Patents

Literature

37results about How to "Improve sealing pressure resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for improving pressure resistance of magnetic liquid seal in low-temperature working environment

InactiveCN104405886ASmall amount of shrinkageImprove sealing pressure resistanceEngine sealsWorking environmentMagnetic liquids

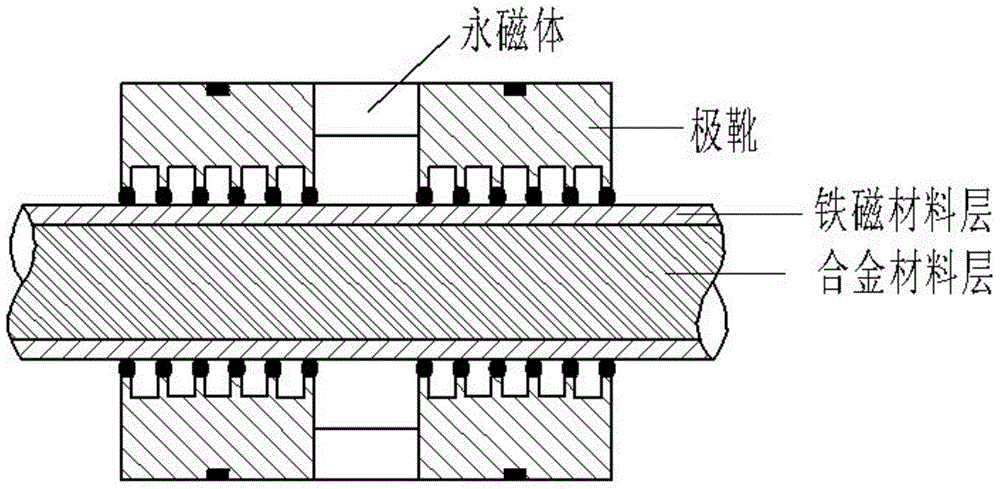

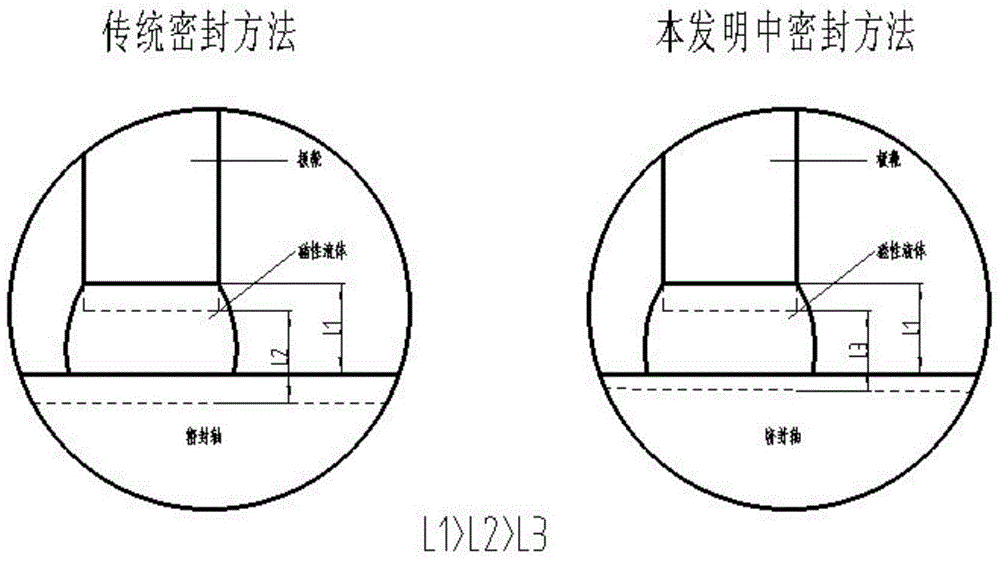

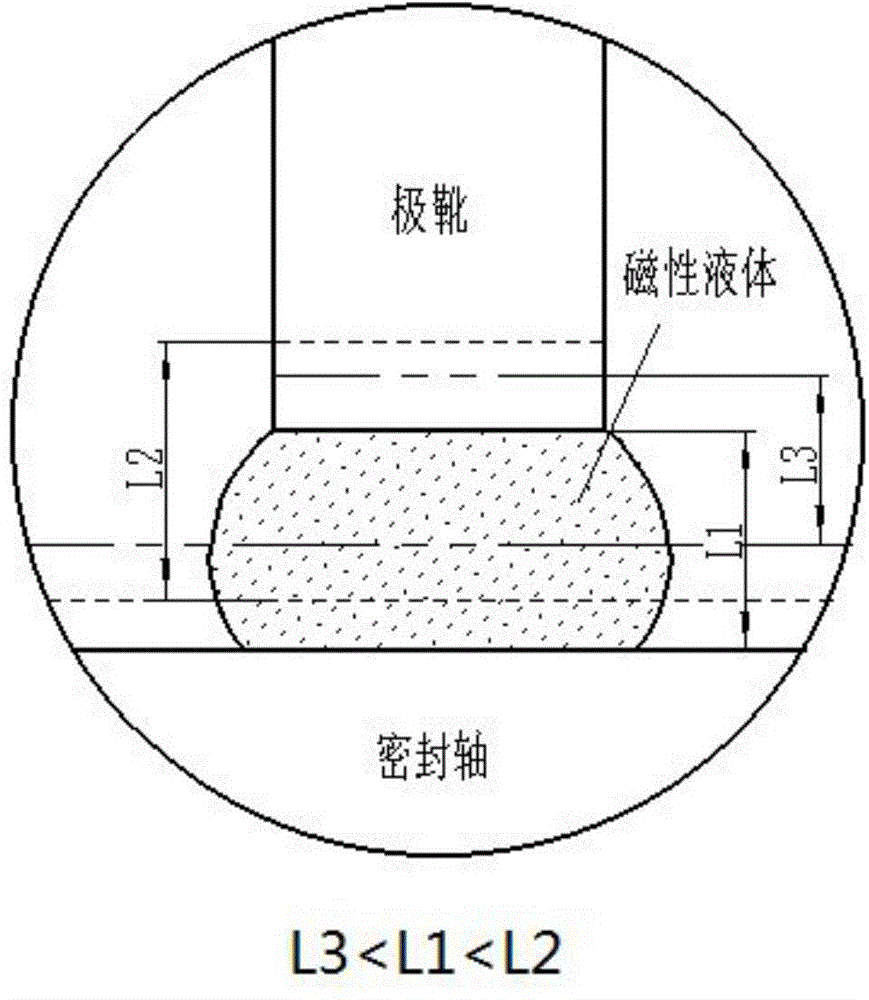

The invention provides a method for improving pressure resistance of magnetic liquid seal in a low-temperature working environment, belongs to the technical field of sealing of mechanism engineering, and in particular applies to magnetic liquid seal. The method comprises the steps of selecting a ferromagnetic material with high permeability and large expansion coefficient, and an alloy steel material with small thermal expansion coefficient and high comprehensive mechanical performance; manufacturing a pole shoe with the ferromagnetic material; manufacturing and processing a composite material shaft being 50 to 100mm in diameter by using the ferromagnetic material and the alloy steel material as an outer layer material and an inner layer material, respectively, wherein the radial length ratio of the ferromagnetic material layer to the alloy steel material layer is 1: 3; applying the pole shoe and the composite material shaft into a magnetic liquid seal device of which a gap ranges from 0.1 to 0.25. With the adoption of the method, the shortages of the existing method for magnetic liquid seal under a low temperature can be overcome, the problem of applying to magnetic liquid seal in a low-temperature environment is solved, the applicable scope of magnetic liquid seal is expanded, and the method is of an important significance.

Owner:BEIJING JIAOTONG UNIV

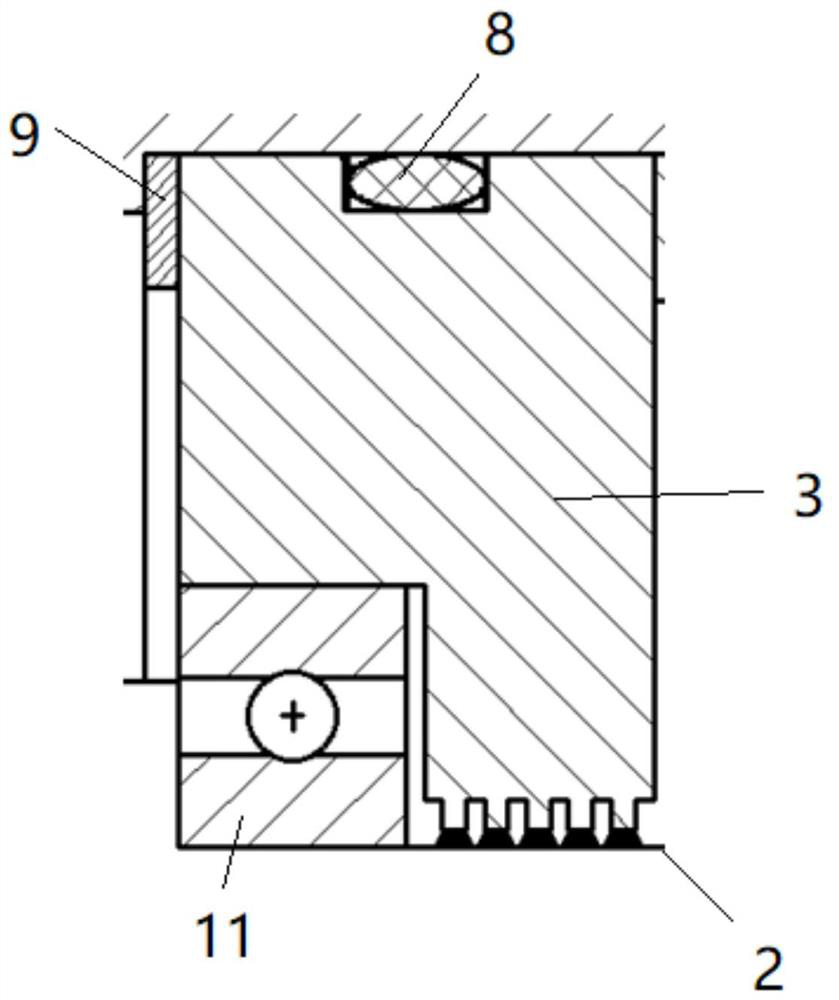

Embedded maze type magnetic fluid sealing device

PendingCN109764138AOvercoming the problem of low sealing performanceImprove pressure resistanceEngine sealsEngineeringHeavy load

The invention aims to provide an embedded maze type magnetic fluid sealing device. The embedded maze type magnetic fluid sealing device comprises a stepped shaft, a shell, a left first pole shoe ring,a right first pole shoe ring, a middle sleeve and a middle permanent magnet ring; and the stepped shaft comprises a first-stage shaft with the largest diameter and one or more secondary first-stage shafts which are sequentially reduced in diameter, the secondary first-stage shafts are arranged on the two sides of the first-stage shaft in sequence along the side face of the first-stage shaft, andthe secondary first-stage shafts which take the middle radial section of the first-stage shaft as a boundary are symmetric. The invention aims to solve the problem that an existing sealing device is low in pressure resistance, so that the sealing technology is successfully applied to the fields of high-speed heavy load and the like.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

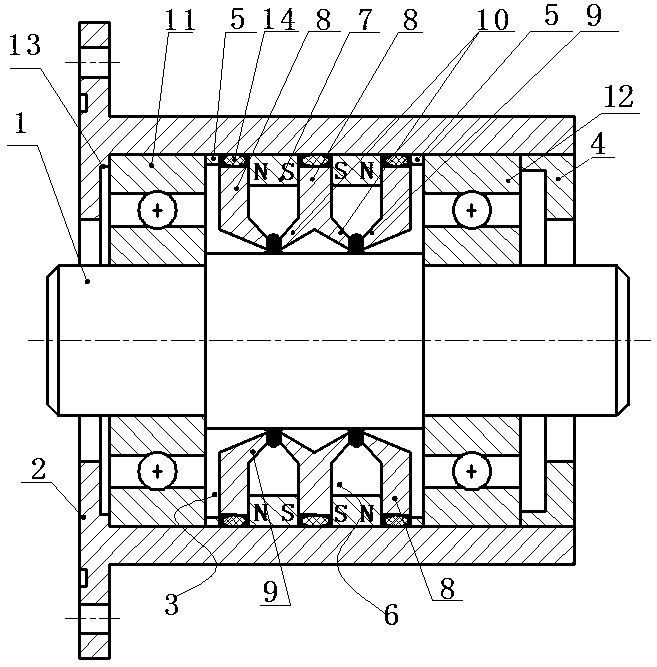

Convex arc type magnetic fluid sealing device

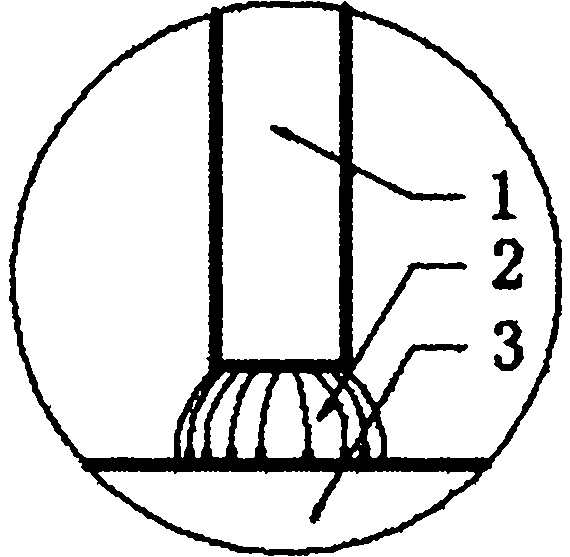

The invention discloses a convex arc type magnetic fluid sealing device which comprises a shaft, a shell, pole shoes, magnet fluid and permanent magnets. The convex arc type magnetic fluid sealing device is characterized in that the shaft penetrates and extends out of the two ends of the shell; the part, located in the shell, of the shaft is provided with at least one circular ring; the outer circumferential faces of the circular rings are in a convex arc shape; at least two pole shoes are arranged on the inner surface of the shell; the part between every two adjacent pole shoes is provided with the corresponding annular permanent magnet; the pole hoes are of circular-ring-shaped structures; the inner circumferential faces of the pole shoes located between the circular rings and the shellare in a concave arc shape; and the magnetic fluid is arranged in sealing clearances between pole teeth and the shaft. By means of the convex arc type magnetic fluid sealing device, the sealing pressure-resisting capability of the magnetic fluid is greatly improved, and the problem that an existing sealing device cannot meet the requirement for high sealing performance under special conditions such as high speeds and heavy loads is solved.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

