Microminiature feeding and discharging valve

A kind of technology of adding and exhausting valves, which is applied in valve devices, engine components, mechanical equipment, etc., can solve the problems of low sealing performance of adding and exhausting valves, large volume of adding and exhausting valves, etc., reducing space requirements and overcoming poor sealing performance. Low, maneuverable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with accompanying drawing description and specific embodiment:

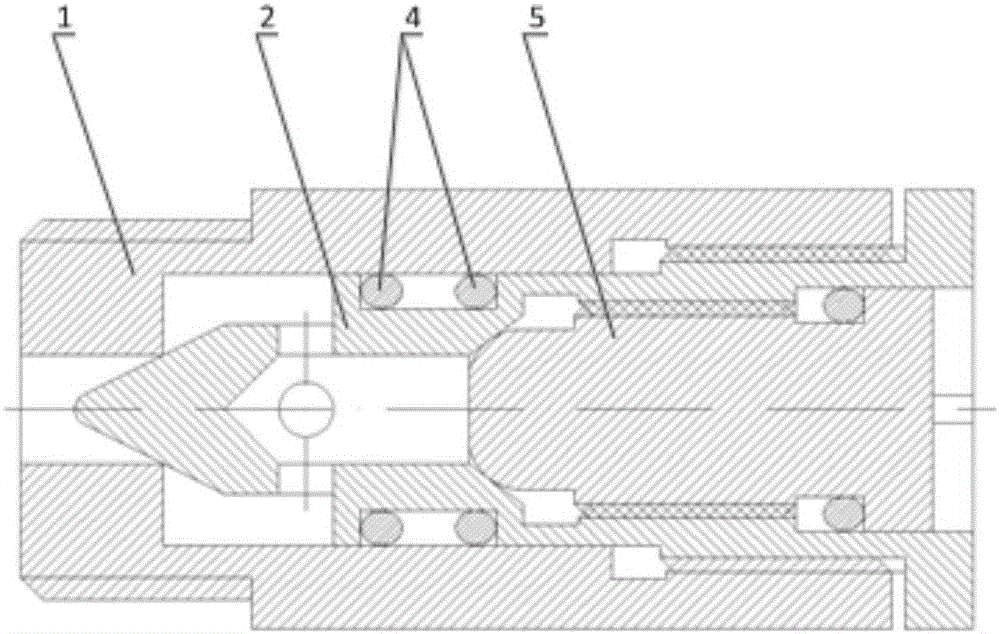

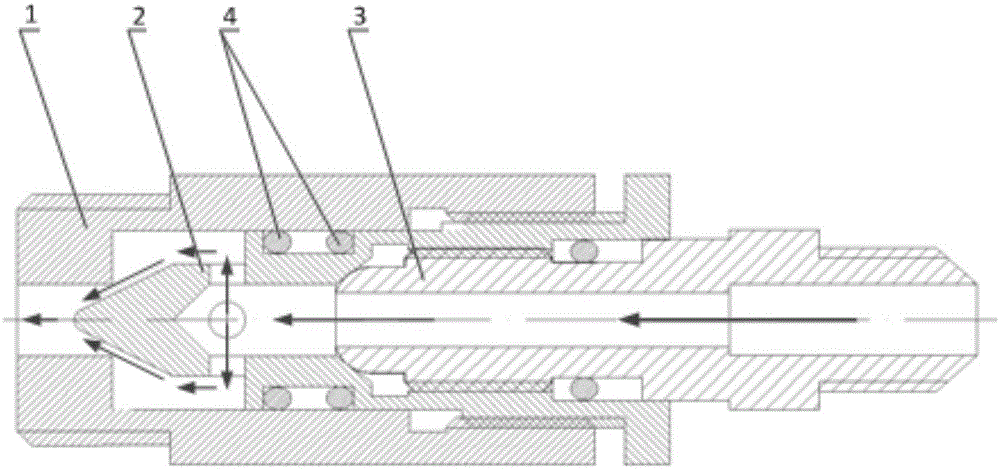

[0033] Such as figure 1 or image 3 As shown in the figure, a miniature discharge valve includes a housing 1, a valve core 2 and an adapter 3; The other end fits with the adapter 3.

[0034] The housing 1 and the valve core 2 are sealed by a sealing ring 4 , and the valve core 2 is sealed by a plug 5 .

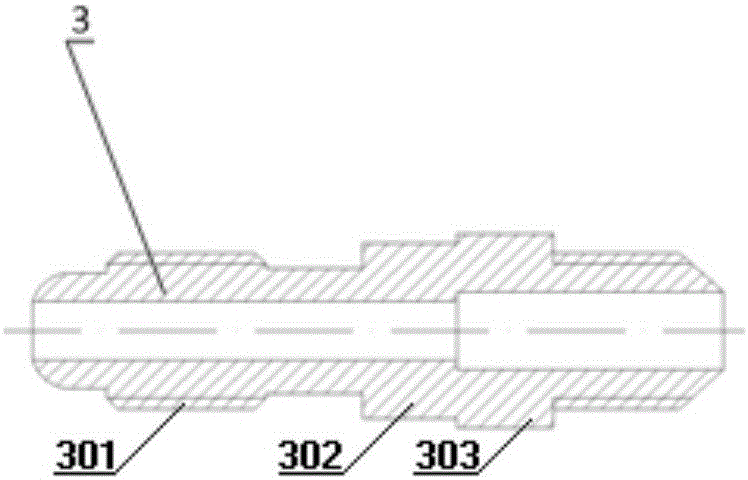

[0035] Such as figure 2 As shown, the adapter 3 is a cylindrical structure, and the adapter 3 is provided with a first flange 301, a second flange 302 and a third flange 303 in sequence, and the first flange 301, the second flange 302 and the third flange The radius ratio of the flange 303 is 3:4:5, and both ends of the adapter 3 are chamfered.

[0036] The housing 1 has a cylindrical structure, and a stepped through hole for matching the valve core 2 is provided in the housing 1, and both the housing 1 and the plug 5 are made of ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com