Patents

Literature

191results about How to "Unlimited shape" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of copper alloys with high strength and high electric conductivity

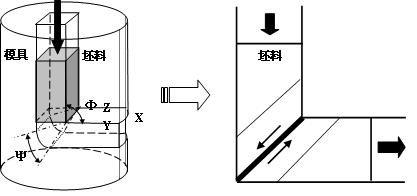

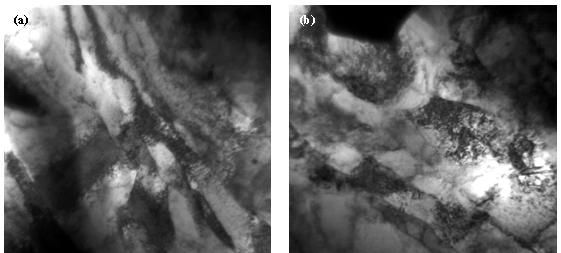

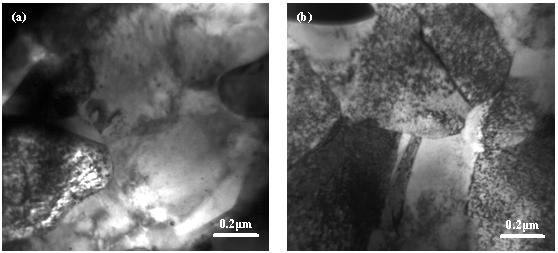

The invention relates to a preparation method of copper alloy materials, in particular to a preparation method of aged copper alloys with high strength and high electric conductivity. The aged copper alloys comprise copper chromium (Cu-Cr) alloy, copper zirconium (Cu-Zr) alloy and copper chromium zirconium (Cu-Cr-Zr) alloy, wherein the content of Cr is 0.1-0.6% and the content of Zr is 0.01-0.5%. The preparation method mainly comprises the following steps: according to the percentages by weight, casting by mixed smelting to obtain the Cu-Cr alloy, the Cu-Zr alloy and the Cu-Cr-Zr alloy; performing solution treatment on the cast ingots; performing equal channel deformation at room temperature on the copper alloys after solution treatment; then performing the machining processes such as extruding, drawing or rolling and the like on the Cu-Cr alloy, the Cu-Zr alloy and the Cu-Cr-Zr alloy after equal channel deformation; and finally performing aging treatment on the workpieces. The preparation method overcomes the defect of limited strengthening effect of single components, reduces the adverse effect of excessive elements on the electric conductivity, acquires ultra-fine grains under the conditions of not changing the shapes and sizes of samples, can be combined with the machining processes such as extruding, drawing or rolling and the like, can be used for producing a product with an expected shape, and fully plays the roles of fine grain strengthening and aging strengthening.

Owner:CHANGZHOU UNIV

Material and method for preparing aluminum alloy structural member by using laser 3D (Three-Dimensional) printing technology

InactiveCN104759625AImprove performanceIncrease profitAdditive manufacturing apparatusComputer Aided DesignMaterial synthesis

The invention discloses a material and method for preparing an aluminum alloy structural member by using a laser 3D (Three-Dimensional) printing technology. Technologies such as a CAD (Computer Aided Design) three-dimensional entity model slicing technology, a digital programming technology and a laser quick forming technology and a material synthesis technology are combined integrally; under the condition that no any special mold or tool is used, multi-layer cladding accumulation is performed through quick melting and solidification of a laser beam on an aluminum alloy substrate by taking the powder of Al, Fe, Cu, Si, Ti, B, Mn, C and Ce according to the mass percentage of 80.0, 3.0, 2.0, 3.0, 4.0, 3.0, 1.5, 2.0 and 1.5 as a raw material; an aluminum alloy structural member with good comprehensive performance such as high performance, full compactness and high fatigue life is directly finished from a part digital model in one step. The method has the characteristics of low cost, short period and high material utilization rate, and is suitable for integrated quick forming manufacturing of large-sized and complex aluminum alloy structural members; the shapes and the sizes of the prepared parts are not limited, and the requirement on structural integration can be met.

Owner:GUILIN UNIV OF ELECTRONIC TECH

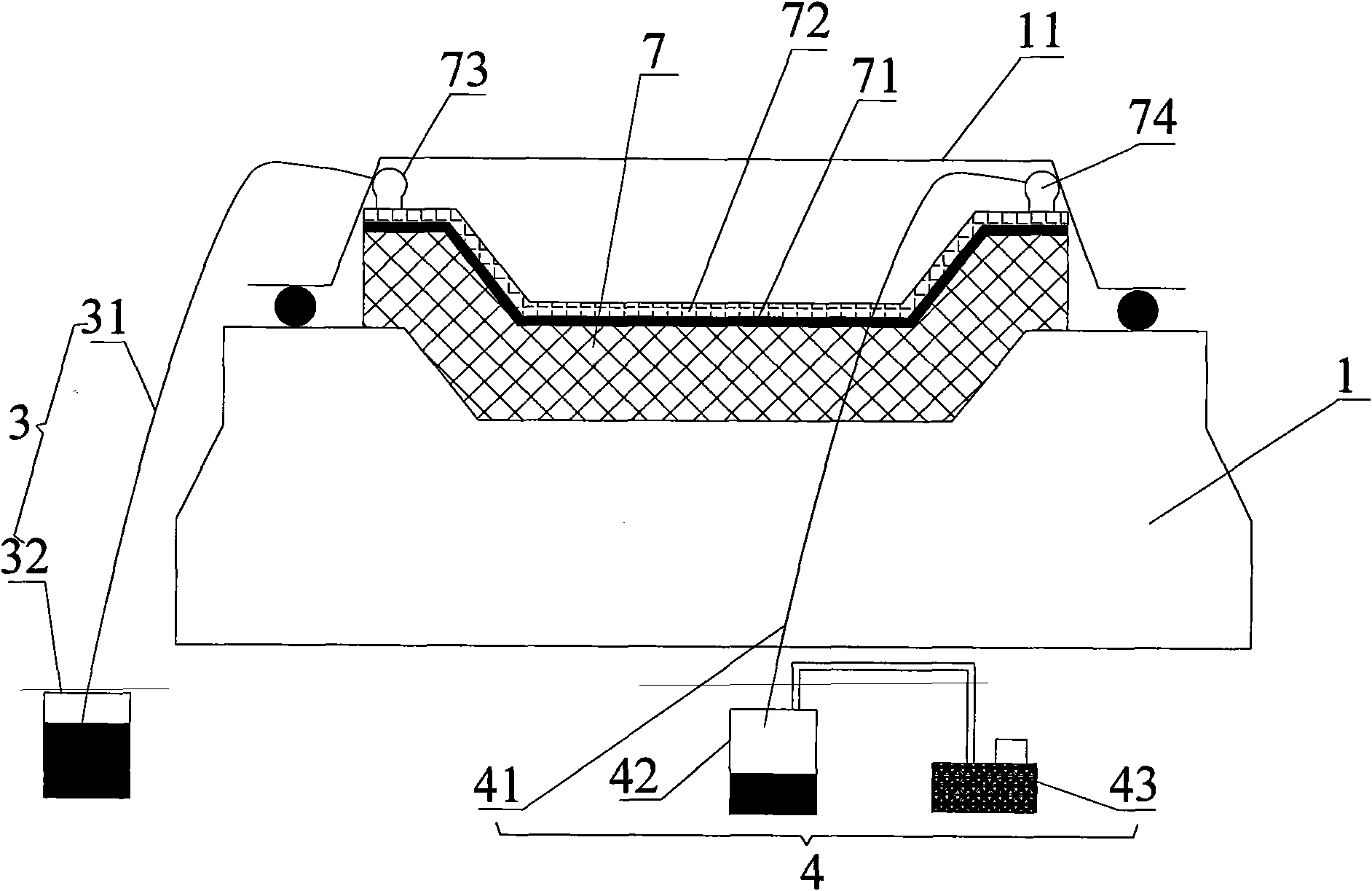

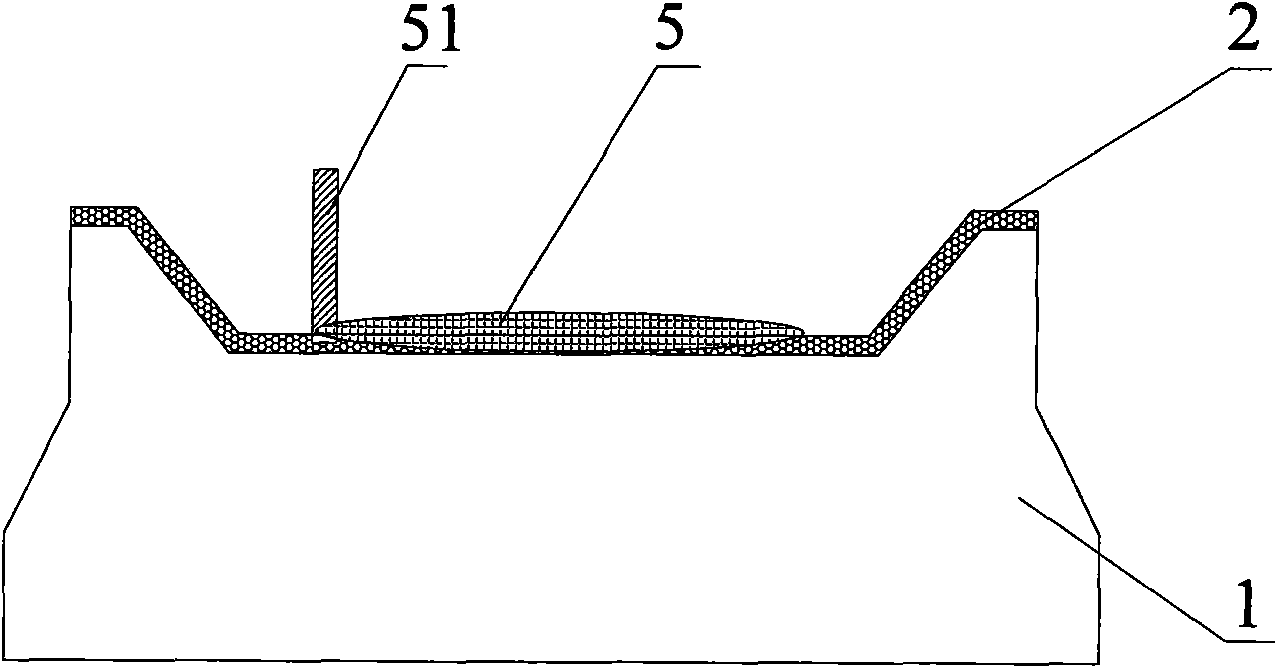

Composite material member with surface function layer and VIMP preparation method thereof

InactiveCN101830095AFast impregnationGood surface qualitySynthetic resin layered productsSurface functionMaterial system

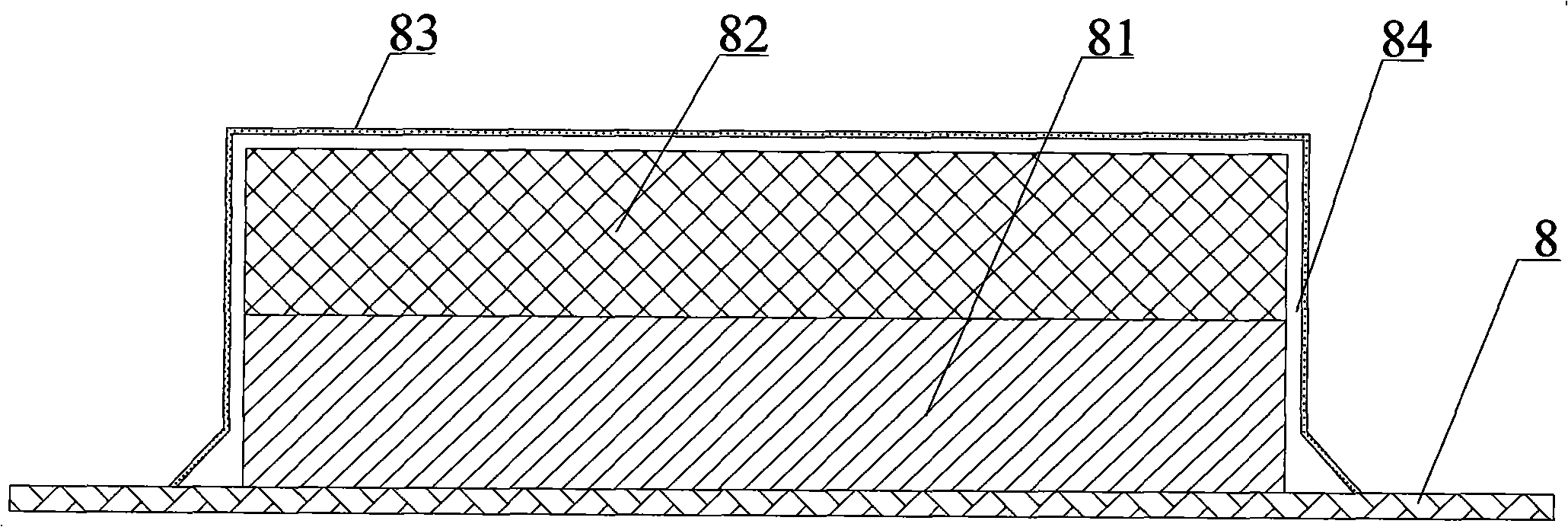

The invention belongs to the technical field of a multilayer structural composite material member and a preparation method thereof and specifically discloses the composite material member with a surface function layer and a VIMP preparation method thereof. The composite material member comprises an outer surface layer and a main body layer, wherein, the outer surface layer and the main body layer are respectively a first composite material system and a second composite material system; and the first composite material system takes epoxy resin, phenolic resin and the like as a matrix, the second composite material system takes unsaturated polyester resin as a matrix, and the two systems take fiber cloth of carbon fiber or glass fiber as reinforcement. The VIMP preparation method comprises the following steps: firstly preparing a reinforced resin film on a die surface for vacuum dip molding by a resin film infiltration process, and then preparing the composite material member with a molding die covered with the reinforced resin film through the vacuum dip molding process. The VIMP process of the invention combines the double advantages of an RFI process and the VIMP process; and the obtained composite material member has better surface quality, better integrity and excellent comprehensive performances.

