Patents

Literature

196results about How to "Small amount of shrinkage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

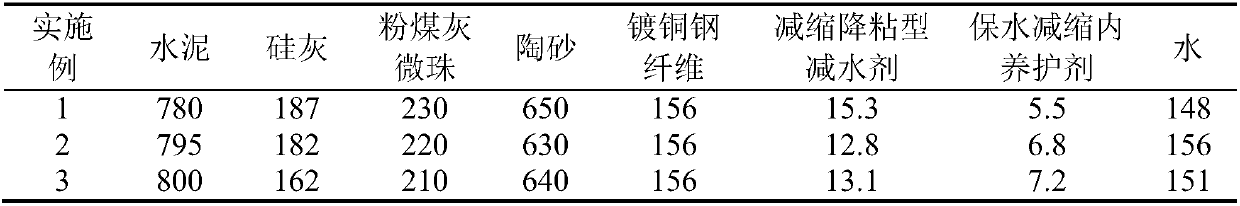

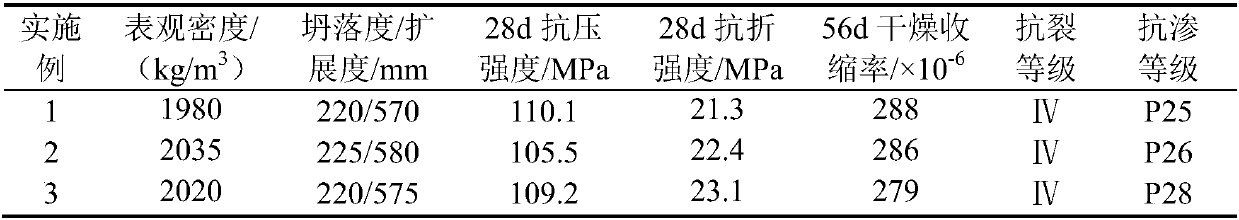

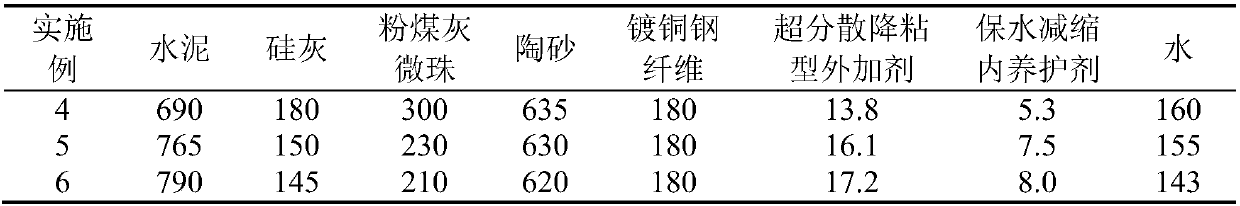

Light low-shrinkage super-high performance concrete and preparation method thereof

The invention discloses light low-shrinkage super-high performance concrete which is prepared from cement, coal ash beads, silica fume, pottery sand, a brass coated steel fiber, shrinkage and viscosity reduction type water reduction agent, a water-retention shrinkage-reduction inner curing agent and water as main raw materials. According to the concrete, the pottery sand is adopted as aggregate, the self weight of the concrete is reduced, and a high-strength and dense 'arch housing' interface area is formed on the surface of the pottery sand by using a pre-mixing process, so that the interfacestrength is improved, and the mechanical properties and the anti-penetrability performance of the concrete are improved; due to the adoption of the shrinkage and viscosity reduction type water reduction agent and the coal ash beads, the working performance and the density of the concrete are improved; due to the adoption of the pre-wetted pottery sand and the developed water-retention shrinkage-reduction inner curing agent, reduction of wetness inside the concrete is retarded, the self-shrinkage and the drying shrinkage of the concrete are reduced, and the volume stability of the concrete isimproved. While the self weight of the concrete is reduced, the light low-shrinkage super-high performance concrete disclosed by the invention is good in working performance, mechanical property, anti-penetrability and durability, and has significant practical application values.

Owner:WUHAN UNIV OF TECH

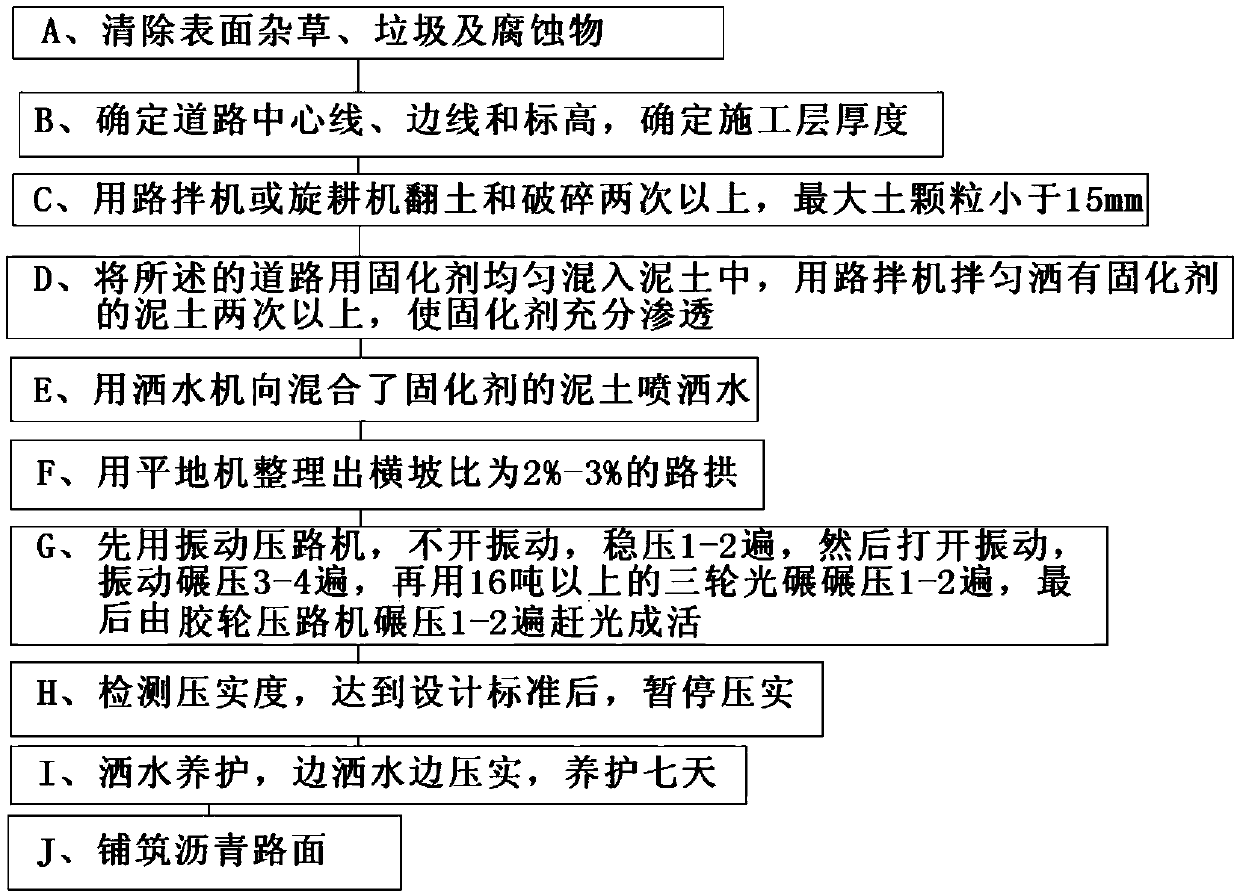

Hardening agent for road and roadbed hardening method

ActiveCN105367010AImprove physical and mechanical propertiesImprove engineering propertiesSolid waste managementEpoxyPhosphate

The invention discloses a hardening agent for a road. The hardening agent is prepared from, by weight, 10-15% of cement, 1-5% of lime, 2-3% of fly ash, 2-3% of gypsum, 1-2% of coal gangue, 1-2% of zeolite, 3-15% of sulfonated oil, 1-2% of phosphate, 1-2% of caustic alkali, 1-2% of potassium permanganate, 2-4% of sodium chloride, 2-4% of sodium carbonate, 2-3% of calcium carbonate, 2-3% of silicon powder, 1-2% of asphalt, 5-10% of sodium silicate, 1-2% of polyacrylamide, 1-2% of polyacrylic acid, 1-2% of magnesium sulfate, 1-2% of calcium carbonate, 7-10% of tar, 0.1-1% of epoxy resin, 0.6-1% of aniline furfural, 0.3-1% of calcium acrylate and 0.5-2% of carboxymethyl cellulose. The invention discloses a roadbed hardening method. The hardening agent for the road is adopted for hardening.

