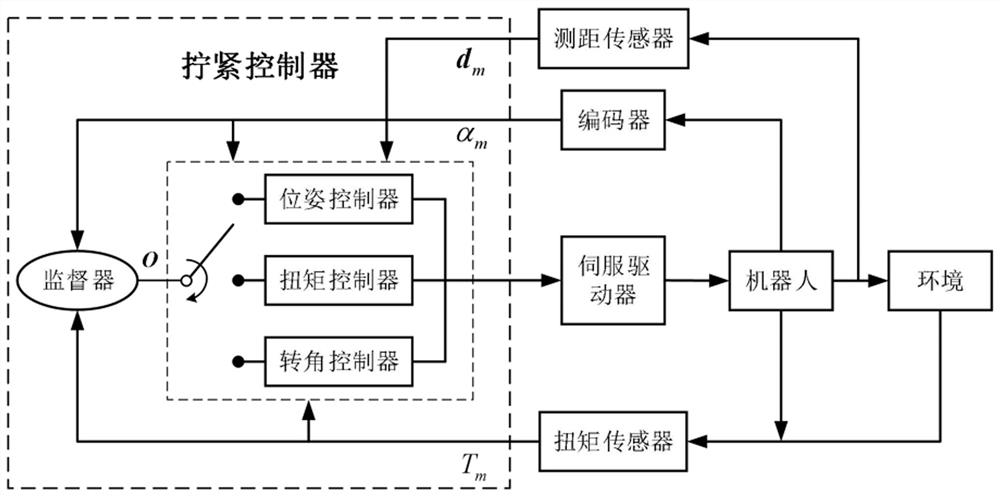

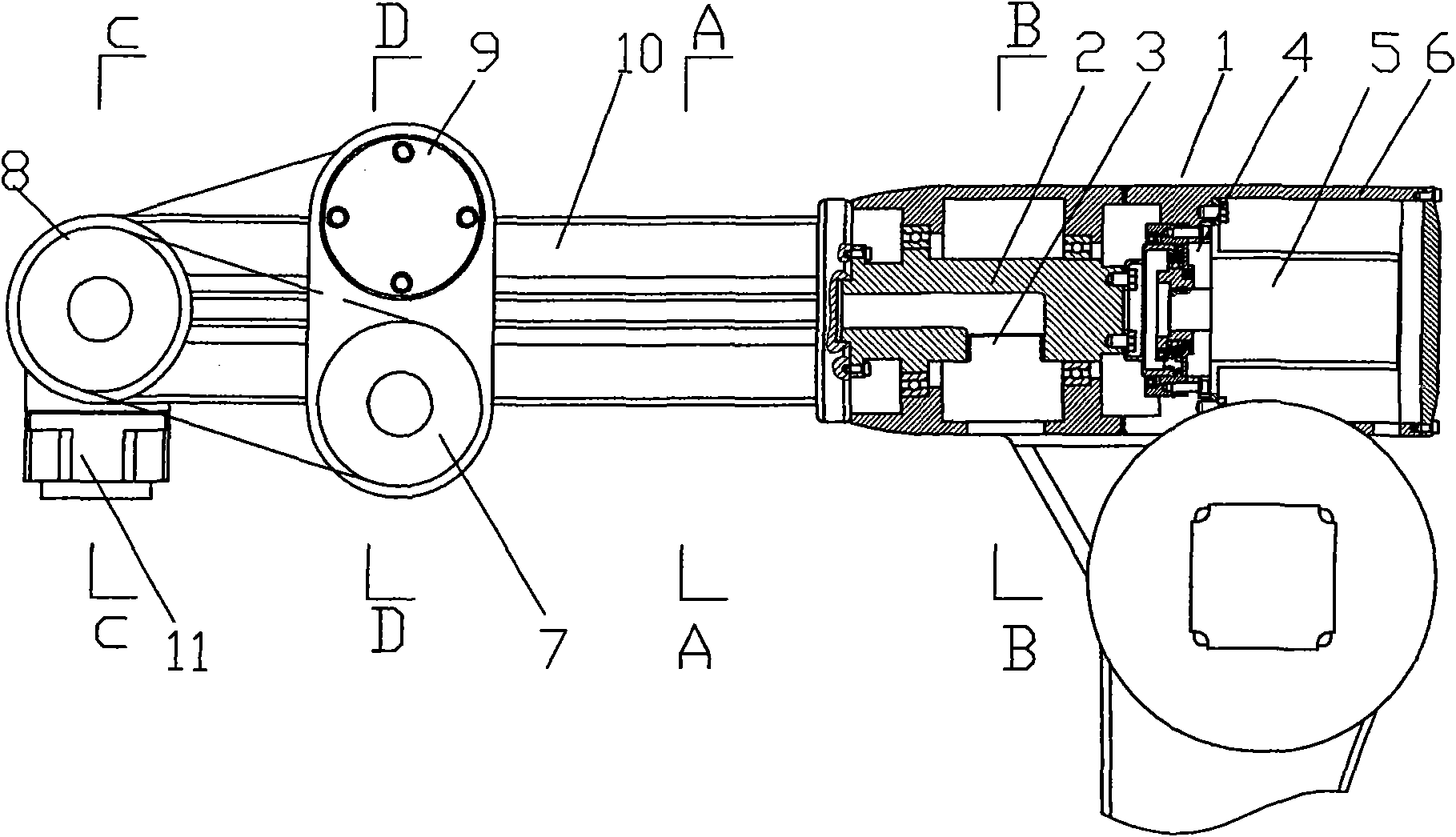

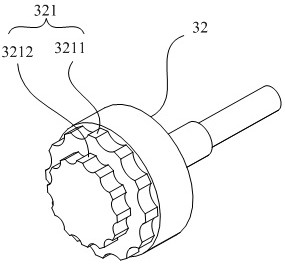

Nine-degree-of-freedom robot tightening control method for assembling thin-wall large threaded part

ActiveCN112720473AEnables automatic alignmentTo achieve error compensationProgramme-controlled manipulatorLaser rangingHandoff control

The invention discloses a nine-degree-of-freedom robot tightening control method for assembling a thin-wall large threaded part. The robot tightening control system comprises a tightening controller, a six-degree-of-freedom Stewart platform and a three-degree-of-freedom series mechanism, wherein the six-degree-of-freedom Stewart platform is located at the bottom and used for adjusting the pose of an upper platform tightening mechanism; the three-degree-of-freedom series mechanism is fixed to the six-degree-of-freedom Stewart platform and used for executing tightening control; a laser ranging module is used for collecting information about the distance between a shell and a to-be-assembled bolt piece, and axial alignment of the bolt piece and the shell and pose error correction in the fitting stage are achieved through a pose compensation algorithm; and a switching control method based on a pose / torque / corner controller is used, and a segmented switching control strategy is executed according to feedback information of various heterogeneous sensors. According to the method, automatic alignment, error compensation and tightening control operations in the assembly of the thin-wall large-thread part are realized, the occurrence probability of the thread pair jamming phenomenon can be reduced, and the assembly efficiency and quality of the thin-wall large-thread part are effectively improved.

Owner:HENAN UNIV OF SCI & TECH

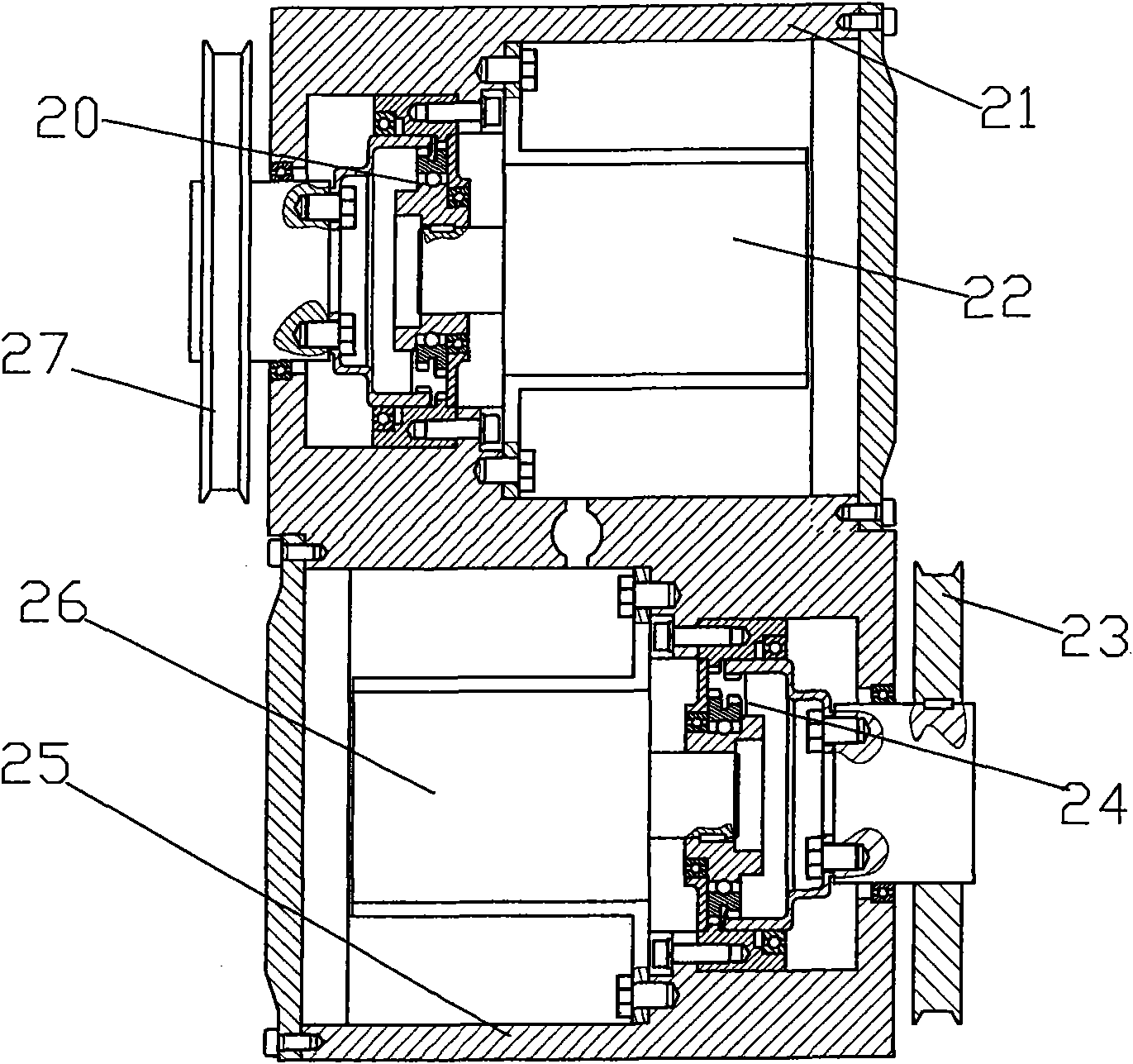

Filtering driving device and intelligent robot integrated system

The invention discloses a filtering driving device and intelligent robot integrated system, comprising a filtering driving device, a mechanical arm and a mechanical wrist; wherein rotation of the mechanical arm around self axis, pitching movement of the wrist and rotation of the mechanical wrist around self axis all adopt a filtering driving device with high precision less differential gear reducer. The mechanical arm of the invention is flexible smoothly, arm driving and transmission gear is arranged in an integrated way, assembly error can be reduced to utmost extent, transmission accuracy is improved, running state of a transmission gear is improved, bite phenomenon in running is avoided, abrasion among running components is reduced, running noise of mechanism is reduced, transmission efficiency is improved, high performance electromechanical transmission and robot integrated system with high precision, high reliability, long service life, low energy consumption, small volume and light weight is realized, and meanwhile manufacturing processing technology is simple, production manufacturing cost is low, mounting and committing are easy, and dismounting and maintenance are convenient. The invention can be widely applied to engineering equipment in fields of robot, space flight, shipping, automation, advanced manufacturing and the like.