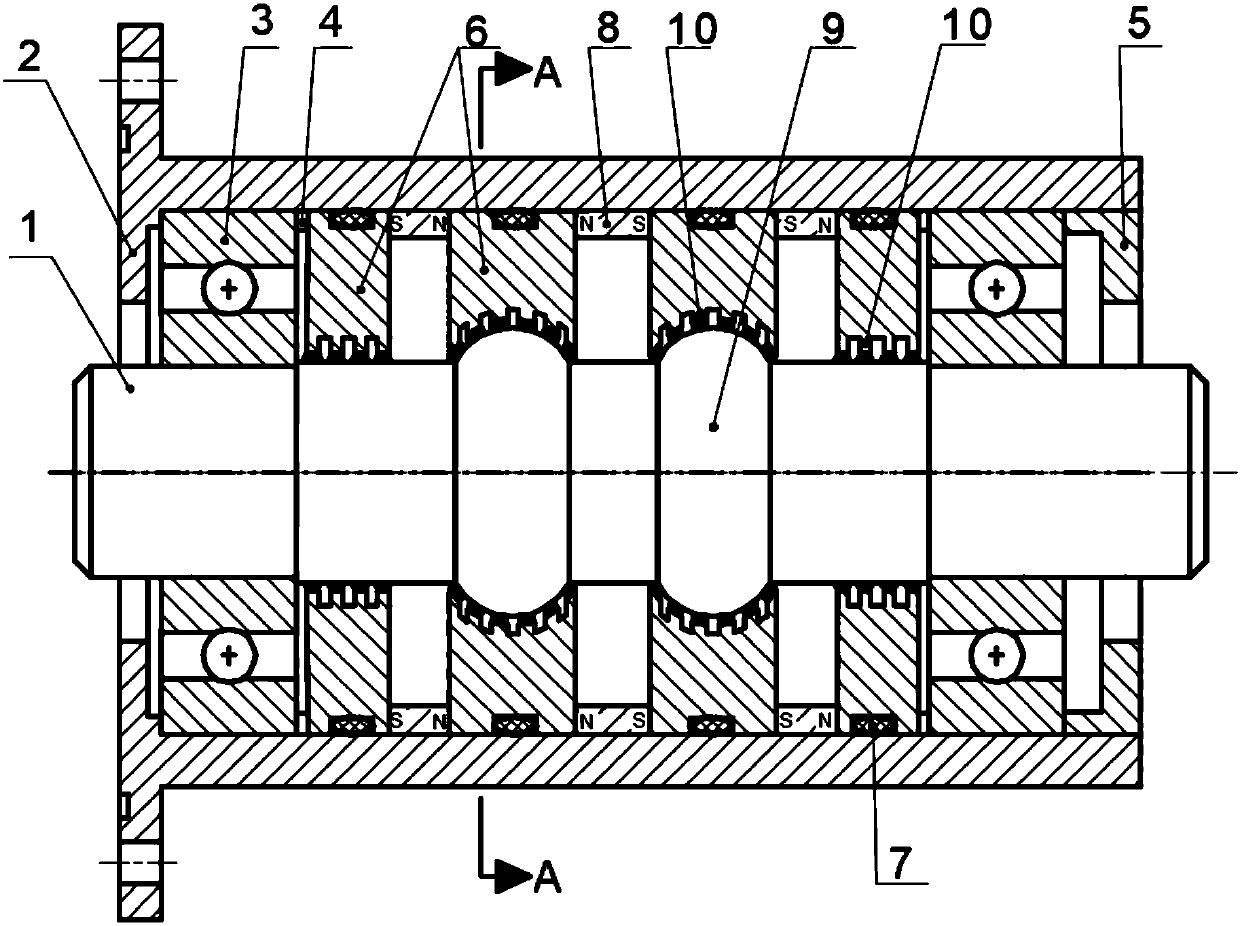

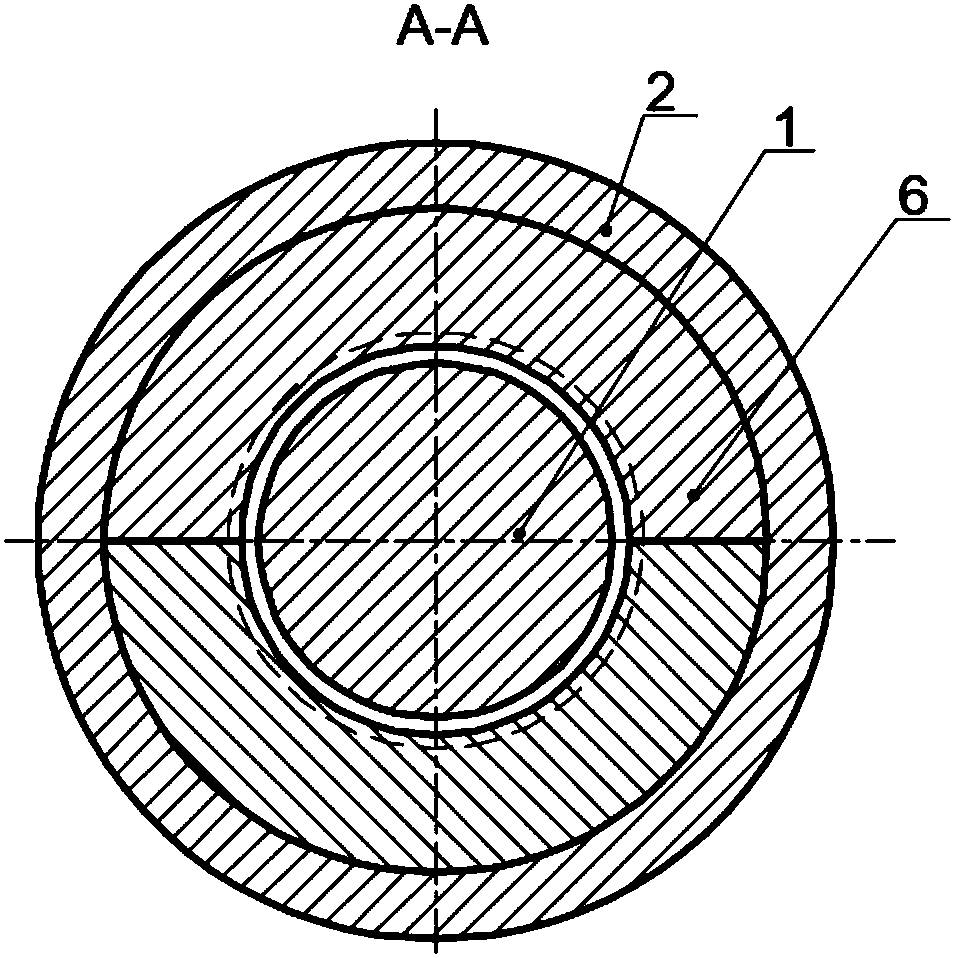

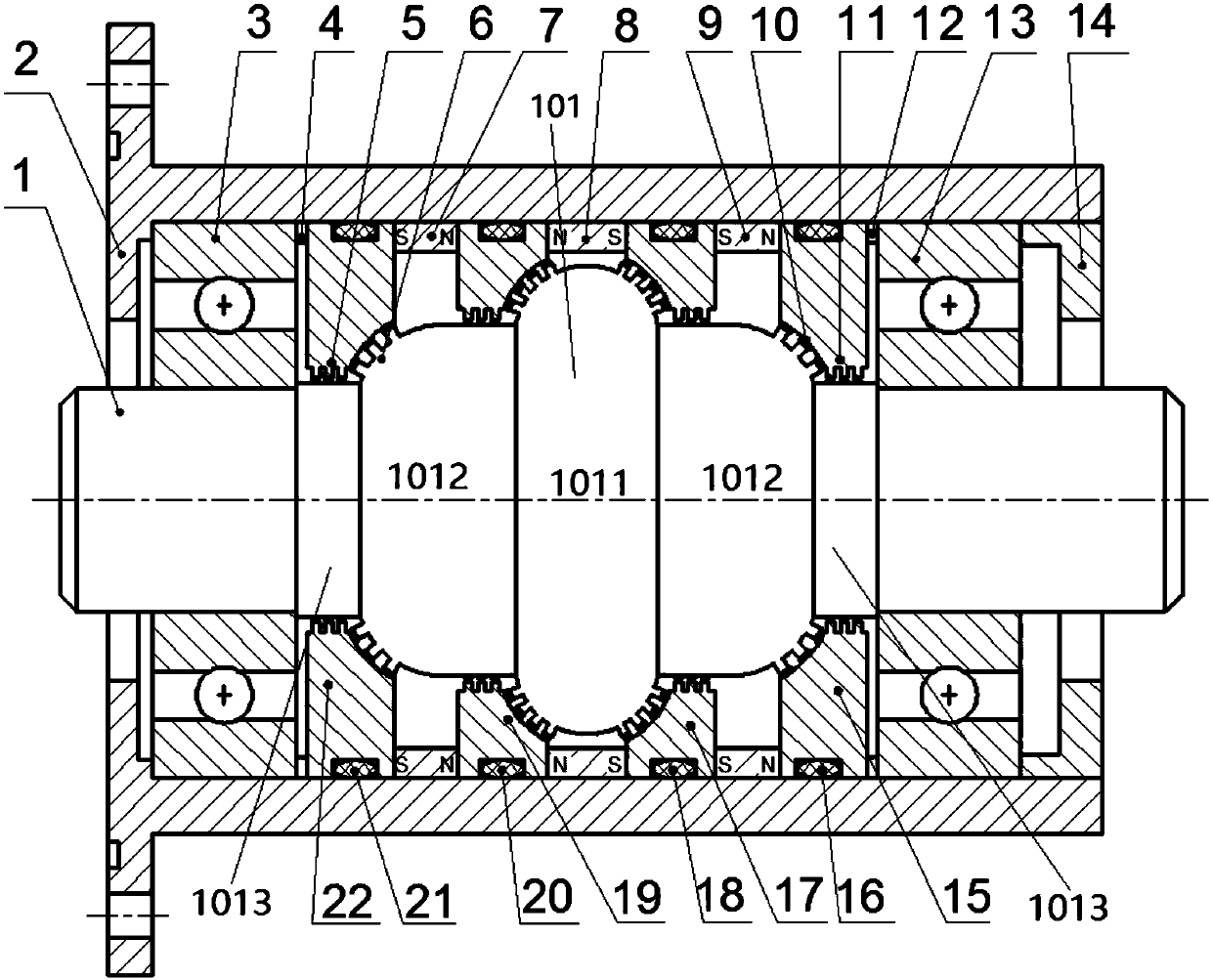

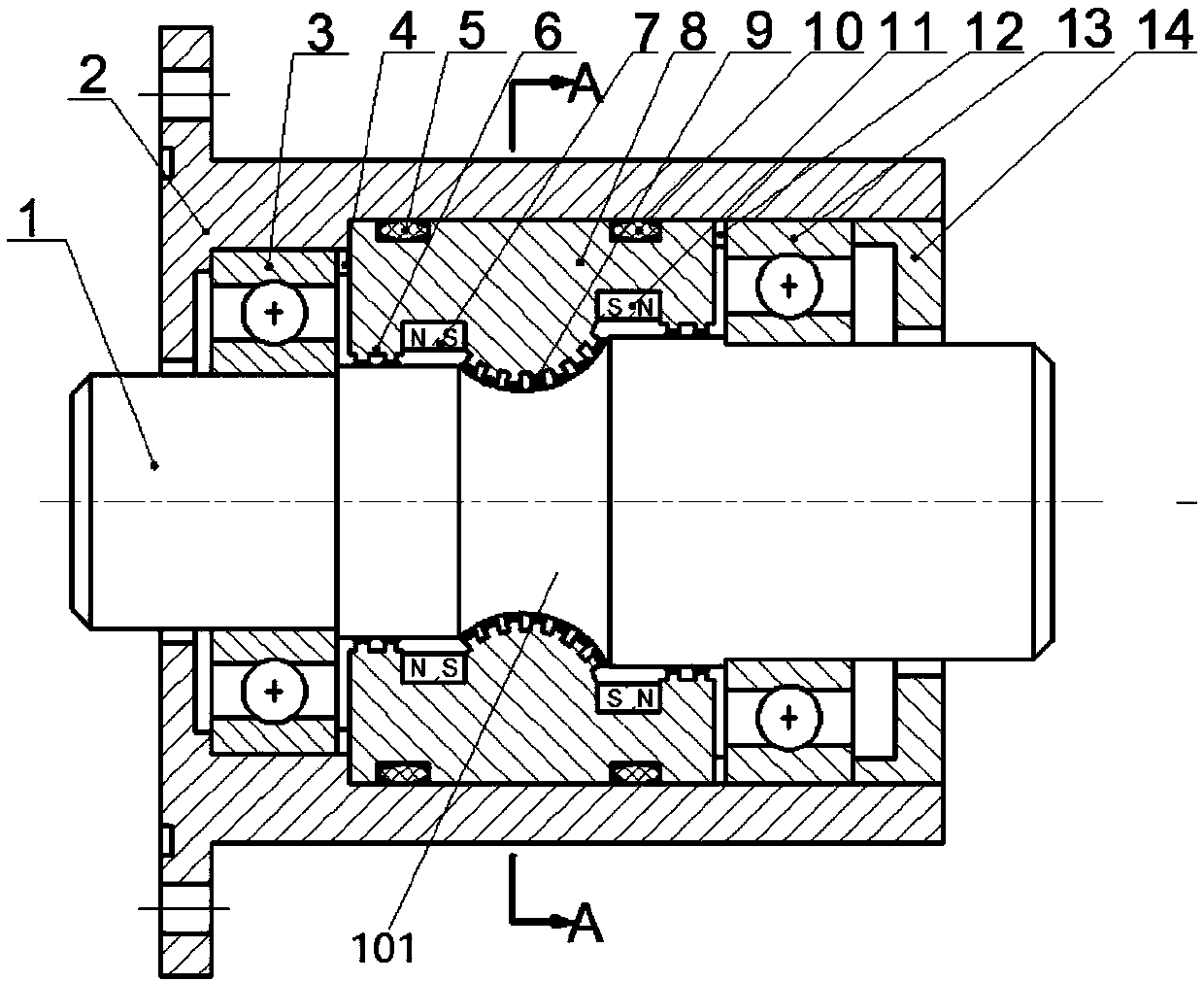

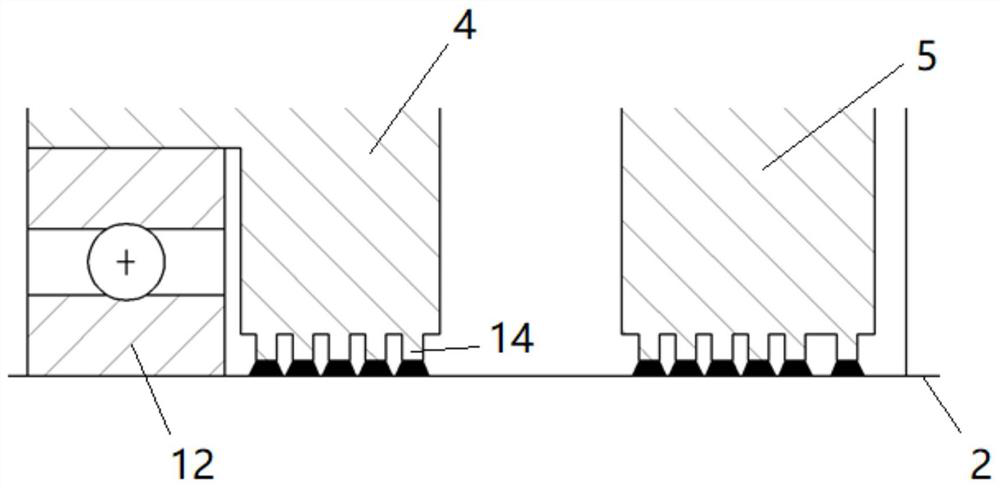

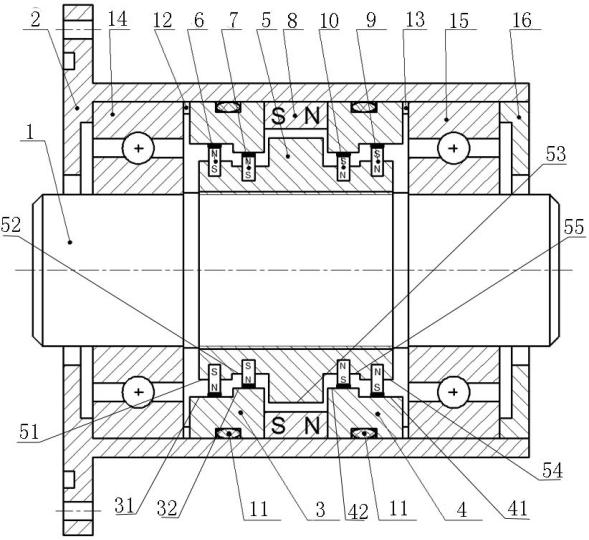

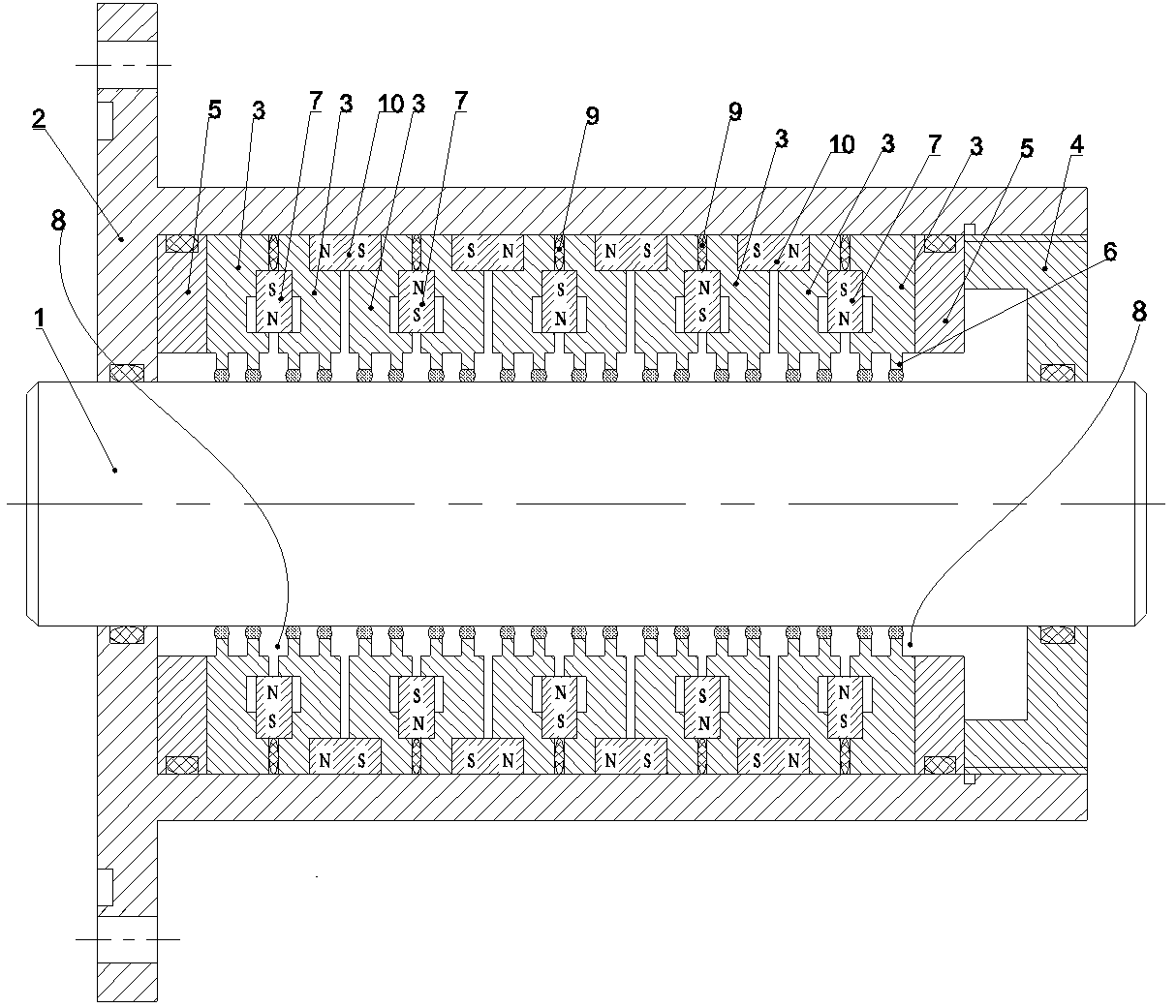

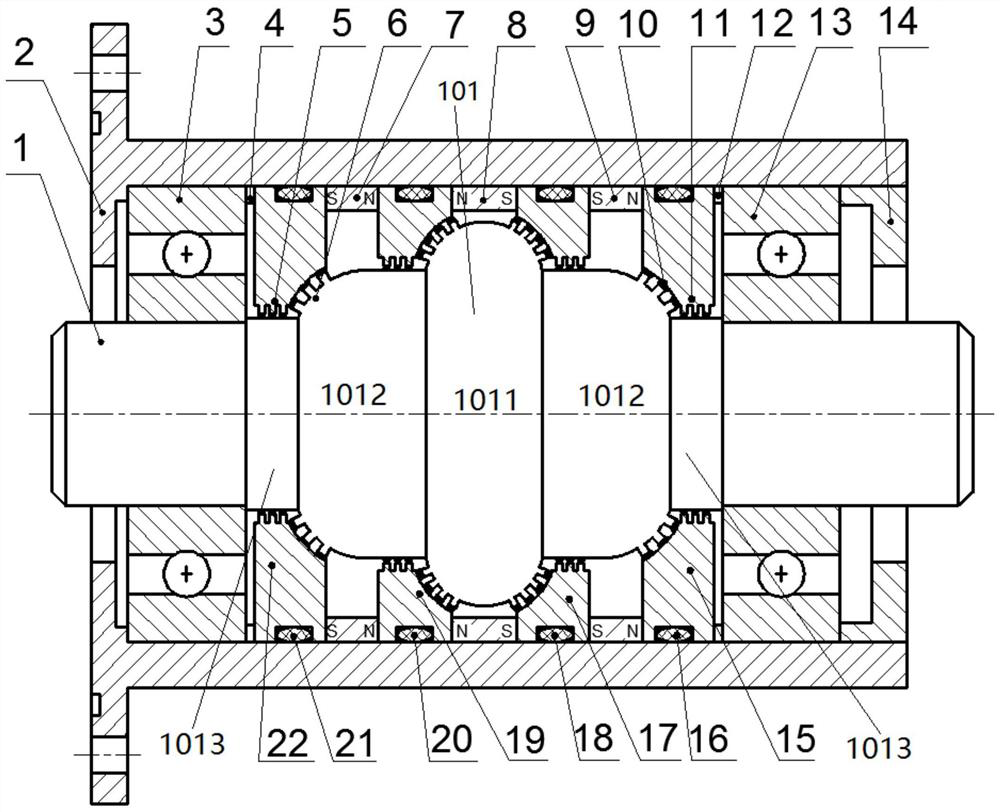

Multistage disc magnetic fluid sealing device

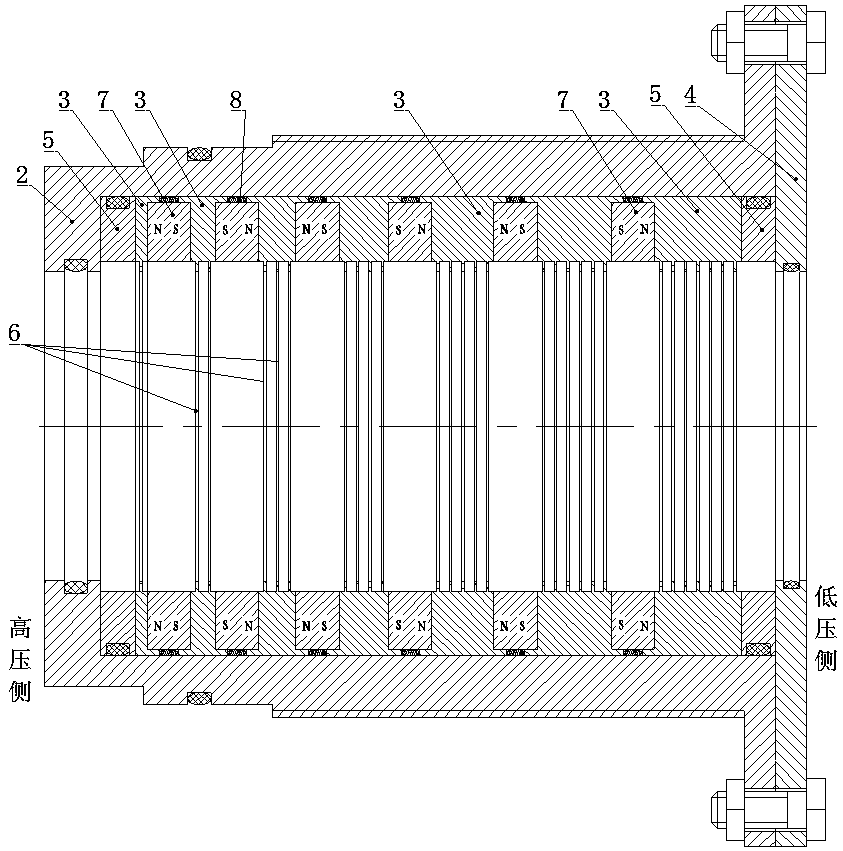

ActiveCN107956882ASolve the problem of insufficient pressure resistanceAchieve sealingEngine sealsMagnetic sourceCircular disc

The invention relates to a multistage disc magnetic fluid sealing device. The multistage disc magnetic fluid sealing device comprises a shaft, a shell, a left pole shoe ring, a middle pole shoe ring,a right pole shoe ring, inner permanent magnet rings and outer permanent magnet rings; the left pole shoe ring and the right pole shoe ring sleeve the portion between the shell and the shaft; two or more permanent magnet ring groups are arranged between the left pole shoe ring and the right pole shoe ring in the axial direction; and every two adjacent permanent magnet ring groups are separated bythe middle pole shoe ring, and the middle pole shoe ring sleeves the portion between the shell and the shaft. According to the multistage disc magnetic fluid sealing device, the problem that the pressure resistance of an existing single-stage disc magnetic fluid sealing device and a multi-magnetic-source magnetic fluid sealing device is low can be solved, so that the sealing technology is successfully applied to the fields such as high-speed heavy load.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