Owner:郑卫忠

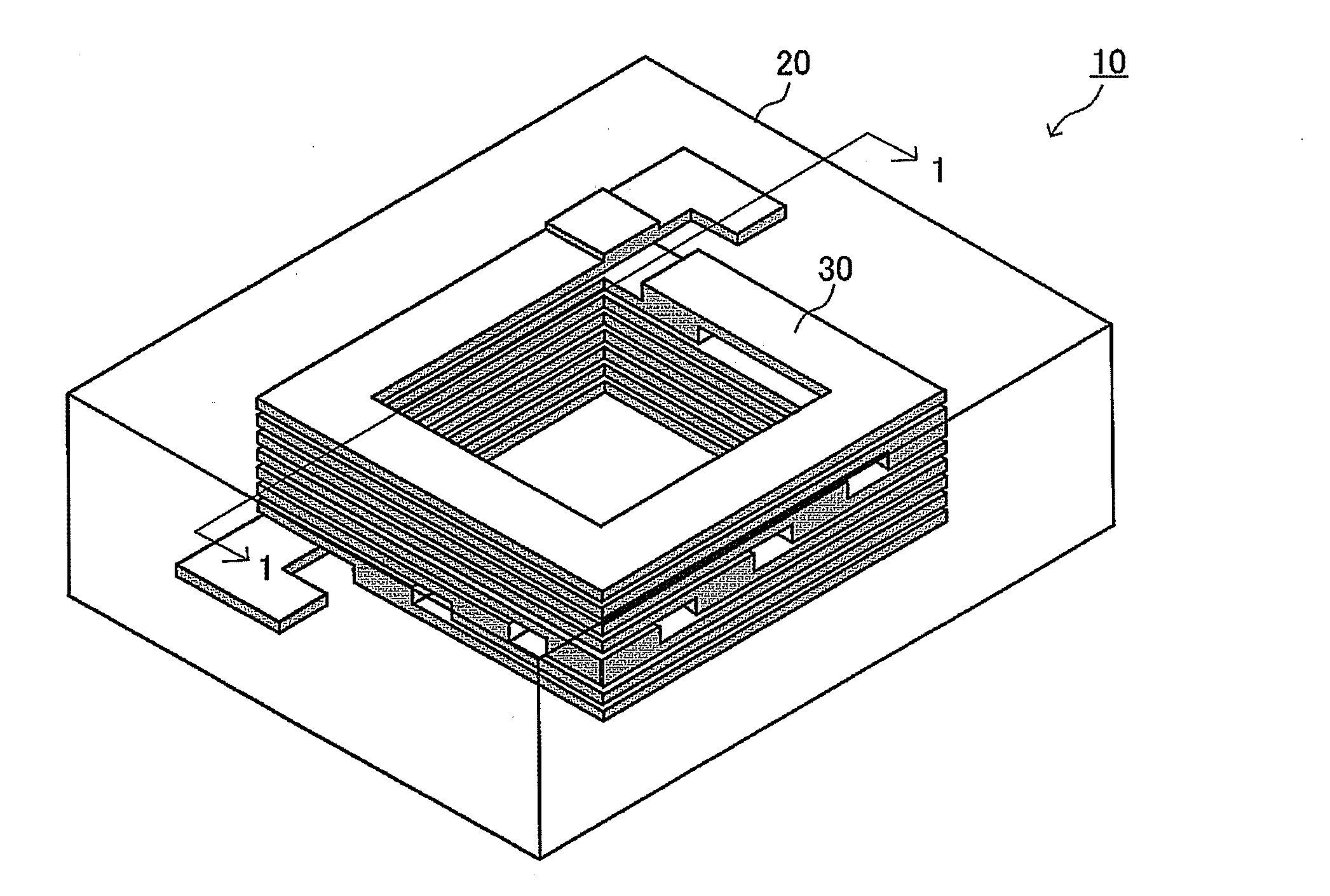

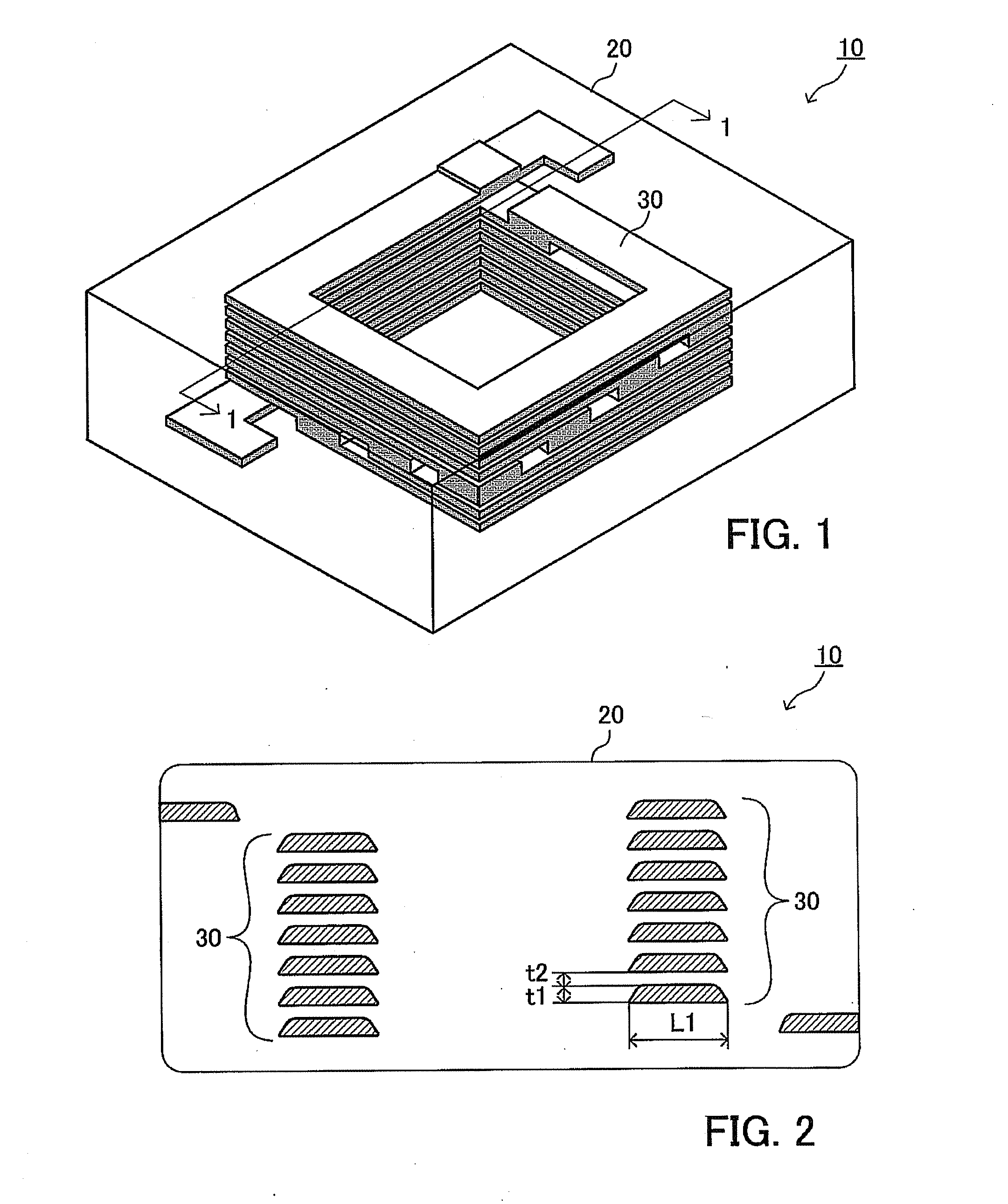

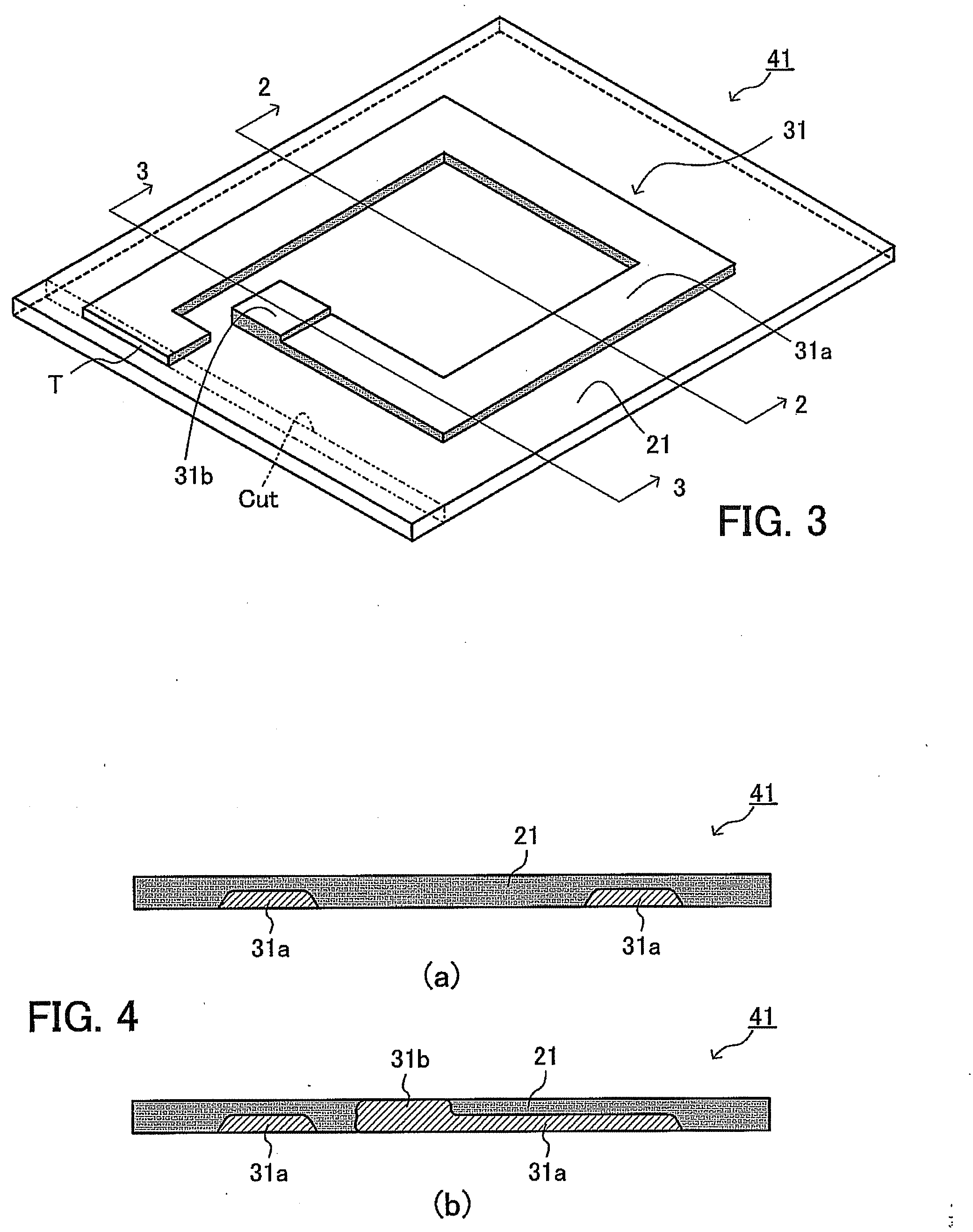

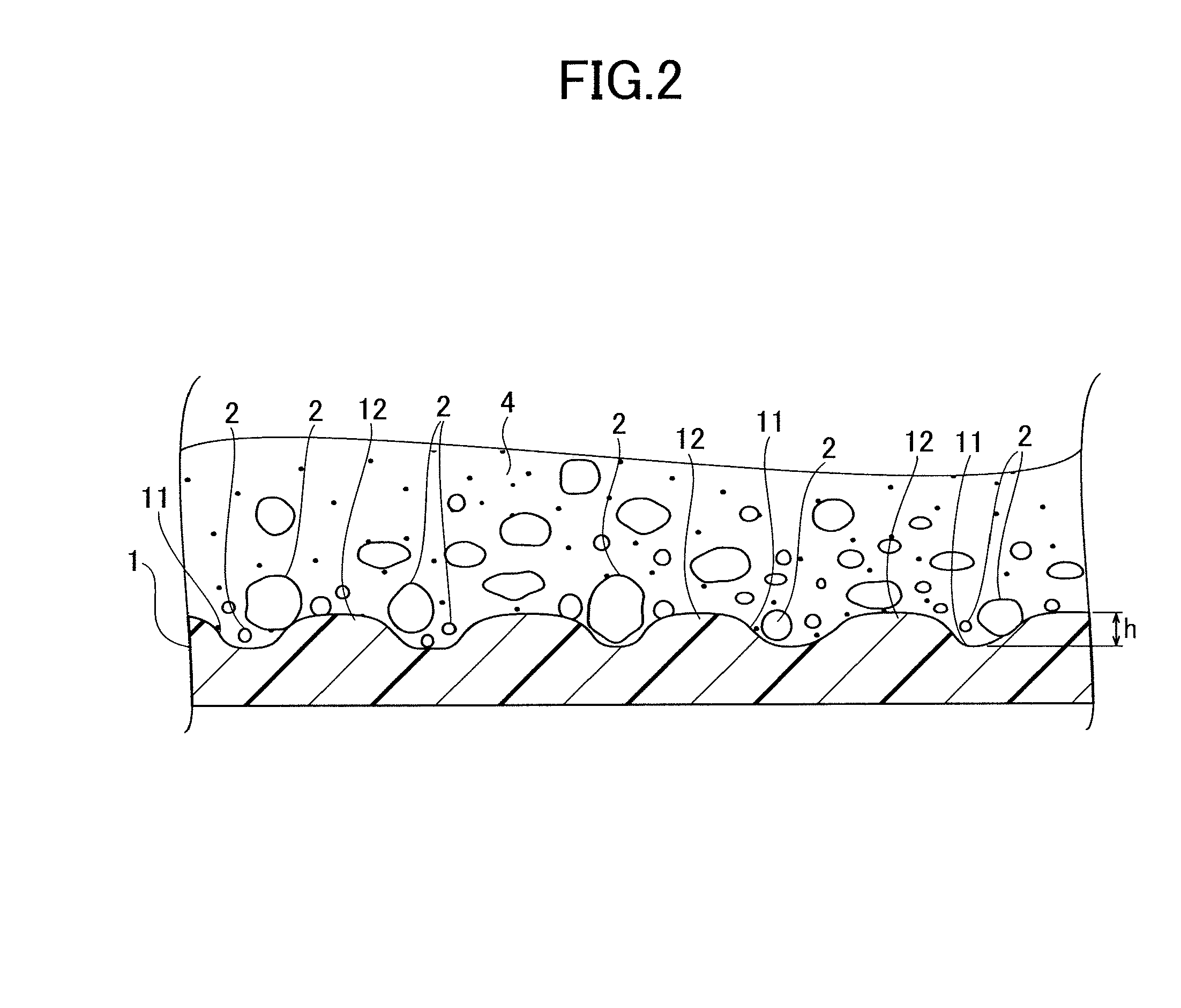

Layered inductor

InactiveUS20100194513A1Low reliabilityHigh reliabilityTransformers/inductances coils/windings/connectionsPrinted circuit aspectsInductorMagnetic layer

A layered inductor 10 is manufactured by layering “silver-based conductive layers” and “ferrite-based magnetic layers” and simultaneously firing these layers. The conductive layers are via-connected to form a helical coil 30. A shape of a cross sectional surface of the conductive layer, cut by a plane perpendicular to a longitudinal direction of each of the conductive layers is a substantial trapezoid shape, having an upper base and a lower base. A base angle θ of the trapezoid shape at both ends of the lower base is equal to or greater than 50° and is smaller than or equal to 80°.

