Patents

Literature

56results about How to "Reduce seal gap" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

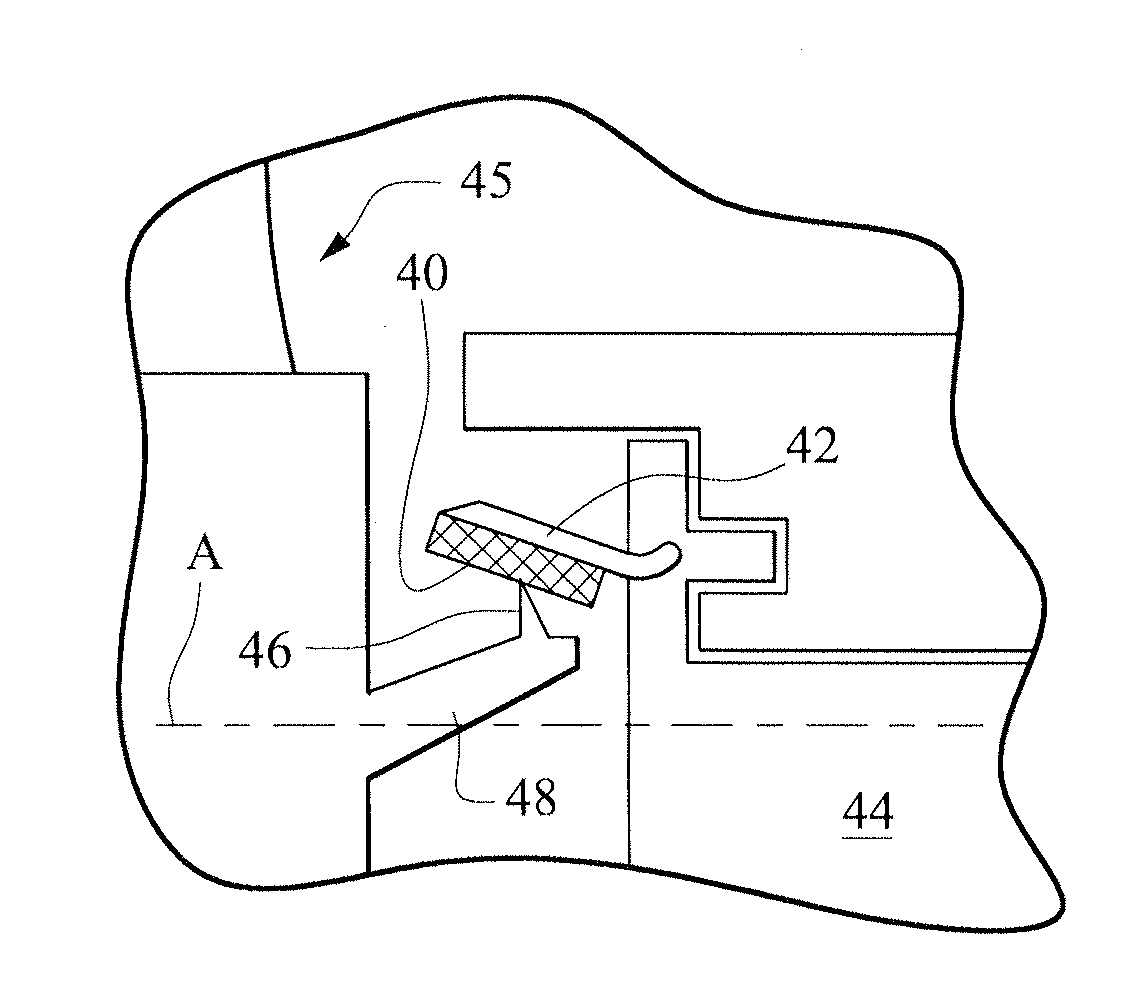

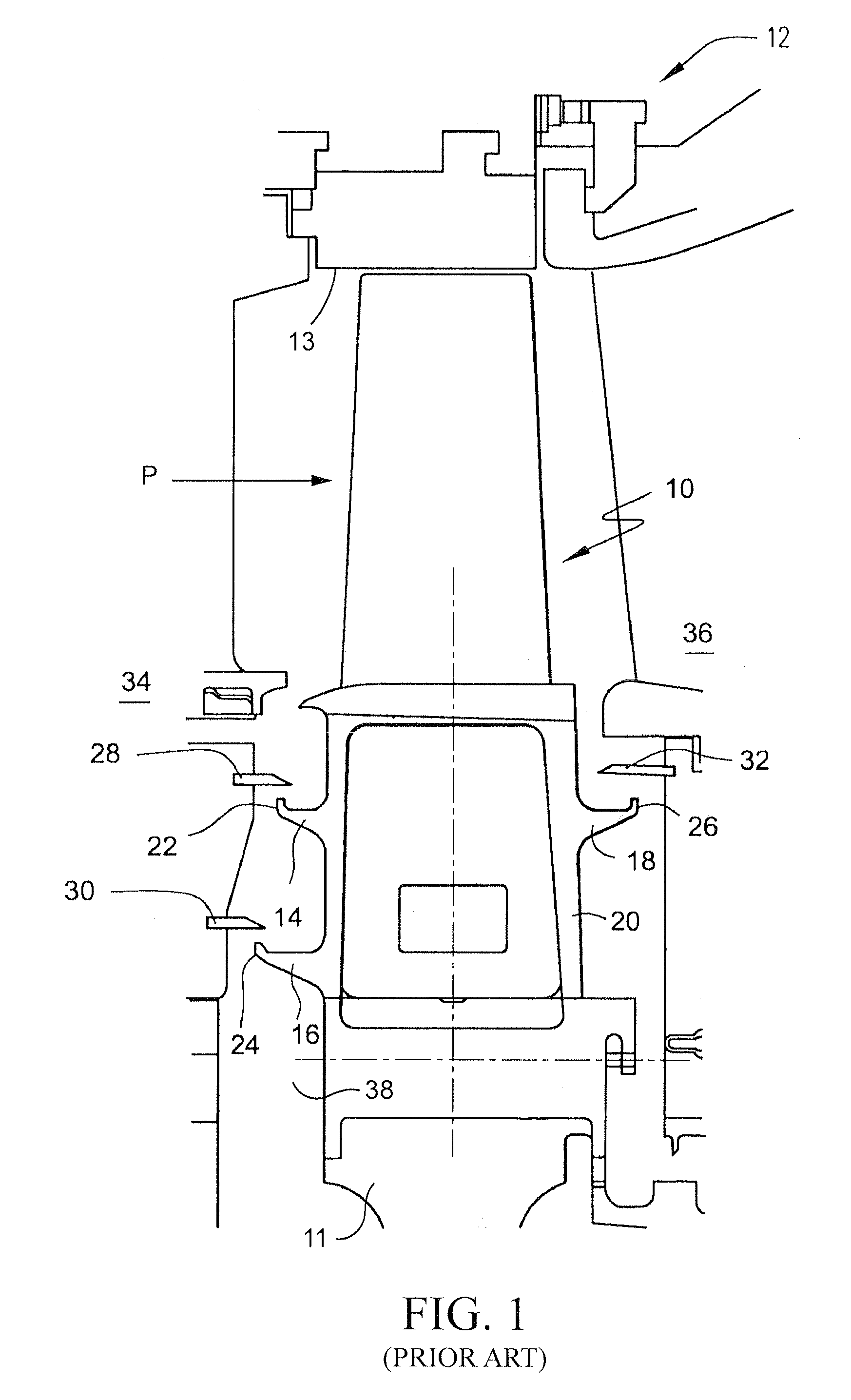

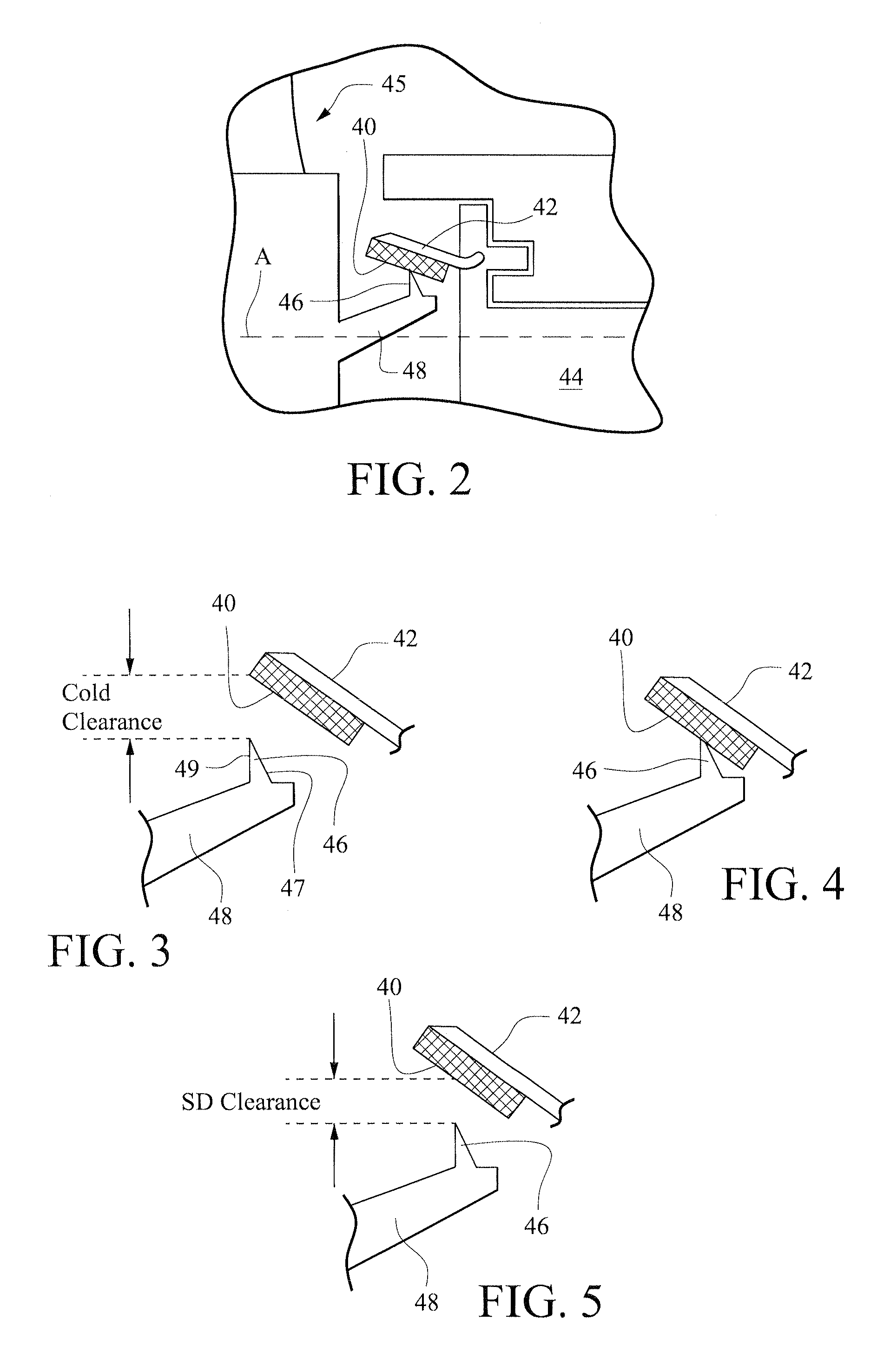

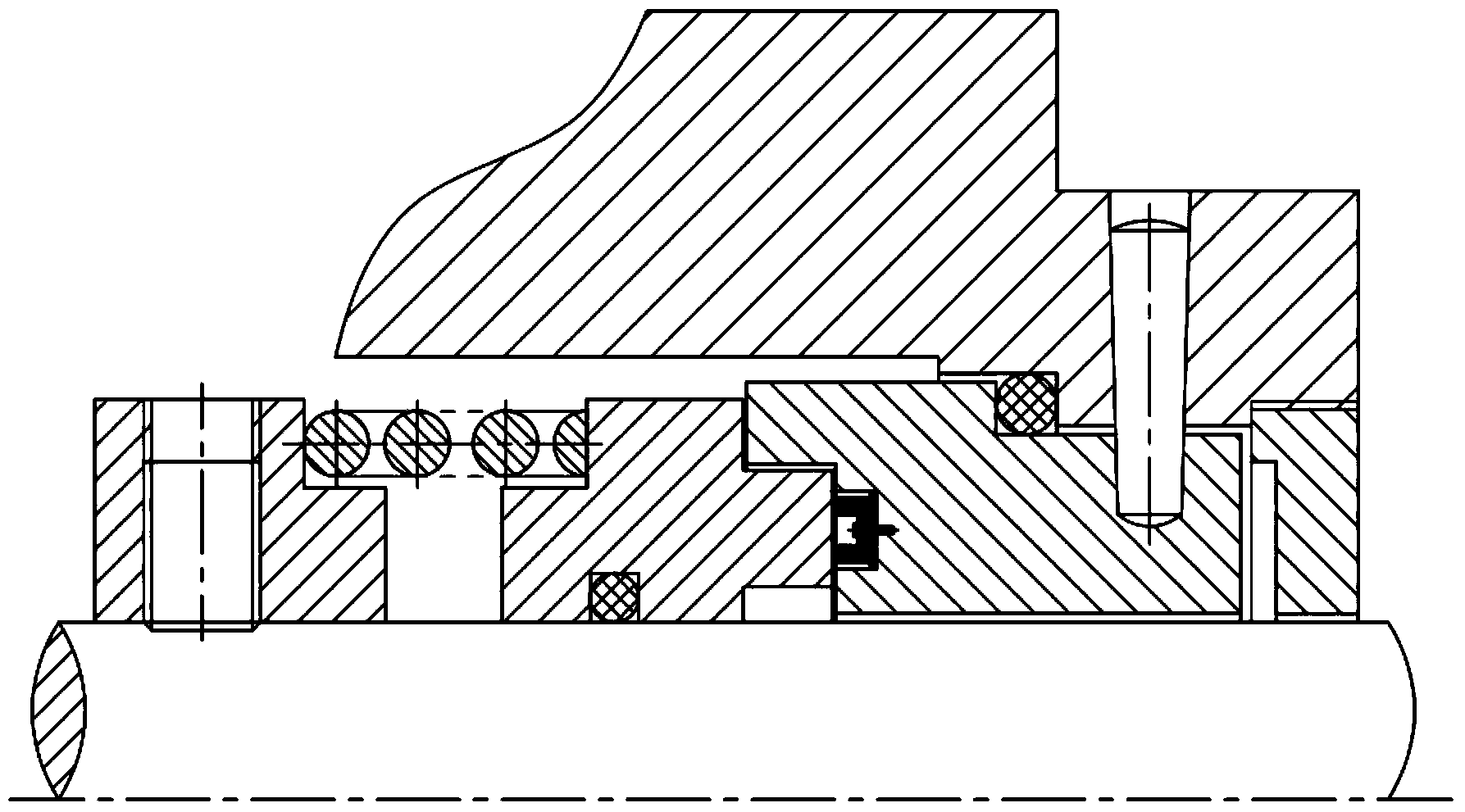

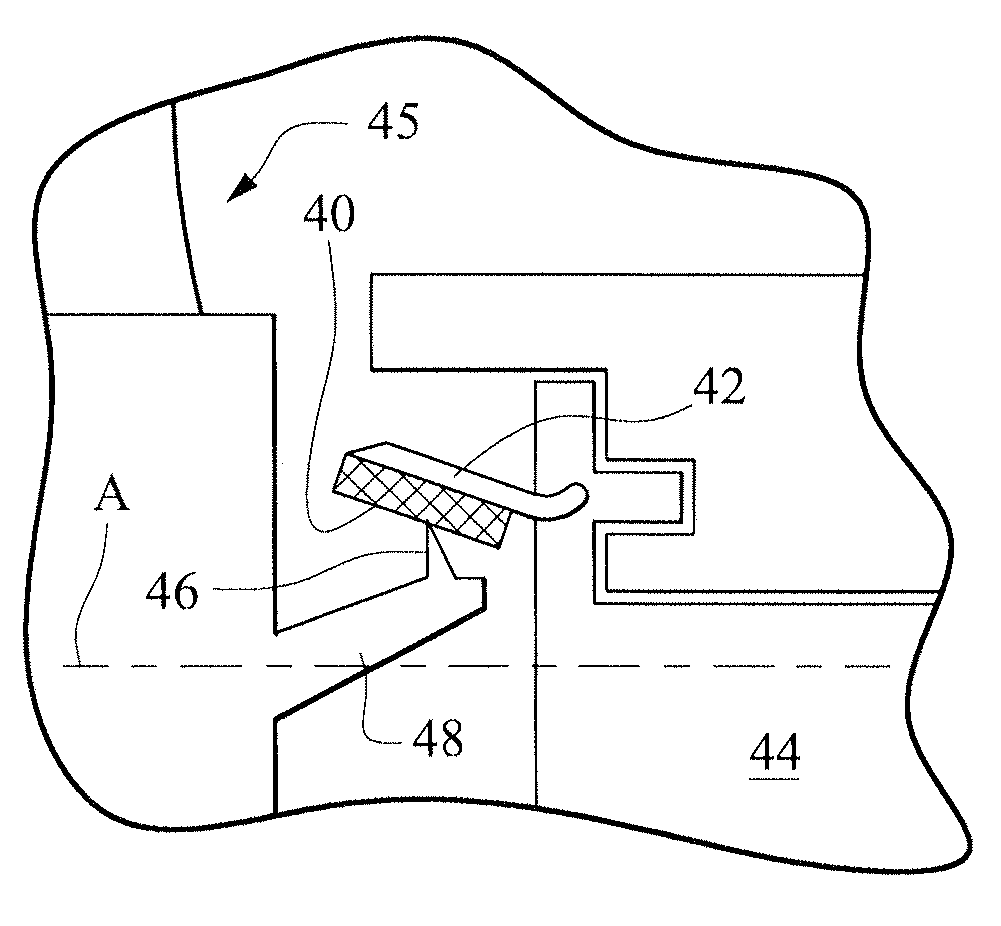

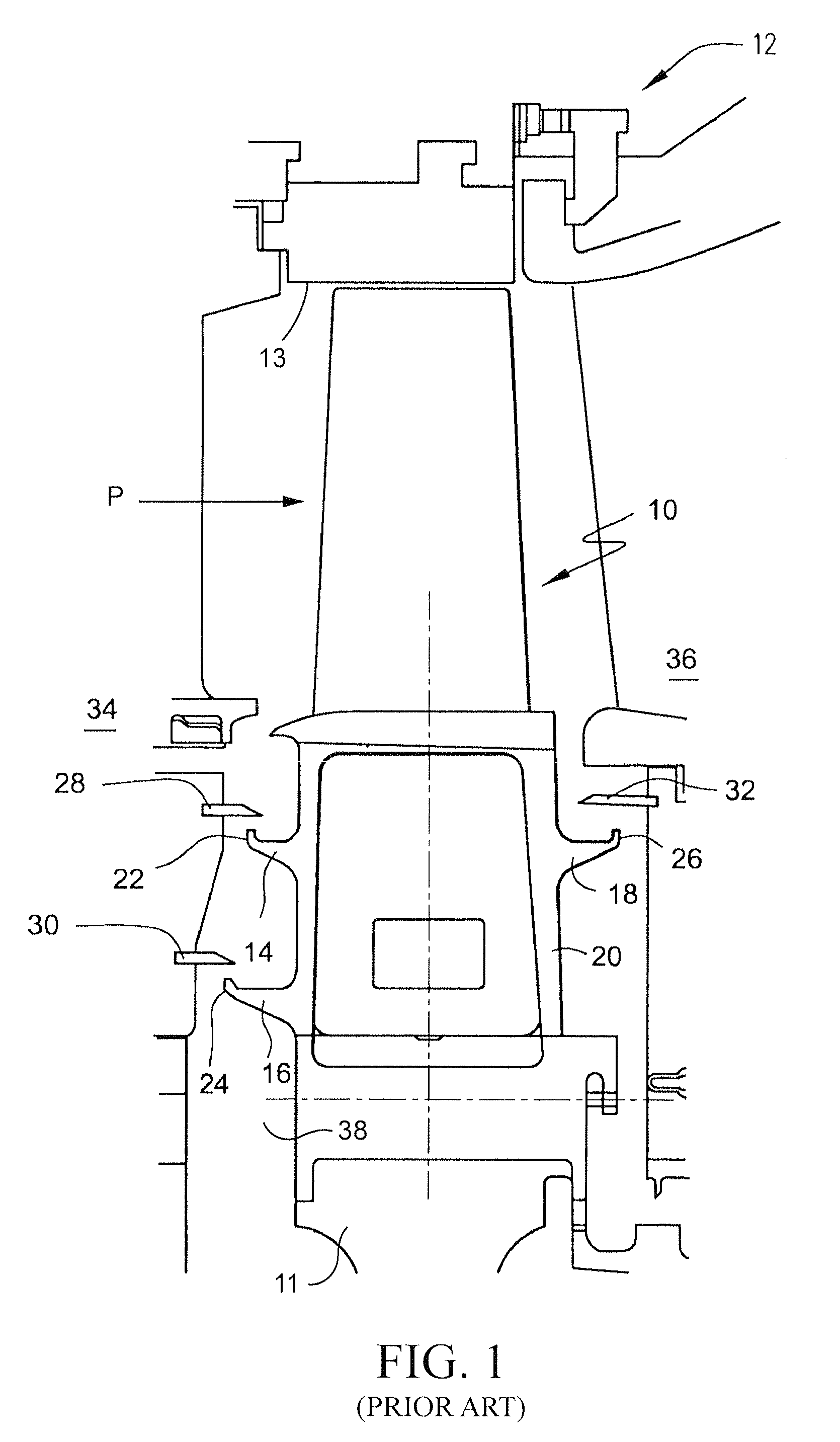

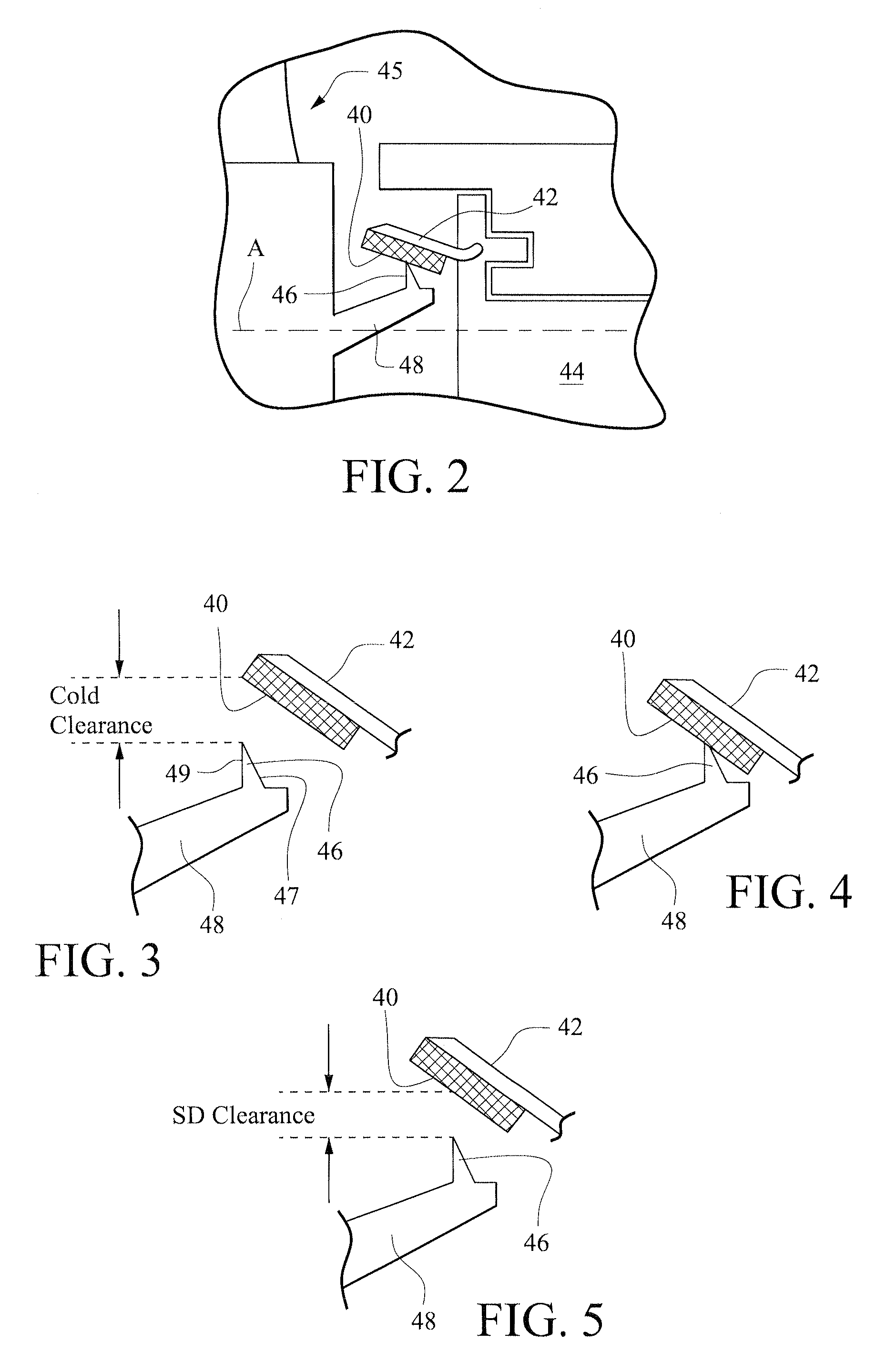

Retrofittable interstage angled seal

InactiveUS20130189073A1Reduce seal gapReduce radial dimensionEngine manufacturePump componentsAcute angleStator

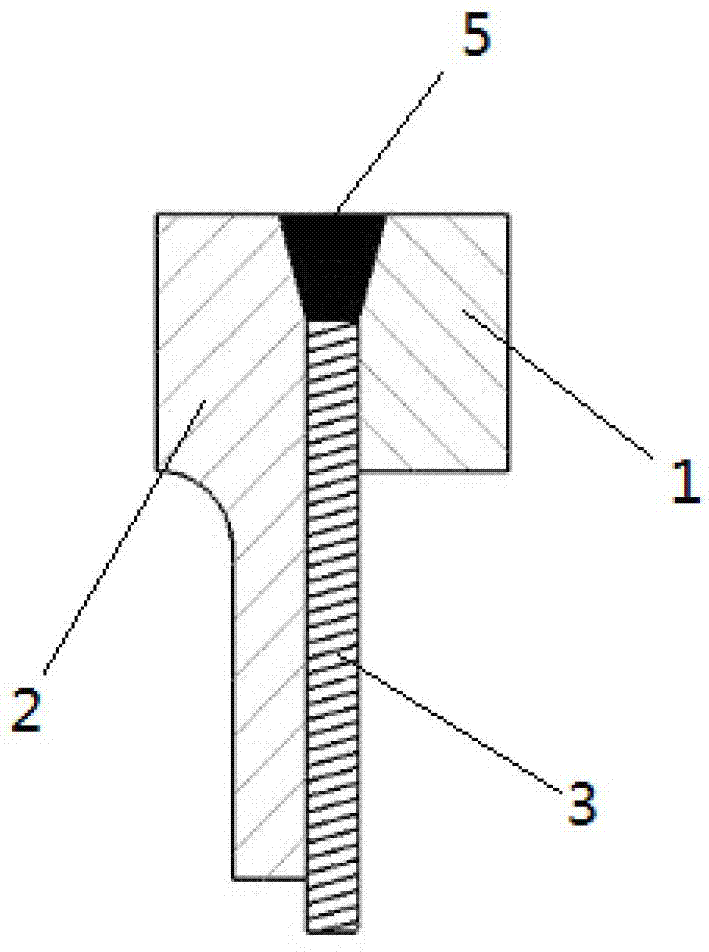

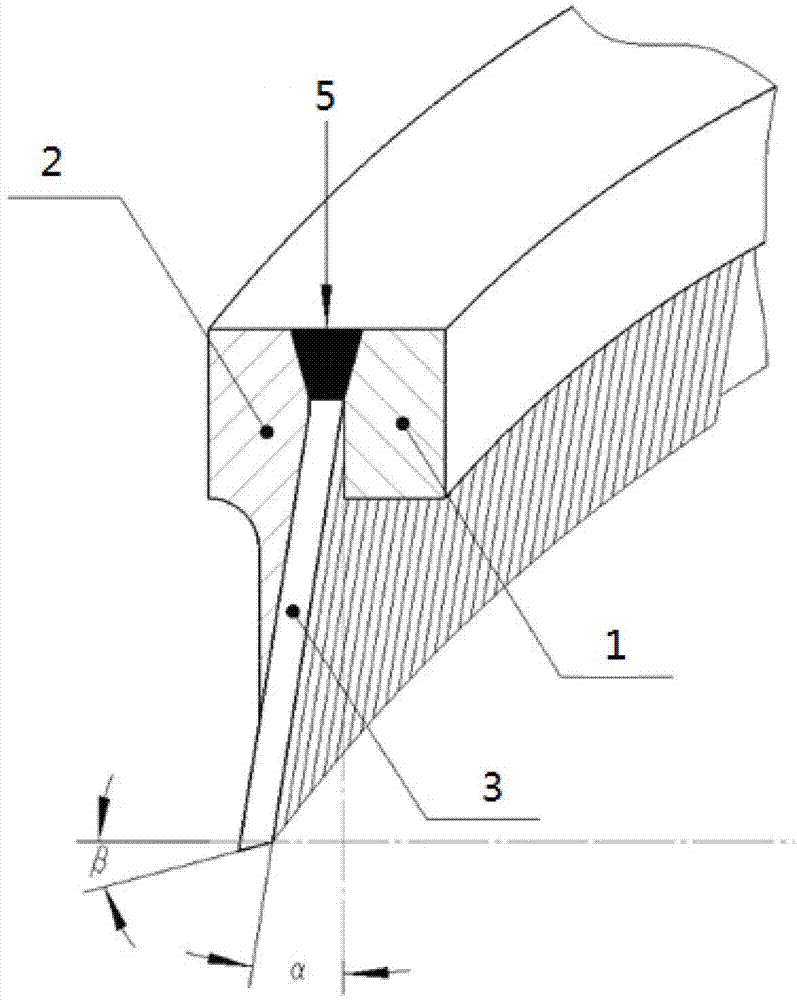

A rotary turbomachine includes a rotor mounting at least one disk having an outer surface and at least one bucket extending radially from said outer surface. A stationary stator component is located adjacent the disk, and a seal plate extends from a portion of the stationary stator component. An angel wing seal extends from the bucket, thereby defining a clearance gap between the seal plate and the angel wing seal. An abradable seal element is disposed on the seal plate, and the abradable seal element and the seal plate are canted at an acute angle relative to a center axis of the rotor extending radially outwardly in a direction toward the angel wing seal.