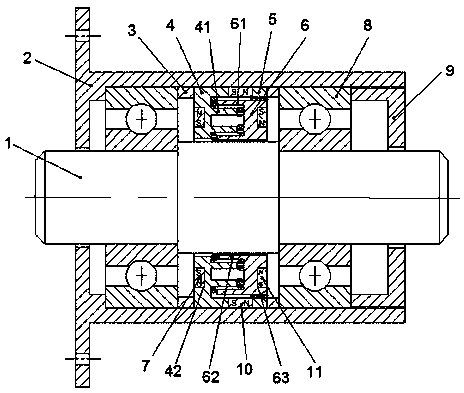

Labyrinth-type magnetofluid sealing device

ActiveCN106015360AAchieve axial positioningPrevent leakageEngine sealsBearing componentsCircular surfaceMagnet

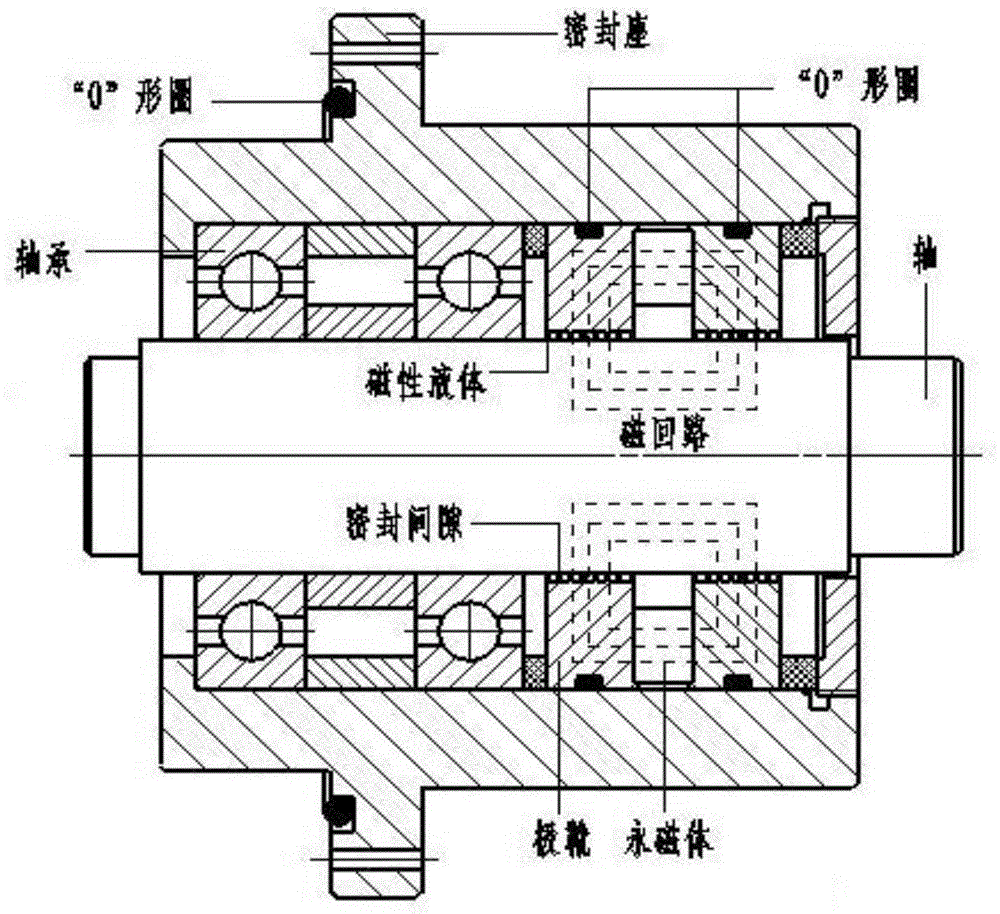

The invention relates to the field of machinery engineering sealing, and concretely relates to a labyrinth-type magnetofluid sealing device. The device comprises a shaft, a housing, a first pole shoe ring, a second pole shoe ring, and a third pole shoe ring; the first pole shoe ring is positioned at the left side of the second pole shoe ring, a pole tooth I is established at the right end of the first pole shoe ring, an annular groove I is established at the left end of the first pole shoe ring, a permanent magnet I is arranged in the annular groove I, a pole tooth II and a pole tooth III are established at the left end of the second pole shoe ring, an annular groove II is established at the right end of the second pole shoe ring, a permanent magnet III is arranged in the annular groove II, the third pole shoe ring is arranged at the external circular surface of the second pole shoe ring, a space is kept between the third pole shoe ring and the first pole shoe ring, a permanent magnet II is arranged in the space, the pole tooth II is positioned over the pole tooth I at the top of the first pole shoe ring, the pole tooth III is positioned below the pole tooth I at the bottom of the first pole shoe ring, and the pole tooth I stretches into the space composed of the pole tooth II and the pole tooth III.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

