Patents

Literature

30results about How to "Low mold requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

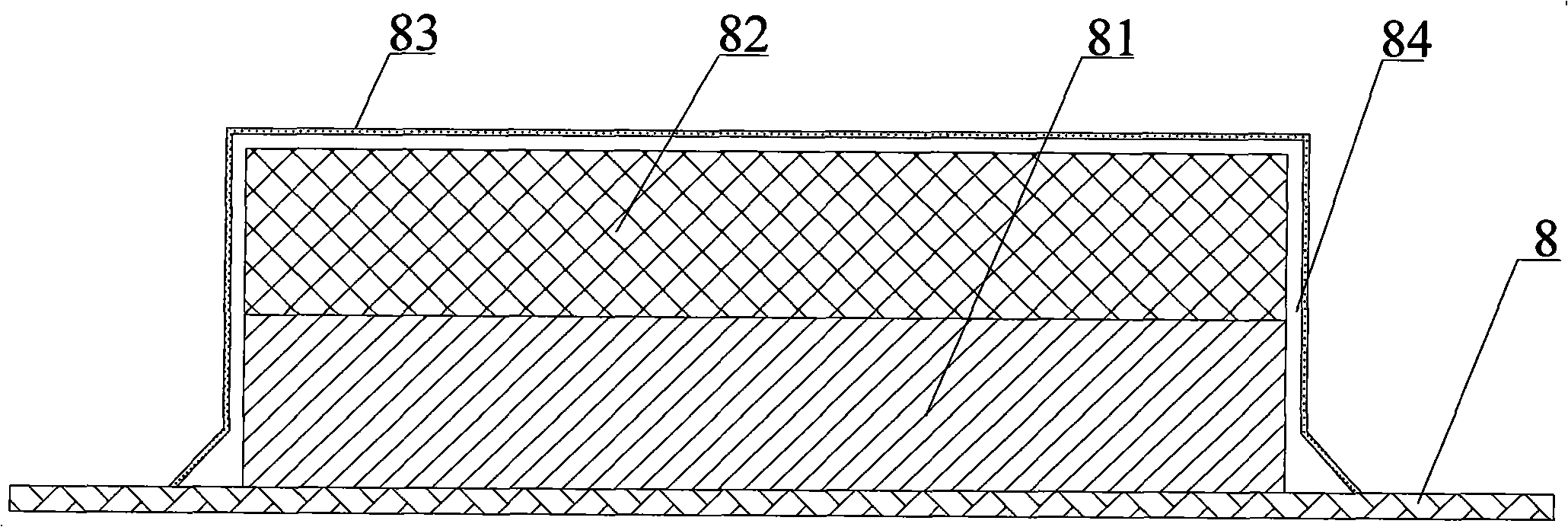

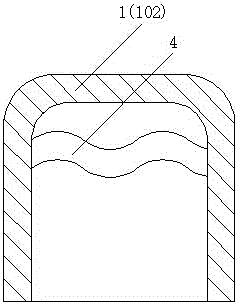

Composite material member with surface function layer and VIMP preparation method thereof

InactiveCN101830095AFast impregnationGood surface qualitySynthetic resin layered productsSurface functionMaterial system

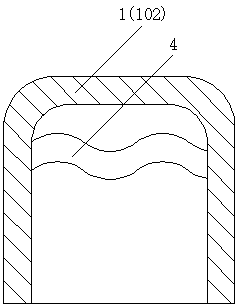

The invention belongs to the technical field of a multilayer structural composite material member and a preparation method thereof and specifically discloses the composite material member with a surface function layer and a VIMP preparation method thereof. The composite material member comprises an outer surface layer and a main body layer, wherein, the outer surface layer and the main body layer are respectively a first composite material system and a second composite material system; and the first composite material system takes epoxy resin, phenolic resin and the like as a matrix, the second composite material system takes unsaturated polyester resin as a matrix, and the two systems take fiber cloth of carbon fiber or glass fiber as reinforcement. The VIMP preparation method comprises the following steps: firstly preparing a reinforced resin film on a die surface for vacuum dip molding by a resin film infiltration process, and then preparing the composite material member with a molding die covered with the reinforced resin film through the vacuum dip molding process. The VIMP process of the invention combines the double advantages of an RFI process and the VIMP process; and the obtained composite material member has better surface quality, better integrity and excellent comprehensive performances.

Owner:NAT UNIV OF DEFENSE TECH

Valve body forging method

ActiveCN104439032ADense microstructureBeautiful appearanceValve arrangementsPressure grooveMaterials science

The invention relates to the field of valve body manufacturing, in particular to a valve body forging method. The valve body forging method saves materials and energy and reduces consumption on the condition of meeting the requirement of customers for product diversification. At first, blank forming is achieved by utilizing free forging for executing the following steps of A, selecting round steel with the weight being 1.15-1.25 times the weight of a finished valve body, riveting the two ends of the round steel, conducting indentation material separation, and forging the round steel into the preset size; B, enabling the two ends of the round steel to get off a table, forging eccentricity of the middle and the two ends, and forging the two ends into 260-degree octagons; C, then utilizing pressing blocks for making octagonal pressure grooves in the two ends into the preset size, and ensuring that flanges and grooves of a green body are within the design size range. Then, final forming is achieved by adopting semi-die forging for executing the following steps of a, forging the middle octagon of the green body in a vertical die buckling and pressing mode; b, after the middle octagon is formed, controlling the height of the flanges at the two ends through cushion blocks and forging the flanges to be rounded; c, finally, trimming the sizes of all parts of the forged piece into the designed sizes.