Owner:NAT UNIV OF DEFENSE TECH

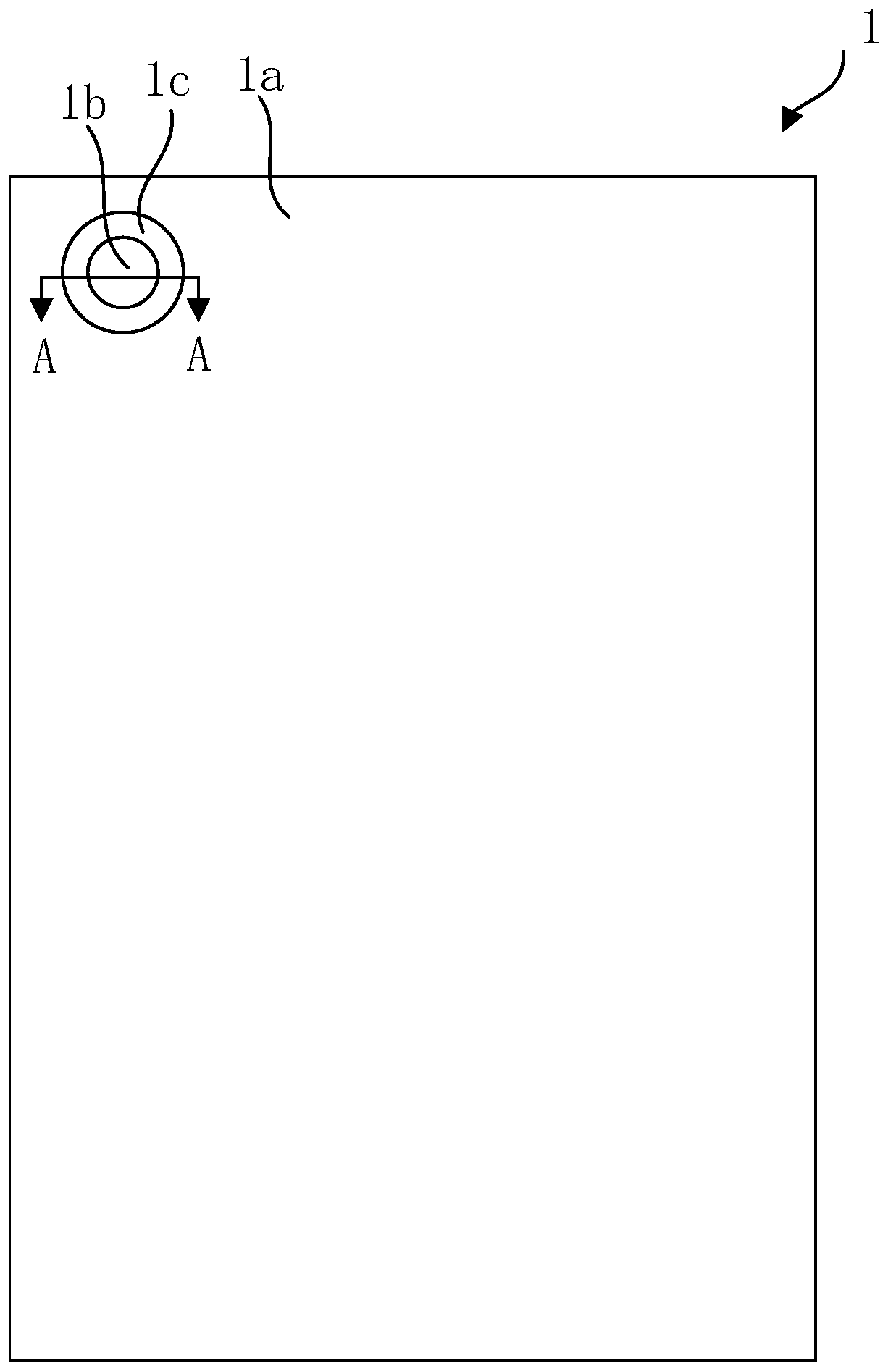

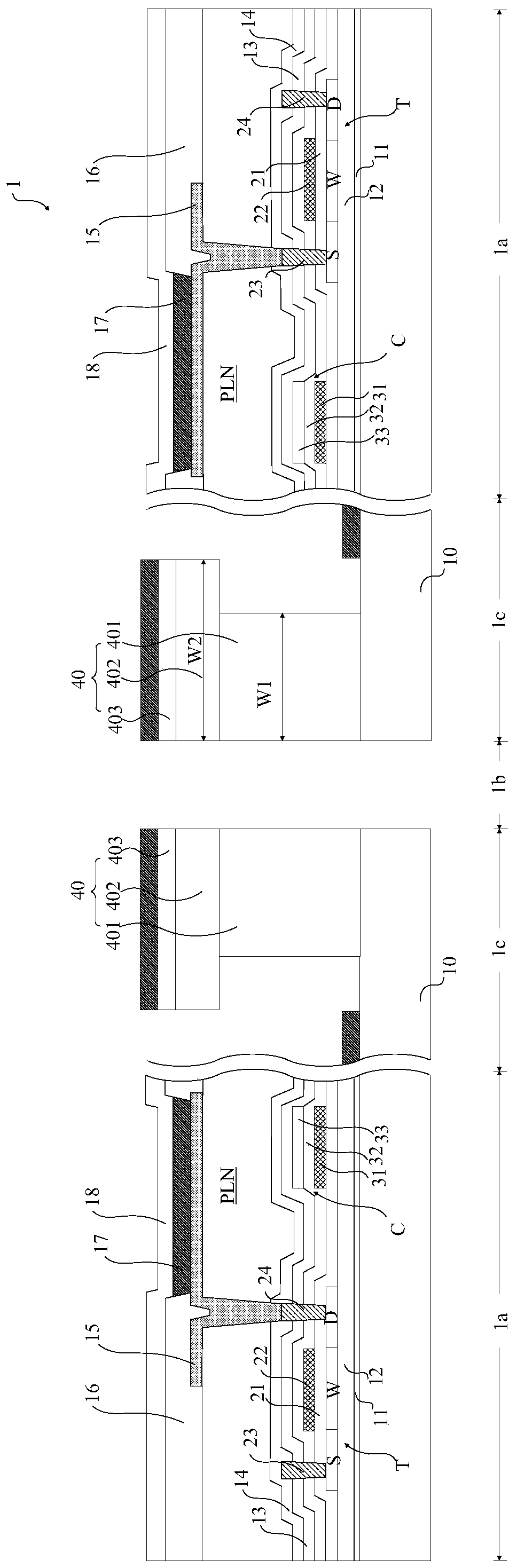

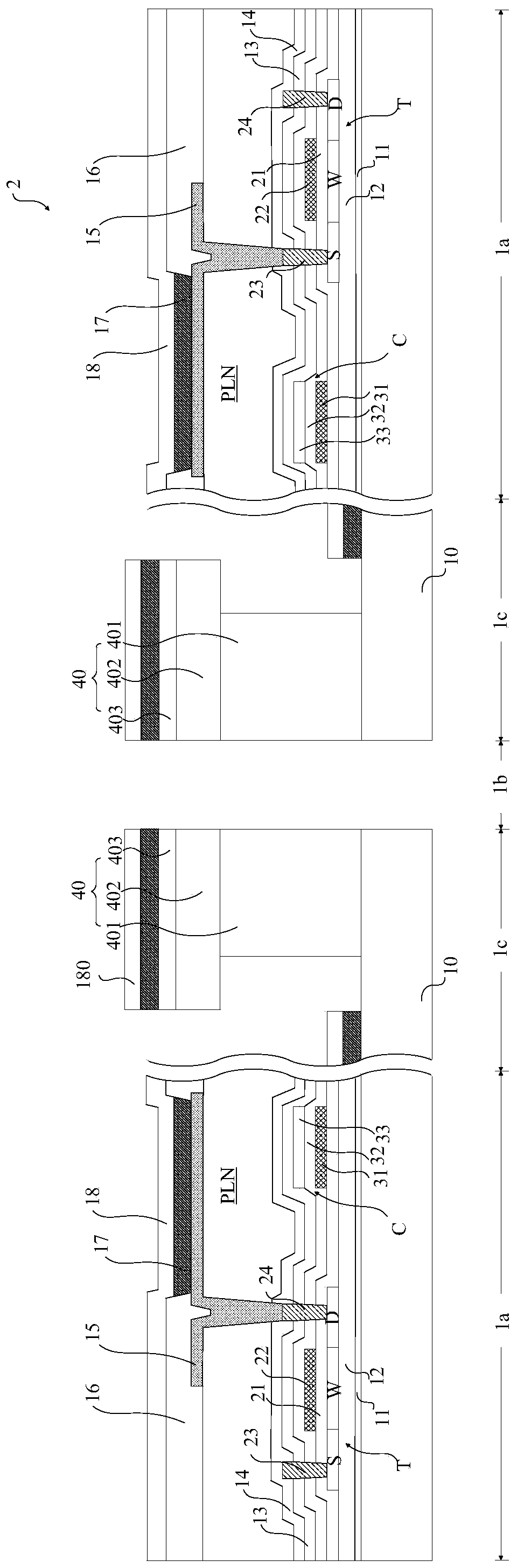

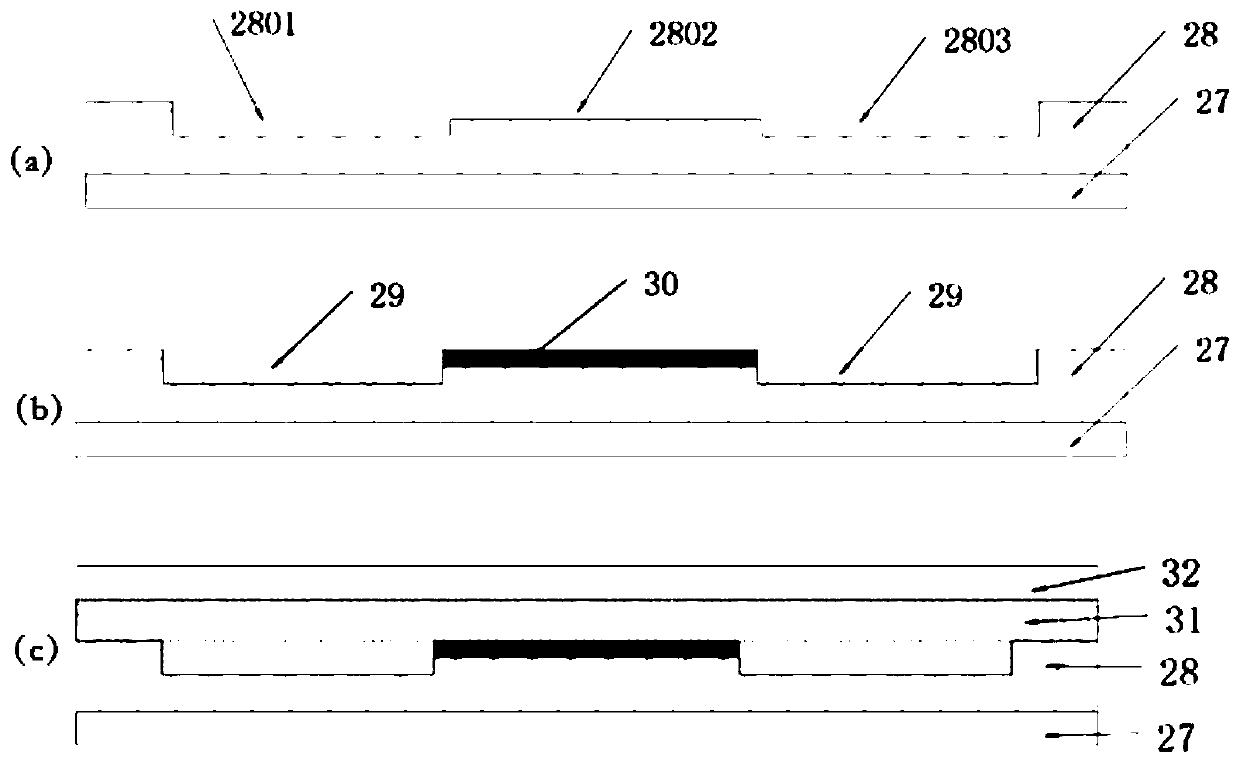

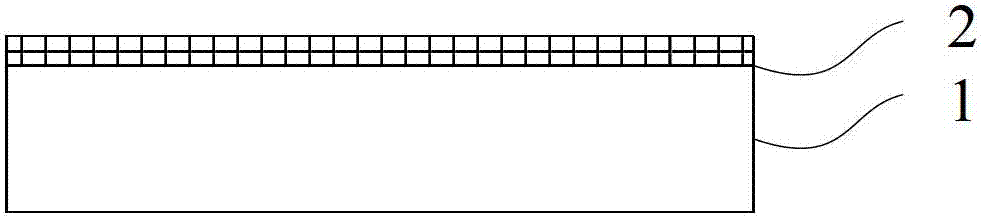

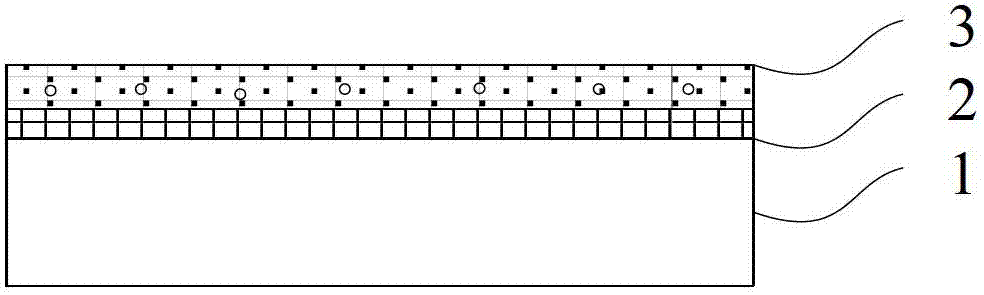

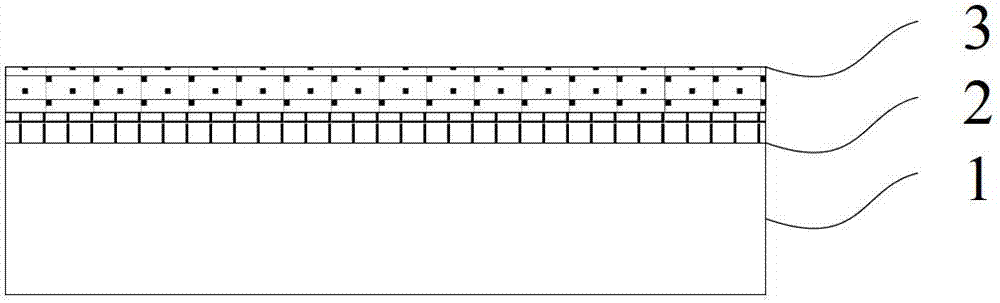

Display device and display substrate thereof

PendingCN110416282AGood partitionImprove pass rateSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceOxygen

The invention provides a display device and a display substrate thereof. The display substrate comprises a display area, a porose area, and a partition area between the display area and the porose area. The partition area is provided with at least one partition ring surrounding the porose area, and is used for partitioning an organic light-emitting material layer. The partition ring comprises at least a support portion and a partition portion. The partition portion is provided with a tensile stress layer used for applying tensile stress to the partition portion. When the organic light-emittingmaterial layer is vapor-deposited, partial section of the partition portion in the partition ring is suspended. The partitioning effect on the organic light-emitting material layer is good, and external water and oxygen can be prevented from entering the display area from the opening. In addition, the partition portion can automatically block the organic light-emitting material layer. The use oflaser burning to remove the organic light-emitting material layer around the porose area is avoided. A hot process is omitted. The spacing between the porose area and the display area is shortened. The border of the porose area is reduced. Third, the tensile stress layer can apply tensile stress to the partition portion to prevent the suspended partition portion from collapsing and falling off. The partitioning performance of the partition portion is reliable.

Owner:YUNGU GUAN TECH CO LTD

Preparation method of high-conductivity aluminum alloy

InactiveCN103276261AHigh affinityPlay the role of hydrogen absorption and hydrogen fixationRare-earth elementElectrical conductor

The invention relates to a preparation method of high-conductivity aluminum alloy and belongs to the field of nonferrous metal materials. The preparation method comprises the following steps of: preparing an aluminum ingot comprising the following alloy elements in percentage by weight: 4.5 to 13.5 percent of Si (silicon), 0.1 to 1.5 percent of Mg (magnesium) and not more than 0.1 percent of impurity elements, smelting the aluminum ingot in a furnace, adding 0.1 to 0.3 percent of zirconium which serves as additive for the alloying treatment, uniformly mixing, then adding 0.1 to 1.35 percent of rare-earth element for degeneration, purifying, degassing and deslagging, and covering the surface of aluminum liquid with a solid covering agent; casting to prepare the aluminum alloy conductor material; and carrying out the first-stage aging treatment and the second-stage aging treatment on the aluminum alloy conductor material, discharging and cooling with air. The manufactured aluminum-silicon alloy can meet the requirements on the aluminum alloy material conductivity and the mechanical property; and moreover, the preparation process is simple, the cost is low, and the mass production is easy to realize.

Owner:JIANGSU UNIV

Activator for magnesium alloy welding

InactiveCN101244497AWell formed weldImprove joint qualityArc welding apparatusWelding/cutting media/materialsAlcoholActive agent

The invention relates to an active agent applying to magnesium alloy welding, belonging to the material engineering technical field, which is characterized in that: the active agent is composed of TiO2, Cr2O3, MgO, MnO2, and CaO and the weight proportion is TiO2: 40 to 70%, Cr2O3: 5 to 20%, MgO: 2 to 20%, MnO2: 5 to 20%, CaO: 5 to 20%. Firstly, the active agent is grinded to powder, then is dried and cooled; secondly, the active agent is mixed with acetone or alcohol and then is equally coated or sprayed on the surface of the welding bead; finally, after the acetone or the alcohol is volatilized, welding can be implemented. The active agent has the advantages that: the weld penetration can increase at least twice; the weld joint of magnesium alloy is well moulded; the joint is of high quality and the intensity can be above the 95% of the intensity of the parent metal; the deformation due to welding is reduced; the invention is of easy operation and high productivity.

Owner:DALIAN UNIV OF TECH

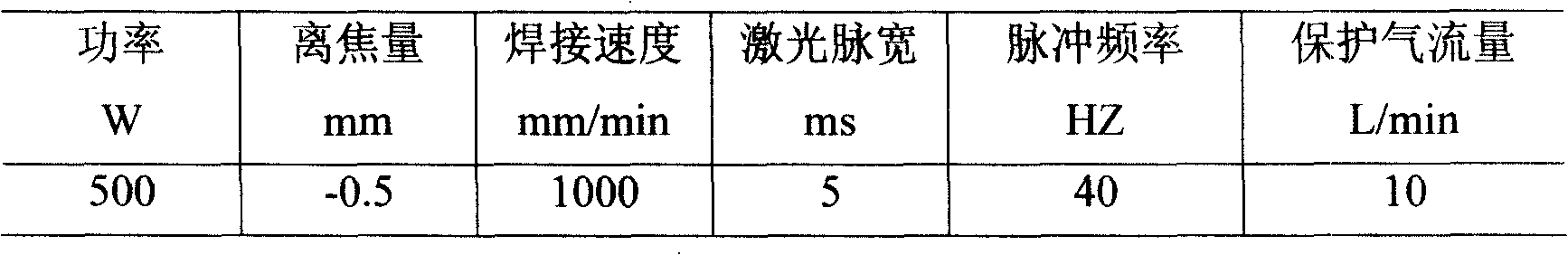

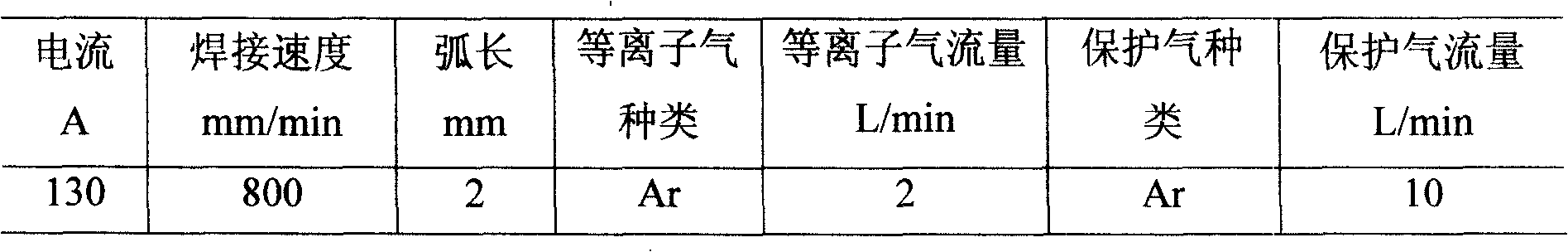

Method of preparing SiCp/Al composite material with complicated shape and high volume percent ratio

The invention discloses a preparing method of SiCp / Al composite with complete shape and high analytic in metal base composite material researching domain, which comprises the following steps: allocating pre-mixing liquid with monomer, cross linker and disperser; adding into SiC powder; balling; getting stable suspension with SiC volume content at 50-70%; adding into trigger and activator; stirring evenly; injecting into unapertured mold; solidifying and shaping in incubator with temperature at 50-70 deg.c; getting green compact; drying; discharging glue; presintering; getting SiC bone; placing Al alloy of 4-8% Mg, 6-12% Si on the adaptive position of bone; putting into heater; heating-up at 900-1200 deg.c under the protection of inert gas; inflating high pure nitrogen; keeping the temperature at 1-6 h; cooling; getting the product. This invention possesses the merit of cheap cost.