Owner:SICHUAN UNIV +1

Compensation dropper full-pneumatic screening and storing device and drip irrigation pipe belt production line

The invention provides a compensation dropper full-pneumatic screening and storing device and a drip irrigation pipe belt production line. The compensation dropper full-pneumatic screening and storingdevice comprises a dropper screening device and a dropper storing device. The dropper storing device comprises a groove plate, a bottom plate, a pressing plate and an air supply module. The groove plate is provided with a first spiral groove and further provided with a plurality of ventilation holes. The ventilation holes are distributed in the extending direction of the first spiral groove and communicate with the first spiral groove. The bottom plate is arranged at the bottom of the groove plate and further provided with an air inlet. A second spiral groove is formed in the upper surface ofthe bottom plate. The air inlet communicates with the second spiral groove. The second spiral groove is located below the first spiral groove and communicates with the ventilation holes. The air supply module is connected with the air inlet and used for delivering air to an air inlet cavity. The pressing plate covers the first spiral groove. The first spiral groove is connected with an outlet ofa delivering channel. Accordingly, the circumstance that droppers are jammed is reduced, the using reliability is improved, and thus, the requirement for continuous running of the production line is met.

Owner:QINGDAO XINDACHENG PLASTIC MACHINERY

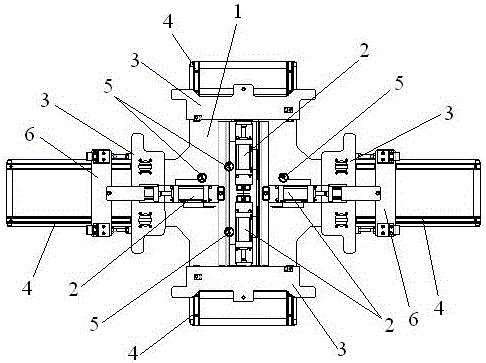

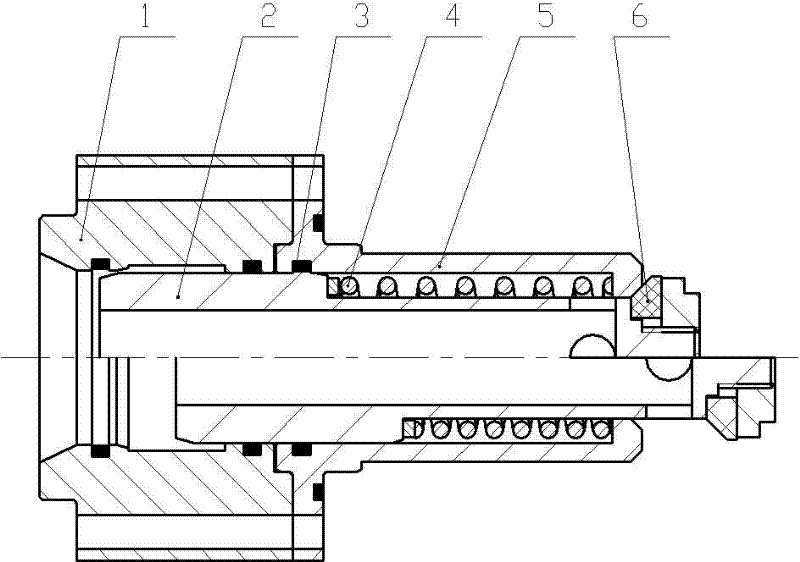

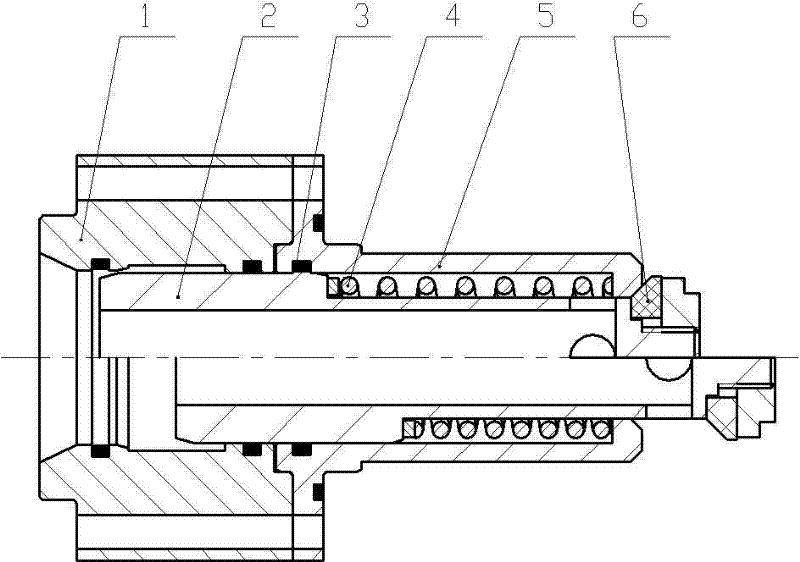

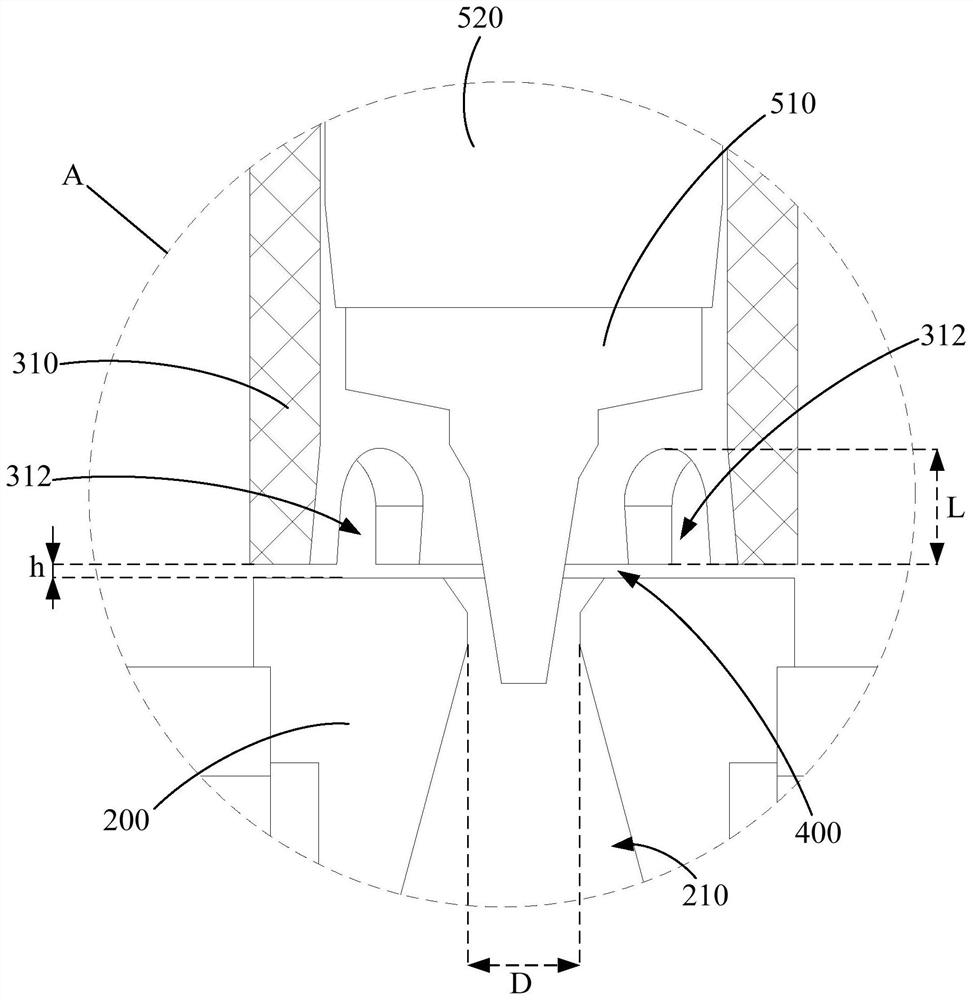

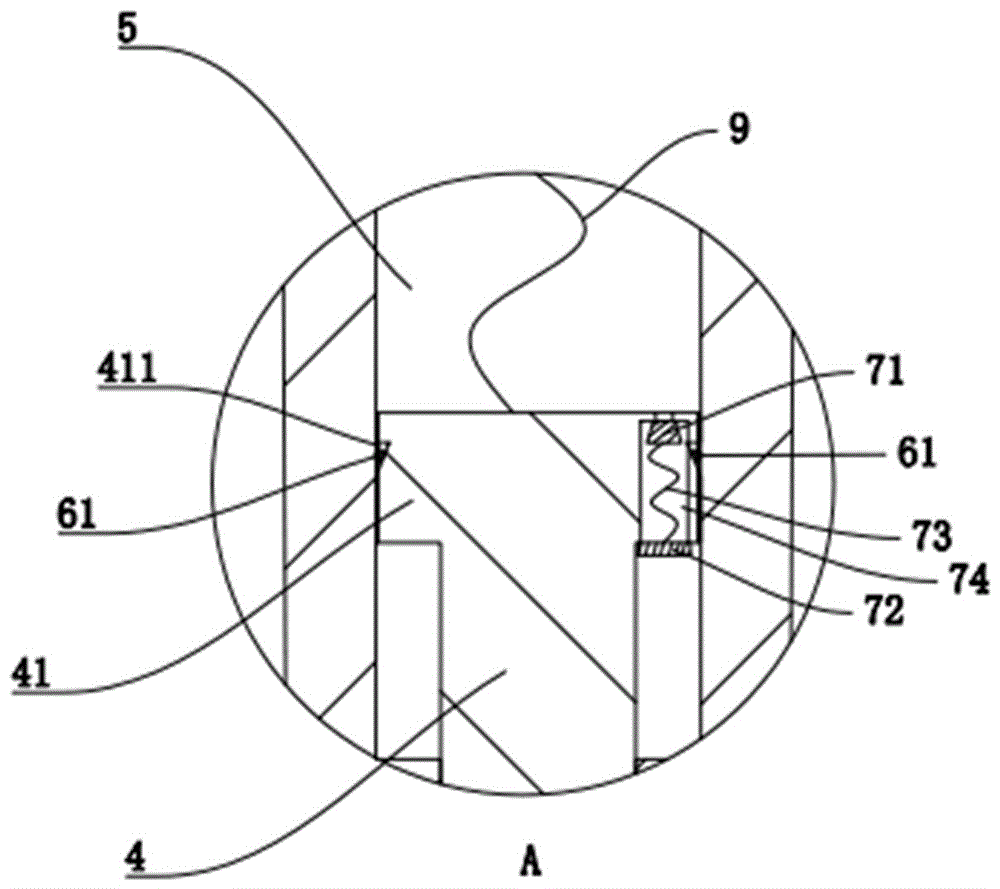

Pneumatic flexible core assembling tool

InactiveCN106180575AReduce stuck not in placeReduce core movementFoundry mouldsFoundry coresPneumatic cylinderPiston

The invention relates to the field of casting technologies, in particular to a pneumatic flexible core assembling tool. The pneumatic flexible core assembling tool comprises four sets of pneumatic core assembling tables. The pneumatic core assembling tables are arranged in the X direction and the Y direction of a plane core assembling platform correspondingly, and every two sets of pneumatic core assembling tables are arranged oppositely. Each set of pneumatic core assembling table comprises a pneumatic cylinder, a clay core positioning block, guide rails and a regulating valve. A piston of each pneumatic cylinder is connected with the corresponding clay core positioning block through a connecting rod. Each clay core positioning block is installed on the corresponding guide rails. Each regulating valve communicates with the corresponding pneumatic cylinder. The guide rails are further provided with buffer type clay core positioning blocks. Each clay core positioning block is connected with the corresponding buffer type clay core positioning block. The pneumatic flexible core assembling tool has the beneficial effects that first, the phenomenon that castings with a high dimensional accuracy requirement cannot get stuck in place is reduced, and brittleness core assembly damage and scrapping are also reduced; and second, as for castings with a low dimensional accuracy requirement, the fit clearance of clay cores can be made relatively small, clay core movement can be reduced, and dimensional accuracy of inner cavities of the castings is improved.