Owner:NGK INSULATORS LTD

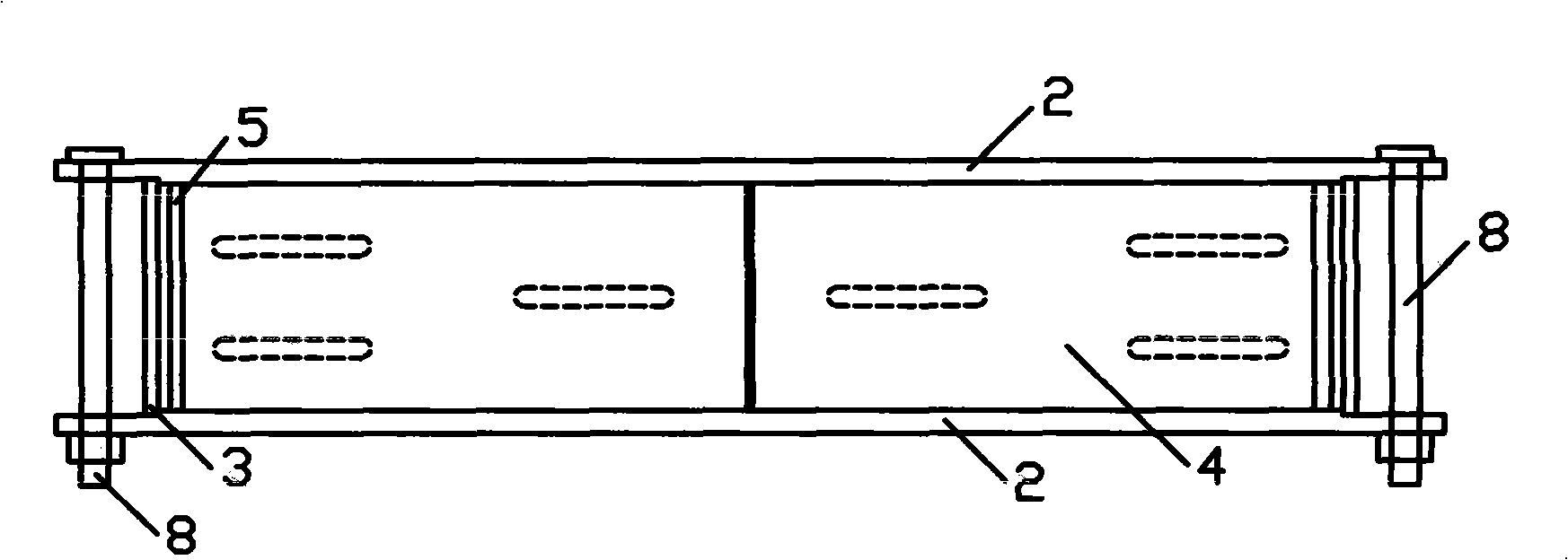

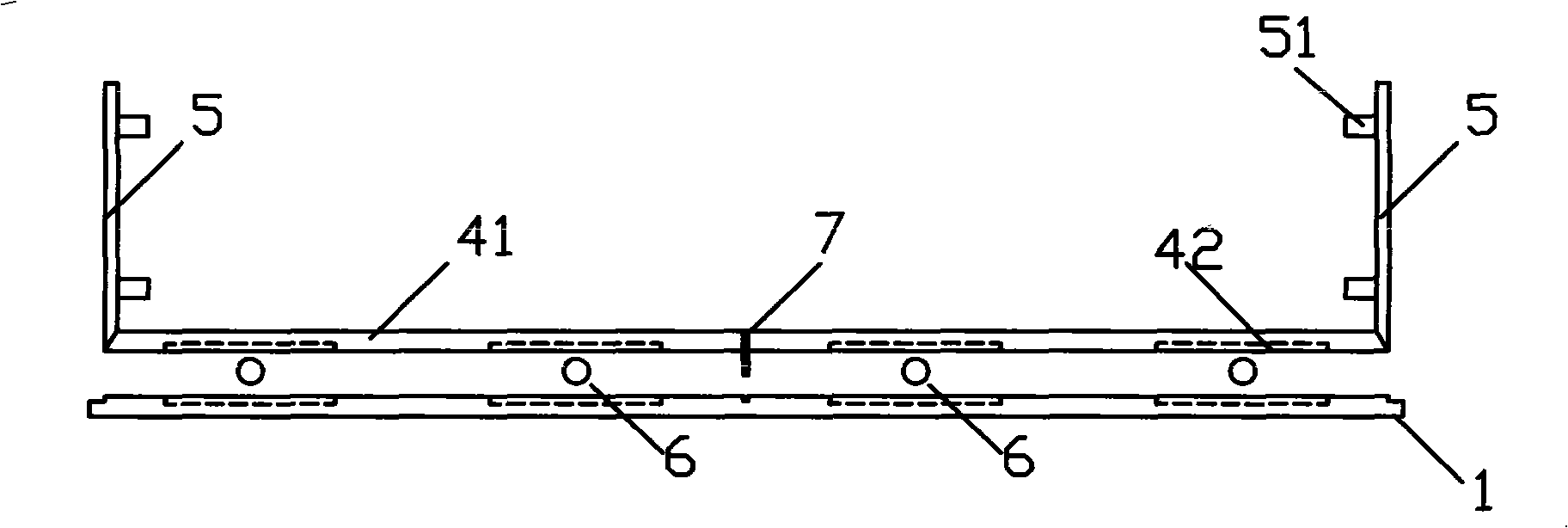

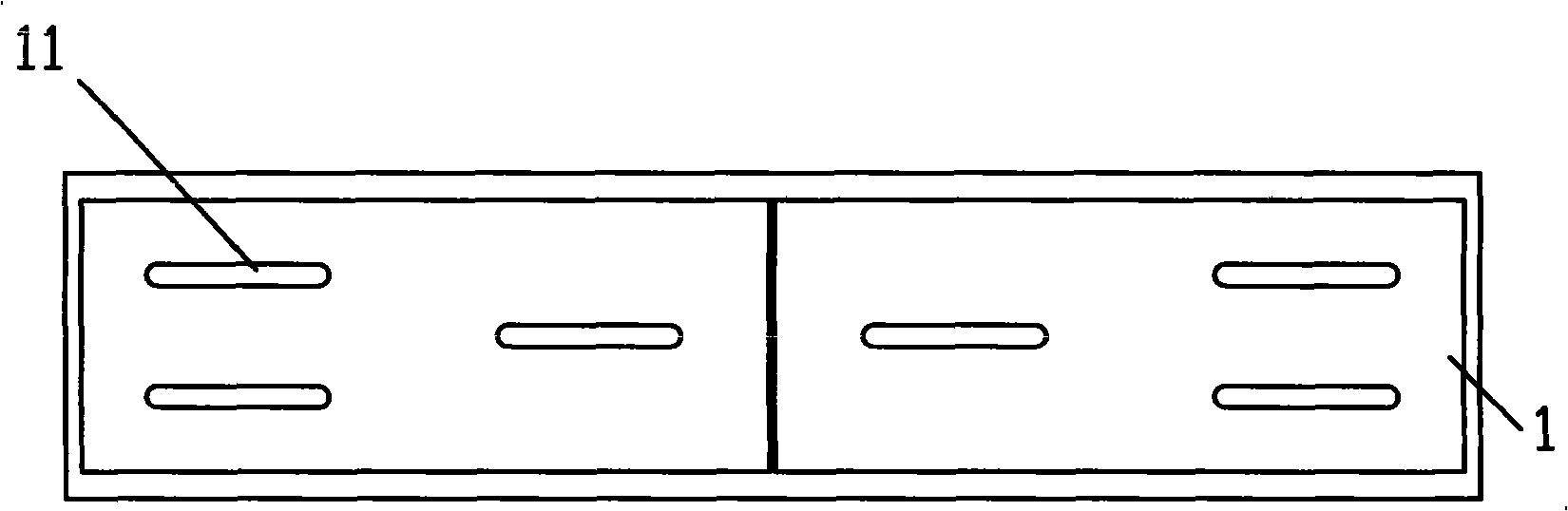

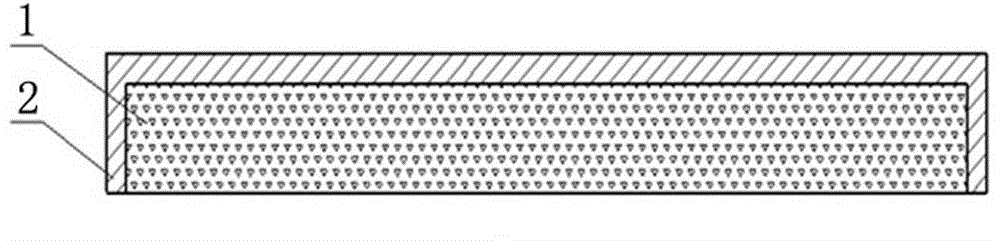

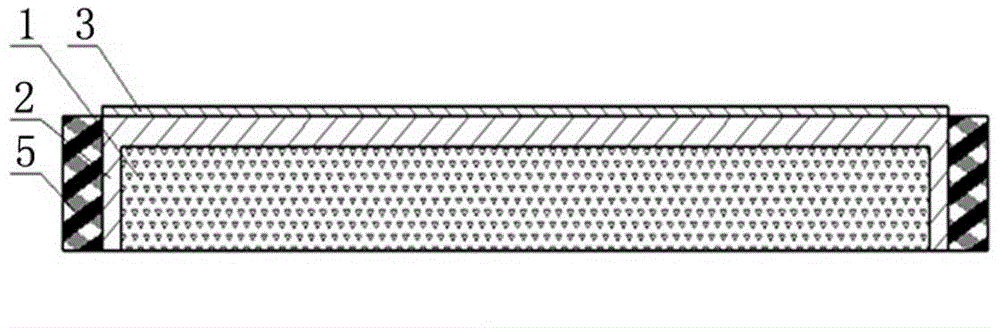

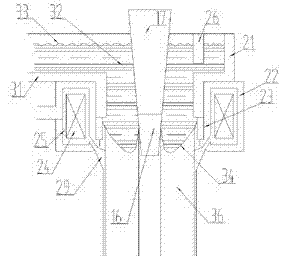

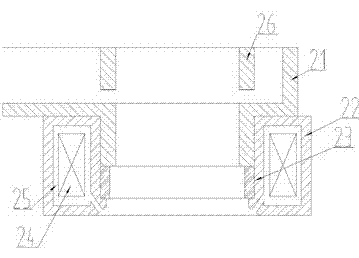

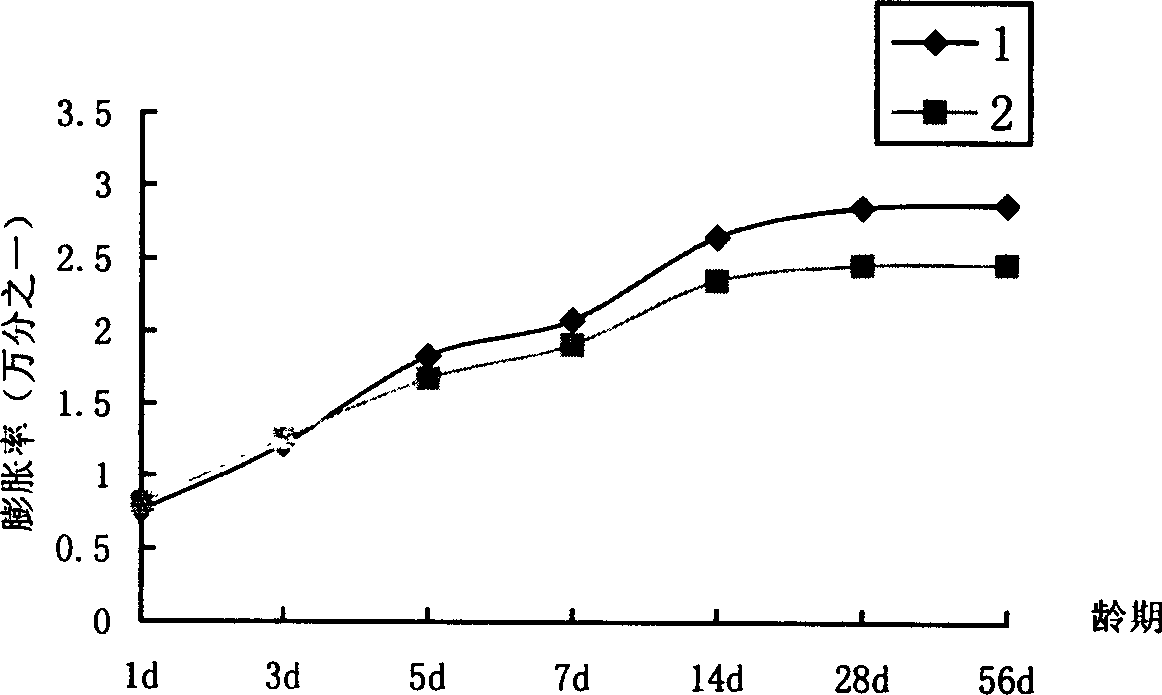

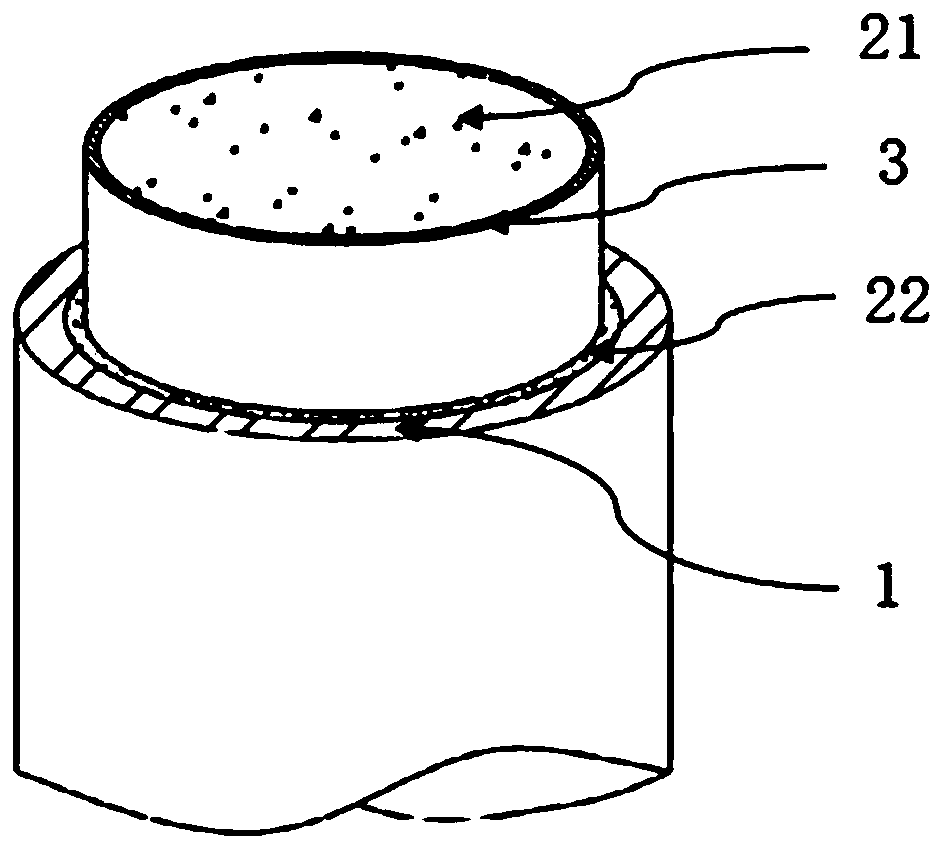

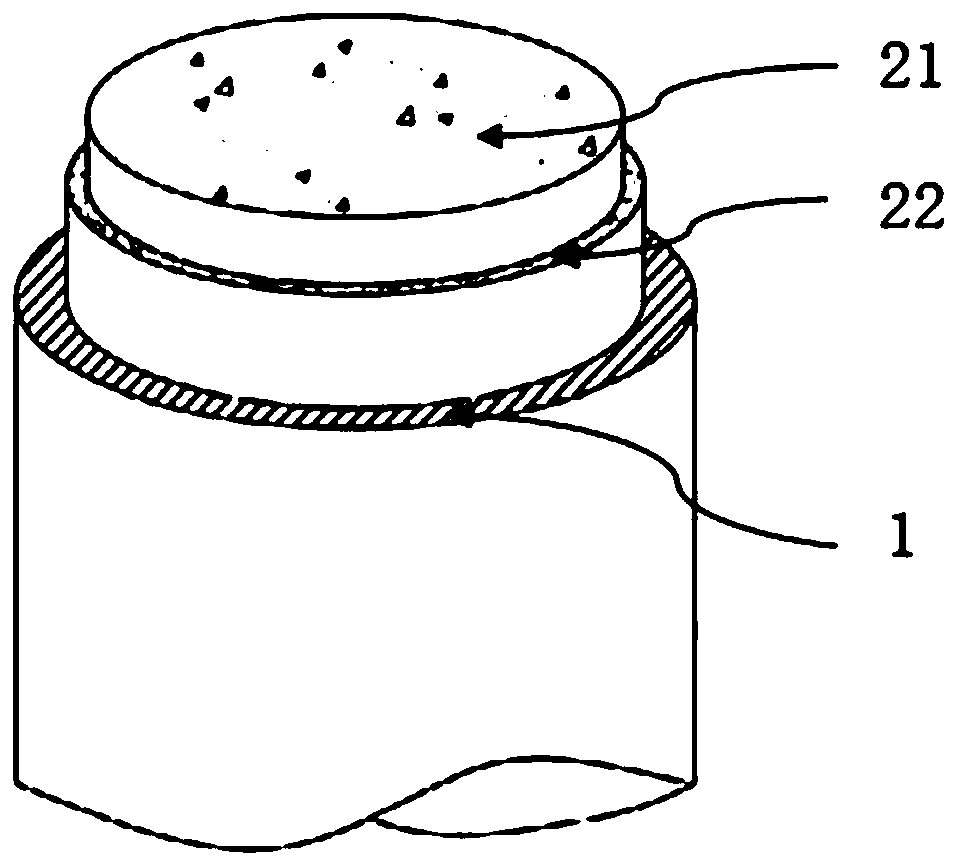

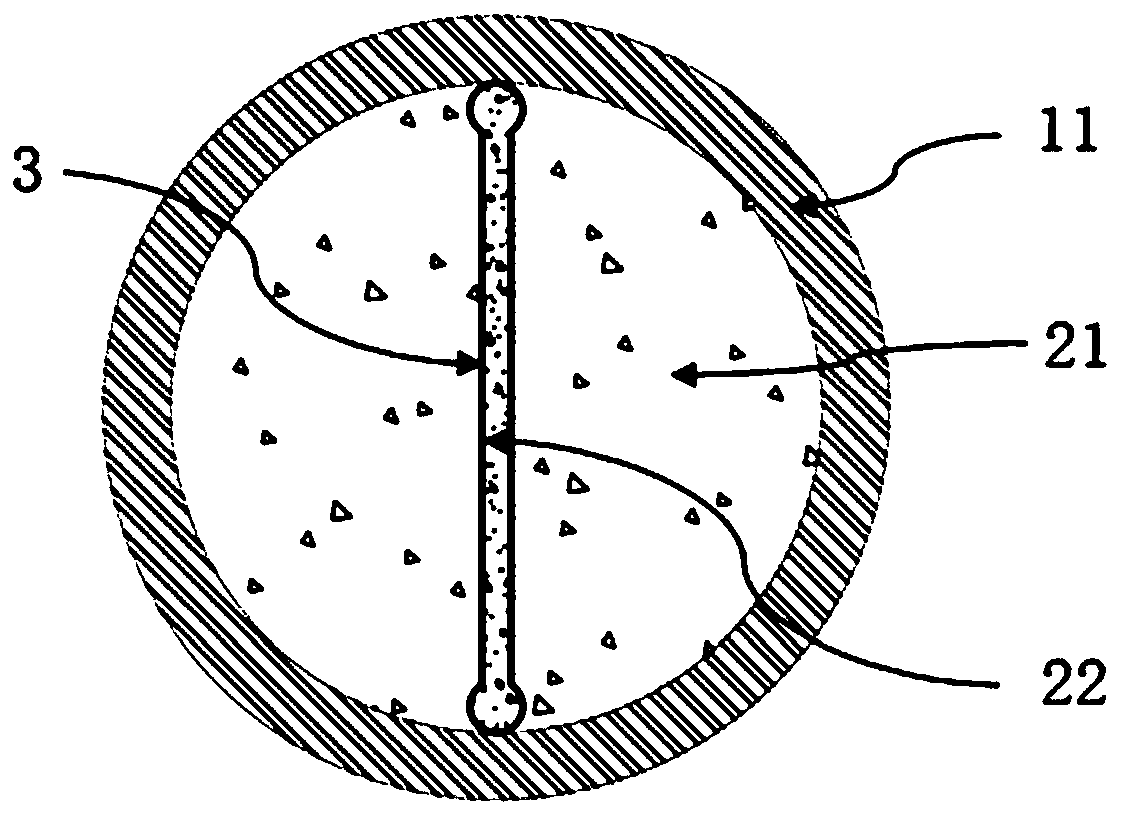

Device and method for measuring early age period linear deformation of cement based material

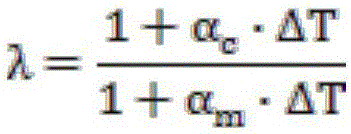

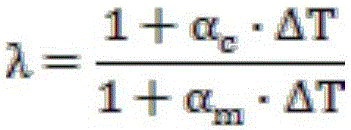

InactiveCN101344371AReduce frictionHigh measurement accuracyMaterial thermal coefficient of expansionMaterial testing goodsMeasurement deviceEngineering

The invention discloses a measurement device and a measurement method of early-age linear deformation of cement-based materials; the measurement device comprises: a measurement containing cavity which is provided with an opening at the upper end and composed of a bottom board, a side board and an outer end board, wherein, a sliding template is further arranged on the bottom board, inner end boards are arranged at the both ends of the template, and a separation groove is arranged in the middle of the template for dividing the template into two sliding templates. Compared with the prior art, the sliding template is arranged on the bottom board of the measurement device of the invention, the template is divided into two by the separation groove, when a cement-based material sample is deformed, the displacement thereof can be measured by the sliding template which is bonded with the cement-based materials, the properties of the early-age linear deformation of the cement-based materials can be accurately reflected without the need of waiting for hardening of the cement-based materials. Sliding slots are respectively arranged on the bottom board and the template, rolling balls are arranged in the sliding slots, thereby changing sliding friction into rolling friction, greatly reducing the friction and improving the measurement precision.

Owner:HOHAI UNIV +1

Method for preparing self-supporting diamond film

ActiveCN104561925AGood bonding strengthAvoid cracksChemical vapor deposition coatingTitaniumAcid corrosion

The invention discloses a method for preparing a self-supporting diamond film and belongs to the technical field of chemical vapor deposition diamond films. The method disclosed by the invention comprises the following steps: pre-depositing a titanium metal coating on the upper surface and side surface of a silicon substrate; depositing a molybdenum metal coating on the upper surface of the silicon substrate containing the titanium metal coating; depositing a diamond film on the upper surface of the silicon substrate which is pre-deposited with the titanium / molybdenum metal coating by adopting a chemical vapor deposition method; and finally, obtaining the self-supporting diamond film by using an oxalic acid solution corroding sample, and recycling the silicon substrate. Compared with the prior art, the method disclosed by the invention has the advantages that the diamond film is fast in nucleation, and the deposition time can be shortened; the silicon substrate can be repeatedly used, and the production cost can be reduced; and the environmental pollution caused by conventional acid corrosion of the silicon substrate can be avoided.

Owner:山西新碳超硬材料科技有限公司

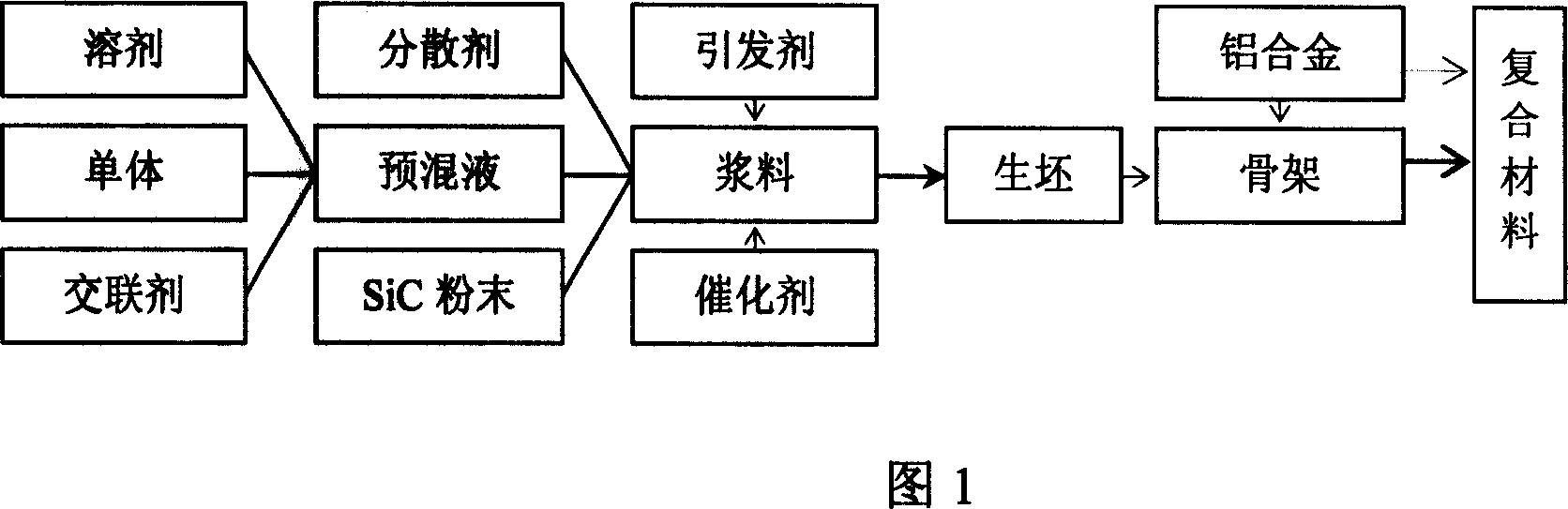

Method of preparing SiCp/Al composite material with complicated shape and high volume percent ratio

The invention discloses a preparing method of SiCp / Al composite with complete shape and high analytic in metal base composite material researching domain, which comprises the following steps: allocating pre-mixing liquid with monomer, cross linker and disperser; adding into SiC powder; balling; getting stable suspension with SiC volume content at 50-70%; adding into trigger and activator; stirring evenly; injecting into unapertured mold; solidifying and shaping in incubator with temperature at 50-70 deg.c; getting green compact; drying; discharging glue; presintering; getting SiC bone; placing Al alloy of 4-8% Mg, 6-12% Si on the adaptive position of bone; putting into heater; heating-up at 900-1200 deg.c under the protection of inert gas; inflating high pure nitrogen; keeping the temperature at 1-6 h; cooling; getting the product. This invention possesses the merit of cheap cost.