Owner:GENERAL ELECTRIC CO

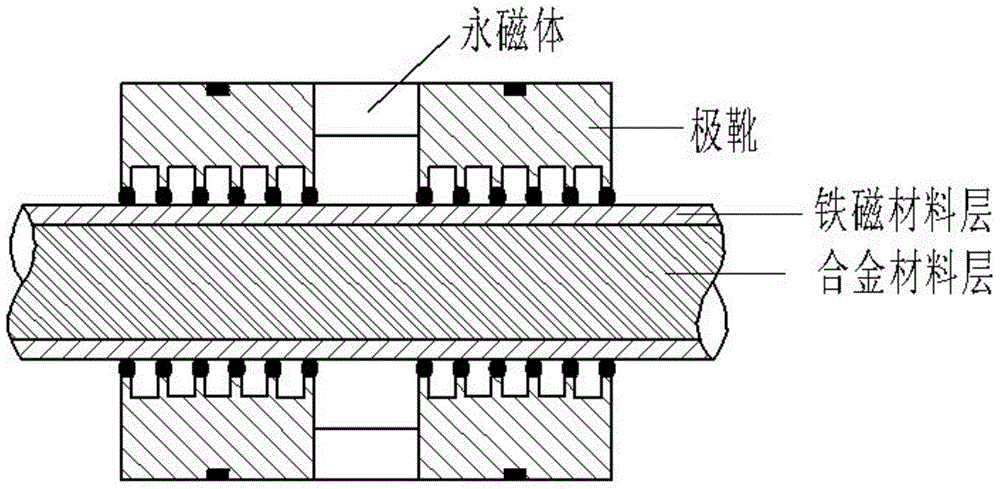

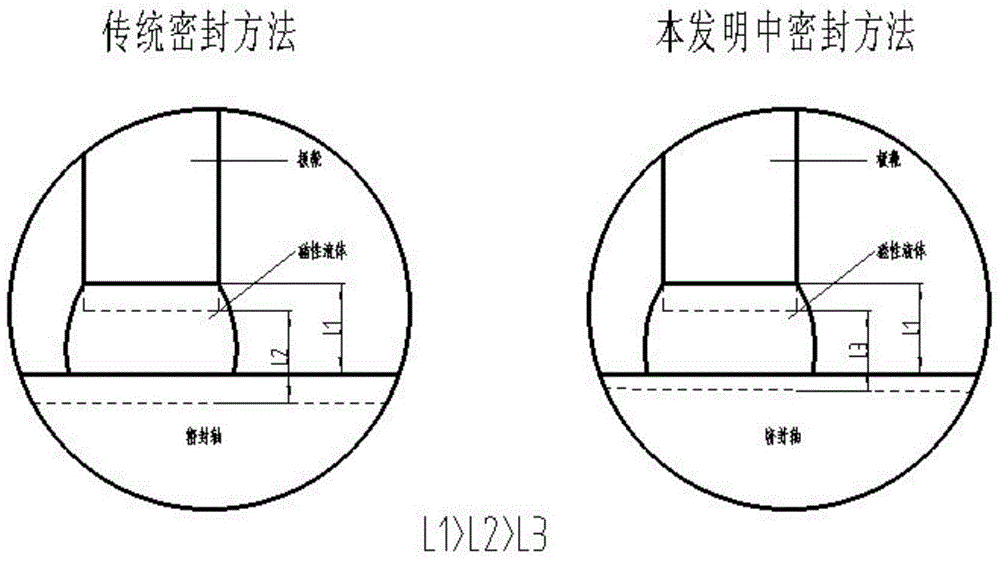

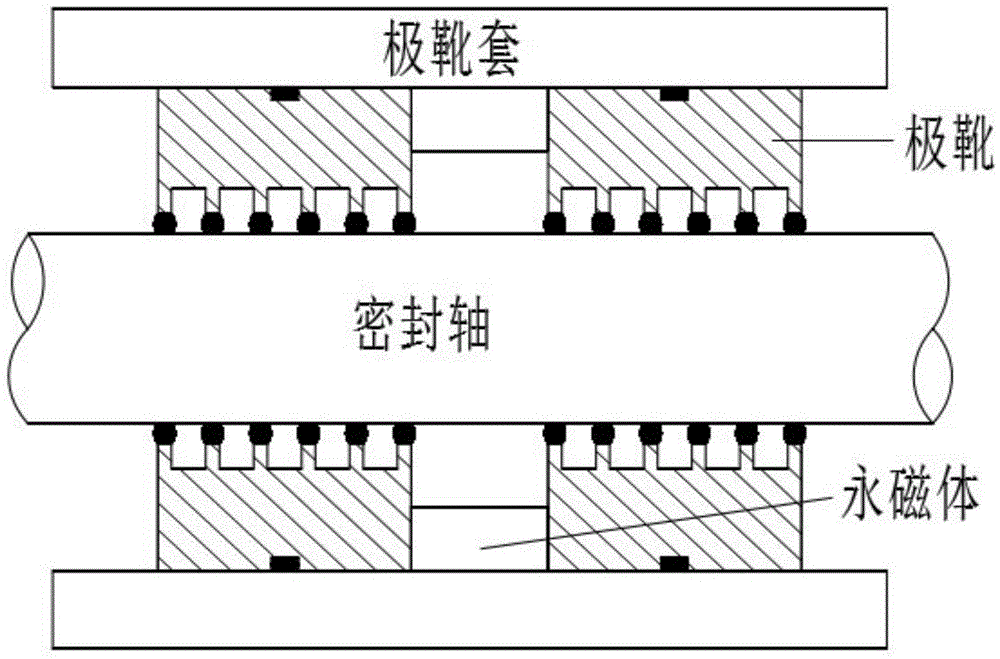

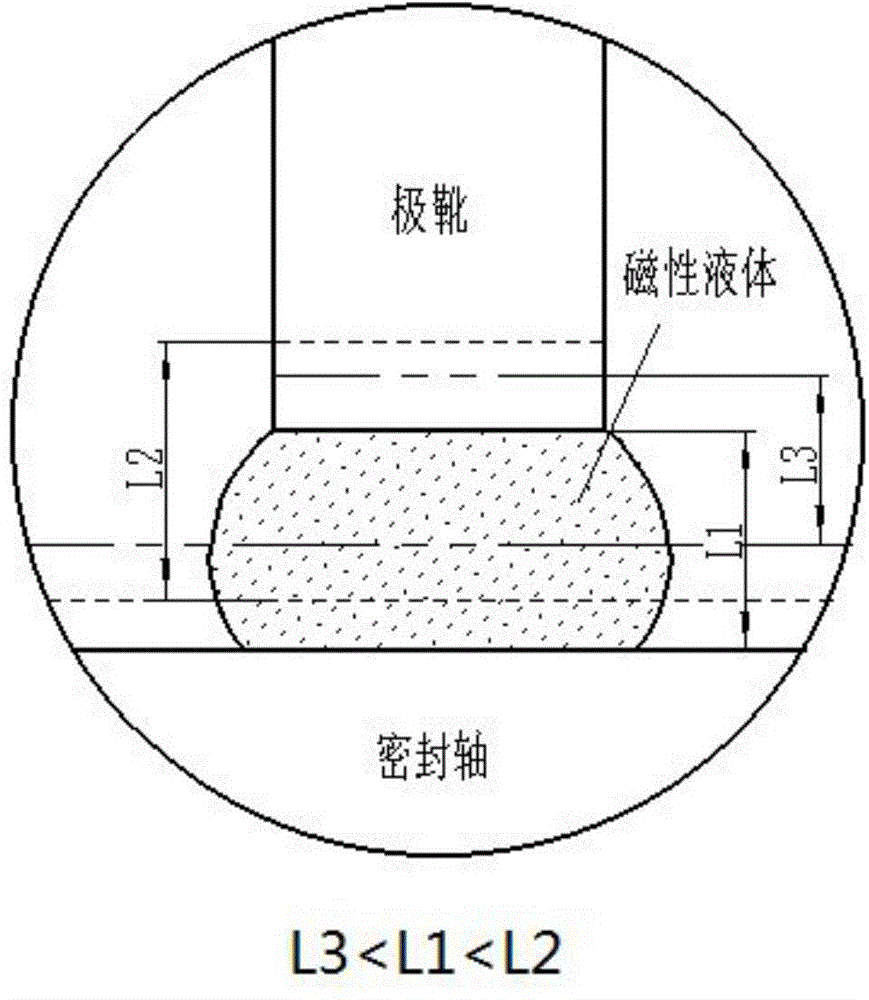

Method for improving pressure resistance of magnetic liquid seal in low-temperature working environment

InactiveCN104405886ASmall amount of shrinkageImprove sealing pressure resistanceEngine sealsWorking environmentMagnetic liquids

The invention provides a method for improving pressure resistance of magnetic liquid seal in a low-temperature working environment, belongs to the technical field of sealing of mechanism engineering, and in particular applies to magnetic liquid seal. The method comprises the steps of selecting a ferromagnetic material with high permeability and large expansion coefficient, and an alloy steel material with small thermal expansion coefficient and high comprehensive mechanical performance; manufacturing a pole shoe with the ferromagnetic material; manufacturing and processing a composite material shaft being 50 to 100mm in diameter by using the ferromagnetic material and the alloy steel material as an outer layer material and an inner layer material, respectively, wherein the radial length ratio of the ferromagnetic material layer to the alloy steel material layer is 1: 3; applying the pole shoe and the composite material shaft into a magnetic liquid seal device of which a gap ranges from 0.1 to 0.25. With the adoption of the method, the shortages of the existing method for magnetic liquid seal under a low temperature can be overcome, the problem of applying to magnetic liquid seal in a low-temperature environment is solved, the applicable scope of magnetic liquid seal is expanded, and the method is of an important significance.

Owner:BEIJING JIAOTONG UNIV

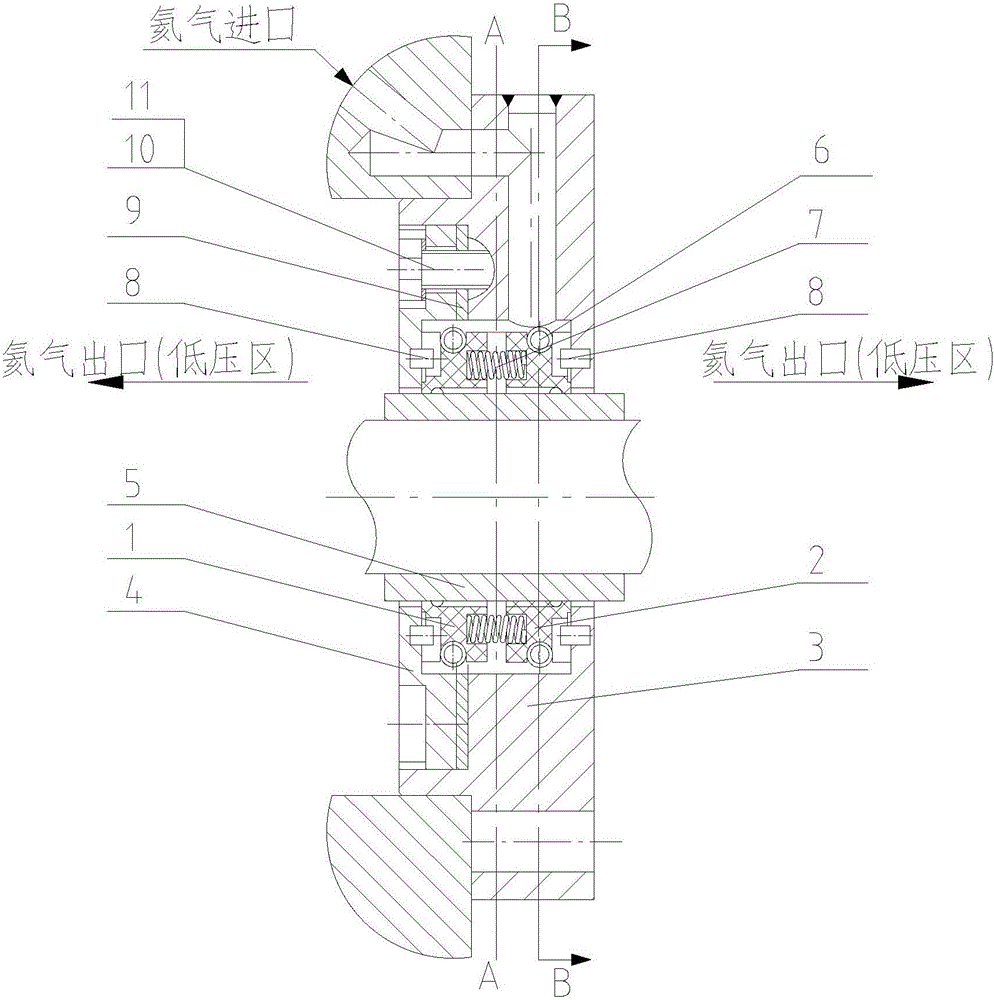

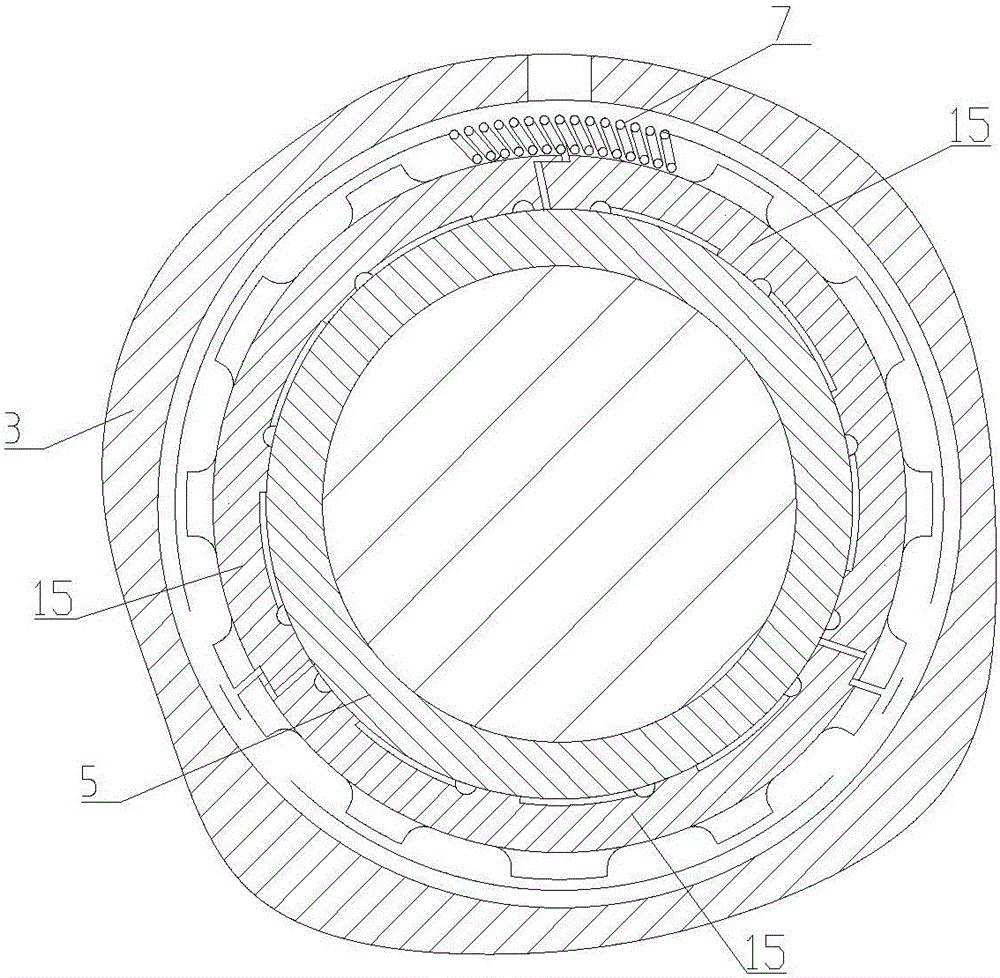

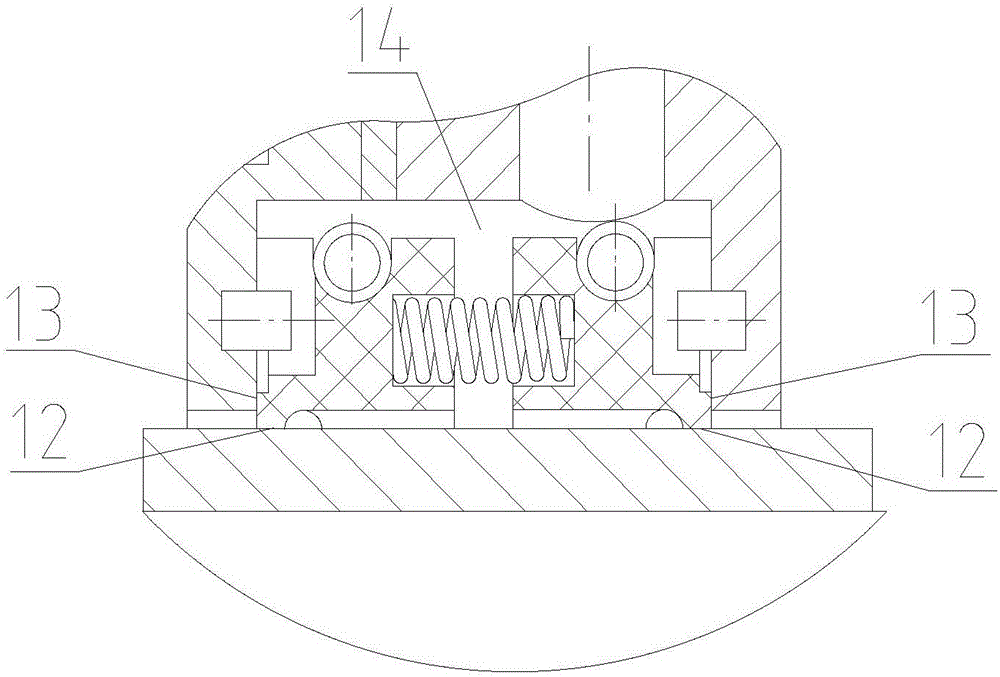

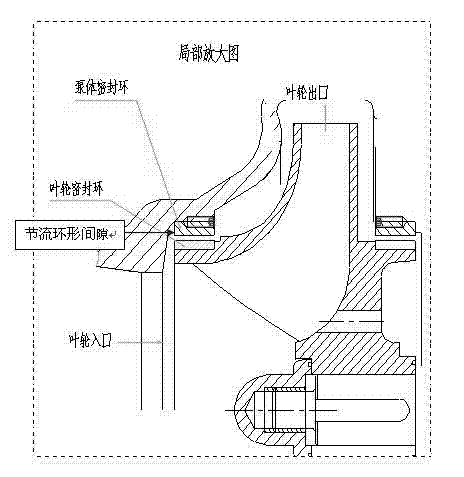

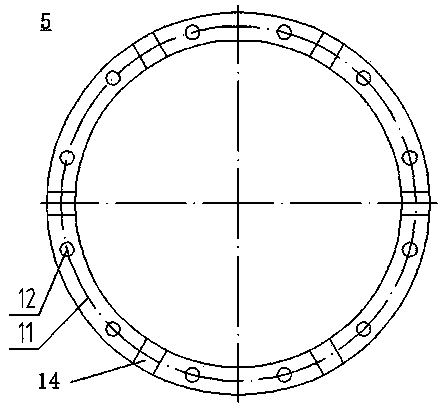

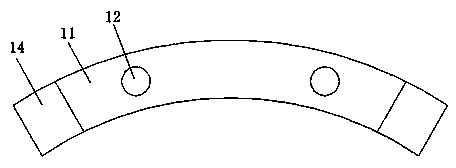

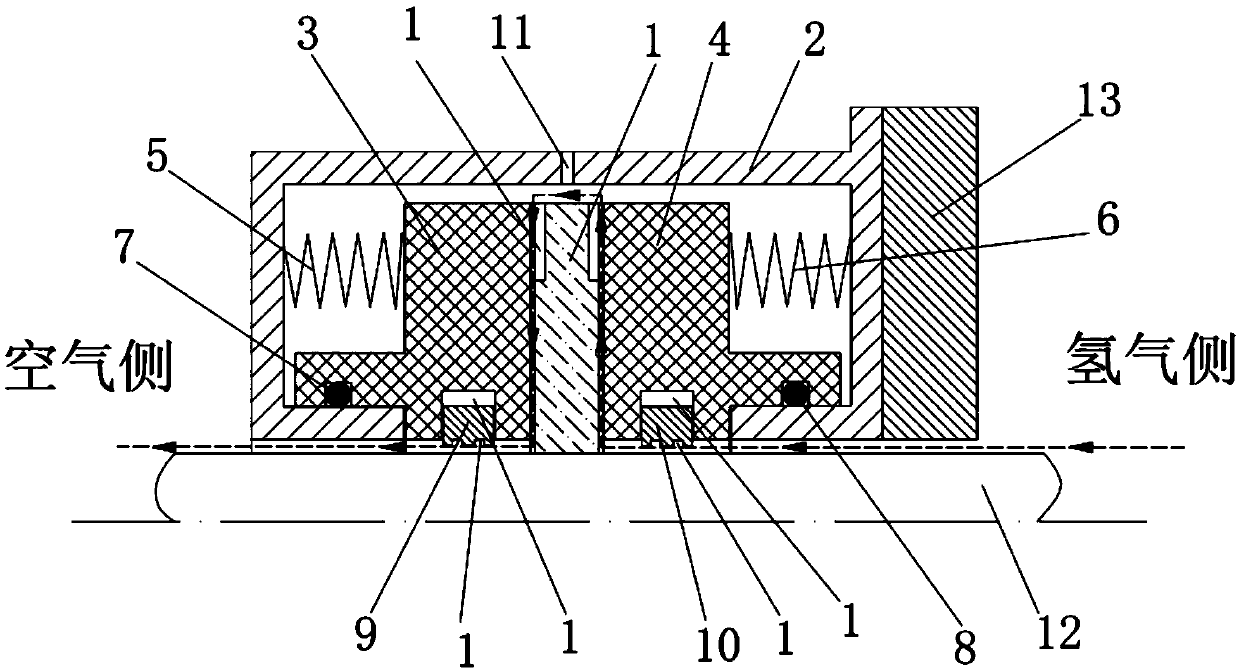

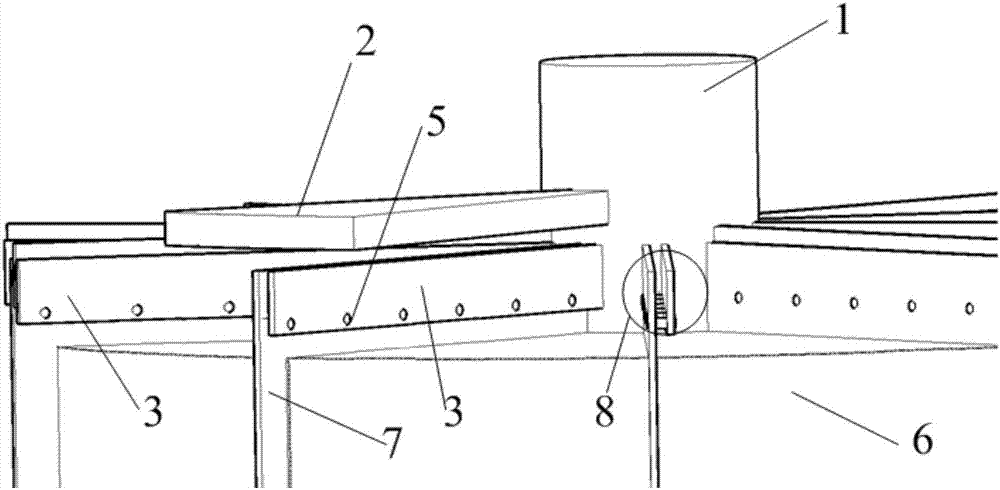

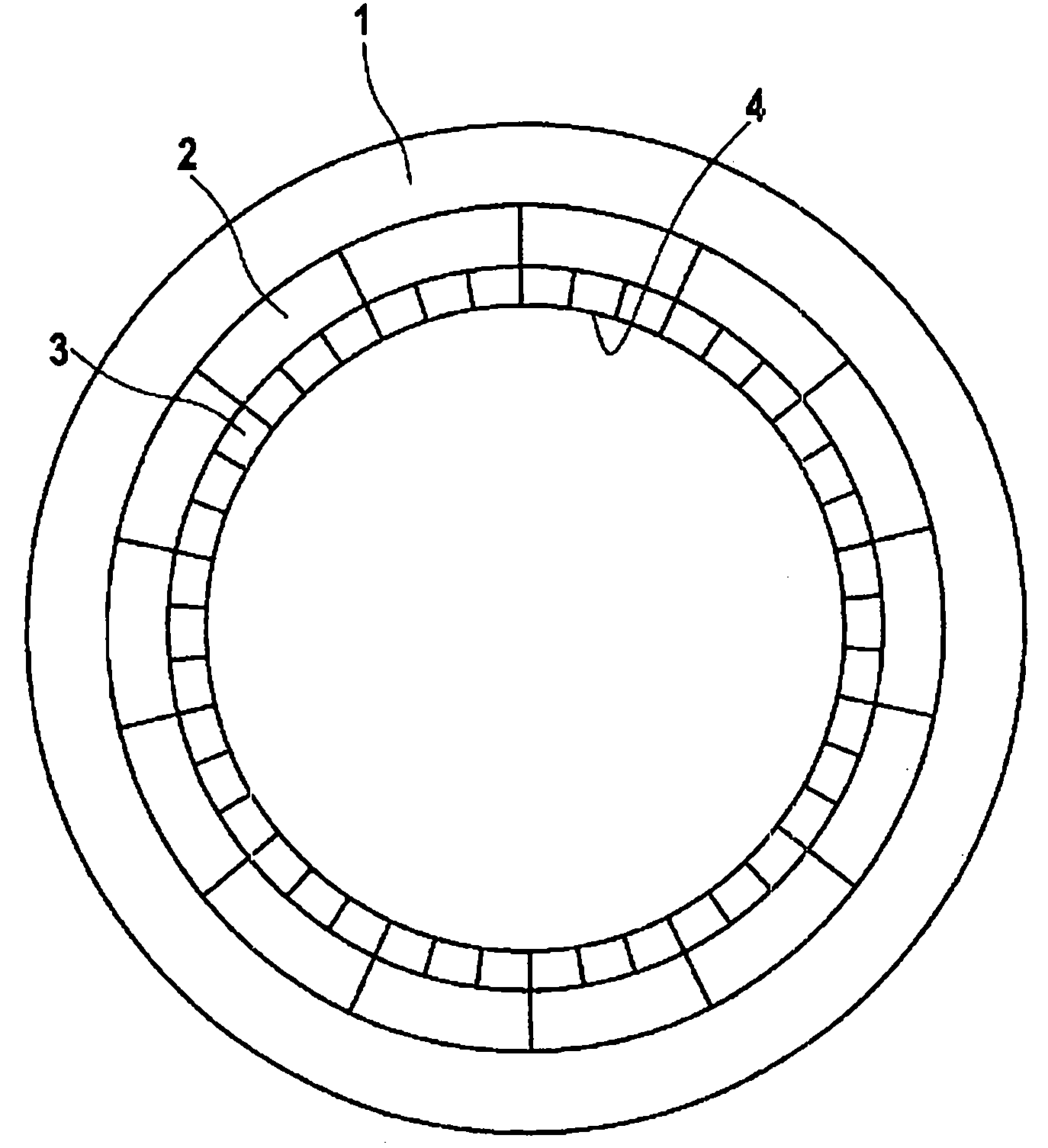

Circumferential sectioned helium sealing device for oxygen turbine pump of hydrogen oxygen engine

The invention discloses a circumferential sectioned helium sealing device for an oxygen turbine pump of a hydrogen oxygen engine. According to the circumferential sectioned helium sealing device, a circumferential sectioned sealing ring I and a circumferential sectioned sealing ring II are placed in a cavity formed by a cover plate and a sealing shell; sealing shaft sleeves are placed in rings of the circumferential sectioned sealing ring I and the circumferential sectioned sealing ring II; the circumferential sectioned sealing ring I and the circumferential sectioned sealing ring II are oppositely placed and pre-tensioned by virtue of pre-tensioning springs; and each of the circumferential sectioned sealing ring I and the circumferential sectioned sealing ring II is formed by connecting a plurality of fan-shaped arc sections with the same structure end to end, and constrained on an excircle surface through garter springs. According to the circumferential sectioned helium sealing device, each sealing ring is composed of the plurality of fan-shaped arc sections, a hydrodynamic groove structure is introduced, and a hydrodynamic effect of a sealing clearance fluid is adequately utilized, thus the helium sealing device reliably works under an extremely small clearance, and a low leakage amount is maintained.