Owner:JIANGLING MOTORS

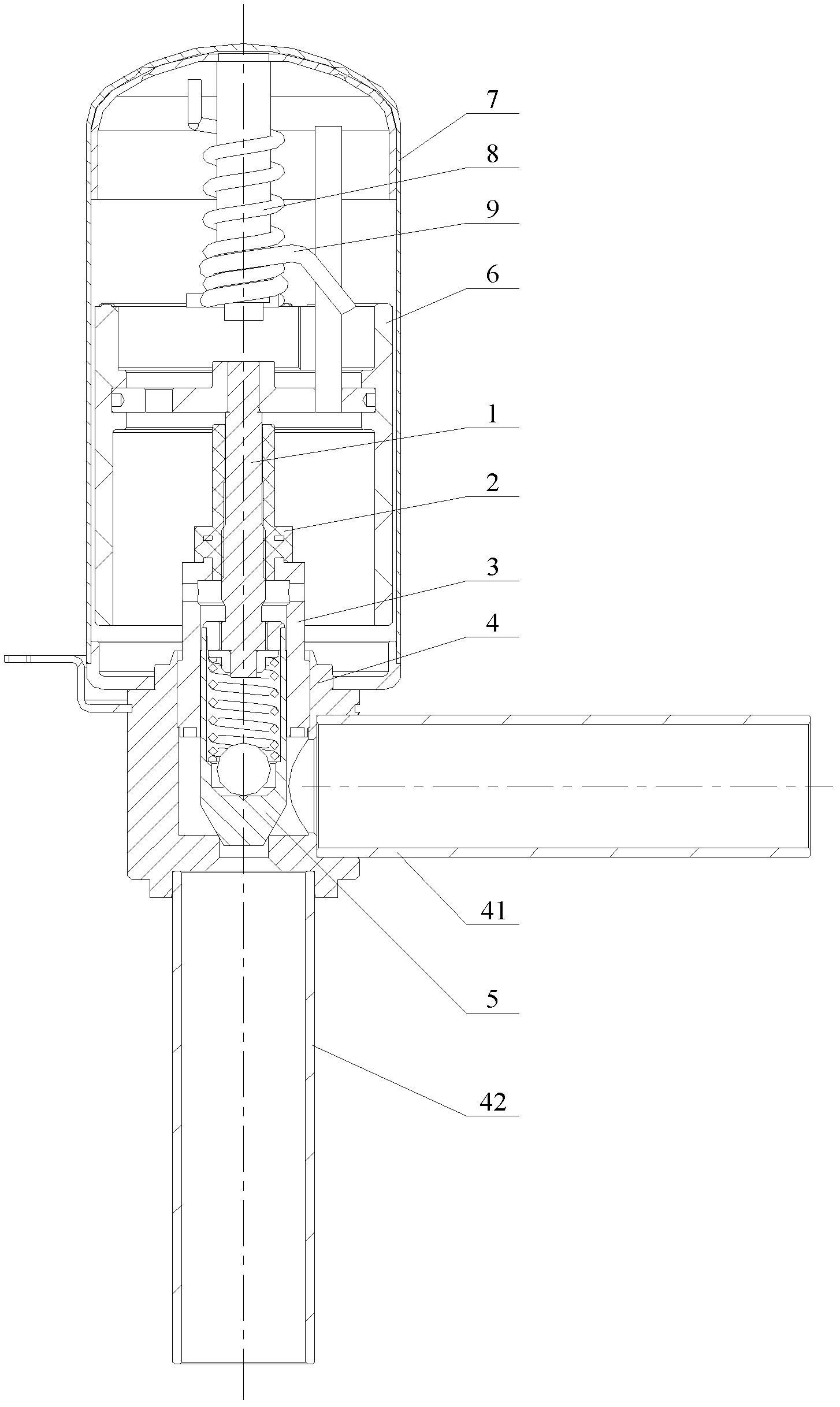

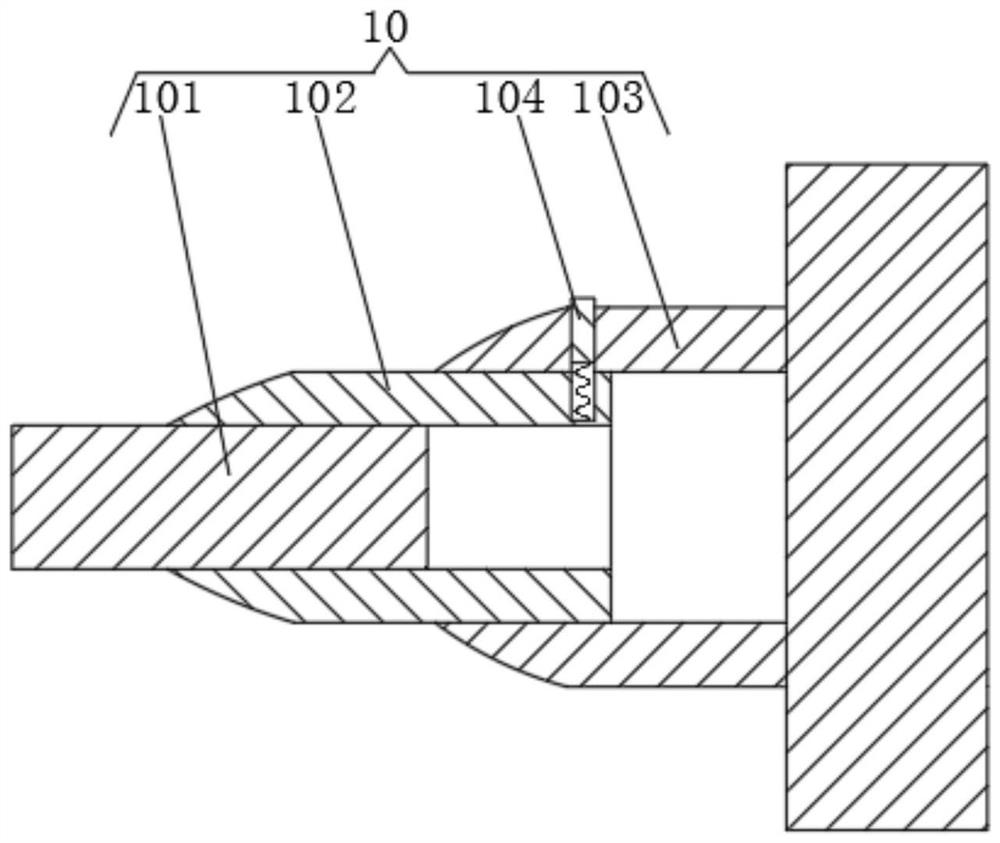

Rapid water joint structure of mill frame

InactiveCN102228906AReduce stuck phenomenonGuaranteed service lifeMetal rolling stand detailsRollsEngineeringJoint surface

The invention provides a rapid water joint structure of a mill frame. The structure is capable of avoiding the phenomenon of valve core block in the use process and has good tightness and long service life. The structure comprises a valve shell formed by connecting a joint with a sleeve; and a T-shaped valve core is buckled in the valve shell. The structure is characterized in that the rod part of the T-shaped valve core and the valve shell define a cavity; a spring is arranged in the cavity; the two ends of the cavity respectively press against a buckled joint surface of the valve core and the valve shell; the head part of the valve core is hollow; the tail part of the valve core is a blind end; the tail part of the valve core and the body of the valve core are provided with through holes; a tail sleeve of the valve core is provided with a gasket nut; and the gasket nut abuts against the end of the sleeve under the condition of the reset of the valve core, and the through holes are arranged inside the valve shell.