Owner:UNIV OF SCI & TECH BEIJING

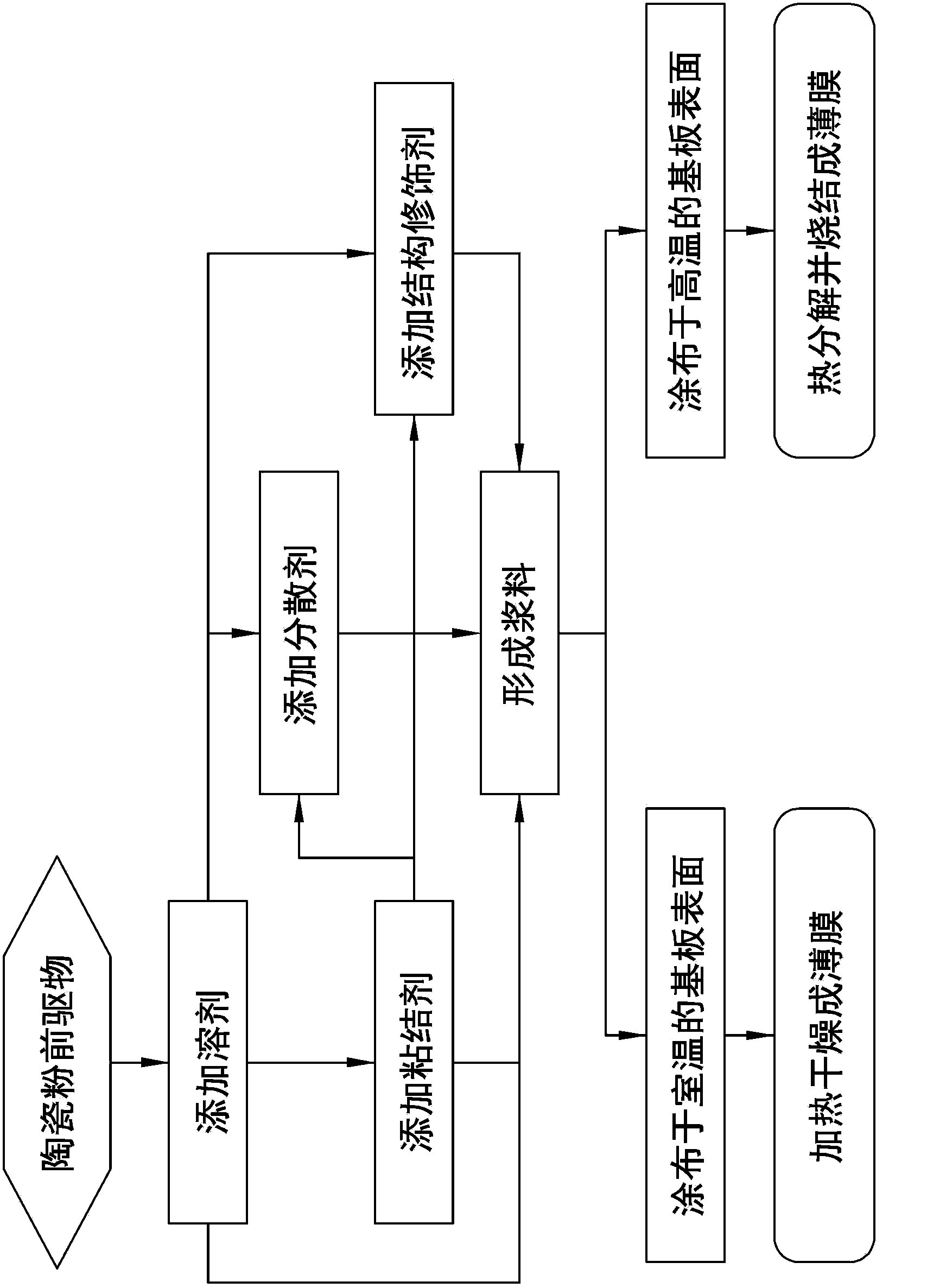

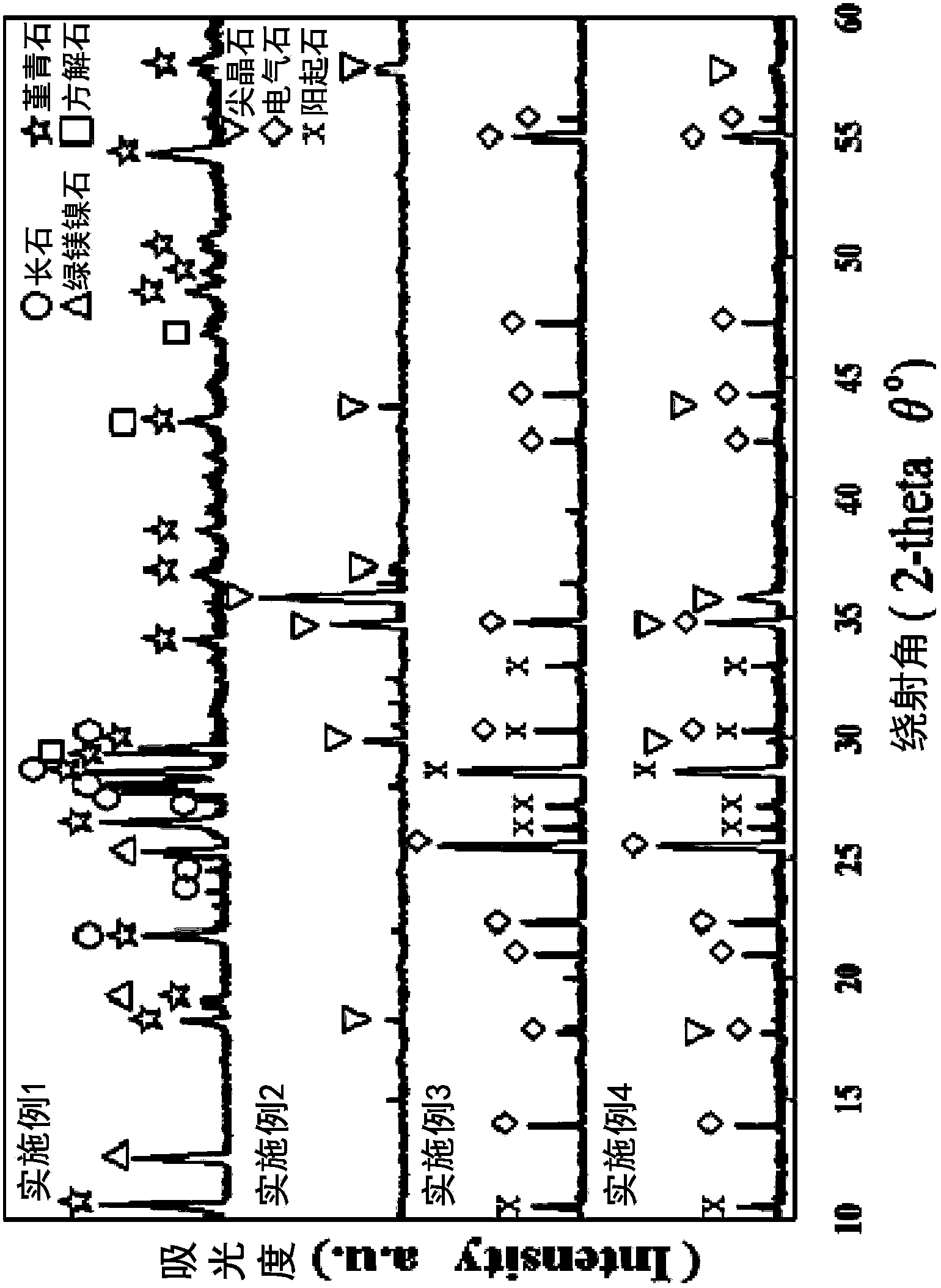

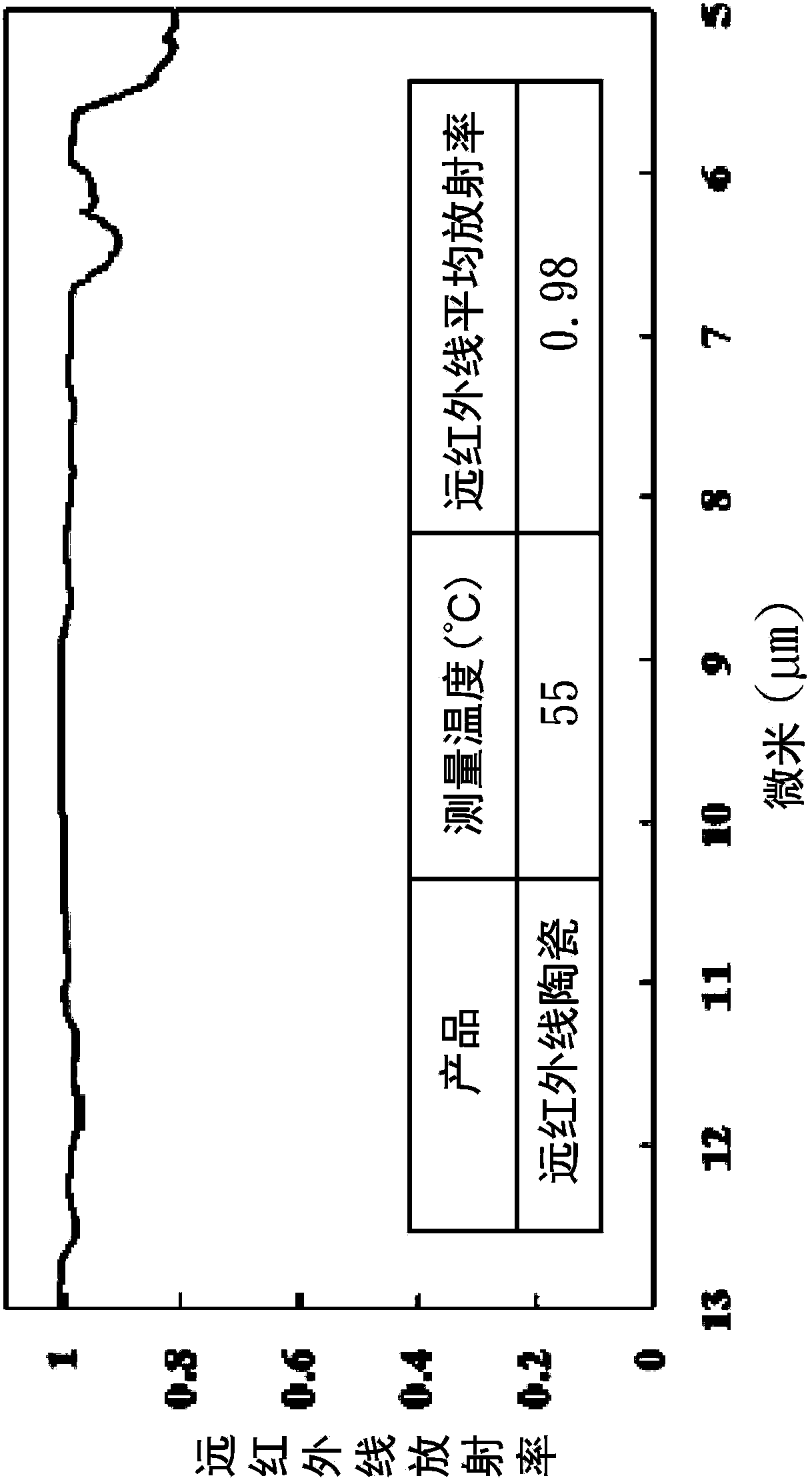

Far infrared heat-radiation ceramic slurry, fiber cloth, thin film and preparation methods thereof

InactiveCN103570360AHigh radiation emissivityLow costMonocomponent polyesters artificial filamentArtifical filament manufactureInfraredFiber

The invention discloses a far infrared heat-radiation ceramic slurry, the far infrared heat-radiation ceramic slurry is prepared by mixing a ceramic powder precursor with a corresponding solvent, a bonding agent, a dispersing agent or a structure modification agent, and the ceramic powder precursor is selected from a composition of salts or oxides of Na, Mg, Ca, B, Al, C, Si, Sn, Mn, Fe, Co, Ni and Cu. A functional ceramic body is obtained by coating the far infrared heat-radiation ceramic slurry on the surface of a substrate or adding the far infrared heat-radiation ceramic slurry into a polymer material, and then heating for drying. The functional ceramic body is a composition or a derivative with at least one or more than one structure of feldspar, olivine, cordierite, chlorite, green magnesium nickel ore, tourmaline, tremolite, actinolite, serpentine, spinel or calcite, has the far infrared radiation rate reaching 0.90-0.98, can rapidly transfer heat energy into radiation waves for spreading to the outside so as to achieve a rapid heat-radiation effect.

Owner:BOSIN TECH

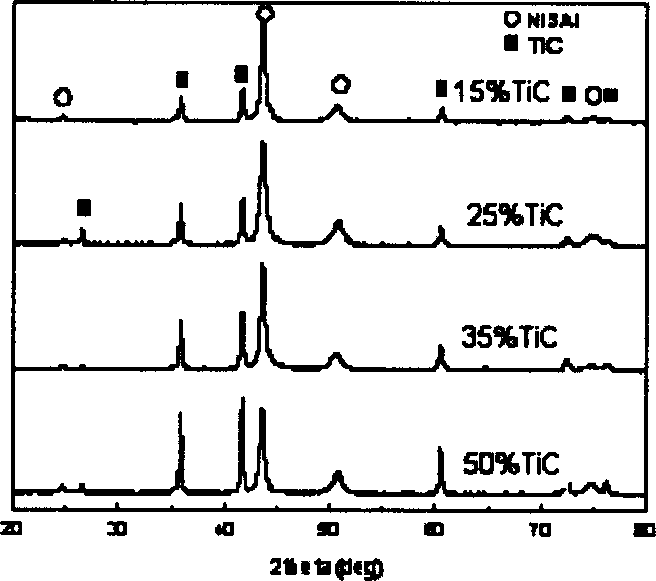

Method for preparing TiC/Ni3Al intermetallic compound based surface composite coating

The invention relates the Cast-SHS preparation technology used for TiC / Ni3Al surface composite coating. The technology comprises the following steps: using Ni, Al, Ti, C powders as raw material, mixing them in proper proportion, pressing them to form precast block, drying, stick organic binding agent on the mould wall; preheating mould, pouring molten steel, and forming the TiC / Ni3Al intermetallic compound surface composite coating on the surface of steel. By adjusting the powder composition, intermetallic compound surface composite coatings which contain different ceramic enhancement phase contents can be obtained. The method possesses the advantages of simple technology, low cost, strong binding force and good combination property.

Owner:SUZHOU UNIVERSAL GRP TECH CO LTD

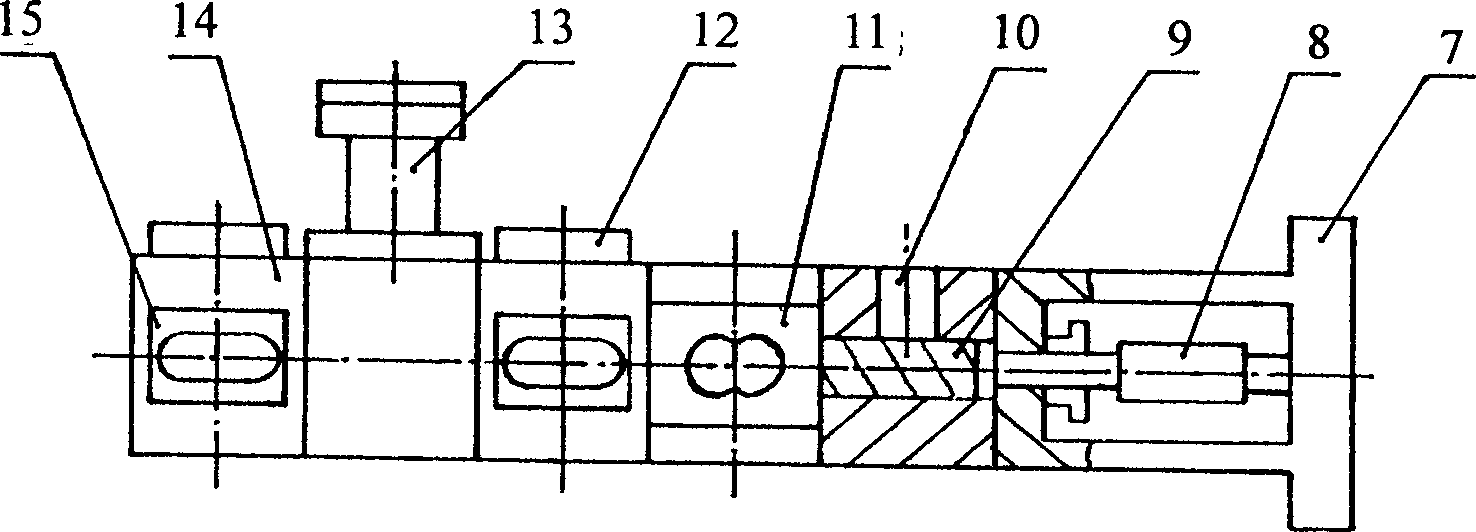

Method for continuously extrauding super-high molecular-weight polytene composite material by double screw-rod

The method for continuously extruding ultrahigh molecular weight polyethylene composite material by using extruder twin screw is characterized by that 100 portions of polyethylene whose molecular weight is 150-350 ten thousand, 10-30 portions of flow modifying agent, 10-20 portions of filling reinforcing agent, 0.2-5 portions of coupling agent, 0.1-5 portions of lubricating agent, 0.1-1 portions of nuclear-forming agent and 0.1-10 portions of fire-resisting agent are added into a high-speed mixing machine, mixing at 100-120 deg.C for 20-30 min. to obtain the ultrahigh molecular weight polyethylene composite granule (powder) material said material is added into a meshed equidirectional rotation extruder twi screw, and continuously formed in forming machine cylinder with 200-250 deg.c, then formed, cooled, drawn and cut to obtain the product.

Owner:SICHUAN UNIV

Preparation method for water treatment microbe immobilization carrier

InactiveCN101560016AMeridian toughness is goodNo osmotic degradationSustainable biological treatmentBiological water/sewage treatmentVacuum pumpPolymer

The invention discloses a preparation method for a water treatment microbe immobilization carrier. The preparation method comprises the following steps: (1) foaming, namely evenly mixing 50 to 100 mass portions of polyether glycol, 10 to 50 mass portions of polymer glycol, 0.1 to 0.3 mass portion of tin catalyst, 0.1 to 0.5 mass portion of amine catalyst, 3 to 9 mass portions of water, 5 to 30 mass portions of blowing promoter and 0.6 to 5 mass portions of foam stabilizer, adding 45 to 60 mass portions of toluene diisocynate, evenly agitating the raw materials, and then pouring the mixture into a die for foaming; (2) tapping through an explosion method, namely adding the foaming materials in a tapping device, carrying out the vacuum pumping on the device to 0.1 to 1 MPa, then filling the device with H2 to 0.1 to 0.5 MPa, filling the device with O2 to 0.2 to 0.8 MPa, and detonating the gases after 10 to 30 minutes of diffusion; and (3) granulation. The method has the advantages of simple process, convenient operation, cleanness and hygiene, and difficulty in environmental pollution. The carrier is widely applied to biological reaction water treatment systems, particularly to sewage treatment systems.

Owner:ENVIRONMENTAL SCI RES & DESIGN INST OF ZHEJIANG PROVINCE

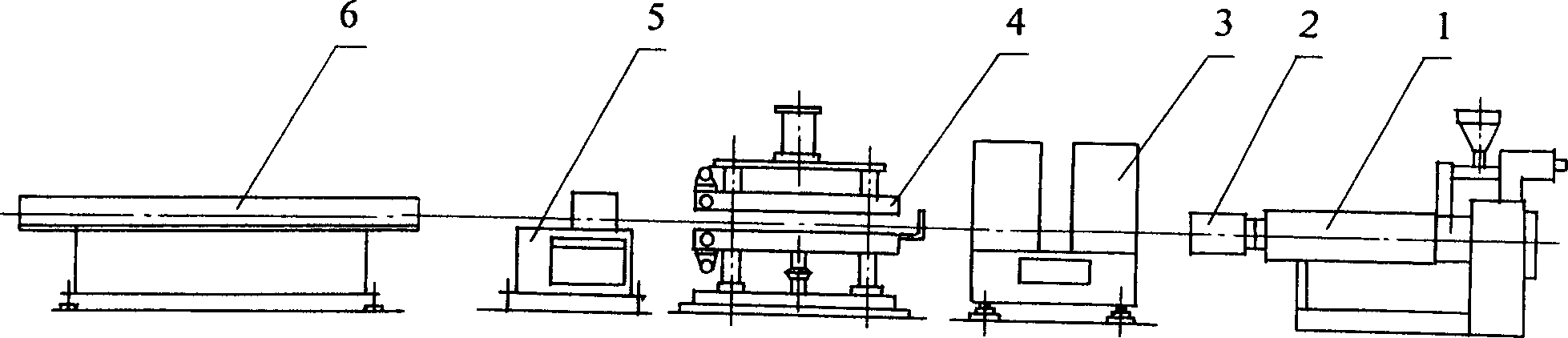

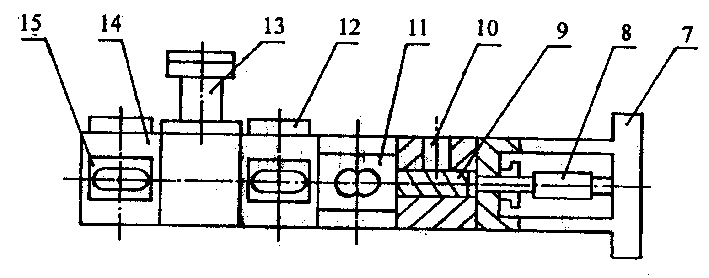

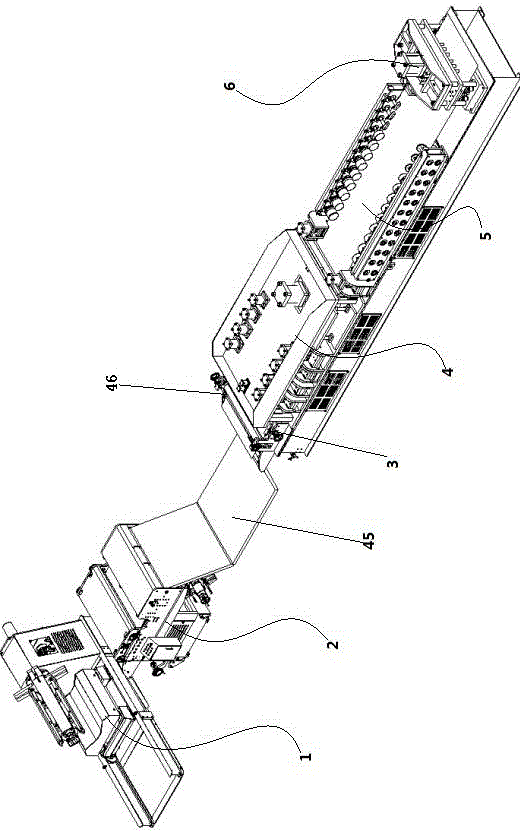

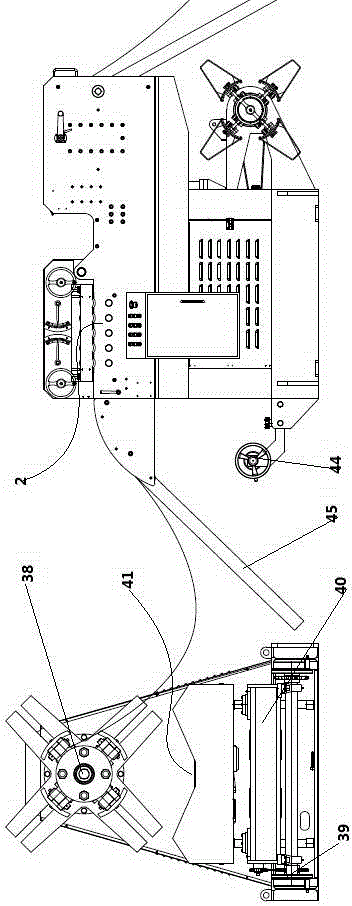

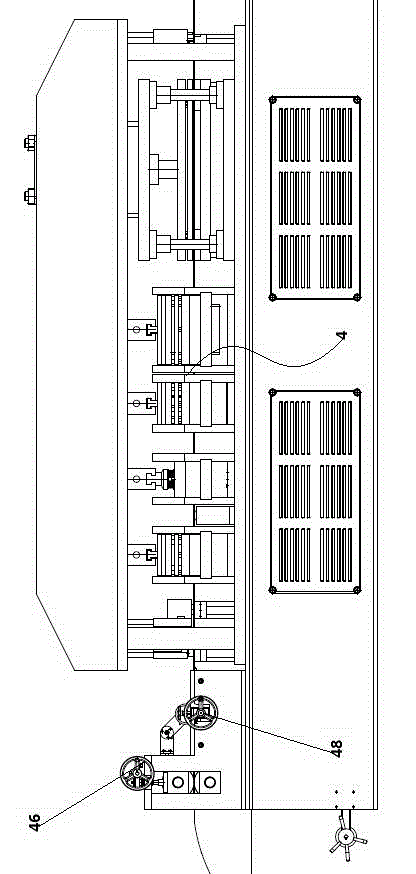

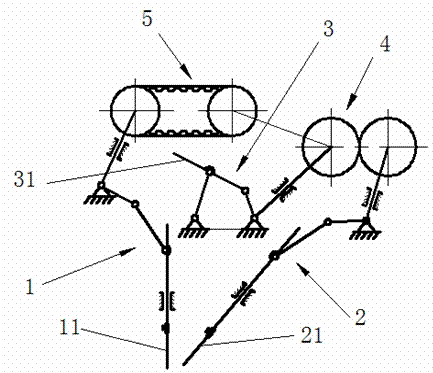

Multifunctional metal-plate flexible production line

The invention relates to a multifunctional metal-plate flexible production line. The multifunctional metal-plate flexible production line comprises a placing device, a leveling device, a punching device, a rolling device and a shearing device which are arranged in sequence, and is characterized in that the punching device is provided with a punching platform, a plurality of punching dies are arranged on the punching platform, the positions of the punching dies on the punching platform can be changed, the positions of two forming roll sets of the rolling device correspond to two side edges of a metal plate, and each forming roll set comprises an upper roll and a lower roll. As leveling, punching, side-edge forming and final shearing and bending of the metal plate are integrated on the same production line, the production efficiency is greatly improved; all-position coverage punching can be realized and the punching shapes are not restricted; the forming device can realize one-pass and integrated finish of repeated various bending; during the final shearing, integrated bending can be realized, so that the production efficiency is improved and the production process is simplified.