Owner:BEIJING AEROSPACE PROPULSION INST

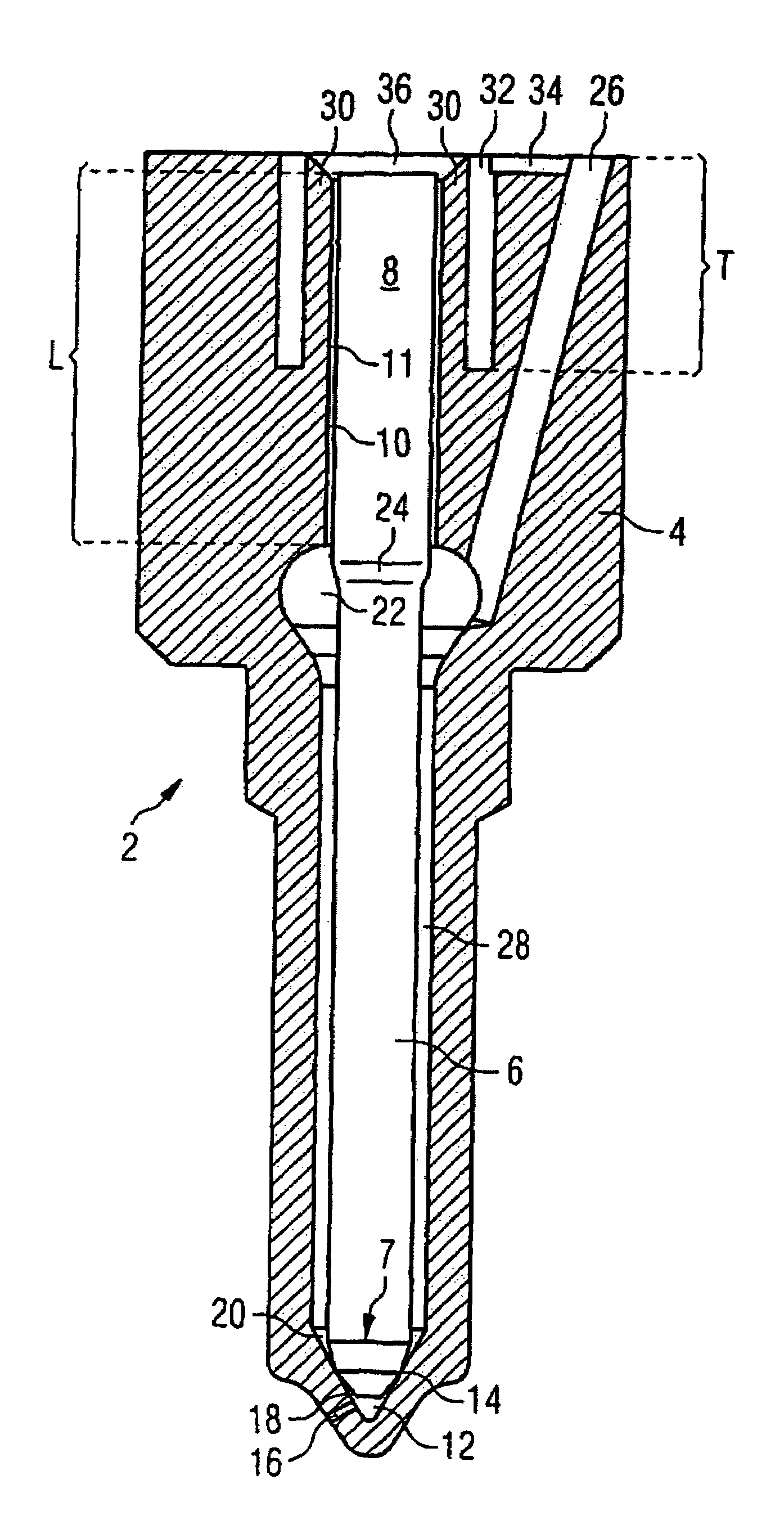

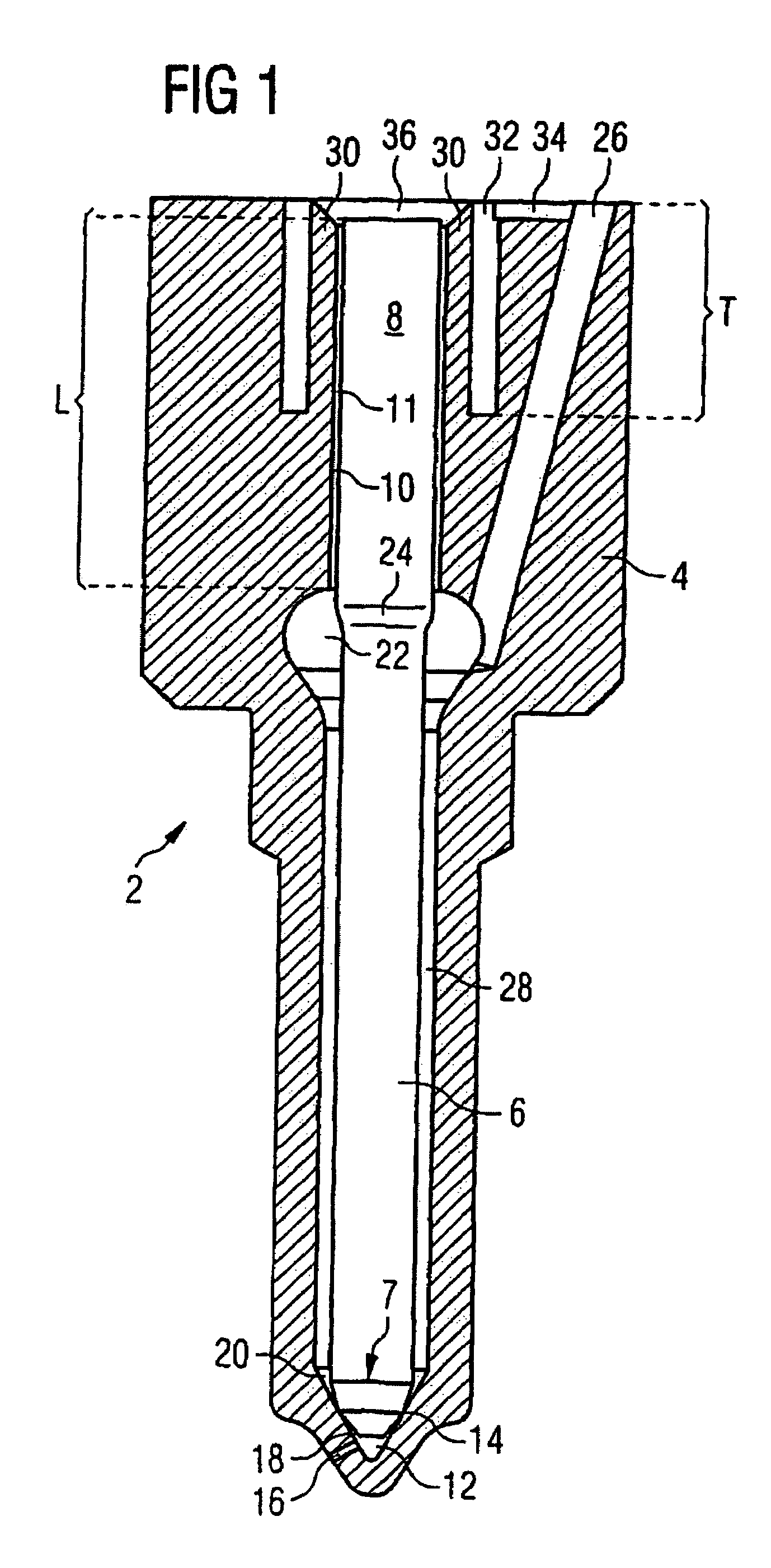

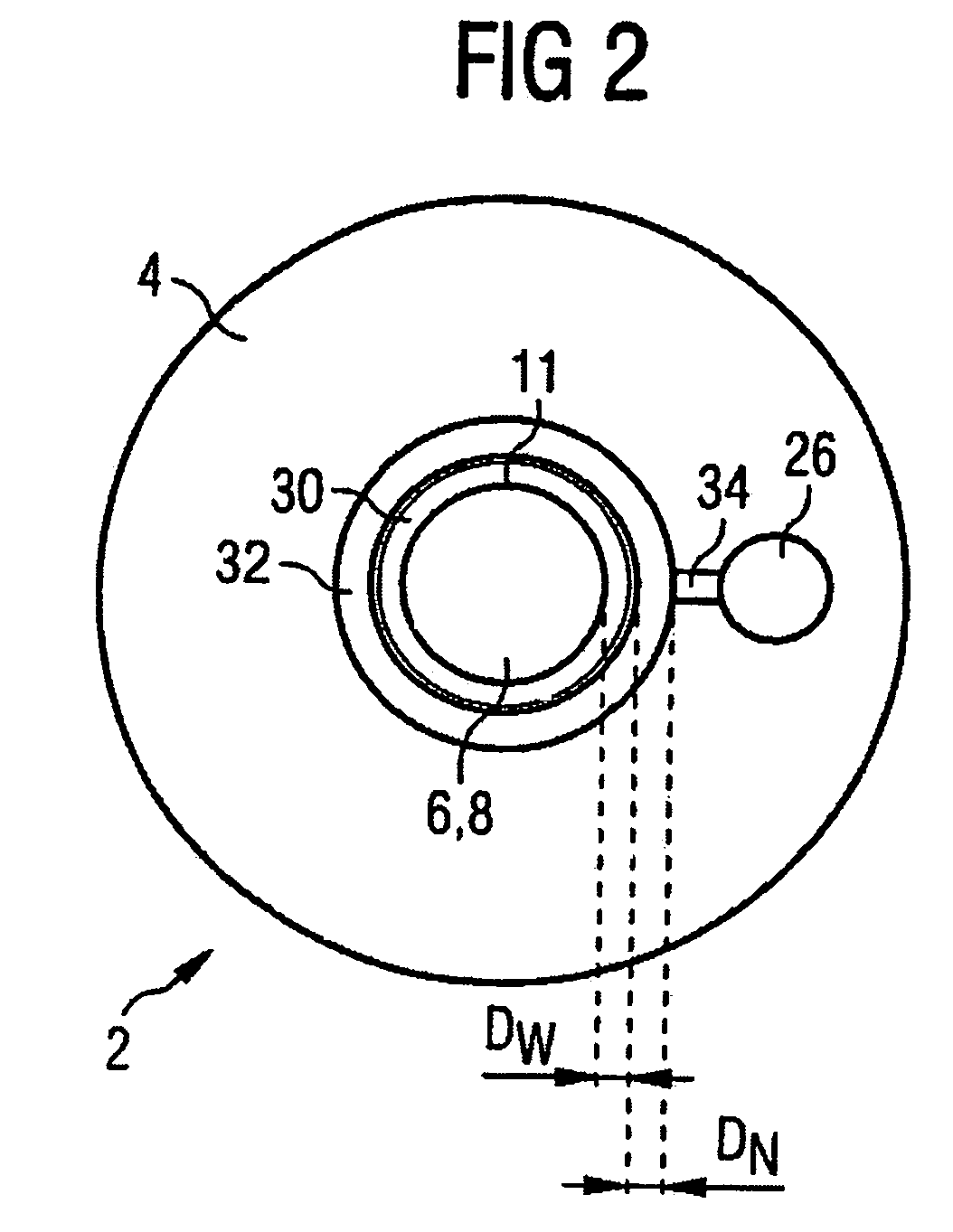

Fuel injection valve

InactiveUS7066397B2Minimize fuel leakageReduce leakageMachines/enginesFuel injecting pumpsEngineeringInternal combustion engine

The invention relates to a valve, in particular a fuel injection valve for a high-pressure accumulator injection system of an internal combustion engine. Said valve comprises a valve body, provided with a valve body seat and a valve needle, guided over a guiding length in said valve body within a stationary circular cylindrical guiding surface and provided with a valve needle seat for controlling a spray orifice. According to the present invention, a pressure reservoir under high pressure, in the shape of an annular groove arranged coaxially in relation to the guiding surface, is provided in said valve body.

Owner:SIEMENS AG

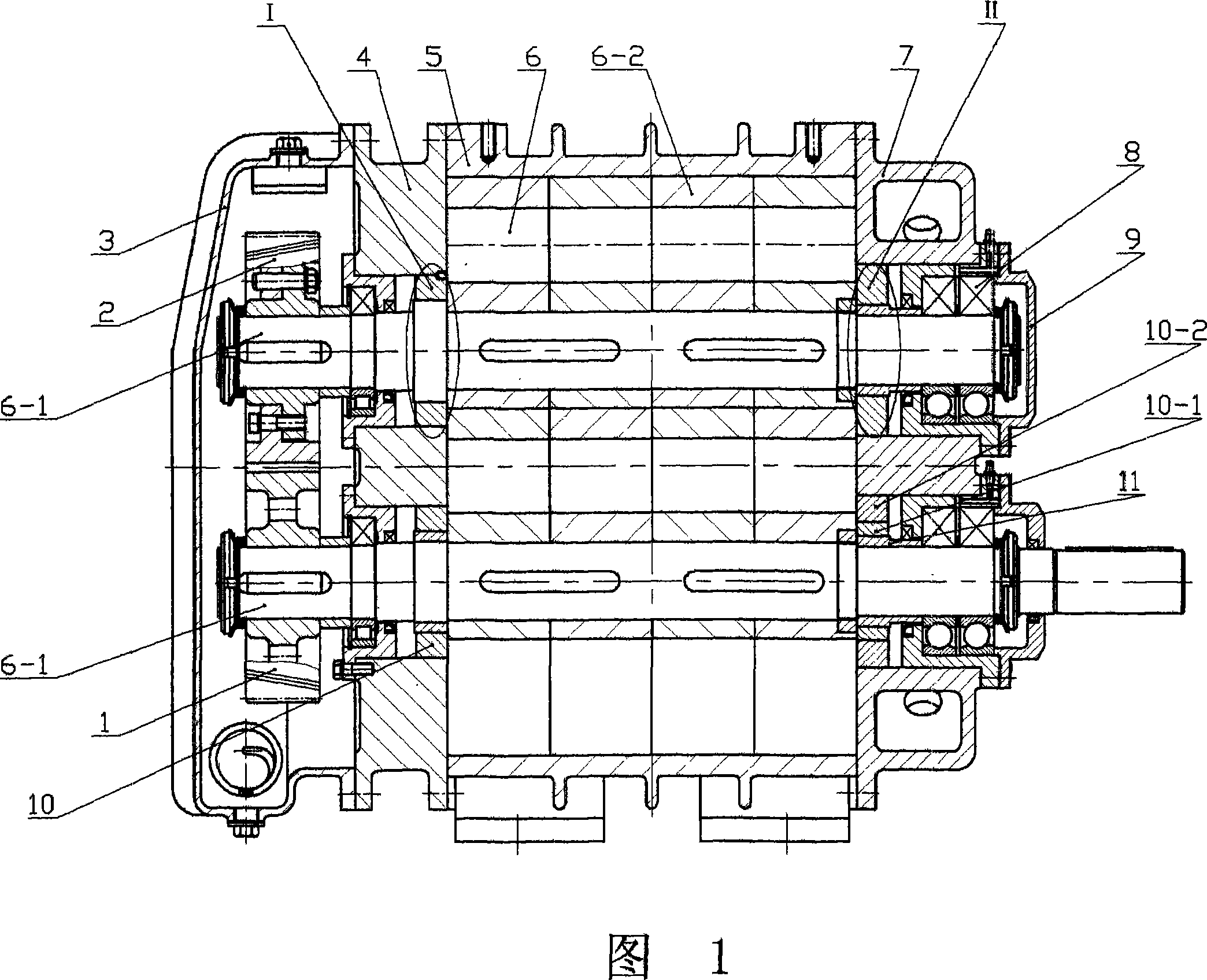

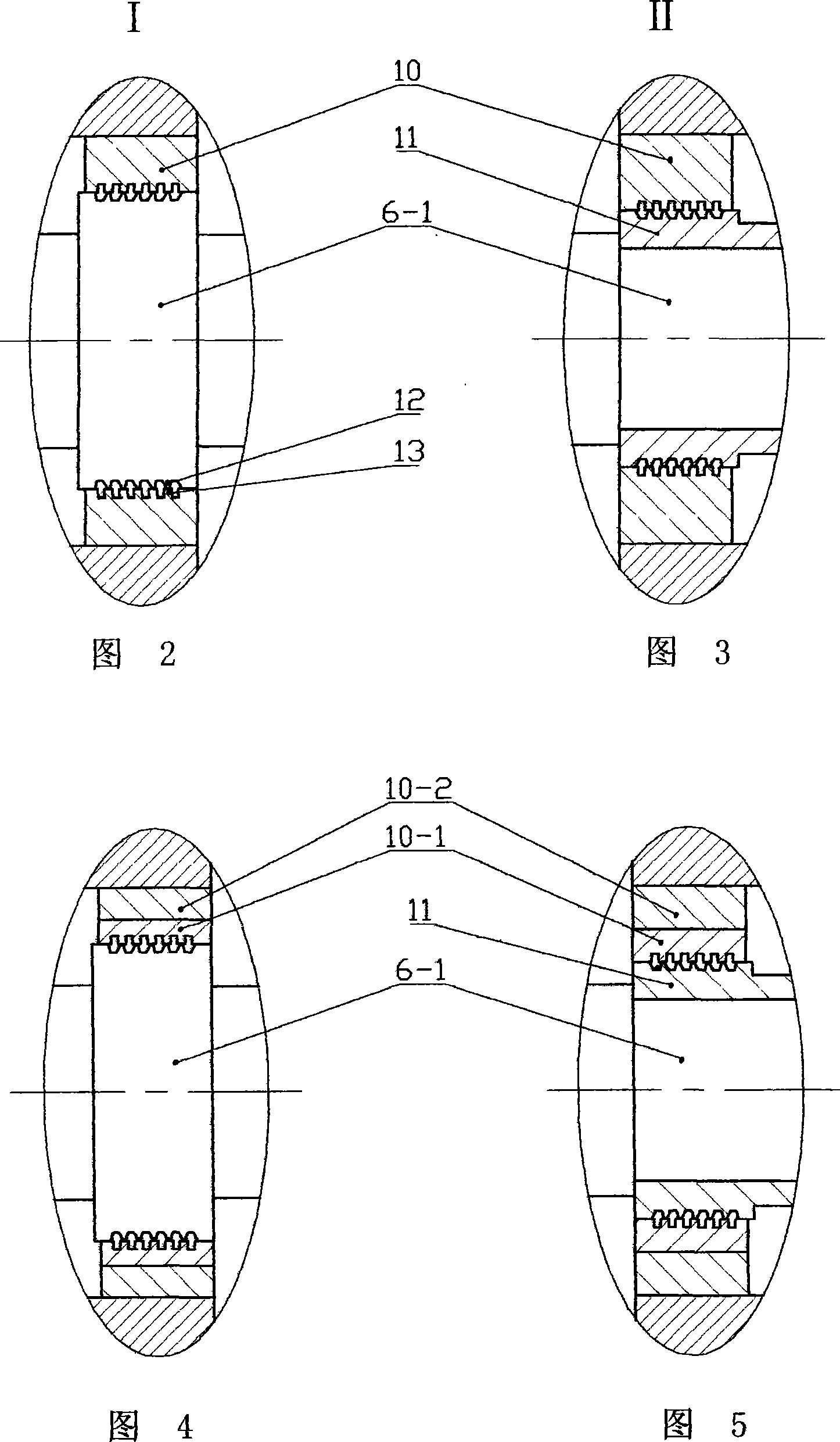

Roots blower

InactiveCN101092961AIncrease volumeImprove efficiencySealing arrangement for pumpsRotary piston pumpsImpellerEngineering

This invention relates to a Roots fan with a maze close device including an active gear, a driven gear, a gear box cover, a left wall plate, a shell, a rotor, a right wall plate, a bearing and a cover, in which a staged outer gear is set on an impeller shaft of the rotor or a staged outer gear is fixedly set on the maze shaft jacket on the impeller shaft and a rectangle inner gear is set on the maze sleeve in the shaft hole of the right and left wall plates, and cast-Al is used for the maze jacket, which is fastened by inner and outer jackets and the outer jacket can be made of cast-iron material.

Owner:常州市风机制造有限公司

Hydraulic cylinder with sealing follow-up device

A hydraulic cylinder with a sealing follow-up device comprises a piston, a sealing follow-up ring, a clamp ring and a hydraulic cylinder. The sealing follow-up ring is fixed onto the piston by the clamp ring, a cone frustum hole with a seam allowance is arranged at one end of an inner hole of the sealing follow-up ring, a cylindrical hole with a spiral oil groove is disposed at the other end of the inner hole of the sealing follow-up ring, a sealing ring groove is arranged on an outer circle of the sealing follow-up ring, a plurality of sealing follow-up ring oil inlet holes are arranged on a flange on the side, which is opposite to the cone frustum hole, of the sealing ring groove, a sealing follow-up ring internal pressure oil cavity is formed between the cone frustum hole and an outer conical surface of a rodless side of the piston, the sealing ring follow-up internal pressure oil cavity is connected with an oil cavity of a rodless side of the hydraulic cylinder by the spiral oil groove, an L-shaped seal is mounted in the sealing ring groove is disposed on the outer circle of the sealing ring follow-up ring, and an L-shaped sealing inner O-shaped seal is mounted between an inner circle of the L-shaped seal and the sealing ring groove.

Owner:TIANJIN HEAVY EQUIP ENG RES +1

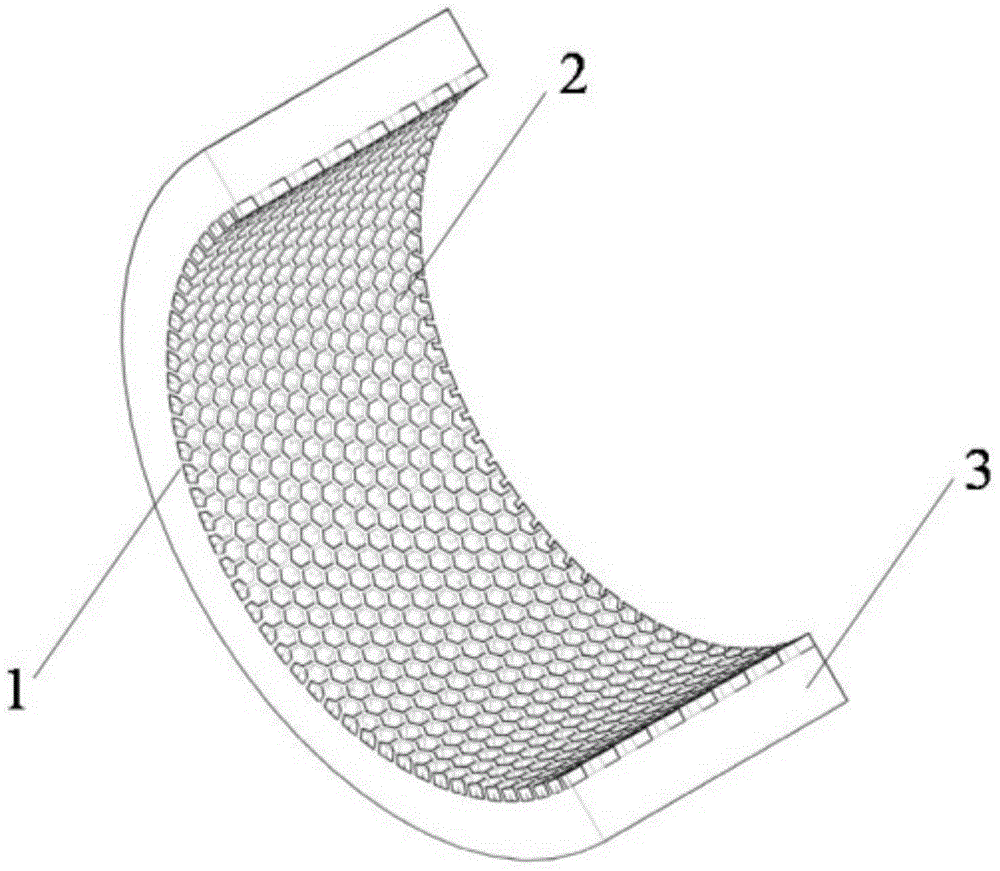

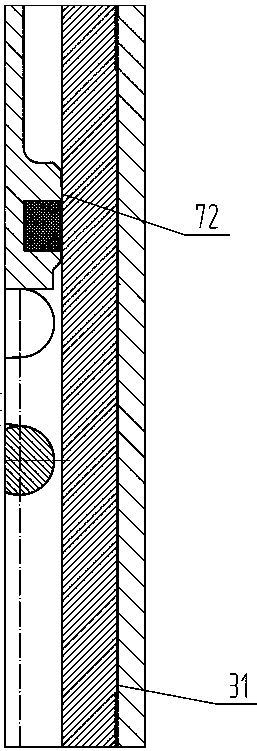

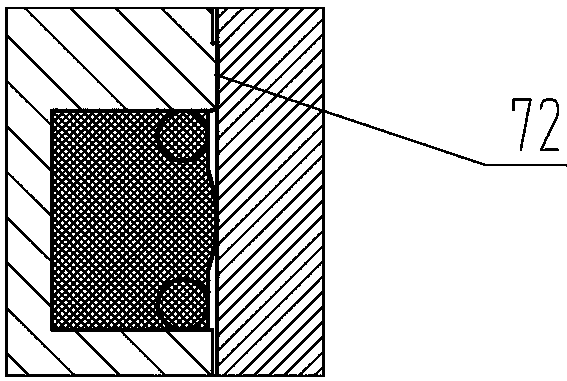

Combined honeycomb seal made of polyether-ether-ketone resin materials and method for manufacturing combined honeycomb seal

ActiveCN103557328AHigh temperature resistantHigh strengthEngine sealsHoneycombPolyether ether ketone

The invention provides a combined honeycomb seal with a metal base and a nonmetal honeycomb seal strip made of polyether-ether-ketone resin. The combined honeycomb seal aims to overcome shortcomings in the prior art. The combined honeycomb seal is characterized in that the honeycomb seal strip and the metal base are assembled in an inlaid manner by a mechanical method to form the combined honeycomb seal, the honeycomb seal strip is made of polyether-ether-ketone resin nonmetal materials by an injection molding method, honeycomb seal holes in the honeycomb seal strip are regularly hexagonal through holes or blind holes and are neat in shape, the opposite side distance of each honeycomb seal hole ranges from 4mm to 10mm, the wall thickness of each honeycomb seal hole ranges from 0.5mm to 3mm, and the depth of each honeycomb seal hole ranges from 1.6mm to 8mm. Compared with a metal honeycomb seal, the combined honeycomb seal has the advantages that seal gaps of the honeycomb seal can be reduced by the technology, the sealing performance and the running stability of the combined honeycomb seal can be improved, noise can be reduced, and the honeycomb seal can be used under severe explosive and corrosive conditions and the like; owing to injection molding and a combined structural design, the production efficiency can be improved, energy can be saved, and the cost can be lowered.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