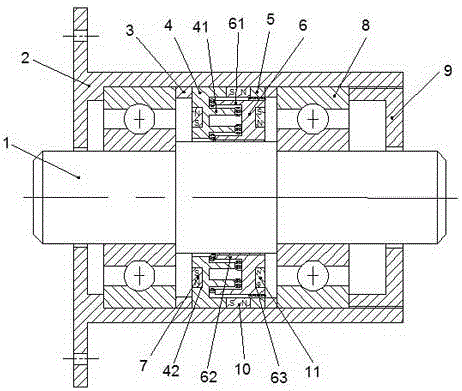

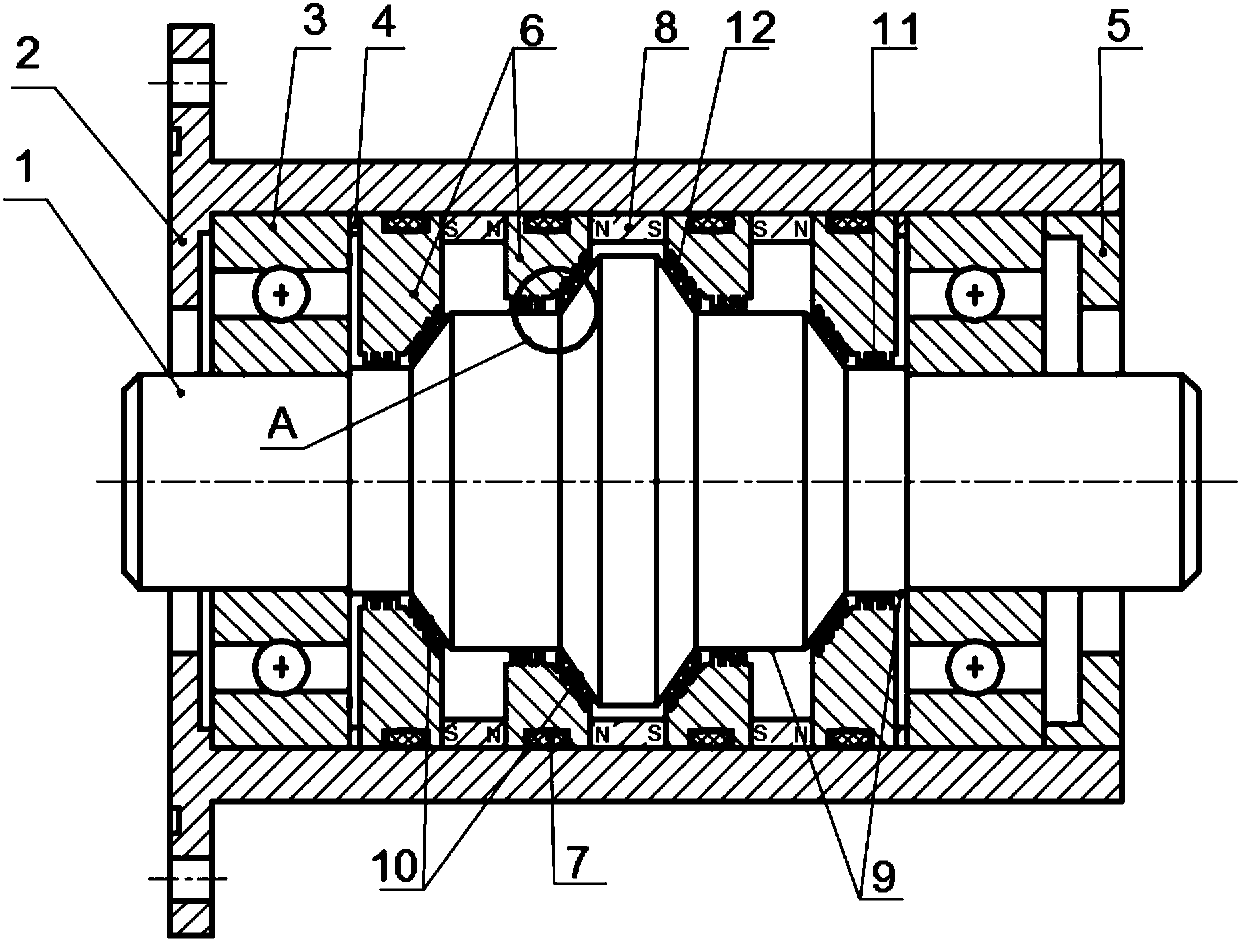

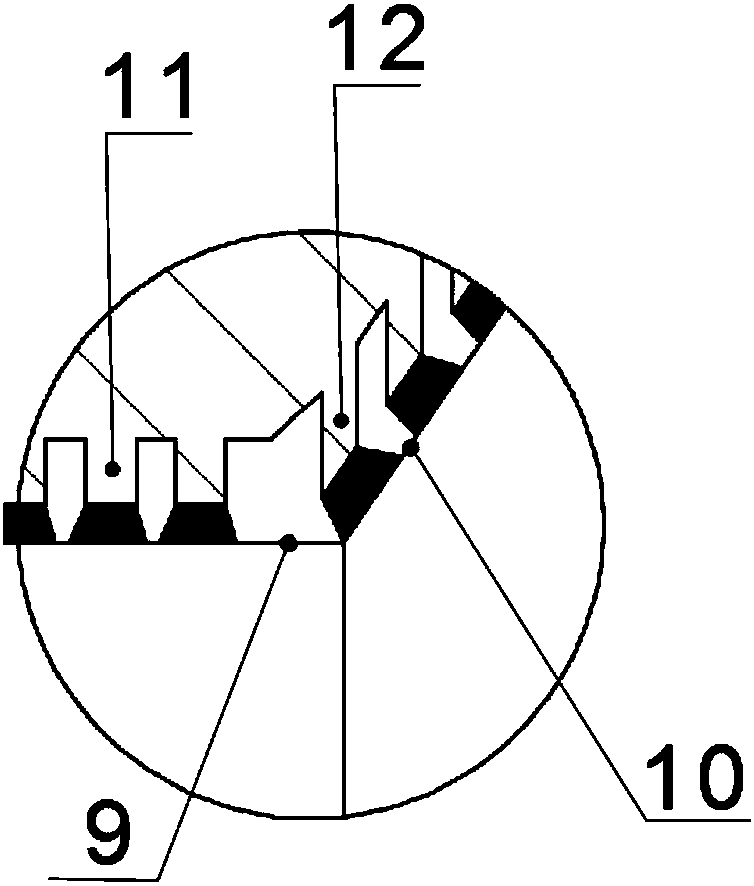

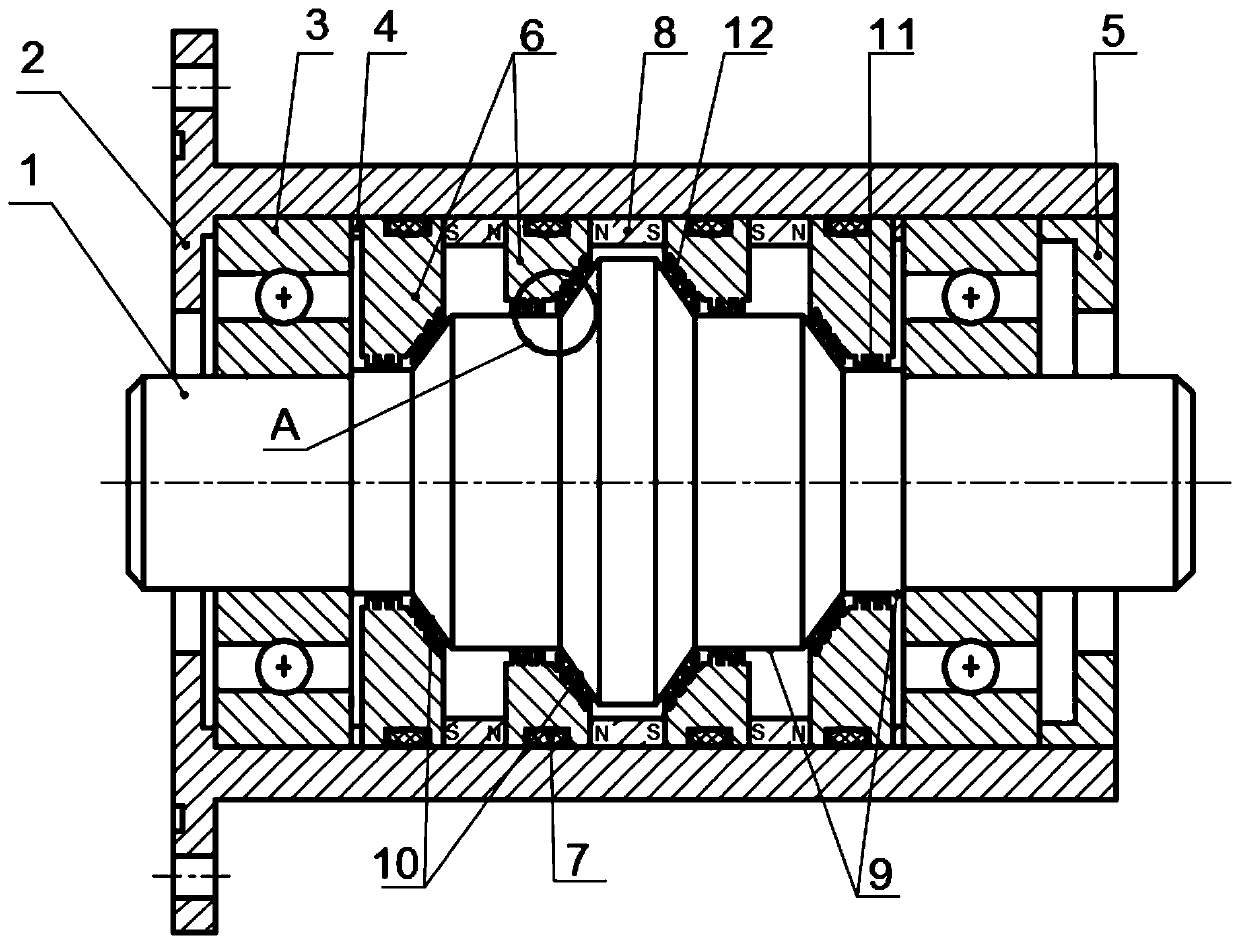

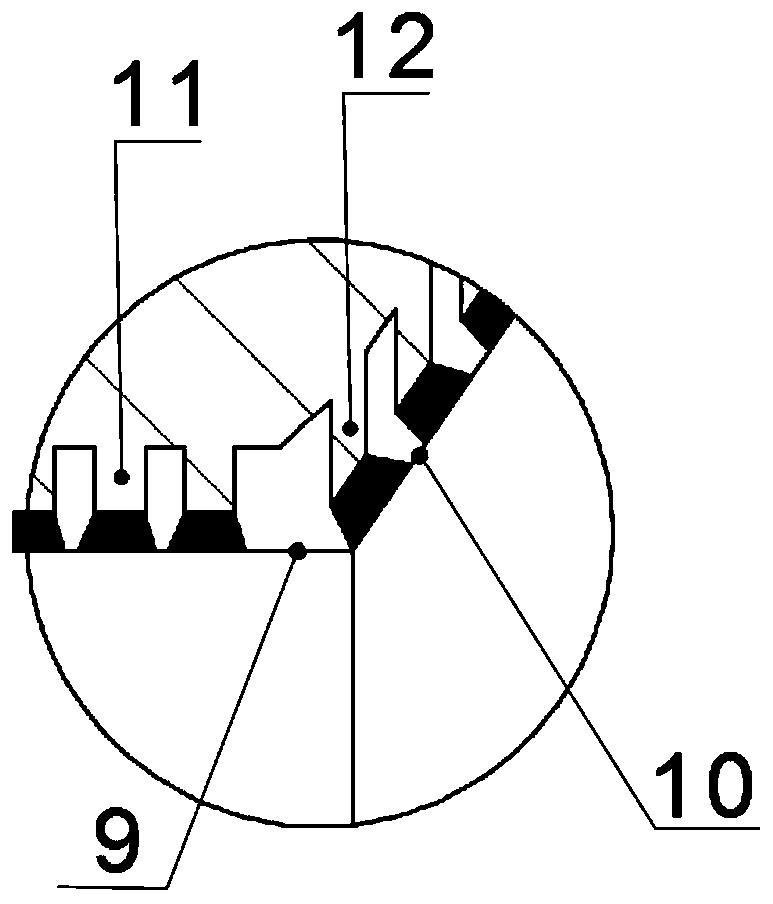

Convex step shaft magnetofluid sealing device

ActiveCN107893853ASolve the problem of insufficient pressure resistanceImprove sealing pressure resistanceEngine sealsMagnetSelf repair

The invention relates to a convex step shaft magnetofluid sealing device. The convex step shaft magnetofluid sealing device comprises a shell, a sealing assembly and an end cover. The sealing assemblycomprises a shaft. The shaft is rotationally arranged in the shell through a bearing. The shaft comprises at least one convex step part. The convex step part comprises a plurality of steps sequentially arranged in the axial direction, and the outer walls of the adjacent steps are connected through arc chamfered transition faces. Each transition face is sleeved with a pole shoe matched with the transition face, wherein the pole shoe extends towards one or two sides of the transition face to the position corresponding to the corresponding step on the side portion of the transition face. Gaps are reserved between the inner walls of the pole shoes and the corresponding transition faces and between the inner walls of the pole shoes and the steps. Pole teeth are arranged on the inner walls of the pole shoes and / or the parts, corresponding to the inner walls of the pole shoes, of the shaft. Permanent magnets are arranged between the adjacent pole shoes. The convex step shaft magnetofluid sealing device is high in pressure resisting capability, the secondary pressure bearing capability and the self-repairing capability are high, the pressure resisting capability and the sealing reliability of magnetic fluid seals under the condition of large gaps are high, and the safety work range is wide.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

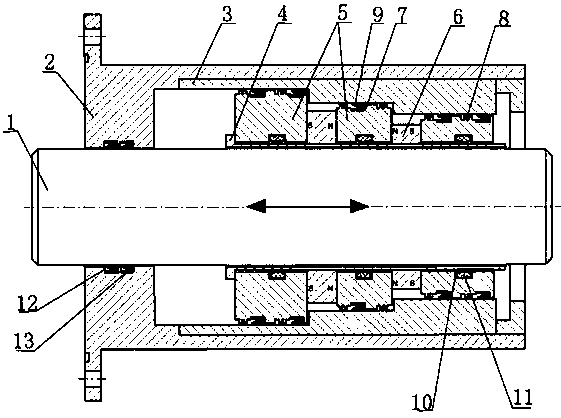

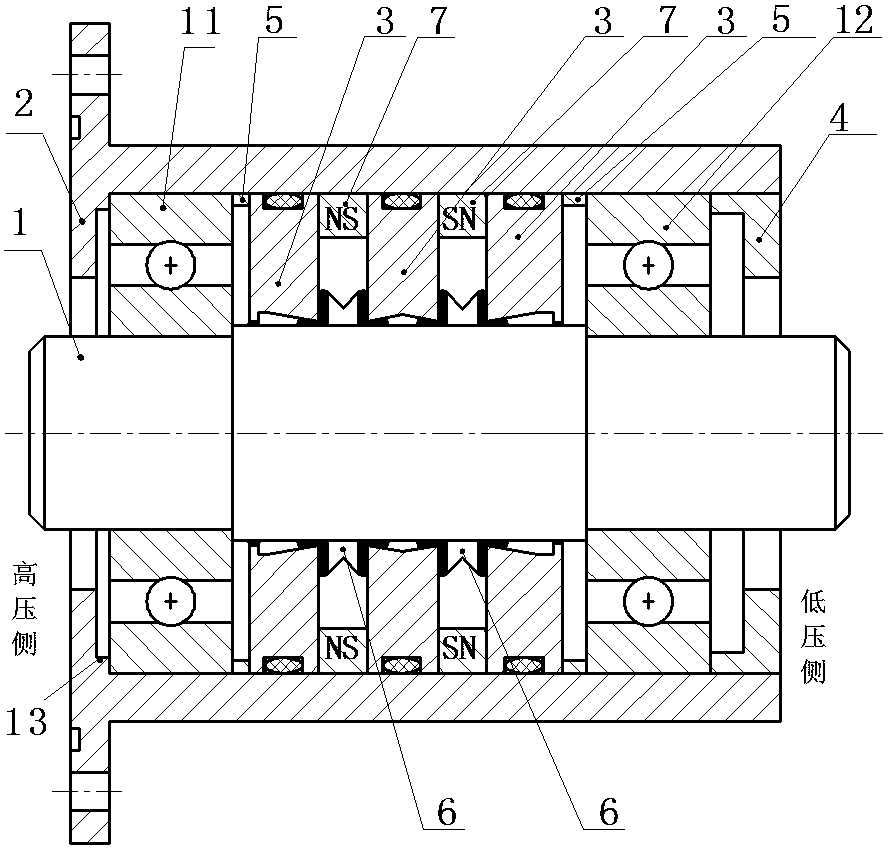

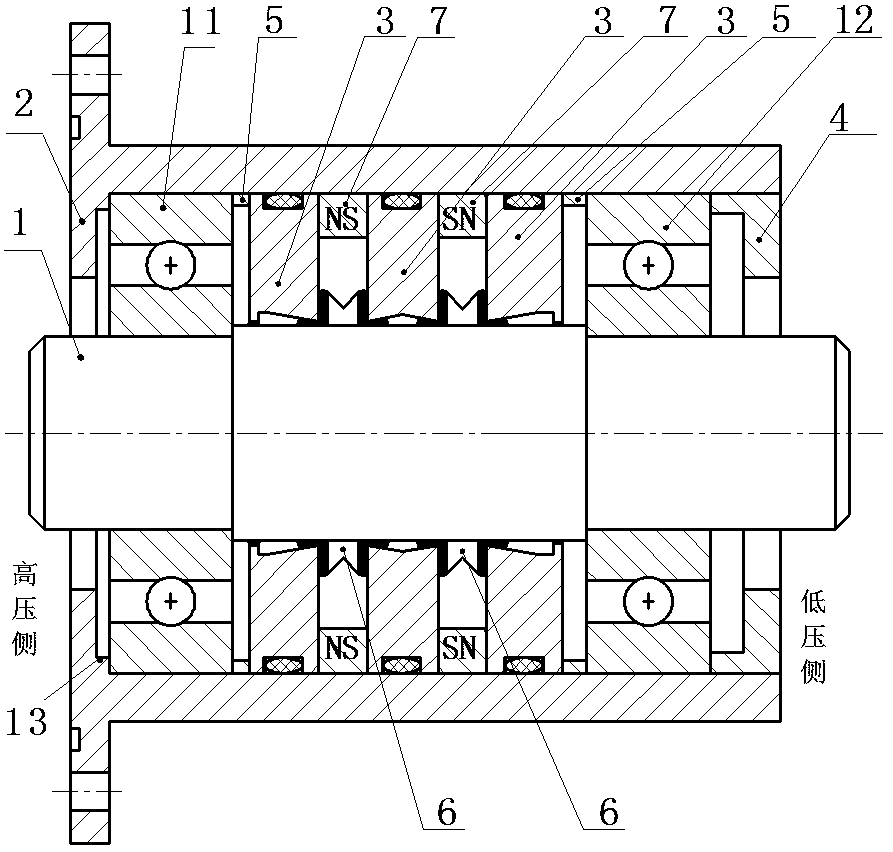

Magnetofluid sealing device

The invention relates to a magnetofluid sealing device which comprises a shell, a sealing assembly and an end cover. The two ends of the shell are provided with openings, and the end cover is used forpressing the sealing assembly into the shell. The sealing assembly comprises a shaft, the shaft is rotationally installed in the shell through a bearing, the shaft comprises at least one concave portion, the outer side of the shaft is provided with split shoe poles, the concave portion is located in a cavity defined by the split shot poles, the shape of the outer wall of the split shot poles is matched with the appearance of the shaft corresponding portion, the split shoe poles are provided with a first permanent magnet and a second permanent magnet which are located on the two sides of the concave portion correspondingly, a gap is reserved between the inner wall of the split shoe poles and the outer wall of the shaft, and the inner wall of the split shoe poles is provided with pole teeth. Assembling is easy, the structure is simple, magnetofluid sealing pressure resistance is high, the secondary pressure bearing capacity and self-repair ability of the device are high, pressure resistance and sealing reliability under the large gap condition are good, the safe working range is large, and the requirements of occasions such as high-speed heavy load can be met.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

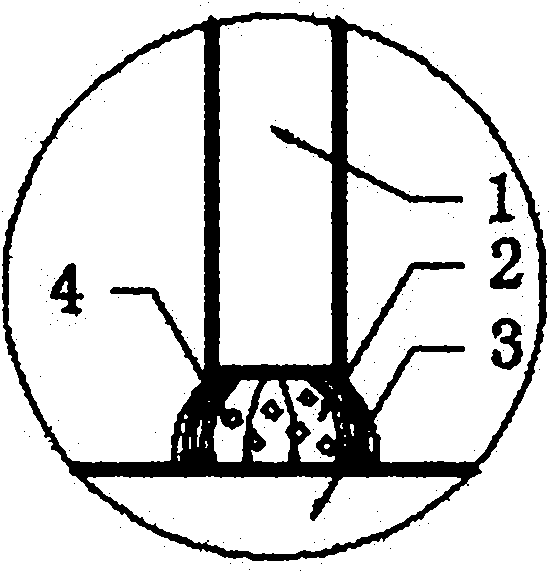

Magnetic liquid for improving pressure resistance capability in case of magnetic liquid seal

The invention discloses magnetic liquid for improving pressure resistance capability in the case of magnetic liquid seal, belonging to the technical field of mechanical engineering seal and being particularly applicable to magnetic liquid seal. The magnetic liquid is prepared by adding 1 mu m-50 mu m of nonmagnetic solid particles the volume of which is 9%-11% of that of the magnetic liquid to the existing magnetic liquid and then stirring for 30-40 minutes. The nonmagnetic solid particles comprise silicon oxide powder or aluminum oxide powder, and the existing magnetic liquid comprises diester-based magnetic liquid or kerosene-based magnetic liquid. By using the magnetic liquid in the invention, the problem that the pressure resistance capability of the magnetic liquid is reduced caused by unevenly distributed magnetic solid particles in the existing magnetic liquid is solved.