Owner:WUXI SEAMLESS OIL PIPE

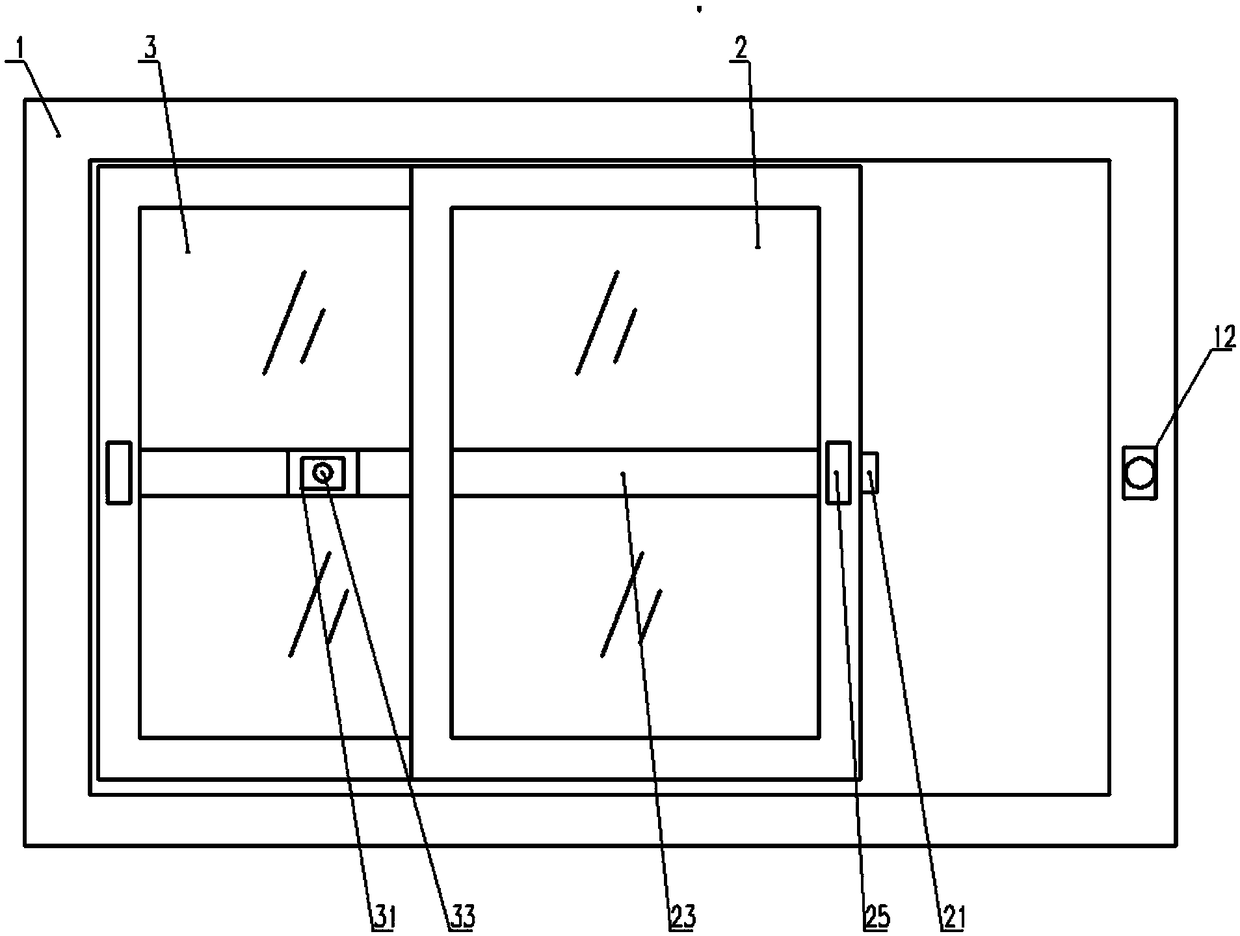

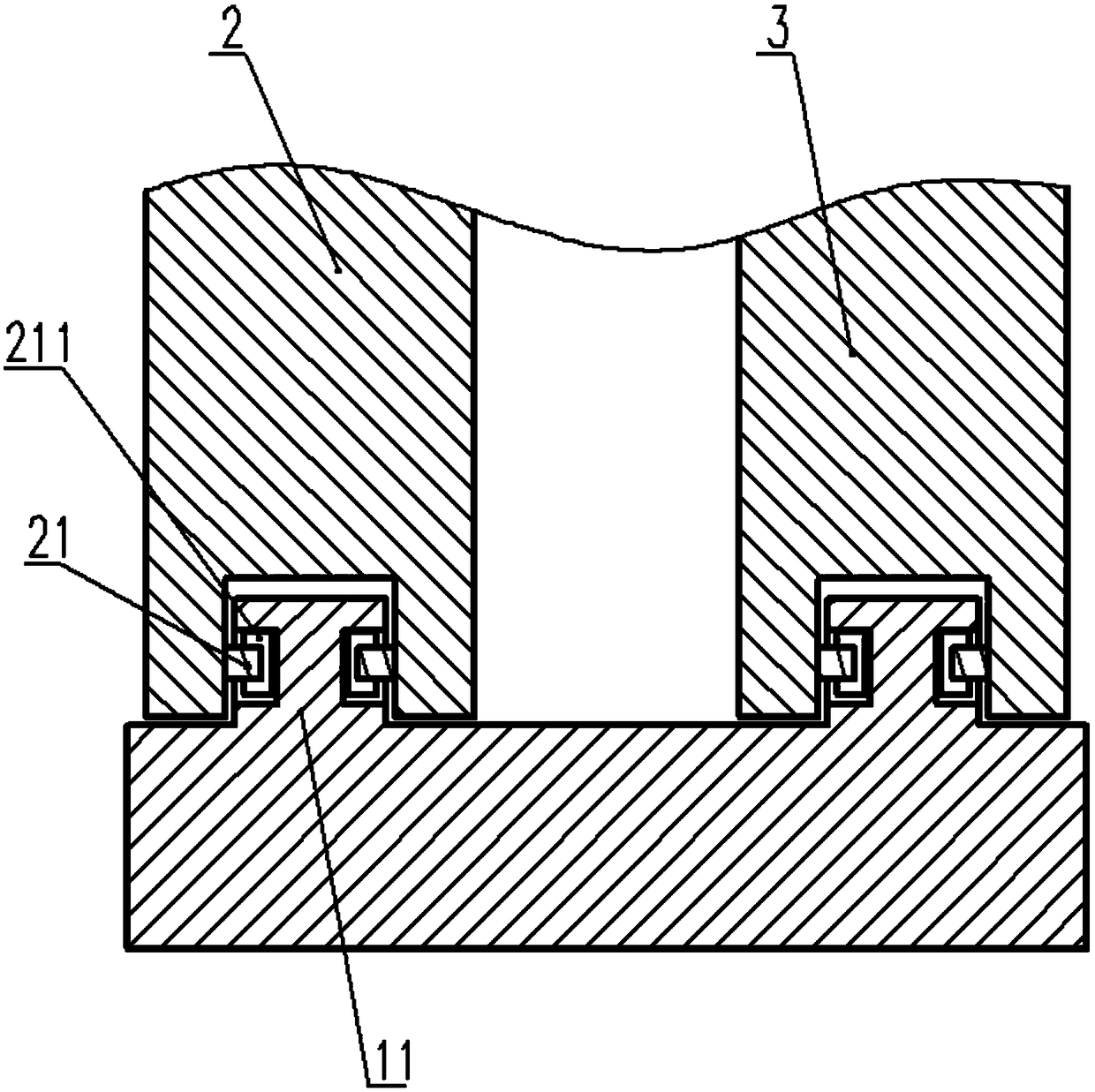

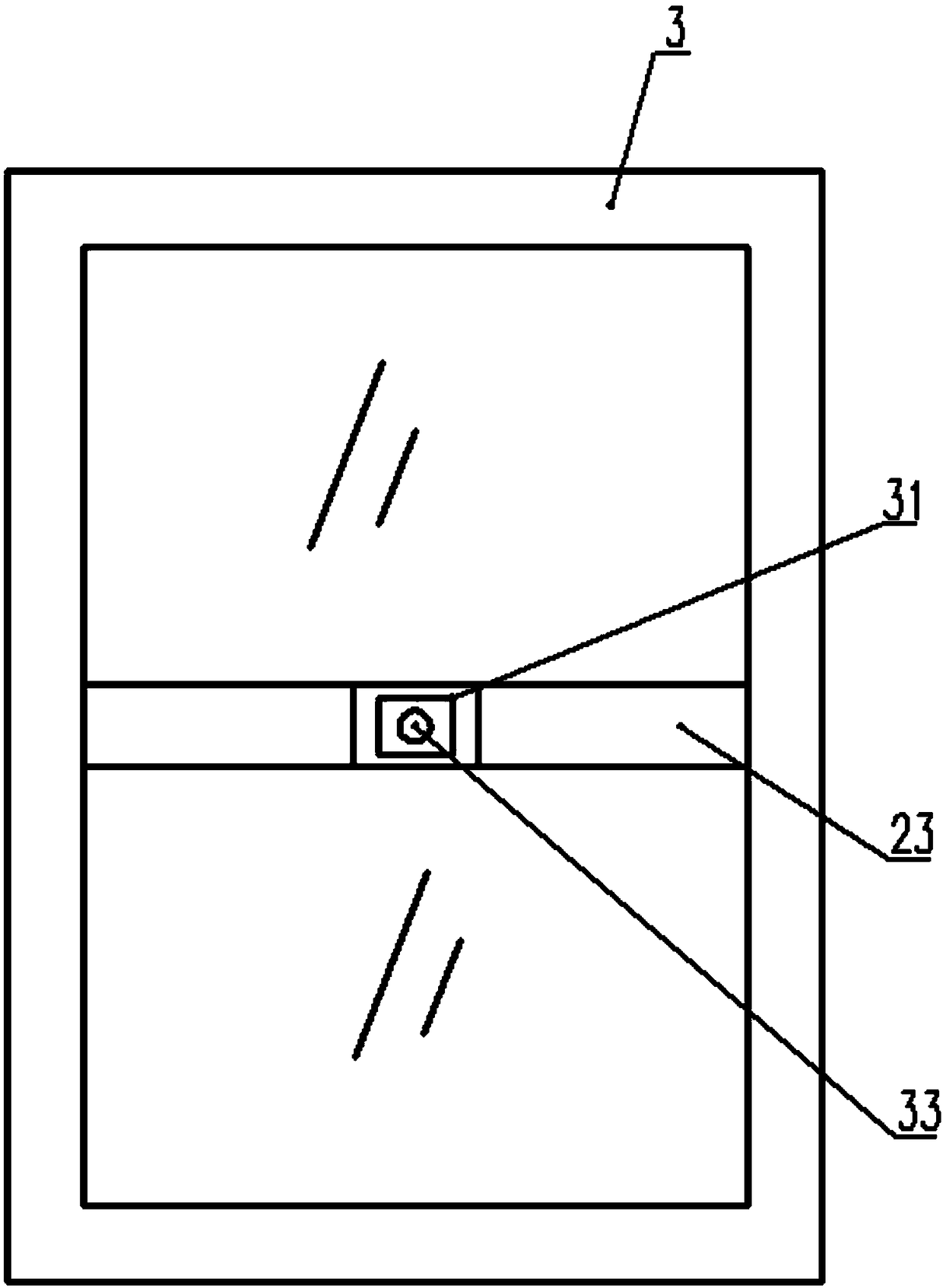

Aluminum alloy window convenient to push and pull

InactiveCN109386214ASlide to achieveDifficult to escapeWing arrangementsWing suspension devicesPush and pullSlide window

The invention discloses an aluminum alloy window convenient to push and pull, and relates to the field of building materials. The aluminum alloy window comprises a frame, an outer-layer sliding windowbody and an inner-layer sliding window body; the upper and lower ends of the frame are provided with two sliding rails front and back respectively, the upper and lower ends of the outer-layer slidingwindow body and the upper and lower ends of the inner-layer sliding window body are provided with sliding grooves, the outer-layer sliding window body is installed on the frame through the sliding rail at the back portion, and the inner-layer sliding window body is installed on the frame through the sliding rail at the front portion; the left and right sides of the frame are provided with lockingdevice respectively, the left side of the outer-layer sliding window body and the right side of the inner-layer sliding window body are provided with locking blocks, and the locking blocks correspondto the two locking devices respectively. The aluminum alloy window solves the problems that in the prior art, an aluminum alloy push-and-pull window is easily stuck during sliding, and when inner andouter window bodies are located at the same position, the window body at the outer layer cannot be pushed and pulled.

