Method for preparing TiC/Ni3Al intermetallic compound based surface composite coating

A technology of intermetallic compound and surface compounding, which is applied in heat exchange equipment, rotors, cylinders, etc., and can solve the problems of high cost, limited size and compounding position, and low production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Preparation of TiC(15wt%) / Ni 3 Al coating

[0022] Ti powder (500 mesh) with purity ≥99.8%, graphite powder (particle size ≤30μm) with purity ≥99.85%, Al powder (300 mesh) with purity ≥98% and Ni powder (200 mesh) with purity ≥99% , according to Ti, C, Al, and Ni as the molar ratio of 1:1 and 1:3 respectively, Ti, C accounted for 15% of the total amount of mixed powder, mixed powder on a planetary ball mill for 16 hours, and the ball-to-material ratio was 3 : 1. The evenly mixed powder is pressed into a φ20mm×2mm compact on a 10-ton press, with a density of 55%, and dried at 150°C for 5 hours in a vacuum state, and then pasted with 3% PVA aqueous solution to dry the prefabricated block in air The 12h sand mold wall, after preheating at 400°C for 30min, poured molten steel at a temperature of 1600°C, reaction compounding and densification occurred, and 15wt% TiC / Ni was obtained after solidification 3 Composite coatings on Al intermetallic-based surfaces.

Embodiment 2

[0024] Preparation of TiC(35wt%) / Ni 3 Al coating

[0025] Ti powder (300 mesh) with purity ≥99.8%, graphite powder (particle size ≤30μm) with purity ≥99.85%, Al powder (300 mesh) with purity ≥98% and Ni powder (200 mesh) with purity ≥99% , according to Ti, C, Al, Ni as the molar ratio of 1:1 and 1:3 respectively, Ti, C accounted for 35% of the total amount of mixed powder, mixed powder on a planetary ball mill for 20h, the ball-to-material ratio was 3 : 1. The evenly mixed powder is pressed into a compact of φ20mm×6mm on a 10-ton press, with a density of 58%, and dried under vacuum at 150°C for 5 hours, and then pasted with 3% PVA aqueous solution on the air-dried 12h The sand mold wall, after preheating at 400°C for 30 minutes, poured molten steel at a temperature of 1580°C, reaction compounding and densification occurred, and 35wt% TiC / Ni was obtained after solidification 3 Composite coatings on Al intermetallic-based surfaces.

Embodiment 3

[0027] Preparation of TiC(50wt%) / Ni 3 Al coating

[0028] Ti powder (300 mesh) with purity ≥99.8%, graphite powder (particle size ≤30μm) with purity ≥99.85%, Al powder (300 mesh) with purity ≥98% and Ni powder (200 mesh) with purity ≥99% , according to Ti, C, Al, and Ni as the molar ratio of 1:1 and 1:3 respectively, Ti and C account for 50% of the total amount of mixed powder, and mix the powder on a planetary ball mill for 24 hours, and the ball-to-material ratio is 3 : 1. The evenly mixed powder is pressed into a compact of φ20mm×10mm on a 10-ton press, with a density of 52%, and dried under vacuum at 150°C for 5 hours, and then pasted with 3% PVA aqueous solution on the air-dried 12h The sand mold wall, after preheating at 400°C for 30 minutes, poured molten steel at a temperature of 1550°C, reaction compounding and densification occurred, and 50wt% TiC / Ni was obtained after solidification 3 Composite coatings on Al intermetallic-based surfaces.

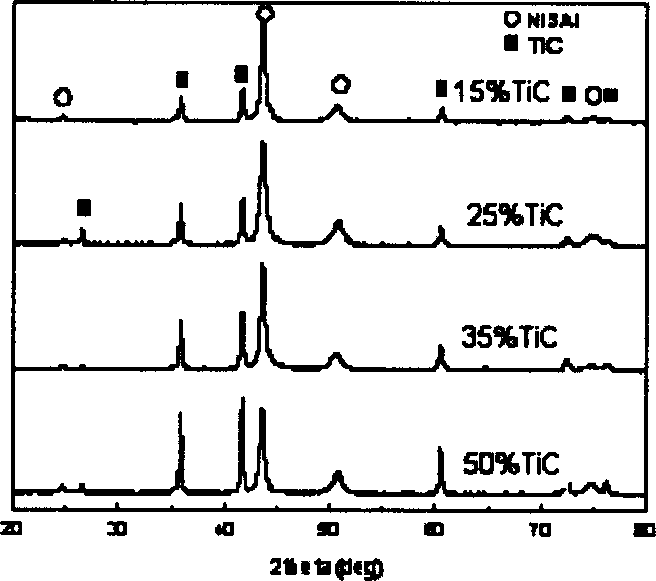

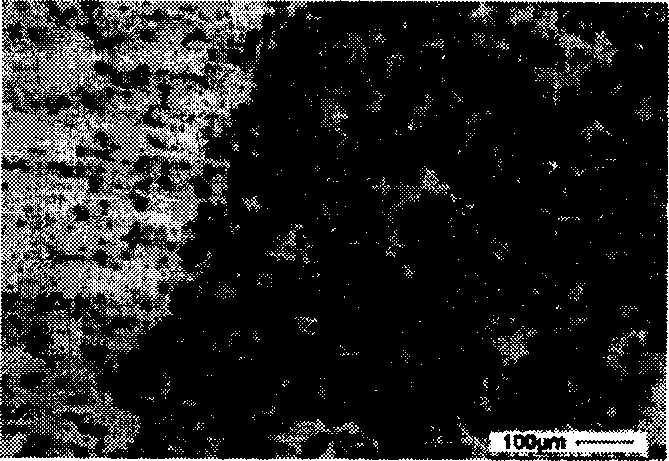

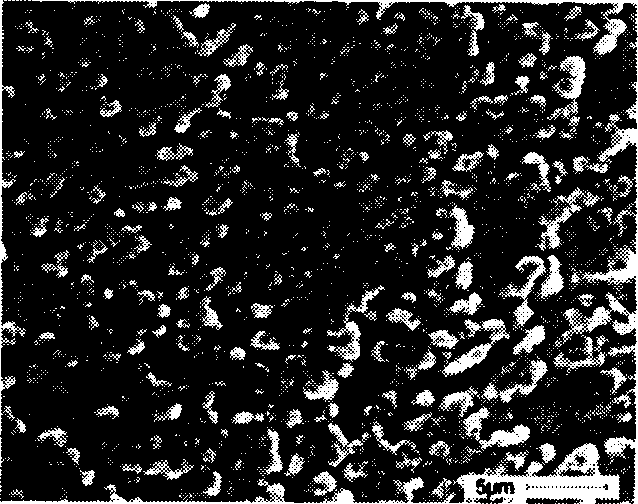

[0029] Depend on Fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com