Stranded wire

A stranded wire and carbon nanotube technology, applied in the field of stranded wire based on carbon nanotubes, can solve the problems of low electrical conductivity of carbon nanotubes, inability to replace metal wires, and high resistance at contact points, and achieve excellent mechanical properties and light weight , the effect of high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

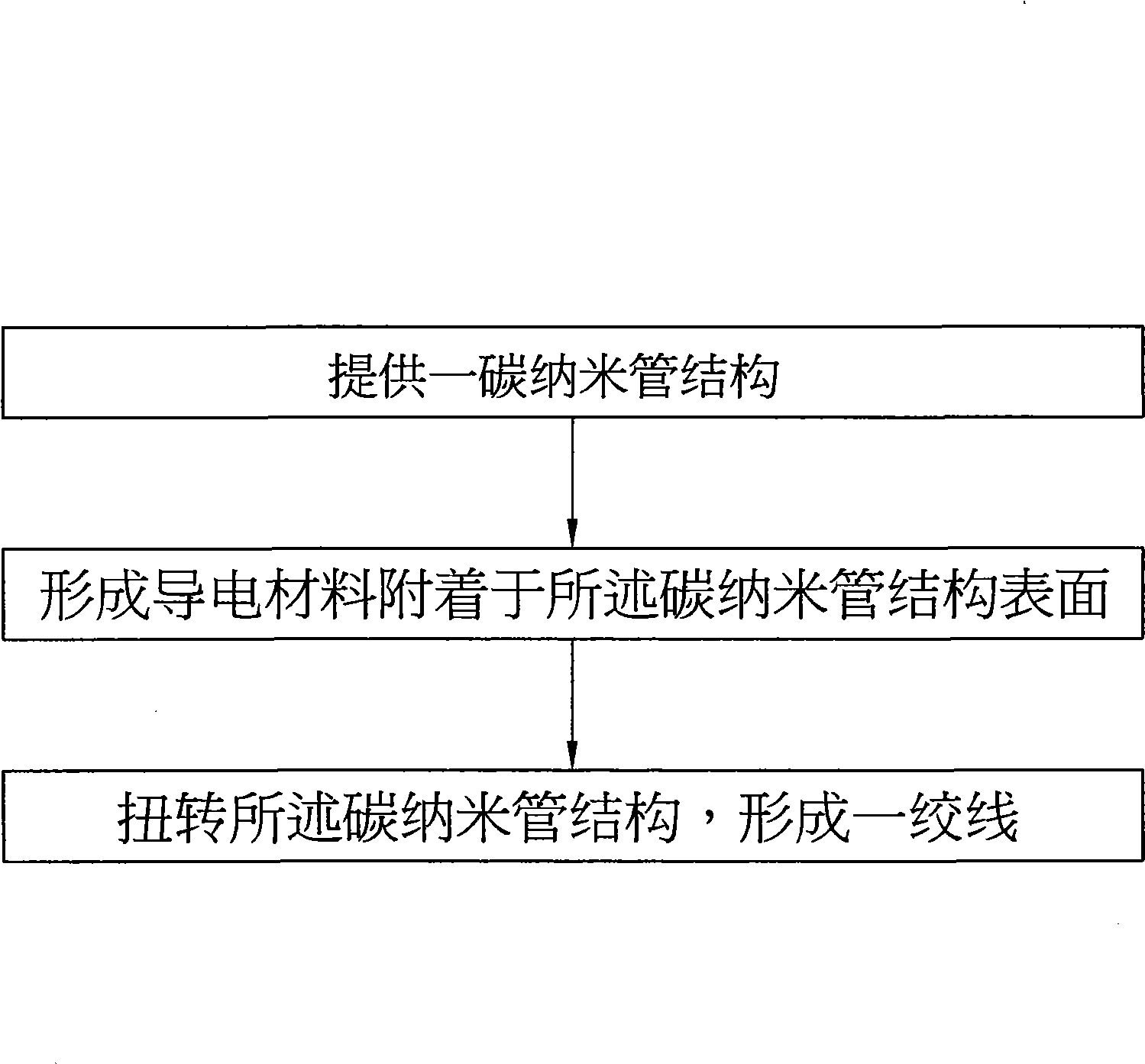

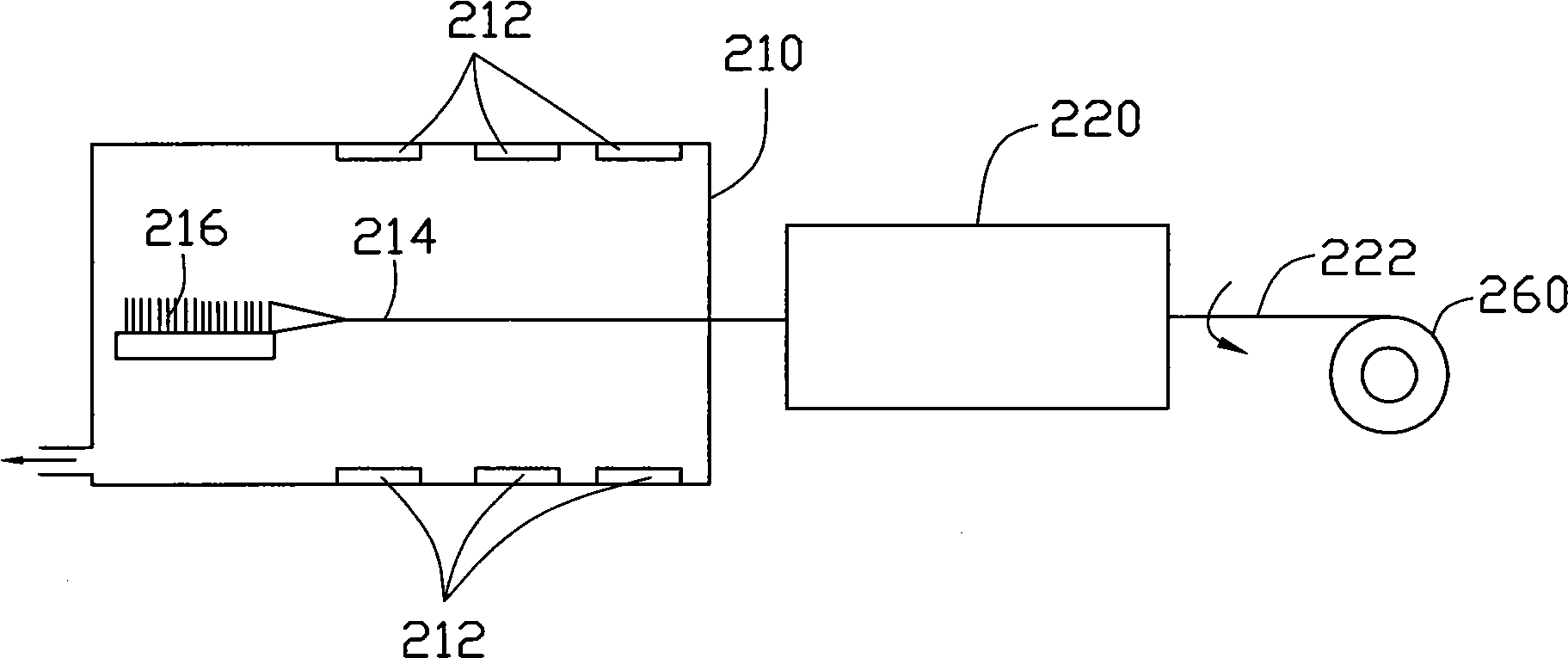

[0024] See figure 2 and image 3 , The preparation method of stranded wire in the embodiment of the present invention mainly includes the following steps:

[0025] Step 1: Provide a carbon nanotube structure 214.

[0026] The carbon nanotube structure 214 may be a carbon nanotube film or a plurality of stacked carbon nanotube films. The carbon nanotube film includes a plurality of carbon nanotubes, and there are gaps between adjacent carbon nanotubes. The carbon nanotubes are parallel to the surface of the carbon nanotube film. The carbon nanotube film may have a self-supporting structure. The so-called self-supporting structure means that a plurality of carbon nanotubes in the carbon nanotube film are attracted to each other through van der Waals force, so that the carbon nanotube film has a specific shape.

[0027] The preparation method of the carbon nanotube film may include the following steps:

[0028] First, a carbon nanotube array 216 is provided. Preferably, the array is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com