Owner:广信铝业股份有限公司

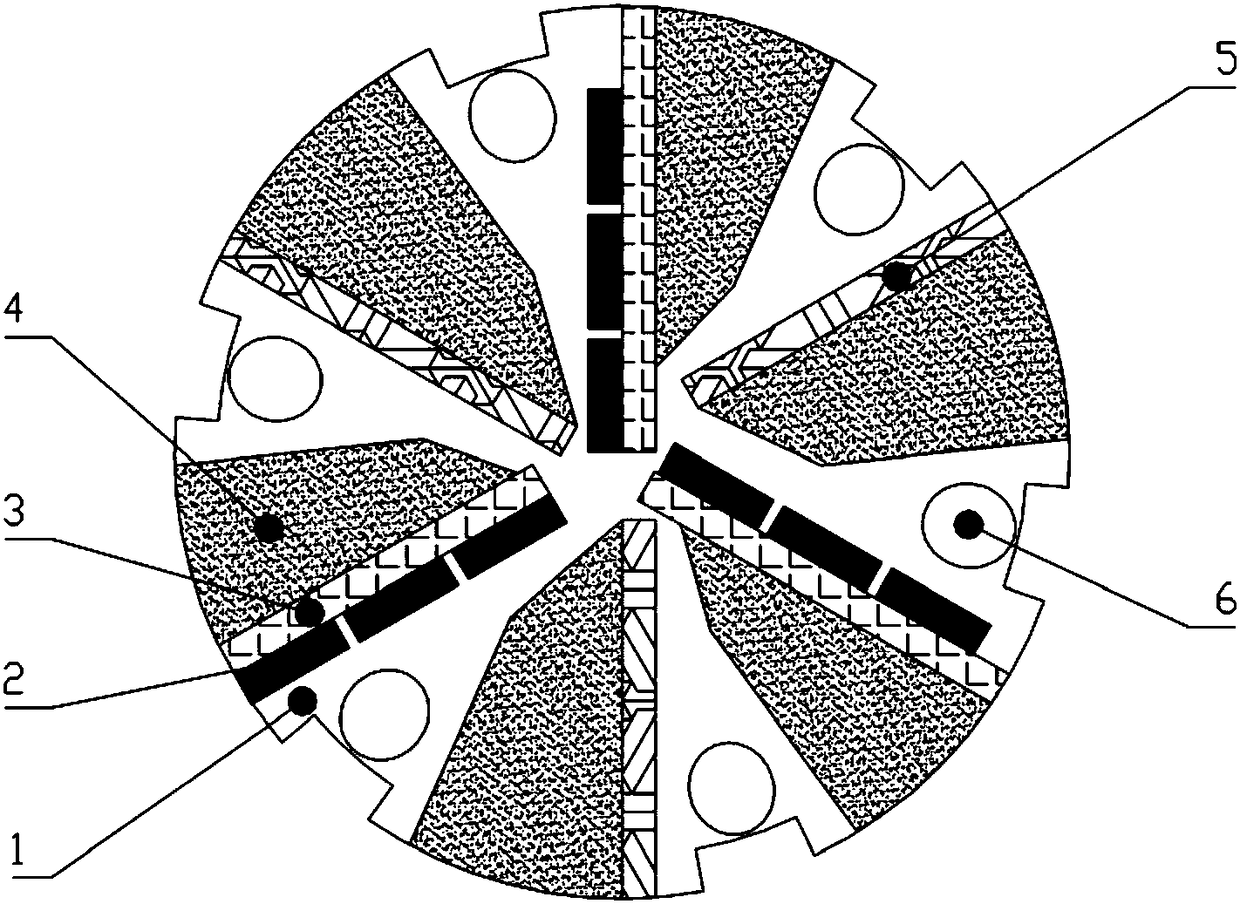

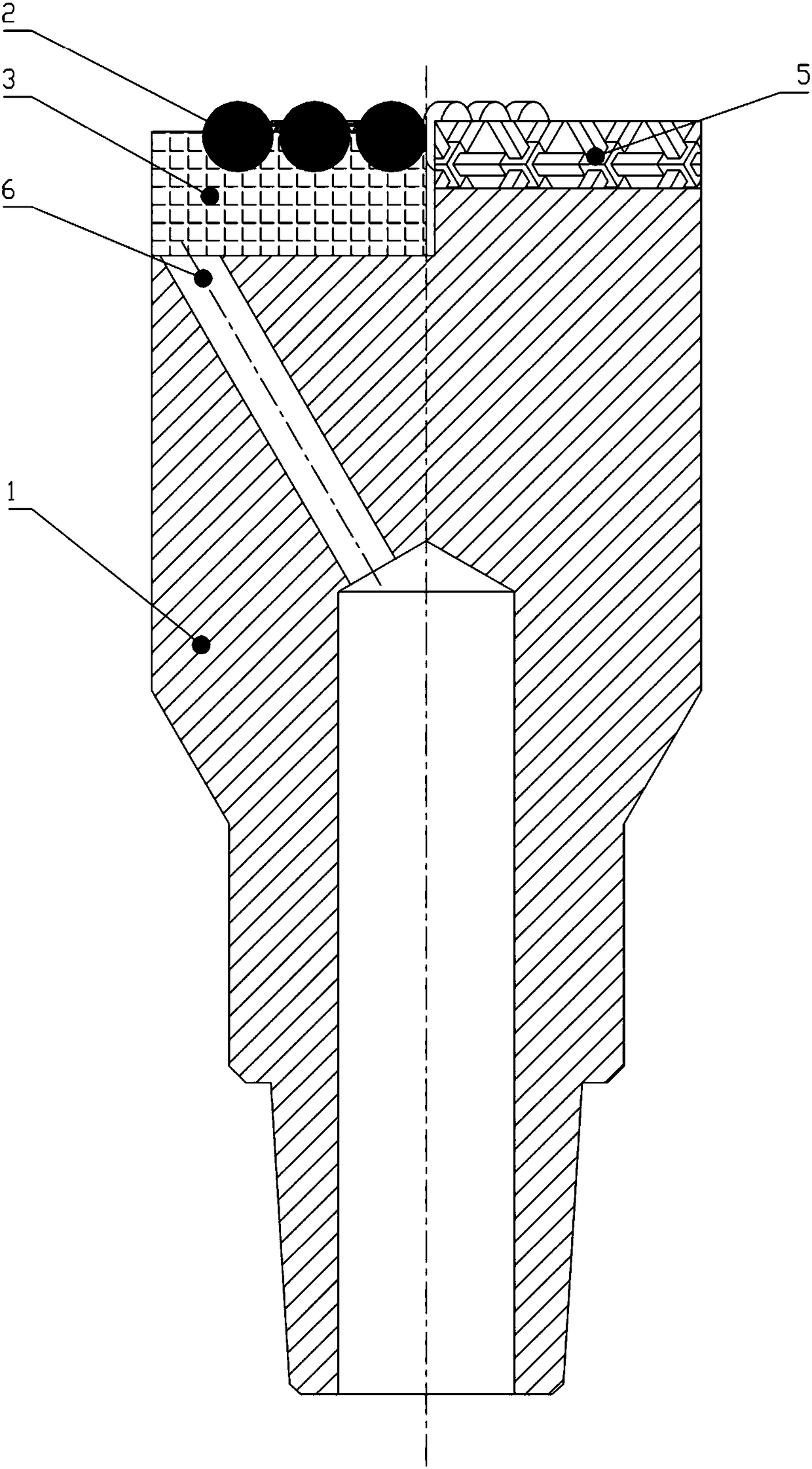

Compound milling shoes with various cutting elements

InactiveCN108590558AHigh speedImprove efficiencyBorehole/well accessoriesPolycrystalline diamondCemented carbide

The invention discloses compound milling shoes with various cutting elements. The compound milling shoes with the various cutting elements comprise milling shoe bodies 1, polycrystalline diamond compact blades 3 and second-stage cutting blades 5 are distributed in the milling shoe bodies 1 at intervals, a plurality of polycrystalline diamond compacts 2 are arranged in front of the polycrystallinediamond compact blades 3 in the radial direction, and irregular cemented carbide cutting particles 4 are welded behind the polycrystalline diamond compact blades 3 and second-stage cutting blades 5 ina overlaying mode. The fluid cools the working milling shoes and brings the debris of drilling and milling out of the bottom of a well through water holes 6 formed between every two blades. The compound milling shoes with the various cutting elements have the advantages that the various cutting elements can improve the adaptability of the milling shoes to drill and mill various types of bridge plugs, the service life of the milling shoes is prolonged, the size of drill and grind debris particles is reduced, and the drilling milling speed and efficiency are improved.

Owner:四川安苏能源科技有限公司

Sealing assembly and sealing equipment

PendingCN106677737AGuaranteed sealing performanceIt has the function of sand discharge and self-cleaningSealing/packingEngineeringMechanical engineering

The invention provides a sealing assembly and sealing equipment comprising the sealing assembly. The sealing assembly comprises a sliding sleeve, a sealing sleeve, a first limiting sleeve, a second limiting sleeve and an inner fixed sleeve. The first limiting sleeve and the second limiting sleeve are fixed to the two ends of the inner fixed sleeve correspondingly. The sliding sleeve is formed by splicing at least two sliding branched petals, and the two ends of each sliding branched petal are mounted in the first limiting sleeve and the second limiting sleeve in a radial moving fit mode correspondingly. The outer wall of the sealing sleeve is in seal fit with the inner wall surface of the sliding sleeve. The sealing sleeve is formed by splicing at least two sealing branched petals, and each splicing gap of the sliding branched petals corresponds to one sealing branched petal. An outer boss stretching outwards is arranged on the outer wall of the inner fixed sleeve. An inner boss stretching inwards is arranged on the inner wall of the sliding sleeve. The first side face of the outer boss is in seal fit with the end face of the first side of the inner boss. The sealing performance of the sealing assembly can be guaranteed when the outer diameter of the sealing assembly changes.

Owner:BEIJING AOSAIQI PETROLEUM TECH DEV CO LTD

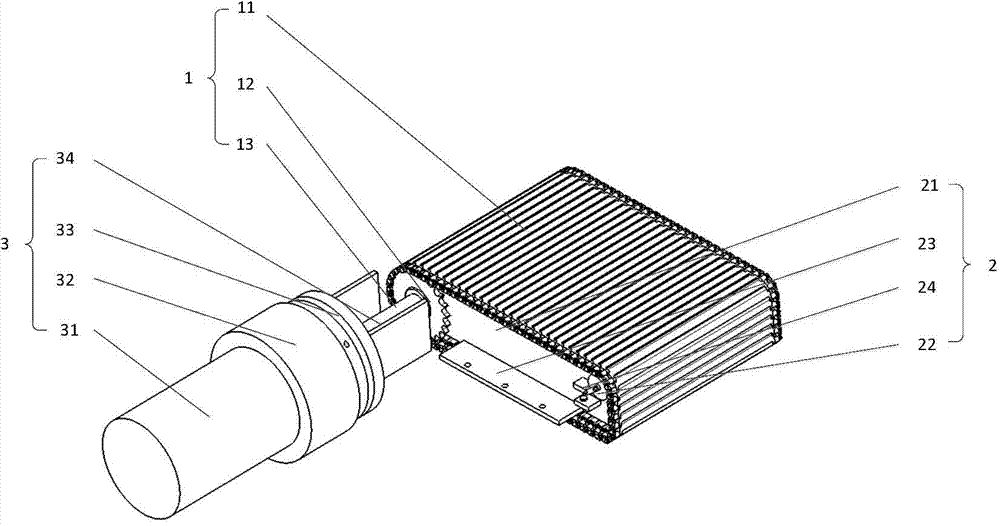

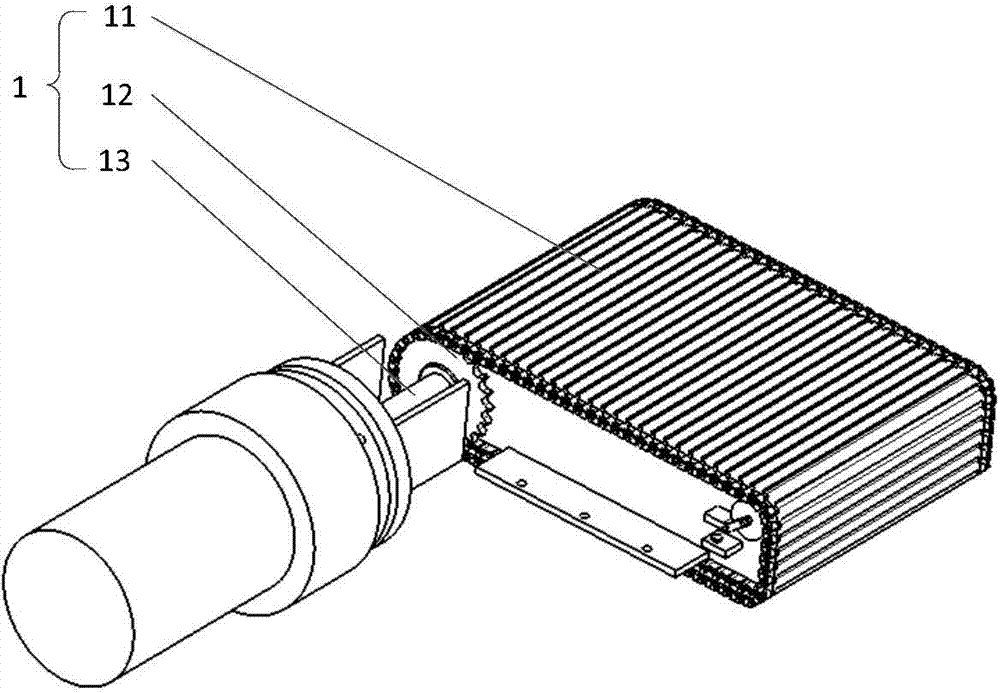

Crawler follower mechanism for thin steel material quenching and leveling process