Owner:CHENGDU SHUANGLIU HENGSHENG FORGING

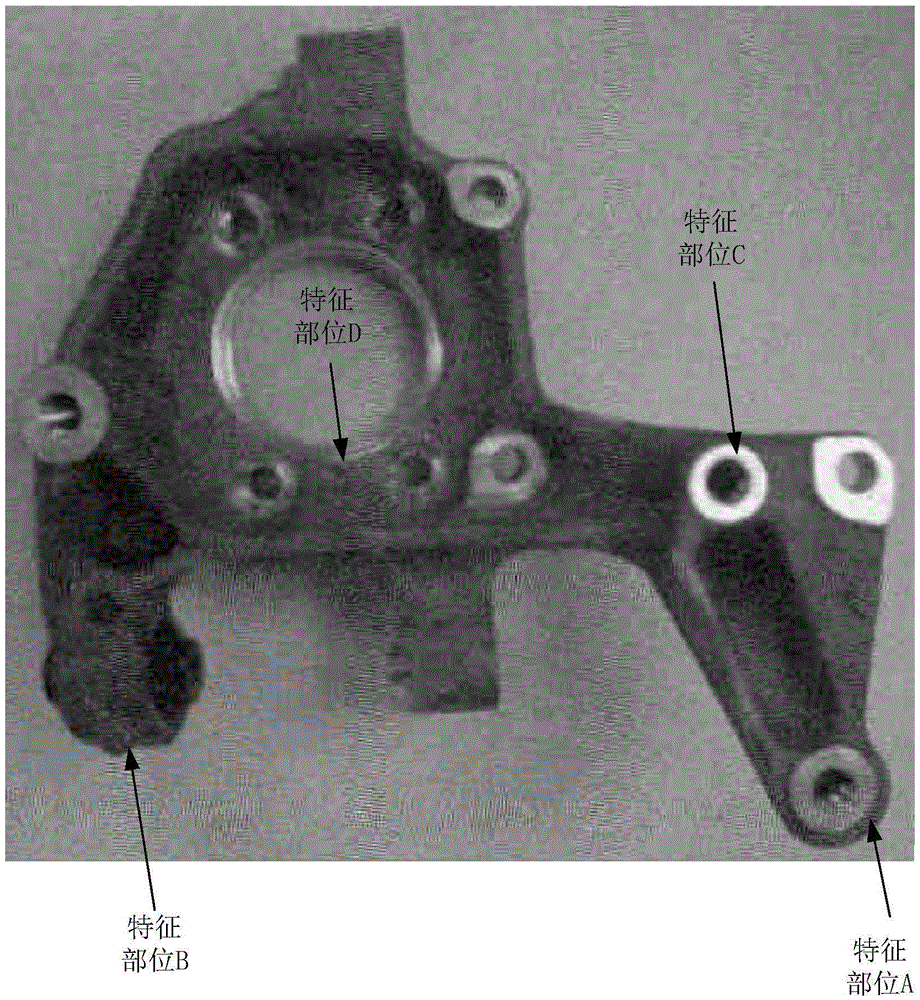

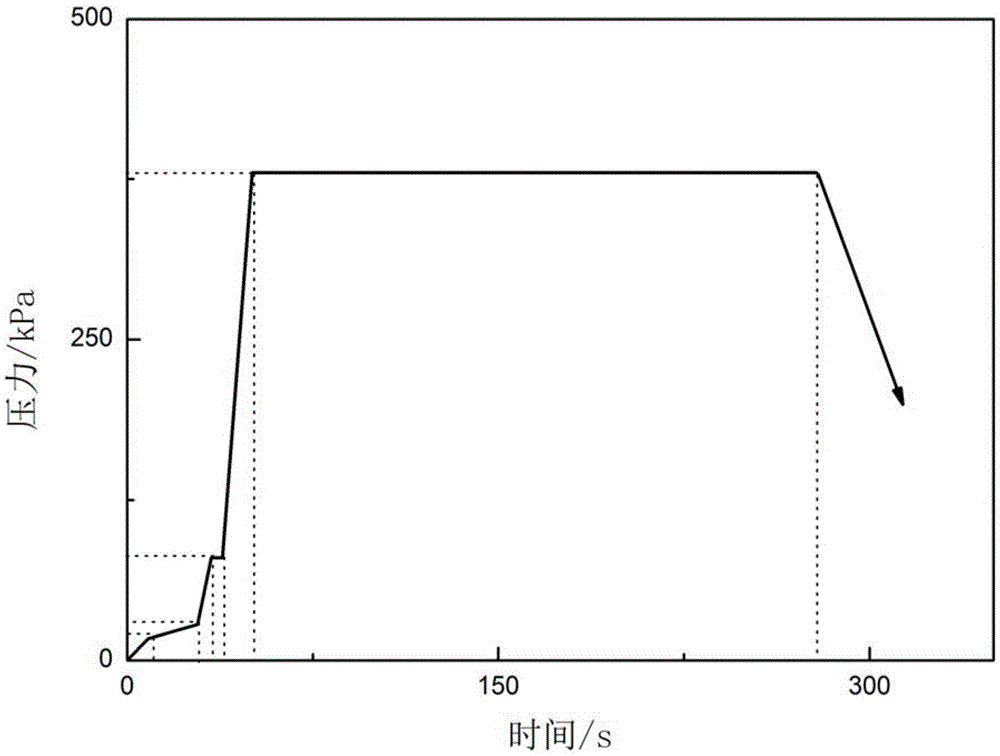