Owner:UNIV OF SCI & TECH BEIJING

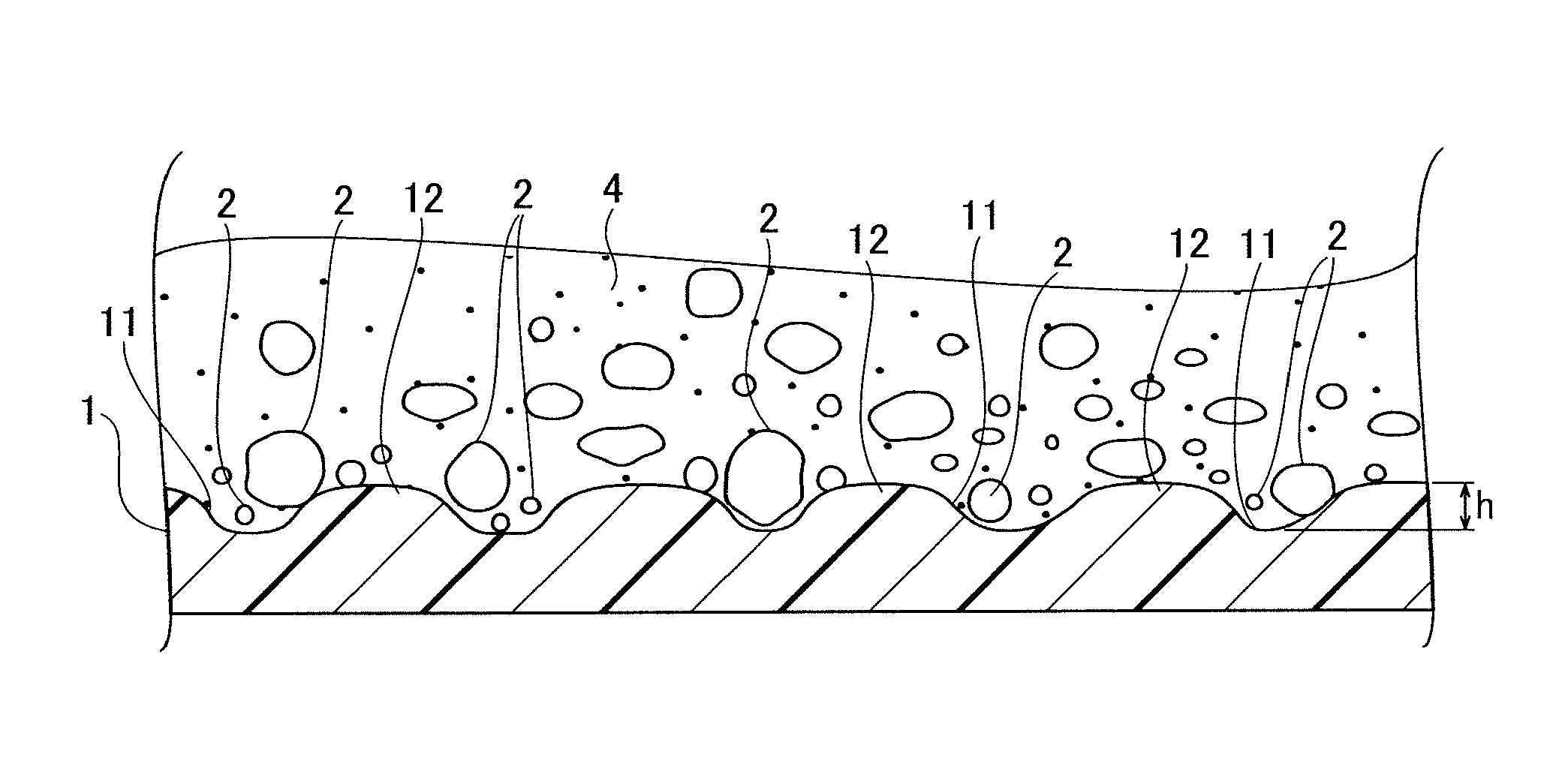

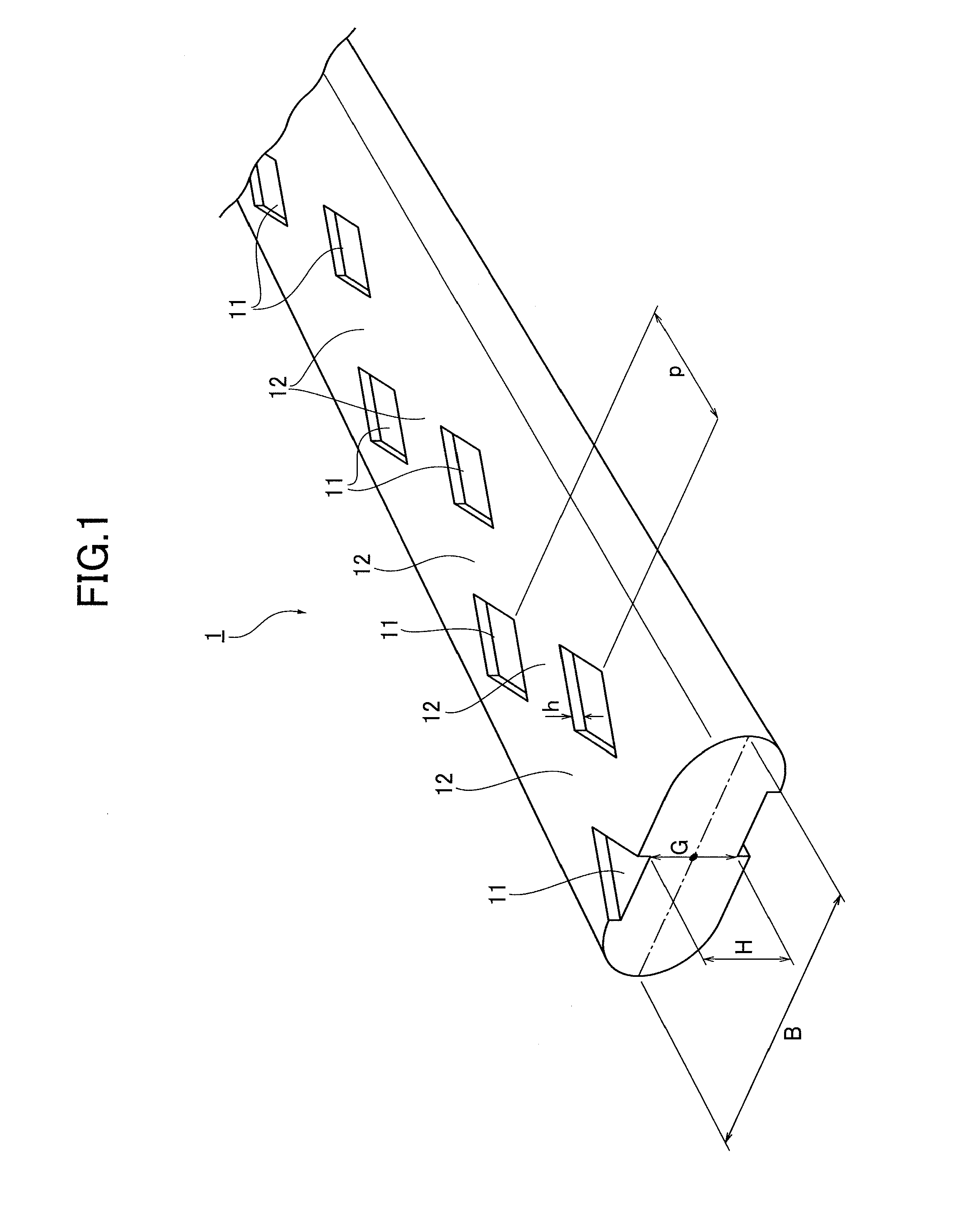

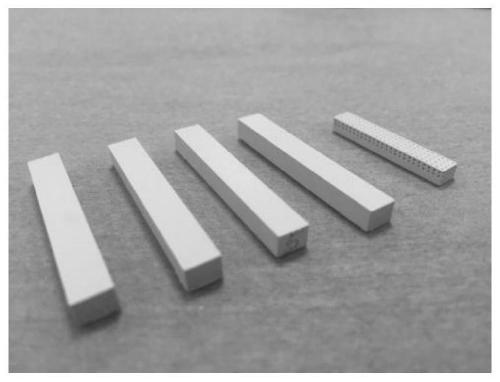

Fiber reinforced cement based mixed material

ActiveUS20140326168A1Small amount of shrinkageRapid early strength developmentSolid waste managementChemical admixturePolymer science

Provided is a fiber reinforced cement based mixed material having high tensile strength and high toughness, the mixed material comprising a cementitious composition with fast development of early strength; a small hydration heat temperature; and a small shrinkage during curing. The fiber reinforced cement based mixed material contains 100 wt. parts of cement, 5-30 wt. parts of silica fume, 30-80 wt. parts of at least one pozzolanic material excluding the silica fume, 5-25 wt. parts of limestone powder, at least one chemical admixture, water, 70-150 wt. parts of aggregate having a largest aggregate diameter of 1.2-3.5 mm, and fibers, wherein at least some of the fibers comprise a fiber having asperities formed in the surface, the fiber having asperities being formed such that a ratio (h / H) of a depth h of each of recessed portions among the asperities to a smallest cross-sectional diameter H thereof is 0.05-0.8.

Owner:TAISEI CORP

Gypsum mold formula for casting magnesium alloy and preparation method thereof

The invention discloses a gypsum mold formula for casting a magnesium alloy and a preparation method thereof, relating to preparation of a gypsum mold for casting a magnesium alloy. The gypsum mold formula comprises an additive component consisting of four basic components, including alpha-semihydrated gypsum, quartz powder, bauxite and magnesium sulfate as well as seven substances such as trisodium orthophosphate, barium chloride, a water reducing agent and the like. The invention further discloses a preparation method for the gypsum mold formula. Due to the adoption of scale graphite, oxidation of the magnesium alloy is effectively prevented; the water reducing agent is added into the formula, so that the fluidity of gypsum slurry is improved, the water consumption is lowered by 30 percent simultaneously, and the gypsum mold strength and drying efficiency are increased; the linear shrinkage of the gypsum mold can be remarkably lowered by using the gypsum mold formula together with barium chloride and urea; moreover, a solvent component consisting of tap water is adopted, so that the problems of high water consumption, poor fluidity, low strength, large size deformation, difficulty in breaking and the like existing in an ordinary gypsum mold are solved; and meanwhile, the problems of oxidization and combustion of the magnesium alloy are solved.

Owner:HUAZHONG UNIV OF SCI & TECH

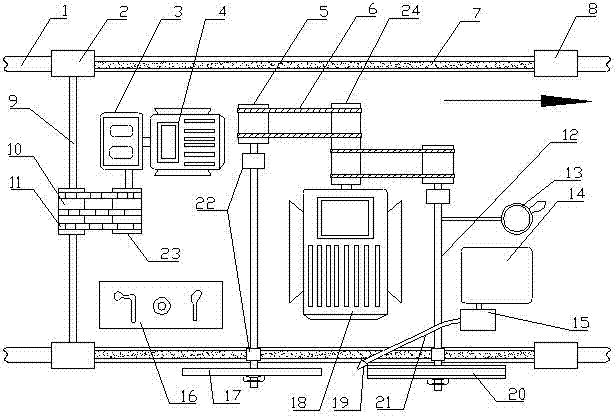

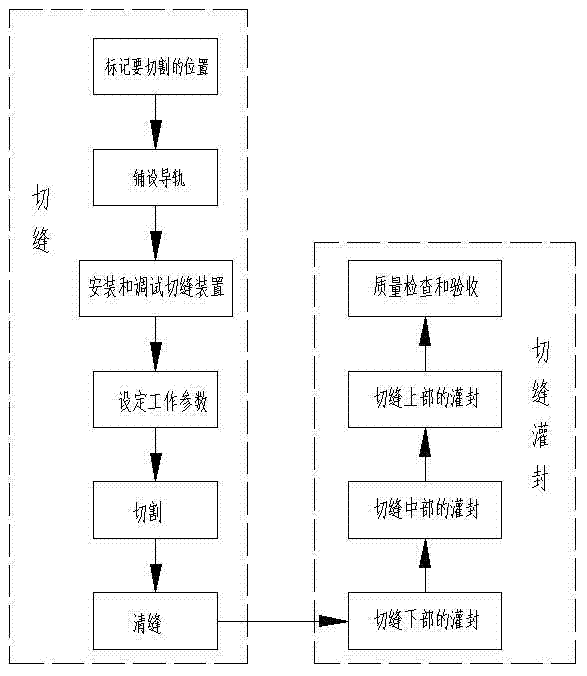

Cement concrete pavement Y-shaped joint cutting device and cut joint filling and sealing process

ActiveCN102828464AIncrease productivityReduce manufacturing costRoads maintainenceRoad surfaceEngineering

The invention discloses a cement concrete pavement Y-shaped joint cutting device and a cut joint filling and sealing process. The device comprises a rack, wherein a travelling mechanism, a cutting mechanism and a cooling mechanism are arranged on the rack. The process is characterized that filling and sealing are carried out by adopting three layers of joint sealants, wherein the middle joint sealants are rubber strips. The device and the process have the following positive effects that wide and narrow joints are cut once by adopting double blades for cutting, thus improving the production efficiency and saving the production cost; and the device has good self-motion property and mobility and has the advantages of simple structure, good joint cutting effect, low pavement destructiveness, high joint cutting efficiency, strong mobility, simple construction process and long service life after construction.

Owner:河南万里交通科技集团股份有限公司

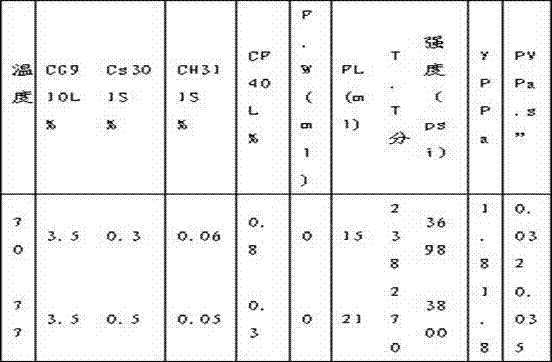

Formula for preparing white faced as-cast finish concrete composition

ActiveCN101955342AThe proportion of components is scientific and reasonableSmall amount of shrinkageWork performanceTitanium

The invention discloses a formula for preparing a white faced as-cast finish concrete composition. The formula comprises the following components in part by weight: 200 to 280 parts of cement, 85 to 105 parts of water, 330 to 390 parts of sand, 500 to 580 parts of stone, 2.2 to 4.0 parts of admixture and 1 part of titanium white powder. The component proportion of the formula for preparing the white faced as-cast finish concrete composition is scientific and reasonable, the working performance of the formula meets the concrete pumping and casting requirements, and the formula can achieve the effects on no bleeding, no dissociation, low shrinkage and compactness and strong texture of the formed concrete. The high-flow white as-cast finish concrete prepared by adopting the formula has the advantages of good liquidity, good workability and good water-retaining property during concrete construction, low loss in slump, strong pumping property and the like; and the formula can ensure good strength and surface finish of the formed concrete and ensure that the chromatic aberration meets the quality requirement of the faced as-cast finish concrete.

Owner:ZHEJIANG CONSTR ENG GRP CO LTD

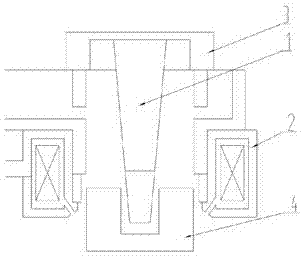

Equipment for producing aluminum alloy hollow casting ingot and method of equipment

The invention relates to the technical field of aluminum alloys, in particular to equipment for producing an aluminum alloy hollow casting ingot and a method of the equipment. The equipment for producing the aluminum alloy hollow casting ingot comprises a core die, a crystallizer, a bracket and a dummy ingot, wherein the core die is positioned at the center of the crystallizer and is concentric with the crystallizer; the bracket arranged on the crystallizer is used for supporting the core die; the dummy ingot is arranged at the lower part of the core die; a space between the core die and the crystallizer is a die cavity; the core die is designed into a taper with a large upper part and a small lower part; and the size of the taper is 1-30 degrees; a cooling system and a lubricating system are arranged in the core die; a coil is arranged in a water chamber of an aluminum sleeve of the crystallizer; and a shunt and a stop block are arranged on the crystallizer. According to the equipment for producing the aluminum alloy hollow casting ingot and the method for the equipment disclosed by the invention, a friction force between the casting ingot and the die core in the hollow casting process of the aluminum alloy is reduced and the core locking and breakout are avoided.

Owner:NORTHEASTERN UNIV

Photocureable silicon nitride ceramic paste and preparation method thereof

The invention discloses a photocureable silicon nitride ceramic paste and a preparation method thereof. According to the invention, stearic acid powder and a premixed solution are additionally used asraw materials on the basis of ceramic powder, wherein the premixed solution is composed of a plurality of substances. According to the invention, through addition of the stearic acid powder, the compatibility of the ceramic powder and subsequent resin can be improved, and the solid phase content of silicon nitride ceramic can be easily improved; through optimized selection of all substances in the premixed solution, resin with high refractive index can be introduced into a resin system to reduce the difference of refractive indexes of the ceramic powder and the resin, so the single-layer curing depth of a ceramic paste can be improved; in addition, rigid group containing epoxy resin, isobornyl methacrylate (IBOMA) and the like are added into the resin to reduce shrinkage generated in theprocess of curing; and through optimization of the varieties of all substances, the photocureable ceramic paste provided by the invention has the following advantages: the solid phase content and single-layer curing depth of the isobornyl methacrylate are improved, and the shrinkage amount of the paste photocured into ceramic is reduced.

