Magnetic liquid for improving pressure resistance capability in case of magnetic liquid seal

A technology of magnetic liquid and pressure resistance, which is applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of decreased pressure resistance of magnetic liquid, uneven distribution of magnetic solid particles, etc., to achieve improved distribution, low cost, The effect of improving the sealing pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

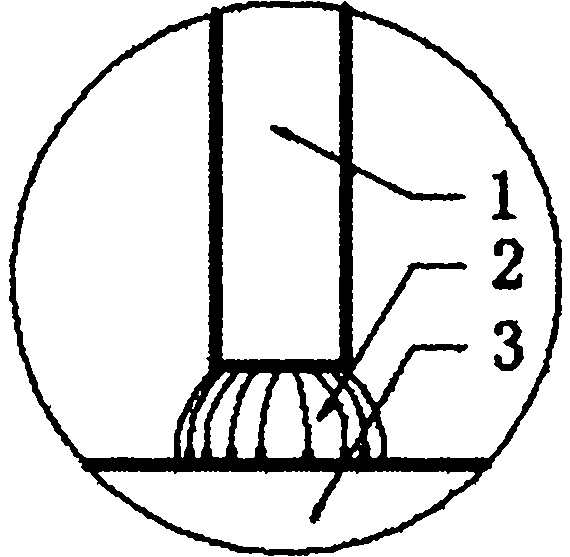

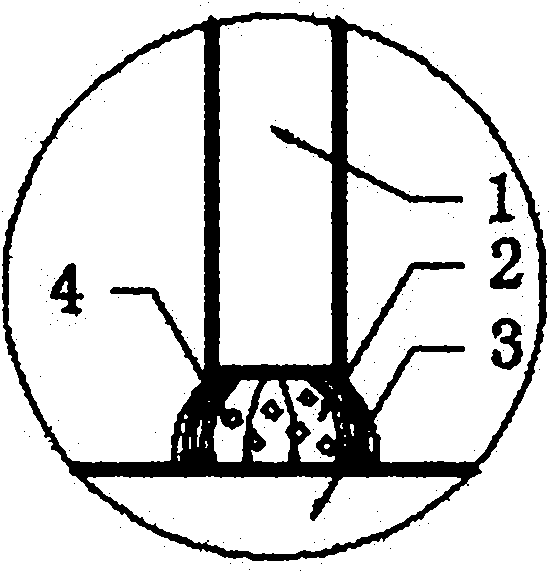

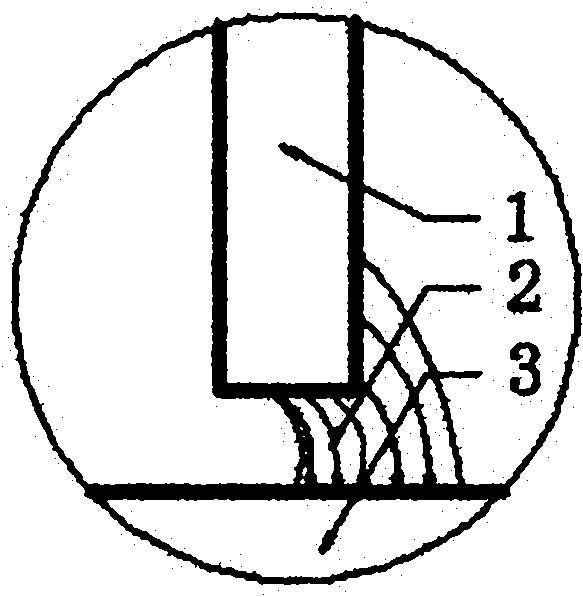

Method used

Image

Examples

Embodiment approach 1

[0017] In the purchased diester-based magnetic liquid, 1 μm non-magnetic solid particle silicon oxide powder with a volume of 9% of the volume of the magnetic liquid was added, and stirred for 40 minutes.

Embodiment approach 2

[0019] Into the purchased diester-based magnetic liquid, add 50 μm non-magnetic solid particle silicon oxide powder with a volume of 9% of the volume of the magnetic liquid, and stir for 30 minutes.

Embodiment approach 3

[0021] Add 30 μm non-magnetic solid particles of aluminum oxide powder with a volume of 10% of the volume of the magnetic liquid to the purchased diester-based magnetic liquid, and stir for 30 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com