Owner:SUZHOU JINTONG MACHINERY MFG

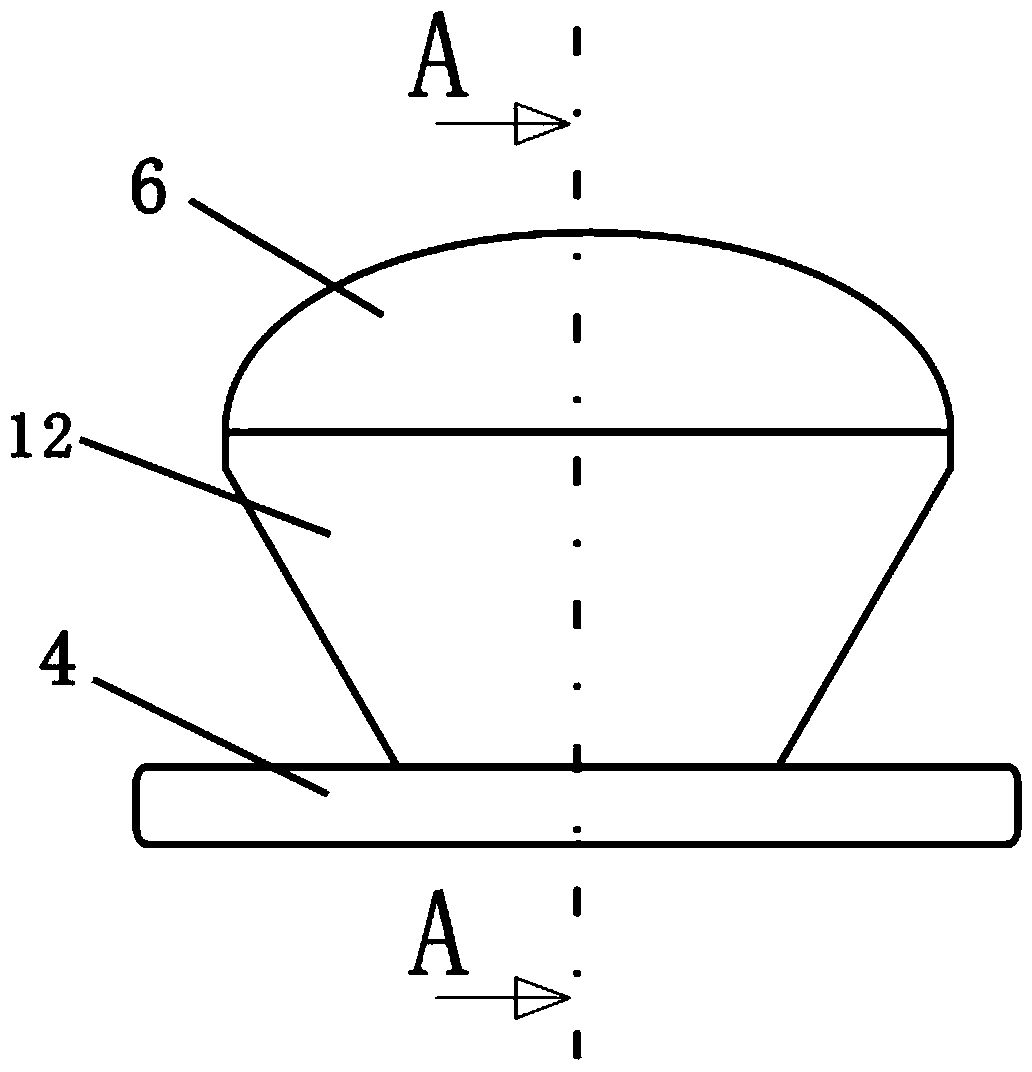

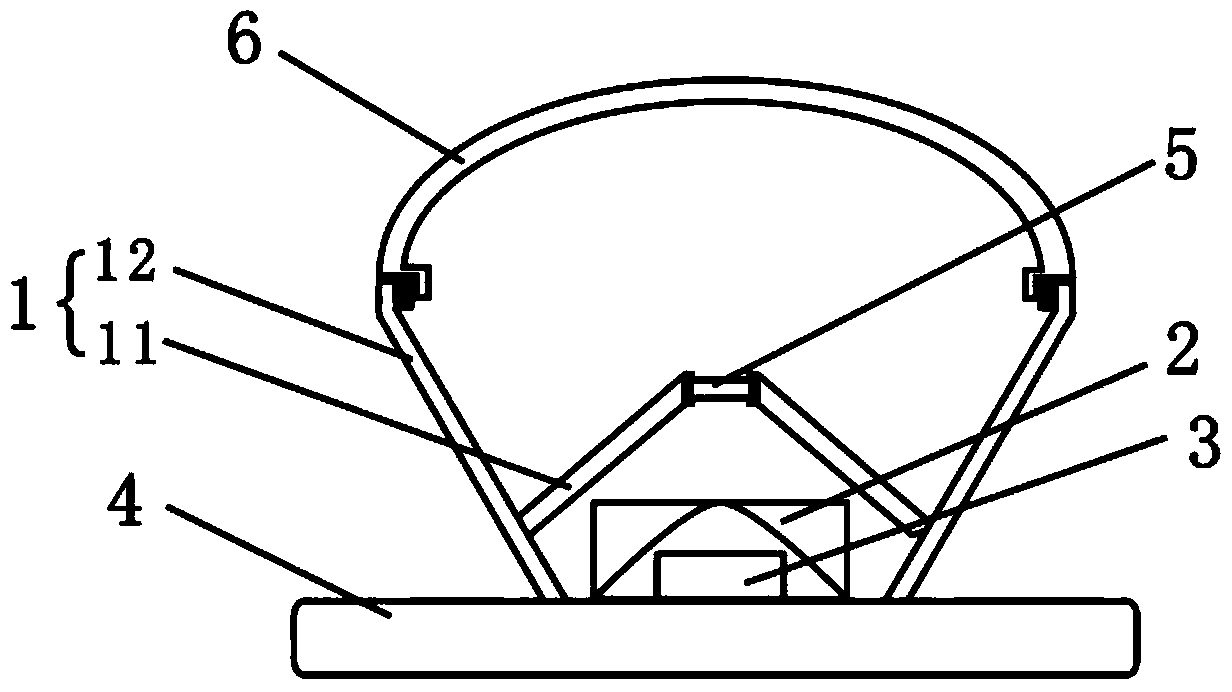

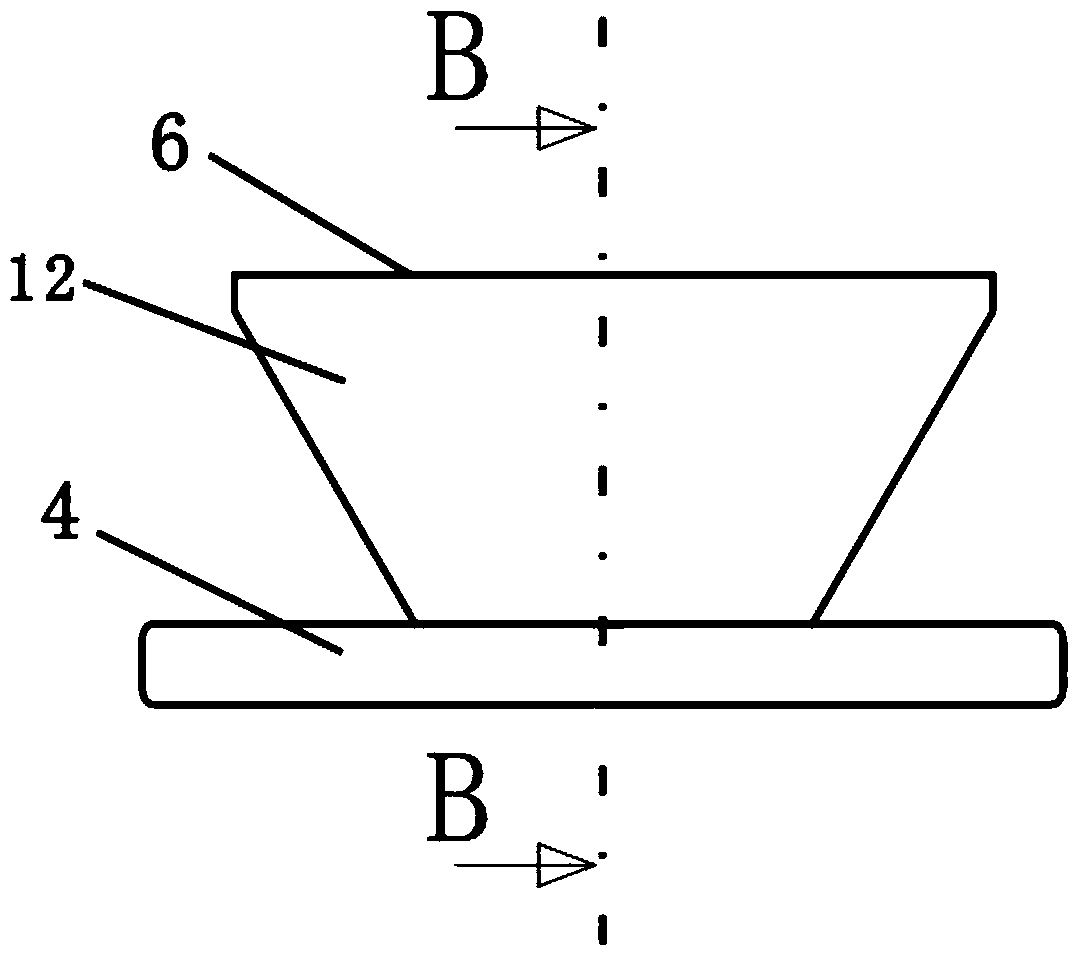

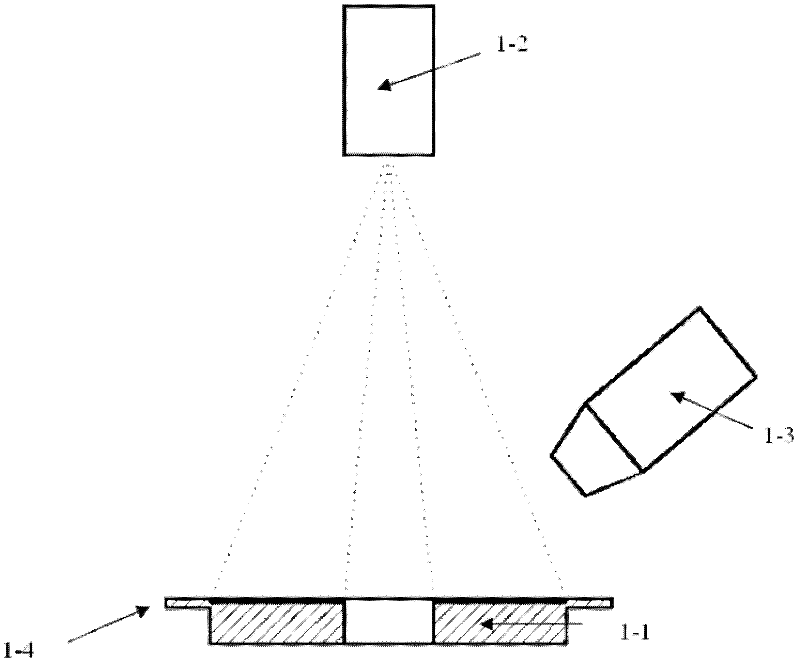

Remote fluorescent LED (Light Emitting Diode) device

InactiveCN103557453AAvoid attenuationExtended service lifePoint-like light sourceElectric lightingRare earthEngineering

The invention discloses a remote fluorescent LED (Light Emitting Diode) device which comprises a light diffusion lampshade, a rare-earth fluorescent resin sheet, an LED condensing lens, an LED chip and a combined reflection cup, wherein the combined reflection cup comprises an outer reflection cup and an inner reflection cup; the inner reflection cup is upside-down and is combined with the outer reflection cup; a first sealed space is formed after the opening of the bottom of the inner reflection cup is combined with the rare-earth fluorescent resin sheet; the LED condensing lens and the LED chip are located in the first sealed space; the LED chip is located below the LED condensing lens and above the outer reflection cup; the outer reflection cup and the light diffusion lampshade are tightly connected to form a second sealed space; the first sealed space is located in the second sealed space. Fluorescent powder is separated from the LED chip to be conductive to heat radiation of the chip and keep use stability of the fluorescent powder; a light conversion range is limited in a small region, so that use amount of the fluorescent resin sheet is reduced, and cost is lowered; the light diffusion lampshade protects the inner part, so that the lights are soft and the appearance is beautiful.

Owner:SOUTH CHINA NORMAL UNIVERSITY

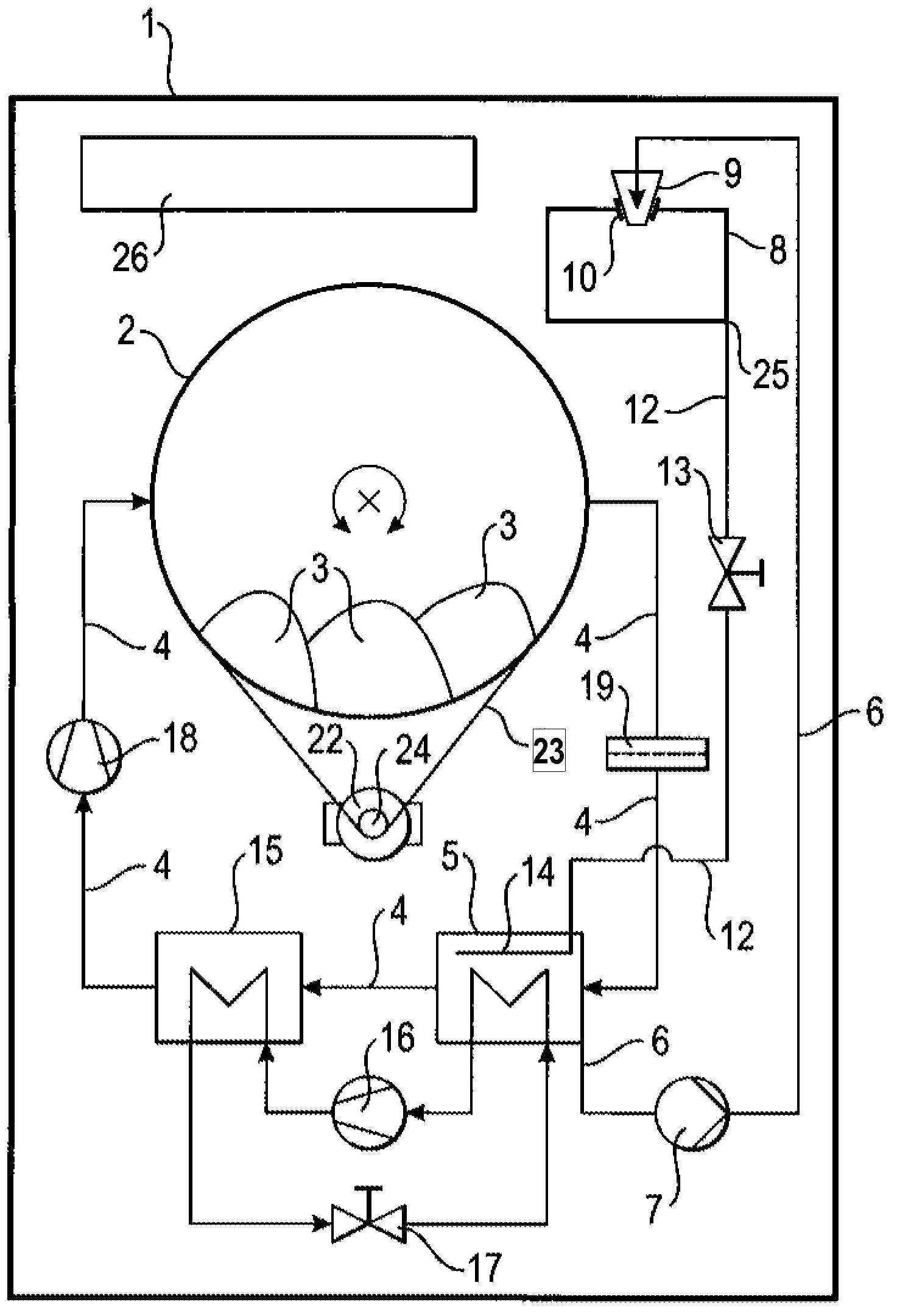

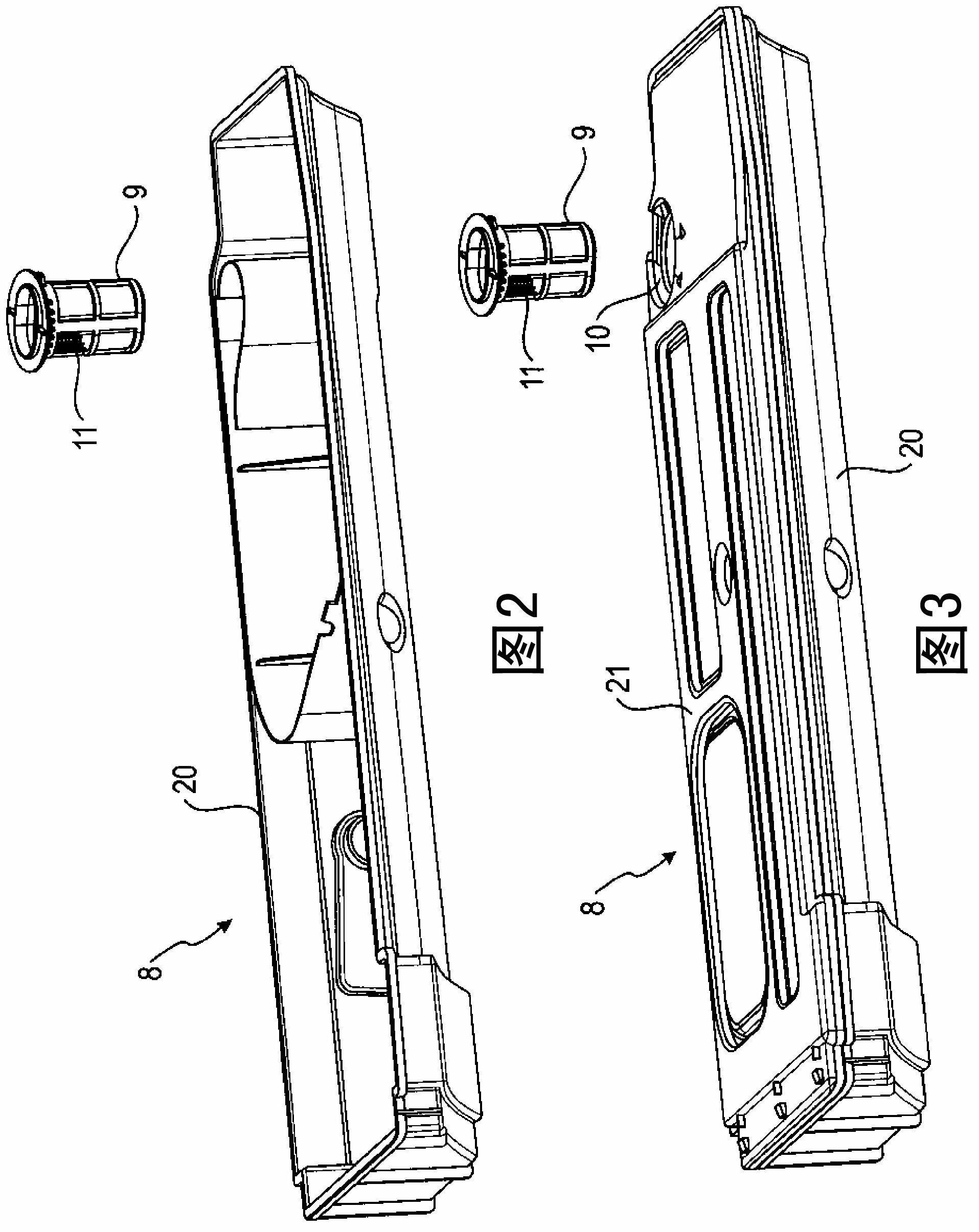

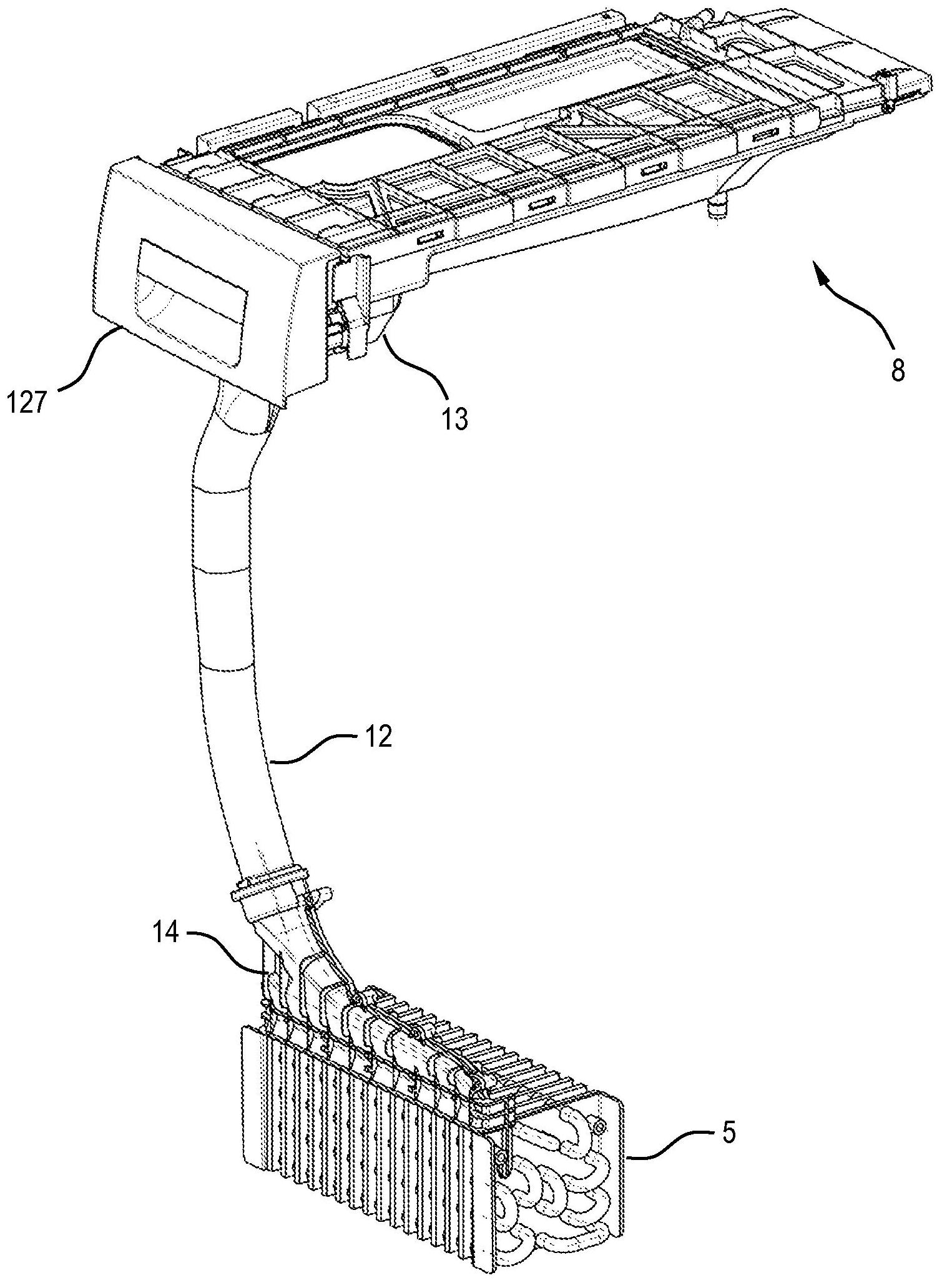

Laundry dryer having a condensate collector

ActiveCN102666966ASquirting Hazard to AvoidIncrease volumeTextiles and paperLaundry driersEngineeringLaundry