InactiveCN104120243AIncrease stiffnessIncreased contact areaFurnace typesHeat treatment furnacesRolling-element bearingFuel tank

The invention discloses a crawler follower mechanism for a thin steel material quenching and leveling process. The crawler follower mechanism comprises chain-plate crawler units, an oil tank assembly and a motor transmission system, wherein the chain-plate crawler units are arranged surrounding tank bodies, each chain-plate crawler unit comprises chain wheels, a chain wheel shaft and a closed-ring crawler which is formed through connecting a plurality of chain-plate assemblies in series, and thus, the closed-ring crawlers cyclically revolve around the face of an oil tank under the drive of the chain wheels; each chain-plate assembly comprises a chain plate, chain plate pin shafts, rollers, embedded shafts and rolling bearings; the motor transmission system is connected with the chain wheel shafts and is used for transferring motor power, so that the closed-ring crawlers are driven to cyclically revolve, and meanwhile, relative-sliding-free follow-up with a quenched thin material is realized. Through the crawler follower mechanism, the phenomena that folds appear after the thin material is quenched, the thin material is stuck due to the fact that the rolling bearings are burnt out due to too high temperature of the thin material, and the like can be effectively avoided; meanwhile, the surface quality of the quenched thin material is remarkably improved, and the leveling efficiency of the quenched thin material is remarkably increased.

Owner:WUHAN UNIV OF SCI & TECH

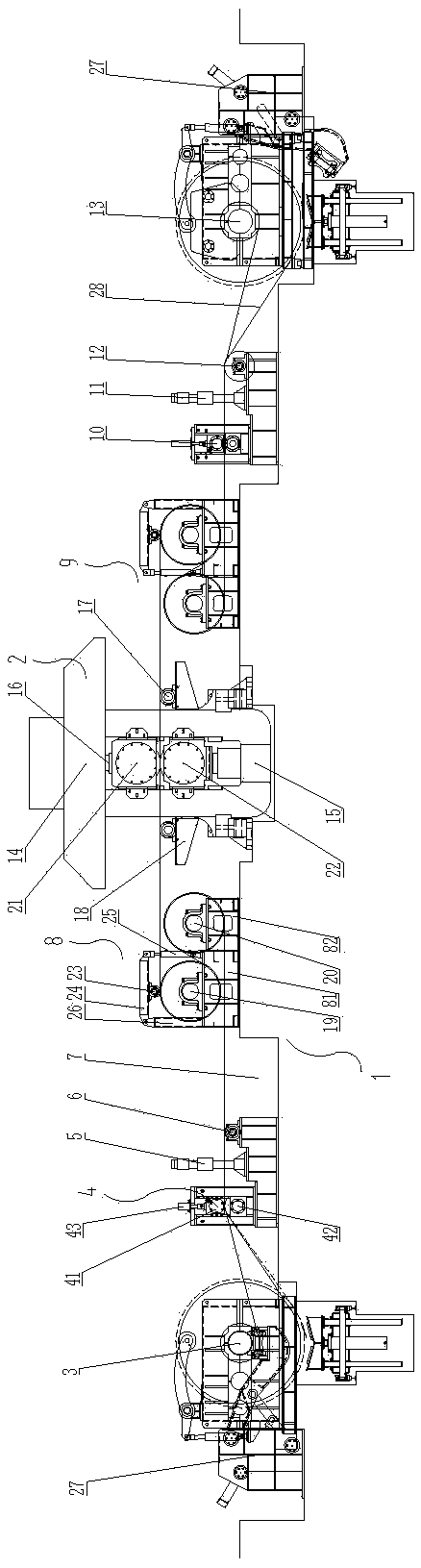

Strip steel flattening machine

InactiveCN108273870ASmooth throughSolve uneven thicknessMetal-working feeding devicesPositioning devicesEngineeringStrip steel

The invention provides a strip steel flattening machine. The strip steel flattening machine comprises a base. A roller is arranged on the base through a roller support and comprises a two-roller flattening machine. One side of the two-roller flattening machine is sequentially provided with a first tension S roller, a welding machine reserved gap, a first steering carrier roller, a first hydraulicshear, a first clamping conveying roller and an uncoiling machine, and the other side of the two-roller flattening machine is sequentially provided with an upper roller and a lower roller which are arranged on an upper base and a lower base in an up-down symmetry manner correspondingly. A first drive device is arranged at the upper end of the upper roller. Each of the first tension S roller and the second tension S roller comprises a first tension roller and a second tension roller which are arranged on a left support and a right support in a left-right symmetry manner, wherein a first pressing roller is arranged above the first tension roller and is hinged and installed to the left support through a swing arm, and a second drive device is arranged on the swing arm.

Owner:WUXI CITY XIDONG RUBBER & PLASTICS MACHINERY

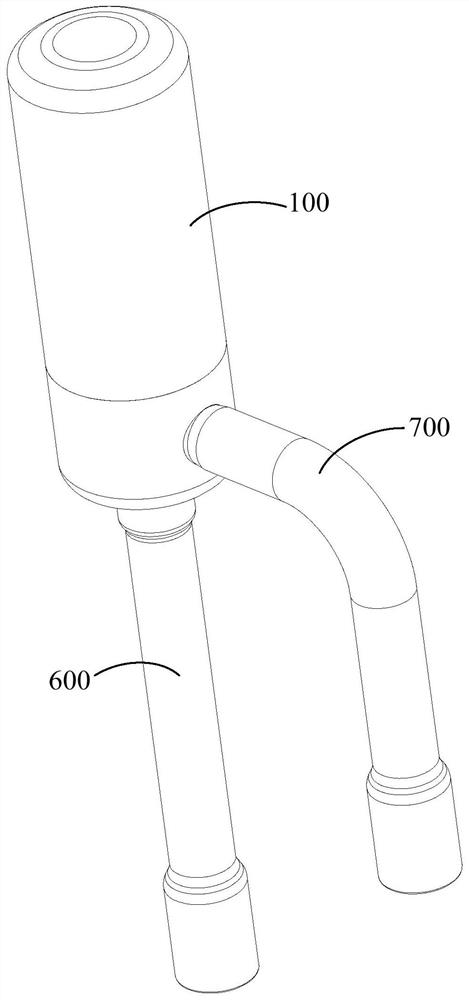

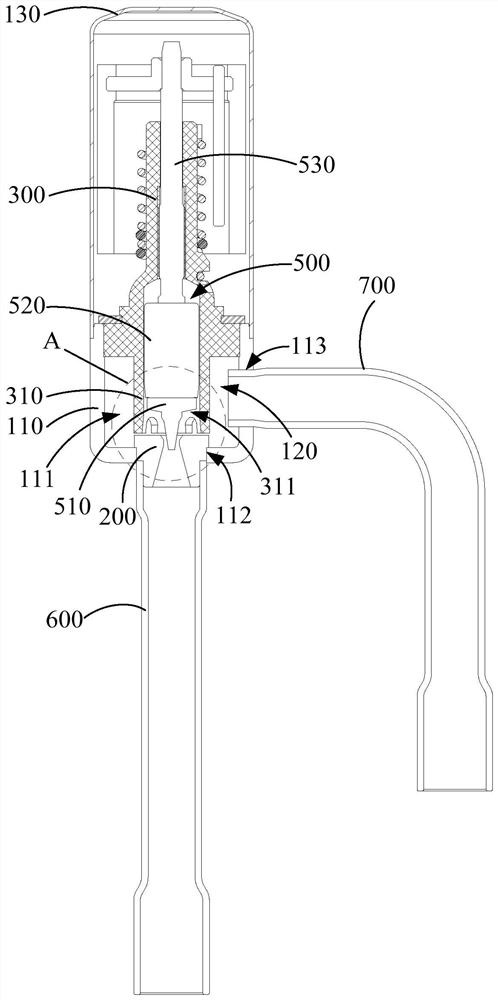

Electronic expansion valve and refrigeration equipment

PendingCN112483719AEasy to useReduces the chance of a ruptured blastOperating means/releasing devices for valvesValve members for absorbing fluid energyEngineeringElectronic expansion valve

The invention discloses an electronic expansion valve and refrigeration equipment. The electronic expansion valve comprises a valve shell, a valve element base, and a nut; the valve element base is installed on the valve shell, and a valve port is formed in the valve element base; and the nut is installed on the valve shell, and a silencing gap is formed between the nut and the valve element base.According to the electronic expansion valve, noise can be effectively lowered, the risk that the valve needle gets stuck is reduced, and the using effect of the electronic expansion valve is improved.