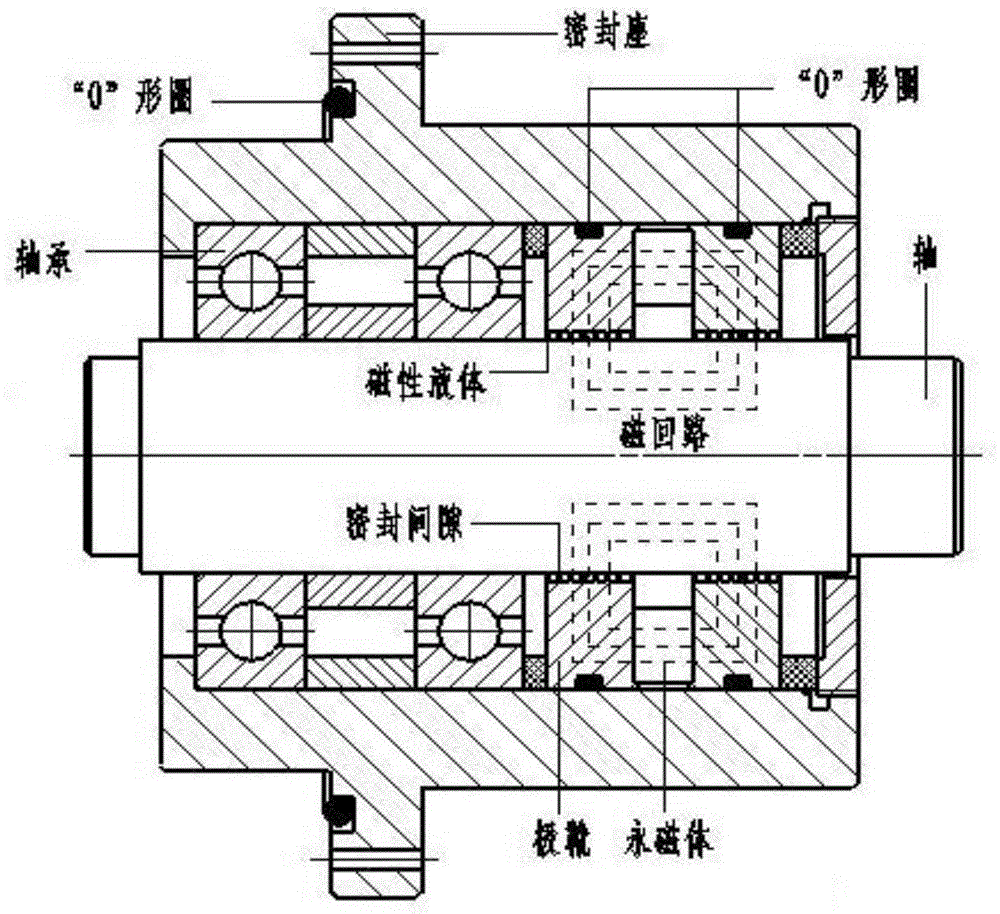

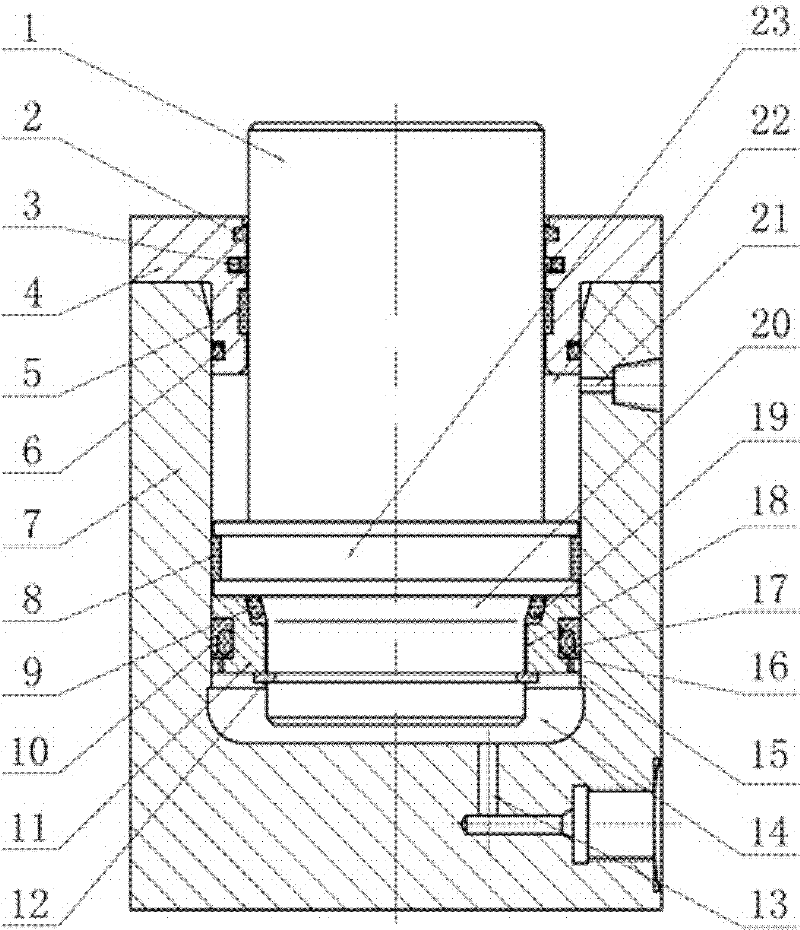

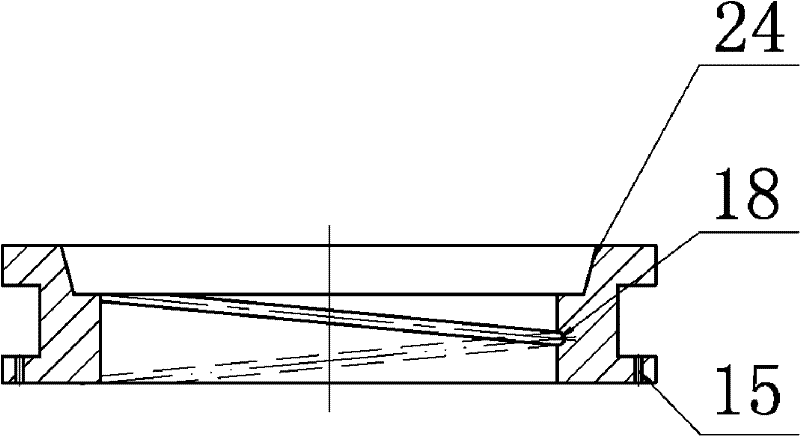

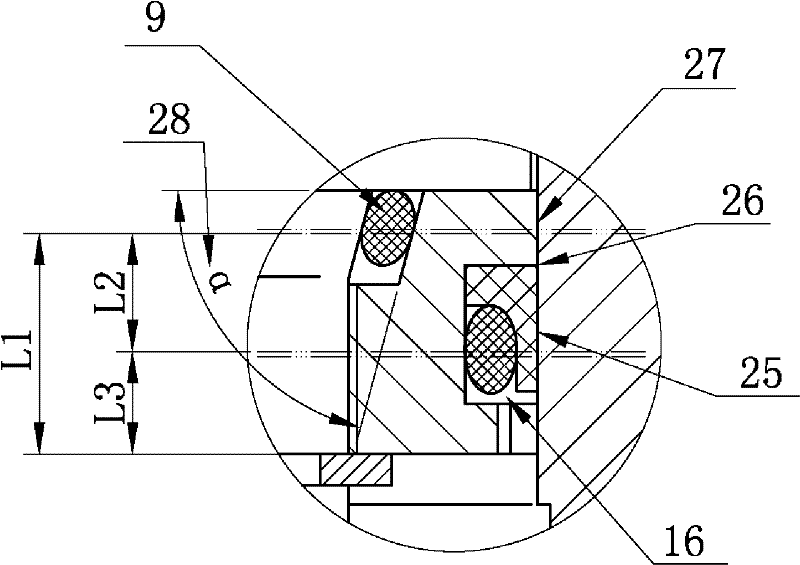

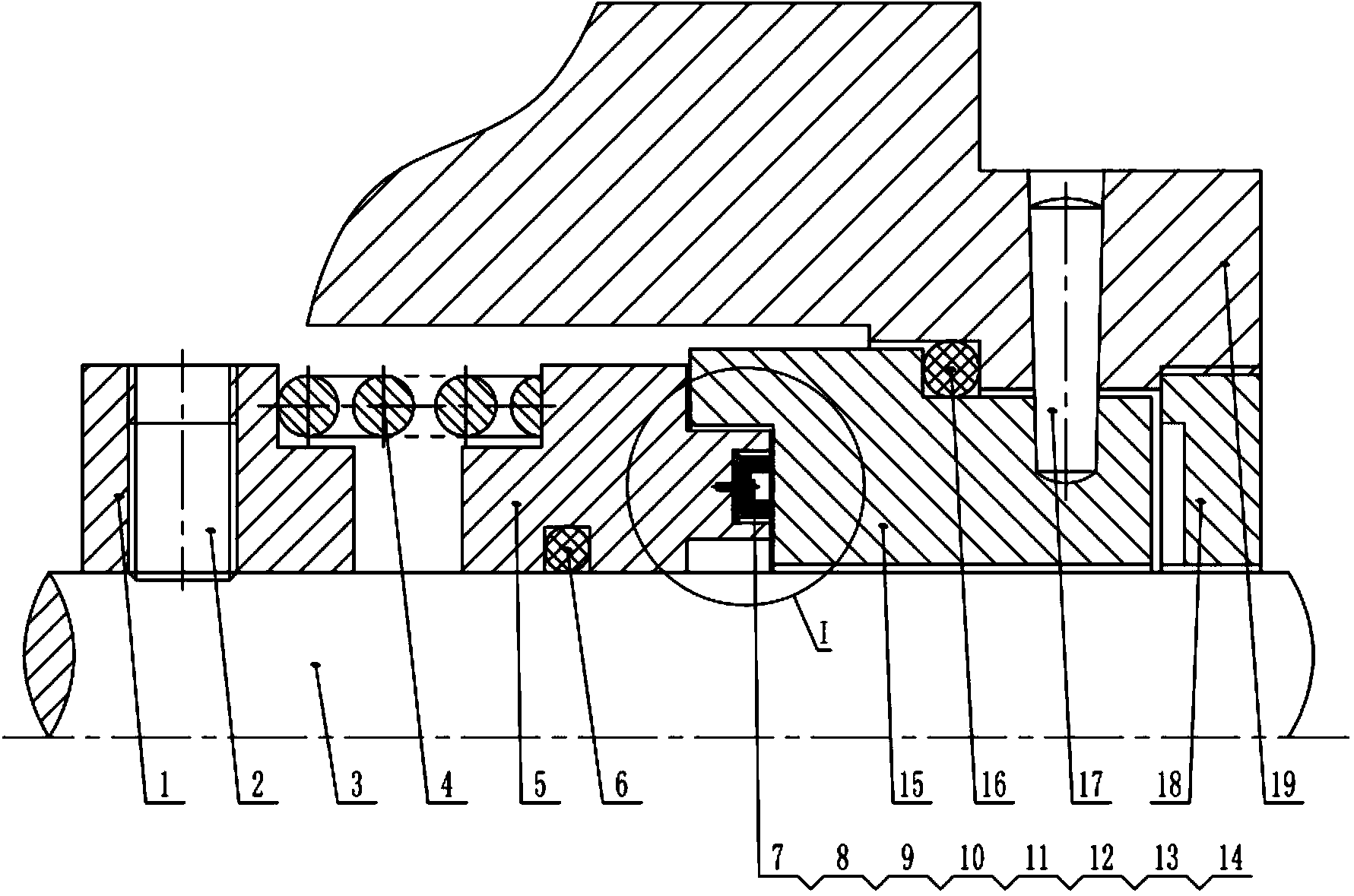

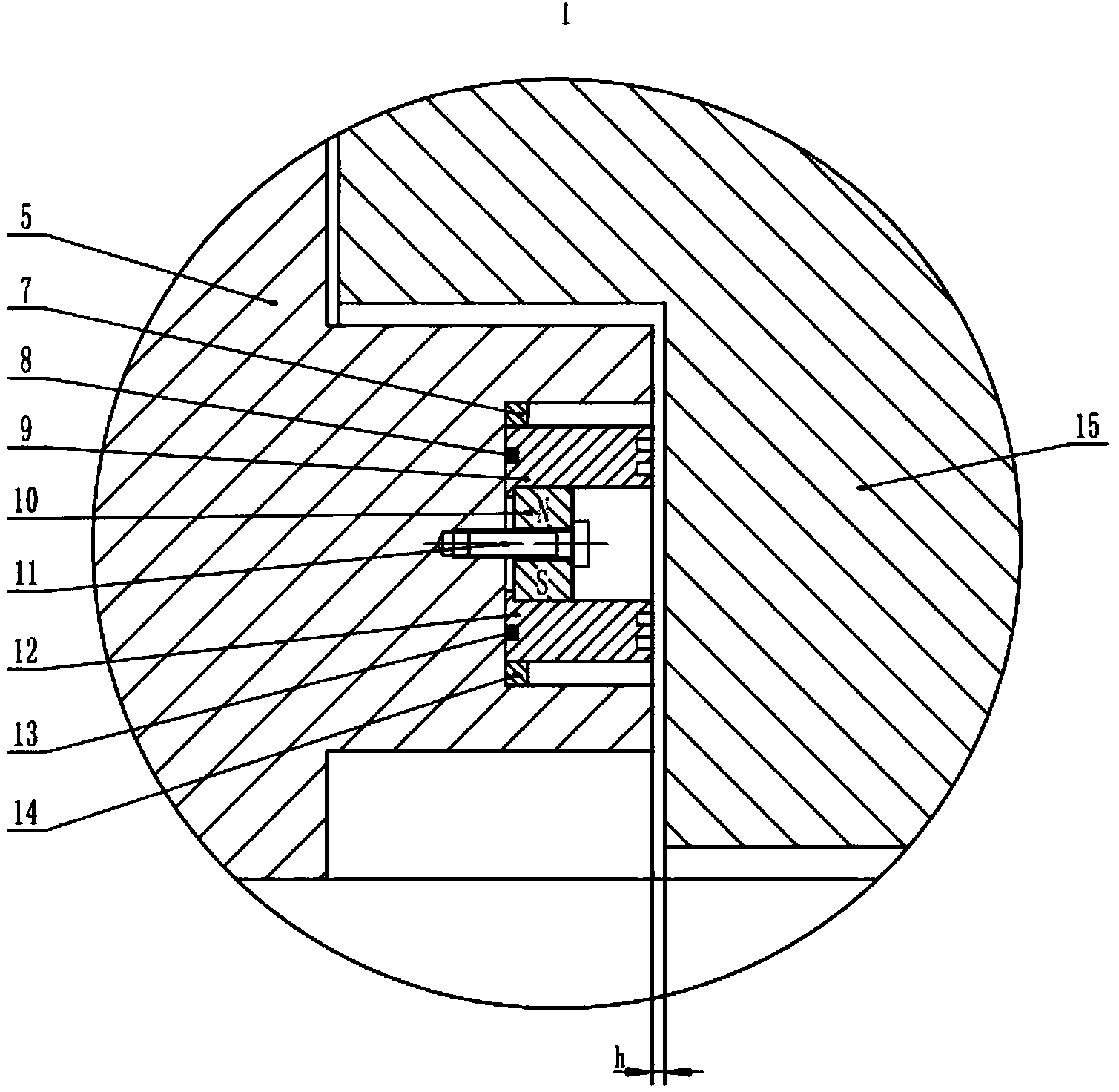

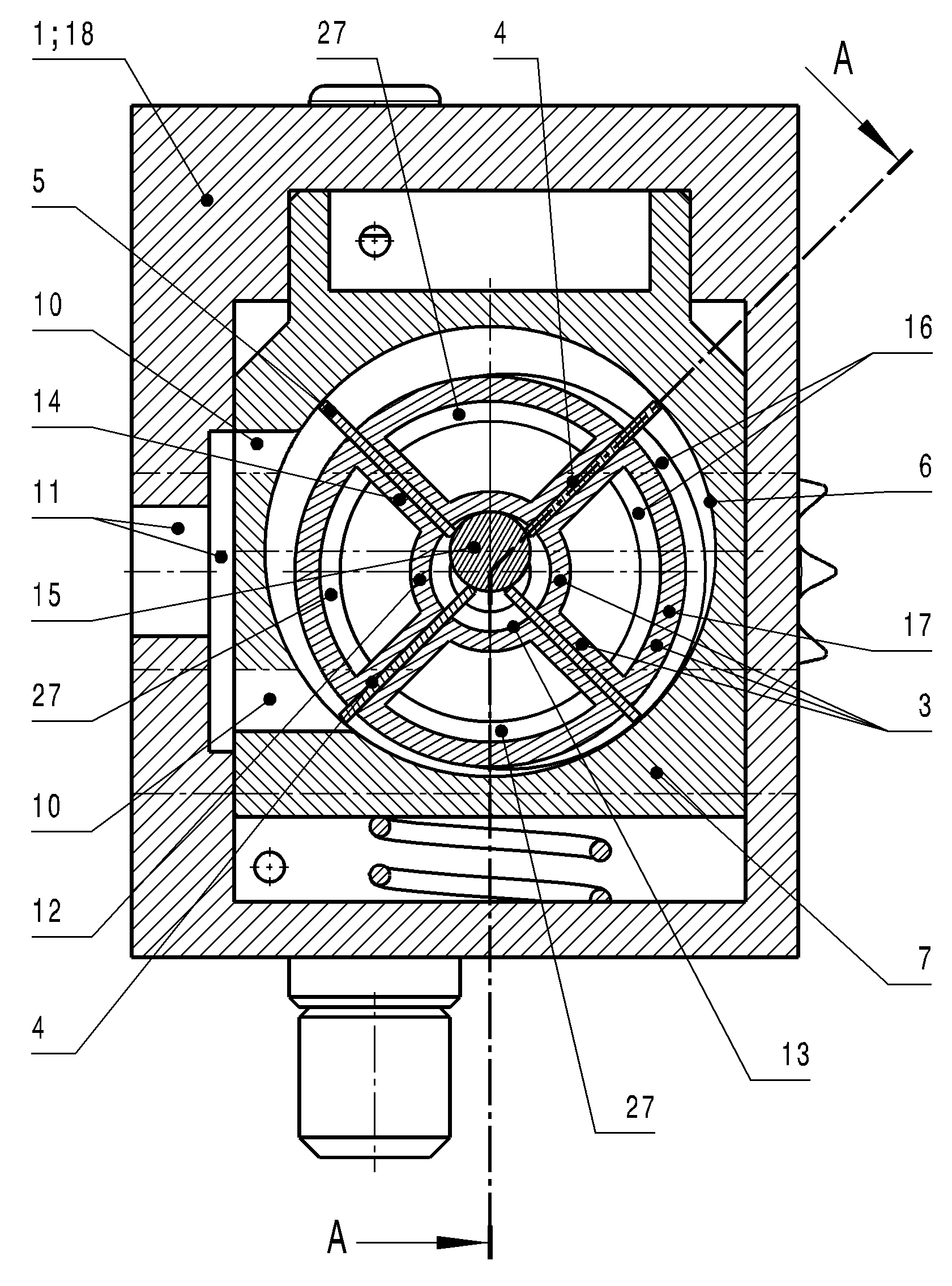

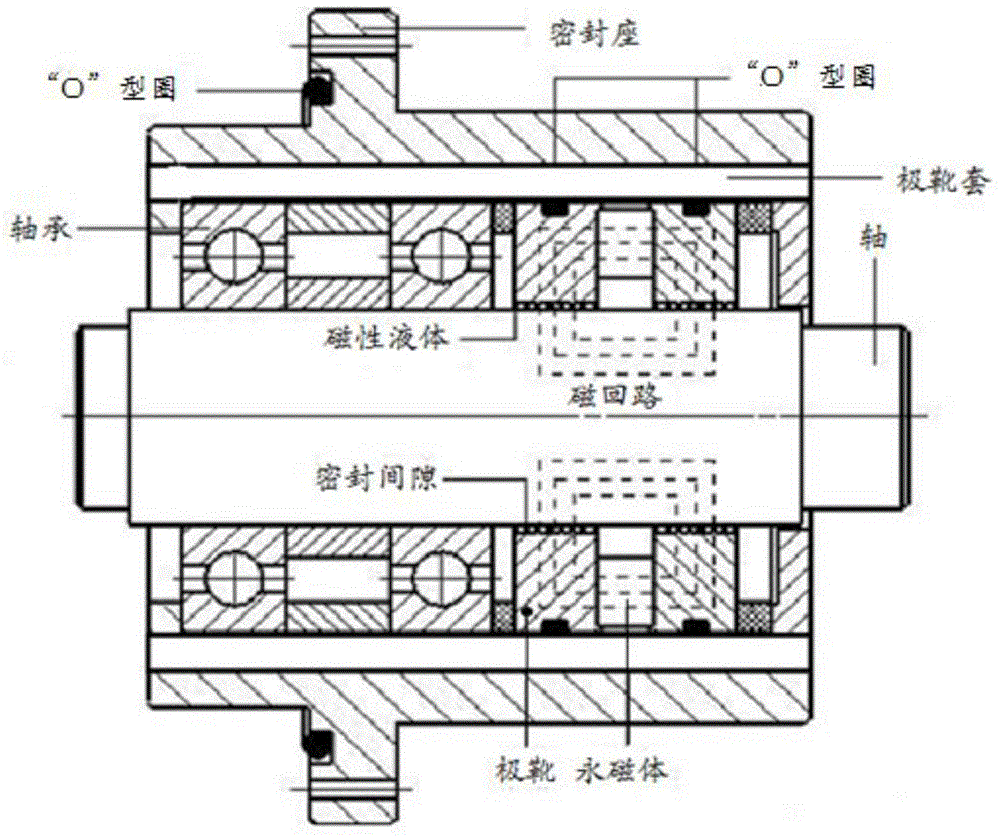

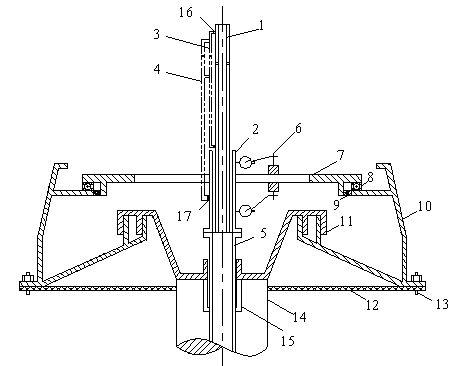

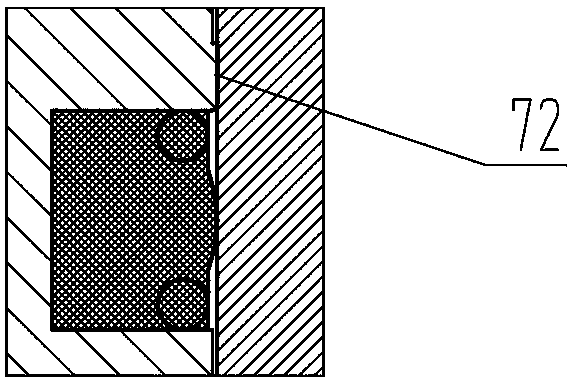

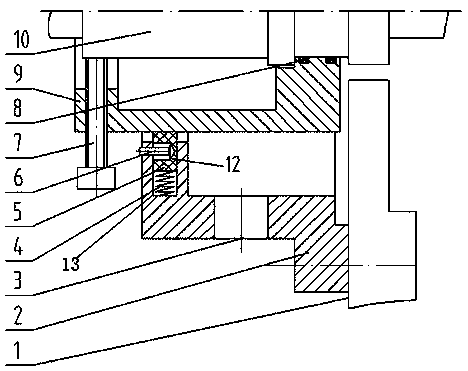

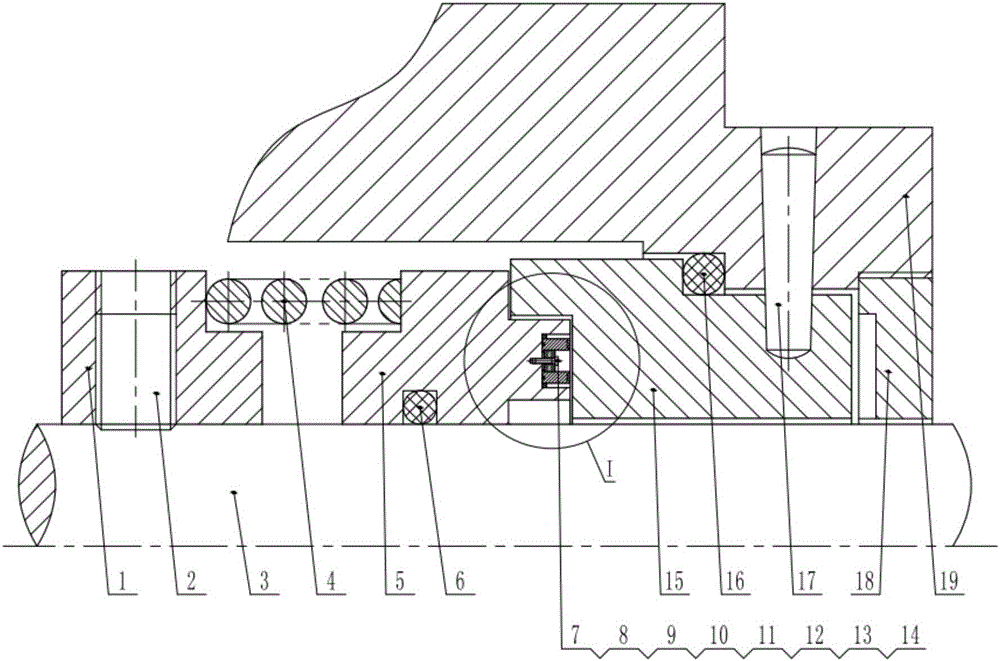

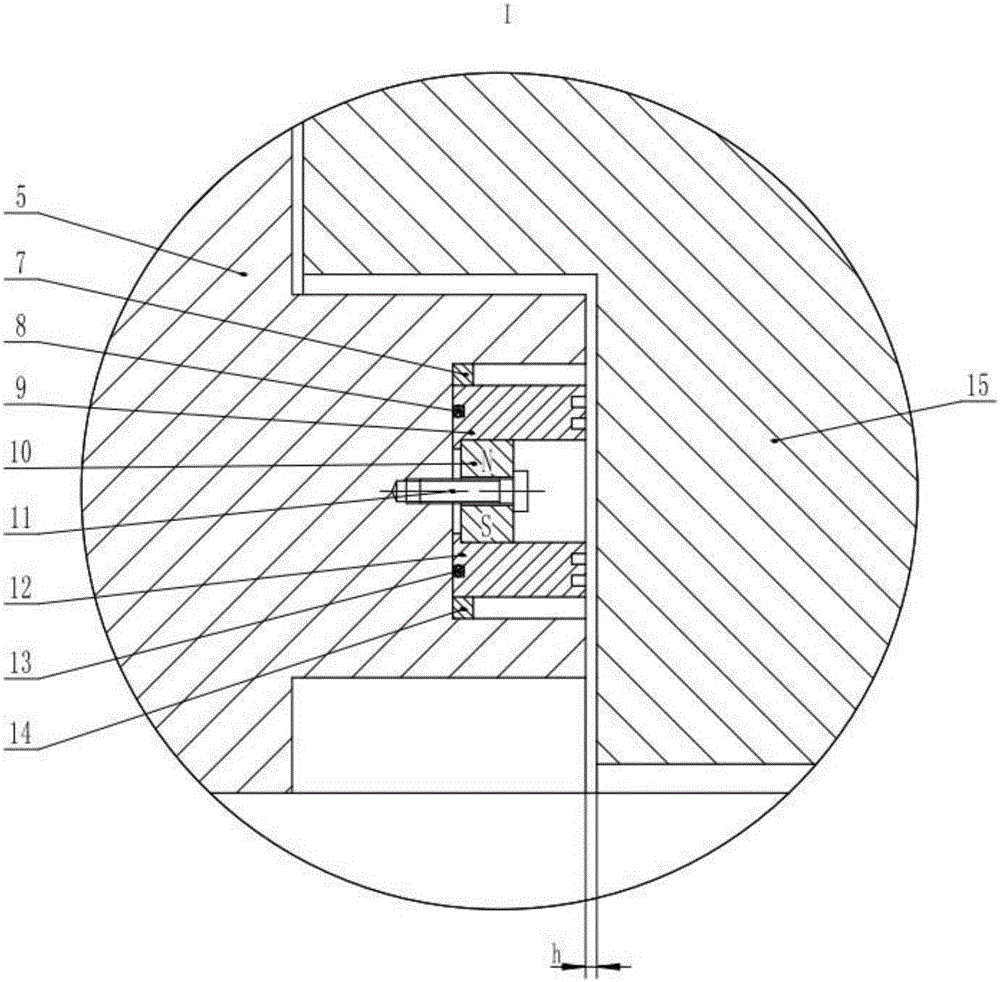

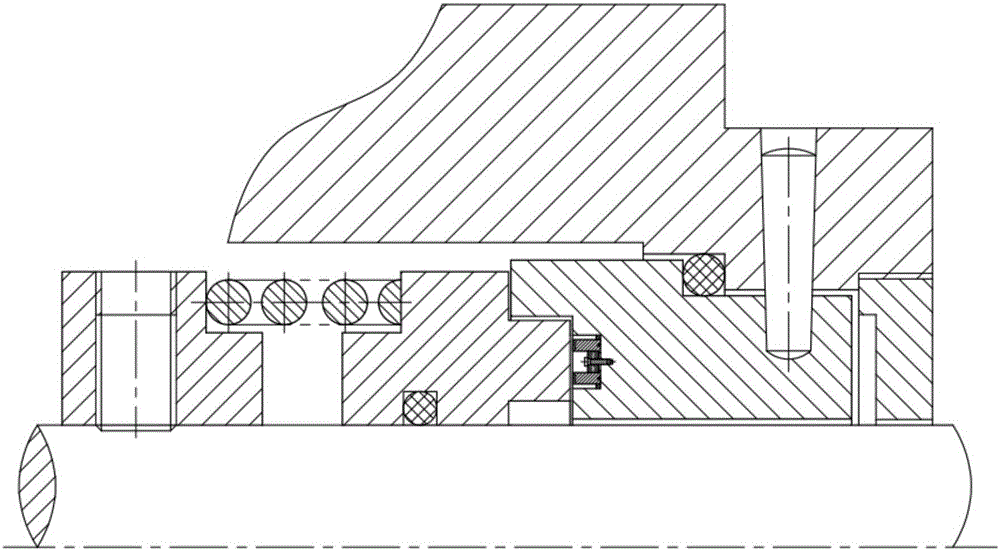

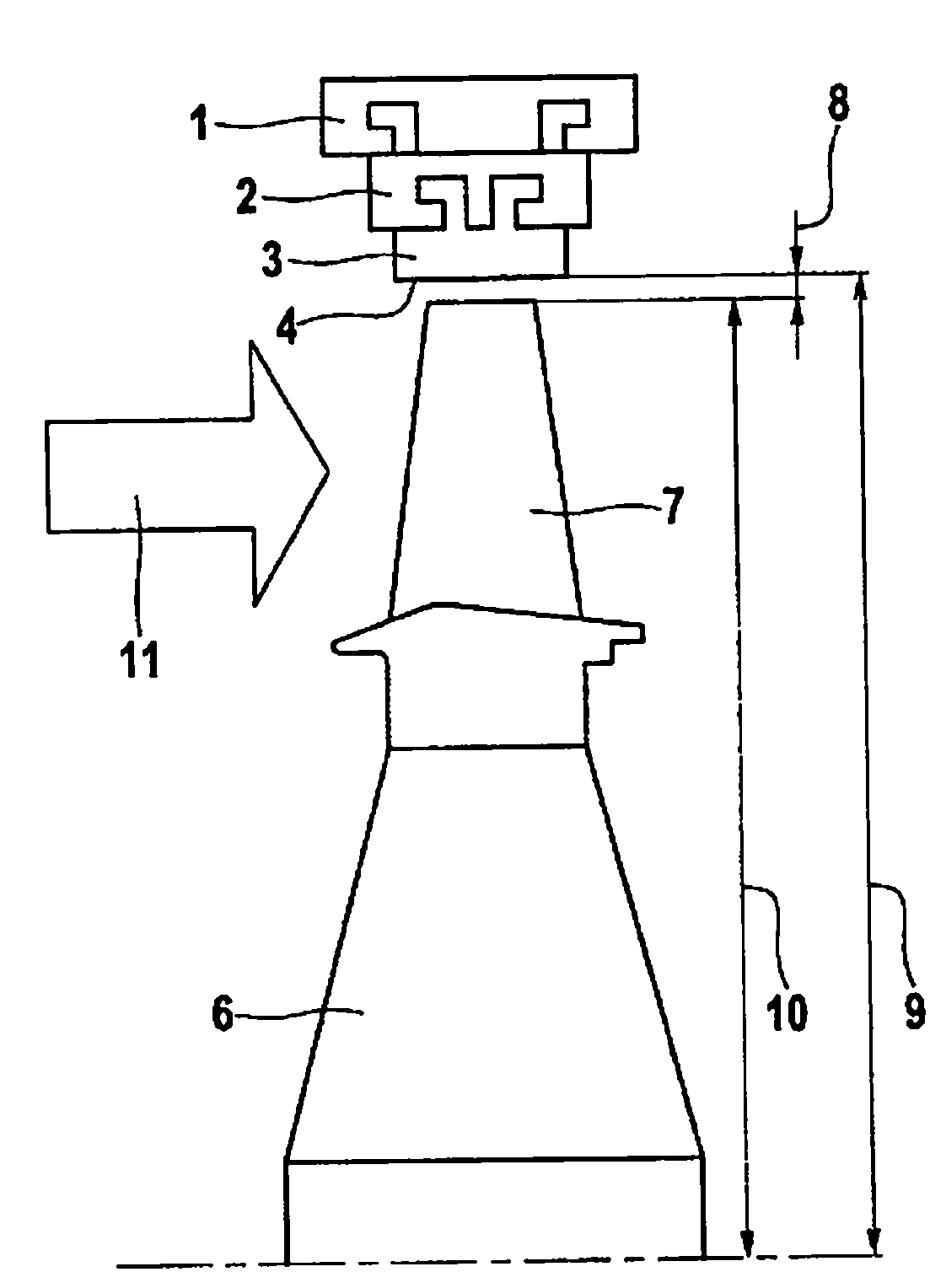

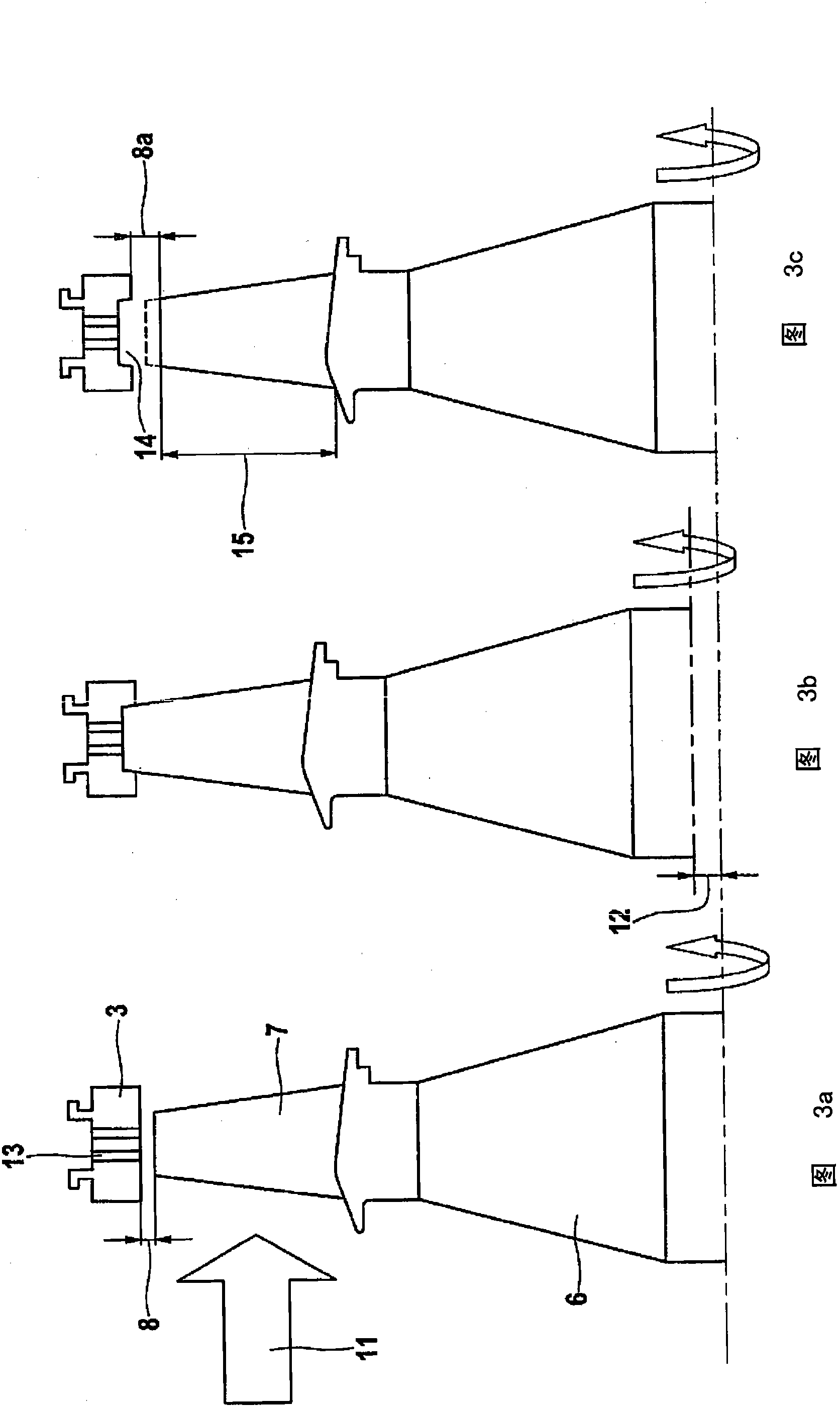

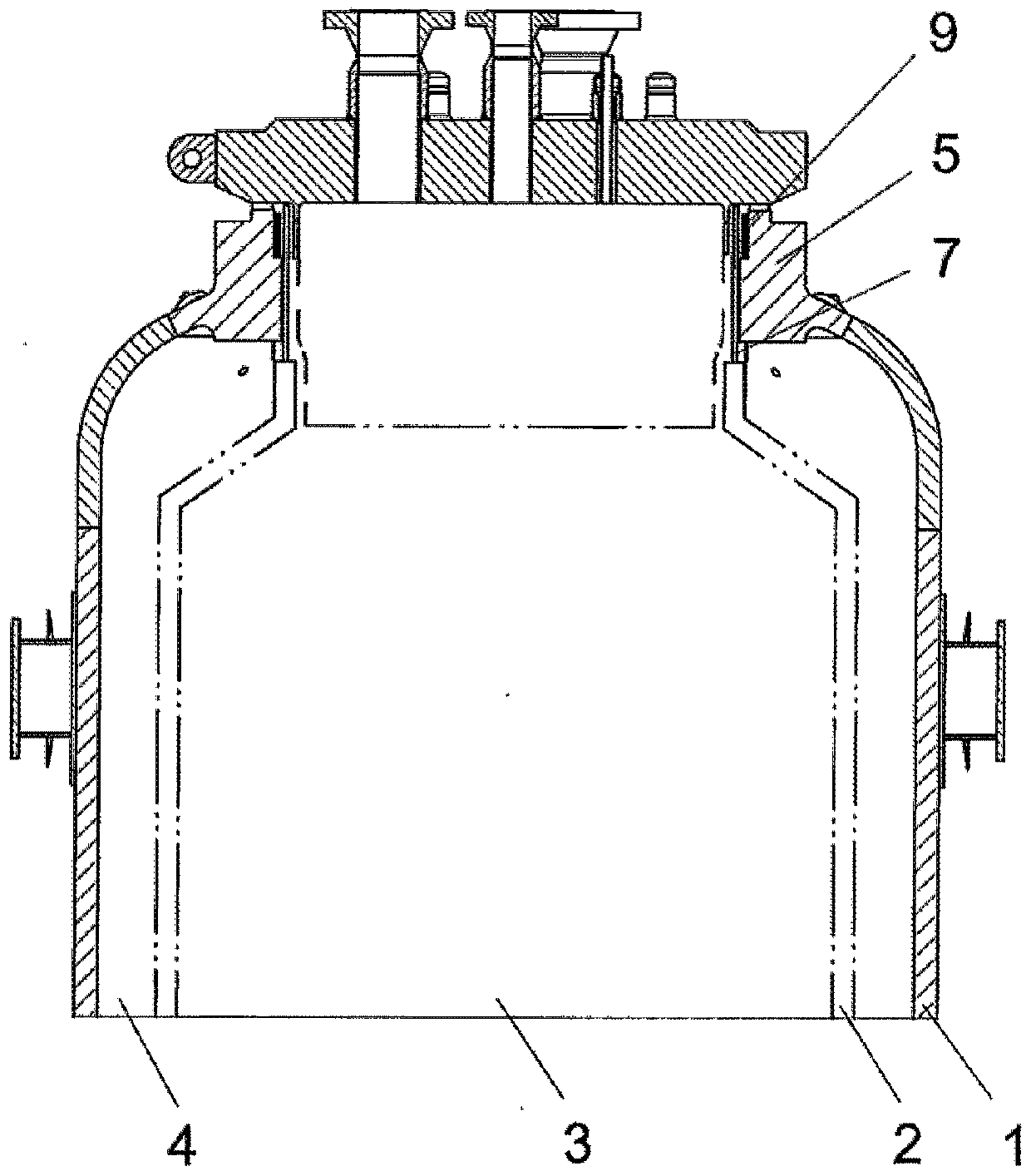

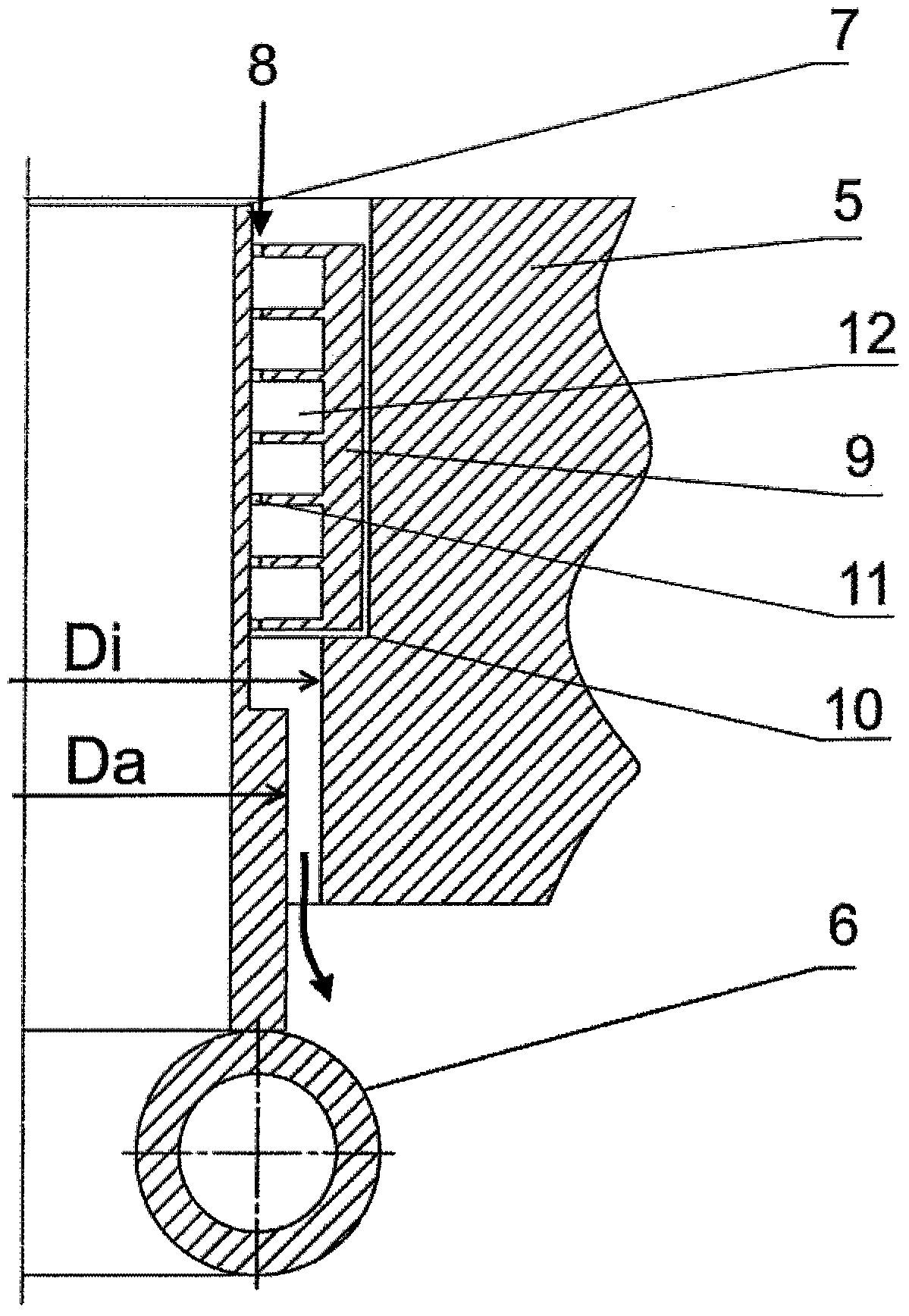

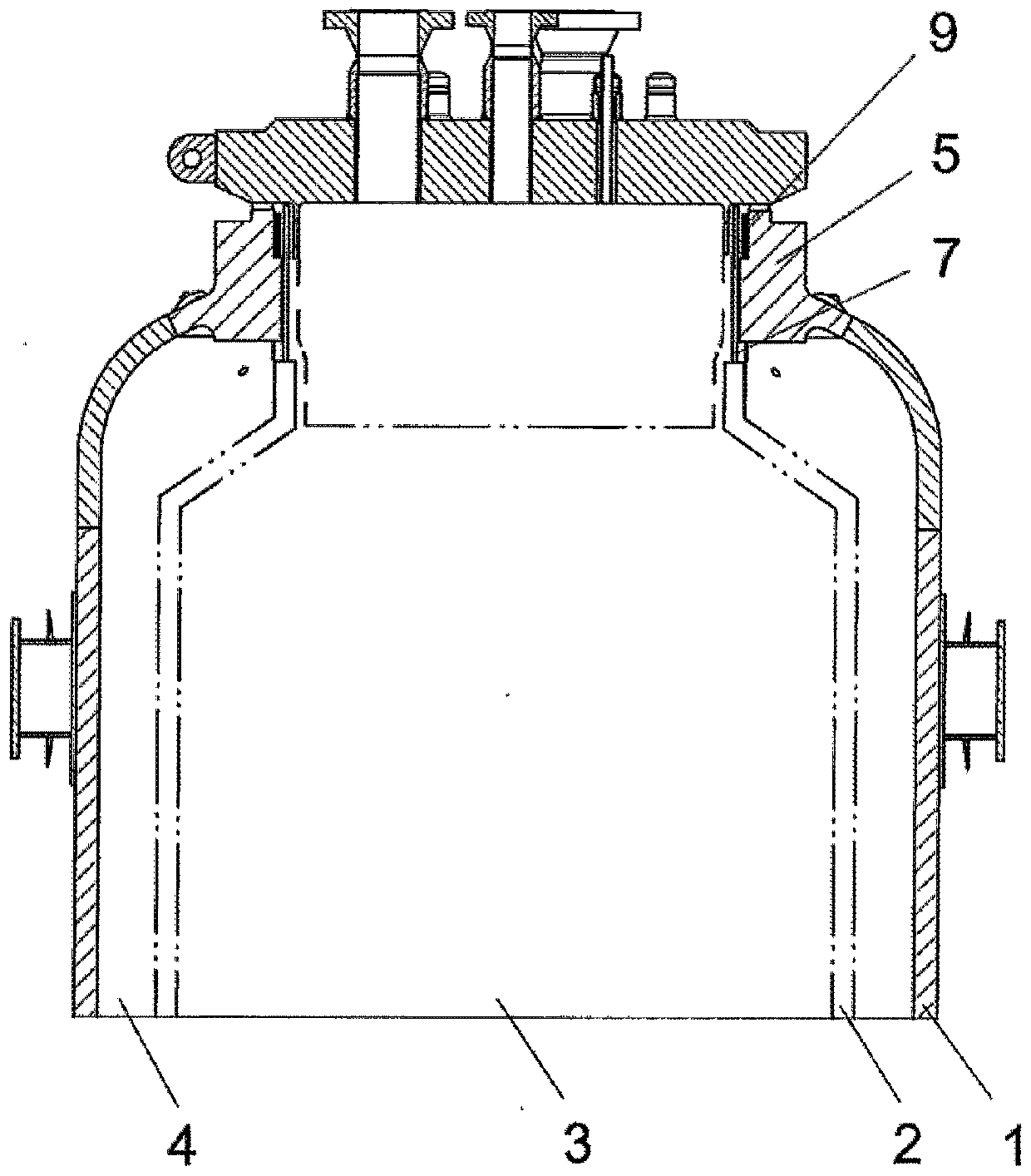

Magnetic liquid sealing device for sealing liquid

InactiveCN103759018AReduce seal gapIncrease the magnetic field strengthEngine sealsMagnetic liquidsMagnet

The invention discloses a magnetic liquid sealing device for sealing liquid, and belongs to the field of mechanical engineering sealing. The magnetic liquid sealing device comprises a spring seat (1), a set screw (2), a rotary shaft (3), a spring (4), a movable ring (5), an auxiliary sealing ring (6) of the movable ring, a first non-magnetic ring (7), an auxiliary sealing ring (8) of a first pole shoe, the first pole shoe (9), an annular permanent magnet (10), a non-magnetic-permeability screw (11), a second pole shoe (12), an auxiliary sealing ring (13) of the second pole shoe, a second non-magnetic ring (14), a static ring (15), an auxiliary sealing ring (16) of the static ring, an anti-rotating pin (17), a threaded end cover (18) and a shell (19). The magnetic liquid sealing device is arranged on an end surface, relative speeds of two types of liquid on a contact surface of the sealed liquid and the magnetic liquid are nearly zero, shearing movement between the magnetic liquid and the sealed liquid can be prevented, and accordingly the sealing life can be prolonged advantageously.

Owner:BEIJING JIAOTONG UNIV

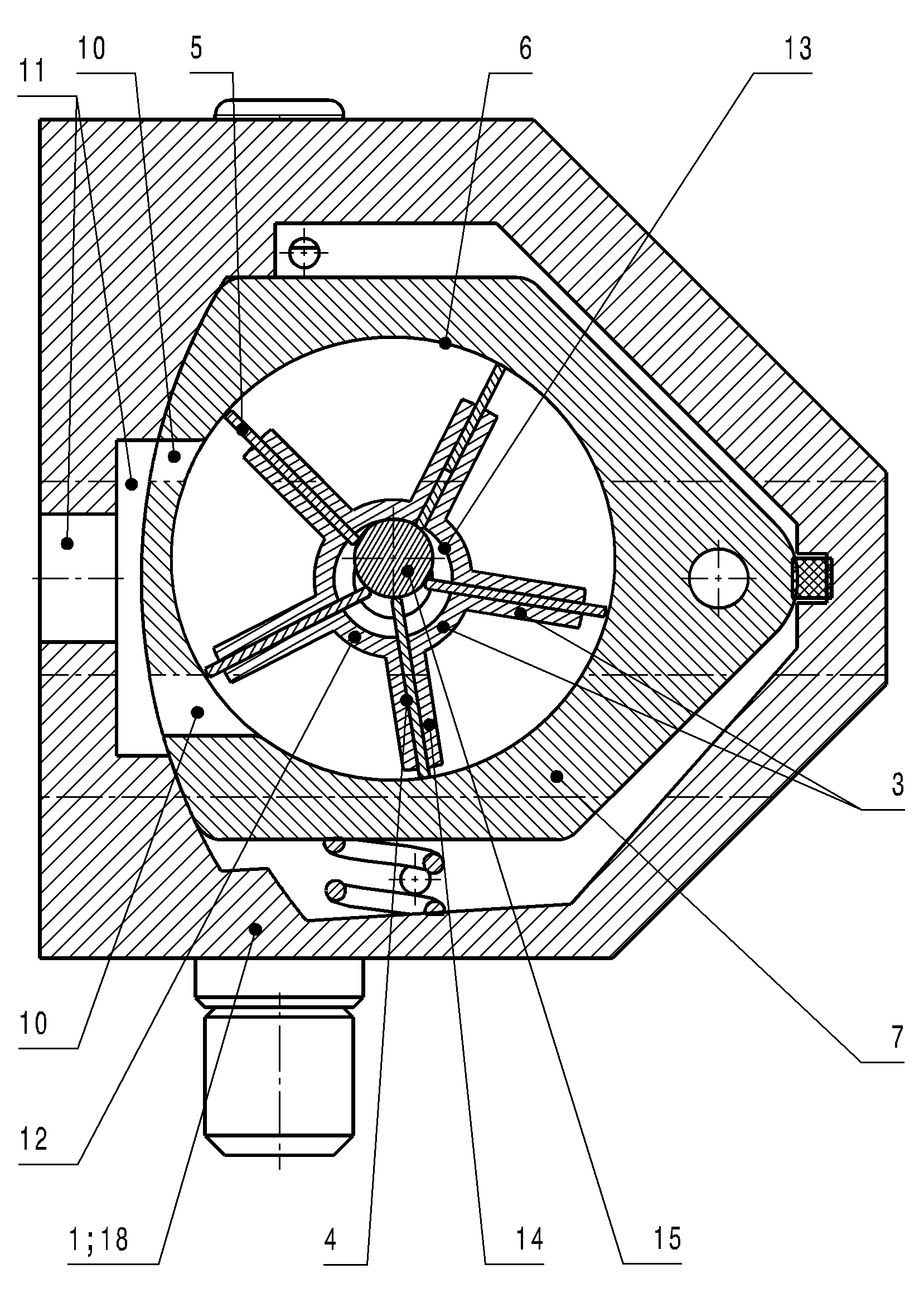

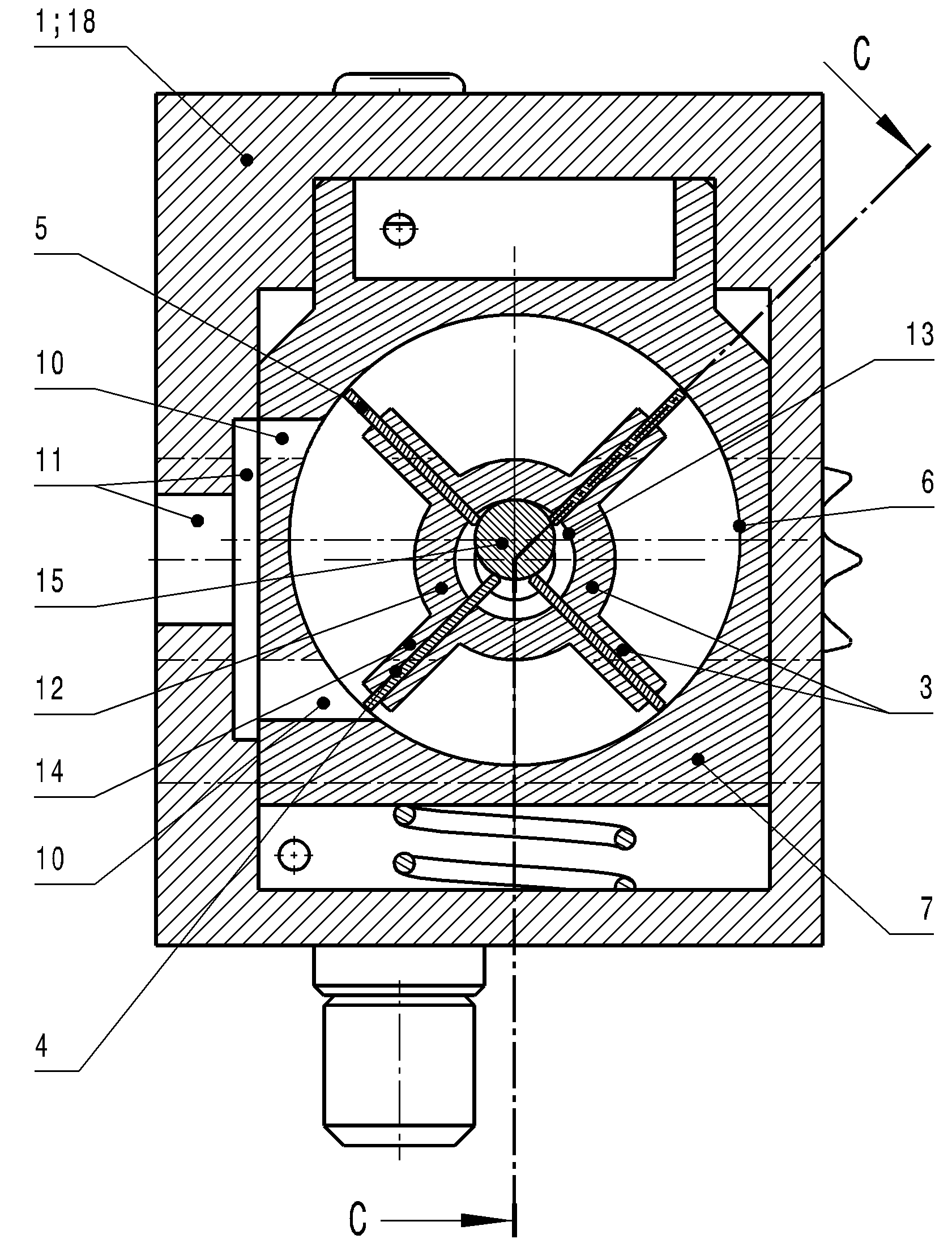

Vane pump

InactiveCN103221690AImprove stabilityEasy to fillRotary piston pumpsRotary piston liquid enginesPump chamberEngineering

