Preparation method for titanium alloy TiAl3-Al composite coating

A composite coating, titanium alloy technology, applied in the direction of metal material coating process, coating, melting spray plating, etc., to achieve the effect of controllable coating thickness, high production efficiency and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Powder pretreatment: the particle size is 15~120μm TiAl 3 The powder and pure Al powder with a particle size of 10-100μm are mechanically mixed at a weight ratio of 92:8 for 24h, put in a 50℃ oven for 5h, and then taken out for use.

[0027] (2) Pre-treatment of TC4 titanium alloy substrate: the burrs on the surface of the TC4 titanium alloy substrate are polished with sandpaper, ultrasonically cleaned with alcohol for 10 minutes, and then sandblasted on the surface of the TC4 titanium alloy substrate, and ultrasonically cleaned with alcohol for 5 minutes.

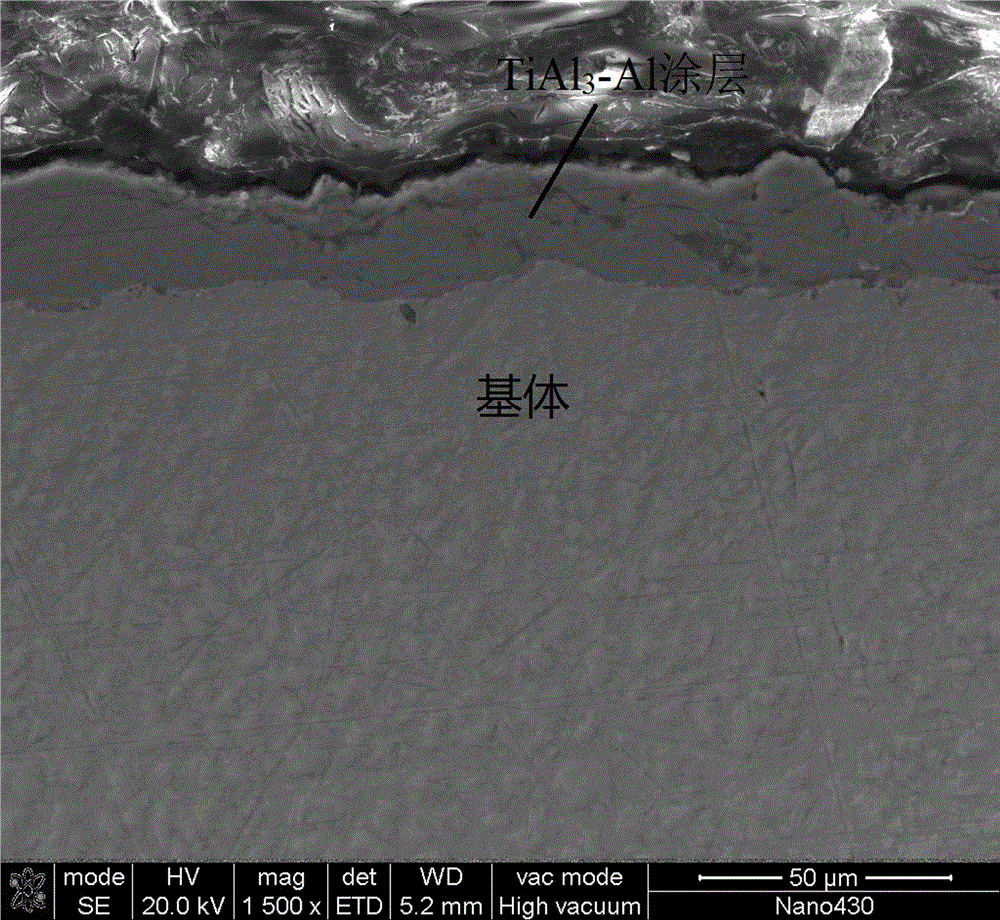

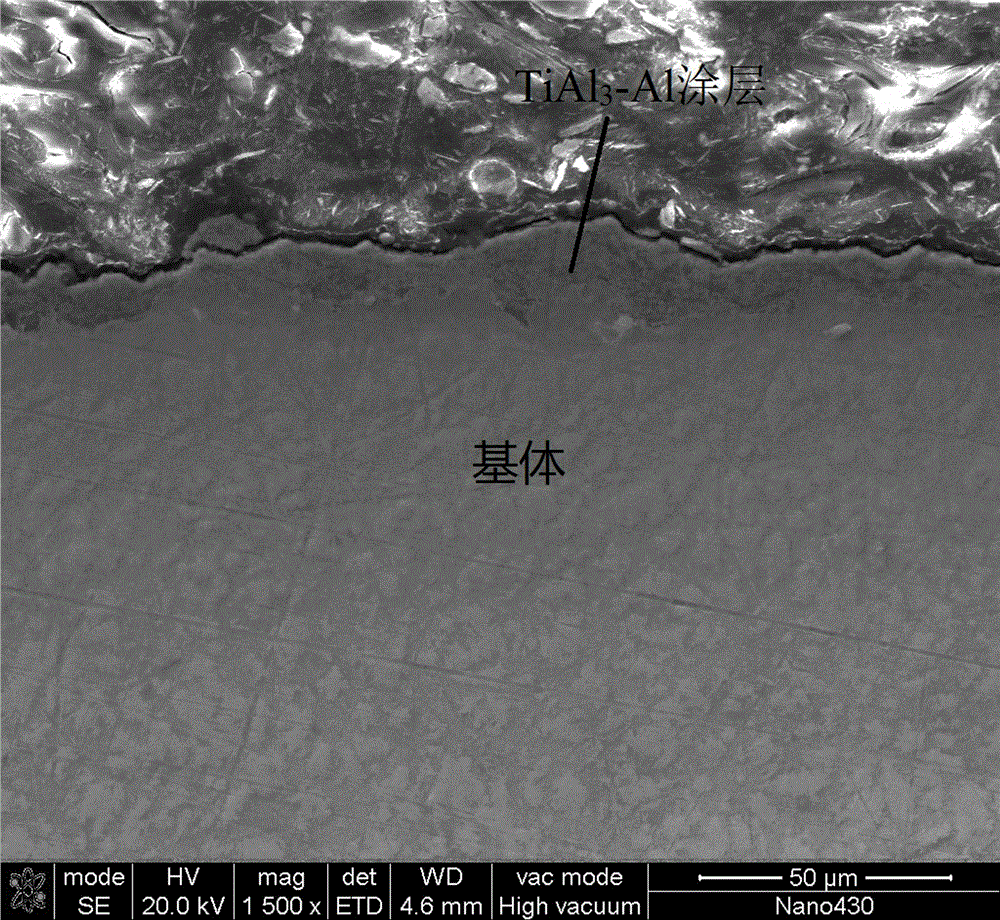

[0028] (3) Low-temperature supersonic flame spray coating: TiAl 3 The mixed powder of powder and pure Al powder is thermal spray powder, and TiAl is prepared on the surface of titanium alloy substrate using low-temperature supersonic flame spray equipment 3 -Al coating. The process parameters are: the combustion chamber pressure is 1.8MPa, the powder feeding carrier gas is nitrogen, the flow rate is 9l / min, the spray ...