Owner:NAT INST CORP OF ADDITIVE MFG XIAN

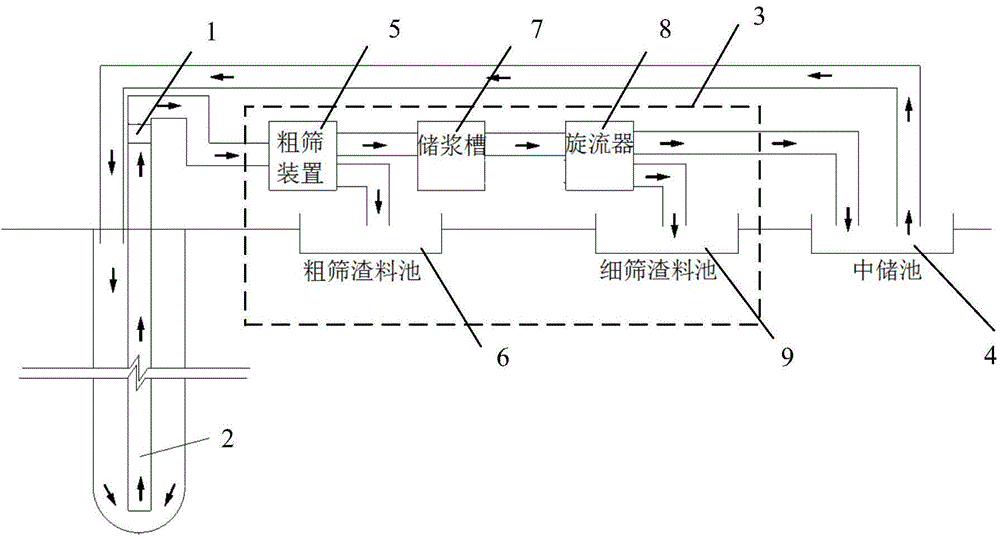

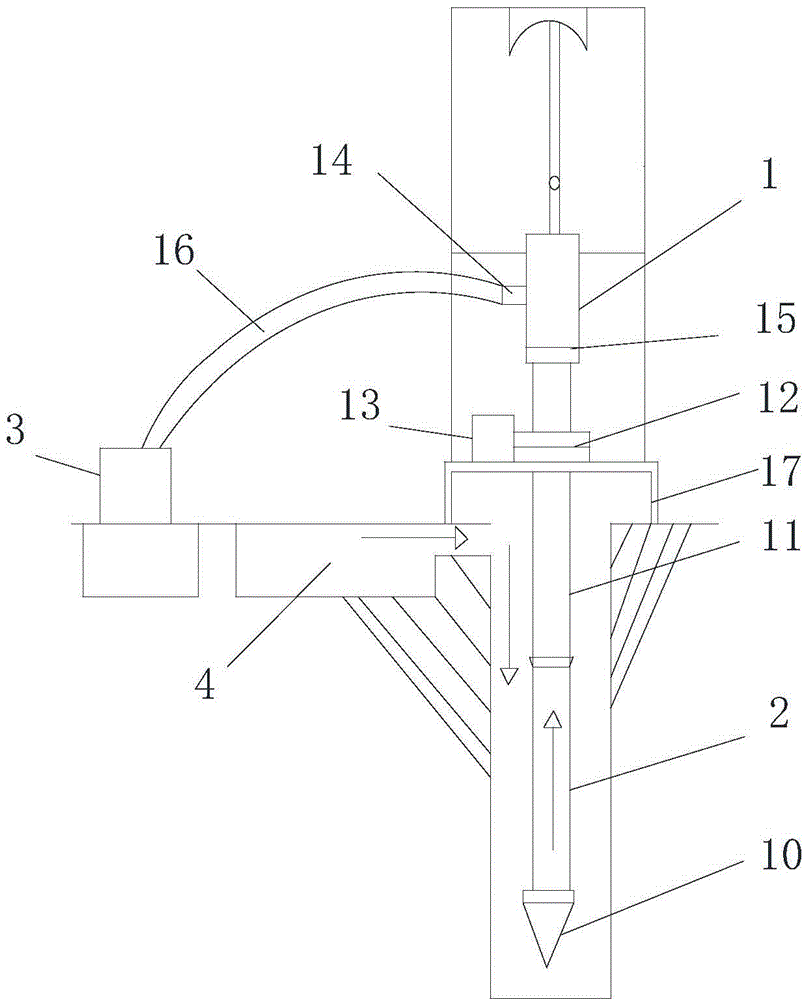

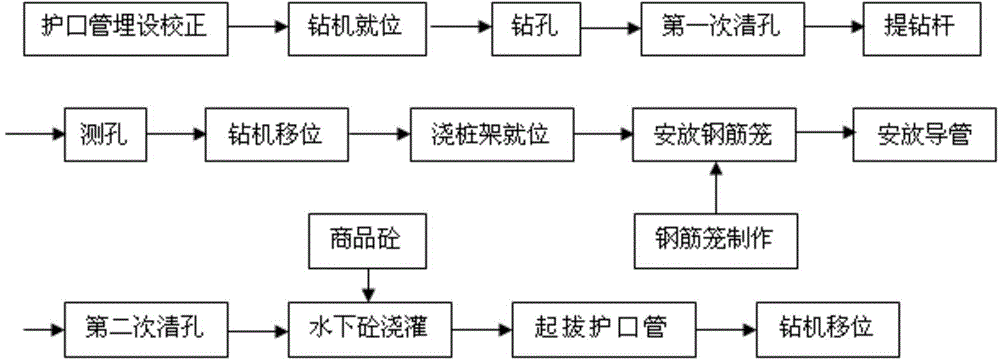

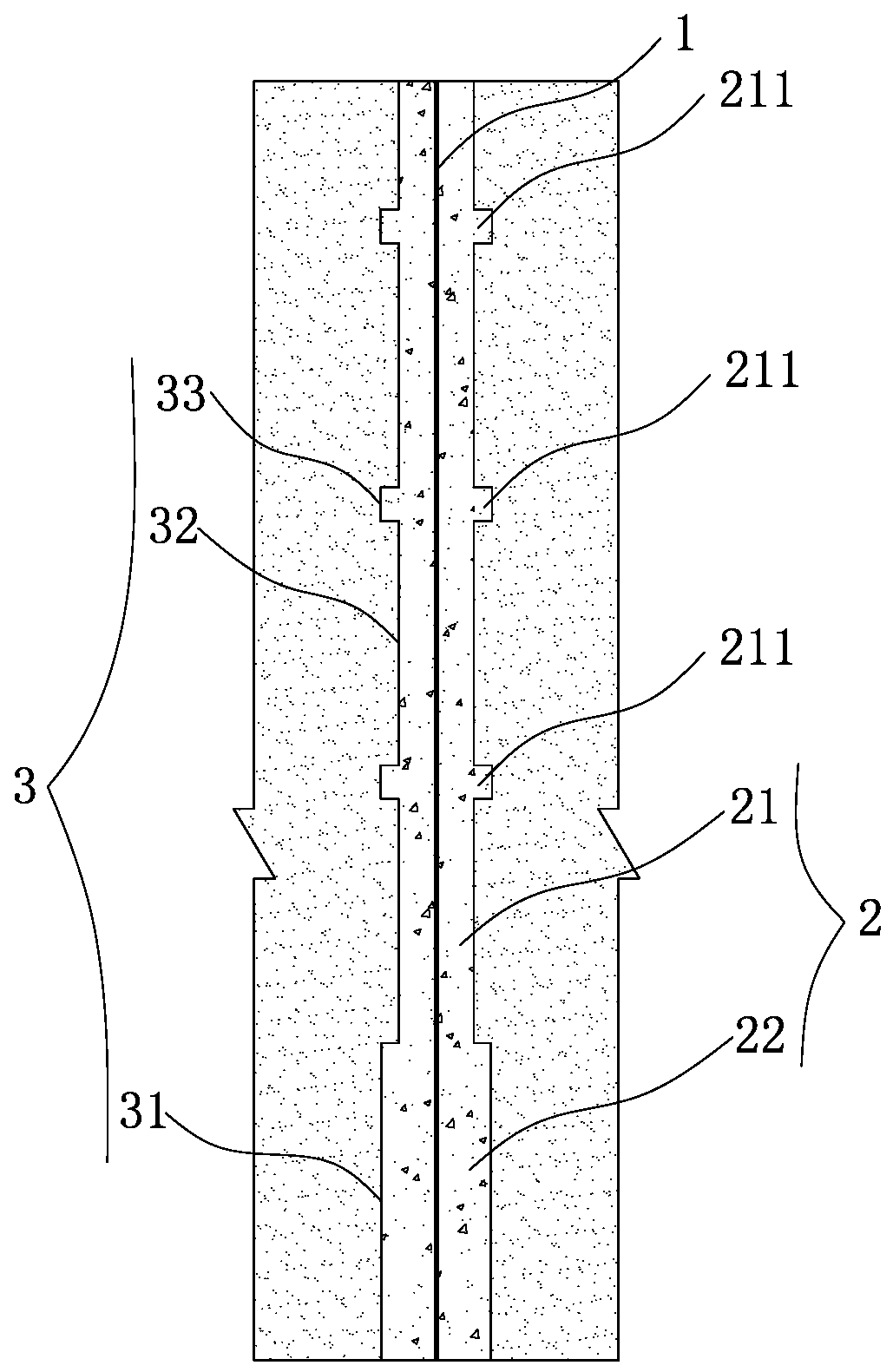

Cast-in-situ bored pile hole-forming device and method

ActiveCN105804059ASmall amount of shrinkageEmission reductionFlushingBulkheads/pilesSlagStorage tank

The invention discloses a cast-in-situ bored pile hole-forming device and method. Dirt slurry at the hole bottom is conveyed to a coarse screening device through a drilling rod by means of a gravel pump, a coarse slag material flows into a coarse screening slag material pool after the dirt slurry is subject to coarse screening through the coarse screening device, and the rest of the dirt slurry flows into a slurry storage tank; the slurry in the slurry storage tank is conveyed to a hydrocyclone through a slag slurry pump and is subject to fine screening through the hydrocyclone, then a fine slag material flows into a fine screening slag material pool, and the rest of the slurry flows into a middle storage tank; and the slurry inside the middle storage tank is conveyed to space between the drilling rod and the hole wall by an overflowing opening formed in the pool wall or through a slurry pump, and therefore a reverse circulation loop is formed. By adopting a pumping suction reverse circulation hole cleaning manner, the hole-forming rate and the hole cleaning efficiency can be improved, the waste slurry discharge amount is less, the single-pile construction time is shortened, the inward contraction amount of the hole wall is reduced, and the construction quality is improved. By means of two-stage screening through the coarse screening device and the hydrocyclone, the quality of slurry circulated back to holes can be improved, slag sinking to the hole bottom is further reduced effectively, and the hole wall is more stable.

Owner:SHANGHAI MECHANIZED CONSTR GRP

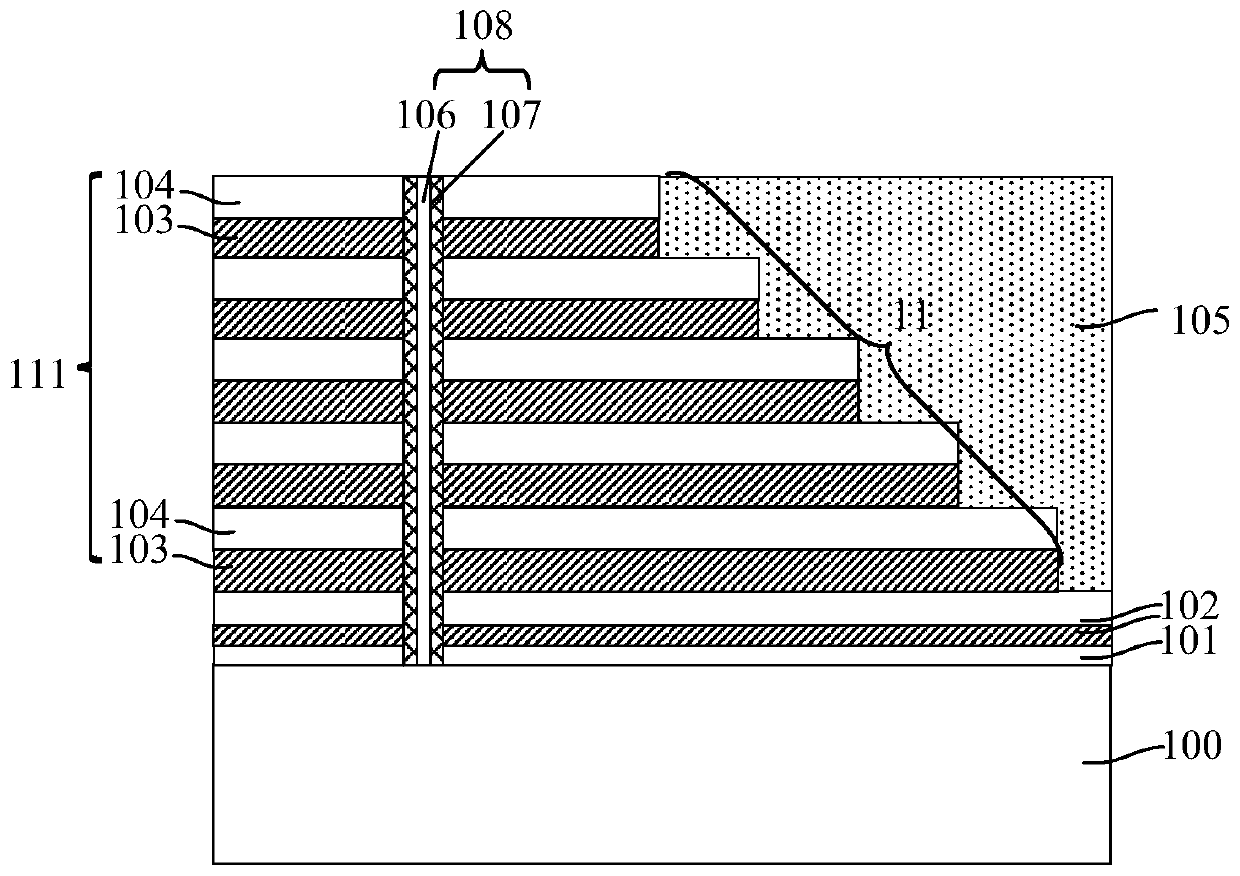

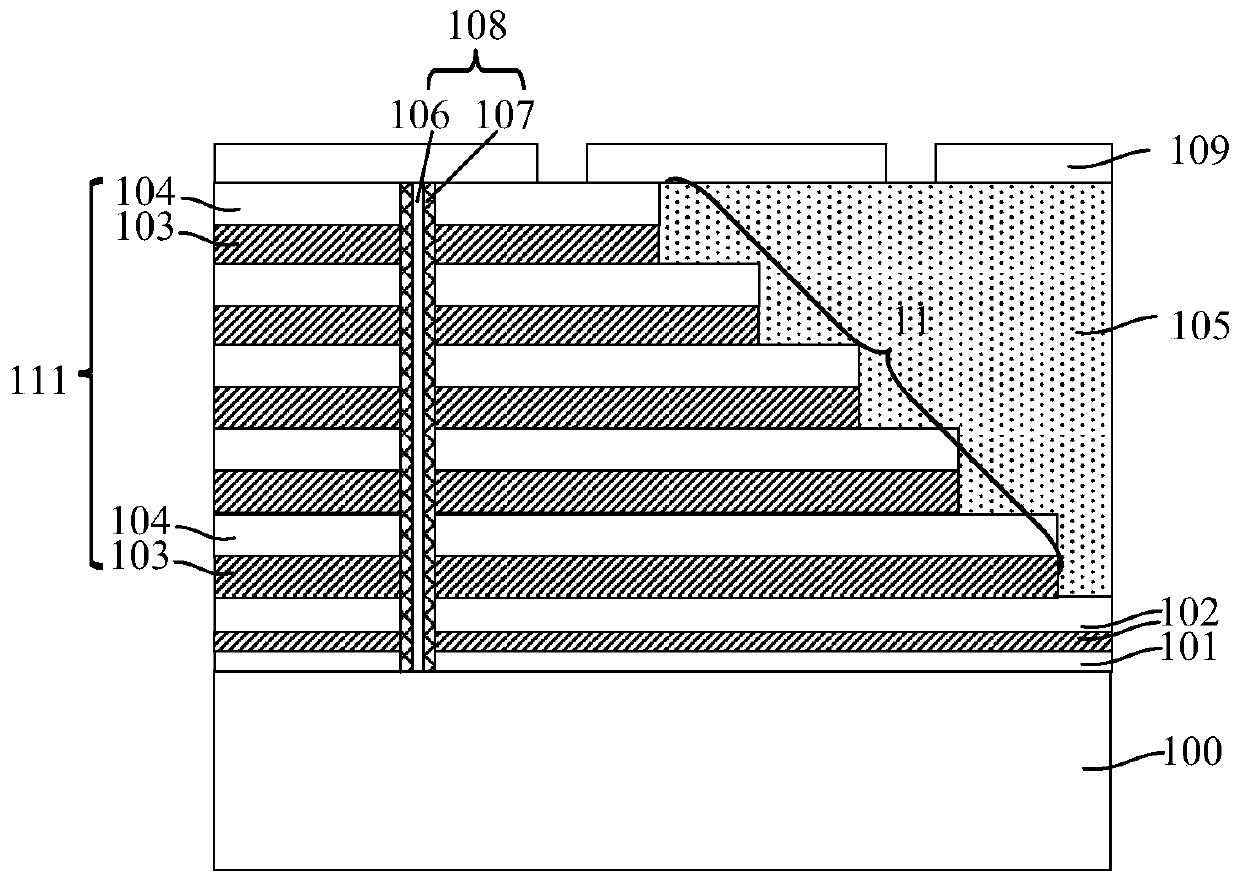

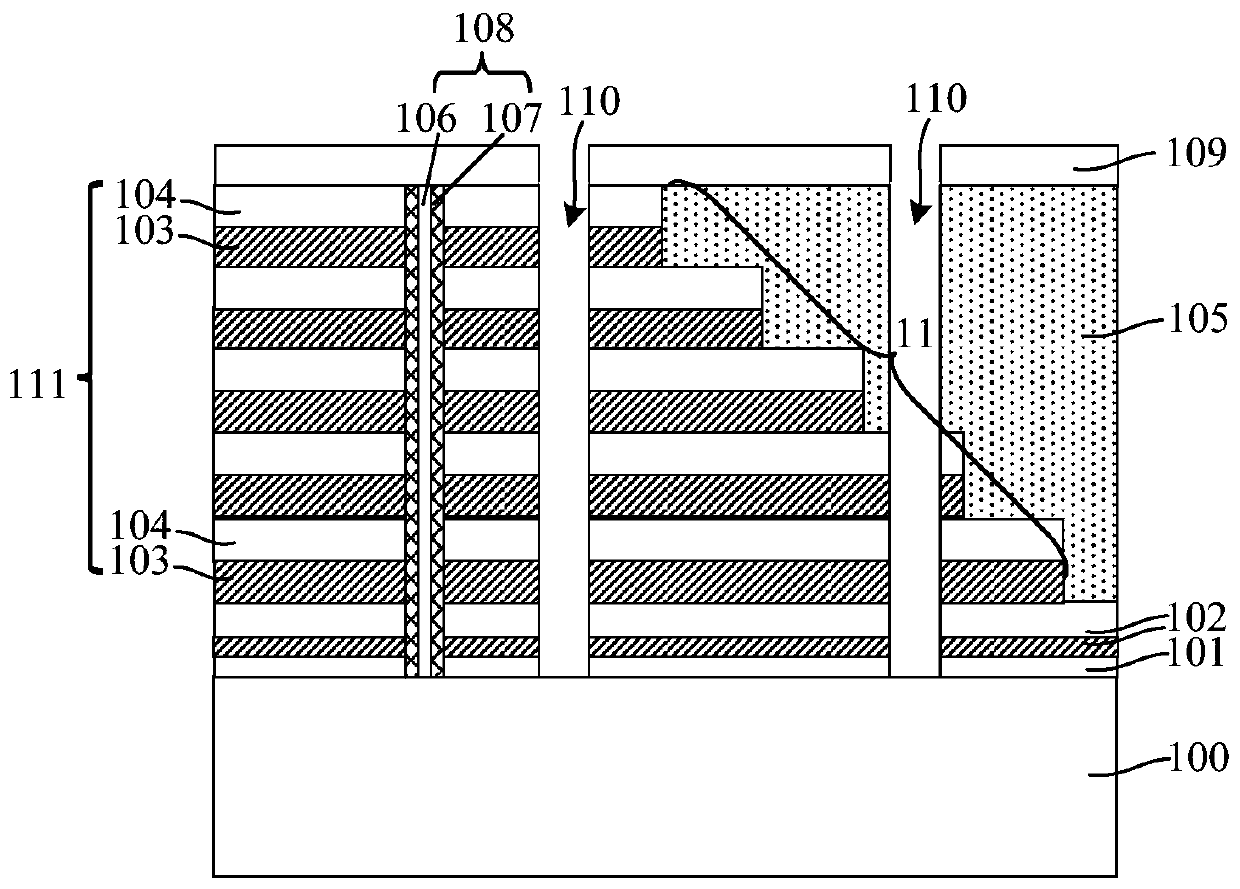

3D NAND memory and forming method thereof

ActiveCN109817623APrevent dent defectsHigh temperature deformation is smallSolid-state devicesSemiconductor devicesHardnessDielectric layer

The invention discloses a 3D NAND memory and a forming method thereof, and the forming method comprises the steps: forming a dielectric layer covering a step structure; forming a plurality of pseudo-through holes in the dielectric layer and the step structure, and placing pseudo-through hole material layers in the pseudo-through holes, wherein the hardness of the pseudo-through hole material layers is greater than that of the dielectric layer; forming a plurality of gate isolation grooves in the dielectric layer and the step structure after the pseudo through hole material layers are formed; forming conductive semiconductor layers in the gate isolation grooves, wherein the surfaces of the conductive semiconductor layers are lower than the surface of the dielectric layer; and forming metallayers on the conductive semiconductor layers, wherein the metal layers are disposed in the gate isolation grooves. The method provided by the invention avoids the residual of the metal layer.