Owner:BSH BOSCH & SIEMENS HAUSGERAETE GMBH

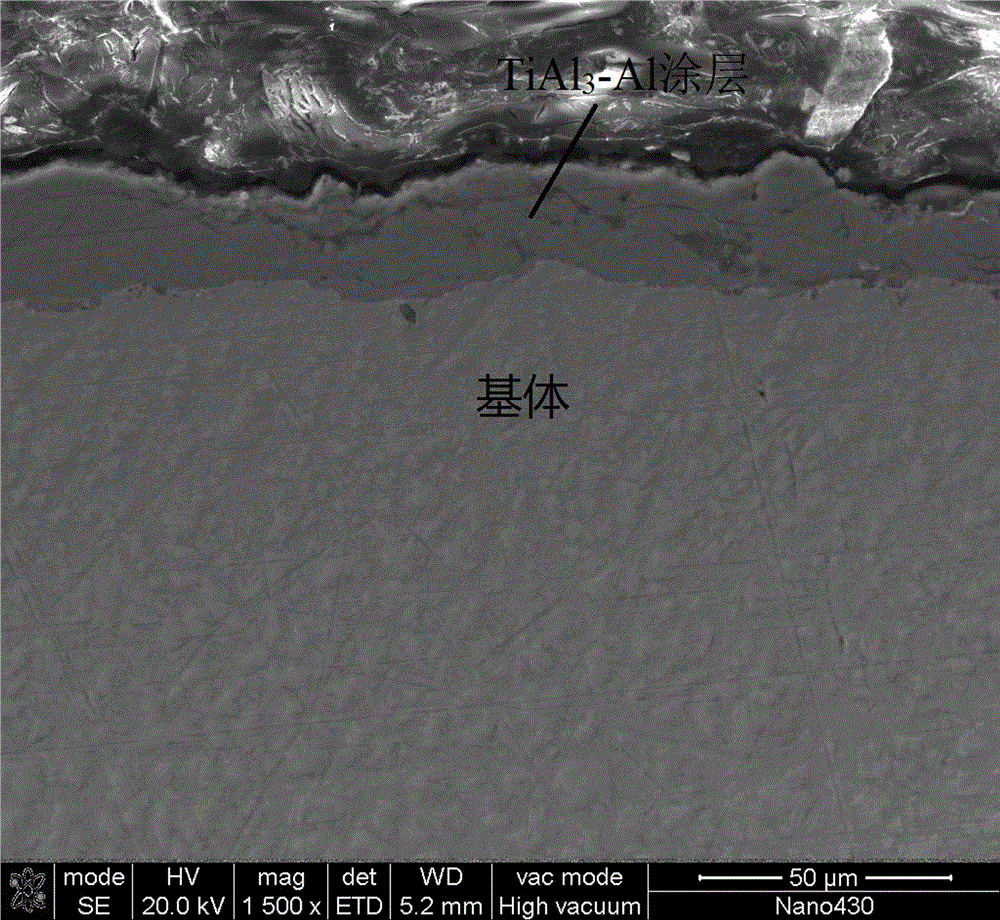

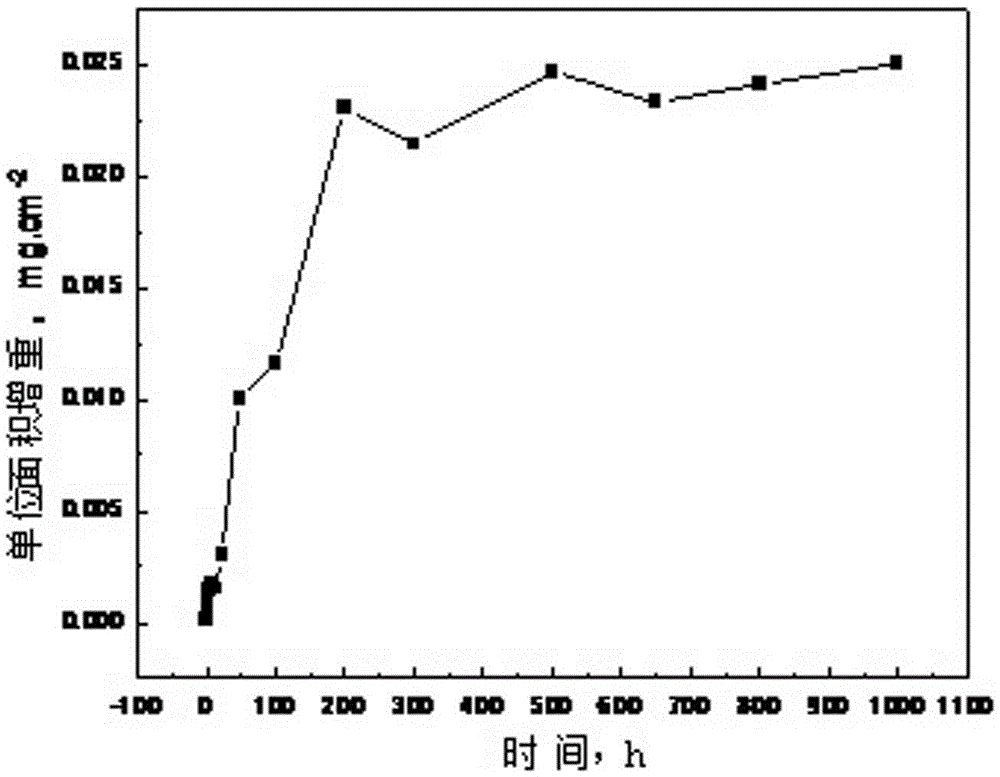

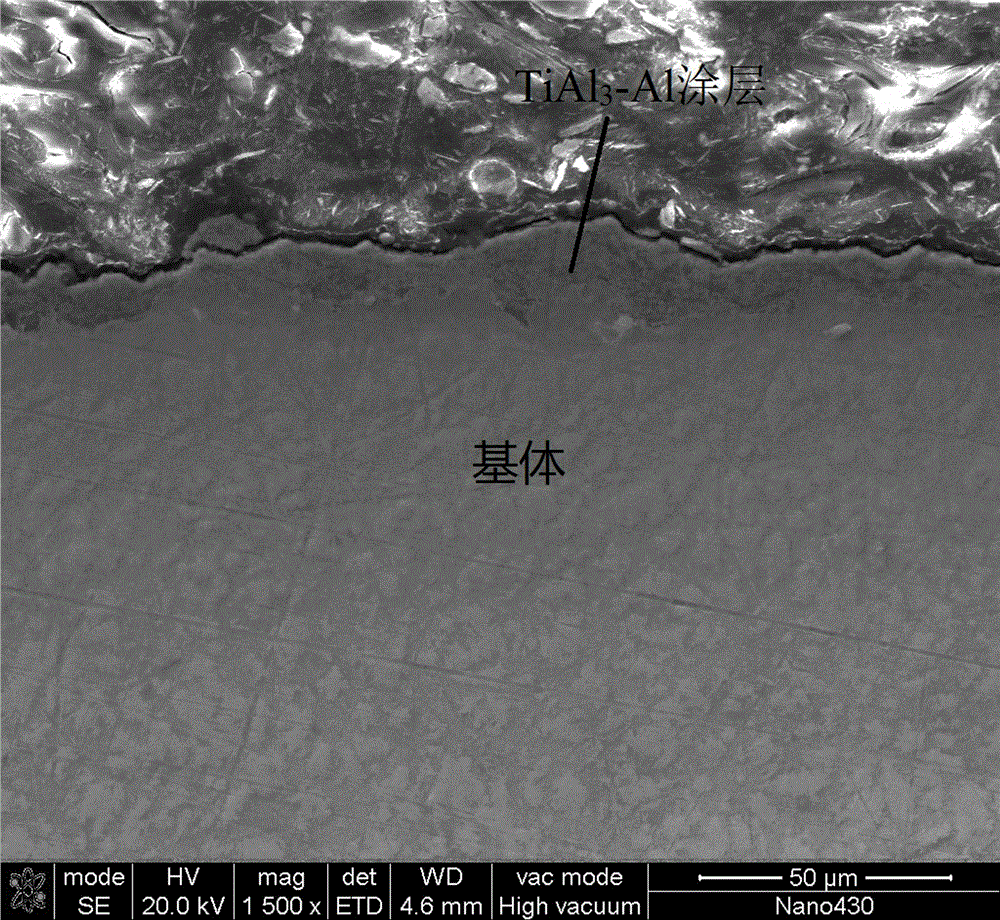

Preparation method for titanium alloy TiAl3-Al composite coating

InactiveCN105401116AEffective against high temperature oxidationEasy to operateMolten spray coatingAl powderCooking & baking

The invention relates to a preparation method for a titanium alloy TiAl3-Al composite coating. The preparation method is characterized by comprising the following steps: (1) TiAl3 powder and pure Al powder are mixed in proportion, and baking is carried out after 24 hours; (2) burrs on the titanium alloy surface are polished with abrasive paper, ethyl alcohol is used for ultrasonic cleaning, sand blasting is carried out on the surface of a titanium alloy, and ultrasonic cleaning with the ethyl alcohol lasts for 5 min to 20 min; and (3) the TiAl3-Al composite coating is prepared on the surface of a titanium alloy base material with a low-temperature high velocity oxy-fuel method or a cold spraying method. By means of the preparation method for the titanium alloy TiAl3-Al composite coating, the antioxygenic property of the titanium alloy can be greatly improved through the coating; the low-temperature high velocity oxy-fuel technology or the cold spraying technology is adopted in the preparation method; and the method is easy and convenient to operate and easy to control, and the quality of the formed coating is good.

Owner:GUANGDONG INST OF NEW MATERIALS

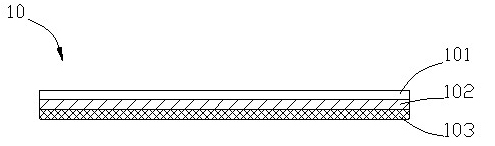

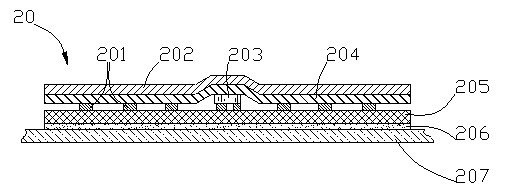

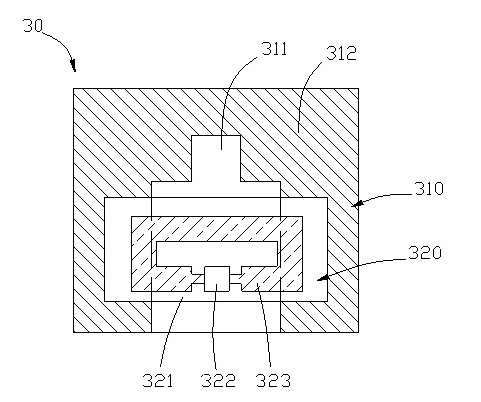

Laser holographic radio frequency identification (RFID) tag using coplanar inverted F antenna

InactiveCN102013032APerformance is not affectedFlexible composite approachRecord carriers used with machinesOptoelectronicsReflective layer

The invention discloses a laser holographic radio frequency identification (RFID) tag using a coplanar inverted F antenna, comprising an RFID tag (50) and a laser holographic film (10) attached to the tag, wherein the RFID tag (50) comprises the coplanar inverted F antenna (510), a substrate (520) and a RFID chip (530); the coplanar inverted F antenna (510) is manufactured on the substrate (520); and the RFID chip (530) is attached to the coplanar inverted F antenna (510). In the invention, the laser holographic RFID tag can be applicable to ultrahigh frequency and microwave frequency bands, a metallic reflective layer or non-metallic reflective layer can be used as the laser holographic film, the shape and size of the laser holographic film are not restricted, and the method for compounding the laser holographic film with the RFID tag is simple and convenient.

Owner:HUAZHONG UNIV OF SCI & TECH

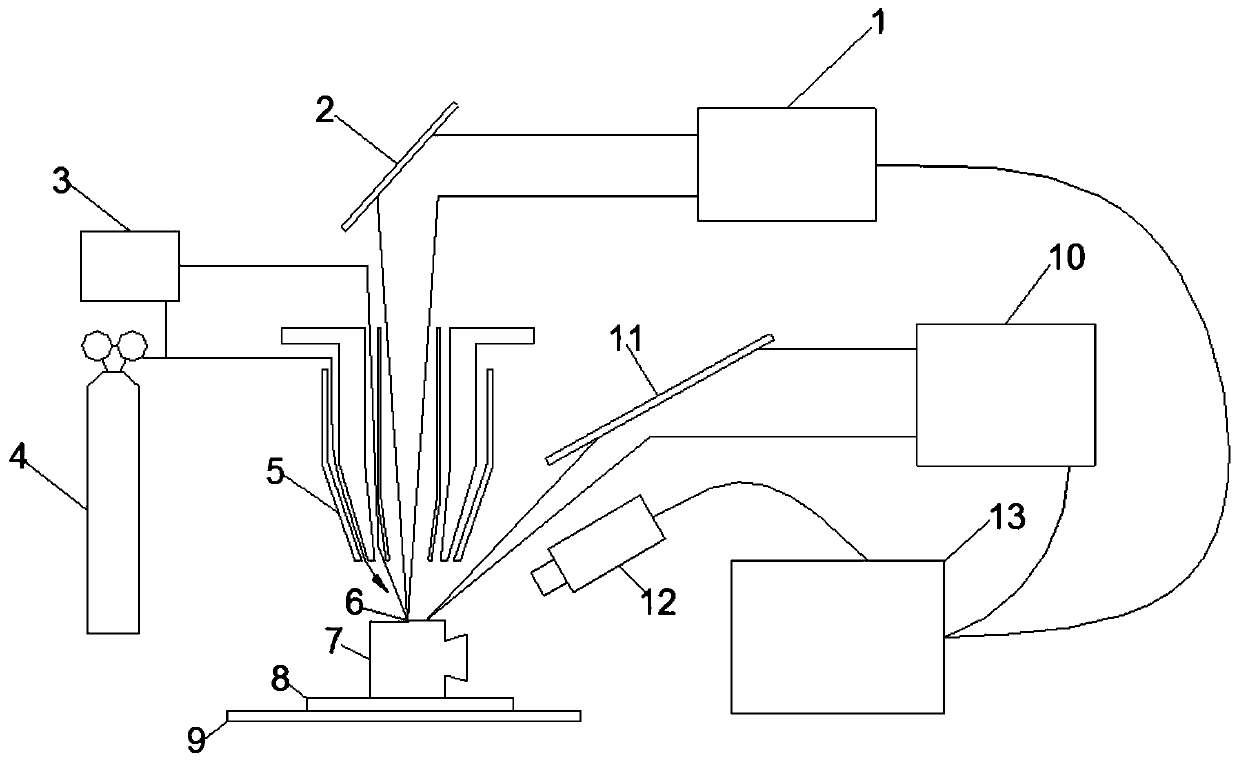

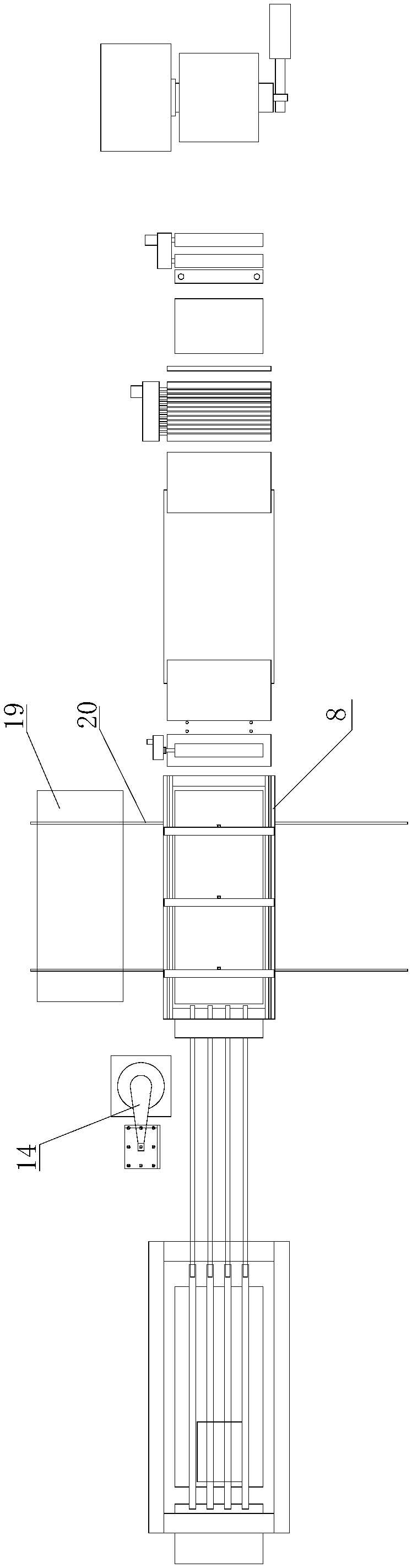

Laser melting deposition and laser shock strengthening combined manufacturing device and method

PendingCN110802226AIncrease stressImprove performanceAdditive manufacturing apparatusIncreasing energy efficiencyControl systemMonitoring system

The invention provides a laser melting deposition and laser shock strengthening combined manufacturing device. The device comprises a melting deposition system, a shock strengthening system and an online monitoring system which are connected by leads; the melting deposition system includes a melting laser device, a laser path assembly, a powder feeder, a melting deposition head and a three-dimensional processing platform; after being guided by the laser path assembly, a laser beam emitted from the melting laser device passes through the melting deposition head and reaches the three-dimensionalprocessing platform to form a laser spot; the shock strengthening system includes a shock strengthening laser device and a laser guide assembly; and the online monitoring system includes an online monitoring sensor and an information collection control system which are connected by leads. The combined manufacturing device can further overcome the problem of combined manufacturing of complex curved surface parts while solving the thermal stress problem in the process of laser melting deposition, and in addition, laser shock control is employed, the combined manufacturing device has the advantages of fast response, no contact, high controllability and the like.