Owner:BEIJING JIAOTONG UNIV

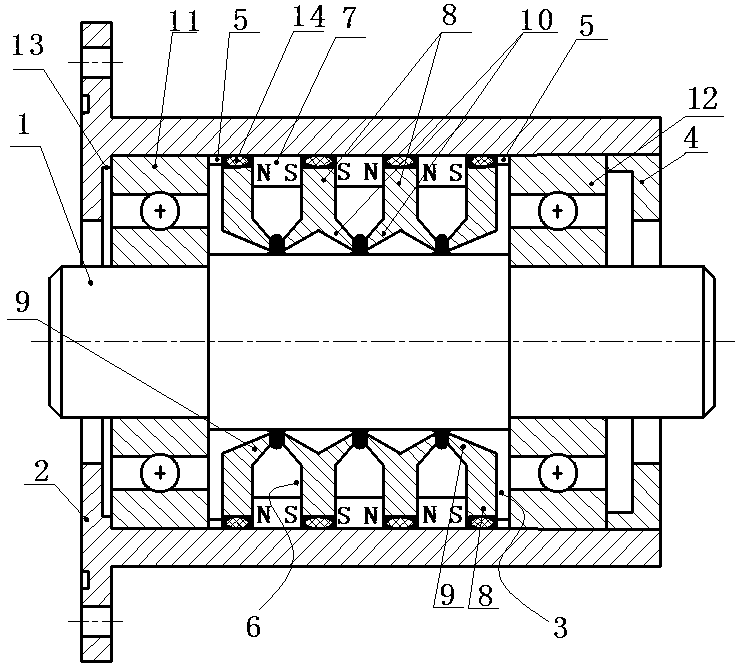

Symmetrical double-step magnetic fluid sealing device

ActiveCN109764137AImprove sealing pressure resistanceOvercoming the Difficulty of Decreasing Sealing PerformanceEngine sealsEngineeringSecondary stage

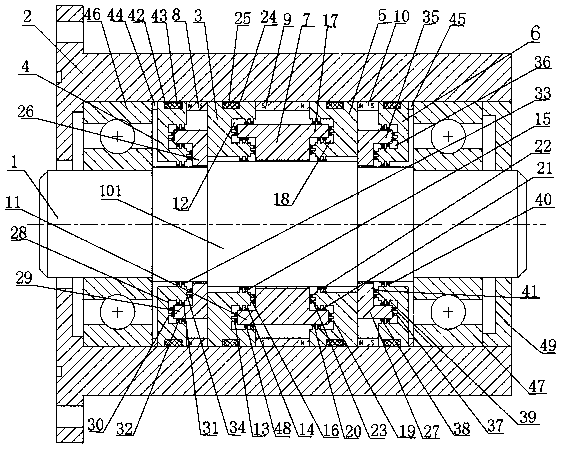

The invention aims to provide a symmetrical double-step magnetic fluid sealing device. The symmetrical double-step magnetic fluid sealing device comprises a stepped shaft, a shell, a left first-stageshoe ring, a right first-stage shoe ring, an intermediate sleeve and an intermediate permanent magnet ring. The stepped shaft comprises a first-stage shaft with the largest diameter and more than twogroups of secondary-stage shafts with diameters reducing in sequence, the secondary-stage shafts are sequentially arranged to the two sides along the side surface of the first-stage shaft, and left and right symmetric is realized by taking the middle radial section of the first-stage shaft as a boundary. The problem of low pressure resistance of an existing sealing device is solved, so that the sealing technology can be successfully applied to fields such as high speed and heavy load.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

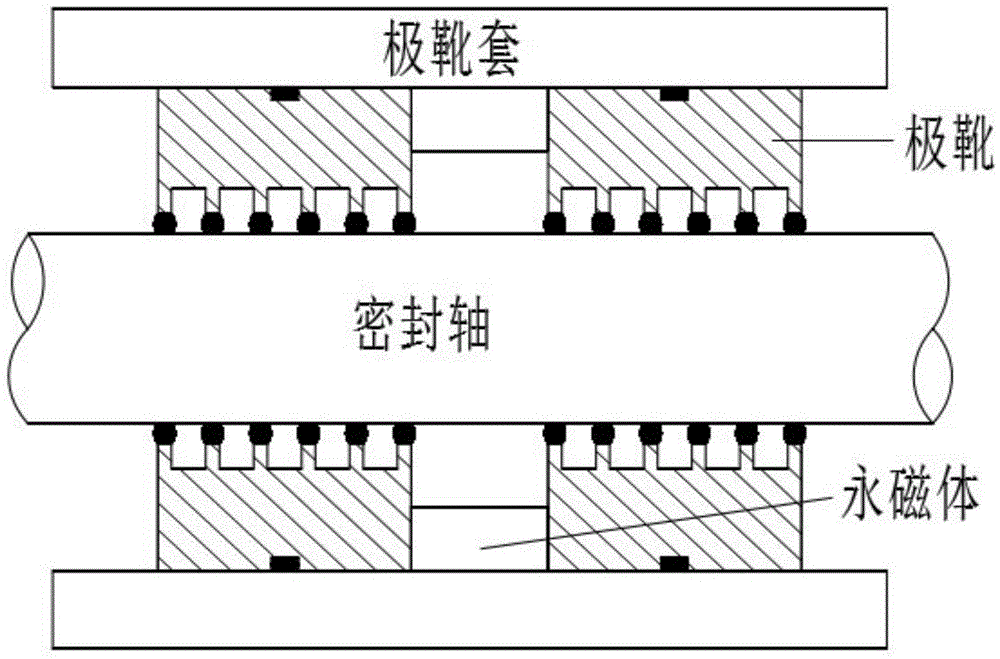

Method for improving pressure-resistant capacity and working reliability of magnetic fluid seal in high-temperature working environment

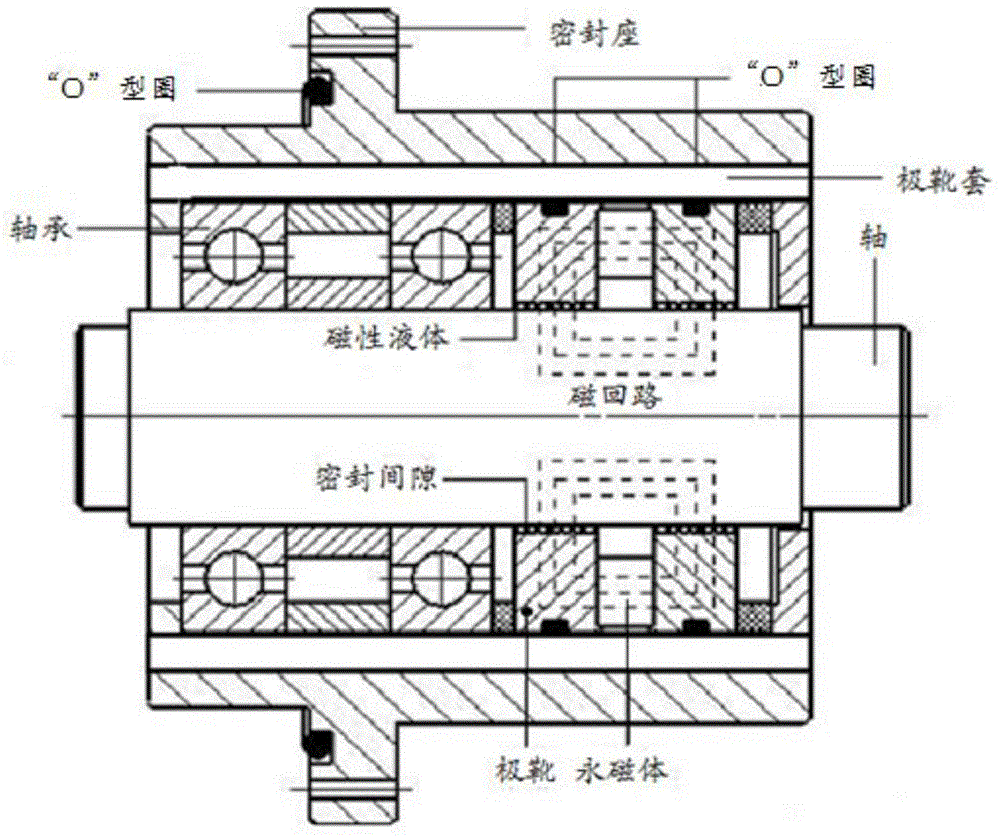

InactiveCN104696529ASmall coefficient of thermal expansionGuaranteed to workEngine sealsInterference fitWorking environment

The invention discloses a method for improving the pressure-resistant capacity and the working reliability of a magnetic fluid seal in a high-temperature working environment, belongs to the technical field of mechanical engineering seals, and is particularly applicable to the magnetic fluid seal. An iron-nickel alloy material with the anomalous thermal expansion characteristic and a ferromagnetic material with the larger thermal expansion coefficient and good comprehensive mechanical properties are selected, pole shoes and a sealing shaft which are matched with each other are made of the selected ferromagnetic material, pole shoe sleeves which are in interference fit with outer rings of the two pole shoes are made of the selected iron-nickel alloy material, and the radial width ratio of each alloy sleeve to each pole shoe is 1:2. With the adoption of the method, defects of existing methods for the magnetic fluid seal at the high temperature are overcome, and the method has the important significance in solving usage problems of the magnetic fluid seal in the high-temperature environment and broadening the application range of the magnetic fluid seal.

Owner:BEIJING JIAOTONG UNIV

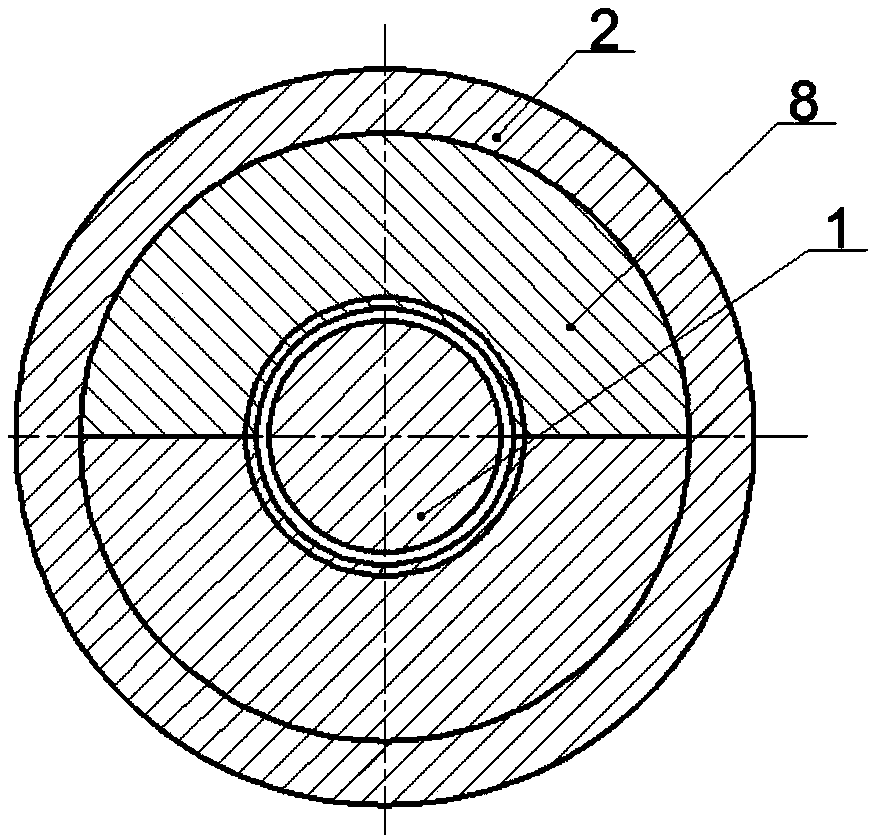

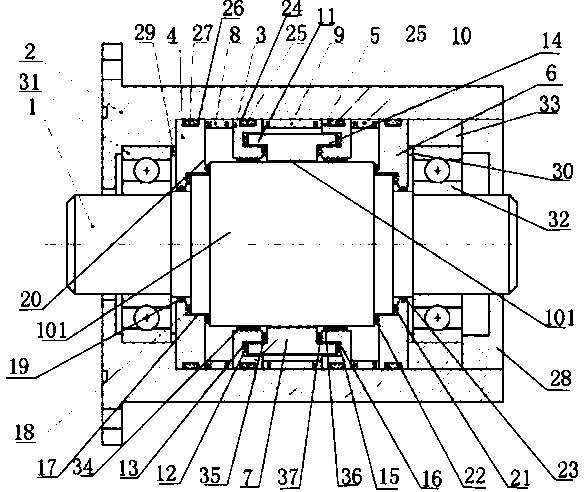

Stepped shaft type magnetofluid sealing device

ActiveCN107816553AImprove sealing pressure resistanceReduce lossesEngine sealsShaftsHeavy loadMagnet

The invention discloses a stepped shaft type magnetofluid sealing device. The stepped shaft type magnetofluid sealing device comprises a shaft, an outer shell, sealing rings, pole shoes, magnetofluidand permanent magnets. The shaft penetrates the outer shell, extends out of the two ends of the outer shell and comprises a stepped shaft part, wherein the stepped shaft part is located inside the outer shell. The diameter of a middle step of the stepped shaft part is the maximum, and the diameters of steps at the left side and the right side are decreased progressively and sequentially. Every twoadjacent steps are in circular-truncated-cone transition. The stepped shaft part is provided with cylinder side faces and multiple circular-truncated-cone side faces, wherein the cylinder side facesare parallel with the axis of the shaft, and the circular-truncated-cone side faces are symmetrical about the axis. The inner surface of the outer shell is provided with the two or more pole shoes. Each annular permanent magnet is arranged between the corresponding two adjacent pole shoes. Each pole shoe is provided with radial pole teeth and bevel pole teeth, wherein the radial pole teeth protrude toward the cylinder side faces, and the bevel pole teeth protrude toward the circular-truncated-cone side faces. The magnetofluid is arranged between the radial pole teeth and the cylinder side faces as well as between the bevel pole teeth and the circular-truncated-cone side faces. By means of the stepped shaft type magnetofluid sealing device, the sealing capability and pressure endurance capability of the magnetofluid are greatly enhanced; and the problem that existing sealing devices cannot meet the high-sealing-performance requirement under special working conditions such as the high speed and heavy load is solved.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

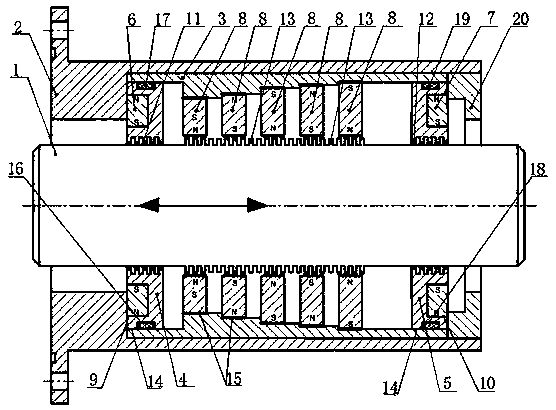

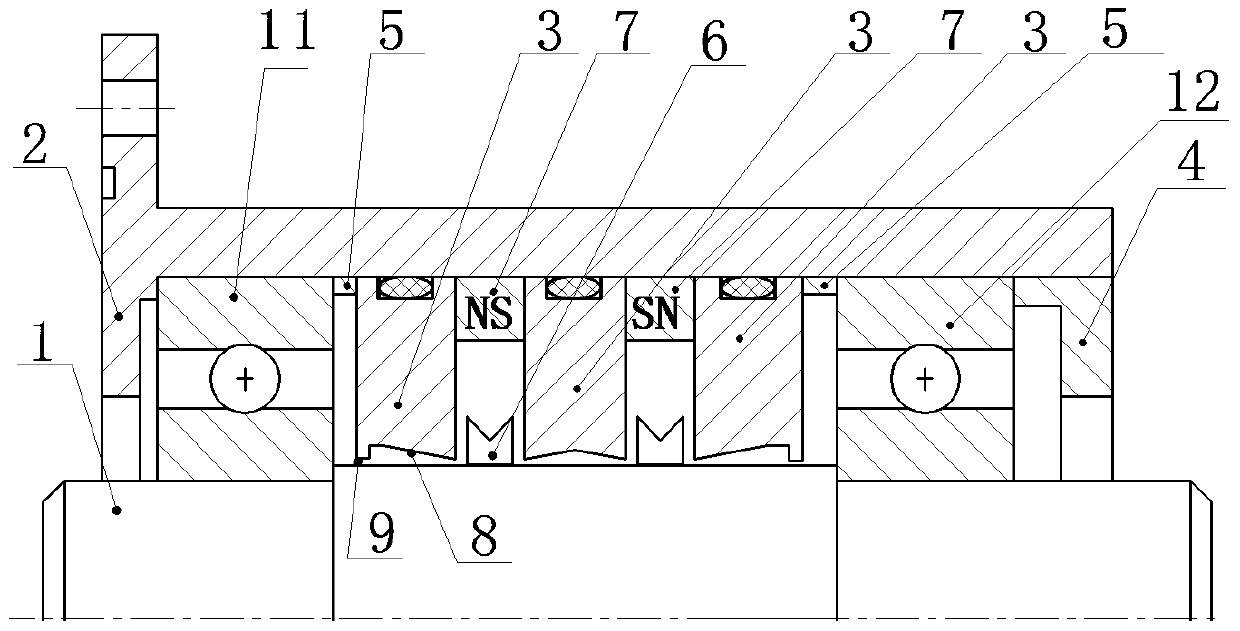

Step type reciprocating sealing device with pole shoes and lip-shaped sealing rings alternatively mixed

The invention relates to a step type reciprocating sealing device with pole shoes and lip-shaped sealing rings alternatively mixed. The step type reciprocating sealing device comprises a shaft, a housing, outer ring concentrating flux sleeves, inner ring concentrating flux sleeves, polar shoe rings and permanent magnet rings, wherein the inner walls of the outer ring concentrating flux sleeve arestep ring surfaces, and the diameter of the step ring surface at each stage is sequentially reduced from left to right; the inner ring concentrating flux sleeves sleeve the shaft and are positioned within the outer ring concentrating flux sleeves; one or more groups of polar shoe rings are arranged on the outer circular surfaces of the inner ring concentrating flux sleeves at intervals; the permanent magnet rings are arranged among the polar shoe rings; each permanent magnet ring is separately in contact with the end surface of the adjacent polar shoe ring; one or more groups of ring-shaped grooves I and polar teeth are axially formed in the outer circular surfaces of the polar shoe rings at intervals; and the ring-shaped grooves A and the polar teeth are alternatively distributed. The step type reciprocating sealing device aims to solve the problem that an existing single-magnetic-source magnetic fluid sealing device and an existing multi-magnetic-source magnetic fluid sealing deviceare low in pressure resistance.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

