Method for improving pressure resistance of magnetic liquid seal in low-temperature working environment

A magnetic liquid and working environment technology, applied in the direction of engine seals, engine components, mechanical equipment, etc., can solve problems affecting the application of magnetic liquid seals, large shaft diameters, etc., to achieve reduced seal gaps, improved pressure resistance, and improved The effect of pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

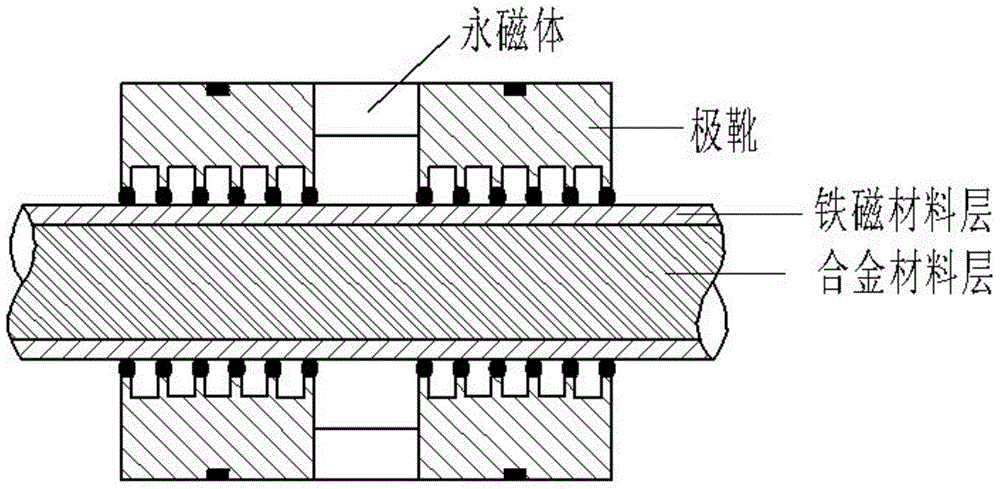

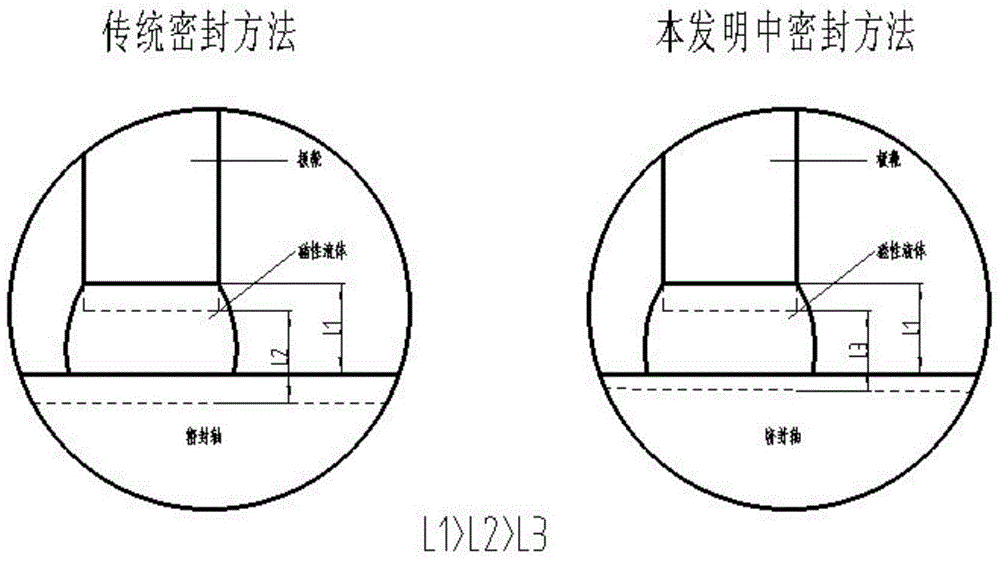

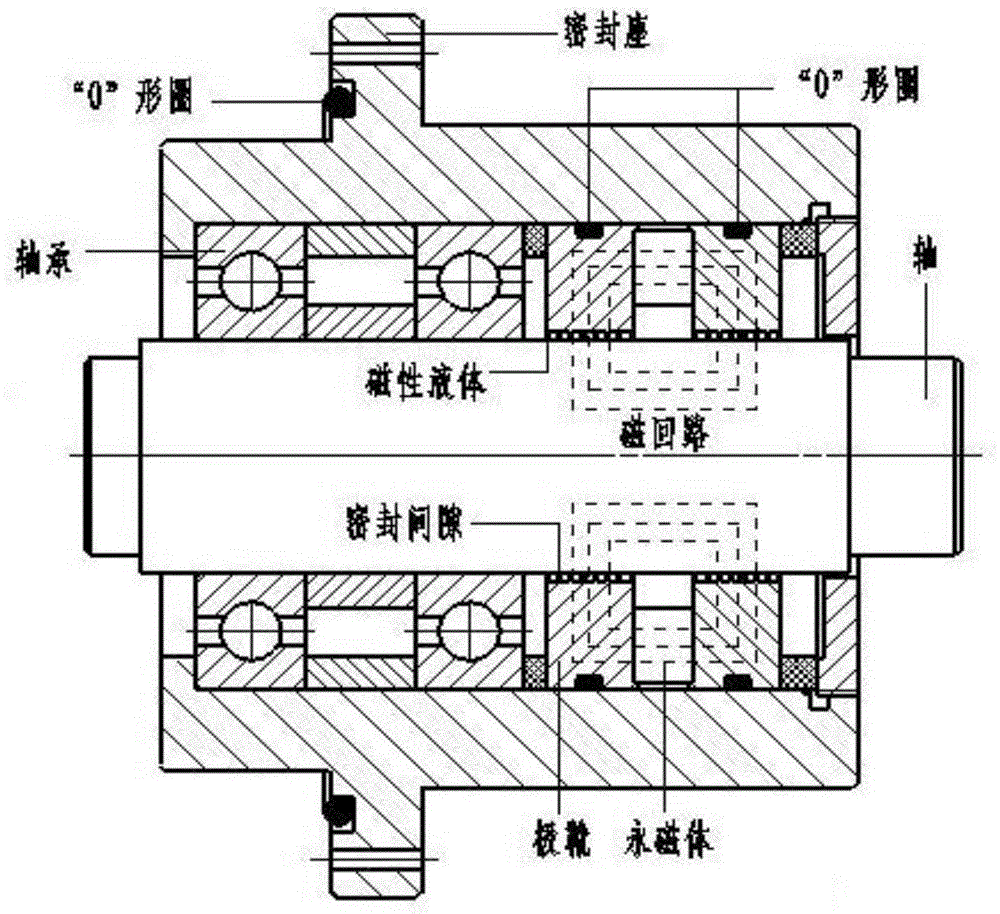

Embodiment approach 1

[0023] Choose 45 steel material and 40Cr13 material, use 45 steel to make pole shoes, and use the 45 steel and 40Cr13 as the outer layer and inner layer materials to manufacture and process composite material shafts with a diameter range of 100mm, in which the 45 steel material layer and 40Cr13 material layer diameter The length is distributed according to 1:3. Cooperate the pole piece and the composite material shaft to form a magnetic liquid sealing device with a gap of 0.2mm. When the device is applied under the low temperature condition of -190, the clearance is 0.011mm smaller than that of the magnetic liquid sealing device in which both the pole piece and the shaft are made of 45 steel.

Embodiment approach 2

[0025] Select 45 steel material and 30Cr13 material, use 45 steel to make pole shoes, and use the 45 steel and 30Cr17 as the outer layer and inner layer materials to manufacture and process a composite material shaft with a diameter of 80mm, in which the 45 steel material layer and 30Cr17 material layer are radial The length is distributed according to 1:3. Cooperate the pole piece and the composite material shaft to form a magnetic liquid sealing device with a gap of 0.1mm. When the device is applied under the low temperature condition of -100, the clearance is 0.005mm smaller than that of the magnetic liquid sealing device in which both the pole piece and the shaft are made of 45 steel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com