Owner:西安空天机电智能制造有限公司

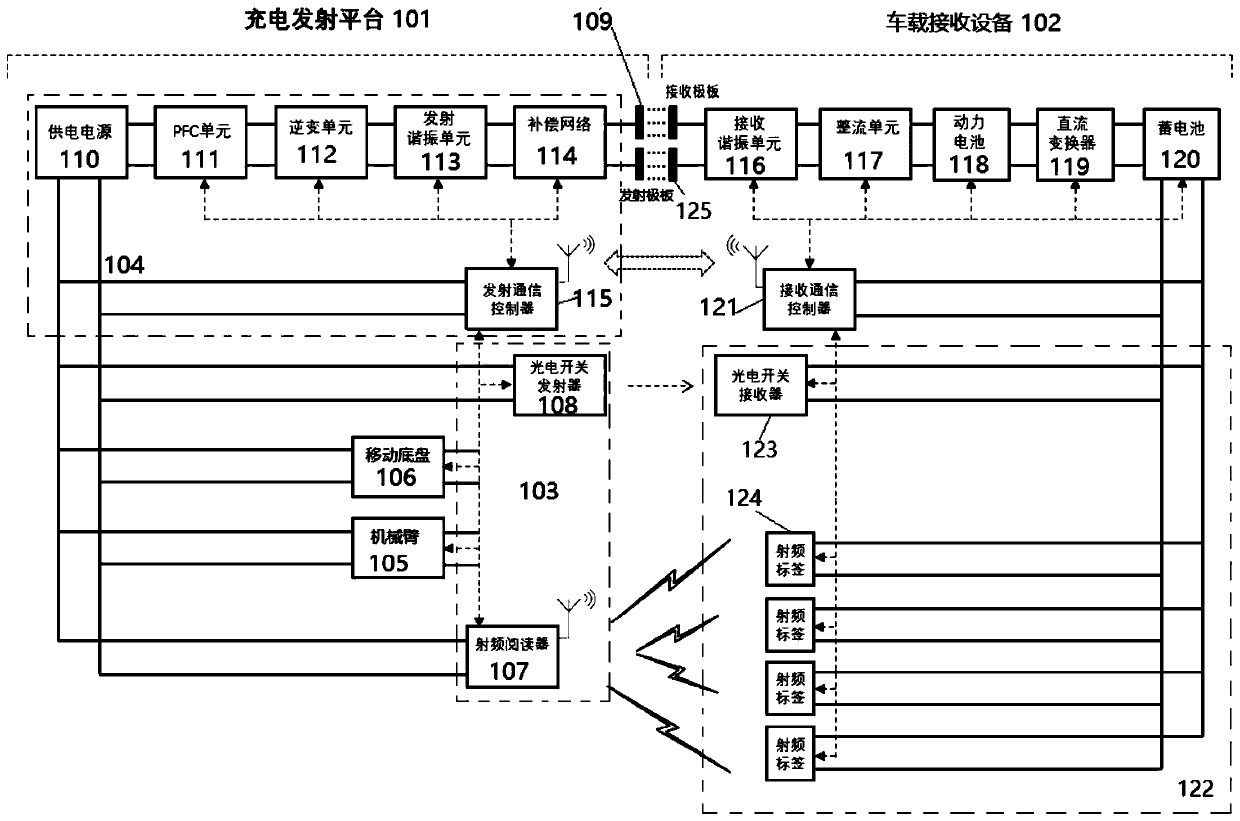

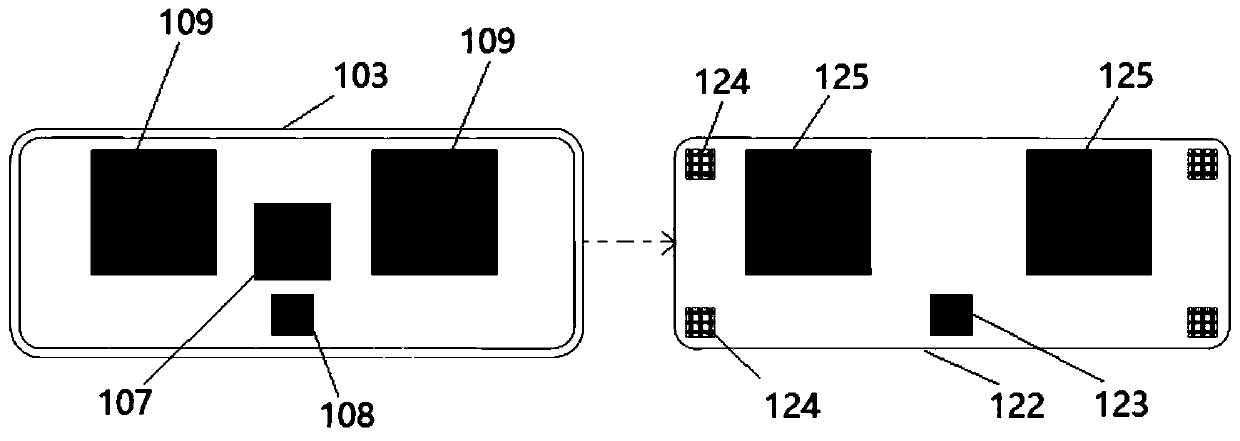

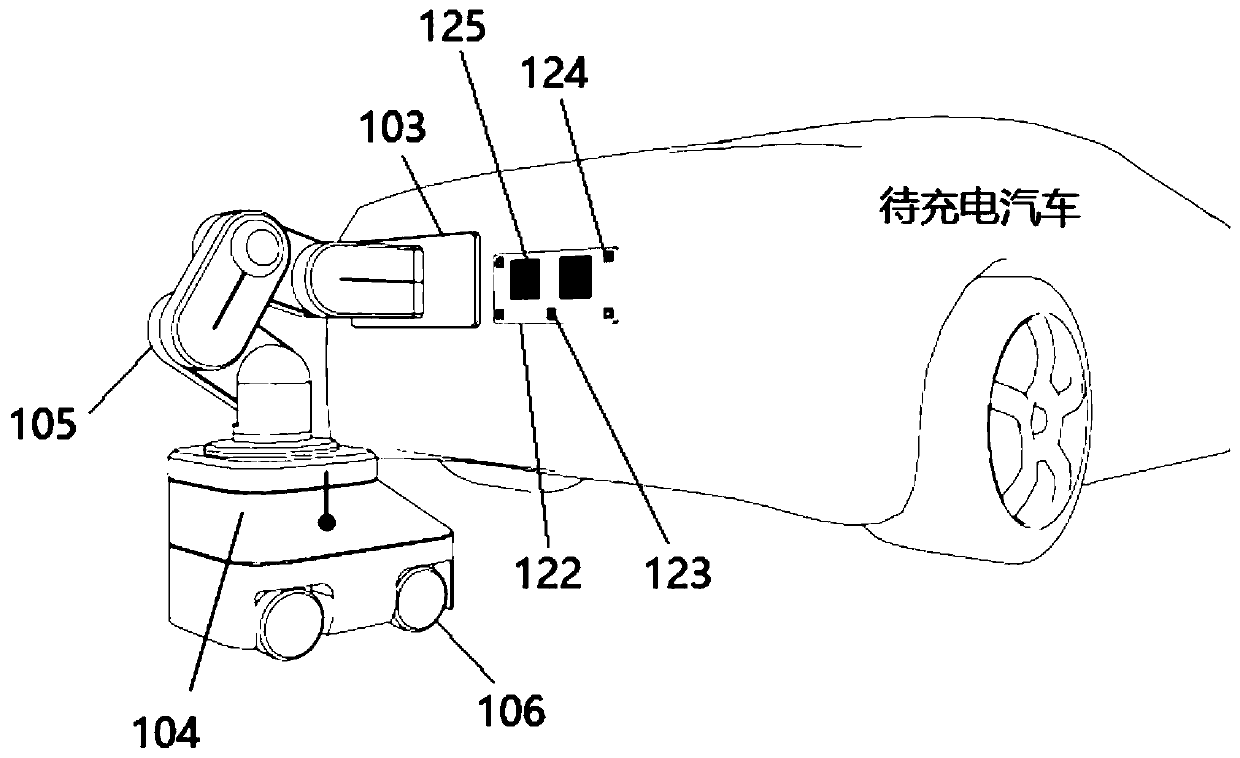

Capacity coupling type automatic wireless charging system and charging method for electric automobile

ActiveCN110293861AEnable wireless chargingLow investment costCharging stationsCircuit arrangementsCapacitanceTransmitted power

The invention discloses a capacity coupling type automatic wireless charging system and charging method for an electric automobile. The system comprises a charging transmitting platform and on-board receiving equipment. The charging transmitting platform comprises a transmitting unit, a transmitting power cabinet, a mechanical arm and a moving chassis. The tail end of the mechanical arm is mountedon the upper portion of the transmitting power cabinet. The transmitting power cabinet is mounted on the upper portion of the moving chassis. The transmitting unit is mounted at the front end of themechanical arm. A radio-frequency reader, an optoelectronic switch transmitter and two transmitting pole plates are mounted at the center position of the transmitting unit. Alignment between couplingmechanisms at the transmitting end and the receiving end does not need to be achieved through manual driving or automatic parking, the to-be-charged electric automobile only needs to be parked at thedesignated parking position, the charging transmitting platform and the multi-freedom-degree mechanical arm carried by the charging transmitting platform can complete the above action, and therefore the problems that during electric automobile wireless charging, coils need to be aligned and operation is inconvenience are solved; and system safety running can be guaranteed, and high conveying efficiency can also be obtained.

Owner:BEIJING INVISPOWER TECH CO LTD

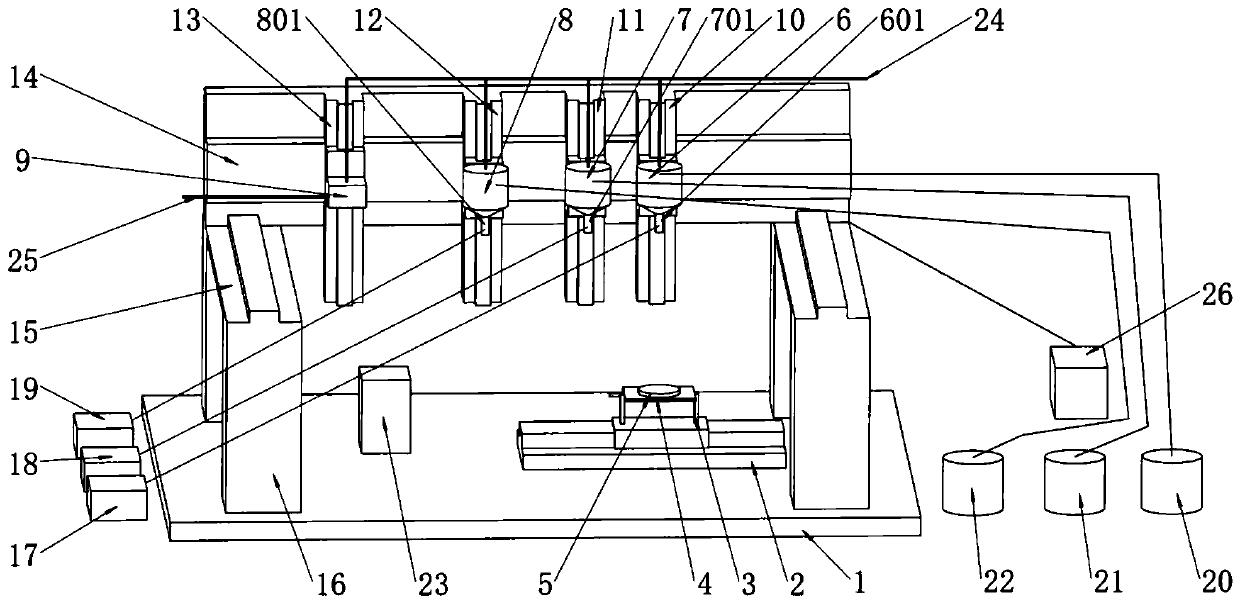

Multi-material 3D printing device for integrally manufacturing stretchable electronic product and working method

PendingCN109732900AAchieving heat curingReduce printing timeManufacturing platforms/substratesManufacturing heating elementsStretchable electronicsMulti material

The invention provides a multi-material 3D printing device for integrally manufacturing a stretchable electronic product and a working method. The device comprises a base and a control module; the base is provided with a three-dimensional workbench, a placing platform, a swing table and a printing bed, wherein the printing bed is arranged on the swing table, and the swing table drives the printingbed with vacuum adsorption and electric heating functions to swing and rotate; and the three-dimensional workbench comprises at least four Z-direction workbenches, the first Z-direction workbench isprovided with a mechanical arm used for grabbing and placing electronic elements, and each of the remaining Z-direction workbenches is provided with a printing nozzle. Movement of the three-dimensional workbench, the swinging table, the mechanical arm and a feeding module are controlled, each printing nozzle executes printing of a flexible base plate, a protective layer, a connecting circuit, an embedded electronic element and a packaging layer of the stretchable electronic product according to a set sequence, and thus integrated manufacturing is realized.

Owner:QINGDAO 5D INTELLIGENT ADDITIVE MFG TECH CO LTD

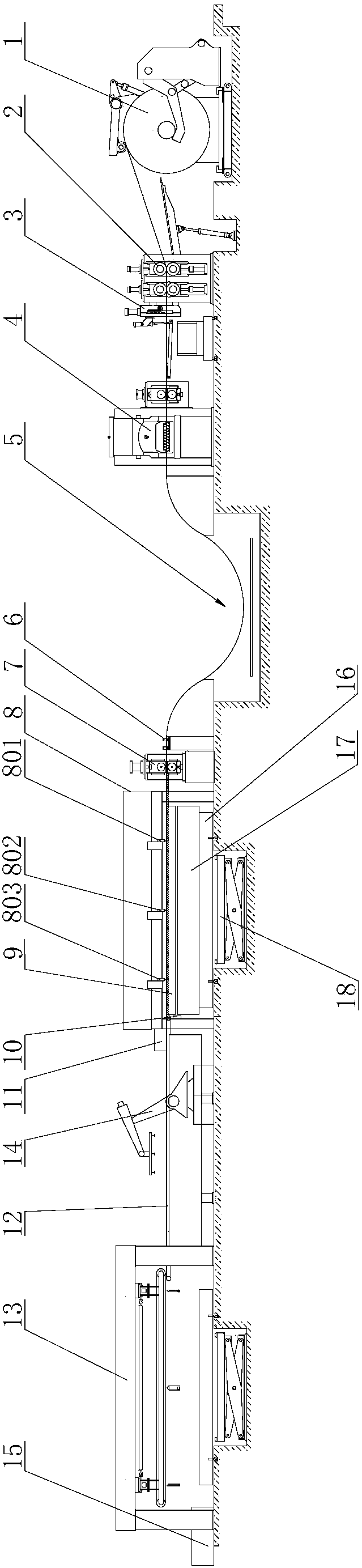

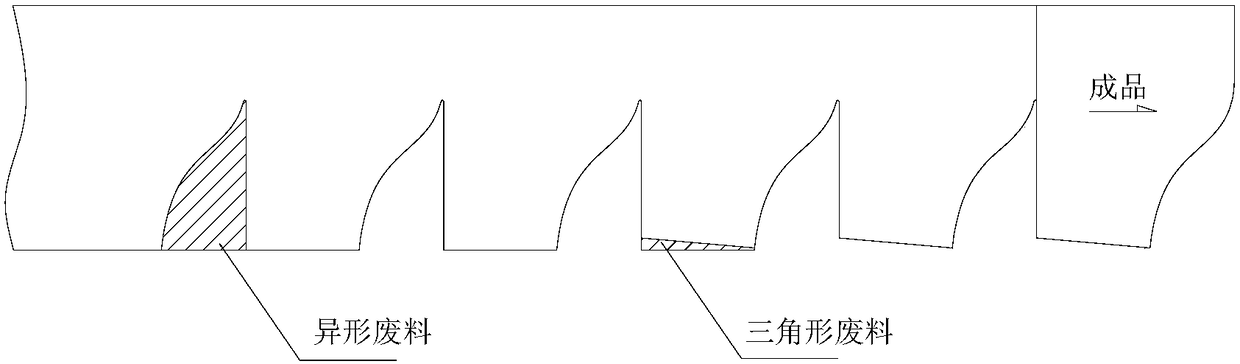

Stepping-type laser cutting uncoiling blanking line

PendingCN108555456ARealize continuous productionReduce designOther manufacturing equipments/toolsLaser beam welding apparatusLaser cuttingEngineering

The invention belongs to the technical field of plate coil material machining, and discloses a stepping-type laser cutting uncoiling blanking line. The stepping-type laser cutting uncoiling blanking line comprises an uncoiling machine, a leveling machine, a fixed-length feeding machine and a laser cutting machine which are sequentially connected in series. A coil material is placed on the uncoiling machine; a special cutting platform is arranged on the laser cutting machine; the laser cutting machine comprises three or more laser cutting heads arranged above the special cutting platform; and ablanking opening is formed in the position, corresponding to cut waste, of the special cutting platform. According to the stepping-type laser cutting uncoiling blanking line, the laser cutting machine is adopted to replace a traditional mechanical press machine, continuous production of laser cutting is achieved, a blanking die is not needed, the layout of parts is unrestricted, arbitrary optimizing can be conducted, the shapes of the parts are unrestricted, the shapes which are hard to machine by a traditional uncoiling blanking line can be machined, and the material utilization rate can beincreased to the largest limit.

Owner:郭志雄

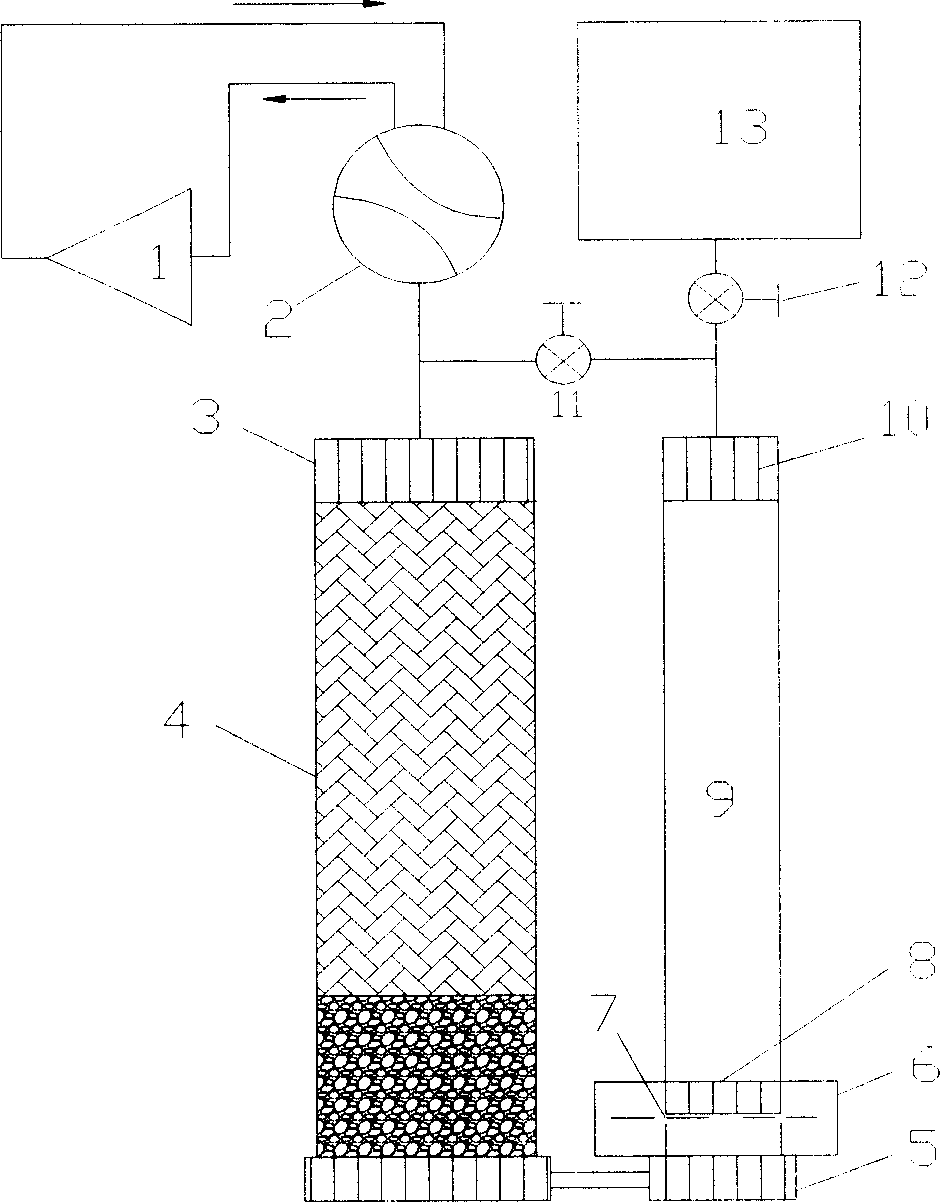

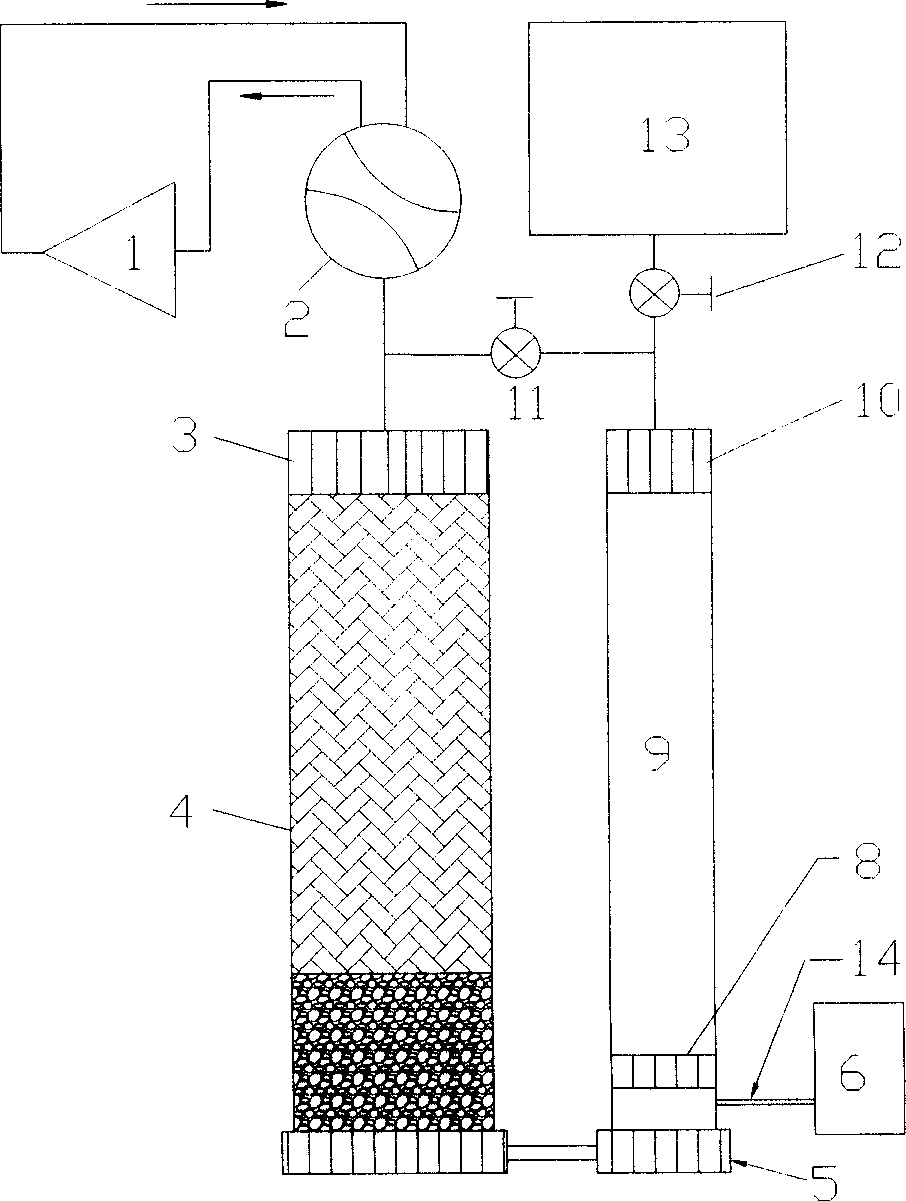

Pulse tube refrigerator with cold end gas storage

InactiveCN1844798AImprove cooling effectImprove cooling efficiencyCompression machinesGas cycle refrigeration machinesPulse tube refrigeratorEngineering

Owner:ZHEJIANG UNIV

Electroconductive Al alloy material and preparation method thereof

The invention discloses an electroconductive Al alloy material and a preparation method thereof. The formula of the Al alloy material is that the Al alloy material comprises the following elements in percentage by mass: 3.5-18.5% of Si, 0.05-2.5% of Mg, 0.5-2.5% of Cu, 0.1-0.6% of Zr, 0.1-1.55% of rare earth, 0-0.15% of inevitable impurity elements and Al in balancing amount; and the sum of the masses of the elements is 100%. The raw materials of the Al alloy material include an Al-Si alloy, an Al-Mg alloy, 10 mu m of Cu powder, rare earth powder and 2-3 mu m of Zr powder. The preparation method of the Al alloy material comprises the steps of melting an Al ingot, adding Al and Cu, adding Zr, adding rare earth, performing casting, performing quenching, performing aging treatment and the like. The Al alloy material prepared according to the preparation method has the advantages of good electric conductivity, high airtightness, excellent mechanical property and the like, meets the material performance requirements of power transmission and transformation equipment in the electric industry, is not limited in size and shape and can be applied to a wide range of occasions and fields.