The invention relates to a vane pump, comprising a rotor, which is supported in a pump housing and driven by a shaft, a plurality of vane plates supported in the rotor in a radially movable manner, and an outer ring that surrounds the rotor and the vane plates, the outer ring being arranged either directly in the pump housing or in an adjusting ring that can be moved in the pump housing along specified paths. The invention is based on the aim of developing a vane pump that among other things lowers the frictional and leakage losses, ensures the pump chambers are filled and drained optimally in regard to flow, in the lower rotational speed ranged as well as in the upper rotational speed range, significantly reduces the power losses, also is easy to manufacture and assemble in regard to production and significantly reduces the production costs, at the same time is insensitive to particles, minimizes the wear of the assemblies, and ensures the reliability and service life and a high specific delivery volume flow at high volumetric efficiency, both at low rotational speeds and high rotational speeds. The vane pump according to the invention is characterized in particular in that a cylinder guide (13) is arranged in the hollow rotor shaft (24), in which cylinder guide a freely rotating synchronizing cylinder (15) that is not rigidly connected to the adjacent assemblies is guided, wherein vane-shaped vane plate guide webs (14), which are associated with bearing grooves (4) arranged in the wall of the hollow rotor shaft (24) and which radially protrude beyond the hollow rotor shaft (24) in the vicinity of said bearing grooves (4) by approximately 0.75 to 1.8 times the diameter of the synchronizing cylinder (15) and which have bearing grooves (4), are rigidly arranged on the hollow rotor shaft (24) in such a way that the hollow rotor shaft (24) forms a vane rotor (3) together with vane plate guide webs (14), and outlet opening(s) (10), which extend completely through the adjusting slide and which extend radially with respect to the inner cylinder (6) and which are opposite the inlet nodule(s) (9) arranged in the side walls of the pump housing (1) on the pump side, are arranged in the adjusting slide (7).