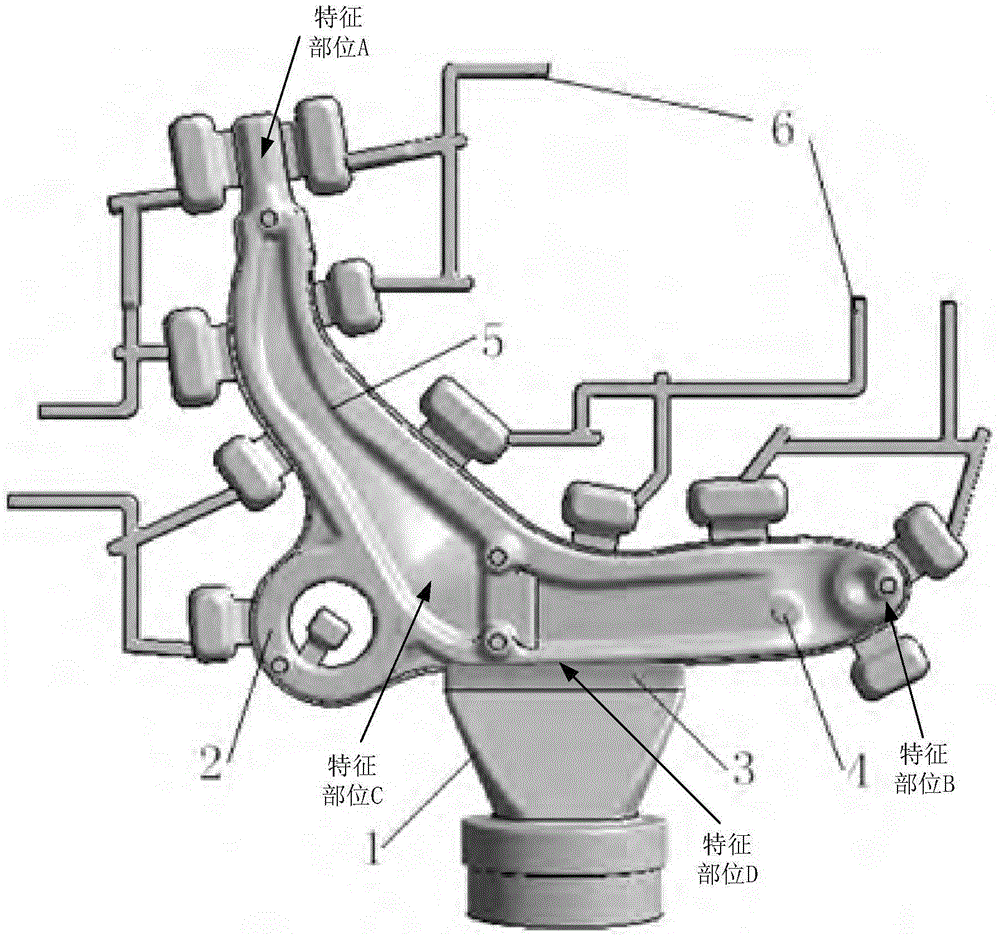

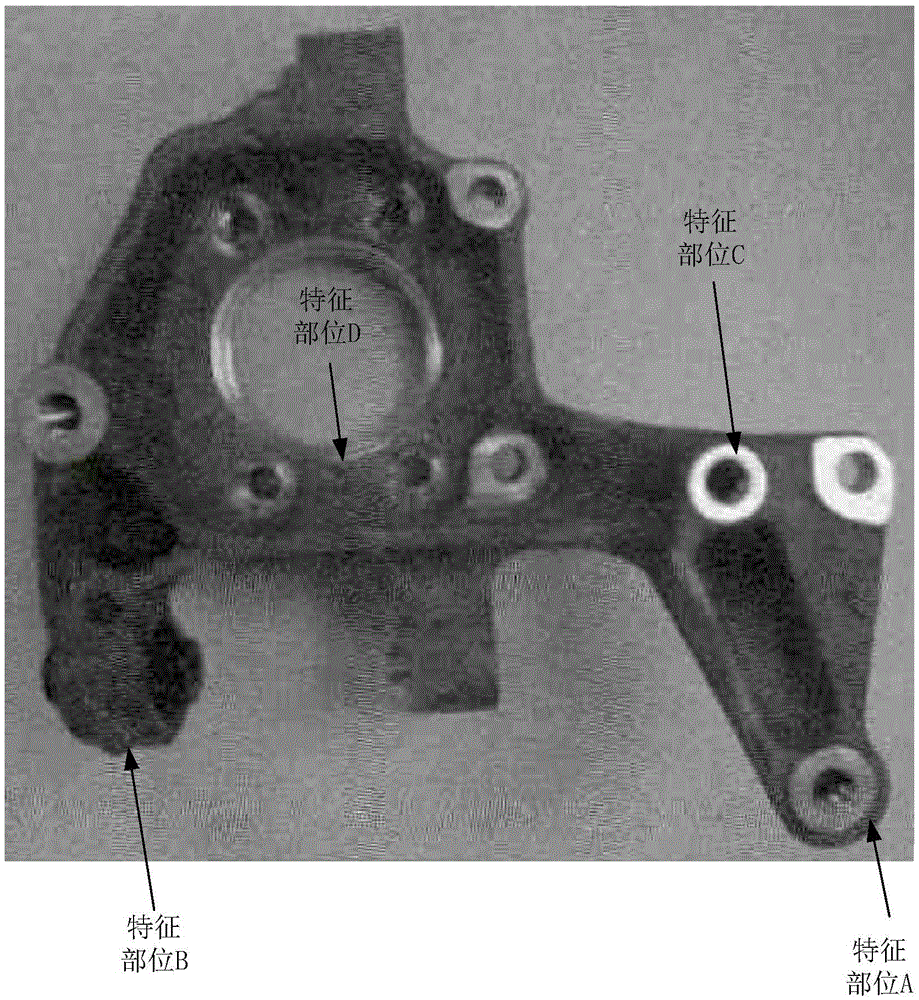

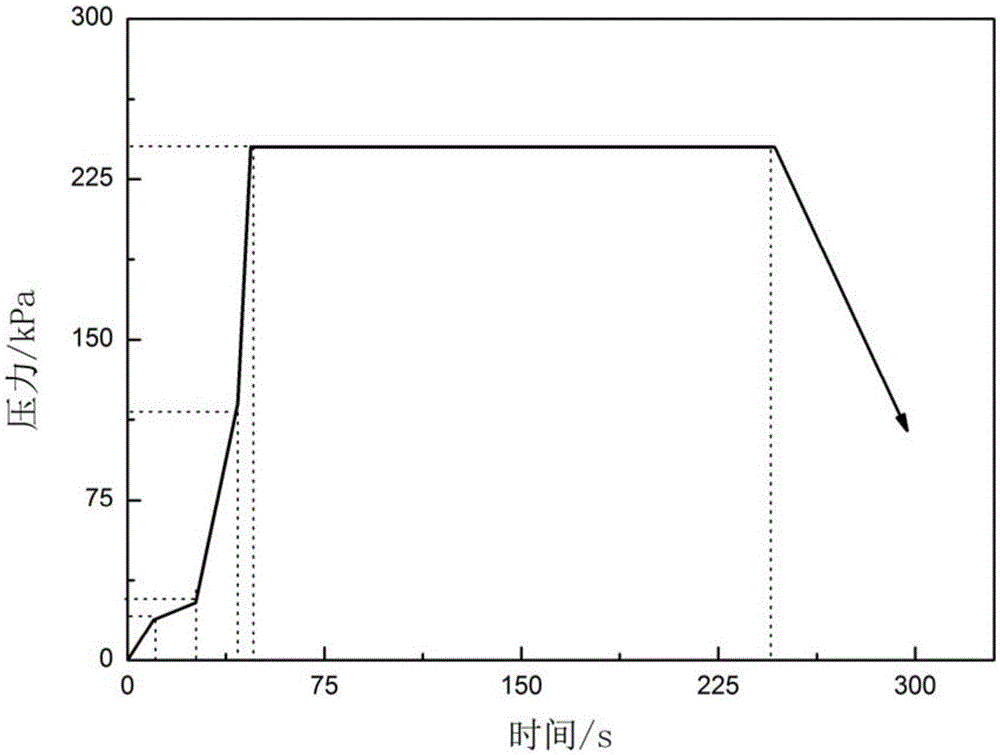

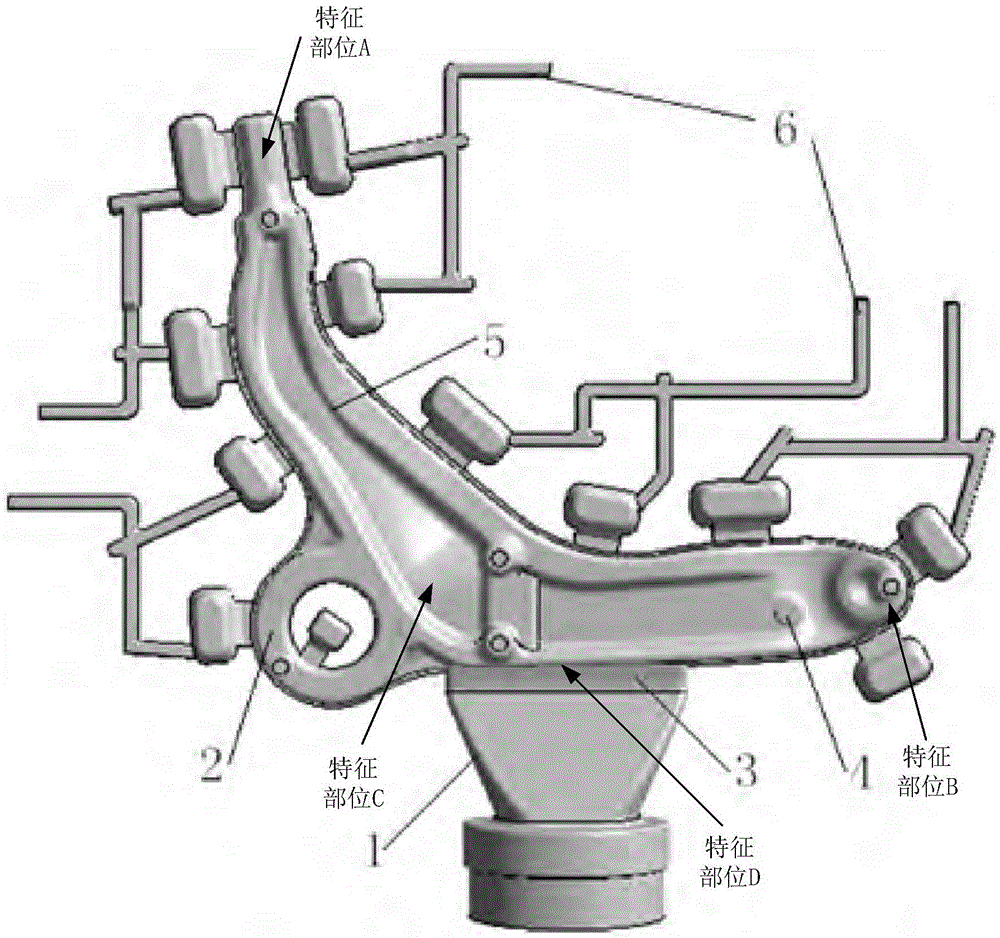