Owner:湖北万佳宏铝业股份有限公司

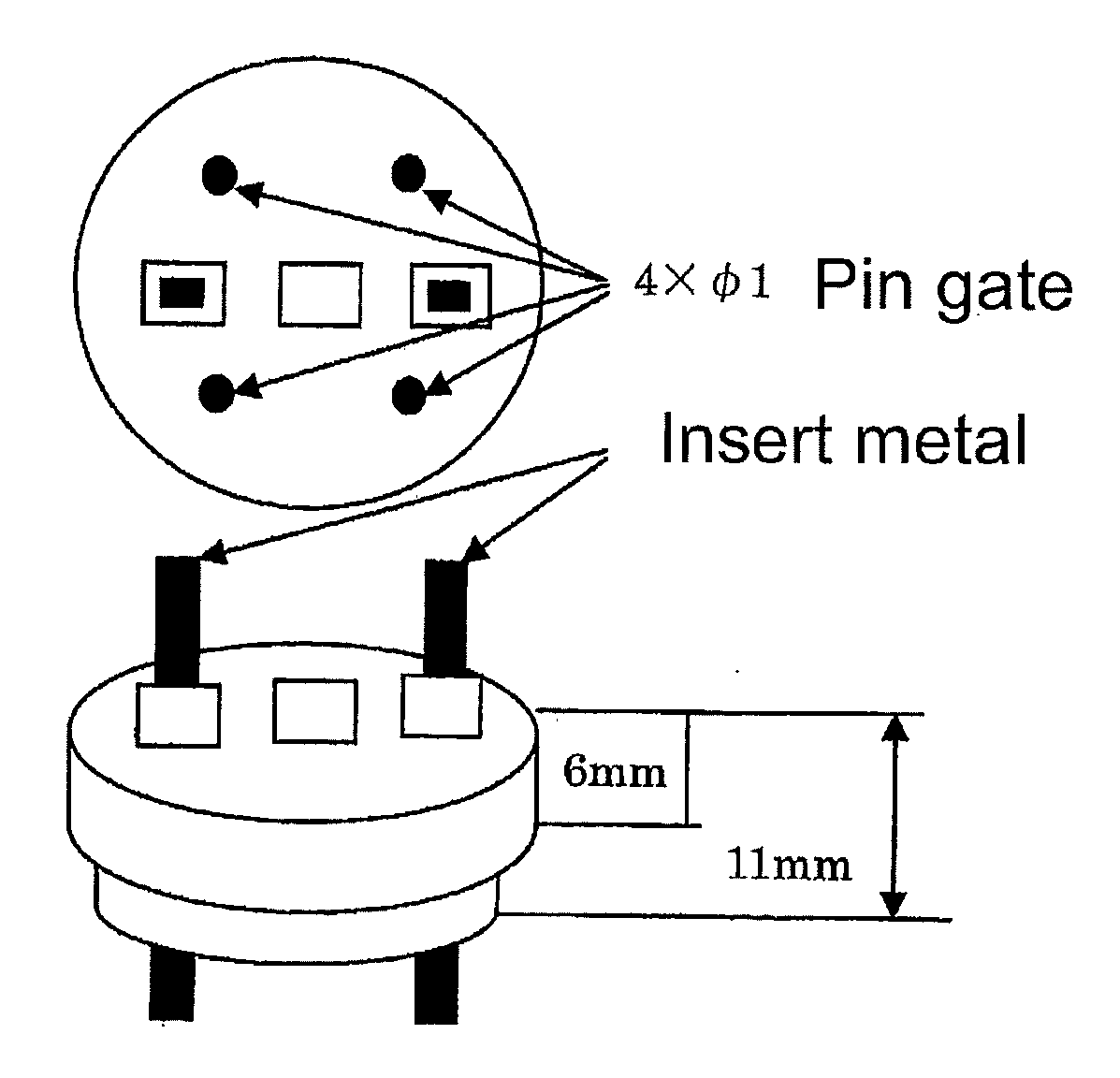

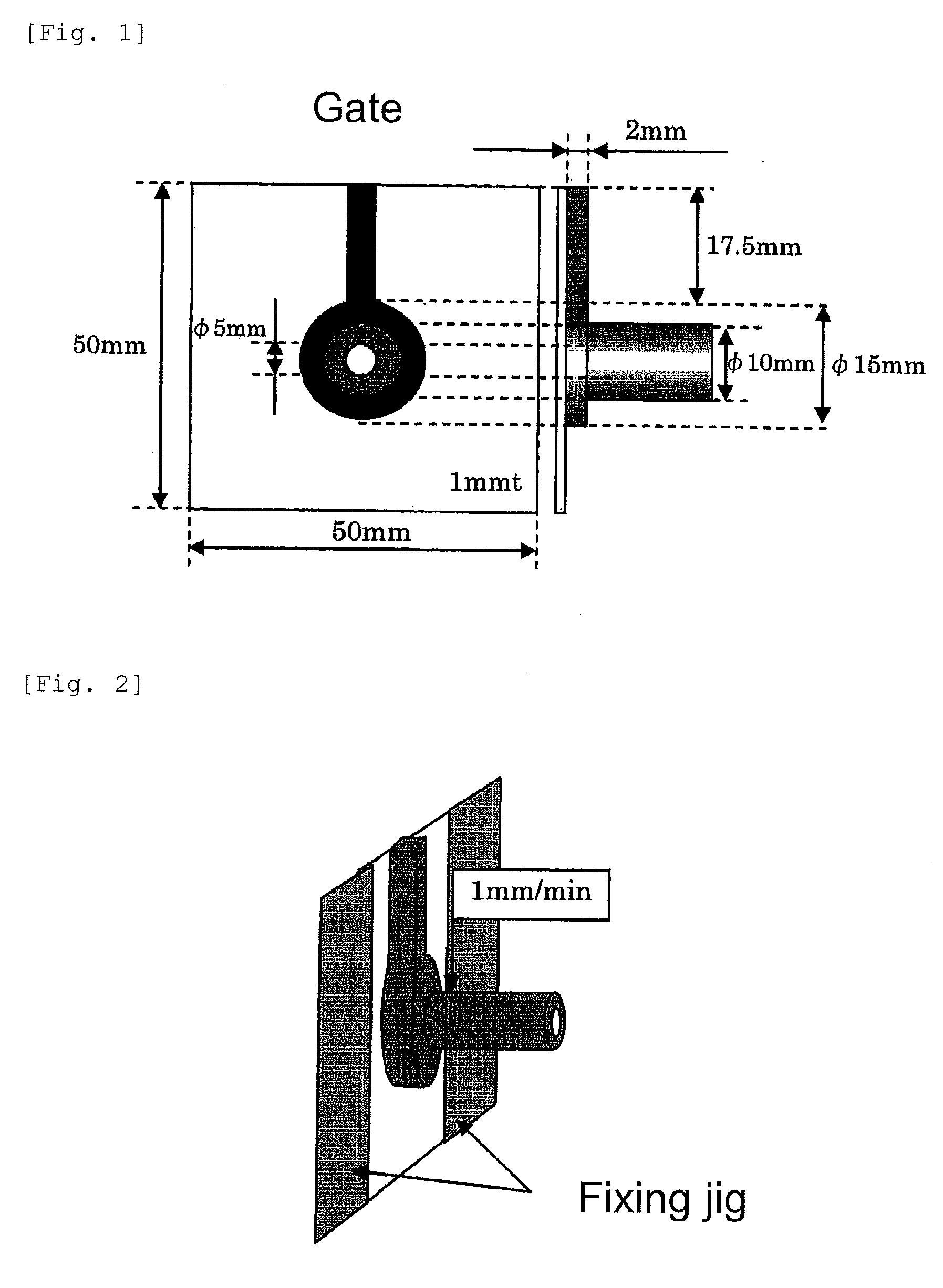

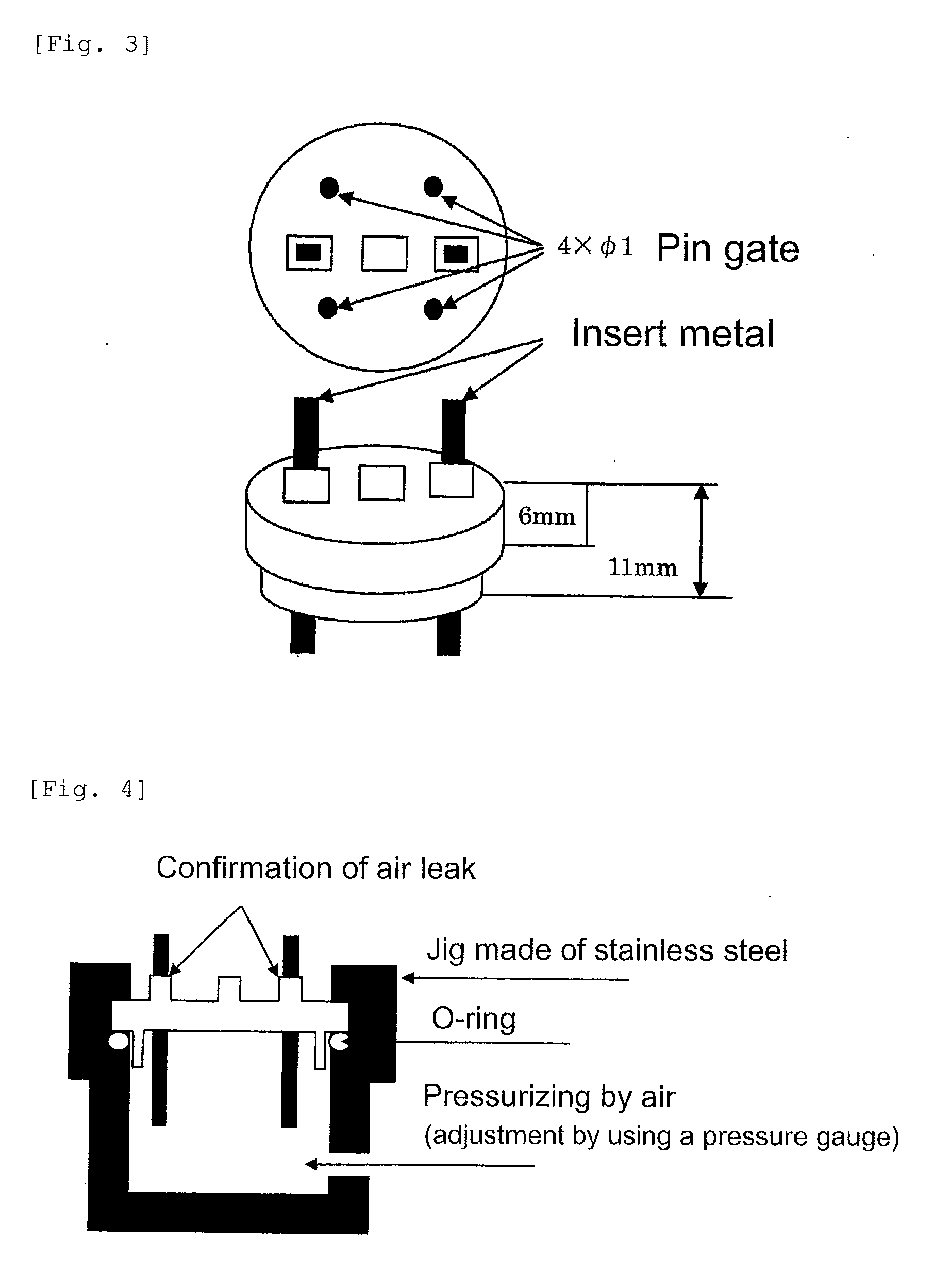

Composite molded product

InactiveUS20100261025A1High bonding strengthImprove adhesionLamination ancillary operationsLaminationPolytetramethylene terephthalateShell molding

Provided is a composite molded product of polybutylene terephthalate resin and metal, having sufficient adhesion strength and being moldable at a mold temperature of 100° C. or lower. Specifically, the composite molded product containing a polybutylene terephthalate resin composition comprising a fibrous reinforcing agent, a polybutylene terephthalate resin and a thermoplastic elastomer, or a modified polybutylene terephthalate resin composition comprising a modified polybutylene terephthalate resin composed of a copolymer of polybutylene terephthalate and isophthalic acid, containing 3 to 50% by mole of isophthalic acid component to the total amount of all the dicarboxylic acid components and a fibrous reinforcing agent and a metal (layer) having a finished finely uneven surface, integrally combined with the composition.

Owner:WIN TECH POLYMER LTD

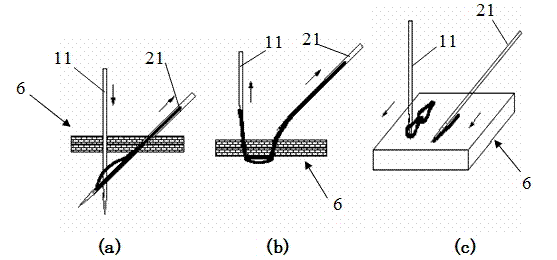

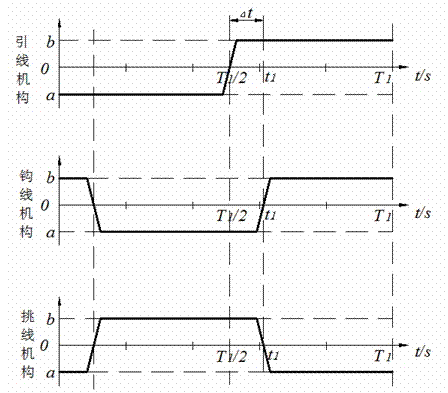

Formation method for single-side suture line stitch of three-dimensional composite material prefabricating component

The invention discloses a formation method for single-side suture line stitch of a three-dimensional composite material prefabricating component. According to the formation method, a line guiding mechanism, a line hooking mechanism and a line picking mechanism are precisely matched to move to obtain the single-side suture line stitch based on time. The formation method mainly comprises four steps: 1, forming a line ring; 2: returning the line ring by hooking; 3, locking the line ring; and 4, cycling operations, wherein suturing works in steps 1 to 3 are repeated, and a reciprocating cycling movement under design cycles is carried out, so that the single-side suture line stitch can be formed. The formation method for the single-side suture line stitch has the characteristics of being simple in technology, good in suturing effect, flexible in operation, and high in adaptability and the like; and a spinning three-dimensional composite material prefabricating component product in shape of complex suturing space is high in interlaminar fracture toughness, and high in fatigue strength.

Owner:TIANJIN POLYTECHNIC UNIV

Method for transferring graphene on hard substrate with PDMS transition layer

ActiveCN103928296ACause physical damageCause damageCarbon compoundsSemiconductor/solid-state device manufacturingCvd grapheneTransition layer

The invention discloses a method for transferring graphene on a hard substrate with a PDMS transition layer. The method comprises the following steps that PDMS glue coats an original substrate coated with graphene; the PDMS glue is solidified to form the PDMS transition layer; plasma treatment is carried out on the PDMS transition layer and the hard substrate, and then the PDMS transition layer and the hard substrate are pressed lightly and bonded; the bonded hard substrate is put into corrosive liquid to etch off the original substrate; a graphene / PDMS transition layer / hard substrate combined body is rinsed repeatedly by using deionized water and is blown dried, and the graphene transferred on the hard substrate with the PDMS layer is obtained. The method is simple in operation, low in cost and wide in application range, the graphene material is not prone to damage in the transferring process, the graphene can be efficiently and stably transferred on the hard substrate with the PDMS transition layer, and the method and a semiconductor technology can be combined to be used for preparing graphene electronic devices.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

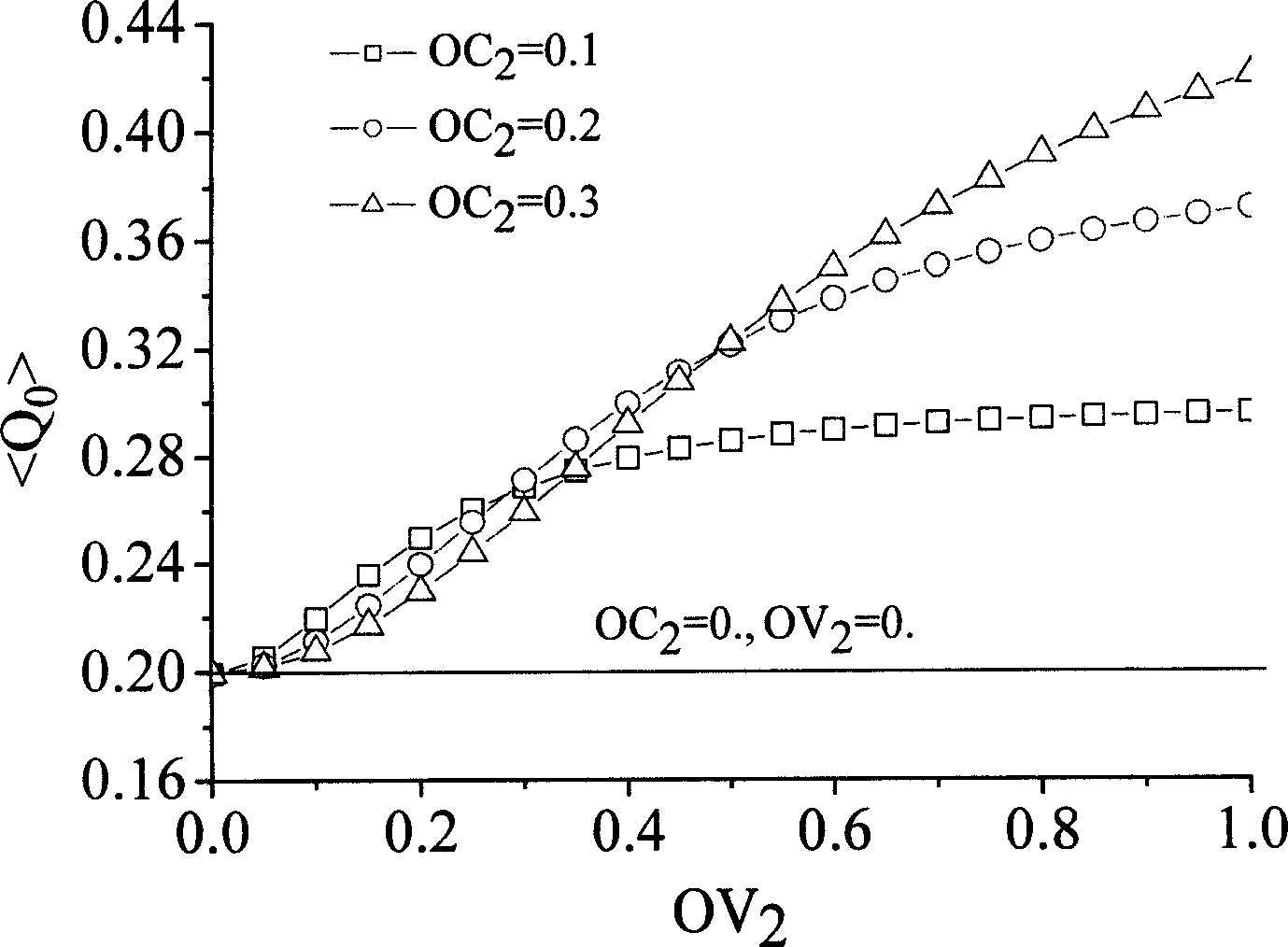

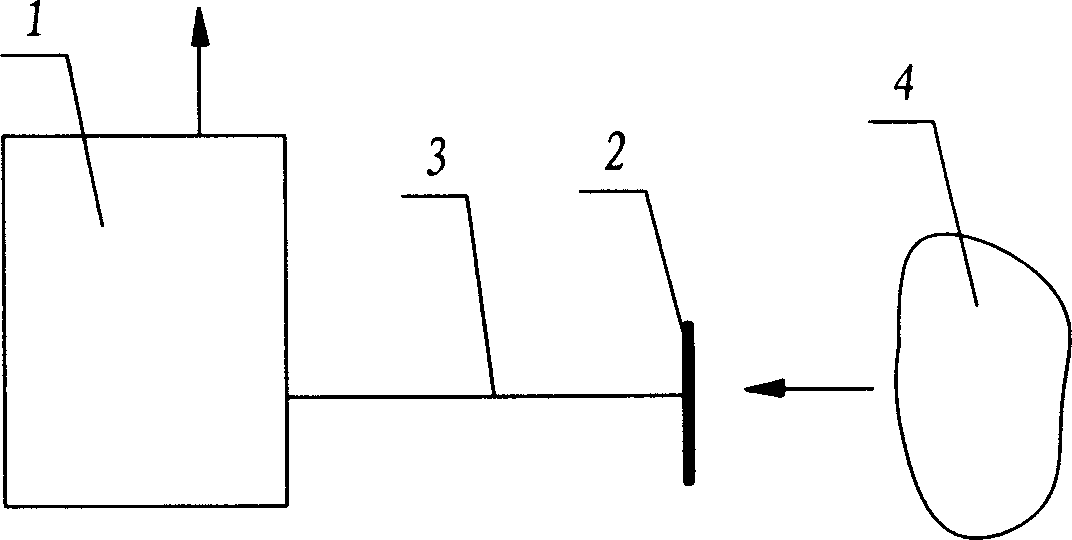

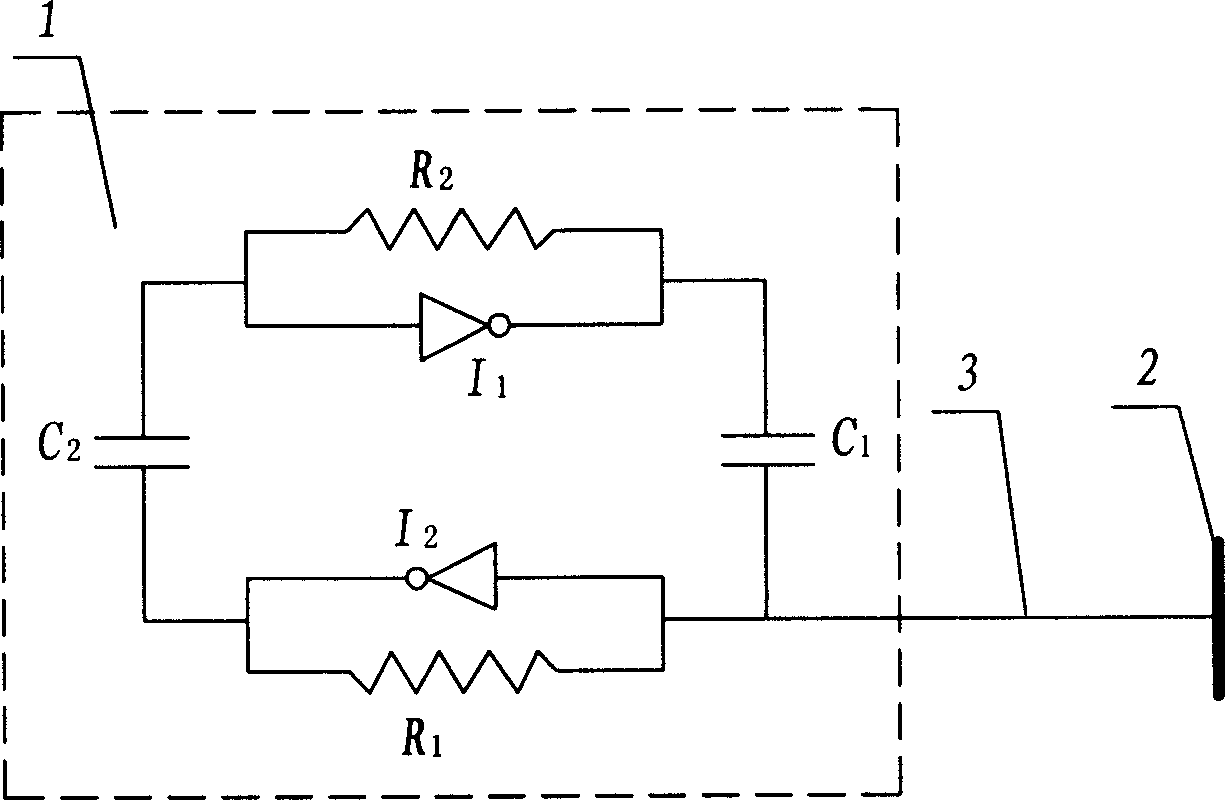

Proximity transducer

InactiveCN1834691AUnlimited shapeIncrease distanceDetection using electromagnetic wavesElectricityCapacitance

The invention discloses a proximity transducer that includes multivibrator and probe. One end of any capacitance of the multivibrator connects to metal probe. When powering on, the multivibrator would charge or discharge capacitance to generate low frequency vibration. The altering current would radiate low frequency electromagnetic wave. Any object closing the probe would adsorb the electromagnetic wave that could influence the quantity of electric charge of the probe to generate micro alteration of vibration frequency to testing the material, volume and shape parameter. The invention has little pollution to the environment and the probe area could be designed in random shape. When probe connects or gets close to metal or conductive object, the probing range would be extended.

