Stepping-type laser cutting uncoiling blanking line

A technology of laser cutting and uncoiling blanking, which is applied in the field of coil material processing, can solve the problems of not being able to adapt to the supply of large-scale automotive stamping parts, and achieve the effects of convenient R&D and trial production, increasing the yield of finished products, and shortening the time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

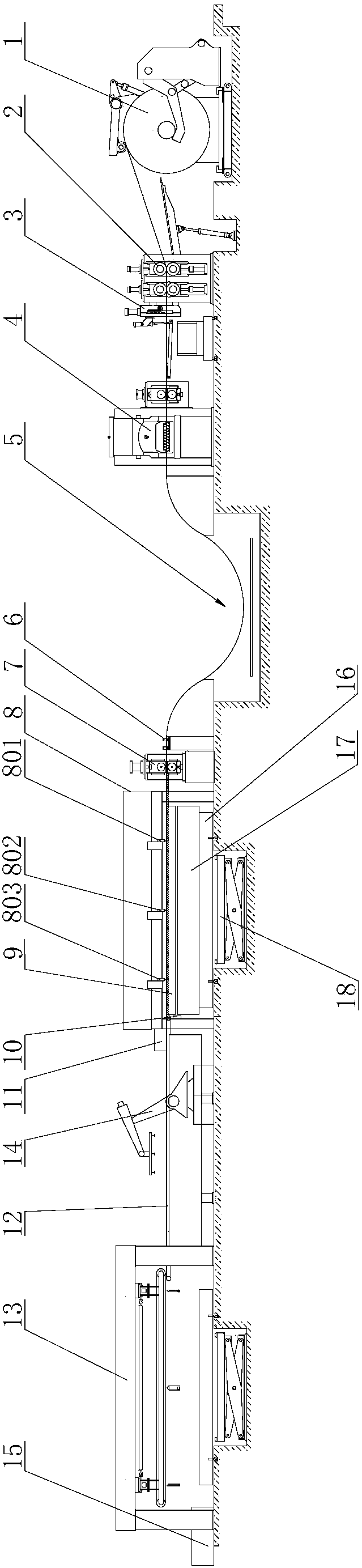

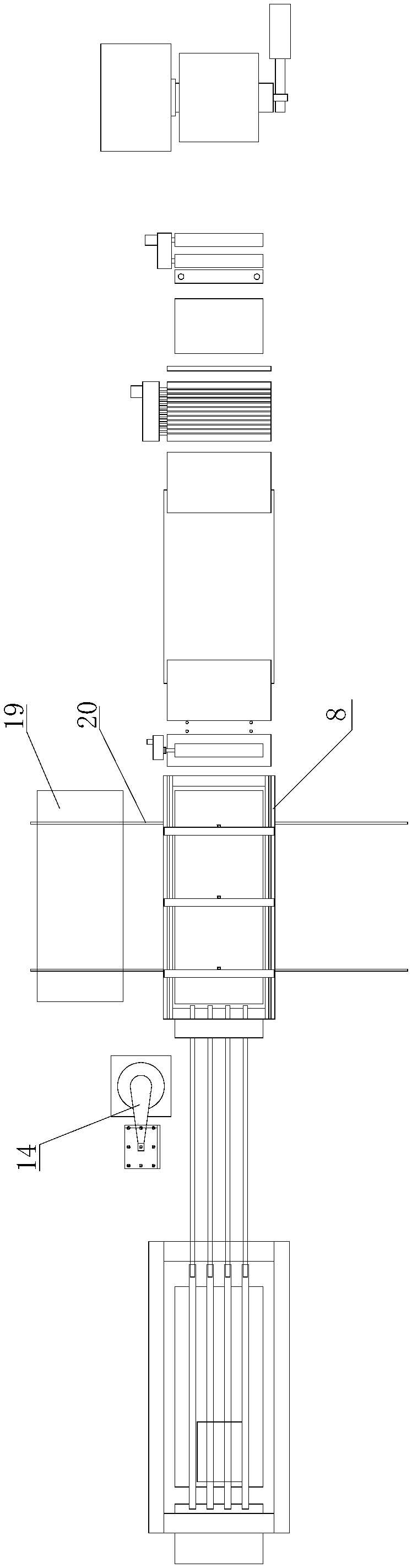

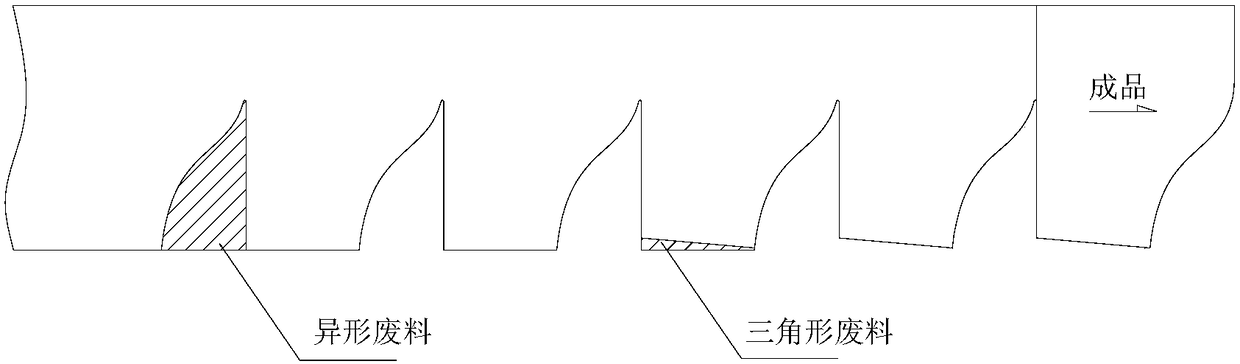

[0032] Such as figure 1 and figure 2 As shown, this embodiment provides a step-by-step laser cutting uncoiling and blanking line, including an uncoiler 1, a leveler 4, a fixed-length feeder 7 and a laser cutting machine 8 connected in series in sequence. The uncoiler 1 is used to place and Fix the coiled material and unfold the coiled material according to the requirements; the leveler 4 straightens the coiled material into a sheet that meets the flatness requirements; the fixed-length feeder 7 accurately sends the sheet to the laser cutting machine 8 according to the set length, and the laser cuts it. The machine 8 can be a gantry type numerically controlled multi-head laser cutting machine. The laser cutting machine 8 includes at least three laser cutting heads, and each laser cutting head is only responsible for cutting a part of the sheet.

[0033] A special cutting platform 9 is installed on the laser cutting machine 8, and the special cutting platform 9 is located unde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com