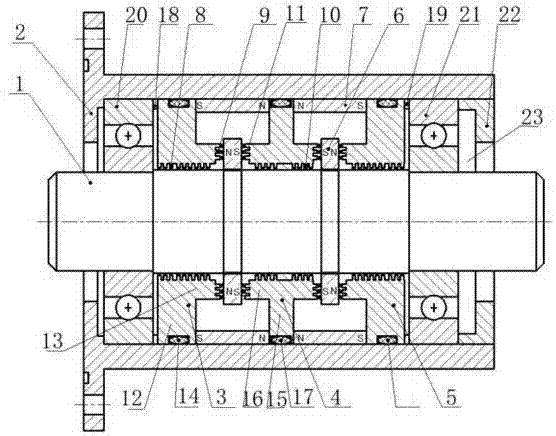

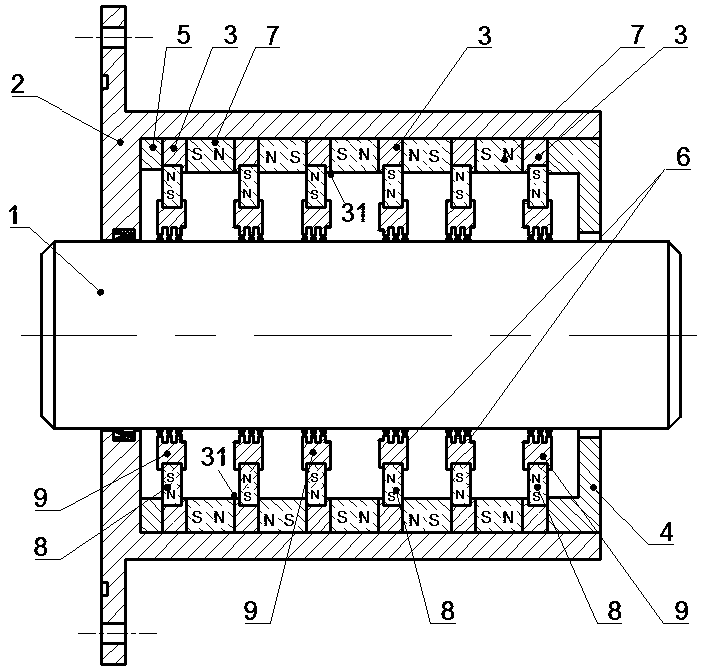

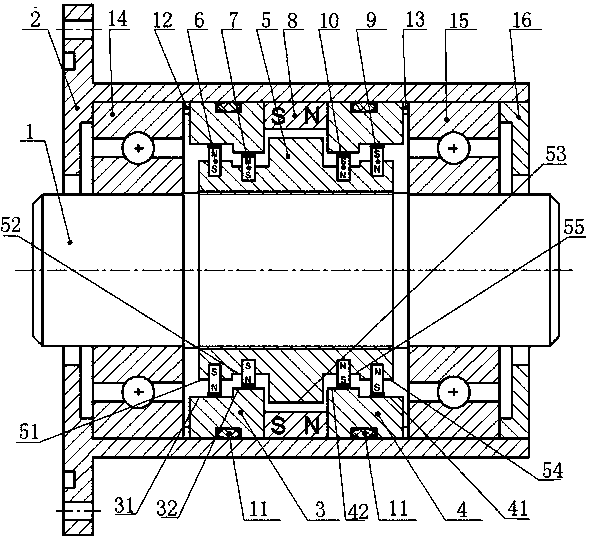

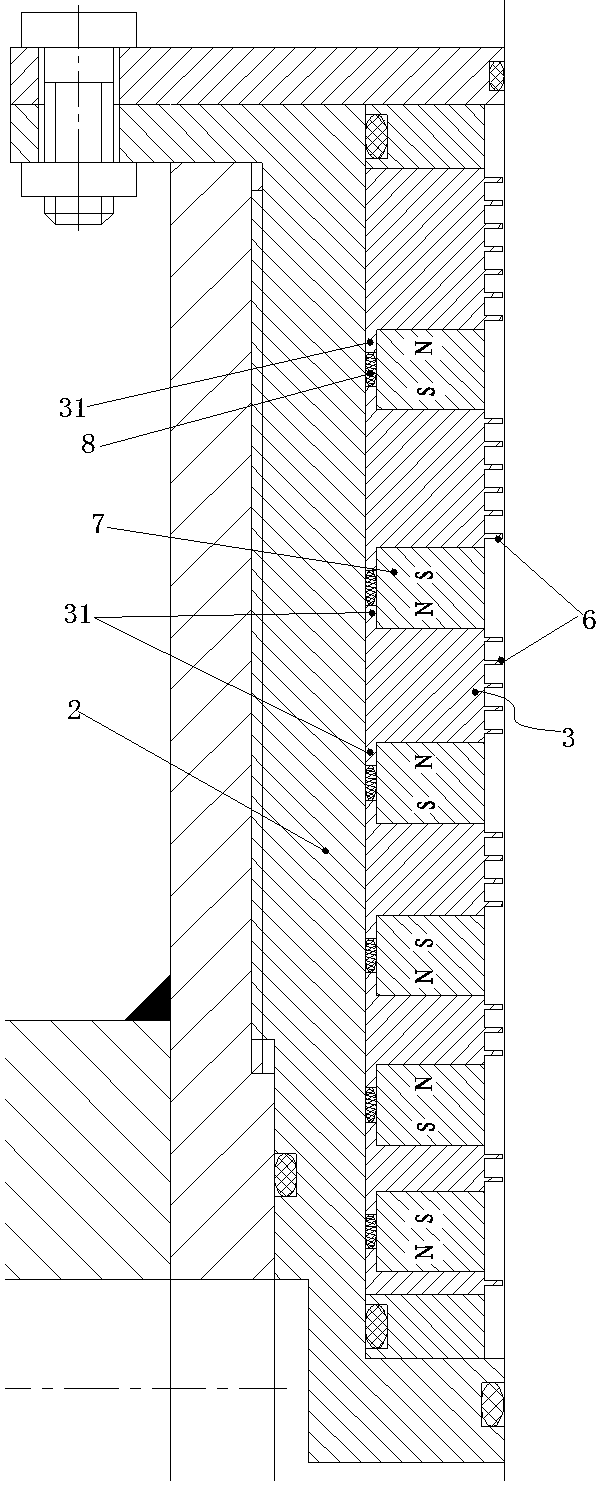

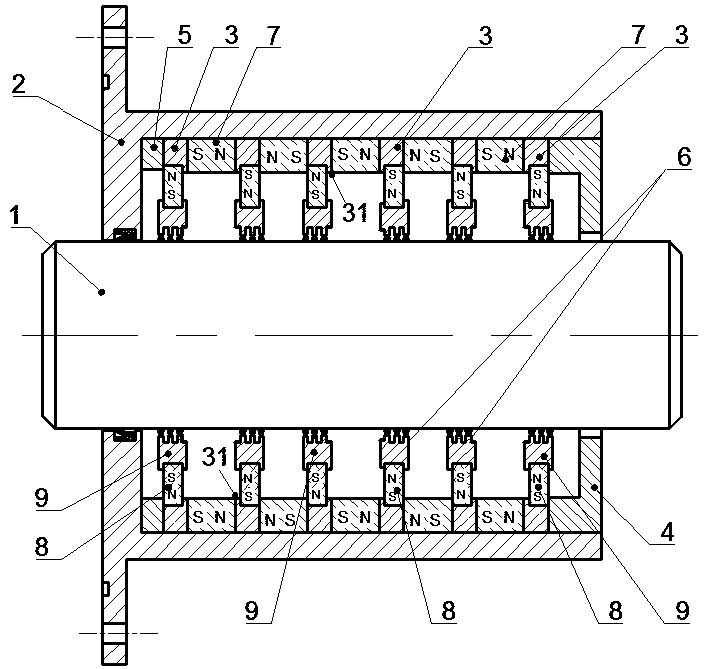

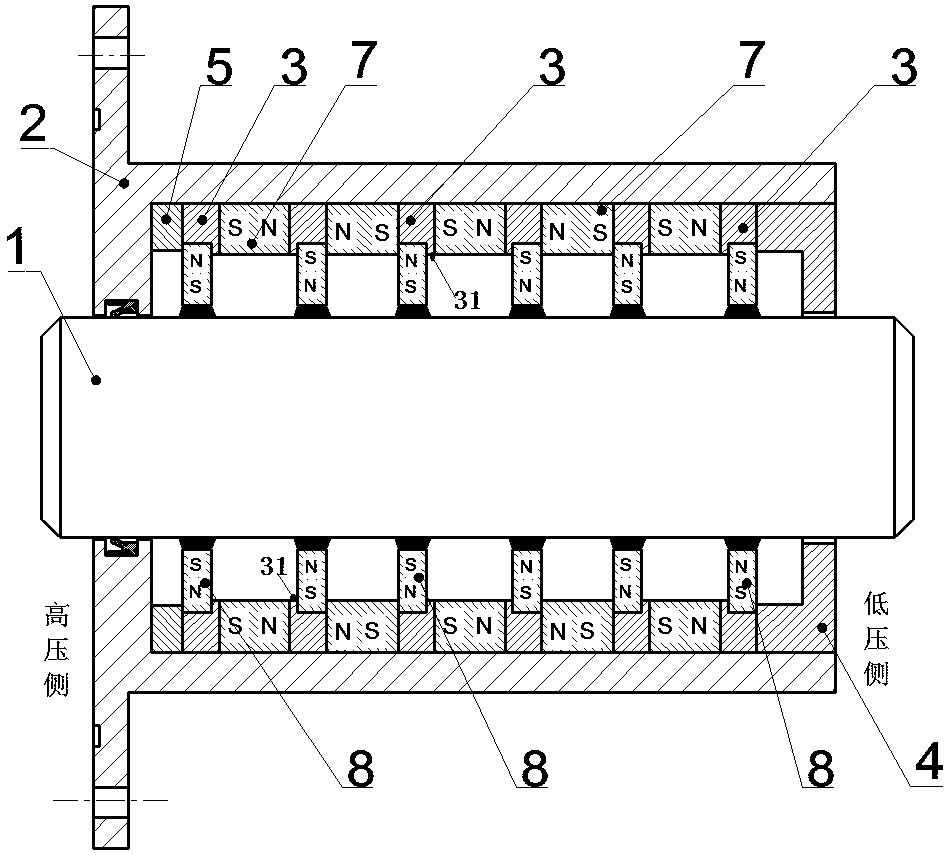

Serial-connected magnetofluid sealing structure

ActiveCN108843791AIncrease the magnetic field strengthImprove sealing pressure resistanceEngine sealsMagnetizationMagnetic poles

The invention discloses a serial-connected magnetofluid sealing structure. Multiple first pole shoes are arranged in space between the outer surface of a shaft and the inner wall of a shell; axial magnetizing permanent magnet rings are clamped between two adjacent first pole shoes; radial magnetizing permanent magnet rings sleeve the inner circular surfaces of all the first pole shoes; second poleshoes sleeve the inner circular surfaces of all the radial magnetizing permanent magnet rings; pole teeth are arranged on the inner circular surfaces of the second pole shoes; magnetofluid is injected between the pole teeth and the outer surface of the shaft; the polarities of magnetic poles of two adjacent radial magnetizing permanent magnet rings are opposite; each radial magnetizing permanentmagnet ring is positioned in a magnetic loop consisting of the axial magnetizing permanent magnet rings and the first pole shoes on two sides thereof; and the magnetic field directions of the radial magnetizing permanent magnet rings are the same with the magnetic loop directions thereof. The serial-connected magnetofluid sealing structure improves the magnetic field intensity, improves the sealing and pressure resisting capacity, enables magnetofluid seals in all gaps to exert effects through gradual increment of saturated magnetization strength of the magnetofluid in different gaps, and guarantees the sealing and pressure resisting performances.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

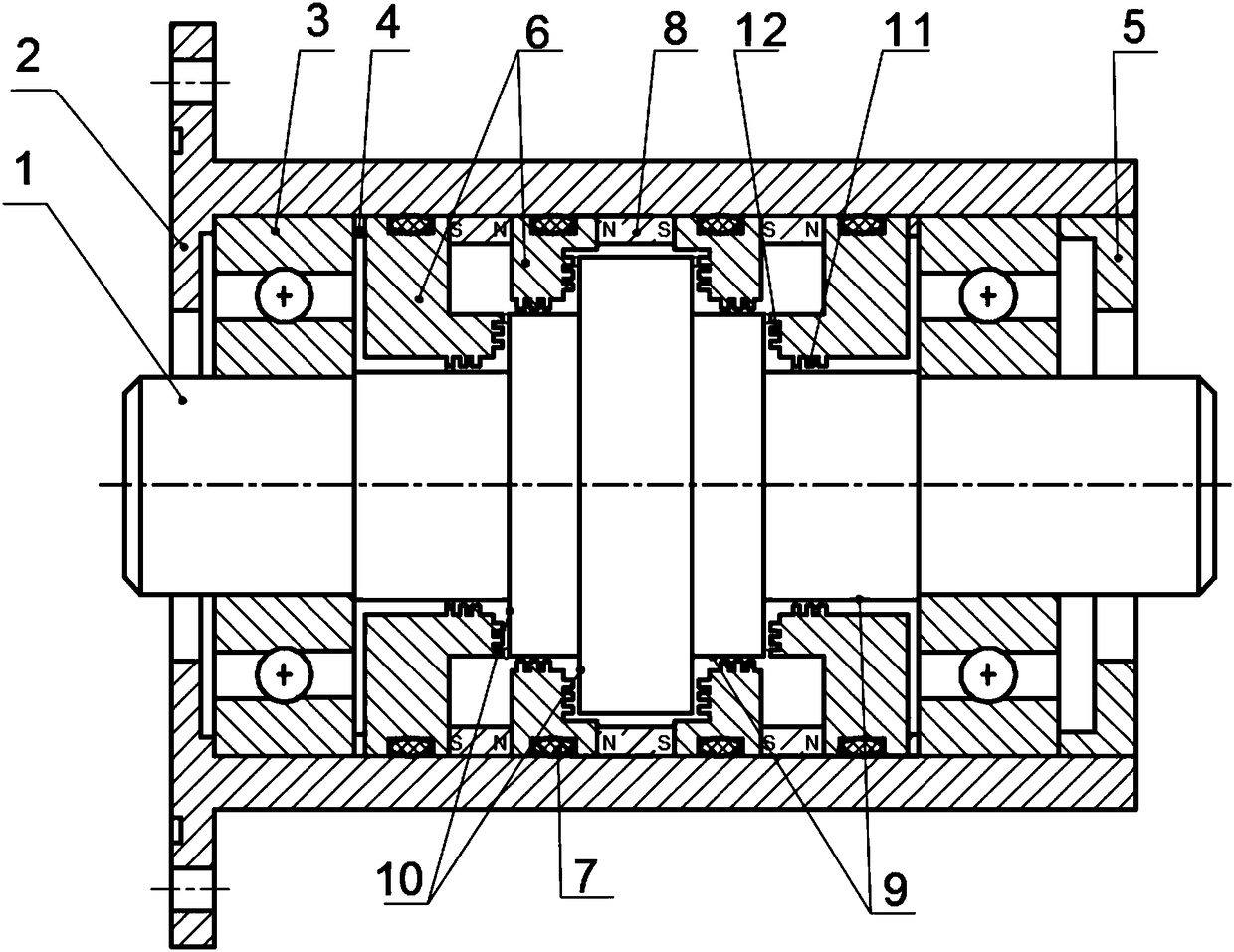

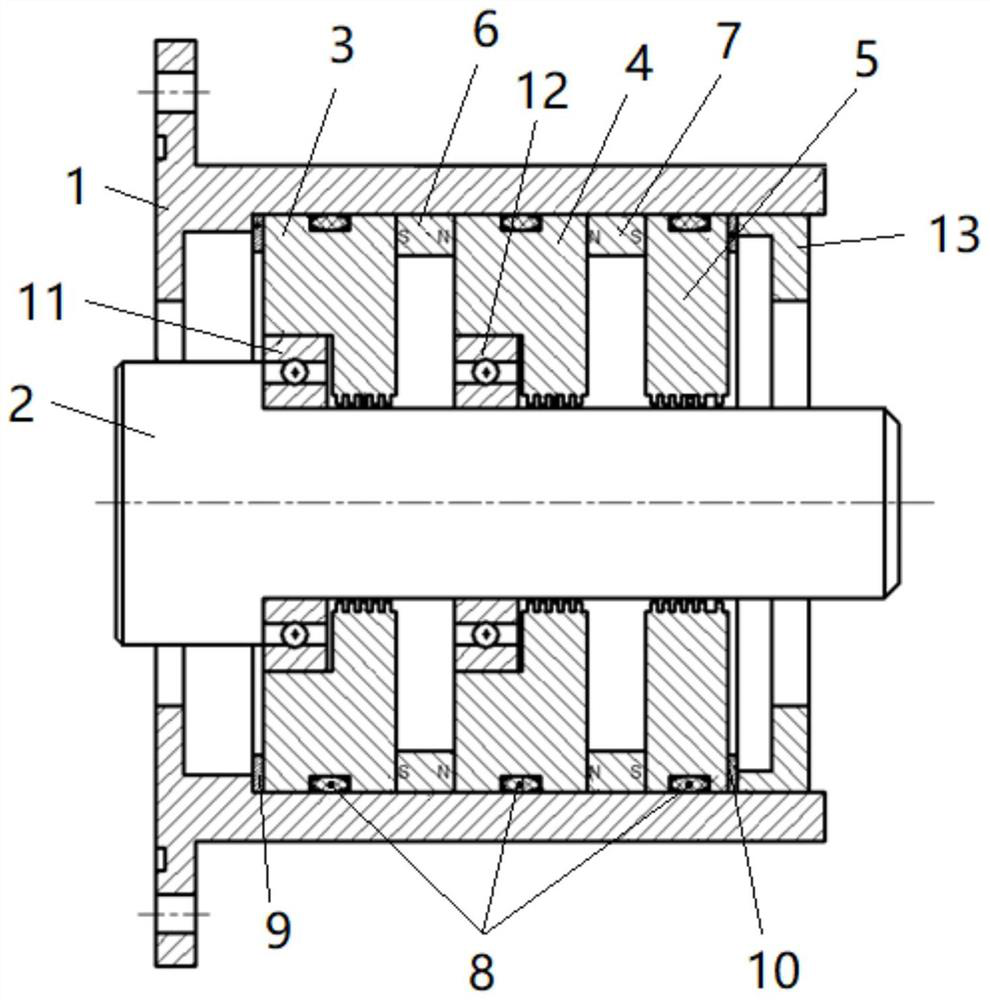

Step-type magnetofluid sealing device

The invention discloses a step-type magnetofluid sealing device. The step-type magnetofluid sealing device comprises a shaft, an outer shell, pole shoes, magnetofluid and permanent magnets. The shaftpenetrates through the outer shell and extends out of two ends of the outer shell. The shaft comprises a stepped shaft part located in the outer shell. The diameter of a middle step of the stepped shaft part is the maximum, and the diameters of the steps on the left side and the right side of the stepped shaft part are gradually reduced. The stepped shaft part is provided with a plurality of firstside surfaces parallel to the axis of the shaft and a plurality of second side surfaces perpendicular to the axis. The at least two pole shoes are arranged on the inner surface of the outer shell. Each annular permanent magnet is arranged between every two adjacent pole shoes. Each pole shoe is provided with radial pole teeth protruding towards the first side surfaces and axial pole teeth protruding towards the second side surfaces, wherein the radial pole teeth and the axial pole teeth are all annular, and the magnetofluid is arranged between the radial pole teeth and the first side surfacesas well as between the axial pole teeth and the second side surfaces. The sealing pressure resistance of the magnetofluid is greatly improved, and the problem that an existing sealing device can notmeet the high sealing performance requirement under special work conditions like high speed and heavy loads is solved.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