Owner:GUANGDONG WELLING ELECTRIC MACHINE MFG

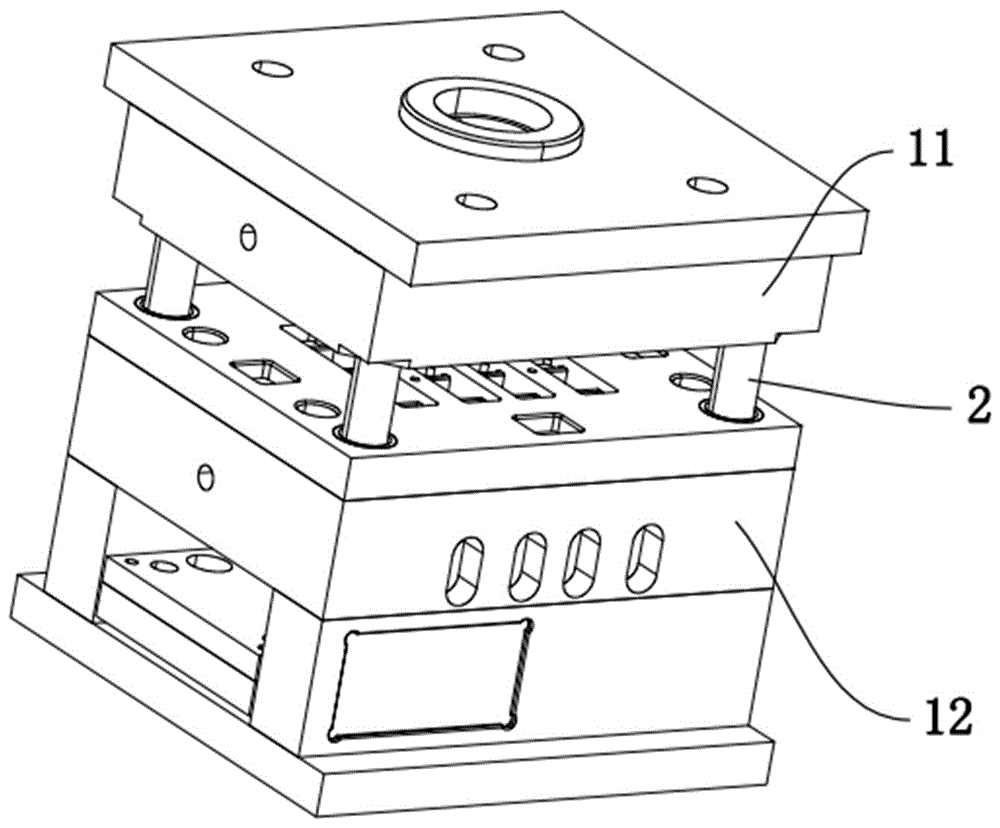

Die for producing computer display screen base and guide structure thereof

InactiveCN106273258AReduce the speed of insertion into the guide bushReduce the burden onEngineering

The invention discloses a die for producing a computer display screen base and a guide structure thereof. The die comprises a guide column arranged on a movable die and a guide sleeve arranged on a fixed die and matched with the guide column, the guide column comprises a fixed column fixed to the movable die and at least one movable column in sliding fit with the fixed column; a buffering portion supportive of being squeezed by the movable column and axially deforming and being compressed is arranged in the guide sleeve, in this way, sliding distance at the end of the guide column is dispersed on the whole guide column, burden at the end of the guide column is reduced, and local wear is reduced, so that matching smoothness of the guide column and the guide sleeve is improved; a one-way air incoming structure and a one-way air outgoing structure are arranged between a sliding block on a penetrating column and a sliding cavity, so that speed at which the guide column is inserted into the guide sleeve can be lowered in the process of die assembly, heat yield and wear between the guide column and the guide sleeve can be lowered, and practical effect of the guide structure is further improved while service life of the same is further prolonged, so that quality of the display screen base produced by injection molding is improved.

Owner:FUZHOU JUANG PRECISION MOLD TECH

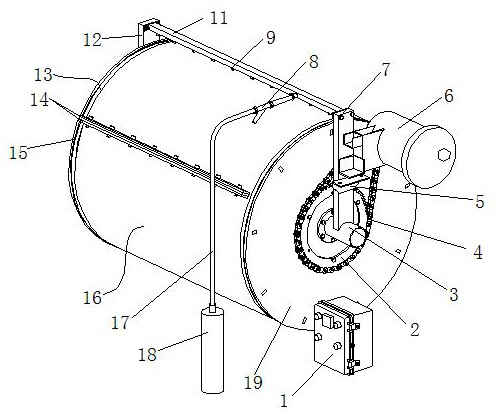

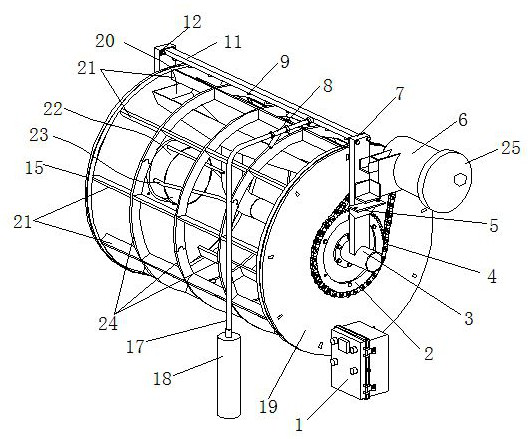

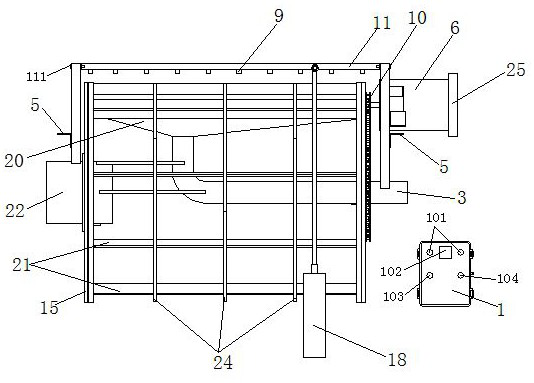

Automatic-backwashing sedimentation type micro-filter

The invention discloses an automatic-backwashing sedimentation type micro-filter, comprising a rotary drum, a backwashing device and a mounting bracket, wherein the backwashing device comprises a central pipe shaft, a high-stroke submersible pump, a spray head mounting pipe, spray heads, a sewage receiving hopper and a transmission mechanism; the central pipe shaft is a stainless steel pipe, and a water inlet pipe and a sewage discharge pipe which are concentric are respectively arranged on the left side and the right side of the central pipe shaft; a gap with a certain width is formed between the water inlet pipe and the sewage discharge pipe and functions as a water outlet; the water inlet pipe and the sewage discharge pipe are welded together via a connecting strip to form an integral body; the sewage receiving hopper and the spray head mounting pipe are mounted right above the central pipe shaft; the transmission mechanism is mounted on the sewage discharging pipe located on the right side of the central pipe shaft; the rotary drum is mounted on the central pipe shaft; the central pipe shaft serves as a shaft the rotary drum; the sewage receiving hopper is in a funnel shape, the lowest part of the sewage receiving hopper is connected and communicated with a blow-off pipe, and the spray head mounting pipe is mounted right above the sewage receiving hopper; and the spray head mounting pipe is a pipe with two closed ends and is fixed on left and right fixed pipes, a plurality of holes are formed right below the spray head mounting pipe for mounting the spray heads, and a hole is formed in the side surface for mounting a water supply pipe which is to be connected and communicated with the high-stroke submersible pump.

Owner:广西木壳科技有限公司

Tamping machine with dust collection function

InactiveCN113047260AWith vacuum functionAvoid vibrationDirt cleaningCleaning using gasesTorsion springRotating disc

The invention relates to a tamping machine with a dust collection function. The tamping machine comprises a main body, an air cylinder, a support plate, a fixed rod, a tamping plate, two moving devices, a dust collection mechanism and two auxiliary mechanisms, wherein the dust collection mechanism comprises a dust collection box, a filter screen, a moving box, two limiting assemblies, two power assemblies and a plurality of first springs, and the auxiliary mechanisms comprise rotating shafts, rotating discs, pull ropes, first torsion springs, one-way bearings, driving shafts, driving rods, vibration assemblies and two first bearings. According to the tamping machine with the dust collection function, through the dust collection mechanism, the dust collection function is realized, the amount of dust inhaled by a human body is reduced, and the harm to the body health of a user is prevented; and through the auxiliary mechanisms, after tamping is completed, the tamping plate is vibrated, so that soil adhered to the lower part of the tamping plate can be shaken off, the function of cleaning the tamping plate is realized, the soil is prevented from being accumulated on the lower part of the tamping plate, the phenomenon that the tamped ground is uneven is avoided, and the tamping plate is not influenced.

Owner:南京极雨环保科技有限公司

Salt covering treatment method for salting smelly mandarin fish

The invention discloses a salt covering treatment method for salting smelly mandarin fish, which comprises the steps of fish cleaning, fishy smell removal, salt frying and salt covering. The method has the beneficial effects that the mandarin fish is transferred by using a moving frame, so that automatic feeding and taking of mandarin fish salt covering operation are realized, manual pushing operation is not needed, and the operation is simple and convenient. The use efficiency of the device is further improved, manpower and time are saved, fatigue of operators is relieved, and meanwhile, manual pushing operation is reduced, so that pollution of hands to mandarin fishes is reduced, the sanitary condition of the whole salt covering operation is improved, deterioration of the mandarin fishes is reduced, and economic benefits are improved. A clamping net is driven by a third motor, the mandarin fish can be rotationally adjusted, so that the mandarin fish can be more comprehensively coated with salt, the situation that the mandarin fish goes bad due to the fact that the mandarin fish is not locally coated with salt is avoided, the mandarin fish salt coating uniformity is improved, and the mandarin fish salt coating effect of the device is improved.

Owner:黄山市鑫黄山特产有限公司

Rubber covered roller rice huller with anti-clamping function

ActiveCN111545271AAchieve uniform entryAchieve entryGrain huskingGrain polishingAgricultural scienceAgricultural engineering

The invention relates to a rubber covered roller rice huller with an anti-clamping function. The rubber covered roller rice huller comprises a main body, a rice hulling device and two supporting columns, and further comprises an anti-clamping mechanism and a clearing mechanism, wherein the anti-clamping mechanism comprises a fixed box, a filter drum, a feed pipe, two driving assemblies, two firstsprings and two transmission assemblies, the clearing mechanism comprises a an air blowing assembly and a collecting assembly, the air blowing assembly comprises an air blowing box, a first air bag, an air inlet pipe, an air outlet pipe, a plurality of nozzles and a plurality of second springs, and the collecting assembly comprises a collecting box, a second air bag, an exhaust pipe, a connectingpipe and a plurality of third springs. According to the rubber covered roller rice huller with the anti-clamping function, the function that grains enter the main body at a constant speed is realizedby the aid of the anti-clamping mechanism, a wind path from left to right is formed in the main body by the aid of the clearing mechanism, so that rice hulls can be blown into the collecting box, a function of collecting the rice hulls is realized, a function of clearing the rice hulls in the rice grains is realized, manual cleaning is not needed, and convenience in cleaning is improved.

Owner:深圳市嘉胜创新贸易有限公司

Hay automatic planting device based on desert sand stabilization and soil improvement

ActiveCN110771438ASmooth sliding contactHigh degree of automationHops/wine cultivationTurf growingAgricultural scienceAgricultural engineering

The invention provides a hay automatic planting device based on desert sand stabilization and soil improvement, relates to the field of desert environmental management devices, and solves the problemsthat grass cannot be laid when pressing is implemented as automation degree is low, maintenance cost is high, and integrated replacement is needed when rollers are severely abraded. The hay automaticplanting device comprises a rotatable adjusting seat, two fixed seats are symmetrically welded on the rear end surface of the rotatable adjusting seat, and a frame is rotatably connected on the frontend surface of the rotatable adjusting seat. A limit structure can vertically slide along the frame under the actions of a sliding rod and a spring, so that the device can adapt to rough ground, thefront end of a limit block is inclined, the inclined angle of the front end of the limit block is 30 degrees, and the limit block is more smooth when slidably contacting with the ground when the device is used on the rough ground, so that locking is decreased.