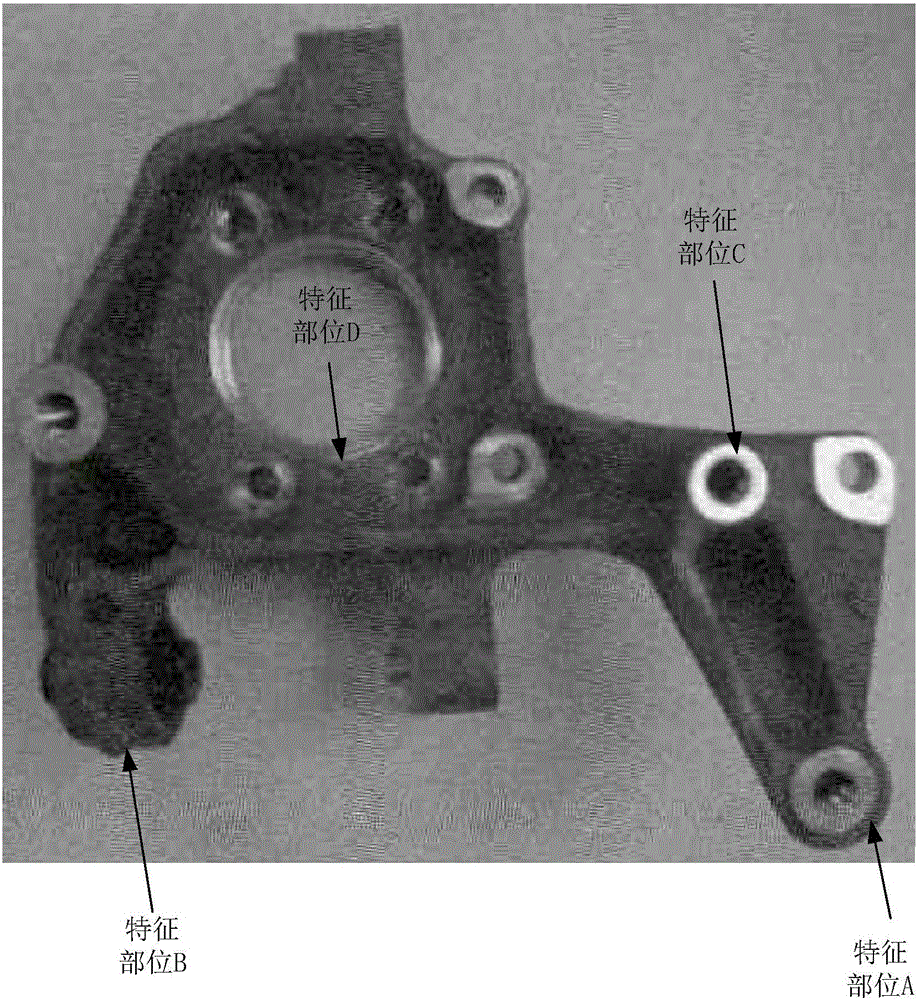

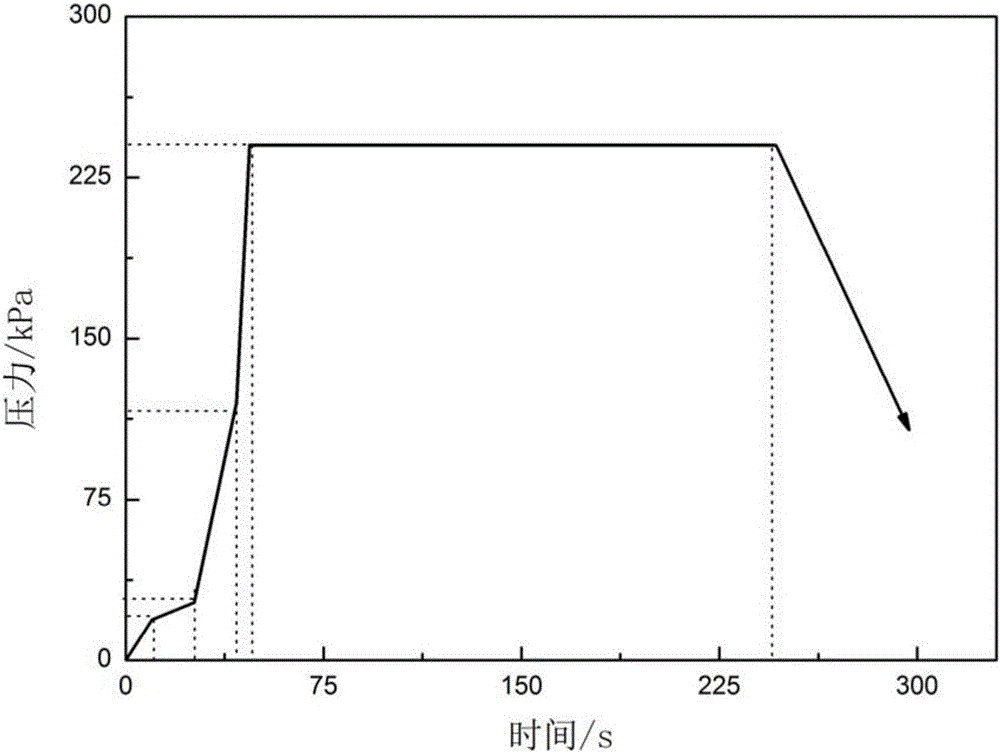

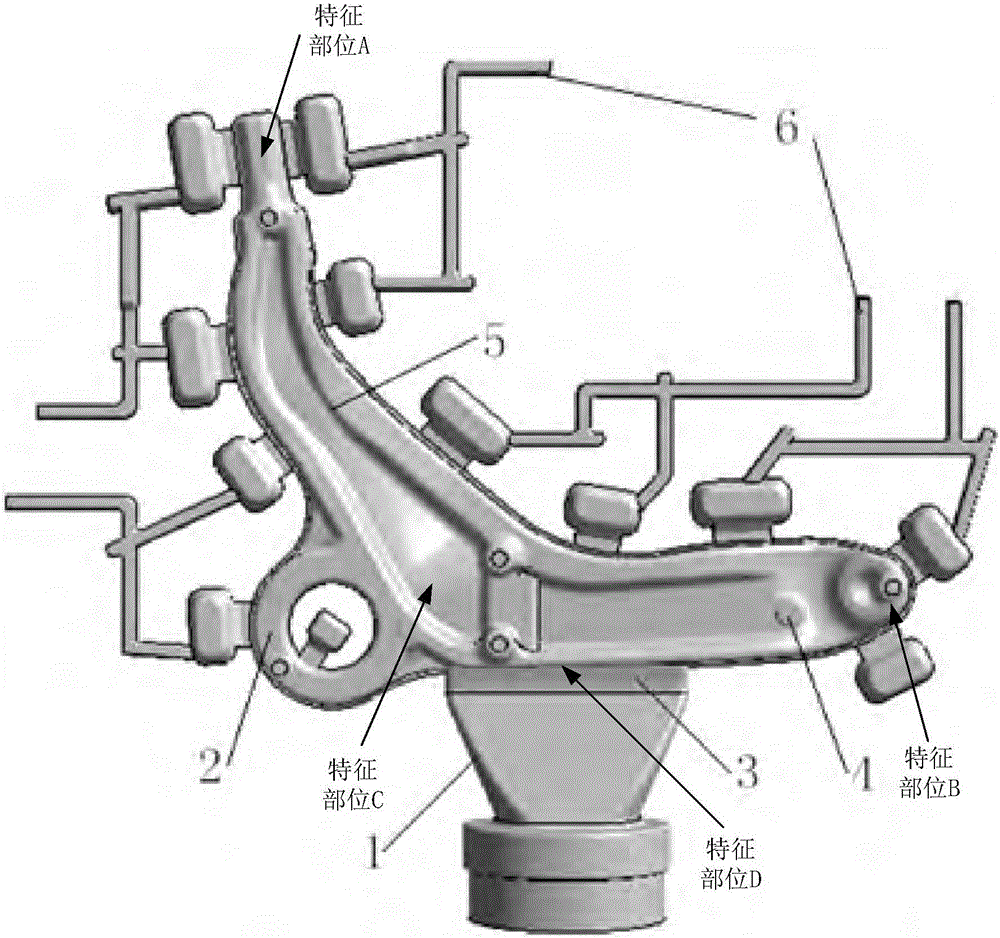

Method for maintaining pressures and then quickly boosting pressures for metal low-pressure casting molding of aluminum alloy automobile chassis castings