Owner:欧根·施密特博士仪器和泵制造有限责任公司

Retrofittable interstage angled seal

InactiveUS9145788B2Reduce seal gapReduce radial sizeEngine manufacturePump componentsCircular discAcute angle

A rotary turbomachine includes a rotor mounting at least one disk having an outer surface and at least one bucket extending radially from said outer surface. A stationary stator component is located adjacent the disk, and a seal plate extends from a portion of the stationary stator component. An angel wing seal extends from the bucket, thereby defining a clearance gap between the seal plate and the angel wing seal. An abradable seal element is disposed on the seal plate, and the abradable seal element and the seal plate are canted at an acute angle relative to a center axis of the rotor extending radially outwardly in a direction toward the angel wing seal.

Owner:GENERAL ELECTRIC CO

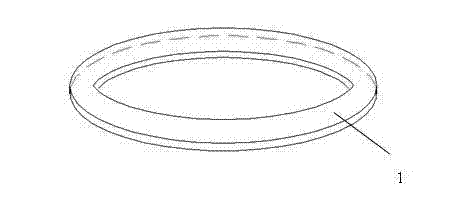

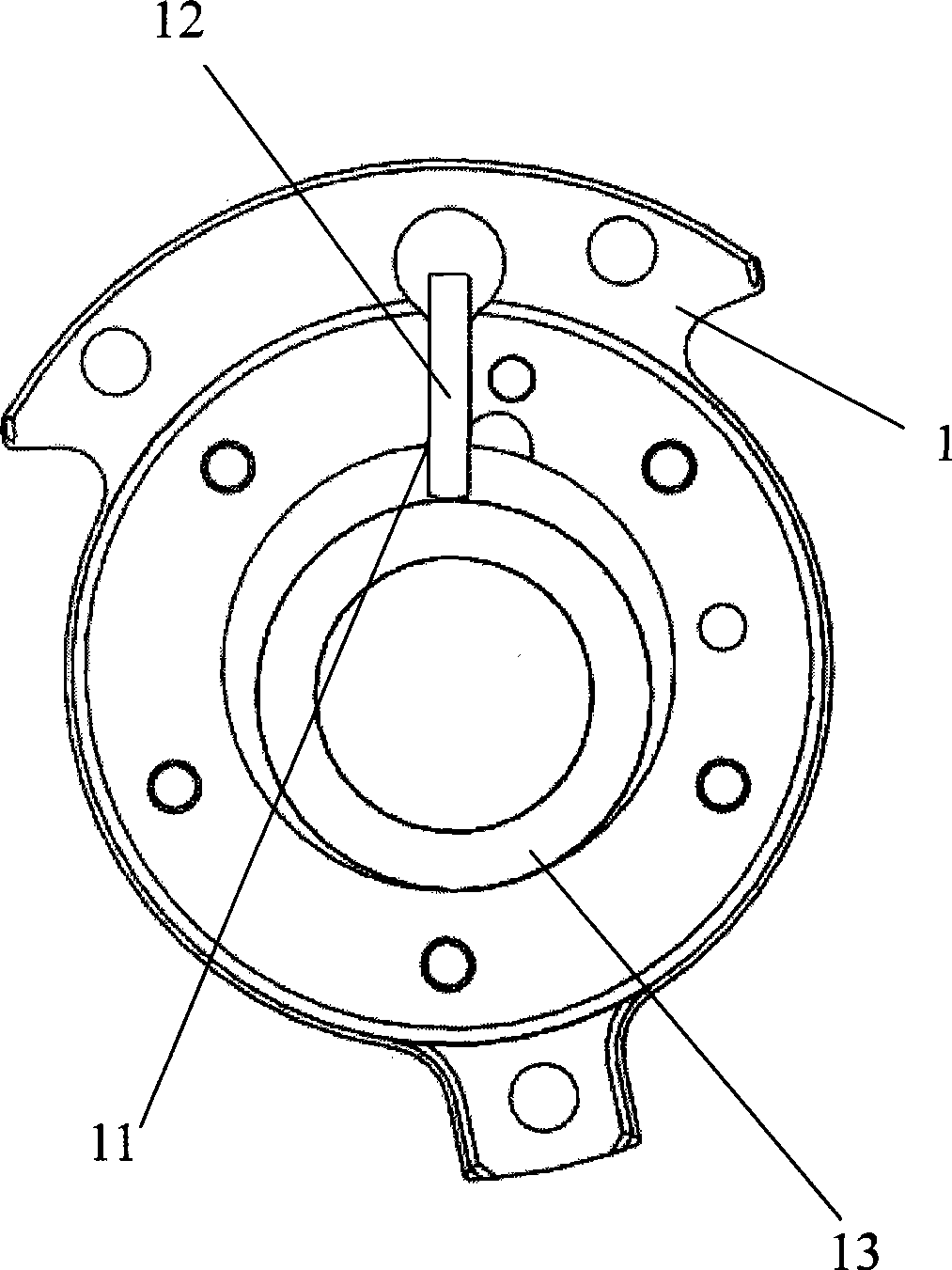

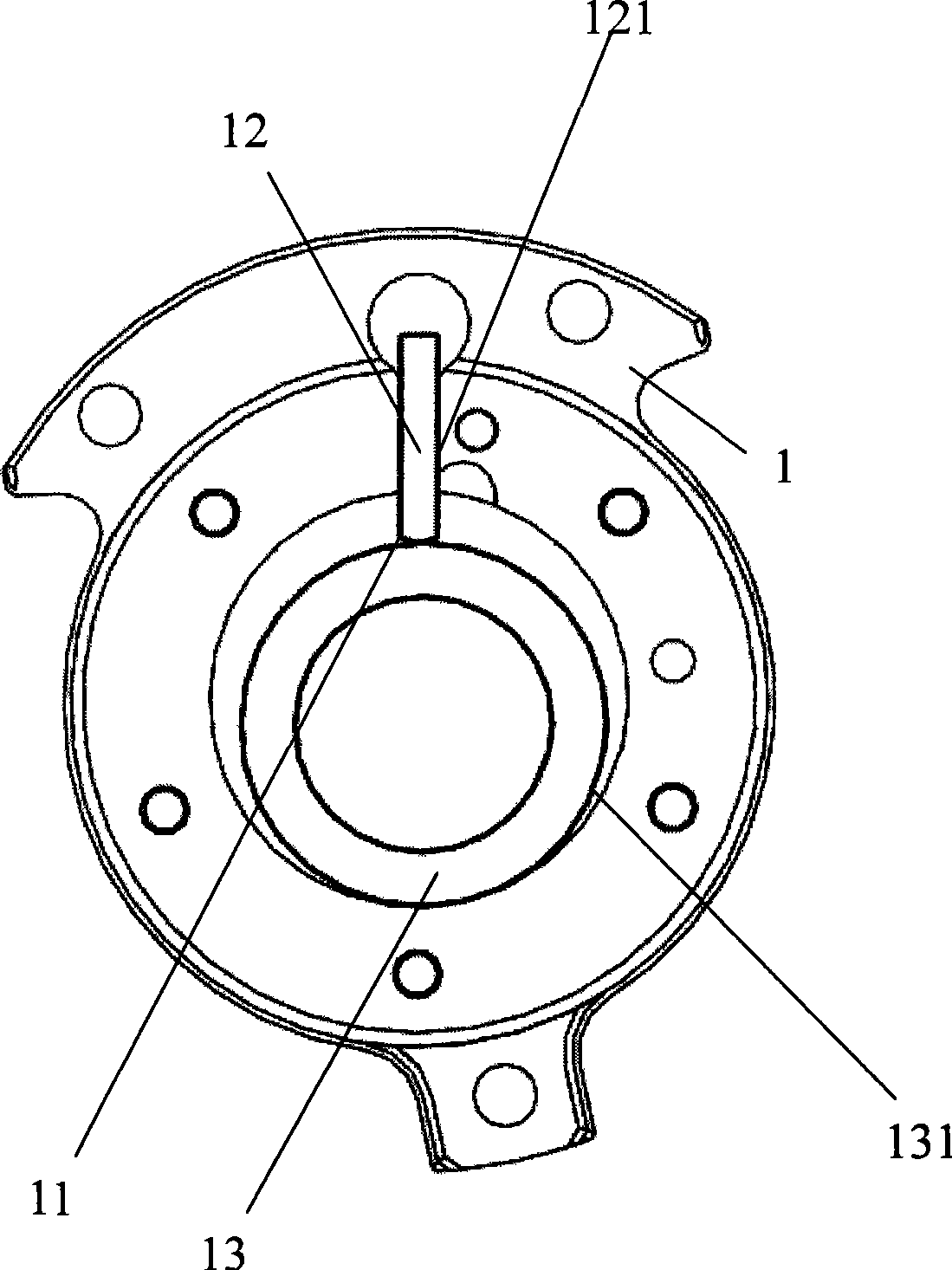

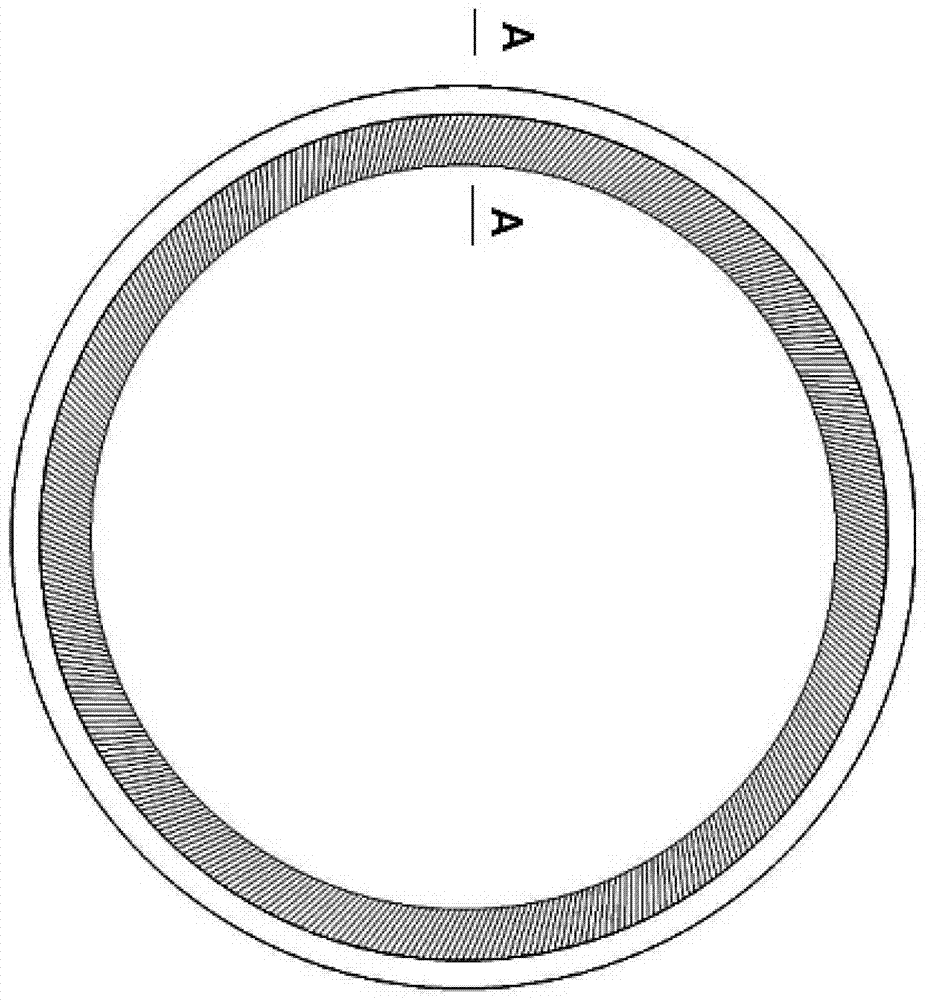

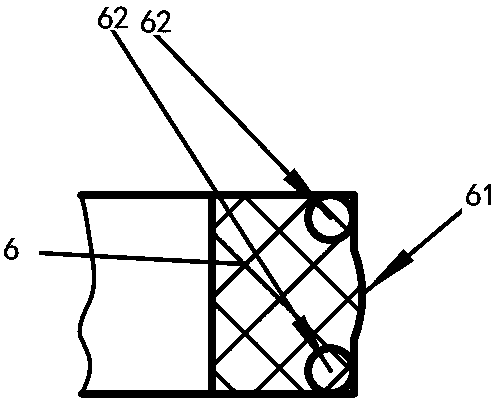

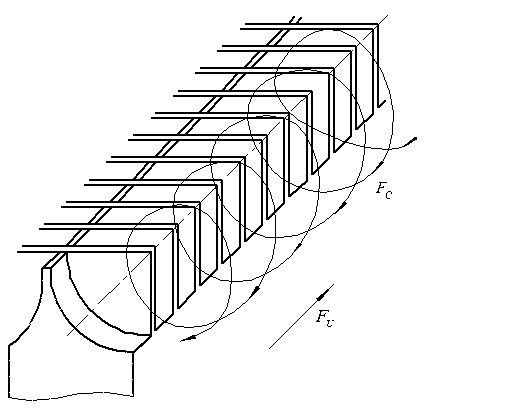

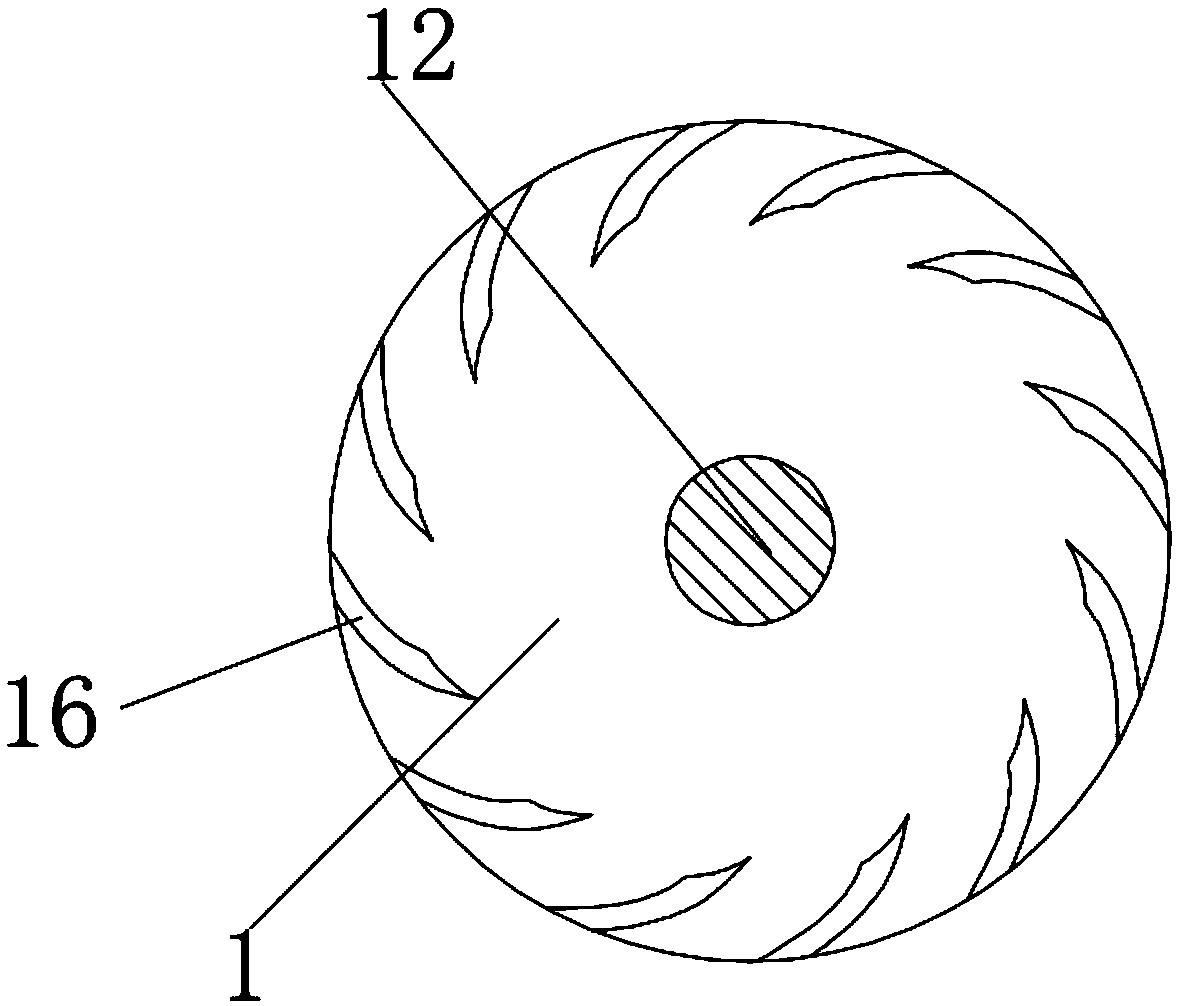

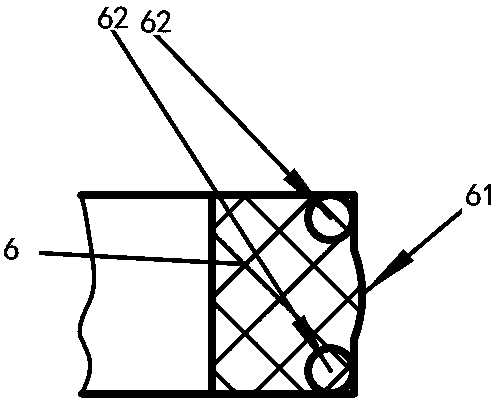

Novel sealing ring for rotary pump and manufacturing method of novel sealing ring

The invention discloses a novel sealing ring for a rotary pump and a manufacturing method of the novel sealing ring. The sealing ring is composed of a set of sheets (2), wherein the axial thickness of the sheets (2) is much smaller than the radial width of the sheets (2). The sealing ring (1) at least comprises two or more sheets (2). The novel sealing ring has the beneficial effects that a sealing clearance of the pump is reduced, and a labyrinth sealing structure is additionally arranged, so that the interior leakage flow is greatly reduced, the working efficiency is improved, and the obvious energy-saving effect is achieved; due to the sheet-type shape, operation is easy, and mounting and maintenance are convenient; and machining is convenient, sheet stamping and integrated blanking can be adopted, materials are fully utilized, and the cost is low.

Owner:杭州大路实业有限公司

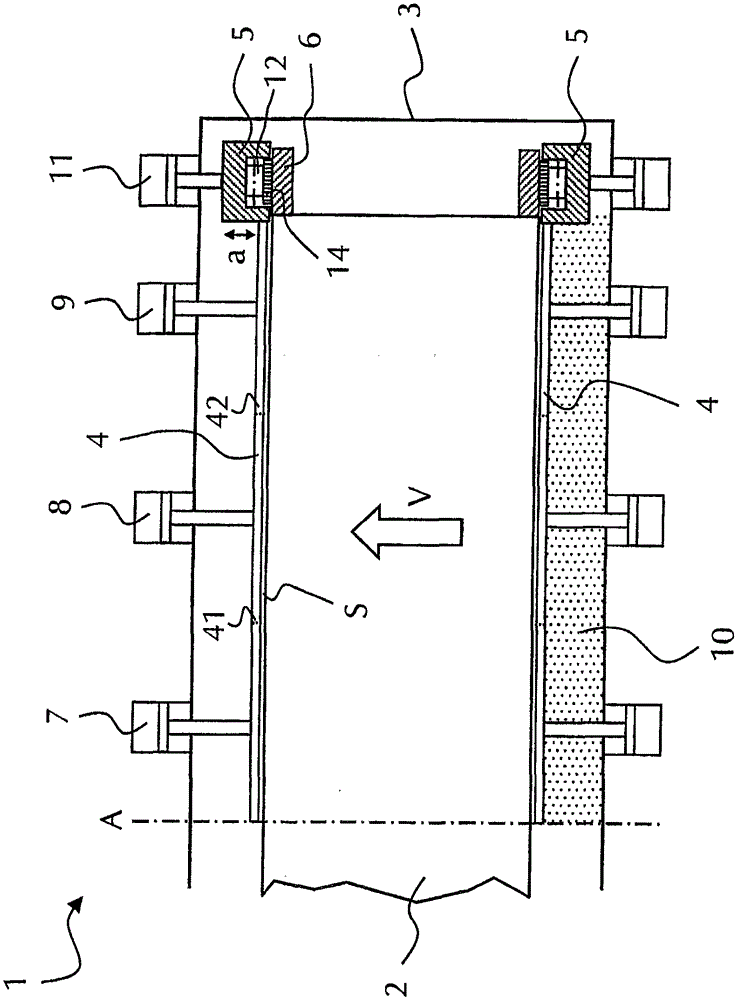

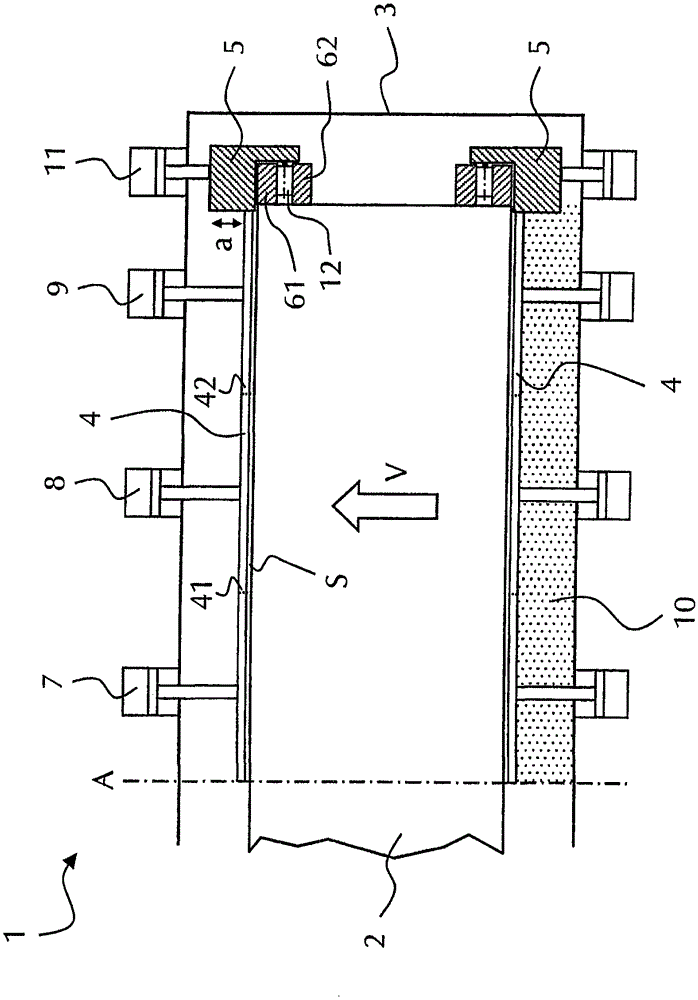

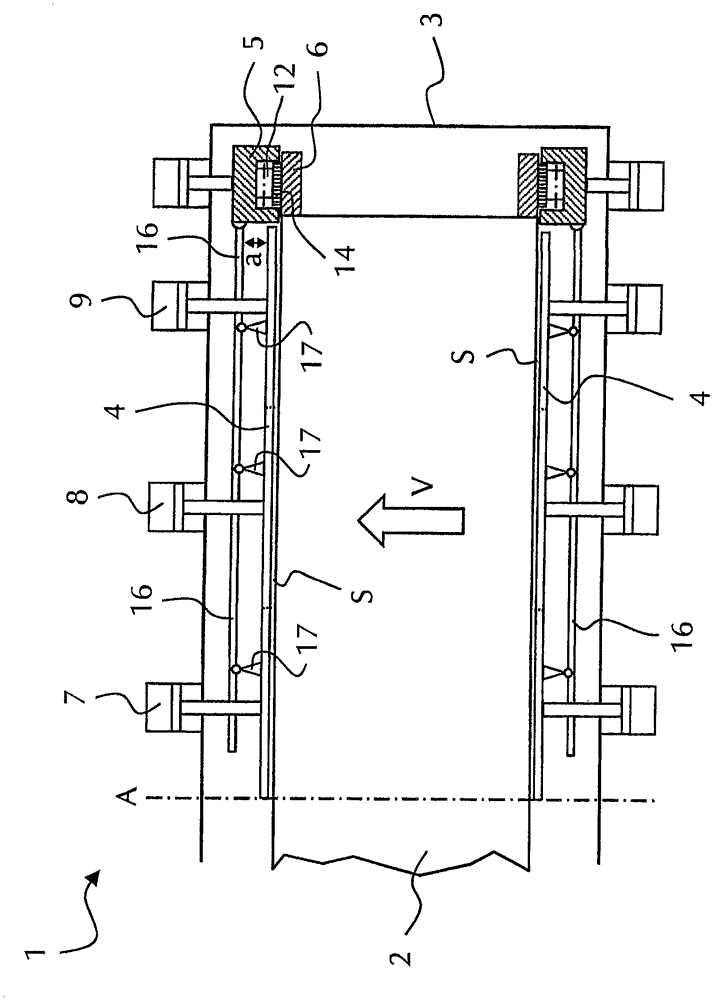

Regenerative heat exchanger with forced guided rotor seal

InactiveCN102767981BSmall and constant sealing gapReduce seal gapEngine sealsRegenerative heat exchangersRotational axisEngineering

Owner:BALCKE DURR AG

Lubrication sealing structure of rotary compressor gas cylinder

InactiveCN101504000AGuaranteed work efficiencyGuarantee working reliabilityRotary piston pumpsRotary piston liquid enginesGas cylinderBoundary friction

The invention provides a lubricating and sealing structure for a cylinder of a rotary compressor, which comprises the cylinder, wherein the front end of the cylinder is provided with a baffle plate groove, a baffle plate which divides a working chamber of the cylinder into an air suction cavity and an air discharge cavity is arranged in the baffle plate groove, and a rolling ring is positioned in the working chamber of the cylinder. The improvements are that the outer surface of the baffle plate is plated with a solid lubricant layer, the outer surface of the rolling ring is plated with a solid lubricant layer; and by means of the action of lubricating and buffering external pressure of a solid lubricant, the baffle plate and the rolling ring avoid the problem of boundary friction in movements through self adjustment so as to achieve the minimum sealing clearance for the cylinder of the compressor, improve the volume efficiency, and ensure the working efficiency and the reliability of the compressor.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Blade-type sealing device

The invention discloses a blade-type sealing device comprising an upper ring, a lower ring and more than one blade. Each blade is a rectangular sheet with one end fixed between the upper ring and the lower ring and the other end served as the free end. The blade-type sealing device can fully carry on concession flexibility of brush-type sealing and stability of fingertip sealing, sealing gap is greatly narrowed, and sealing performance is improved.