Strong magnetic gathering type magnetofluid sealing structure

InactiveCN108980361AIncrease the magnetic field strengthShorten the pathEngine sealsMagnetizationMagnetic reluctance

The invention discloses a strong magnetic gathering type magnetofluid sealing structure. Two first pole shoes are arranged in a space between the outer surface of a shaft and the inner wall of a shellin the axial direction in a spaced manner, and an axial magnetization type permanent magnetic ring is sandwiched between the two first pole shoes; each first pole shoe is annular; the outer circle ofthe axial magnetization type permanent magnetic ring and the outer circle of each first pole shoe are connected with the inner wall of the shell in an abutting manner; each first pole shoe comprisesa ring body; the position, on an inner ring of each ring body, of the end face of one side of the ring body is provided with a first extending ring, and the minimum inner diameter of each first extending ring is larger than the outer diameter of the shaft; the two first pole shoes are arranged in the axis direction perpendicular to the shaft in a mirror symmetry manner; the two first extending rings are oppositely arranged, a gap is reserved between the opposite end surfaces, and magnetofluid is injected to the gap position; and the shaft is made from a non-magnetism-conductive material. Due to the strong magnetic gathering type magnetofluid sealing structure, the magnetic field does not pass through the shaft, the path of the whole magnetic loop becomes shorter, the corresponding magneticresistance is lowered, the magnetic field intensity in the whole magnetic path is greatly enhanced, the magnetism gathering purpose is achieved, and the sealing pressing resisting capacity of the magnetofluid is greatly enhanced.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

A parallel magnetic fluid reciprocating sealing device

ActiveCN108006231BImprove sealingImprove sealing pressure resistanceEngine sealsMagnetic sourceEngineering

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

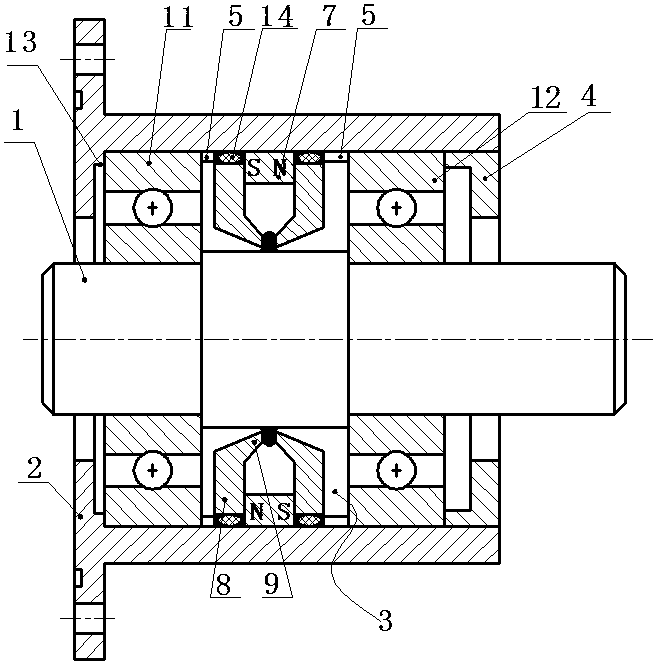

Magnetic fluid sealing structure of vapor compressing distillation device of space station

InactiveCN112303241AOvercoming wear and tearReduce power consumptionEngine sealsWater/sewage treatment by heatingRotational axisEngineering

The invention discloses a magnetic fluid sealing structure of a vapor compressing distillation device of a space station. The magnetic fluid sealing structure is arranged on a rotating shaft and an end face which need to be dynamically sealed, and comprises a shell, a sealing part, an end cover and two bearings, wherein the sealing part, the end cover and the two bearings are located in the shelland arranged the rotating shaft in a sleeving mode, the shell is sleeved on the rotating shaft in a sleeving mode, and the first end of the shell is connected with the end face; the sealing part comprises a pole shoe assembly, a left magnetism isolating ring, a right magnetism isolating ring and permanent magnets, and the left magnetism isolating ring and the right magnetism isolating ring are located on the two sides of the pole shoe assembly; the pole shoe assembly comprises at least two pole shoes, a plurality of pole teeth are arranged on the inner circle face of each pole shoe in a protruding mode, sealing gaps are formed between the pole teeth and the rotating shaft, the sealing gaps are filled with magnetic fluid, and the outer circle faces of the pole shoes are in sealing connection with the inner wall face of the shell; the permanent magnets are arranged between every two adjacent pole shoes, and the magnetic poles of the adjacent sides of every two adjacent permanent magnetsare the same; a step for being attached to the left magnetism isolating ring is arranged on the inner wall face of the shell in an inward protruding mode, and the end cover is installed at the secondend of the shell and used for pressing the sealing part; and the bearings are installed in installation grooves concavely formed in the inner circular faces of the pole shoes.

Owner:SHANGHAI AEROSPACE SYST ENG INST +1

Multi-magnetic-resource sleeve type magnetofluid sealing device

ActiveCN108799507AImprove sealing pressure resistanceImprove self-healing abilityEngine sealsEngineeringMagnet

The invention relates to a multi-magnetic-resource sleeve type magnetofluid sealing device. The device comprises more than one magnetofluid sealing units, wherein each magnetofluid sealing unit comprises a housing, a left pole shoe ring, a right pole shoe ring, a sleeve, a first left permanent magnet ring, a second left permanent magnet ring, an intermediate permanent magnet ring, a first right permanent magnet ring and a second right permanent magnet ring. With the adoption of the device the problem of low pressure resistance of an existing single-magnetic-resource magnetofluid sealing devicecan be solved; in addition, the device is simple to process, and convenient to assemble, so that the sealing technology can be smoothly applied to the fields such as the field of high speed and heavyload.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

Facing tooth stepped type magnetofluid sealing device

The invention aims at providing a facing tooth stepped type magnetofluid sealing device. The facing tooth stepped type magnetofluid sealing device comprises a stepped shaft, a shell, a left pole shoering, a right pole shoe ring, a left permanent magnet ring, a middle permanent magnet ring and a right permanent magnet ring. The stepped shaft comprises a first-level shaft with the largest diameter,and two more or sets of secondary first-level shafts with the diameters gradually reduced. The secondary first-level shafts are sequentially arranged to the two sides along the side face of the first-level shaft and are symmetric about the middle radial section of the first-level shaft left and right. The magnetism gathering effect can be improved, thus, the magnetofluid sealing pressure endurance capacity is improved, meanwhile, magnetofluid sealing failure caused by the centrifugal force effect can be effectively avoided, losses of magnetofluid are reduced, the reliability of sealing is improved, and the service life of sealing is prolonged.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

A multi-magnetic source sleeve type magnetic fluid sealing device

ActiveCN108799507BImprove sealing pressure resistanceImprove self-healing abilityEngine sealsMagnetic sourceMagnet

The invention relates to a multi-magnetic-resource sleeve type magnetofluid sealing device. The device comprises more than one magnetofluid sealing units, wherein each magnetofluid sealing unit comprises a housing, a left pole shoe ring, a right pole shoe ring, a sleeve, a first left permanent magnet ring, a second left permanent magnet ring, an intermediate permanent magnet ring, a first right permanent magnet ring and a second right permanent magnet ring. With the adoption of the device the problem of low pressure resistance of an existing single-magnetic-resource magnetofluid sealing devicecan be solved; in addition, the device is simple to process, and convenient to assemble, so that the sealing technology can be smoothly applied to the fields such as the field of high speed and heavyload.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

A labyrinth magnetic fluid sealing device

ActiveCN106015360BAchieve axial positioningPrevent leakageEngine sealsBearing componentsCircular surfaceMagnet

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

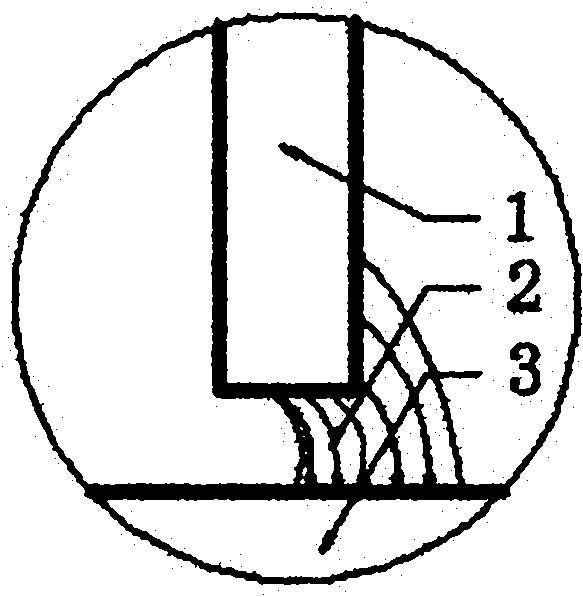

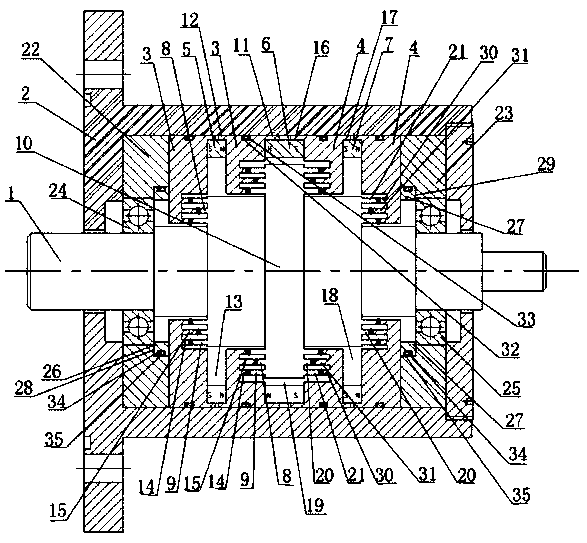

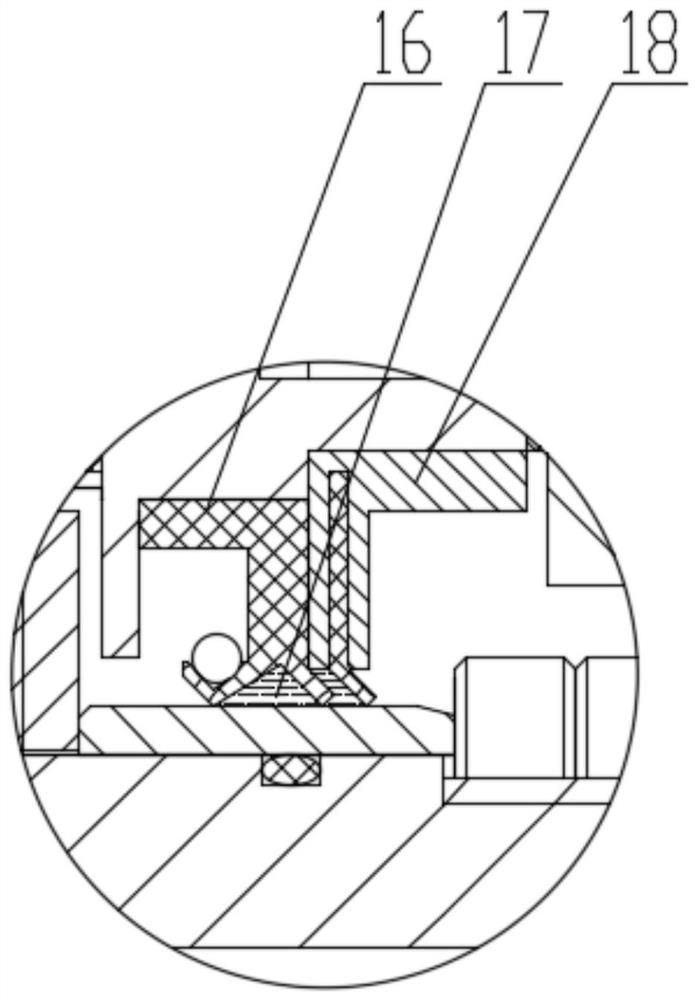

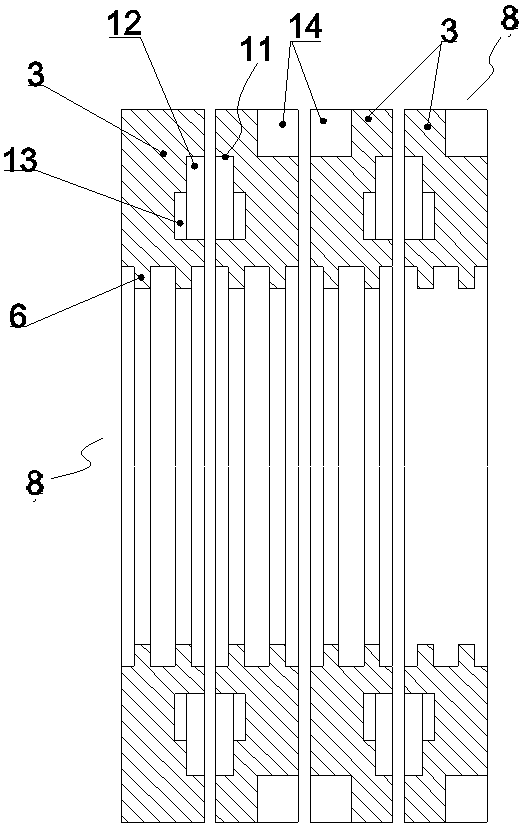

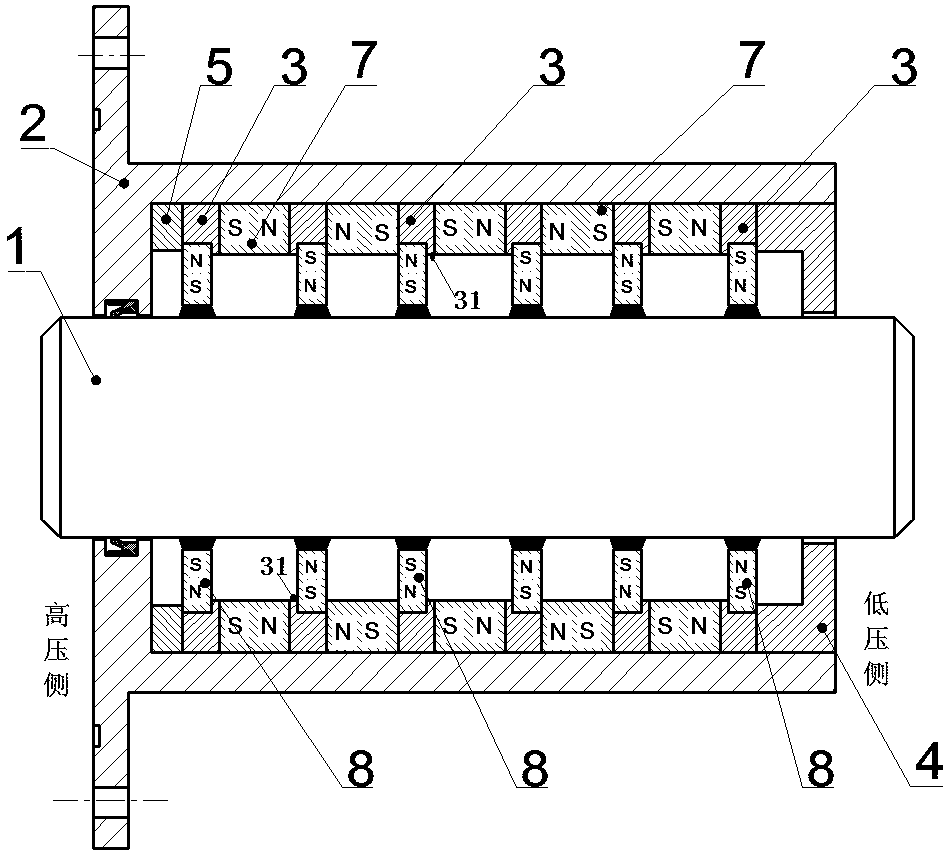

Variable-tooth and variable-gap type magnetic fluid reciprocating sealing structure for hydraulic cylinder

