Method for improving pressure-resistant capacity and working reliability of magnetic fluid seal in high-temperature working environment

A magnetic liquid and working environment technology, applied in the direction of engine seals, engine components, mechanical equipment, etc., can solve the problems of magnetic performance decline, magnetic liquid seal pressure resistance drop, seal gap increase, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

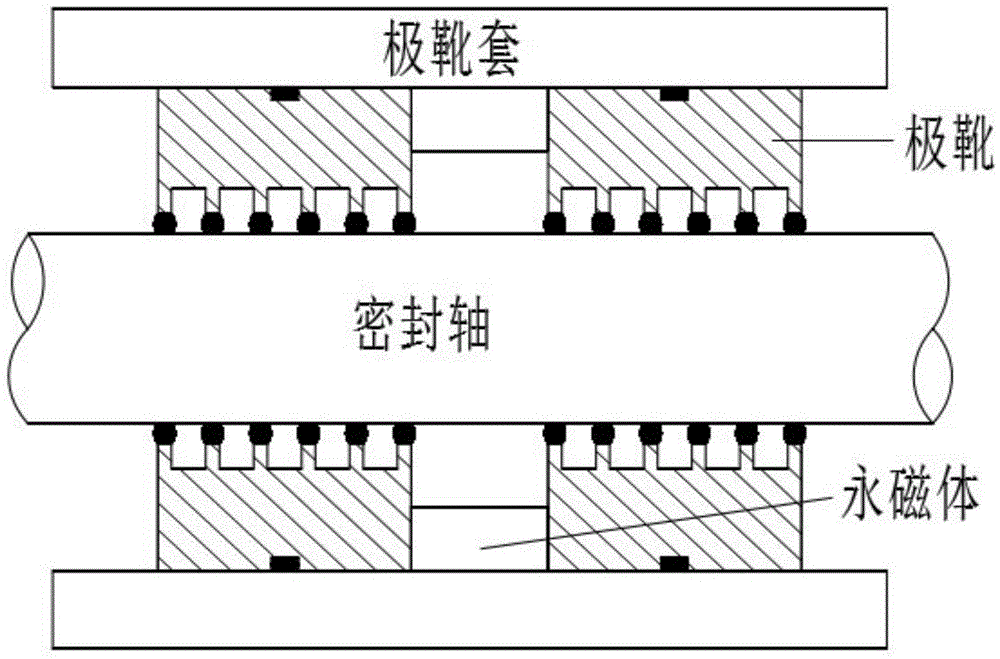

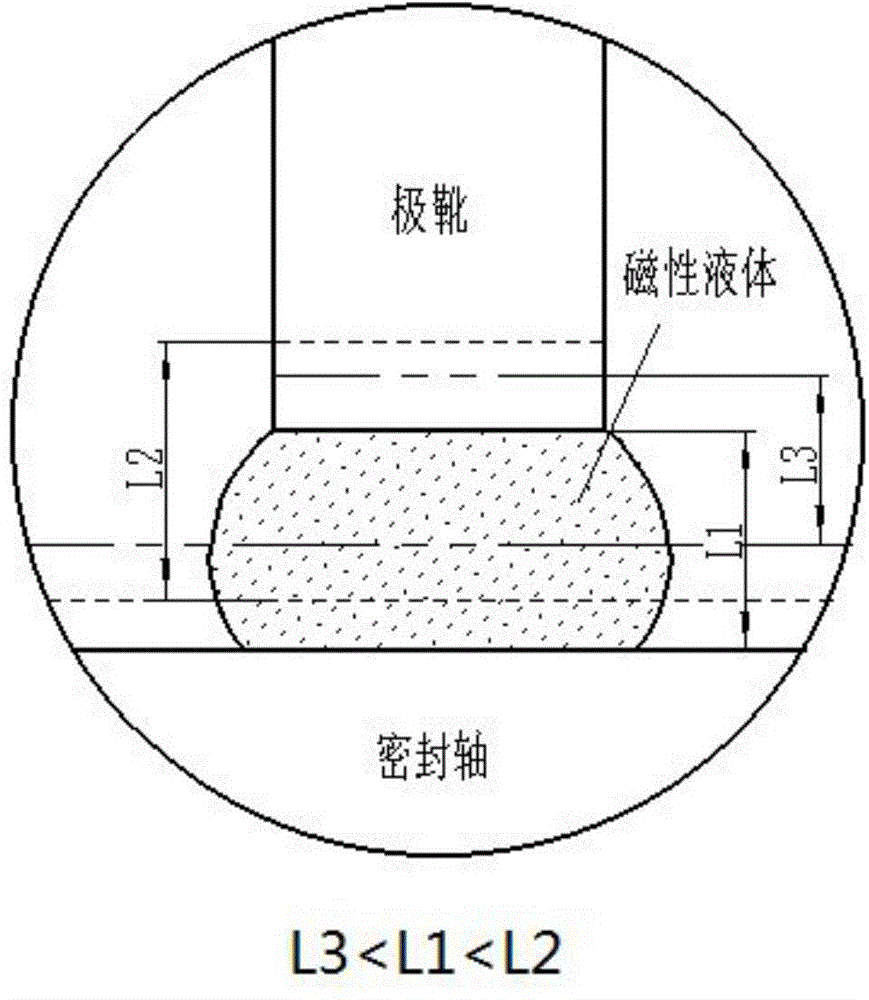

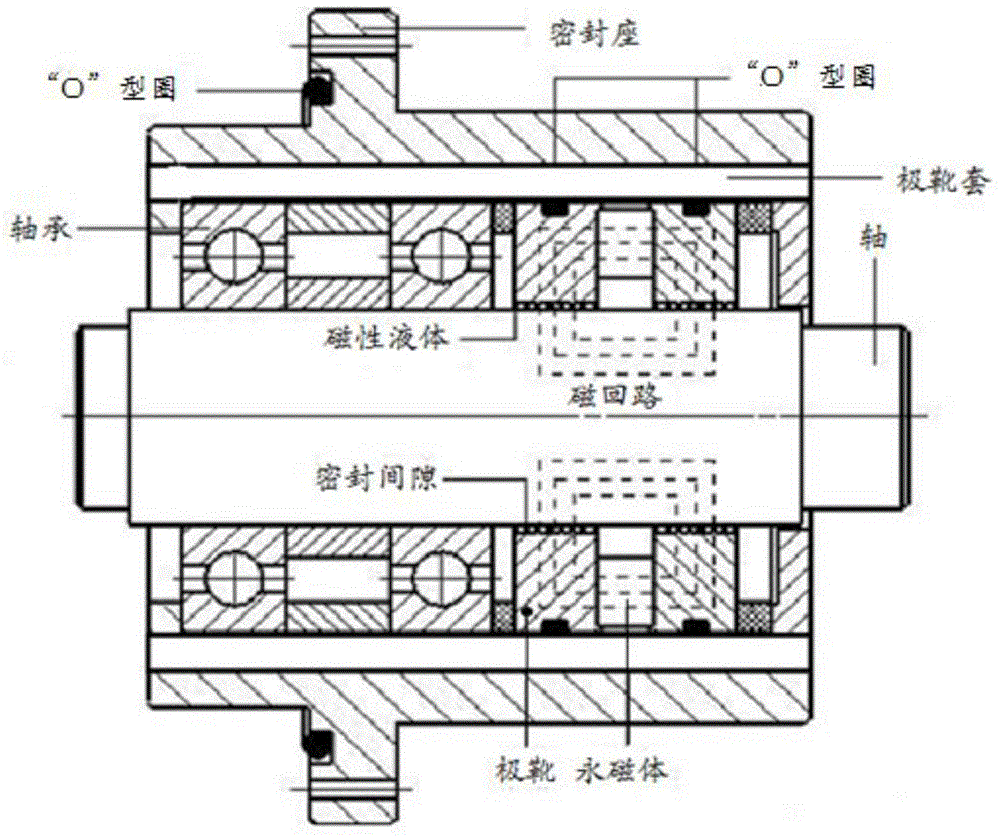

[0019] Choose 4J36 alloy and 45 steel, use 45 steel to make the pole shoe and seal shaft that cooperate with each other, and use the 4J36 alloy to make the pole shoe cover that is interference fit with the outer ring of the two pole shoes. Among them, the diameter of the sealing shaft is 80mm, the outer diameter of the pole piece is 120mm, and the radial width of the pole piece cover is 20mm. The pole piece and the sealing shaft are combined with other parts to form a magnetic liquid sealing device with a gap of 0.2mm. This device is applied to magnetic liquid sealing under the high temperature condition of 100°C.

Embodiment approach 2

[0021] Choose 4J36 alloy and 45 steel, use 45 steel to make the pole shoe and seal shaft that cooperate with each other, and use the 4J36 alloy to make the pole shoe cover that is interference fit with the outer ring of the two pole shoes. The diameter of the sealing shaft is 50mm, the outer diameter of the pole shoe is 80mm, and the radial width of the pole shoe cover is 15mm. The pole shoe and the sealing shaft are combined with other parts to form a magnetic liquid sealing device with a gap of 0.1mm. This device is applied to the magnetic liquid seal under the high temperature condition of 200°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com