Owner:YANGTZE MEMORY TECH CO LTD

Refractory materials and refractory equipment for aluminum alloy melt casting, and method for preparing refractory equipment

The invention discloses a fire-resisting material used for aluminum alloy fusion casting, and a fire-resisting apparatus made of the fire-resisting material and a method for preparing the fire-resisting apparatus, wherein the fire-resisting material comprises aluminum silicate fiber powder, talcum powder, mullite powder, zirconite powder and a silica sol solution. The fire-resisting material has the advantages of no aluminum adhesion and no chemical reaction with an aluminum liquid, no addition of asbestos, rapid deslagging and no damage after using a prefabricated molding assembling part, better thermal-shock resistance, durability, controllable concentration, intensity and thermal-shock resistance, and small shrinkage mass of a cooling process after use to effectively prevent the assembling joint of the prefabricated molding part from cracking. The corresponding fire-resisting apparatus has the advantages of heat shock resistance, washing resistance, corrosion resistance, and small heat expansion coefficient.

Owner:SOUTHWEST ALUMINUM GRP +1

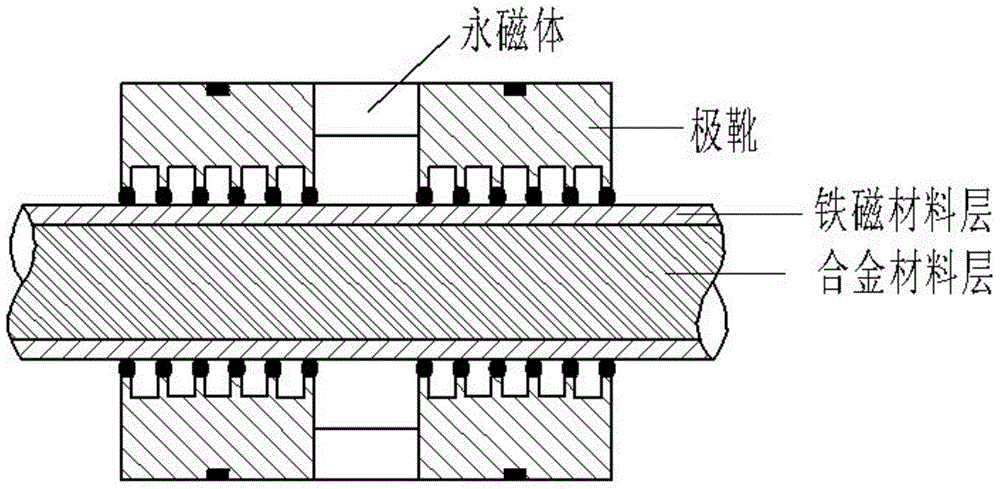

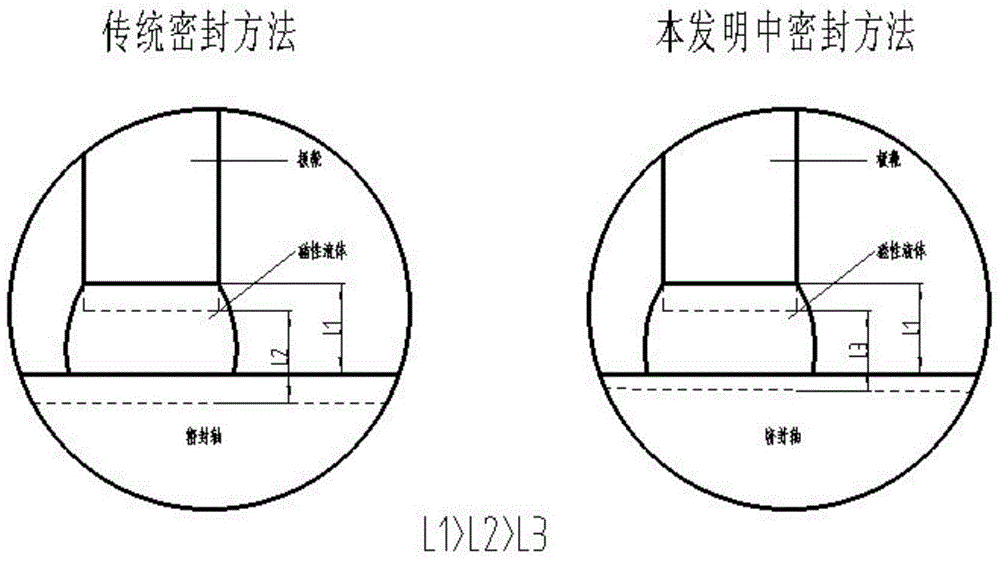

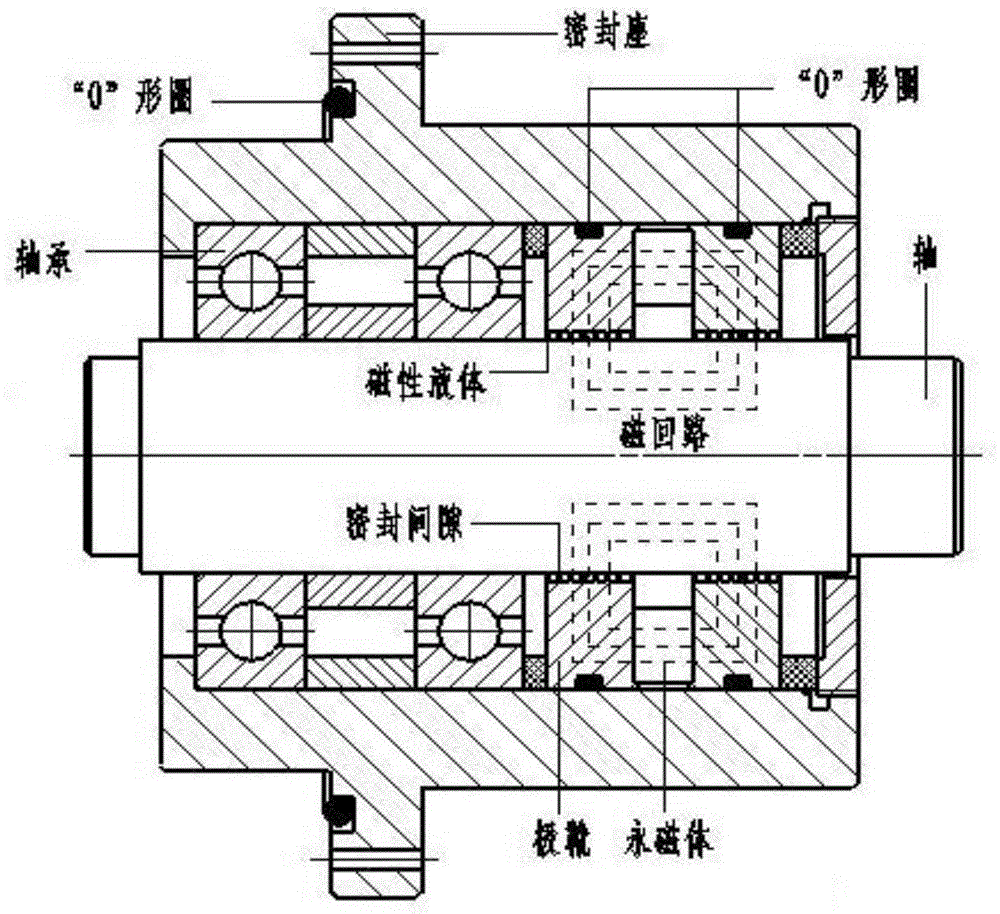

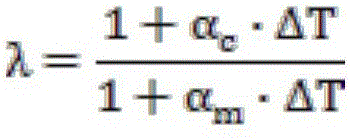

Method for improving pressure resistance of magnetic liquid seal in low-temperature working environment

InactiveCN104405886ASmall amount of shrinkageImprove sealing pressure resistanceEngine sealsWorking environmentMagnetic liquids

The invention provides a method for improving pressure resistance of magnetic liquid seal in a low-temperature working environment, belongs to the technical field of sealing of mechanism engineering, and in particular applies to magnetic liquid seal. The method comprises the steps of selecting a ferromagnetic material with high permeability and large expansion coefficient, and an alloy steel material with small thermal expansion coefficient and high comprehensive mechanical performance; manufacturing a pole shoe with the ferromagnetic material; manufacturing and processing a composite material shaft being 50 to 100mm in diameter by using the ferromagnetic material and the alloy steel material as an outer layer material and an inner layer material, respectively, wherein the radial length ratio of the ferromagnetic material layer to the alloy steel material layer is 1: 3; applying the pole shoe and the composite material shaft into a magnetic liquid seal device of which a gap ranges from 0.1 to 0.25. With the adoption of the method, the shortages of the existing method for magnetic liquid seal under a low temperature can be overcome, the problem of applying to magnetic liquid seal in a low-temperature environment is solved, the applicable scope of magnetic liquid seal is expanded, and the method is of an important significance.

Owner:BEIJING JIAOTONG UNIV

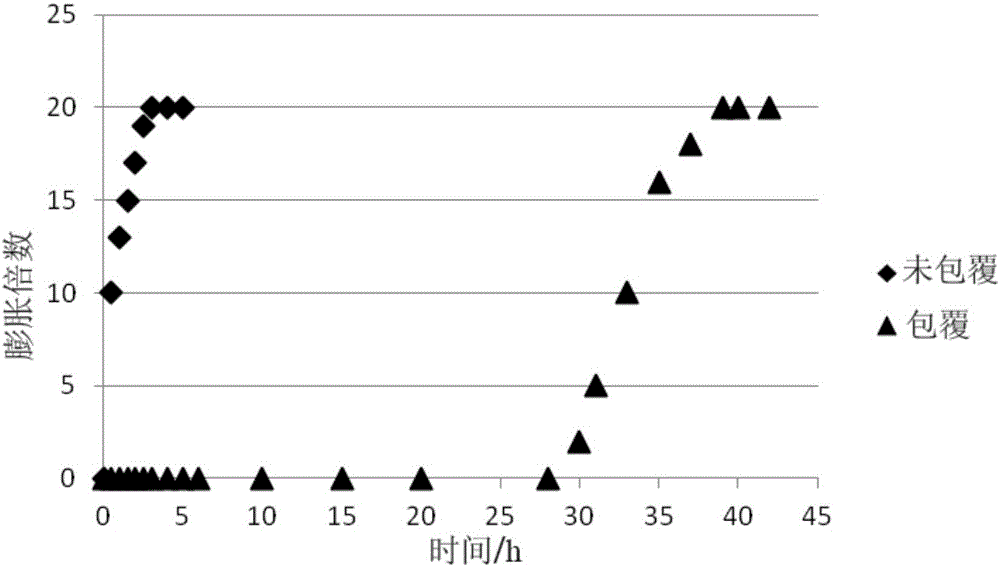

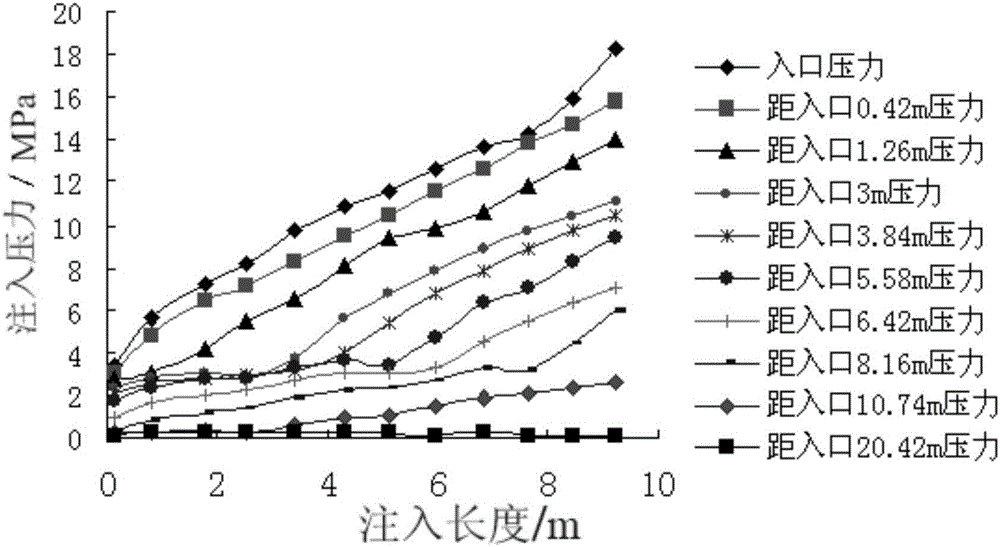

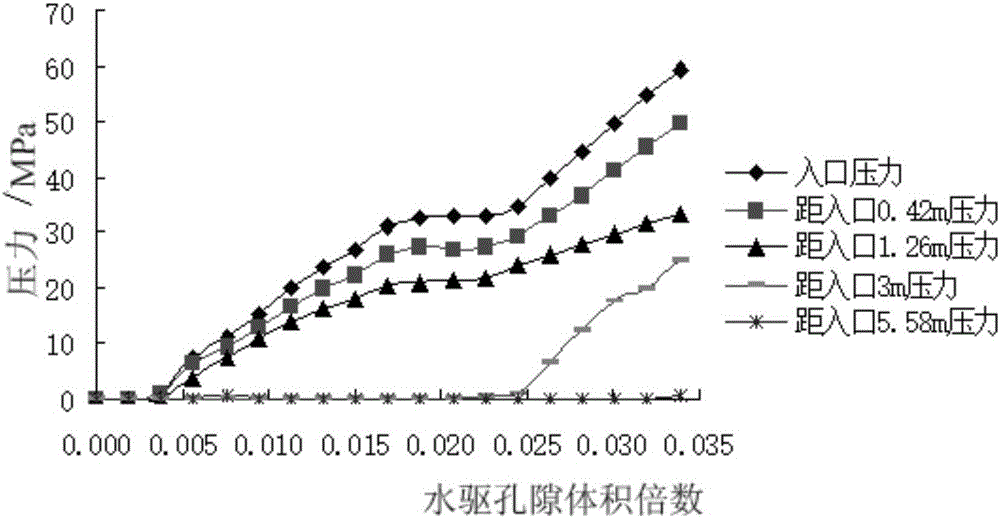

Functional desmosome profile control agent and preparation method and application thereof

ActiveCN105802597AWith water swellingImprove water absorptionFluid removalDrilling compositionEngineeringOil well

The invention provides a functional desmosome profile control agent and a preparation method and application thereof.The functional desmosome profile control agent is prepared from, by weight, 0.5%-11% of functional desmosome profile control agent particles, 0.1%-1% of guanidine gum and the balance water, wherein the total weight of the functional desmosome profile control agent is 100%, the functional desmosome profile control agent particles comprise inner cores, thermal swelling crosslinking resin films and semi-permeable protective films, the surfaces of the inner cores are wrapped by the thermal swelling crosslinking resin films, and the surfaces of the thermal swelling crosslinking resin films are wrapped by the semi-permeable protective films.The invention further provides the preparation method of the functional desmosome profile control agent and application of the functional desmosome profile control agent in oil well deep profile control.The functional desmosome profile control agent has the characteristics of temperature resisting, salt resisting, swelling delaying, crosslinking under heating and the like and is a novel profile control agent which is convenient to construct and easy to operate.