Owner:南京博沃科技发展有限公司

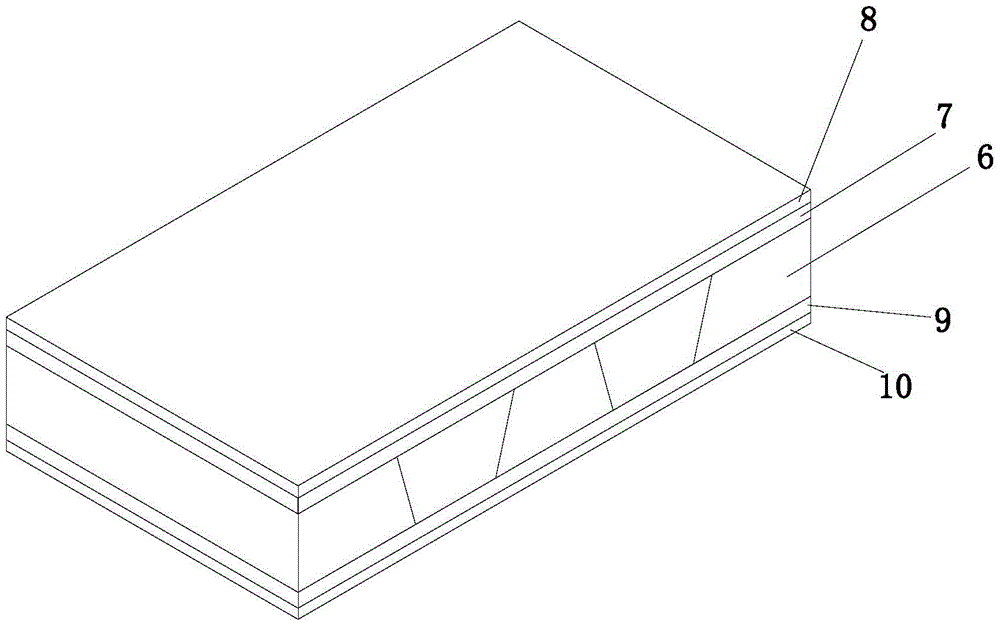

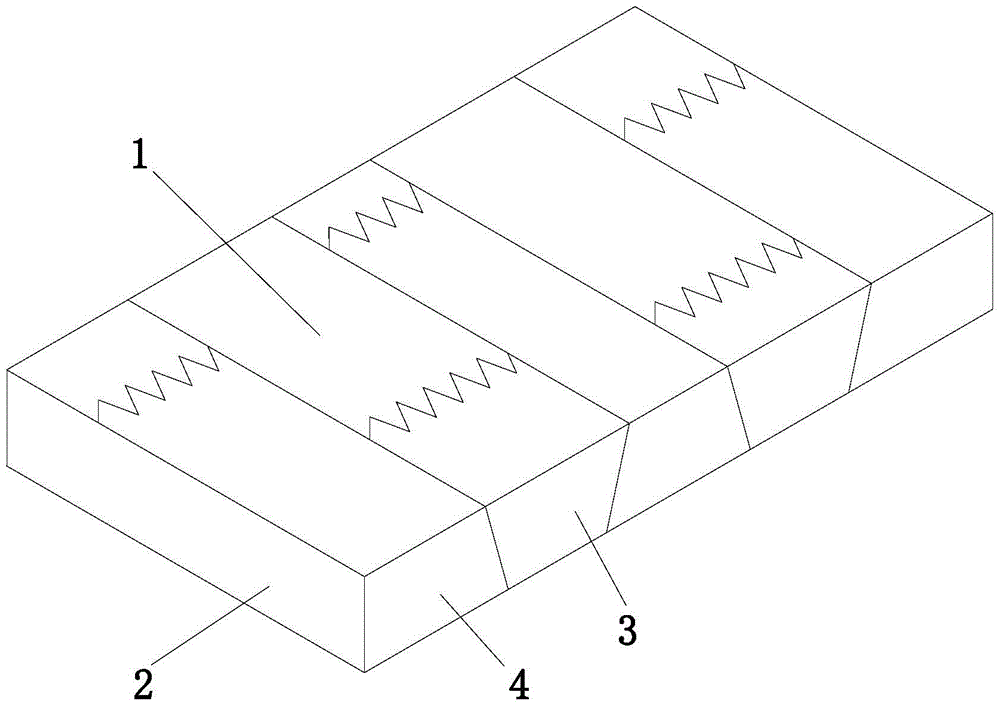

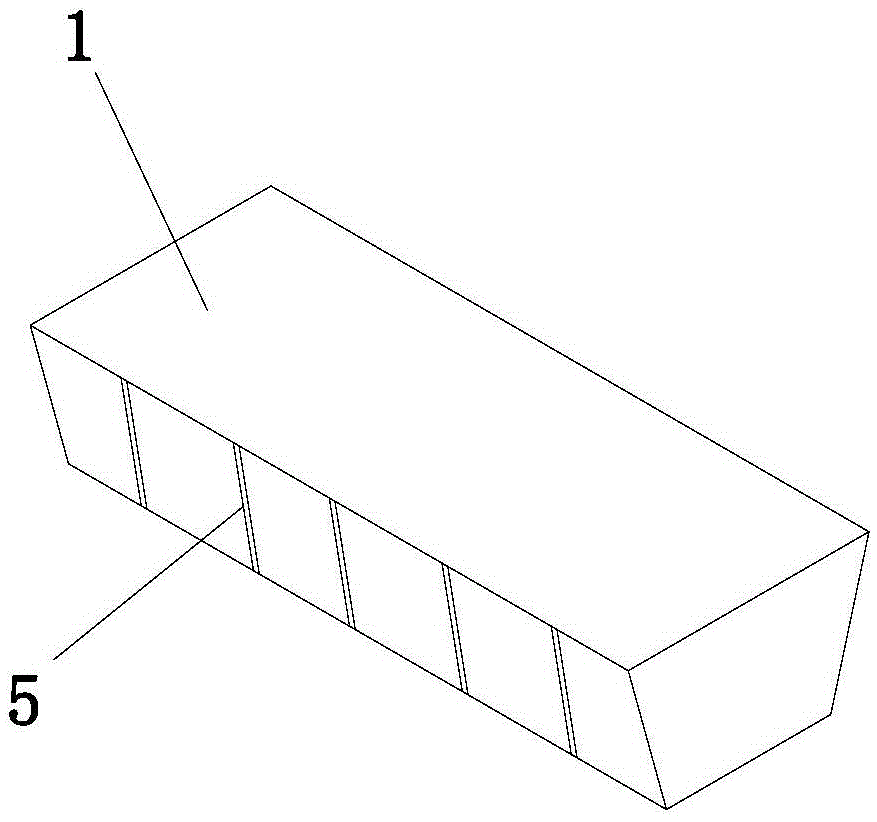

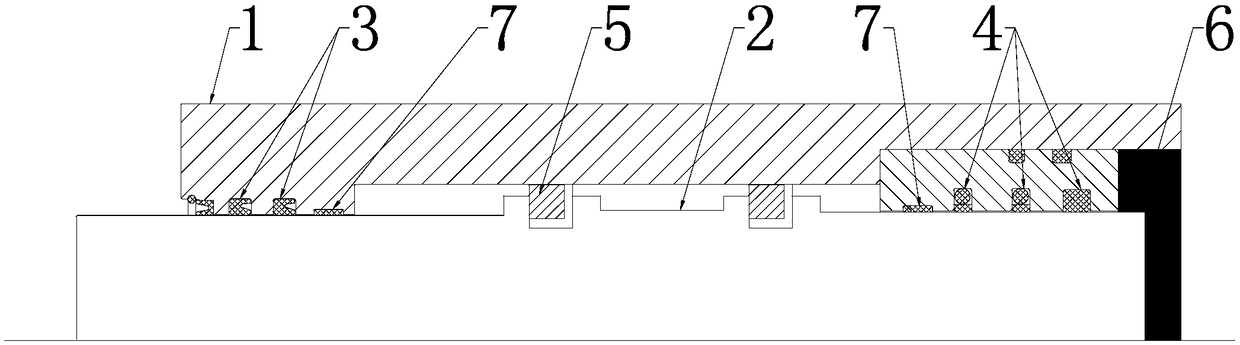

Finger-joint assembled type wood floor

InactiveCN105672619AMaximize utilizationImprove connection strengthFlooringIsosceles trapezoidFinger joint

The invention discloses a finger-jointed assembled wooden floor, which comprises a base plate (6), on which a crack-proof layer (7) and an upper veneer (8) are arranged sequentially, and a moisture-proof layer is arranged under the base plate (6) sequentially (9) and the lower veneer (10), the base plate (6) includes a plurality of staggered middle finger-jointed wood strips (1), the cross-section of the middle finger-jointed wood strips (1) is an isosceles trapezoid (3), and the There are side finger-jointed bars (2) on both sides of a plurality of interlaced middle finger-jointed bars (1), and the cross-section of the side finger-joined bars (2) is a right-angled trapezoid (4); the middle finger-joined bars The inclination angle of the both side inclined surfaces of (1) and the inclination angle of one side inclined surface of the side finger-jointed wooden strips (2) are both 70-80°. The invention has the characteristics of firm connection, high utilization rate and stable use.

Owner:HUZHOU NANXUN SHUANGLIN ZHENSEN WOOD PROCESSING FACTORY

Method for improving pressure-resistant capacity and working reliability of magnetic fluid seal in high-temperature working environment

InactiveCN104696529ASmall coefficient of thermal expansionGuaranteed to workEngine sealsInterference fitWorking environment

The invention discloses a method for improving the pressure-resistant capacity and the working reliability of a magnetic fluid seal in a high-temperature working environment, belongs to the technical field of mechanical engineering seals, and is particularly applicable to the magnetic fluid seal. An iron-nickel alloy material with the anomalous thermal expansion characteristic and a ferromagnetic material with the larger thermal expansion coefficient and good comprehensive mechanical properties are selected, pole shoes and a sealing shaft which are matched with each other are made of the selected ferromagnetic material, pole shoe sleeves which are in interference fit with outer rings of the two pole shoes are made of the selected iron-nickel alloy material, and the radial width ratio of each alloy sleeve to each pole shoe is 1:2. With the adoption of the method, defects of existing methods for the magnetic fluid seal at the high temperature are overcome, and the method has the important significance in solving usage problems of the magnetic fluid seal in the high-temperature environment and broadening the application range of the magnetic fluid seal.

Owner:BEIJING JIAOTONG UNIV

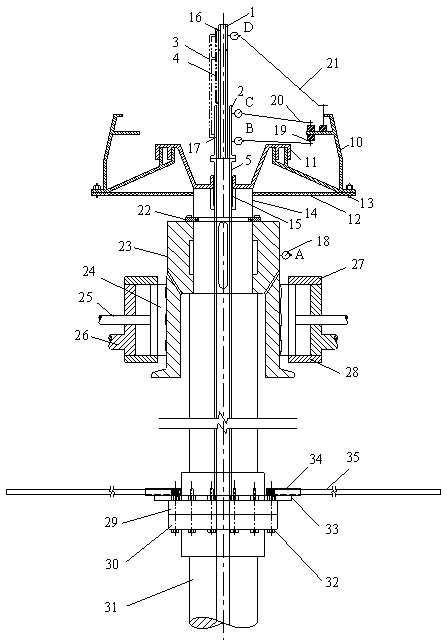

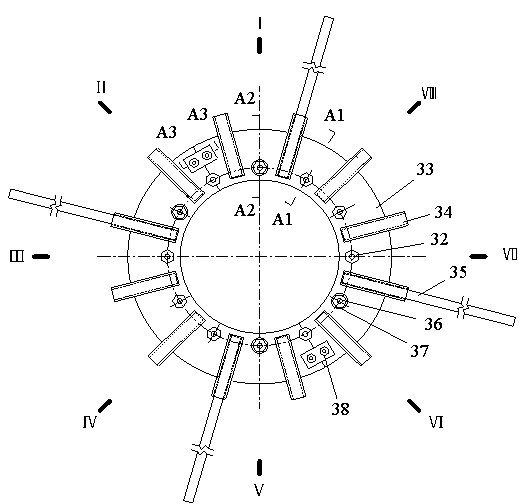

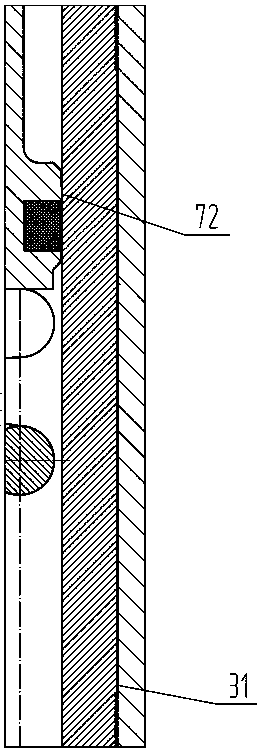

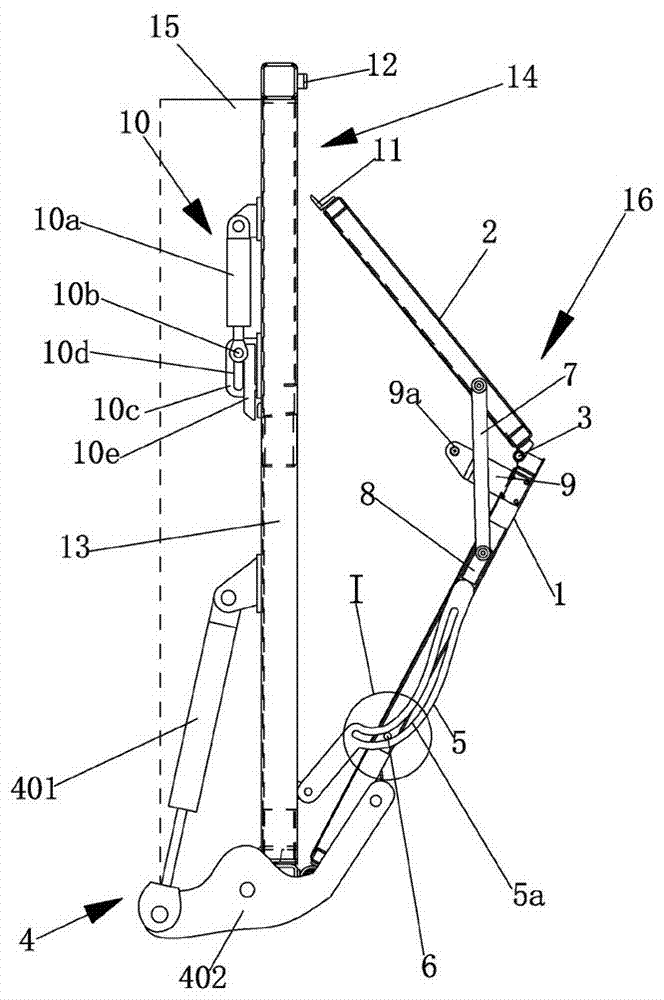

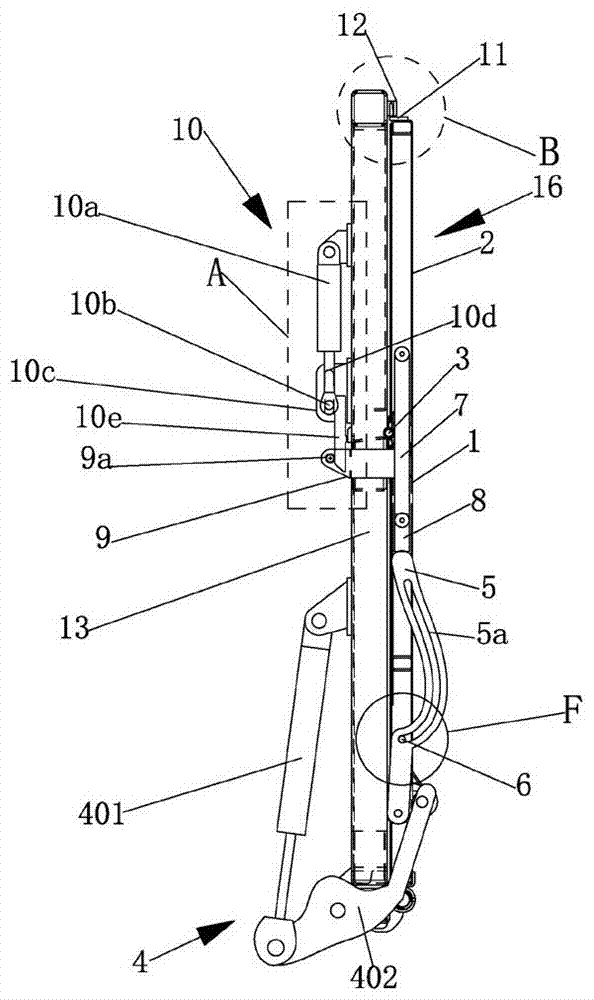

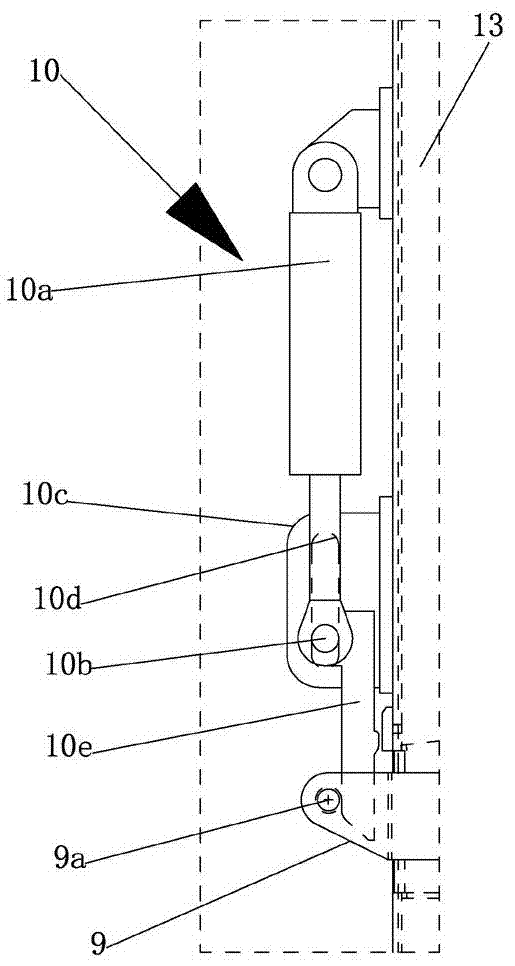

Turning measurement device and method of swing degree of upper operating oil pipe of hydraulic blade all-adjustable water pump

ActiveCN104265651AReduce seal gapGuaranteed uptimeMachine part testingPump componentsStopped workMeasurement device

The invention provides a turning measurement device and calculation method of the swing degree of an upper operating oil pipe of a hydraulic blade all-adjustable water pump. The turning measurement device comprises a turning tool mounted at the upper part of a motor shaft coupling, and four dial indicators respectively positioned on the upper side surface of a thrust head of a motor thrust bearing, on the lower side surface of an outer oil pipe of an upper operating oil pipe, on the upper side surface of the outer oil pipe of the upper operating oil pipe and on the upper side surface of an inner oil pipe of the upper operating oil pipe; turning is carried out on a station building coupling layer of a pump station; the read numbers of the dial indicators are measured and recorded when the eight positions of I, II, III, IV, V, VI, VII, and VIII peripherally spaced by 45 degrees of the upper operating oil pipe are turned to the dial indicators; and the net swing degrees of three parts of the upper operating oil pipe are listed and calculated. The device can reduce the swing of the upper operating oil pipe and a sealing gap between the upper operating oil pipe and a mating hole copper sleeve of an oil head body, guarantees safe and reliable operation of a blade adjusting mechanism in the variable-working condition optimizing operation, the set starting, the stop working condition adjustment and the normal set operation process of the pump station when oil pressure keeps the blade angle, saves the operation and maintenance costs of the pump station, fully exerts the functions of engineering irrigation, drainage and water transfer of the pump station, and guarantees the safety of life and property of the people.

Owner:YANGZHOU UNIV

Oil injection float valve for petroleum drilling

The invention discloses an oil injection float valve for petroleum drilling. An O-shaped ring with poor pressure resistance is replaced by an S-shaped ring with a rectangular section, an arc-shaped sealing surface, annular supporting springs on two sides and high hardness, a high-pressure table is additionally arranged, so that the sealing gap is reduced, and the pressure resistance of the sealingring is improved; the pressed part of a valve bush is internally thickened, an anti-deformation table is additionally arranged, and the gap between the portion and a shell of the oil injection floatvalve is reduced. By means of the combined design, the strength of the whole device is improved, and the sealing effect and the pressure resistance are greatly improved; and meanwhile, a sand prevention seam is additionally arranged, and the O-shaped sealing ring is replaced by a Y-shaped ring with the self-cleaning function, so that the action resistance of a piston is greatly reduced, and the accident rate of sand clamping is reduced.

Owner:东营市创元石油机械制造有限公司

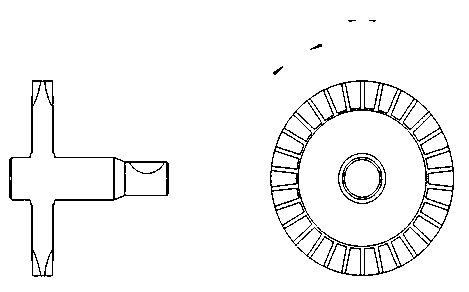

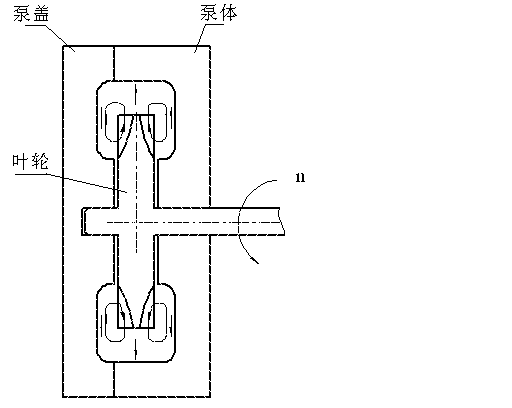

Novel small-flow high-lift peripheral pump

InactiveCN103075363ALow movement resistanceOptimizing the backlash structure of the impellerPump componentsPumpsImpellerEngineering

The invention discloses a peripheral pump which belongs to a new high-tech product, is high in technological content and economic value added, is used in fields such as lorries, ships, large excavators, locomotives, and coal and petroleum mining machinery and has great market potential and popularization and application prospect. The peripheral pump integrates a mechanical transmission technology, a hydraulic technology, a lubricating cooling technology and a material technology, belongs to the new high-tech product, is high in technological content and economic value added, and keeps the advanced level in China in similar products. By adopting an internally-wrapped framework rotary shaft lip sealing ring, the limit of the mechanical sealing mode adopted in the existing product does not exist; and on the aspect of the optimization design of impellers, two-shoulder type impeller structures on two sides are established, the constraint of difficulty in regulation of impeller side play does not exist, and the problems of flow pulsation and unstable operation are eliminated, and therefore minimum axial gaps between the impellers and a pump body as well as a pump cover are ensured.

Owner:XIAN AERONAUTICAL UNIV

Sealed oil catch for main shaft of wind driven generator

InactiveCN103727240AThe sealing gap does not increasePrevents Grease LeakageEngine sealsFinal product manufactureWind drivenWind force

The invention provides a sealed oil catch for a main shaft of a wind driven generator, which is better in sealing effect and simple in structure. The sealed oil catch comprises a static ring, and a mobile ring, wherein the static ring is arranged on an engine shell, and the mobile ring is fixedly arranged on a rotating shaft and rotates together with the rotating shaft; a floating seal ring is arranged between the mobile ring and the static ring, a circular groove is formed in the inner surface of the static ring, the floating seal ring is positioned in the circular groove, and a spring is arranged between the bottom of the circular groove and the floating seal ring. By adopting the floating seal ring, the sealed oil catch for the main shaft of the wind driven generator has elasticity so as to adapt to the rotation of the rotating shaft and ensure no wear after being used for a long time, and the sealing clearance is not increased, so that the purpose of effectively preventing the leakage of lubricating oil, as well as the sealing purpose can be achieved, and the sealed oil catch for the main shaft of the wind driven generator is simple in structure, low in cost, and suitable for wide application.

Owner:秦皇岛华宇通电力科技有限公司

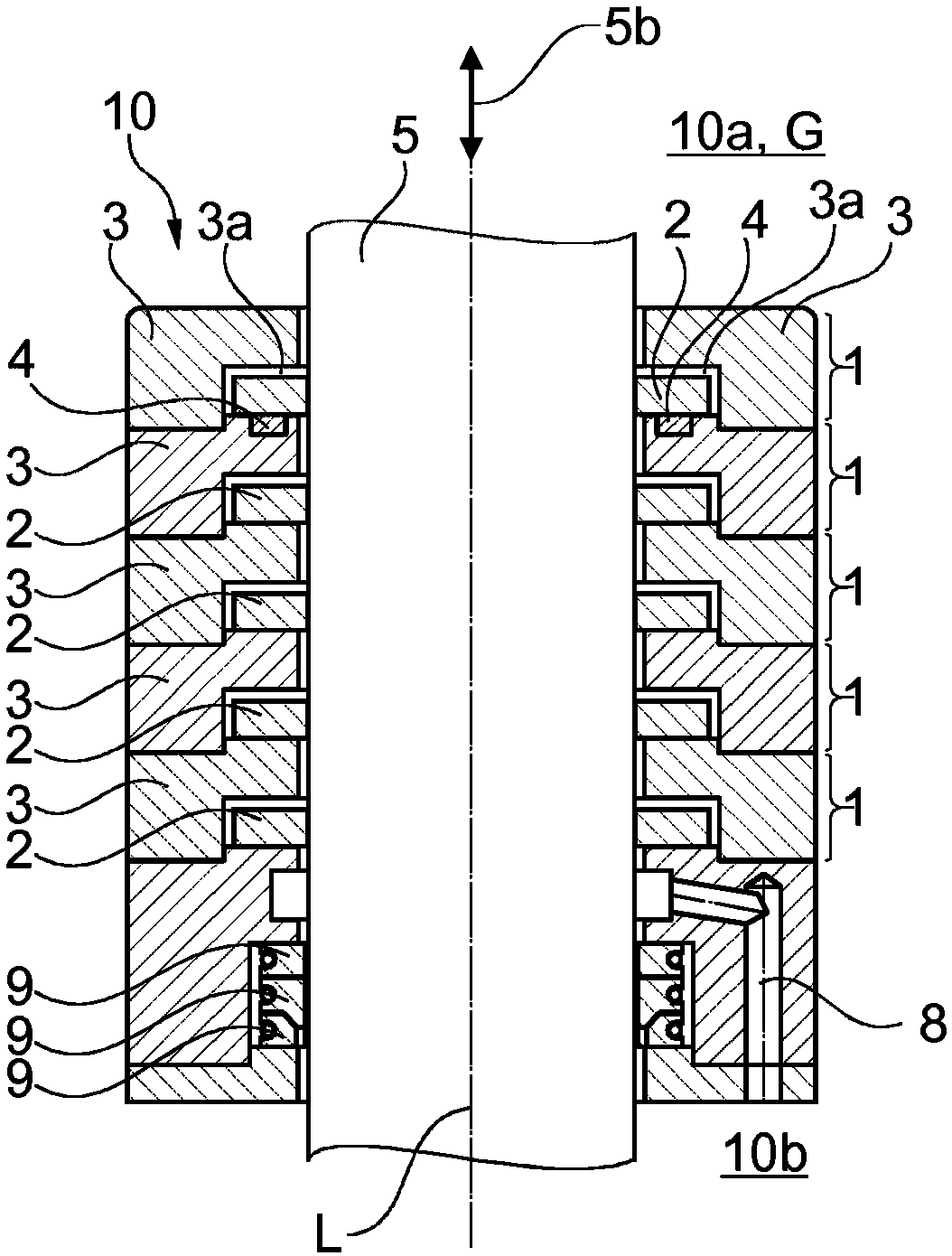

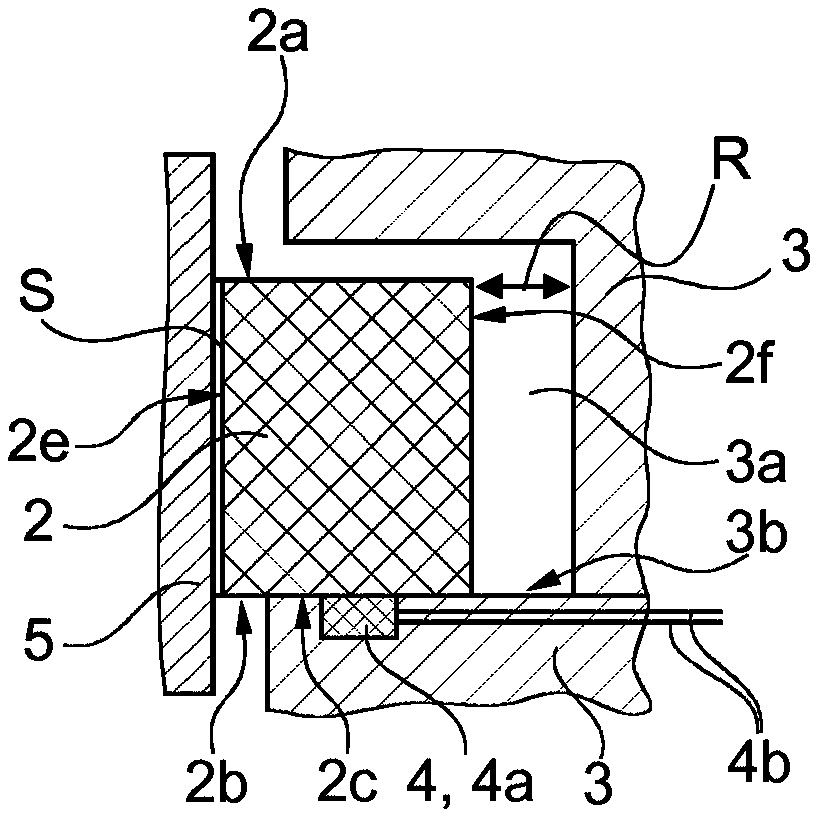

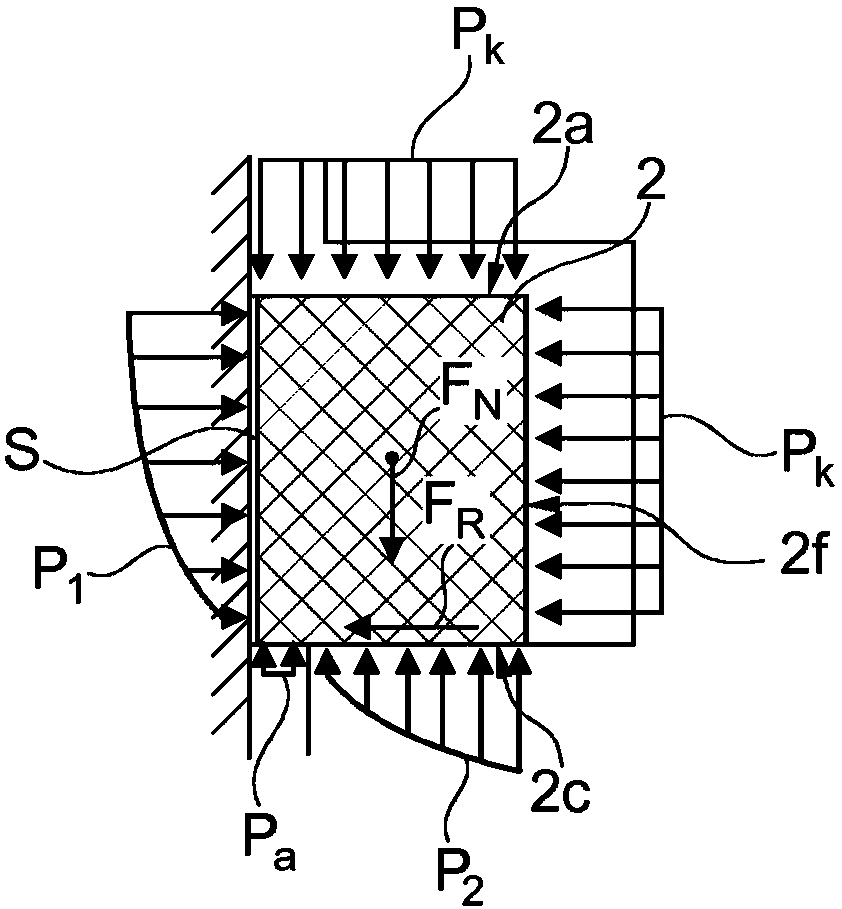

Dry-running piston rod packing and method for operating a dry-running piston rod packing

The dry-running piston rod packing (10) for sealing a piston rod (5) supported in such a way that the piston rod can be moved in a longitudinal direction (L) comprises at least one chamber ring (3), asealing chamber (3a), and a sealing ring (2) arranged in the sealing chamber (3a), wherein the piston rod packing (10) has a high-pressure side (10a) and a low-pressure side (10b), wherein a lift-offdevice (4) is designed and arranged in such a way that the lift-off device can lift and lower the sealing ring (2) in the longitudinal direction (L).