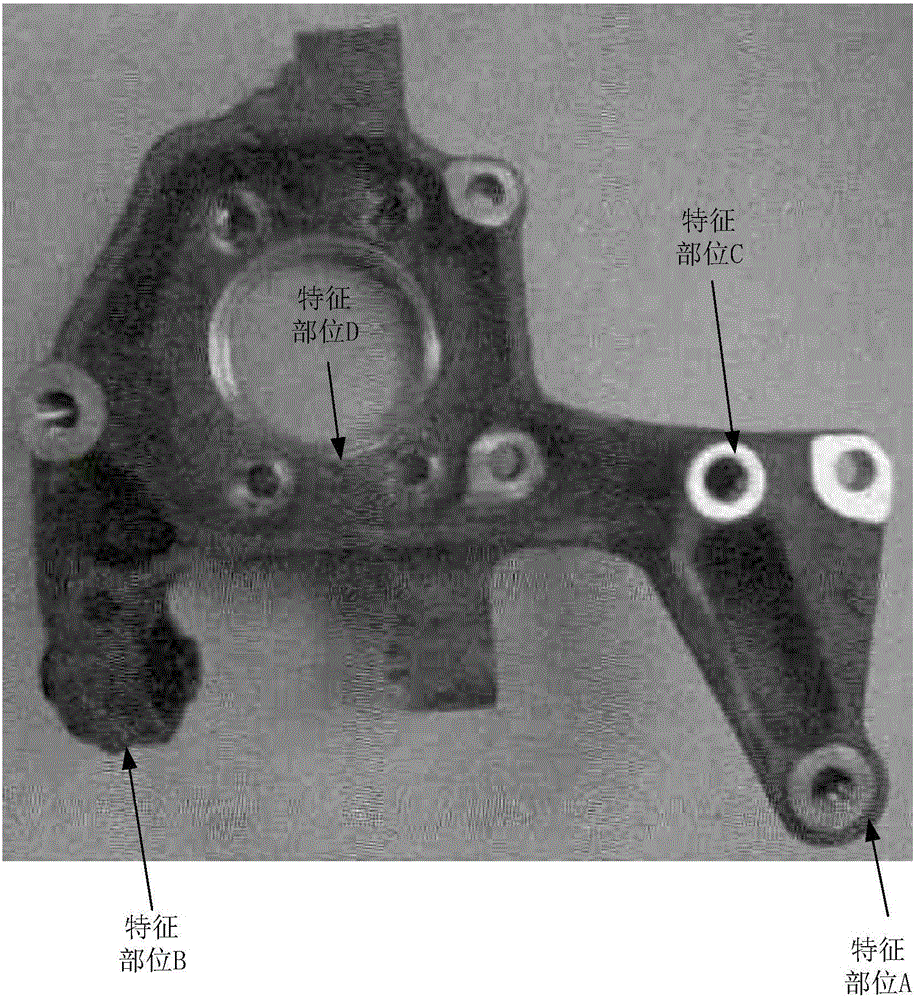

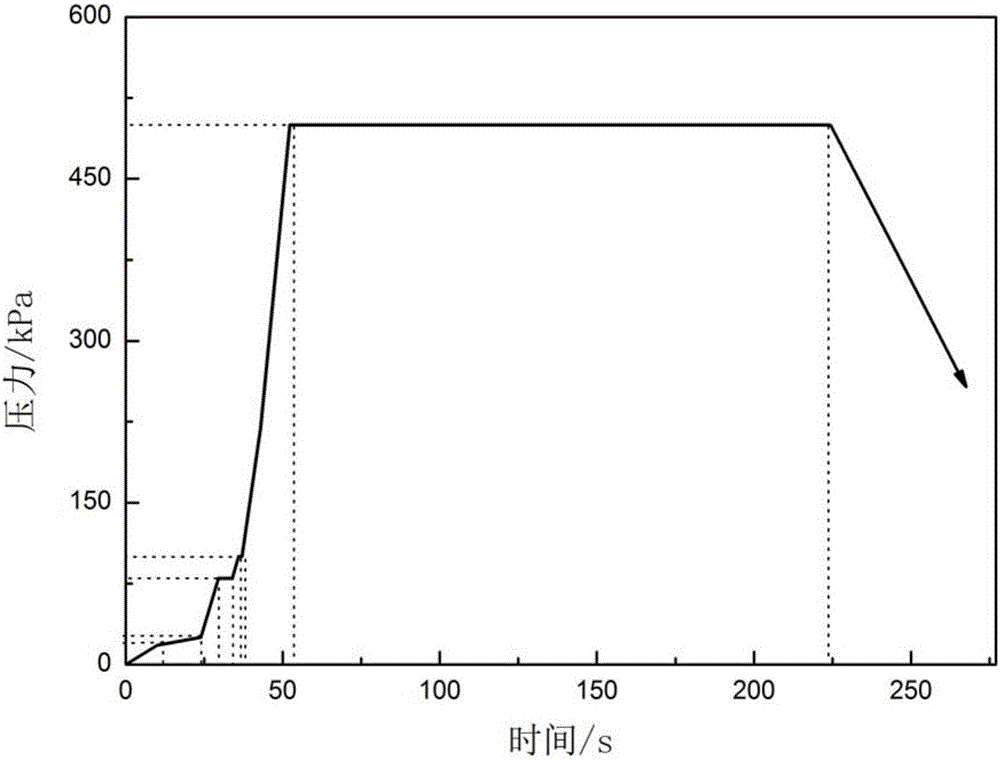

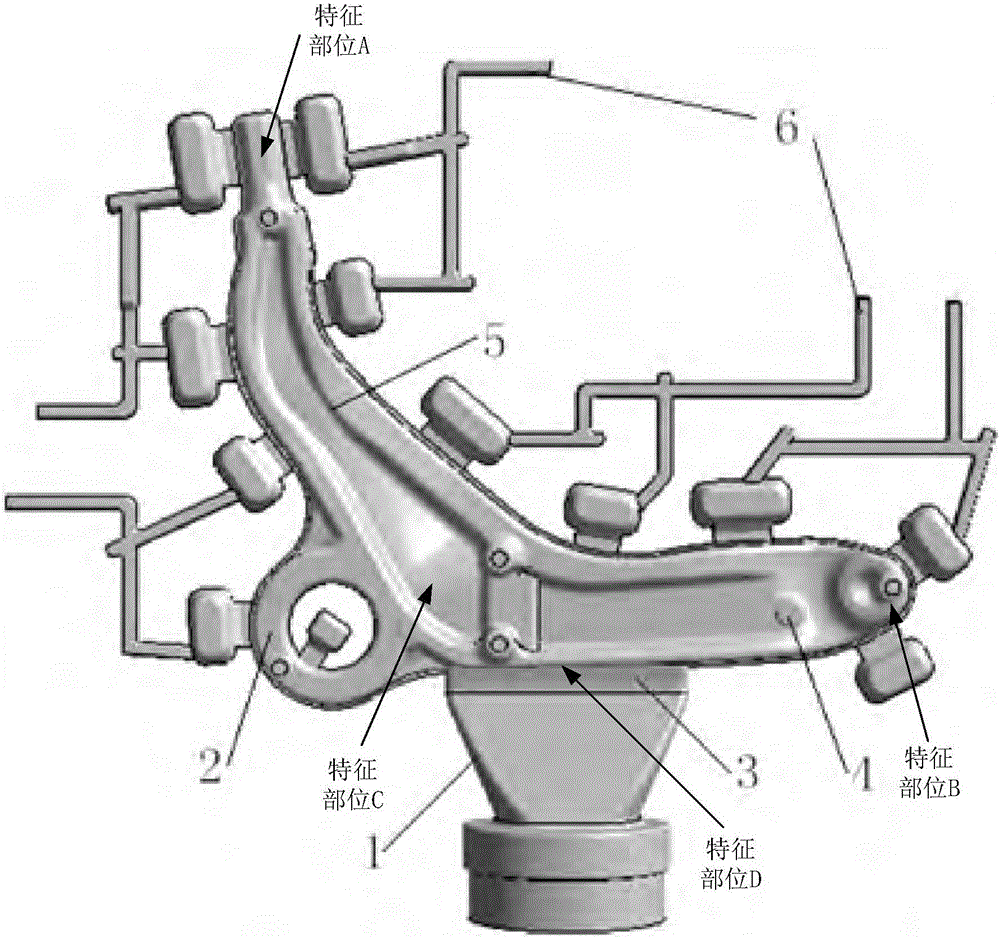

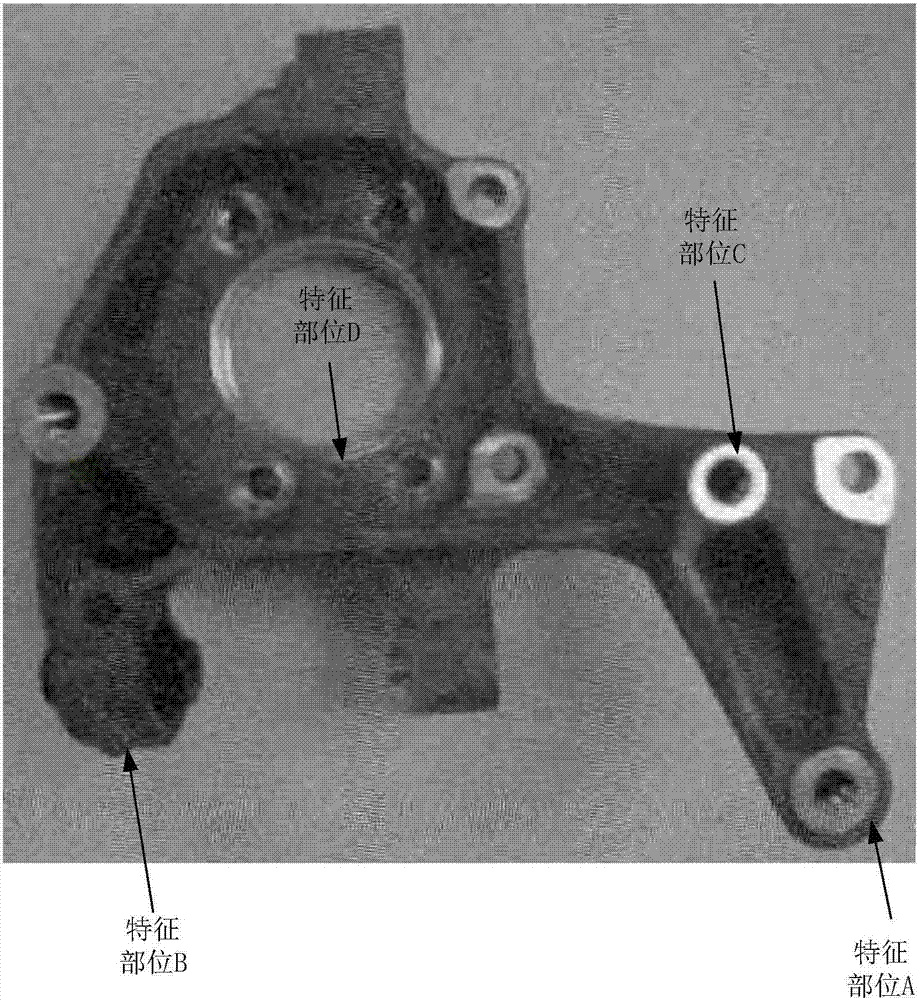

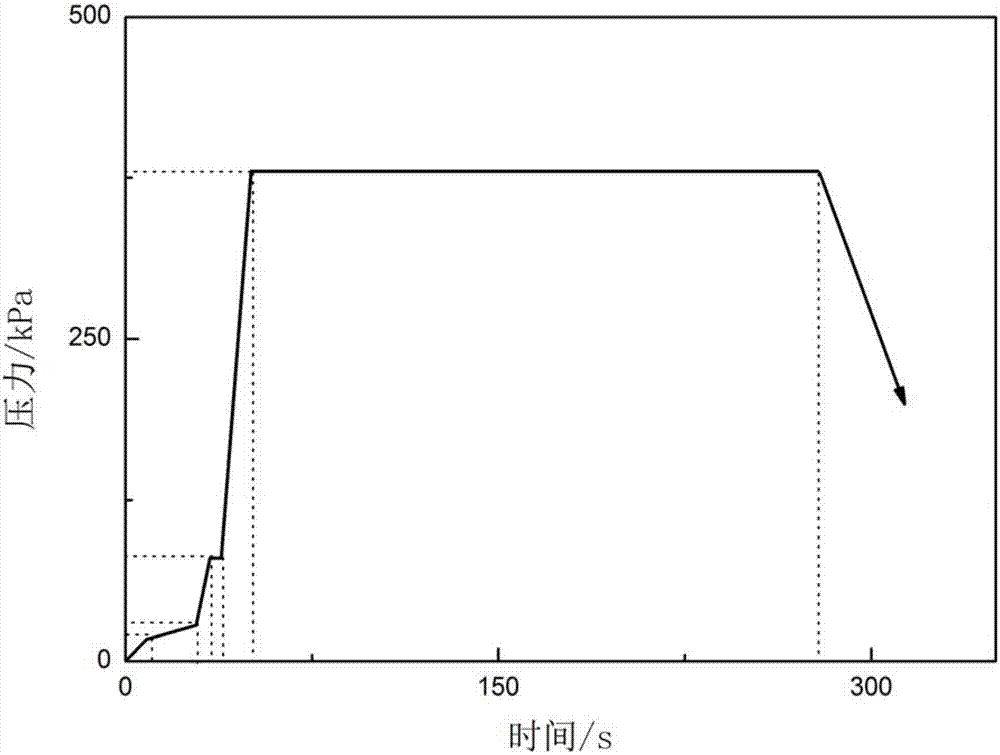

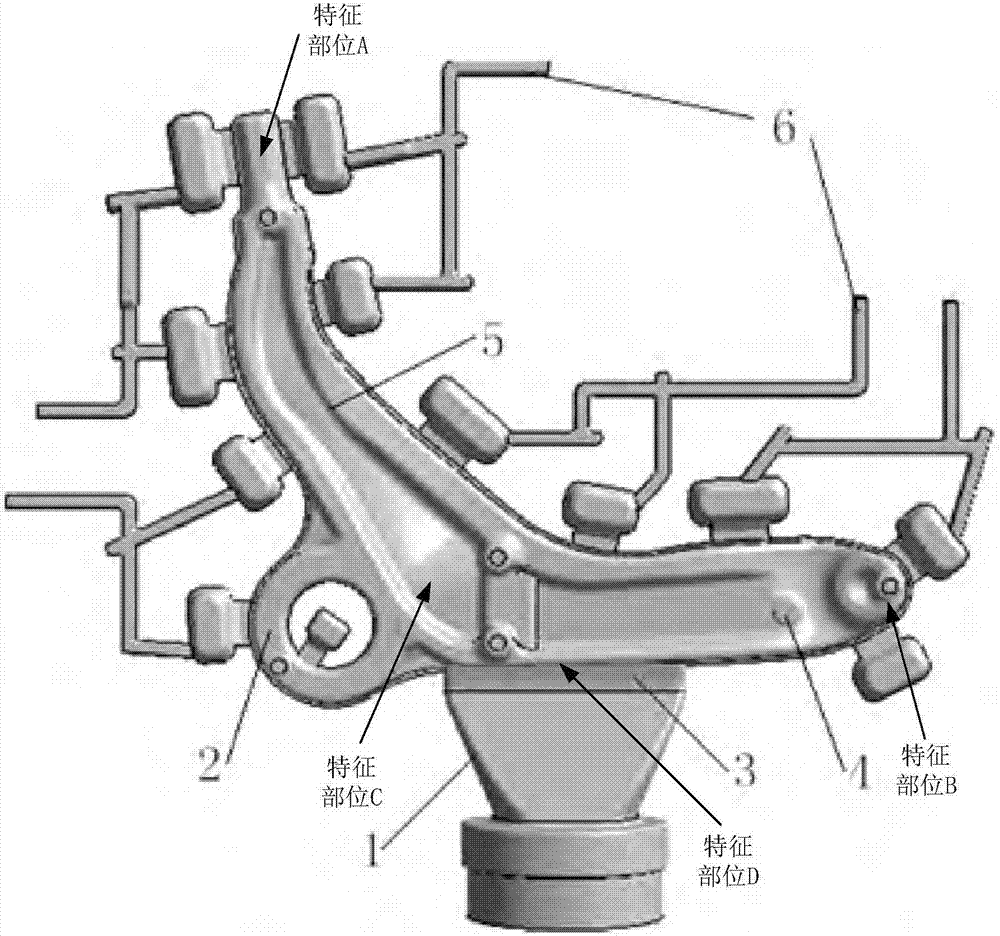

The invention discloses a method for maintaining pressures and then quickly boosting the pressures for metal low-pressure casting molding of aluminum alloy automobile chassis castings. The method includes that existing processes for low-pressure casting of aluminum alloy automobile chassis castings continue to be carried out at liquid lifting, mold filling and crystallization pressure boosting stages, and liquid lifting pressures, mold filling pressures and crystallization boosted pressures are 15-21 kPa, 25-35 kPa and 80-100 kPa under the control respectively; stages for maintaining the pressures and then quickly boosting the pressures are added between crystallization pressure maintaining stages and pressure releasing stages; a plurality of characteristic positions are set according to structure characteristics and solidification sequences of the castings; crystallization maintained pressures start to be