Owner:张奔牛

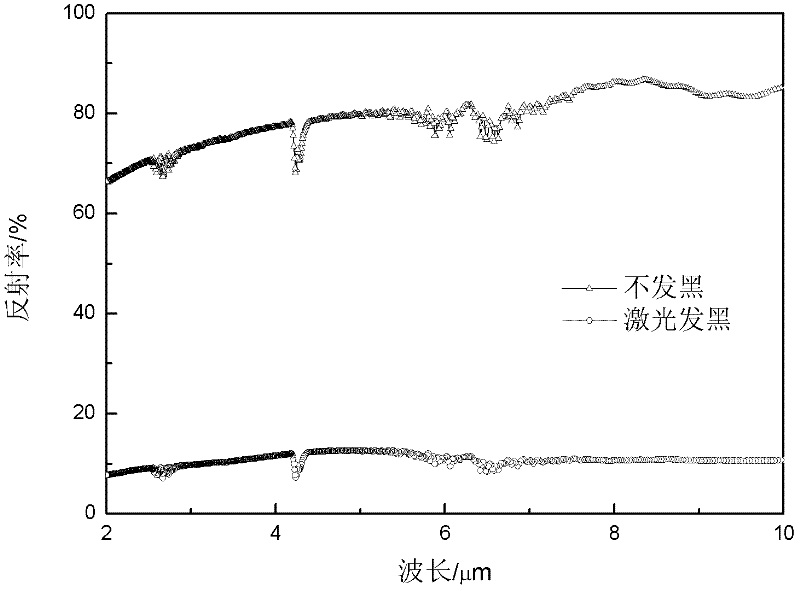

Processing method of local laser blackening for coating metalwork

InactiveCN102242334ASimple and flexible operationLaser Control PreciseSolid state diffusion coatingQuenchingReflectivity

The invention discloses a processing method of coating metalwork which undergoes local laser blackening processing in the packaging of optical assembly. The method is sequentially carried out by the following steps: coating metalwork preparation--laser processing--cleaning.By means of special physical metallurgy and chemical metallurgy effects formed by high energy laser in a molten pool, a black oxide or intermetallic compound cover layer is directly generated in the molten pool in the presence of air, and the cover layer can be generated by the quenching and phase transition of a base material or by the oxidation of the base material and the coating. The processing method can be utilized to arrange blackening areas according to the internal structure of the assembly. The processing areas are controlled by a computer and the geometric shape is formed at random. The blackening areas can be accurately controlled and normal coating areas are not influenced; in addition, the processing method is easy and flexible to operate, and different reflectivities of different areas on the same part can be controlled.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

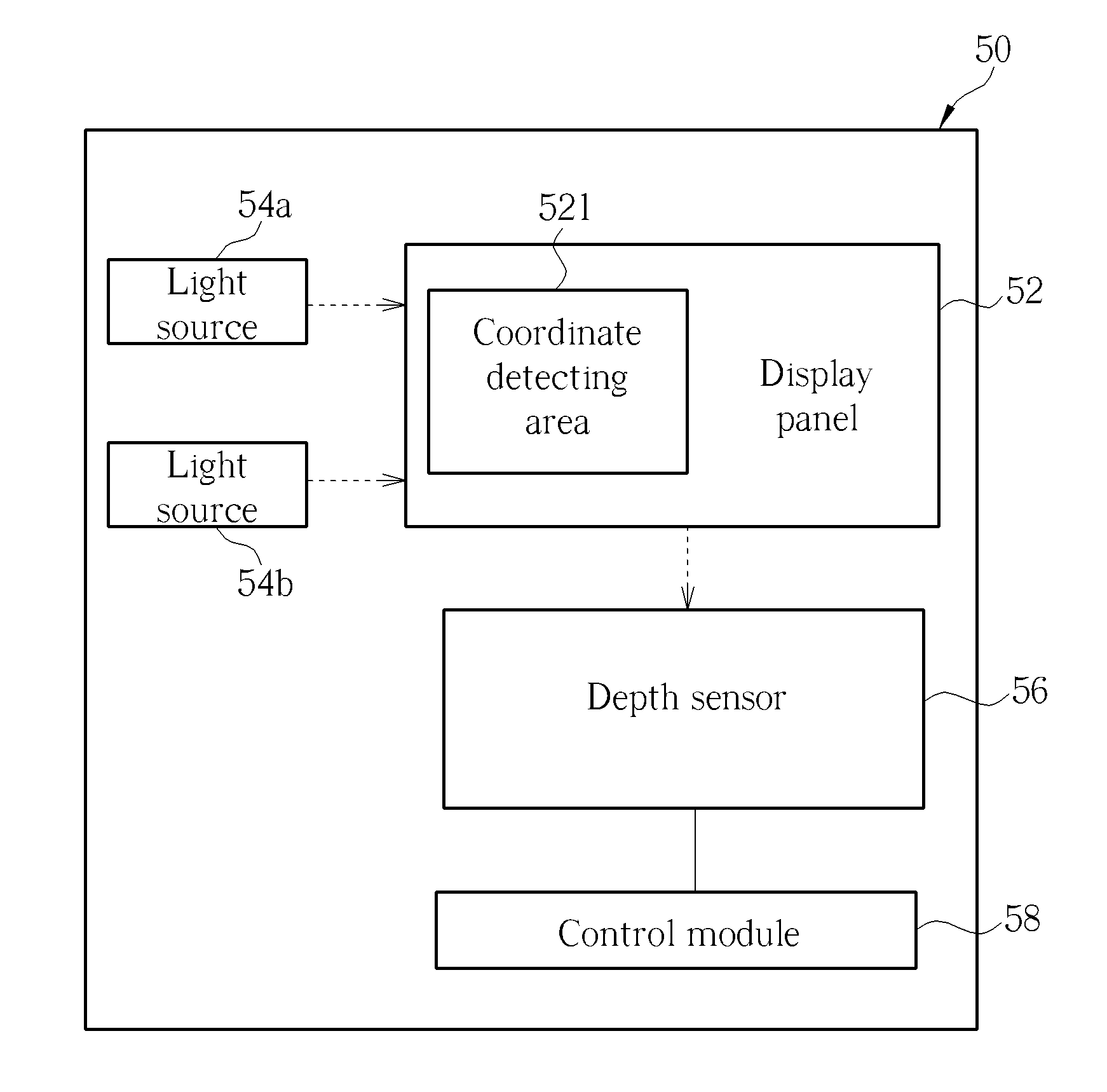

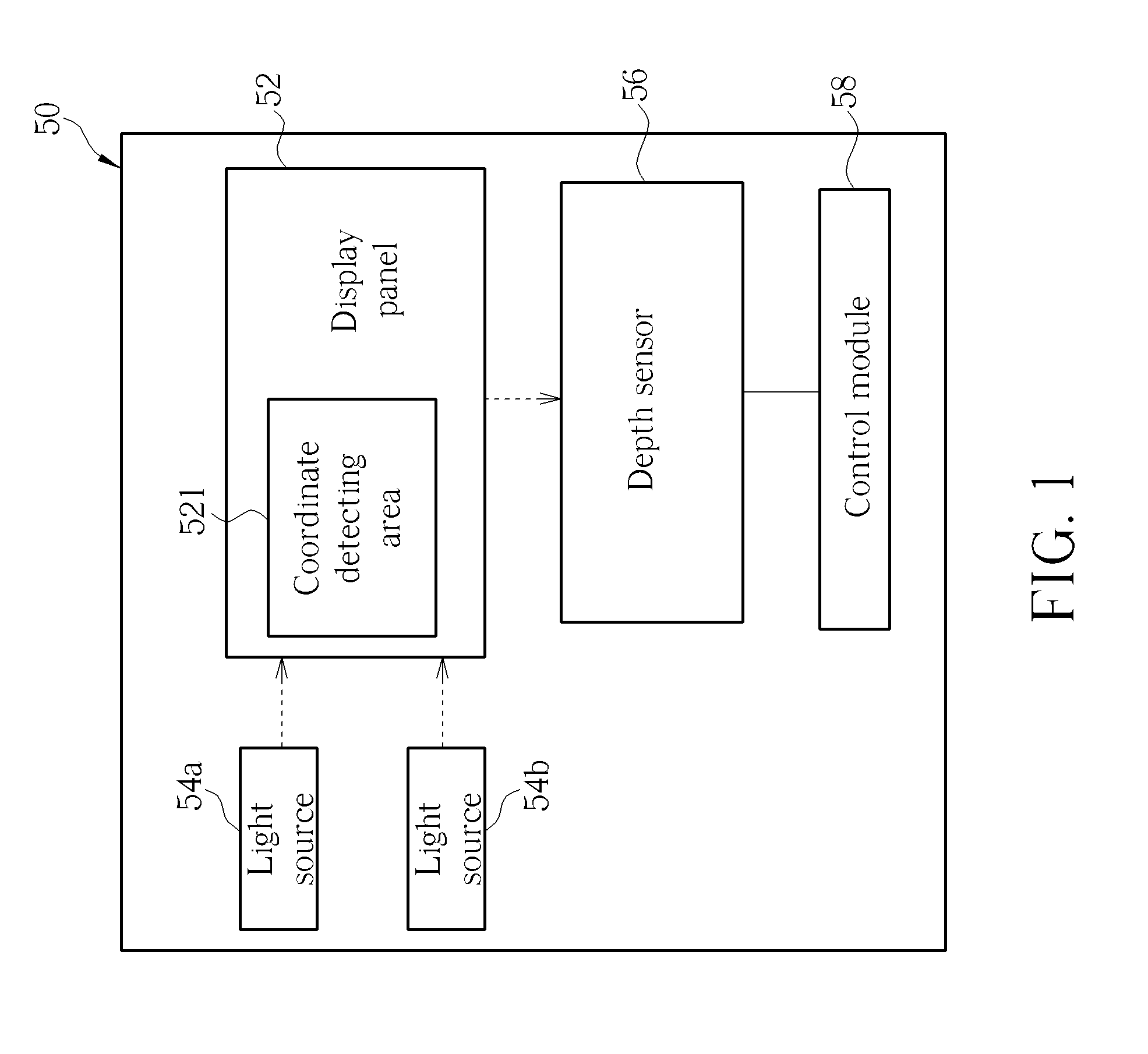

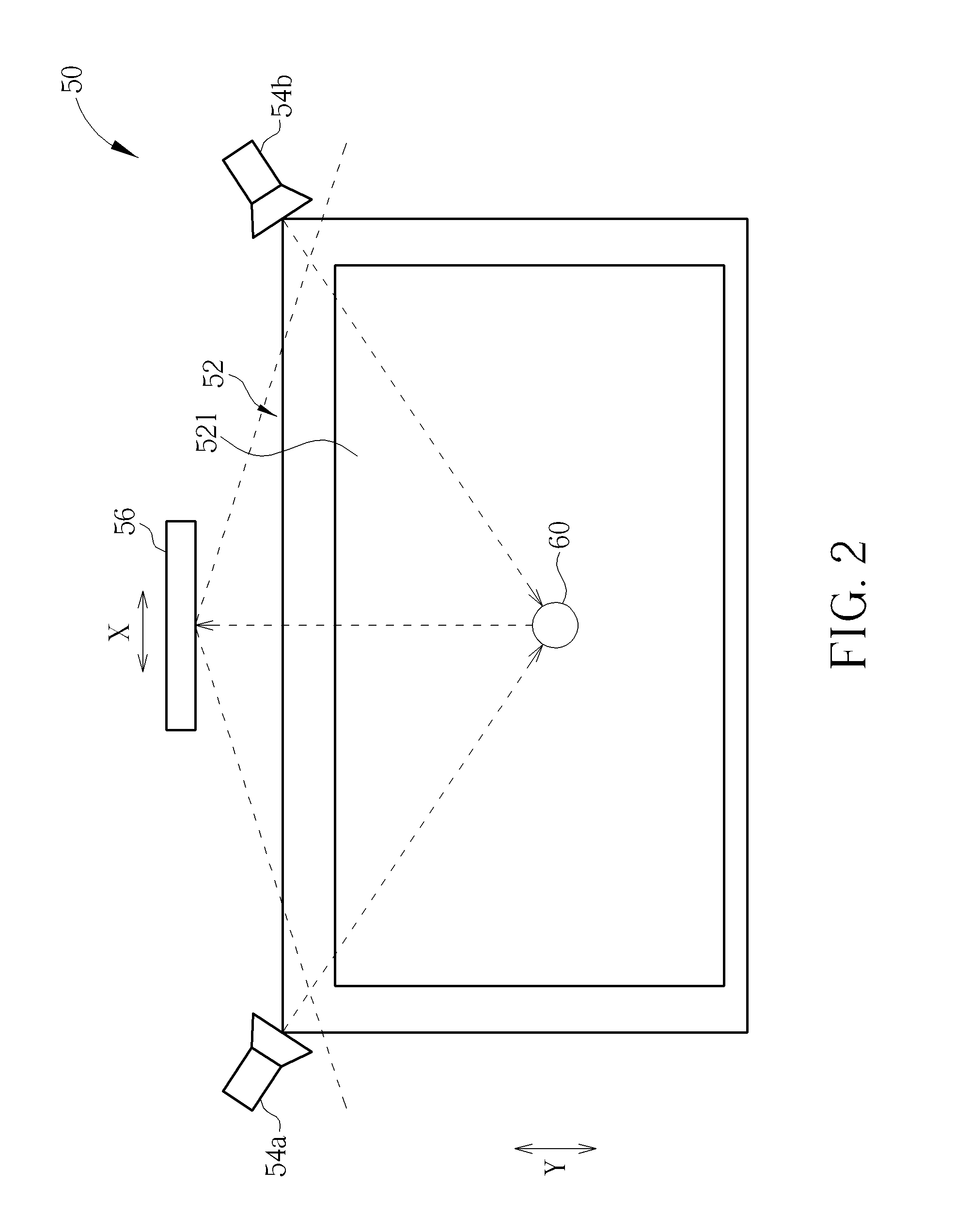

Optical imaging device and imaging processing method for optical imaging device

ActiveUS20130050559A1Reduce the amount of detectionAccurate measurementTelevision system detailsColor television detailsImaging processingComputer science

An optical imaging device includes a display panel whereon a coordinate detecting area is formed, at least one light source disposed outside the display panel for emitting light to illuminate an object, and a depth sensor installed on a side of the display panel for sensing image data of the object. The image data include a width information corresponding to a distance between the object and the depth sensor in a first direction, and a depth information corresponding to a distance between the object and the depth sensor in a second direction. The optical imaging device further includes a control module coupled to the depth sensor for receiving the image data sensed by the depth sensor and for determining whether to calculate a coordinate value of the object according to the width information and the depth information.

Owner:WISTRON CORP

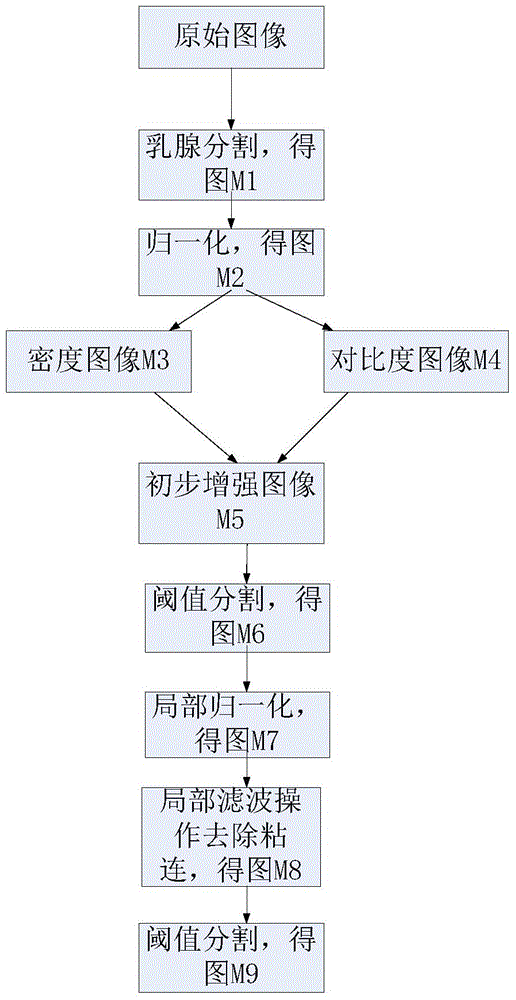

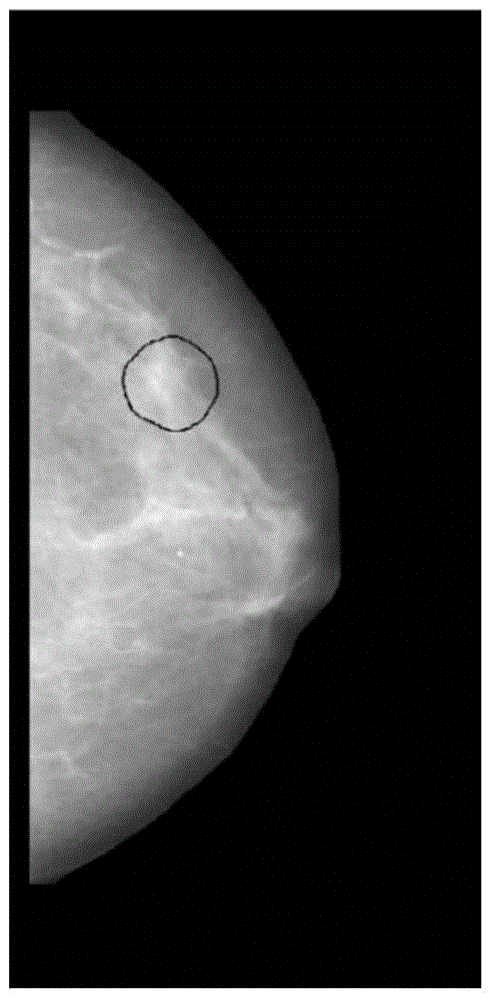

Mammary X-ray image enhancement method

InactiveCN104952044AEnhance image informationIncrease contrastImage enhancementRadiation diagnosticsX ray imageComputer science

The invention provides a mammary X-ray image enhancement method comprising the steps that a mammary X-ray image is provided; and local normalization is performed on the local part in the mammary X-ray image so that image information corresponding to the local part can be enhanced. Local information is enhanced via local normalization so that implicit local information in the global image can be effectively enhanced, i.e. low intensity lesions can be effectively enhanced. Furthermore, local filtering is adopted after local normalization so that local contrast can be enhanced, adhesion between local objects can be suppressed and adhesion of the lesions and background tissues can be effectively suppressed.

Owner:SHANGHAI UNITED IMAGING HEALTHCARE

Preparation method of high-wear-resistance WC-based hard alloy

InactiveCN110735075AImprove corrosion resistanceImprove mixing uniformityChromium carbideWater jet cutter

The invention provides a preparation method of a high-wear-resistance WC-based hard alloy. A certain amount of molybdenum powder, chromium carbide powder and vanadium carbide powder are added before tungsten powder carbonization, and are mixed with carbon powder by a wet grinding mode, so that the powder mixing uniformity is greatly improved; the doped molybdenum powder, chromium carbide powder and vanadium carbide powder can achieve an effect of inhibiting growth of tungsten carbide grains in the tungsten powder carbonization process in the step 2 and the alloy sintering process in the step 4; and meanwhile, in the tungsten powder carbonization process, molybdenum, chromium and alum can be largely or slightly dissolved in tungsten carbide to form (W, Mo, Cr, V) C solid solution, so that guarantee is provided for formation of (W, Mo, Cr, V) C solid solution powder with fine and uniform particle size in the later tungsten powder carbonization process, and the purpose of reinforcing physical performances of the tungsten carbide grains and alloys thereof is achieved. The prepared non-bonded-phase WC-based hard alloy is high in hardness and excellent in wear resistance, and can satisfythe high wear resistance requirements of water jet sand pipes and fracturing nozzles on materials.

Owner:ZIGONG CEMENTED CARBIDE CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com