Remote fluorescent LED (Light Emitting Diode) device

A technology of LED devices and remote fluorescence, applied in lighting devices, lighting device components, light sources, etc., can solve the problems of low work efficiency, unacceptable, rising costs, etc., achieve high production efficiency and product qualification rate, reduce equipment cost, the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

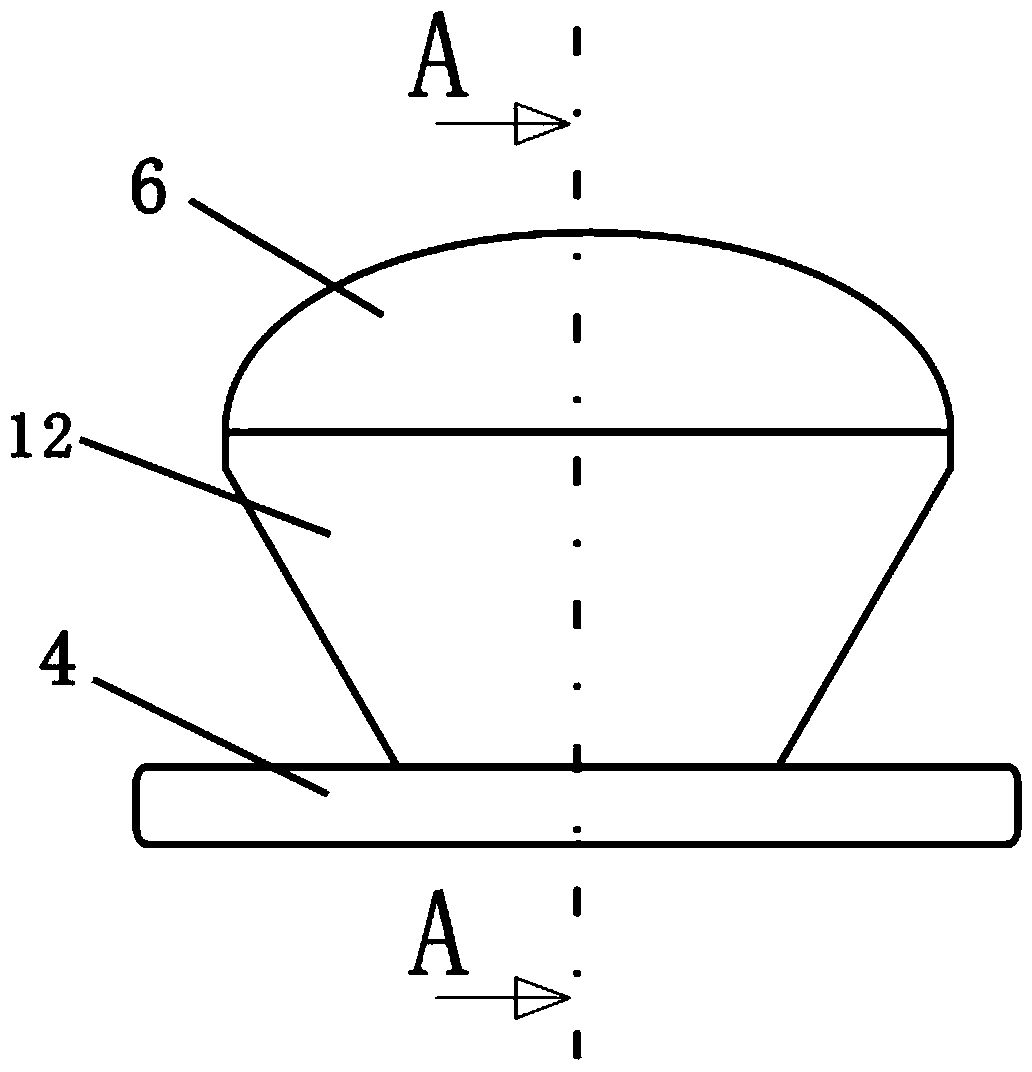

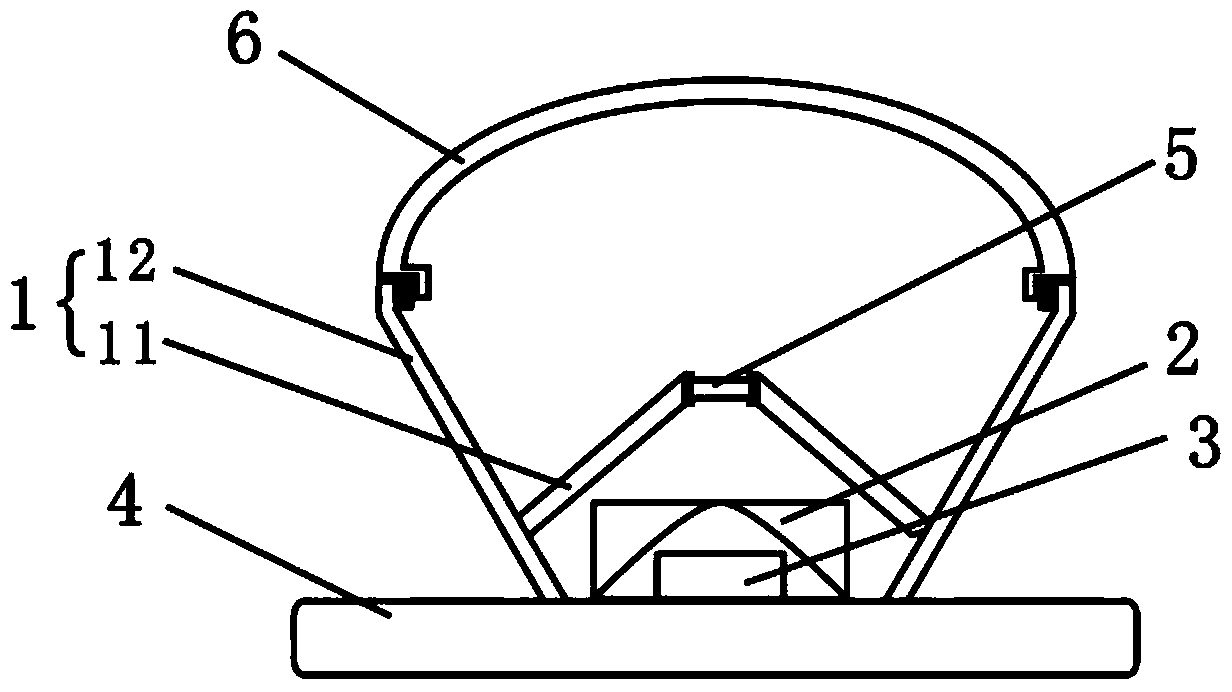

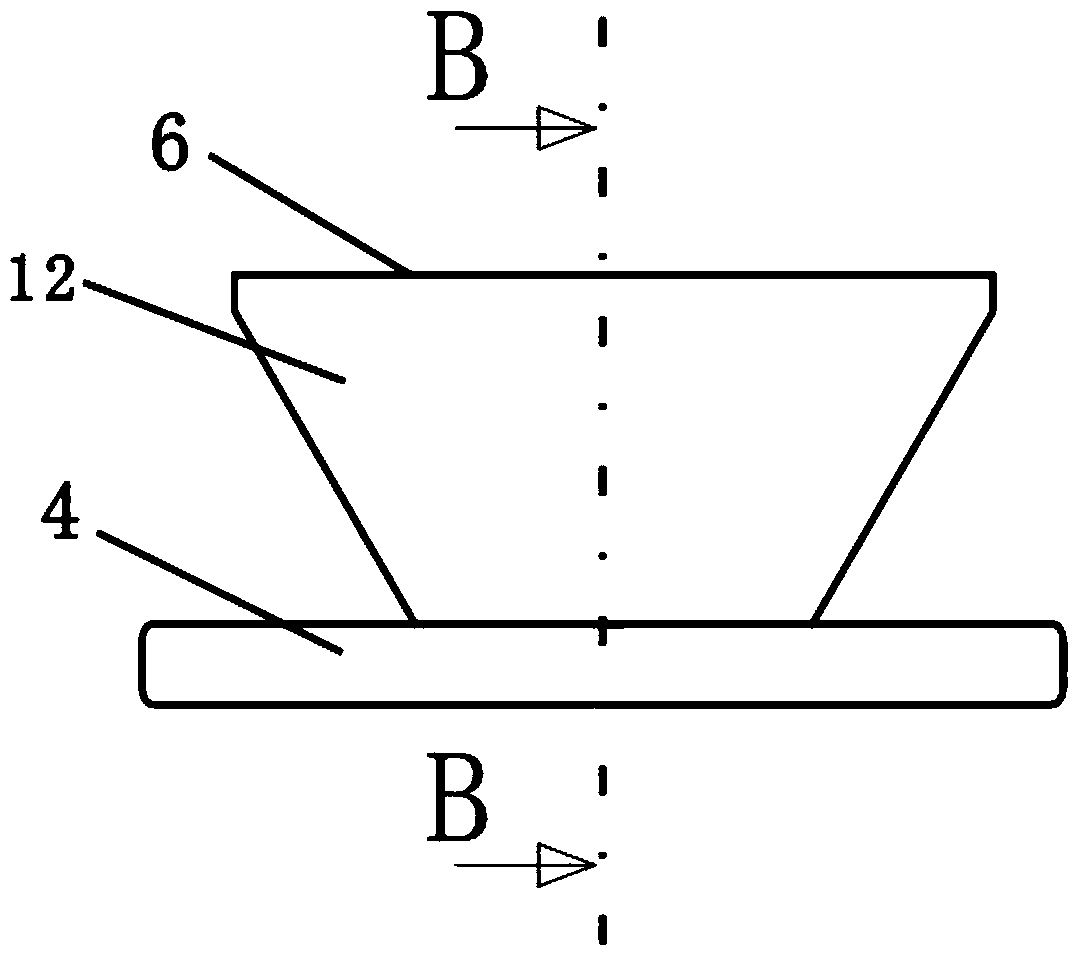

[0048] Rare earth fluorescent resin sheet 5 thickness: 2.3mm, radius 10.8mm; phosphor concentration: 4%; phosphor type: YAG yellow powder; distance between LED chip 3 and rare earth fluorescent resin sheet 5: 0.8cm; distance between light diffusion lampshade 6 and rare earth fluorescent Resin sheet 5 distance: 0.5cm; white paper thickness 0.1mm; white LED: 3W positive white light.

[0049]

[0050]

Embodiment 2

[0052] Rare earth fluorescent resin sheet 5 thickness: 3.0mm, radius 8mm; fluorescent powder concentration: 4%; phosphor powder type: green powder + red powder; distance between LED chip 3 and rare earth fluorescent resin sheet 5: 2cm; distance between light diffusion lampshade 6 and rare earth fluorescent resin Sheet 5 distance: 4.5cm; white paper thickness 0.1mm; white LED: 3W warm white light.

[0053]

[0054] The data from the two examples show that the combination of the blue LED chip and the 30° lens has the best effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com