Owner:佛山市嘉沃农业科技合伙企业(有限合伙)

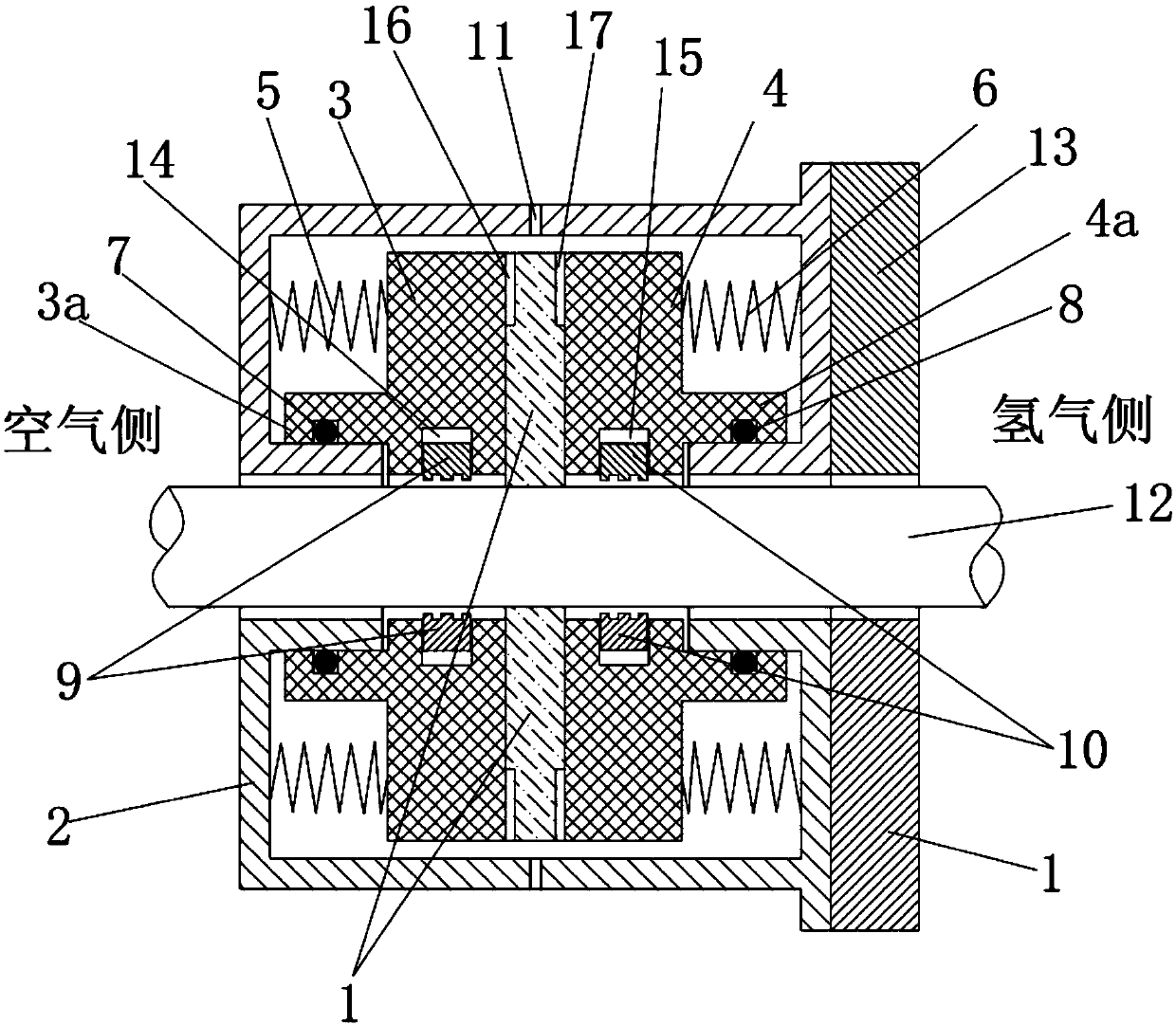

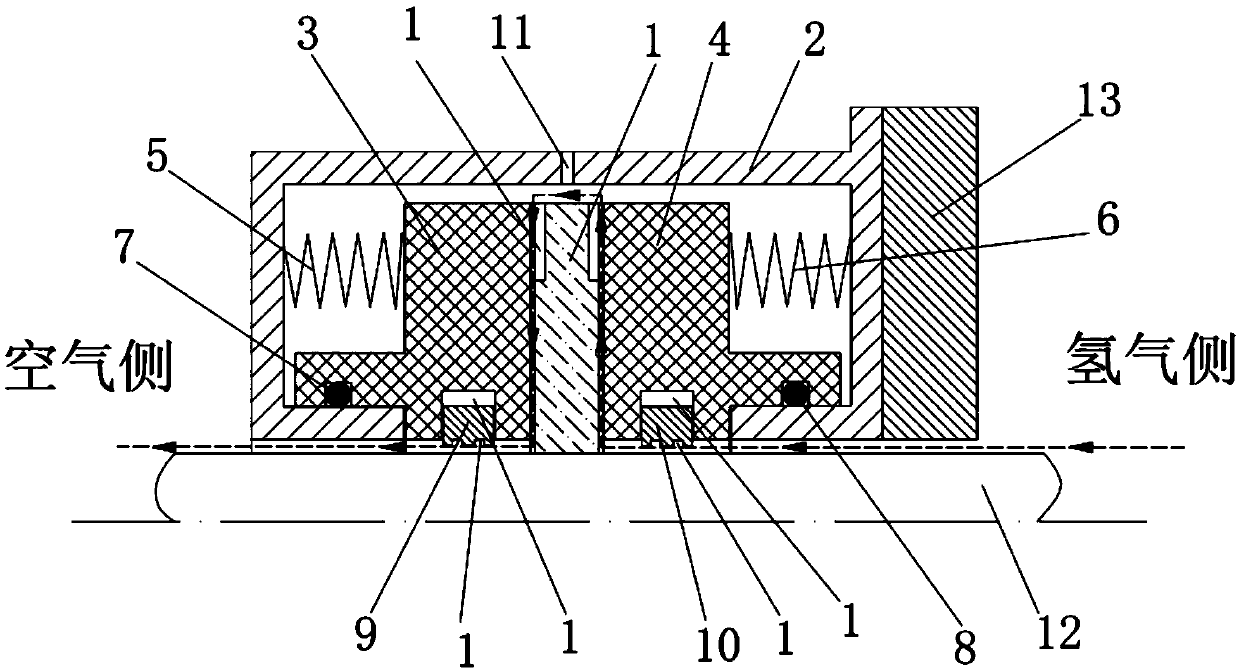

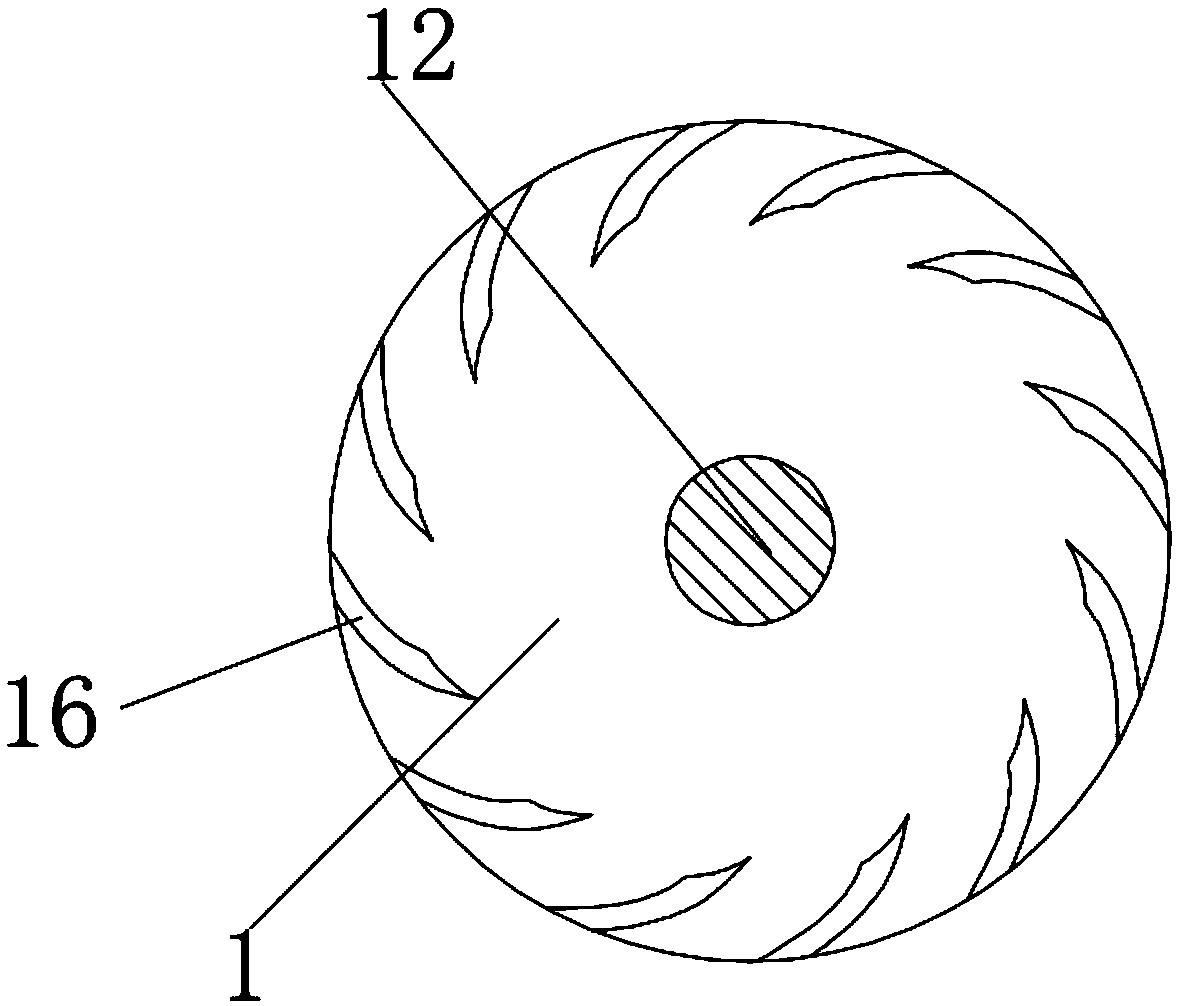

Hydrogen sealing device and sealing method of steam turbine generator set

The invention relates to a hydrogen sealing device and a sealing method for a steam turbine generator set. According to the technical scheme, a generator rotating shaft at the opening of a sealing seat is sleeved with a resistance disc which is fixed together with the generator rotating shaft, and the resistance disc extends into the inner cavity of the sealing seat from the opening of the sealingseat; a first sealing ring and a second sealing ring which slide left and right in the axial direction of the the generator rotating shaft are arranged in the sealing seat on the two sides of the resistance disc correspondingly, a plurality of first spiral grooves which are uniformly distributed are formed in the outer periphery, right opposite to the first sealing ring, of the resistance disc; and a plurality of second spiral grooves which are uniformly distributed are formed in the outer periphery, right opposite to the second sealing ring, of the resistance disc. Compared with the prior art, two-stage spiral groove type dynamic pressure oil film seal between the sealing rings and the resistance disc and two-stage groove type dynamic pressure oil film seal between sealing floating ringsand the generator rotating shaft are required during hydrogen leakage, and the leakage amount is small; and sealing gaps formed between the sealing rings and the resistance disc due to the dynamic pressure effect of the spiral grooves are small, and therefore the leakage can be effectively reduced.

Owner:CENT CHINA BRANCH OF CHINA DATANG CORP SCI & TECH RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com