Embedded maze type magnetic fluid sealing device

A ferrofluid sealing and labyrinth technology, which is applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of low pressure resistance performance, achieve the effect of improving pressure resistance performance, reducing losses, and expanding the safe working range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with accompanying drawing.

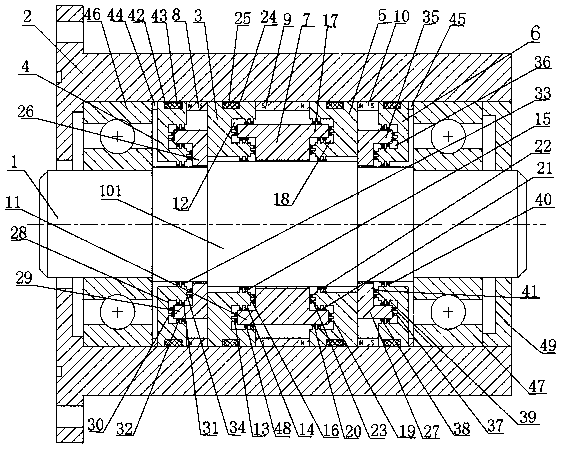

[0036] Such as figure 1 As shown, the embedded labyrinth magnetic fluid seal device includes a stepped shaft 1, a housing 2, a left pole shoe ring 3, a right pole shoe ring 5, a middle sleeve 7, and a middle permanent magnet ring 9;

[0037] The stepped shaft 1 includes a primary shaft 101 with the largest diameter and more than one set of secondary shafts with successively decreasing diameters. The secondary shafts are arranged on both sides along the side of the primary shaft 101, with 1 The middle radial cross-section of the stage shaft 101 is left-right symmetrical;

[0038] The left one pole shoe ring 3, the middle permanent magnet ring 9, and the right one pole shoe ring 5 are sequentially set on the inner wall of the housing 2, and the right end face of the left one pole shoe ring 3 is in contact with the left end face of the middle permanent magnet ring 9 , the ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com