Owner:北京石大瑞伽石油技术开发有限公司

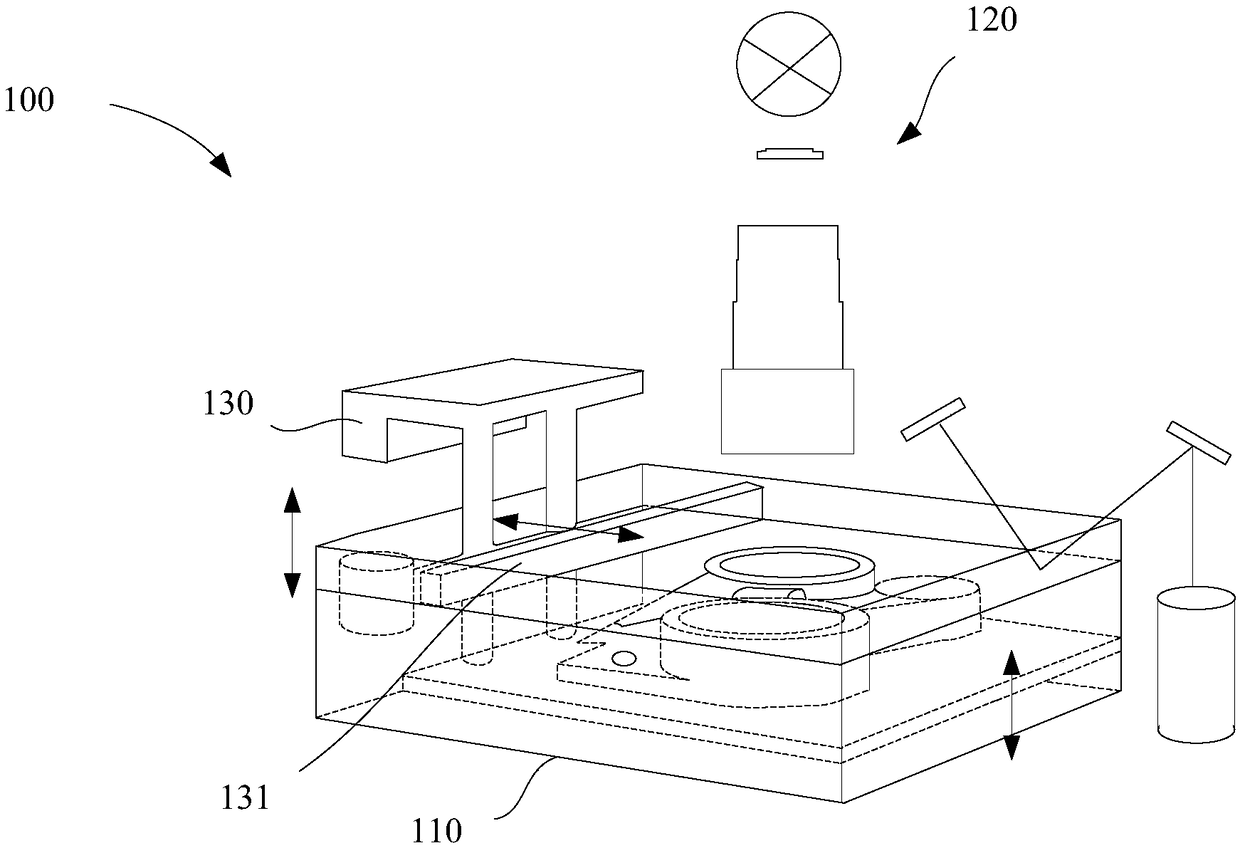

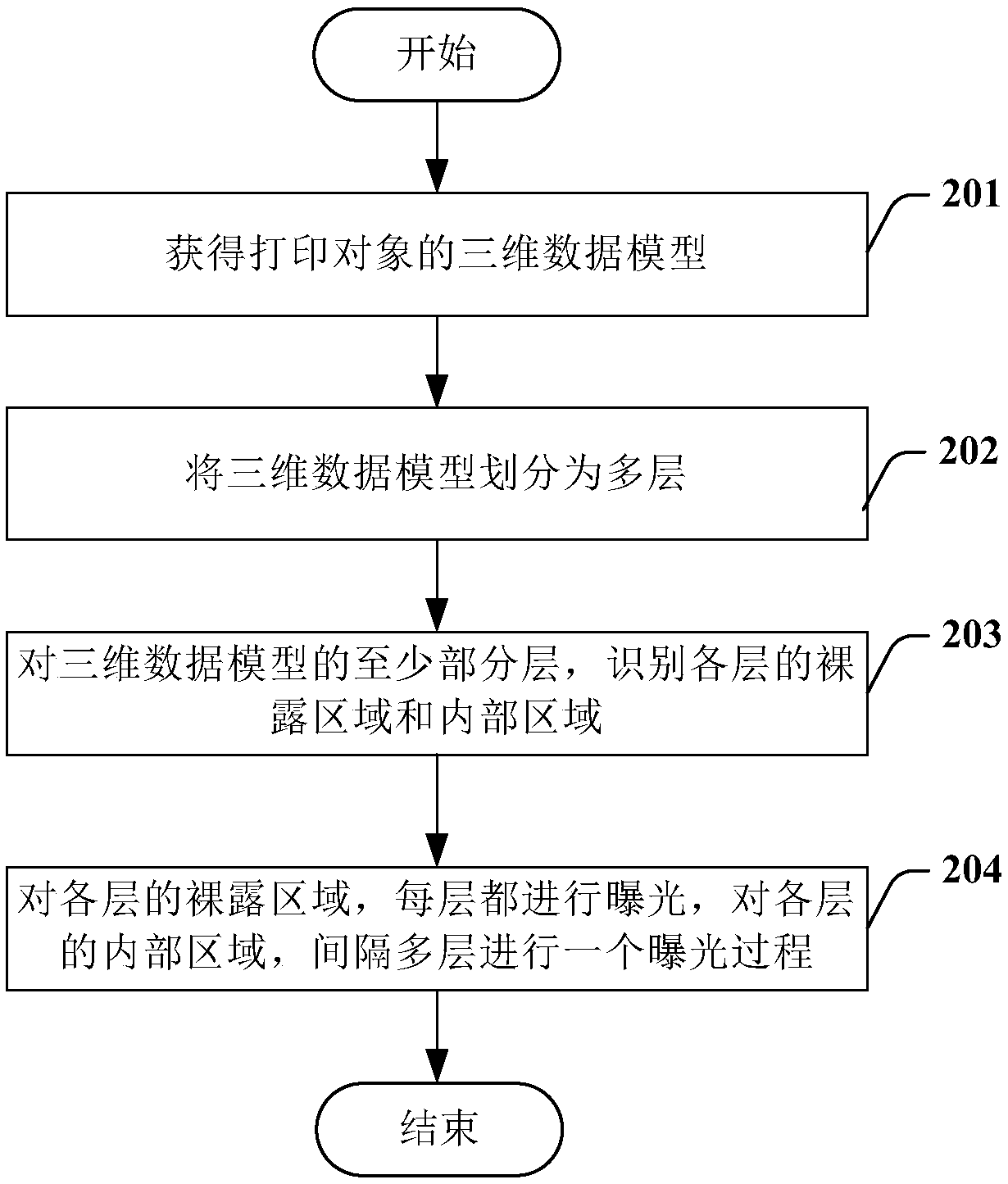

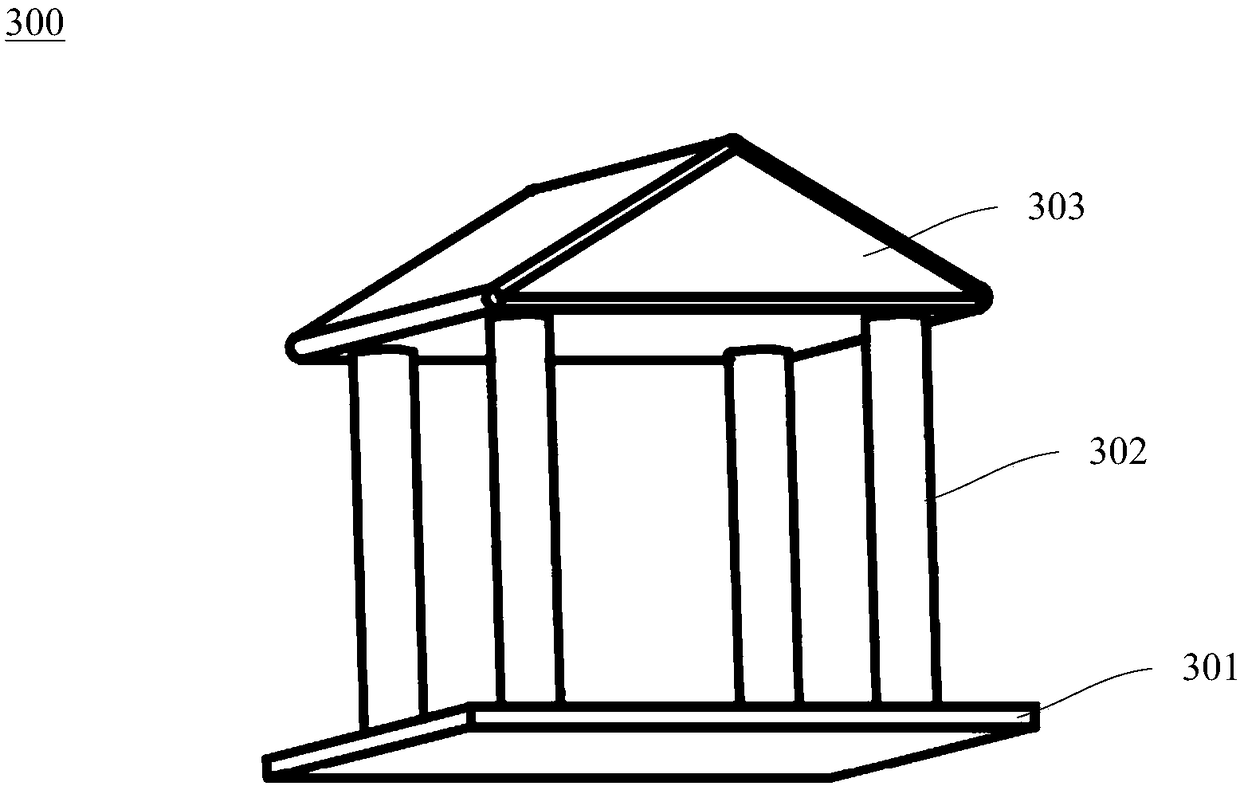

Light curing type three-dimensional printing method and device

ActiveCN108327253AReduce shrinkage buildupLow exposure intensityAdditive manufacturing apparatus3D object support structuresBiomedical engineeringMultiple layer

The invention relates to a light curing type three-dimensional printing method and device. The light curing type three-dimensional printing method comprises the following steps that a three-dimensional data model of a printed object is obtained; the three-dimensional data model is divided into multiple layers; for at least some layers of the three-dimensional data model, the exposed area and internal area of each layer are recognized; for the exposed area in each layer, each layer is exposed, and for the internal area in each layer, one exposing process is carried out on every multiple layersat intervals.

Owner:PRISMLAB CHINA +1

High-strength high-ductility ceramic slab and preparation method thereof

InactiveCN109665811AReduce ignition lossPrecise control of cutting amountCeramic materials productionClaywaresBrickCrack resistance

The invention relates to a high-strength high-ductility ceramic slab and a preparation method thereof. The preparation method includes the steps such as preparation of green bodies, assembling of facilities for a ceramic production line and a glazing line, digital printing and high-temperature firing. By application of the optimum formula with high aluminum, high potassium and low calcium and magnesium, loss on ignition is low; through the improved firing process, the green bodies have low shrinkage, wide range of temperature and high quenching-cracking resistance performance; since polishingis carried out through rigid abrasive blocks and flexible abrasive blocks alternatively, polishing cutting output is reduced and cutting output of the green bodies can be controlled effectively accurately. The ceramic slab prepared by the method has the advantages of high strength and high ductility, and its modulus of rupture is up to 52Mpa.

Owner:FOSHAN SHI WAN YING BRAND CERAMICS CO LTD

Method for keeping expansion of steel tube concrete

InactiveCN1562857AImprove pumping performanceReduce dosageSolid waste managementSuperplasticizerExpanded clay aggregate

The characteristic is that porous ceramsite light aggregate with grain size 1.5-5 mm, water adsorption 8-12 percent, drum pressure strength 6-12 Mpa is preprocesed by soaking and absorbing water, then to be dried in the shade, the dried porous ceramsite light aggregate is used as fine aggregate to instead of 10-20 percent of sand, the matching ratio of each compound (kg / m3) is water 182, silicate cement 460, UEA expanding agent 55, flyash 60, sand (fineness module is 2.5-3.0) 560, breakstone (continuous graded interval grain size is 5-20 mm) 1033, amidogen sulphonate high-efficiency water-reducing agent 12, which are mixed and stirred to produce C60 steel pipe concrete.

Owner:WUHAN UNIV OF TECH

Slag powder-doped composition for preparing white facing as-cast finish concrete

The invention discloses a slag powder-doped composition for preparing white facing as-cast finish concrete. The composition is characterized by consisting of the following components in parts by weight: 180-260 parts of cement, 85-110 parts of water, 330-390 parts of sand, 500-580 parts of stone, 2.0-4.0 parts of additive, 1 part of titanium dioxide and 20-60 parts of slag powder. In the composition disclosed by the invention, the proportion of the components is more scientific and reasonable, and the working performance meets the requirements on concrete pumping and pouring; and moreover, the bleeding and separation are avoided, the shrinkage is low, and the formed concrete is dense and has strong texture. With the formula, the large-flow regime white as-cast finish concrete has the advantages of good fluidity, good workability, good water-retaining property, low slump loss, strong pumpability and the like in concrete construction; and the strength of the formed concrete can be guaranteed, the surface gloss is good, and the chromatic aberration meets the requirement on the quality of the facing as-cast finish concrete.

Owner:ZHEJIANG CONSTR ENG GRP CO LTD

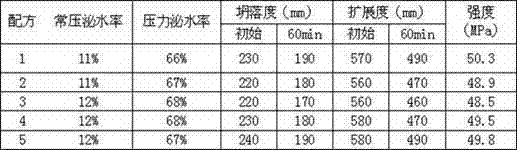

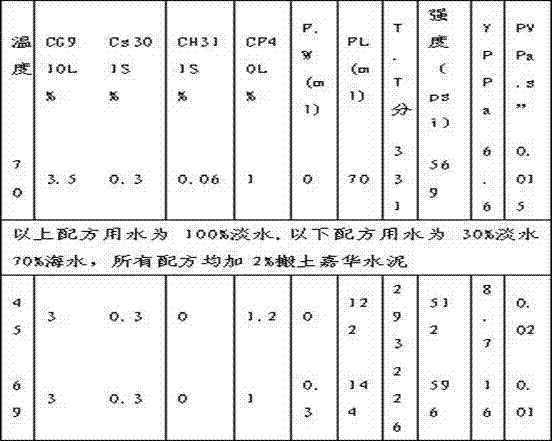

High-temperature salt-resistant fluid loss agent and production method thereof

InactiveCN102643632AGood construction performanceReduce fluid lossDrilling compositionAcrylonitrileCement slurry

The invention relates to a high-temperature salt-resistant fluid loss agent CG910L and a production method thereof, belonging to the field of casing and cementing. The high-temperature salt-resistant fluid loss agent CG910L meets the requirement of casing and cementing work when a well is drilled in case of seep well and complex stratum and aims at improving the construction performance of cement slurry, reducing the filter loss of the cement slurry and reducing the shrinkage mass of cement stone. The high-temperature salt-resistant fluid loss agent CG910L comprises the following components: 2-acrylamido 2-methyl propanesulfonic acid, acrylamide, methacrylic acid, acrylonitrile, an activating agent, an initiator, an emulsifying agent, a terminating agent and deionized water. The high-temperature salt-resistant fluid loss agent CG910L has the following advantages that 1, the construction performance of the cement can be improved; 2, the filter loss of the cement slurry can be reduced; 3, the shrinkage mass of the cement stone can be reduced, and the gluing characteristic among a cement ring, a sleeve and the stratum can be improved; 4, the elasticity and the impact resistance of the cement stone can be improved, the production service life of an oil-gas well can be prolonged, and the fragmentation degree of the cement ring caused by perforation can be reduced; and 5, the use temperature range is: 150-180.

Owner:茂名市三元化工有限公司

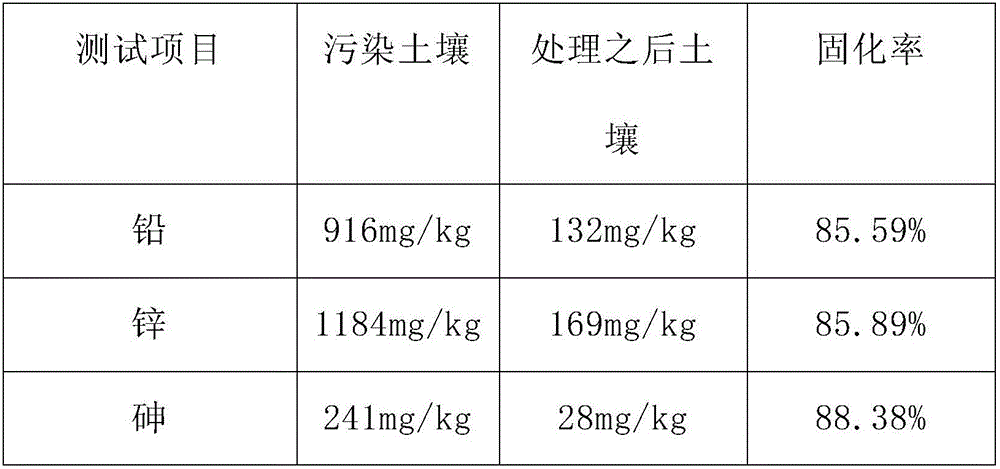

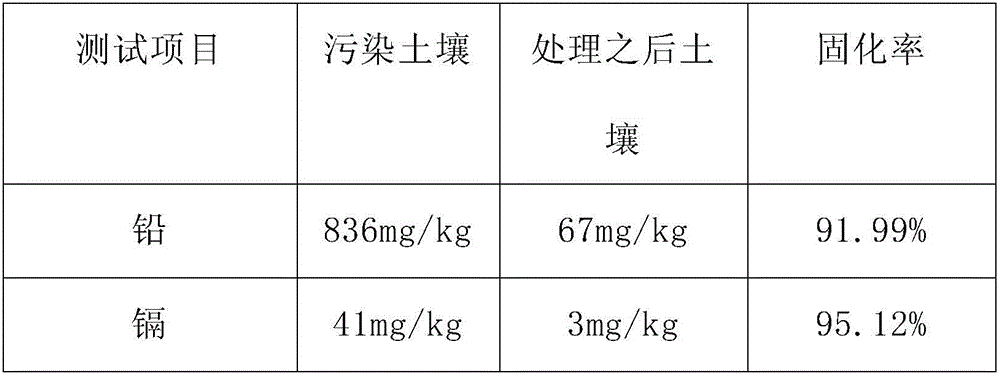

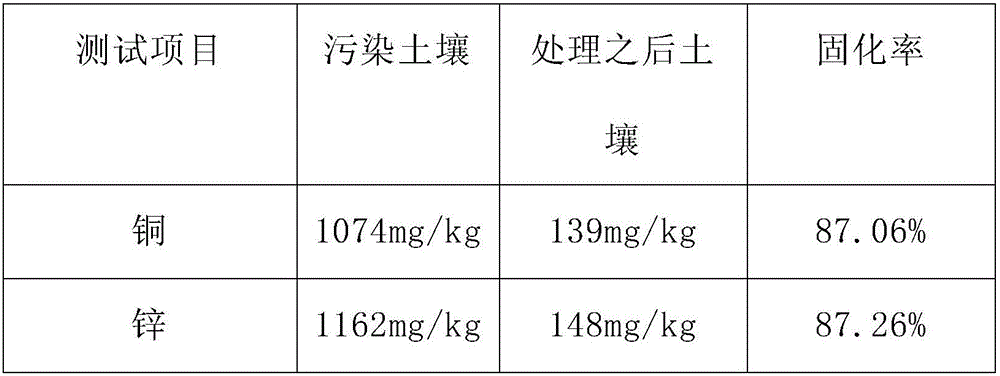

Heavy metal pollution soil restoration agent and use method thereof

InactiveCN106433668AImprove adsorption capacityEffectively fixedOrganic fertilisersSoil conditioning compositionsSocial benefitsTO-18

The invention provides a heavy metal pollution soil restoration agent, and relates to a soil restoration agent. The restoration agent comprises a pretreatment curing ingredient and an excitation curing ingredient, wherein the pretreatment curing ingredient comprises modified expanded vermiculite; the excitation curing ingredient comprises 4 to 18 percent of slaked lime, 4 to 10 percent of chitosan, 16 to 34 percent of water glass and 45 to 60 percent of fly ash. The heavy metal pollution soil restoration agent and the use method have the advantages that the efficient curing of soil heavy metal can be realized; the soil heavy metal pollution problem is solved; in addition, the high acidity or high alkality and secondary pollution can be effectively avoided; the uniformity of environment benefits and social benefits is realized.