Owner:BURCKHARDT COMPRESSION AG

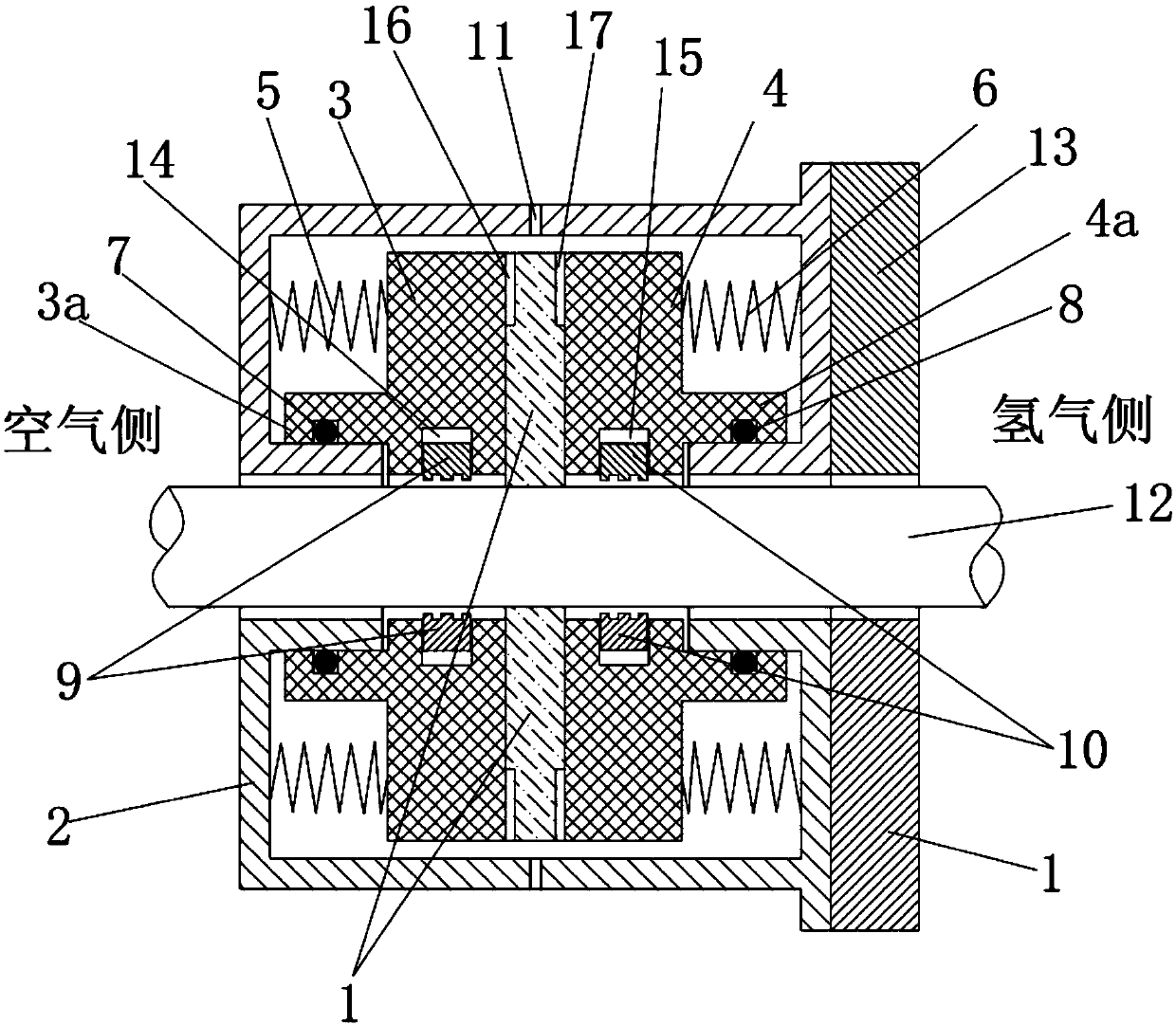

Hydrogen sealing device and sealing method of steam turbine generator set

The invention relates to a hydrogen sealing device and a sealing method for a steam turbine generator set. According to the technical scheme, a generator rotating shaft at the opening of a sealing seat is sleeved with a resistance disc which is fixed together with the generator rotating shaft, and the resistance disc extends into the inner cavity of the sealing seat from the opening of the sealingseat; a first sealing ring and a second sealing ring which slide left and right in the axial direction of the the generator rotating shaft are arranged in the sealing seat on the two sides of the resistance disc correspondingly, a plurality of first spiral grooves which are uniformly distributed are formed in the outer periphery, right opposite to the first sealing ring, of the resistance disc; and a plurality of second spiral grooves which are uniformly distributed are formed in the outer periphery, right opposite to the second sealing ring, of the resistance disc. Compared with the prior art, two-stage spiral groove type dynamic pressure oil film seal between the sealing rings and the resistance disc and two-stage groove type dynamic pressure oil film seal between sealing floating ringsand the generator rotating shaft are required during hydrogen leakage, and the leakage amount is small; and sealing gaps formed between the sealing rings and the resistance disc due to the dynamic pressure effect of the spiral grooves are small, and therefore the leakage can be effectively reduced.

Owner:CENT CHINA BRANCH OF CHINA DATANG CORP SCI & TECH RES INST CO LTD

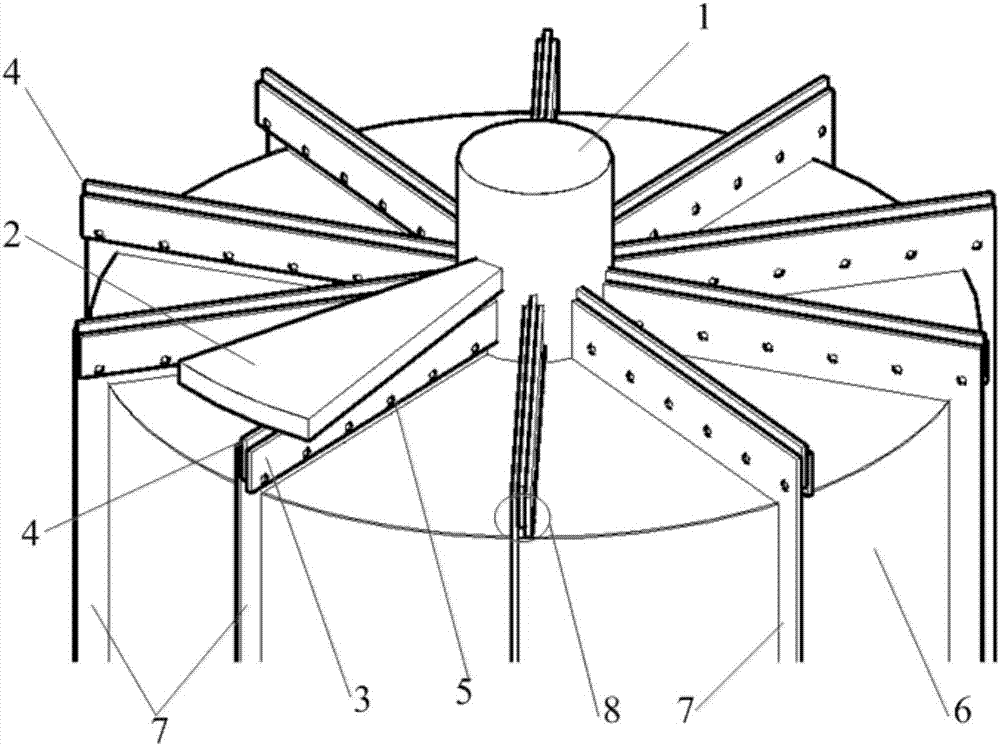

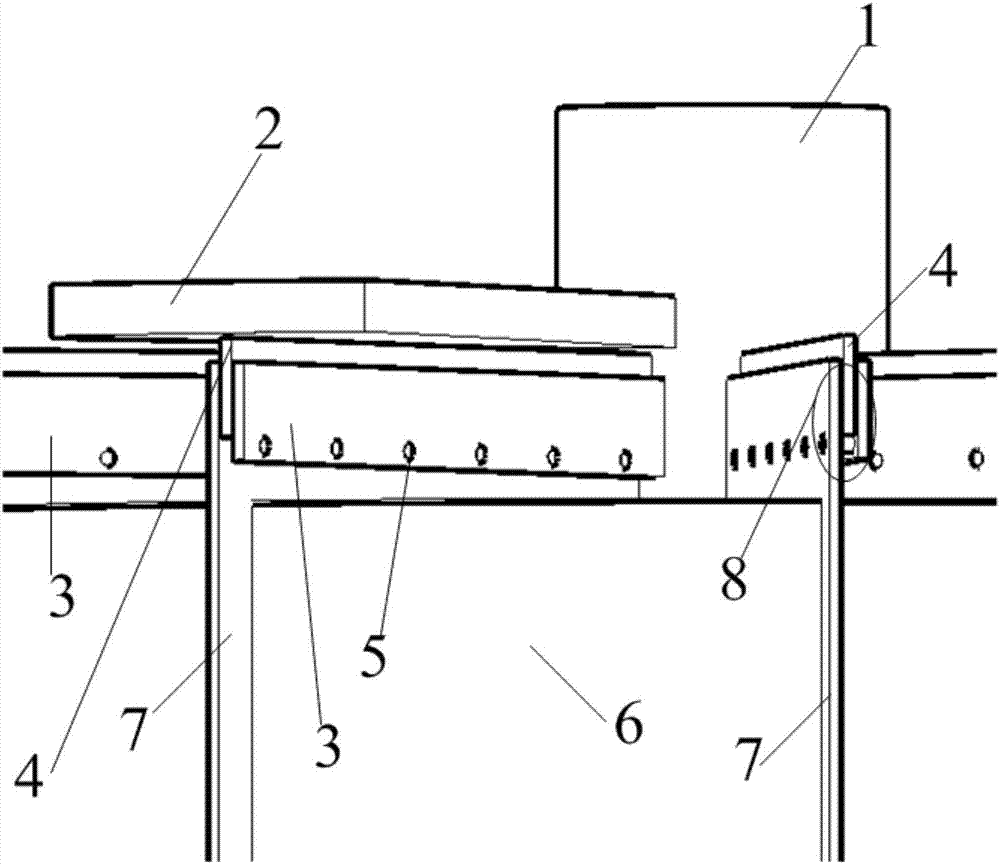

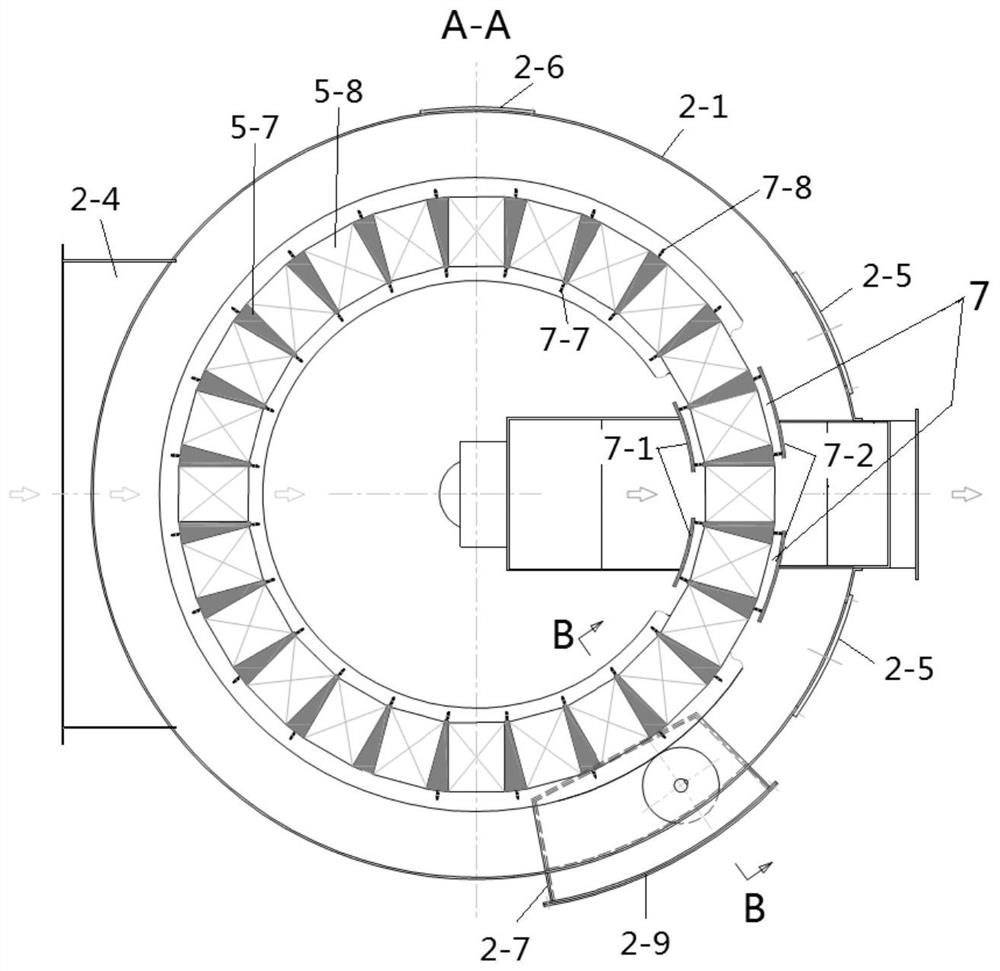

Rotary air preheater sealing structure

PendingCN107355810AReduce power consumptionImprove efficiencyCombustion processHeat exhanger sealing arrangementAir preheaterEngineering

The invention discloses a rotary air preheater sealing structure. The sealing structure is mainly composed of seal washers and seal grooves. The seal grooves are radially arranged on air preheater rotors. The corresponding seal washers are embedded into the seal grooves, and one end of each seal washer is fixed to a central cylinder of an air preheater; the other end of the seal washer is free. The bottoms of the seal washers are embedded into the seal grooves, and the minimum rational clearance is kept between the top of each seal washer and a sector plate. In operation, the seal grooves incline toward the peripheries of the rotors from the central cylinder, while only one section of the seal washers is fixed to the central cylinder, and does not incline with the central cylinder. In this way, the bottoms of the seal washers are still embedded into the seal groove for a certain depth to ensure the sealing effect; and the minimum clearance can still be kept between the top of the seal washer and the sector plate. The air leakage rate of the air preheater is ensured to be unchanged under different working conditions for a long time, and is kept at a low level. The rotary air preheater sealing structure disclosed by the invention has the advantages of rational and simple structure, little maintenance, uneasy jamming, abrasion or deformation, and wide application scope of working conditions, and is an important innovation of a rotary air preheater seal.

Owner:XIAN XIRE ENERGY SAVING TECH

A magnetic liquid sealing device for sealing liquid

InactiveCN103759018BIncrease binding forceImprove pressure resistanceEngine sealsMagnetic liquidsEngineering

The invention discloses a magnetic liquid sealing device for sealing liquid, and belongs to the field of mechanical engineering sealing. The magnetic liquid sealing device comprises a spring seat (1), a set screw (2), a rotary shaft (3), a spring (4), a movable ring (5), an auxiliary sealing ring (6) of the movable ring, a first non-magnetic ring (7), an auxiliary sealing ring (8) of a first pole shoe, the first pole shoe (9), an annular permanent magnet (10), a non-magnetic-permeability screw (11), a second pole shoe (12), an auxiliary sealing ring (13) of the second pole shoe, a second non-magnetic ring (14), a static ring (15), an auxiliary sealing ring (16) of the static ring, an anti-rotating pin (17), a threaded end cover (18) and a shell (19). The magnetic liquid sealing device is arranged on an end surface, relative speeds of two types of liquid on a contact surface of the sealed liquid and the magnetic liquid are nearly zero, shearing movement between the magnetic liquid and the sealed liquid can be prevented, and accordingly the sealing life can be prolonged advantageously.

Owner:BEIJING JIAOTONG UNIV

Opening and closing device of feed inlet of garbage container

PendingCN107310890AReduce workloadReduce seal gapRefuse receptaclesEngineeringMechanical engineering

The invention discloses an opening and closing device of a feed inlet of a garbage container in the technical field of environmental sanitation. The opening and closing device comprises a feed inlet frame and also comprises an opening and closing door for opening and closing the feed inlet. The opening and closing device also comprises a rotary driving mechanism capable of controlling rotary opening and closing motions of the opening and closing door; the opening and closing door is arranged of a foldable door-shaped structure and the rotary driving mechanism is in transmission connection to a main door plate. The opening and closing device also comprises a linking mechanism, two ends of which are separately connected to the main door plate and an auxiliary door plate; the opening and closing device also comprises a movable ejector rod which is rotatably mounted on the feed inlet frame, the free end of which leans against the linking mechanism to drive the whole opening and closing door to expand; a guide pin is fixed on the side edge of the main door plate, a guide slide hole is formed in the movable ejector rod, and the guide pin is movably threaded in the guide slide hole. The rotary opening and closing motions of the opening and closing door are assisted by means of parts such as the movable ejector rod and the linking mechanism, so that the feed inlet of the opening and closing door is conveniently opened and closed.

Owner:YANGZHOU JINWEI ENVIRONMENTAL PROTECTION TECH CO LTD

Method for producing a rotor/stator seal of a gas turbine

InactiveCN102985582ASoft formPreferably have wear-resistant propertiesMolten spray coatingEngine manufactureEngineeringTurbine

The invention relates to a method for applying a ceramic layer (21) to the sealing surfaces (4) of sealing segments (3) arranged on the inner circumference of a turbine housing part (1) of a rotor / stator seal of a gas turbine. According to the invention, the ceramic layer (21) is applied while the sealing segments (3) are in an installed state in the turbine housing part (1).

Owner:LUFTHANSA TECH AG

Oil Float Valve for Oil Drilling

The invention discloses an oil injection float valve for petroleum drilling. An O-shaped ring with poor pressure resistance is replaced by an S-shaped ring with a rectangular section, an arc-shaped sealing surface, annular supporting springs on two sides and high hardness, a high-pressure table is additionally arranged, so that the sealing gap is reduced, and the pressure resistance of the sealingring is improved; the pressed part of a valve bush is internally thickened, an anti-deformation table is additionally arranged, and the gap between the portion and a shell of the oil injection floatvalve is reduced. By means of the combined design, the strength of the whole device is improved, and the sealing effect and the pressure resistance are greatly improved; and meanwhile, a sand prevention seam is additionally arranged, and the O-shaped sealing ring is replaced by a Y-shaped ring with the self-cleaning function, so that the action resistance of a piston is greatly reduced, and the accident rate of sand clamping is reduced.

Owner:东营市创元石油机械制造有限公司

Sealing and guiding structure of a breaking hammer

ActiveCN106545542BImprove sealingReduce reactive powerPiston ringsFluid-pressure actuatorsEngineeringCylinder block

The invention discloses a sealing and guiding structure of a quartering hammer. The sealing and guiding structure of the quartering hammer comprises a cylinder body, a piston, lower cavity seals, nitrogen seals and nitrogen in the cylinder body, wherein the lower cavity seals and the nitrogen seals are arranged between the cylinder body and the piston. Guiding rings are arranged in a cavity formed by the parts, between the lower cavity seals and the nitrogen seals, of the cylinder body and the piston. Floating sealing pieces are arranged between the cylinder body and the piston. The sealing and guiding structure of the quartering hammer has the beneficial effects that structure is durable and sealing effect is good.

Owner:FOSHAN DAMANSEN SEALING TECH CO LTD

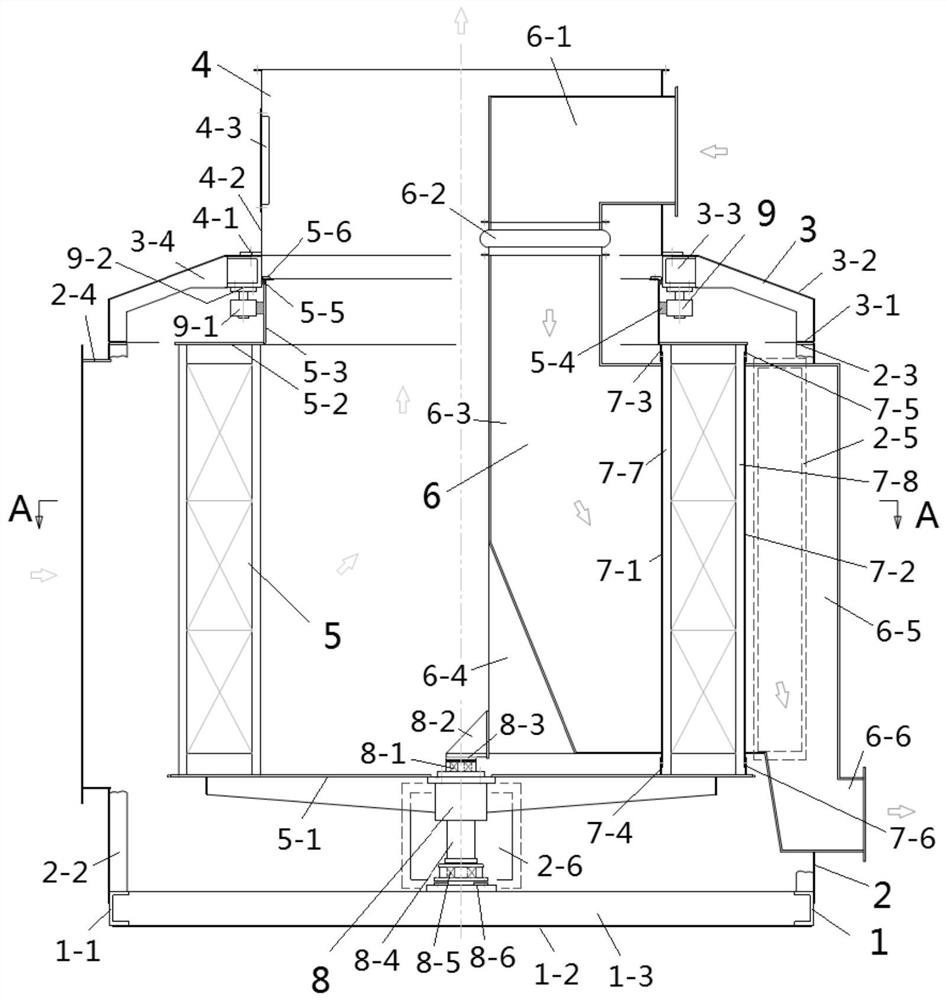

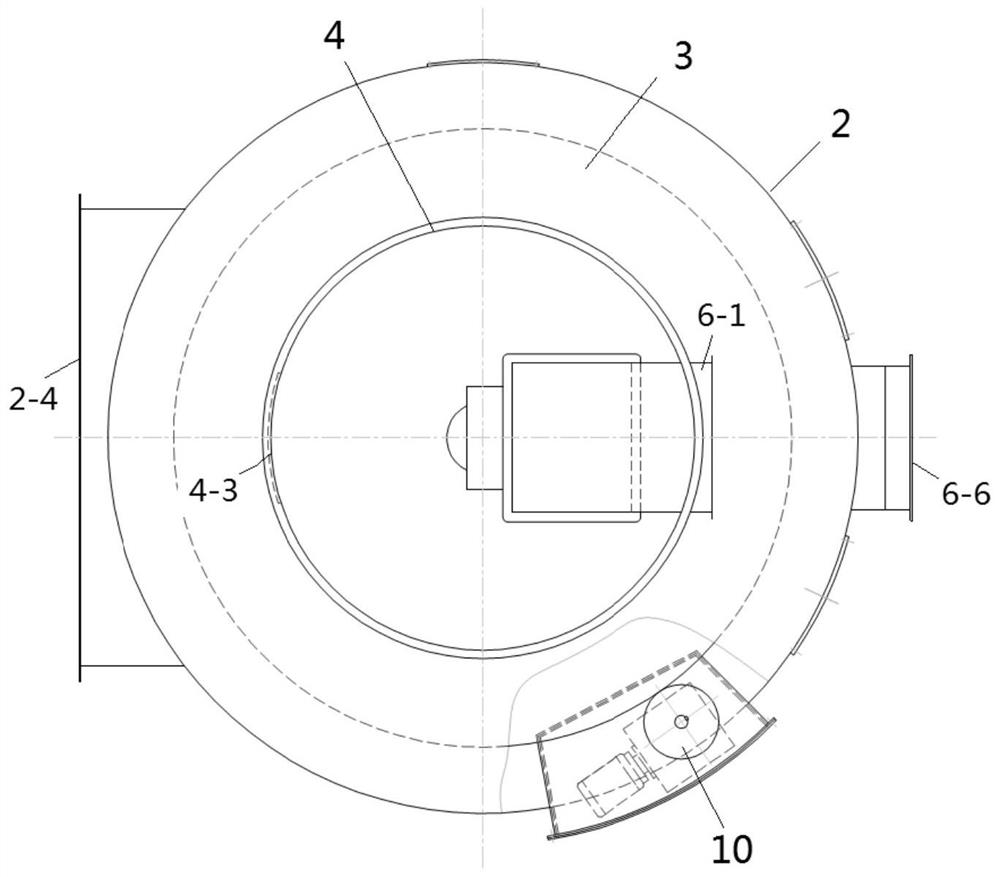

Rotary drum type VOC adsorption machine

PendingCN112316667ASimple structureReduce dosageGas treatmentDispersed particle separationDrive shaftEngineering

The invention discloses a rotary drum type VOC adsorption machine structure which is characterized in that a chassis assembly, a cylindrical shell assembly, an arch-shaped top cover assembly and a topair pipe assembly are connected in a welded mode from bottom to top to form a cavity; the rotary drum supporting assembly is arranged at the bottom of the center of the cavity and supports the rotarydrum assembly and the desorption airflow pipeline assembly which are arranged in the center of the cavity; an inlet of the desorption airflow pipeline assembly is connected with the top air pipe assembly, and the lower part is fixed on the rotary drum supporting assembly; the sealing area assembly is arranged between the rotary drum assembly and the desorption airflow pipeline assembly and divides the rotary drum assembly and the desorption airflow pipeline assembly in a sealed mode; the guide roller assembly is suspended below the arch-shaped top cover assembly, supports the rotary drum assembly from the side surface and is used for bearing the radial dumping force of the rotary drum; the transmission assembly is in driving connection with the rotary drum assembly to provide rotating power; and the transmission shaft sealing assembly seals the rotary drum assembly.

Owner:SHANGHAI BOILER WORKS

Calorific equipment equipped with coaxial heat exchanger

InactiveCN106701195AAvoid abrasionsEnough tightnessCombustible gas productionInterior spacePlate heat exchanger

The invention relates to calorific equipment equipped with a coaxial heat exchanger. The calorific equipment is provided with a pressure shield which is pressureably closed at the flange of a cover plate and is provided with a coaxial, internal heat exchanger which surrounds an internal space and forms an annular space relative to the pressure shield. The object of the present invention is based on the provision of a structural solution for configuring an annular gap between the heat exchanger and the equipment wall (which has a long use time) for transmitting pressure and located in the area of the flange of the cover plate. The object is achieved by providing a maze-type sealed part for loading a purge gas in the annular gap between flange of the cover plate and a tube located at the center of the upper part of the heat exchanger.

Owner:CHOREN INDTECHN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com