Embodiment 2

[0032] (1) Powder pretreatment: the particle size is 15~120μm TiAl 3 The powder and pure Al powder with a particle size of 10-100μm are mechanically mixed in a weight ratio of 80:20 for 24 hours, put in an oven at 40°C for 6 hours, and then taken out for use.

[0033] (2) Pretreatment of the TC11 titanium alloy substrate: sand the surface of the TC11 titanium alloy with sandpaper to remove the surface burrs, ultrasonically clean the surface with alcohol for 10 minutes, and then sandblast the surface of the TC11 titanium alloy with alcohol for 5 minutes.

[0034] (3) Cold spray coating: TiAl 3 The mixed powder of powder and pure Al powder is thermal spray powder, and the cold spray technology prepares TiAl on the surface of TC11 titanium alloy substrate. 3 -Al coating. The process parameters are: the gas used is nitrogen, the preheating temperature is 550°C, the pressure is 2.5MPa, the spray gun moving speed is 100mm / s, and the spraying distance is 30mm.

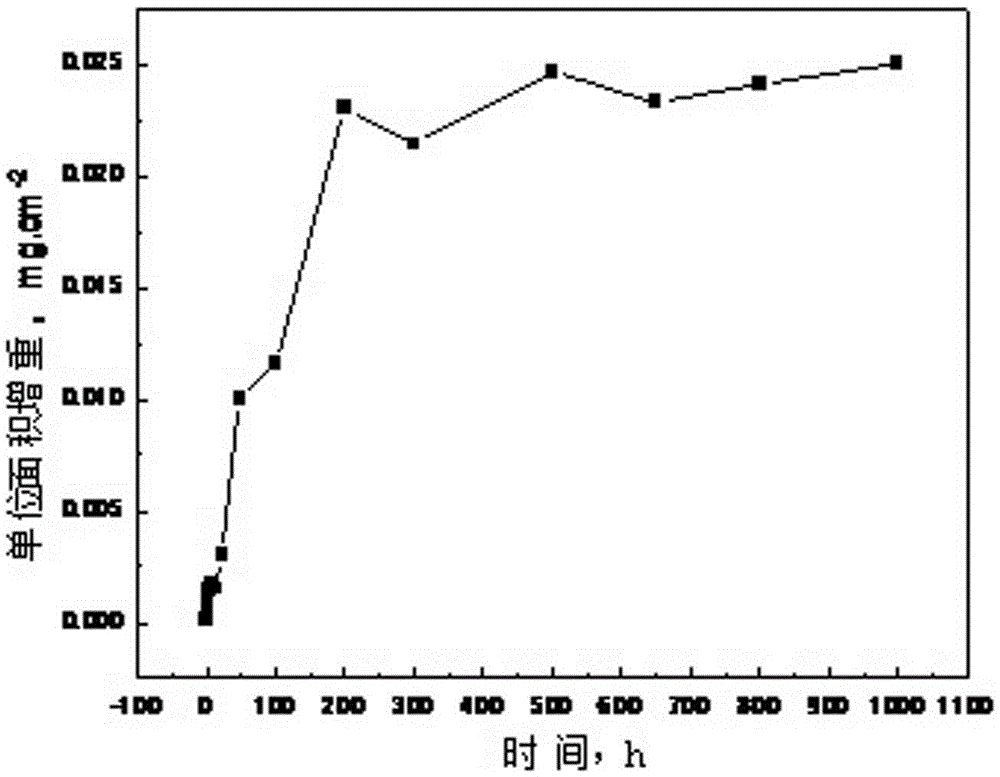

[0035] This example TiAl 3 -...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com