Owner:广东省润土环境治理有限公司

Composite structure and manufacturing method thereof

The invention relates to a composite structure with a high bearing capacity. The composite structure with the high bearing capacity comprises a part A and a part B. The part A is provided with a cavity, and the part B is a solidifiable material filled in the cavity and is under the pressure in the solidification process. The part B comprises a part B1 and a part B2, a material B1 is a cement-basedmaterial, a material B2 is a solidifiable material, and the material B2 has relatively high flowability compared with the material B1. A built-in or / and external volume compensation device is / are arranged. When the material(s) B1 and / or B2 are / is contracted and the material B2 has flowability, the built-in volume compensation device is expanded, or the external volume compensation device squeezesthe flowing and semi-flowing solidifiable material or solid material into a material B2 area in the cavity. The volume compensation device fills up the contracted volume, the pressure of the materialB2 in the cavity is maintained, and the pressure of the material B1 is further maintained. Optimally, the flowing time of the material B2 is larger than the time for the material B1 to arrive at a contraction turning point, and the pressure maintaining time at least exceeds the time for the contraction turning point of the material B1 to appear.

Owner:王哲

Die and compression forming method for composite-material formed parts

InactiveCN105711110ASmall coefficient of thermal expansionSmall amount of shrinkageThermal expansionMetal

The invention relates to a die and a compression forming method for composite-material formed parts. The technology disclosed by the invention is characterized in that a gap between a female die and a male die is increased and greater than the theoretical thickness of products; the female die is made from a material with a low thermal expansion coefficient, for example, invar steel; the male die is made from a material with a high thermal expansion coefficient, for example, aluminium alloy; in order to guarantee that the die achieves correct product dimensions (the shape of the male die and the shape of the female die) at a curing temperature, the normal-temperature dimensions of the die need to be reduced according to the respective shrinkage ratio coefficients of the female die and the male die respectively; the dimension shrinkage amount of the female die is low, and the dimension shrinkage amount of the male die is high, therefore, the normal-temperature gap between the female die and the male die is increased; and during curing heating, the expansion amount of the male die is high, a die cavity gap is reduced, a laying layer is pressed towards the female die, and a metal expansion compression effect is achieved. After curing is concluded, the die starts to cool, the shrinkage amount of the male die is high; and the laying layer is already cured into a composite material, and because the thermal expansion coefficient of the composite material is low, and the shrinkage amount of each composite-material product is low, the male die is separated from the product, and an automatic die release effect is achieved.

Owner:HARBIN

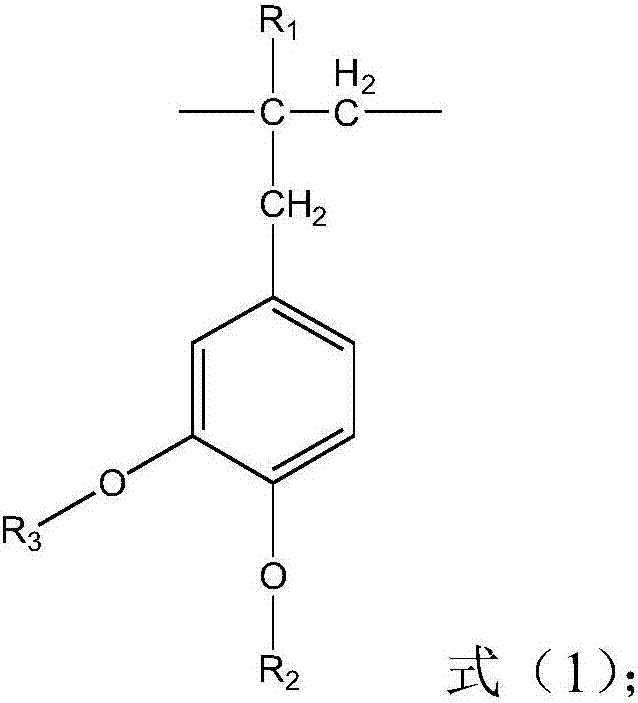

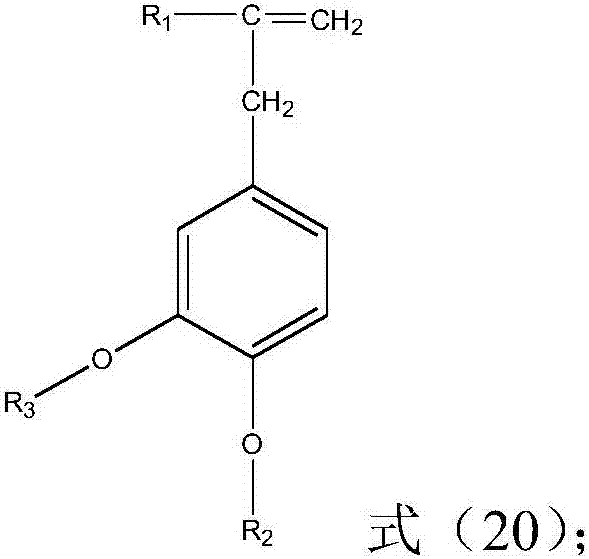

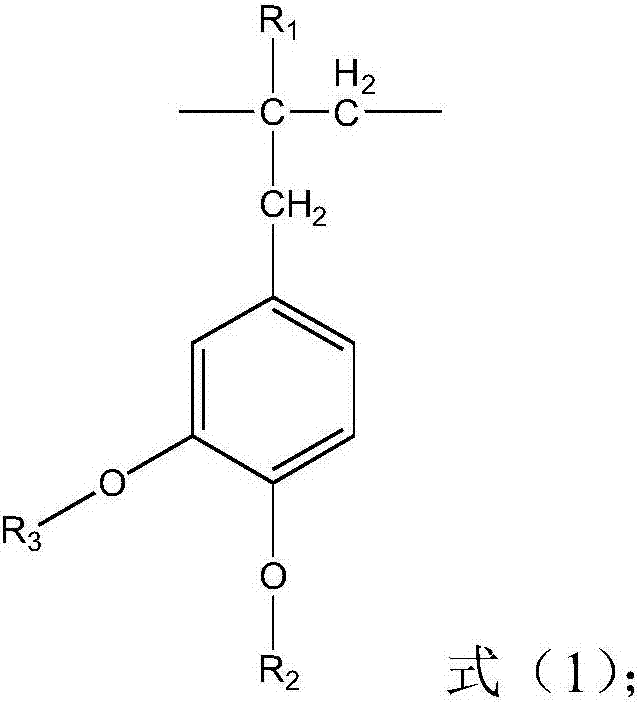

Alkali-soluble resin polymer and preparation method thereof, photosensitive resin composition and applications of alkali-soluble resin polymer and the photosensitive resin composition

ActiveCN108003290AGood flexibilityLower the altitudeOptical filtersPhotomechanical apparatusCooking & bakingSide chain

The present invention discloses an alkali-soluble resin polymer and a preparation method thereof, a photosensitive resin composition and applications of the alkali-soluble resin polymer and the photosensitive resin composition, wherein the alkali-soluble resin polymer is a random copolymer containing a first structural unit and a second structural unit. According to the present invention, the second structural unit containing the flexible ether bond side chain is introduced into the alkali-soluble resin polymer so as to increase the flexibility of the whole resin system; and the shrinkage of the RGB three-color photoresist material prepared from the photosensitive resin composition containing the alkali-soluble resin polymer is reduced during the drying and the hard baking, such that the height of the horn-like projection substance on the overlapping position of the color photoresist material and the black matrix (BM) can be significantly reduced.

Owner:GUAN ETERNAL MATERIAL TECH +1

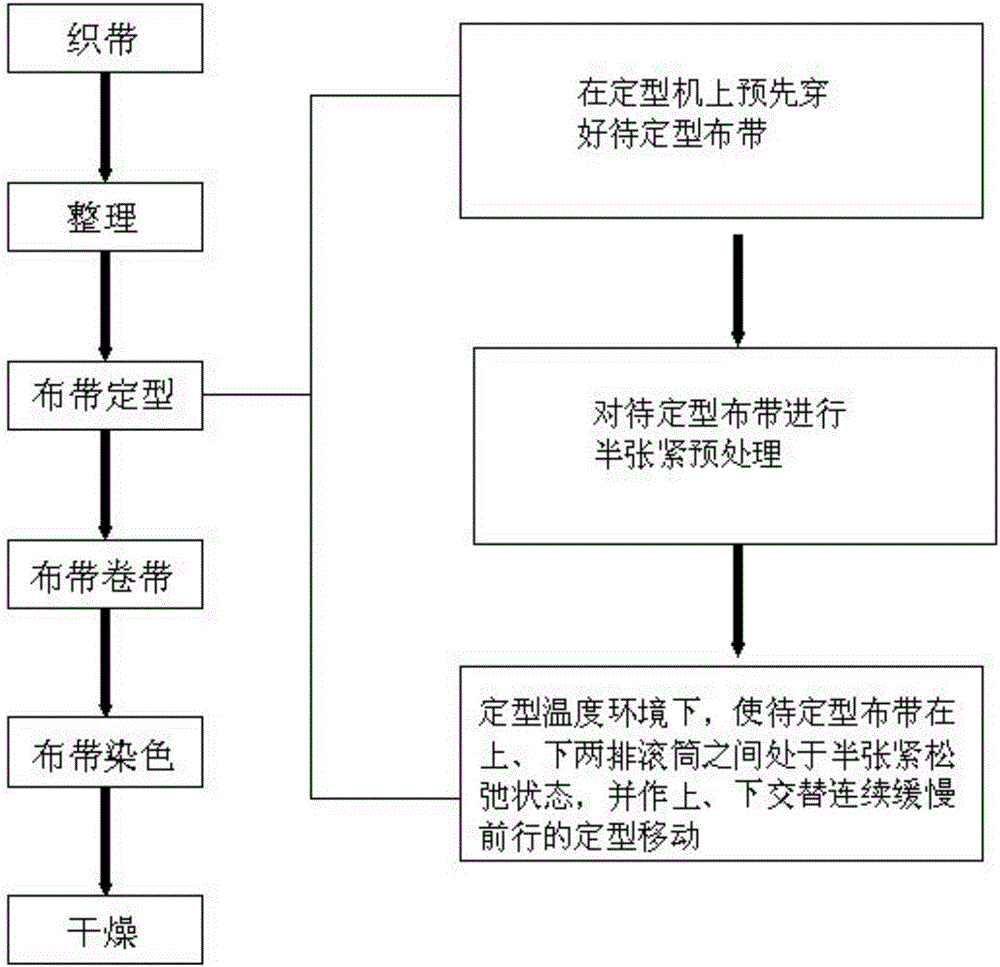

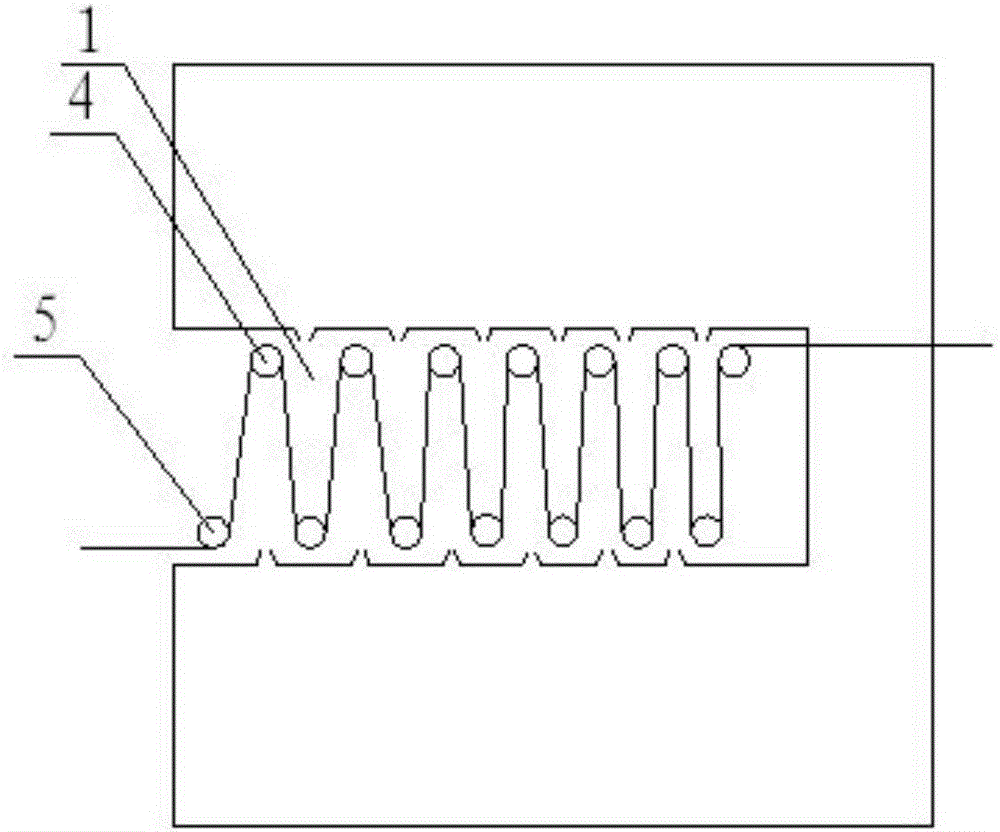

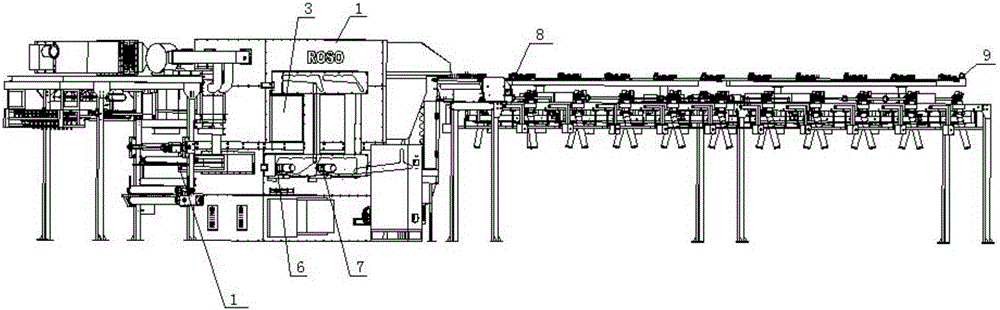

Production technology of zipper cloth tape

InactiveCN105220388AAvoid color differencesTraining step improvementsHeating/cooling textile fabricsElectric machineryEngineering

The invention discloses a production technology of a zipper cloth tape. The production technology comprises a cloth tape setting process, wherein the cloth tape setting process comprises the following steps: penetrating a to-be-set cloth tape on a setting machine in advance, carrying out semi-tensioning pretreatment on the to-be-set cloth tape, starting the setting machine, continuously feeding the to-be-set cloth tape into a setting chamber of the setting machine in a semi-tensioning state by using a tension constant control device driven by a first motor; enabling the to-be-set cloth tape to be in a semi-tensioning relaxed state between upper and lower rows of rollers in the setting chamber, and carrying out up-and-down alternately continuous and slow forward setting movement to a tape outlet direction of the setting chamber, so as to obtain the set cloth tape with the shrinking percentage of 1%-7%; and controlling the rotating speeds of the motors, and enabling the set cloth tape to reach the required shrinking percentage. According to the production technology, the cloth tape is shrunk in set in advance, so that the shrinkage amount is reduced in subsequent dyeing process, and further cloth tape indentation is prevented; the color difference of a zipper among the upper layer, the middle layer and the lower layer in the dyeing process is avoided; and the cloth tape dyeing uniformity is improved.

Owner:CHENGDU ROCK SOLID AUTOMATION TECH

Processing technology for collar

The invention discloses a processing technology for a collar, which comprises the following steps of: putting a top collar fabric and a stand collar fabric into a bonding machine for preshrinking; adding a specific bonding substance into a top collar lining, and putting on the top collar fabric; adding a specific bonding substance into a stand collar lining, and putting on the stand collar fabric; bonding the top collar lining and the top collar fabric for the first time to form a top collar layer, and bonding the stand collar lining and the stand collar fabric for the first time to form a stand collar layer; and putting the top collar layer and the stand collar layer into the bonding machine, and bonding for the second time. By the processing technology of one-time preshrinking and two-time bonding, a shirt collar produced at high temperature and under high pressure has stable quality, is durable and washable, is not bubbled or deformed, and meets the technical requirement of the national standard.

Owner:GUANGDONG PENGYUN IND

Method for producing computer mouse

InactiveCN1609776AImprove performanceSmall amount of shrinkageWood working apparatusInput/output processes for data processingKey pressingEngineering

The present invention provides one kind of computer mouse with bamboo casing and its making process. The computer mouse has the advantages of being environment friendly, easy to clean and low in cost and produces natural feeling. The making process includes splitting bamboo, sterilizing and killing pest, pressing into bamboo plate, processing bamboo plate into the main outer casing of mouse in the required size, cutting the bamboo plate into back cover plate of mouse, mounting the buttons and electronic elements, and connecting to form the mouse.

Owner:珠海市海外海科技有限公司

Anti-floating anchor rod and construction methods thereof

PendingCN108678032AIncrease frictionStrong anti-floating abilityProtective foundationBulkheads/pilesFriction forceBuilding construction

The invention discloses an anti-floating anchor rod. The anti-floating anchor rod comprises an anchor rod body and an anchor rod pile coating the anchor rod body; the anchor rod pile is a concrete pile with the strength being at least C25 and comprises a main pile body and an expanding head connected at the bottom of the main pile body; the expanding head and the main pile body are arranged coaxially and are integrally molded; and the diameter of the expanding head is larger than that of the main pile body. The anchor rod pile of the anchor rod is the concrete pile and comprises the main pilebody and the expanding head connected at the bottom of the main pile body, and the diameter of the expanding head is larger than that of the main pile body, so that the anti-floating anchor rod is high in anti-floating ability. The invention further discloses two construction methods of the anti-floating anchor rod. The two construction methods have the advantages that the methods are simple to operate and the friction force between the molded anchor rod pile and an anchor hole is large.

Owner:黄水森 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com