PendingCN108775304AImprove the pressure resistance performance of the sealImprove sealing pressure resistanceEngine sealsFluid-pressure actuatorsEngineeringHigh pressure

The invention discloses a variable-tooth and variable-gap type magnetic fluid reciprocating sealing structure for a hydraulic cylinder. Multiple annular pole shoes are arranged in the space between the outer surface of a piston rod and the inner wall of the shell in the axial direction at intervals, pole teeth are arranged on the inner circumferential face of each pole shoe, an axial magnetizing type permanent magnetic ring is clamped between every two adjacent pole shoes, the polarities of magnetic poles of every two adjacent axial magnetizing type permanent magnetic rings are opposite, gapsare formed between the pole teeth and the outer surface of the piston rod and filled with magnetic fluid, the sizes of the gaps between the pole teeth and the outer surface of the piston rod are sequentially decreased in the direction from the high-pressure side to the low-pressure side, and the sizes of the gaps between all the pole teeth arranged on the same pole shoe and the outer surface of the piston rod are equal. According to the variable-tooth and variable-gap type magnetic fluid reciprocating sealing structure for the hydraulic cylinder, the condition that the pressure endurance capability is gradually enhanced, and the magnetic fluid leakage resistance is gradually increased is formed through the structure change, and then the effect of further improving the sealing pressure resistance is achieved.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

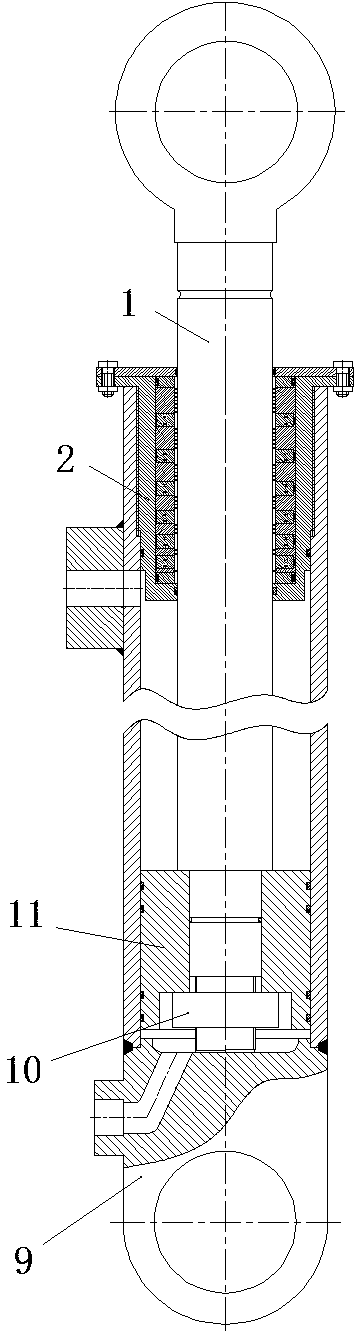

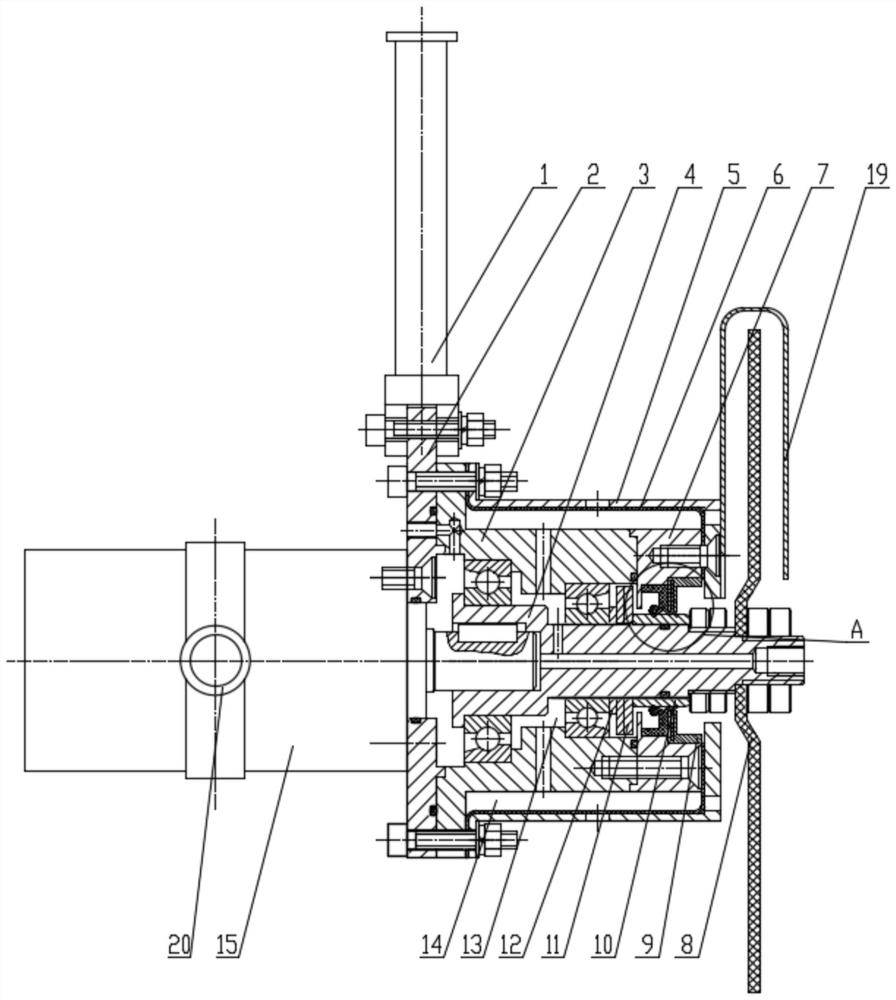

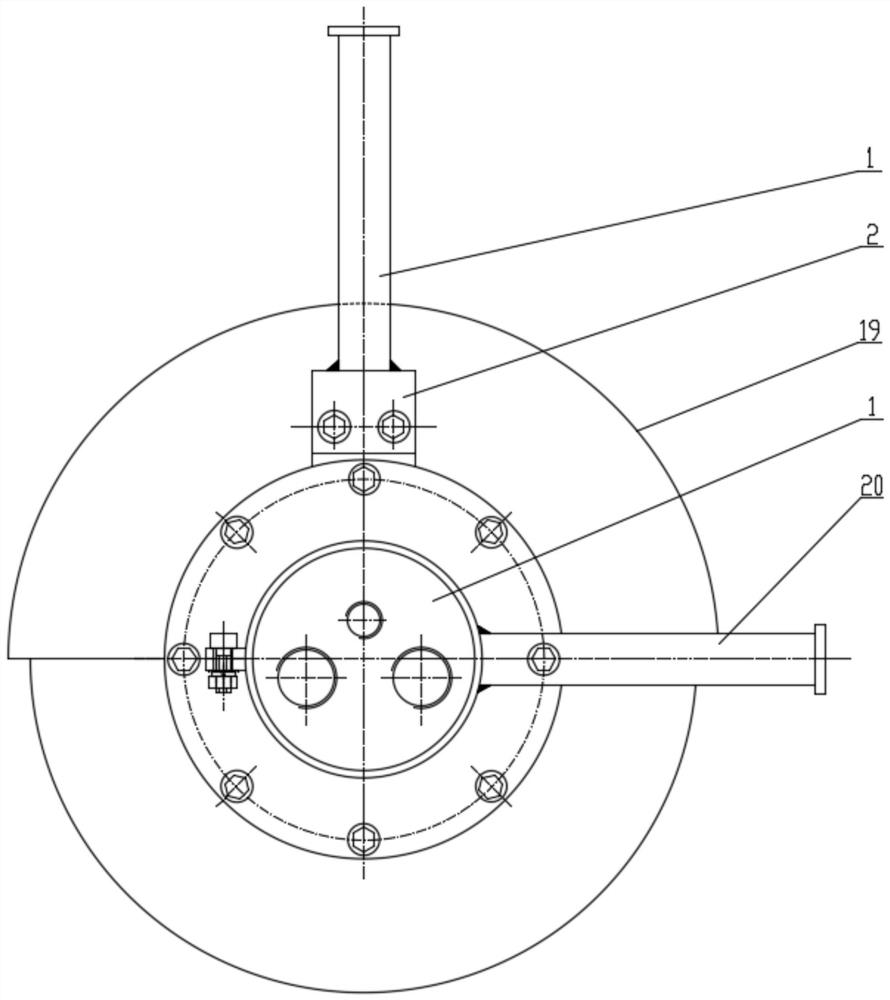

A Pressure Adaptive High Speed Lightweight Underwater Cutting Tool

A pressure-adaptive high-speed light underwater cutting tool, including a power element, the output shaft of which is stepped, and bearing chamber shells are installed on the outer circumferential surfaces of the first stepped surface and the second stepped surface through deep groove ball bearings One end of the housing of the bearing cavity is equipped with a flange through a fastener, and the first handle is installed on the upper part of the flange, and the flange is locked with the power element at the same time; the outer part of the deep groove ball bearing on the second step surface is installed with a A gasket and a pair of disc springs, a sleeve is installed on the second stepped surface outside the disc spring, and a shaft seal assembly is installed on the outside of the sleeve; the outer end surface of the bearing chamber housing is equipped with an end cover through a seal, and the bearing chamber housing A compensation film protection cover is installed at a distance from the outer ring of the end cover at the same time, and a rubber compensation film is installed on the inner wall of the compensation film protection cover, which works reliably and is convenient for divers to work underwater.

Owner:CHINA SHIP SCIENTIFIC RESEARCH CENTER (THE 702 INSTITUTE OF CHINA SHIPBUILDING INDUSTRY CORPORATION)

A hybrid magnetic fluid seal structure

ActiveCN108953615BIncrease contact areaImprove sealing pressure resistanceEngine sealsCondensed matter physicsMaterials science

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

A serial magnetic fluid seal structure

ActiveCN108843791BIncrease the magnetic field strengthImprove sealing pressure resistanceEngine sealsMagnetic polesMagnetization

The invention discloses a serial-connected magnetofluid sealing structure. Multiple first pole shoes are arranged in space between the outer surface of a shaft and the inner wall of a shell; axial magnetizing permanent magnet rings are clamped between two adjacent first pole shoes; radial magnetizing permanent magnet rings sleeve the inner circular surfaces of all the first pole shoes; second poleshoes sleeve the inner circular surfaces of all the radial magnetizing permanent magnet rings; pole teeth are arranged on the inner circular surfaces of the second pole shoes; magnetofluid is injected between the pole teeth and the outer surface of the shaft; the polarities of magnetic poles of two adjacent radial magnetizing permanent magnet rings are opposite; each radial magnetizing permanentmagnet ring is positioned in a magnetic loop consisting of the axial magnetizing permanent magnet rings and the first pole shoes on two sides thereof; and the magnetic field directions of the radial magnetizing permanent magnet rings are the same with the magnetic loop directions thereof. The serial-connected magnetofluid sealing structure improves the magnetic field intensity, improves the sealing and pressure resisting capacity, enables magnetofluid seals in all gaps to exert effects through gradual increment of saturated magnetization strength of the magnetofluid in different gaps, and guarantees the sealing and pressure resisting performances.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

A magnetic source hybrid magnetic fluid sealing structure

ActiveCN108869755BImprove sealingIncrease the magnetic field strengthEngine sealsMagnetic sourceMagnetic poles

The invention discloses a magnetic source mixing type magnetofluid sealing structure. The magnetic source mixing type magnetofluid sealing structure comprises a shell, a shaft and a plurality of poleshoes, wherein the pole shoes are arranged in the axial direction at intervals; an axial magnetizing type permanent magnet ring is sandwiched between each two adjacent pole shoes; the polarities of magnetic poles of each two adjacent axial magnetizing type permanent magnet rings are opposite; a radial magnetizing type permanent magnet ring is inserted in the inner circle surface of each pole shoe;a gap exists between the inner circle surface of each radial magnetizing type permanent magnet ring and the outer surface of the shaft and is injected with magnetofluid; the polarities of magnetic poles of each two adjacent radial magnetizing type permanent magnet rings are opposite; each radial magnetizing type permanent magnet ring is positioned in a magnetic loop formed by the corresponding axial magnetizing type permanent magnet ring and the pole shoes on the two sides of the corresponding axial magnetizing type permanent magnet ring; and the magnetic field direction of each radial magnetizing type permanent magnet ring is the same as the direction of the magnetic loop in which the radial magnetizing type permanent magnet ring is located. The magnetic field intensity is increased, sealing and pressure-resistant pressure are enhanced, magnetofluid seals in all the gaps can play a role, and the sealing pressure resistance is ensured.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

An anti-leakage magnetic fluid sealing structure

ActiveCN108869754BAchieve reciprocating sealImprove sealing pressure resistanceEngine sealsMagnetic polesPole piece

The invention discloses a magnetic flux leakage magnetic fluid sealing structure. A plurality of annular pole shoes are axially arranged in a space between the outer surface of a shaft and the inner wall of a shell at intervals, an axial magnetizing permanent magnet ring is clamped between two adjacent pole shoes, magnetic poles of two adjacent axial magnetizing permanent magnet ring are oppositein polarity, a shaft sleeve sleeving a shaft is arranged between every two adjacent pole shoes, the outer diameter of the shaft sleeve is smaller than the inner diameter of each axial magnetizing permanent magnet ring, gaps are reserved among two side end faces of the shaft sleeve and the end faces of the adjacent pole shoes, and a gap is reserved between the inner circumferential surface of eachpole shoe and the outer surface of the shaft and filled with magnetic fluids. Axial and radial sealing can be achieved, and sealing pressure resistance is enhanced. After leakage paths are changed, path lengths are increased, magnetic fluid loss can be reduced, and self-repairing capability is enhanced.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

Magnetic source mixing type magnetofluid sealing structure

ActiveCN108869755AImprove sealingIncrease the magnetic field strengthEngine sealsMagnetic sourceMagnetic poles

The invention discloses a magnetic source mixing type magnetofluid sealing structure. The magnetic source mixing type magnetofluid sealing structure comprises a shell, a shaft and a plurality of poleshoes, wherein the pole shoes are arranged in the axial direction at intervals; an axial magnetizing type permanent magnet ring is sandwiched between each two adjacent pole shoes; the polarities of magnetic poles of each two adjacent axial magnetizing type permanent magnet rings are opposite; a radial magnetizing type permanent magnet ring is inserted in the inner circle surface of each pole shoe;a gap exists between the inner circle surface of each radial magnetizing type permanent magnet ring and the outer surface of the shaft and is injected with magnetofluid; the polarities of magnetic poles of each two adjacent radial magnetizing type permanent magnet rings are opposite; each radial magnetizing type permanent magnet ring is positioned in a magnetic loop formed by the corresponding axial magnetizing type permanent magnet ring and the pole shoes on the two sides of the corresponding axial magnetizing type permanent magnet ring; and the magnetic field direction of each radial magnetizing type permanent magnet ring is the same as the direction of the magnetic loop in which the radial magnetizing type permanent magnet ring is located. The magnetic field intensity is increased, sealing and pressure-resistant pressure are enhanced, magnetofluid seals in all the gaps can play a role, and the sealing pressure resistance is ensured.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

A magnetic fluid sealing device for a convex stepped shaft

ActiveCN107893853BSolve the problem of insufficient pressure resistanceImprove sealing pressure resistanceEngine sealsClassical mechanicsStructural engineering

The invention relates to a magnetic fluid sealing device for a convex stepped shaft, comprising a casing, a sealing assembly and an end cover; the sealing assembly includes a shaft, the shaft is rotatably installed in the casing through a bearing, and the shaft includes at least one convex stepped portion, so The convex stepped portion includes a plurality of steps arranged in sequence along the axial direction, and the outer walls of adjacent steps are connected by an arc-shaped chamfer-shaped transition surface; The pole piece extends to one side or both sides of the transition surface to the position corresponding to the corresponding step on the side of the transition surface, and there is a gap between the inner wall of the pole piece and the corresponding transition surface and the step. Pole teeth are provided on the shaft corresponding to the inner wall of the pole piece; permanent magnets are arranged between adjacent pole pieces. The invention has the advantages of strong pressure resistance ability, secondary pressure bearing ability and self-repair ability, strong pressure resistance ability and sealing reliability of the magnetic fluid seal under the condition of large gap, and large safe working range.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

A stepped shaft type magnetic fluid sealing device

ActiveCN107816553BImprove sealing pressure resistanceReduce lossesEngine sealsShaftsHeavy loadMagnet

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com