Method of preparing SiCp/Al composite material with complicated shape and high volume percent ratio

A technology of composite materials and complex shapes, which is applied in the field of preparation of SiCp/Al composite materials with complex shapes and high volume ratios, achieving high dimensional accuracy, low cost, and good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

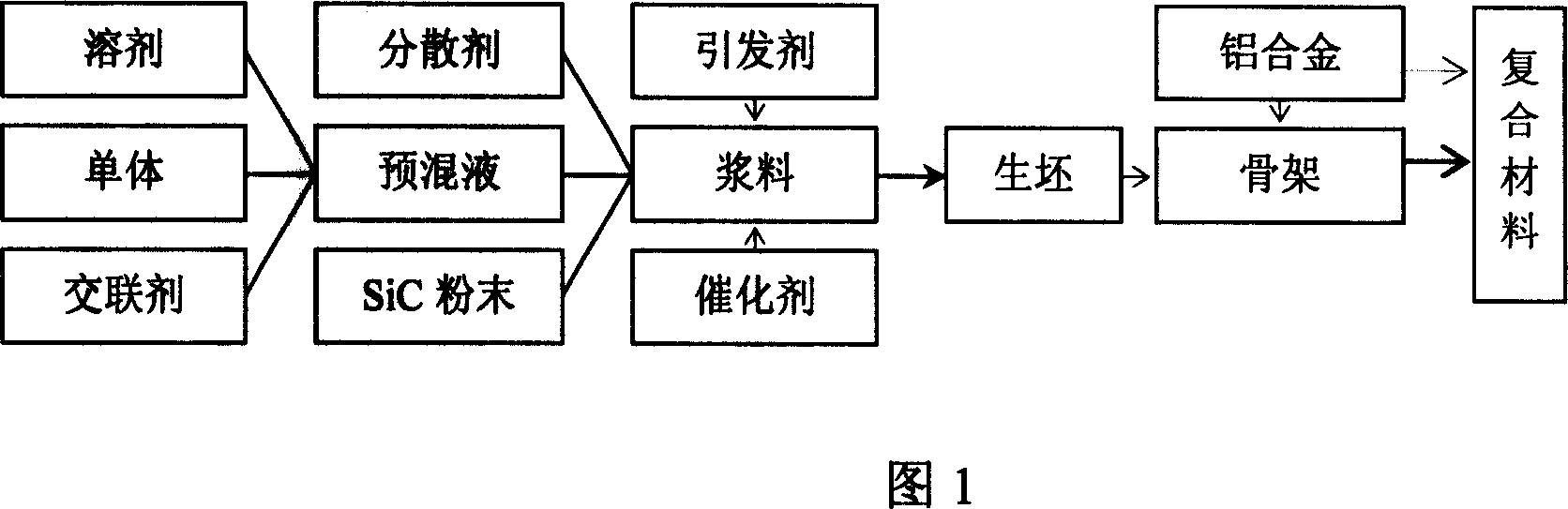

Method used

Image

Examples

Embodiment 1

[0017] Example 1: Preparation of SiC with a volume fraction of 50% p / Al composite parts

[0018] Using deionized water as a solvent, acrylamide (AM) as a monomer, and methylenebisacrylamide (MBAM) as a crosslinking agent, prepare a premix solution with a monomer mass fraction of 10% and a mass ratio of MBAM to AM of 1:30 . Add the powders with a particle size of 2.5 μm and 28 μm to the above-mentioned premixed solution at a mass ratio of 1:4, and simultaneously add a 1.5% powder mass fraction of tetramethylammonium hydroxide 10% (TMAH) aqueous solution as a dispersant , making SiC account for 50% of the overall integral. Use alumina as the ball milling medium, and mix in a ball mill barrel for 2 hours to obtain a uniformly dispersed SiC slurry. Add total volume 0.8% ammonium persulfate 5% aqueous solution (ASP) and 0.08% tetramethylethylenediamine (TEMED) as catalyst in above-mentioned slurry, inject in the non-porous plastic mould, put into Keep warm for 40 minutes in an...

Embodiment 2

[0019] Example 2: Preparation of SiC with a volume fraction of 60% p / Al composite parts

[0020] Using water as solvent, acrylamide (AM) as monomer, and methylenebisacrylamide (MBAM) as crosslinking agent, prepare a premix solution with a monomer mass fraction of 15% and a mass ratio of MBAM to AM of 1:70. Powders with a particle size of 7 μm and 63 μm were added to the above premixed solution at a mass ratio of 1:2, and a 10% aqueous solution of tetramethylammonium hydroxide (TMAH) with a powder mass fraction of 2.0% was added as a dispersant, and ball milled For 4 hours, stir evenly to obtain a uniformly dispersed SiC slurry, stir and add 0.6% ammonium persulfate 5% aqueous solution (ASP) and 0.06%‰ tetramethylethylenediamine (TEMED ) as a catalyst, stir well and pour into a non-porous plastic mold, put it into a 60°C high-humidity incubator and keep warm for 40 minutes, and continue to keep warm for 5 hours after demoulding. Speed up drying until the quality no longer ...

Embodiment 3

[0021] Example 3: Preparation of SiC with a volume fraction of 70% p / Al composite parts

[0022] Using deionized water as a solvent, acrylamide (AM) as a monomer, and methylenebisacrylamide (MBAM) as a crosslinking agent, prepare a premix solution with a monomer mass fraction of 20% and a mass ratio of MBAM to AM of 1:120 , the powders with particle sizes of 0.8 μm, 7 μm and 63 μm were added to the above premixed solution at a mass ratio of 1:2:4, so that the volume of SiC accounted for 70% of the total volume, and the powder mass fraction was added at the same time 2.8% Tetramethylammonium hydroxide 10% (TMAH) aqueous solution was used as a dispersant, ball milled for 6 hours, stirred evenly to obtain a uniformly dispersed SiC suspension, and a 5% aqueous solution of ammonium persulfate with a slurry volume fraction of 0.4% was added to the above suspension (ASP) and 0.04% tetramethylethylenediamine (TEMED) are used as catalysts, stirred evenly and poured into a non-porous ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com