A Split Labyrinth Magnetic Fluid Sealing Device

A magnetic fluid sealing and splitting technology, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of not allowing disassembly, time-consuming, low sealing pressure resistance, etc., to expand the safety work. range, overcoming the effect of low sealing performance and reliable sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

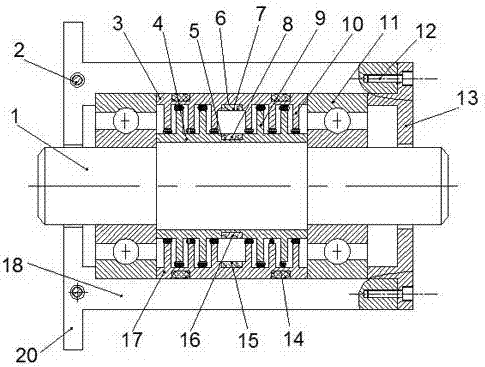

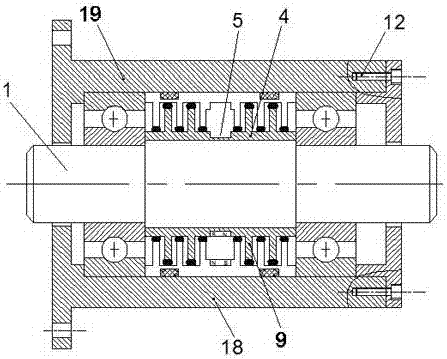

[0023] Such as Figure 1-2 A split-type labyrinth-type ferrofluid sealing device shown includes a shaft 1, a housing, an inner pole shoe ring 4, a split-type outer pole shoe, a split-type inner permanent magnet, and a split-type outer permanent magnet. The shaft 1 is installed in the shell, the outer circle of the shaft 1 is the same as the axis of the inner circle of the shell, the inner pole shoe ring 4 is set on the shaft 1, and the outer circle of the inner pole shoe ring 4 is A concave annular groove I5 is provided in the middle of the surface, and the outer circular surface of the inner pole shoe ring 4 is divided into a left half surface I and a right half surface I by the said annular groove I5, and the said left half surface I and the right half surface I are respectively More than two sets of annular pole teeth I9 are set at intervals;

[0024] The split-ty...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com