increased and reach 150-1000 kPa after the fact that the characteristic positions A start to be solidified is determined, and the pressure boosting speeds are 10-40 kPa / s; then the castings enter pressure maintaining stages, the characteristic positions B, the characteristic positions C and the characteristic positions D are sequentially solidified, and the pressures continue to be maintained for 10-60 s after the characteristic positions D are completely solidified. The method has the advantages that solidification shrinkage supplementing effects and mechanical properties of the castings can be obviously improved, shortcomings of flashing of molten liquid, burr and flash of existing castings and the like can be overcome, and requirements on mold structures and casting mold clamping force can be obviously lowered.

Owner:北京航大新材科技有限公司

Crystallization pressurization method for metal mold low-pressure casting molding of aluminum alloy vehicle chassis casting

The invention discloses a crystallization pressurization method for metal mold low-pressure casting molding of an aluminum alloy vehicle chassis casting. The method continues a traditional low-pressure casting process of the aluminum alloy vehicle chassis casting in the phases of liquid rise, mold filling and crystallization pressurization; and the liquid rise pressure and the mold filling pressure are controlled within 18-21 kPa and 30-35 kPa. The crystallization pressurization is divided into two stages according to the condensation ending time of a characteristic part A: in the first stage: in the stage from the end of the mold filling phase to the condensation end of the characteristic part A, the crystallization pressurization pressure is increased to 80-150 kPa; and in the second stage: after the condensation of the characteristic part A is finished, the crystallization pressurization pressure is quickly increased to 160-1000 kPa, and the pressurization speed is 10-40 kPa / s. Then, the pressure keeping stage and the pressure relief are performed. The method prominently improves the condensation feeding effect and the casting mechanical performance, prevents such defects as molten aluminum splashing and casting flanges and burrs, and prominently reduces the requirements on the mold structure and the casting mold clamping force.

Owner:北京航大新材科技有限公司

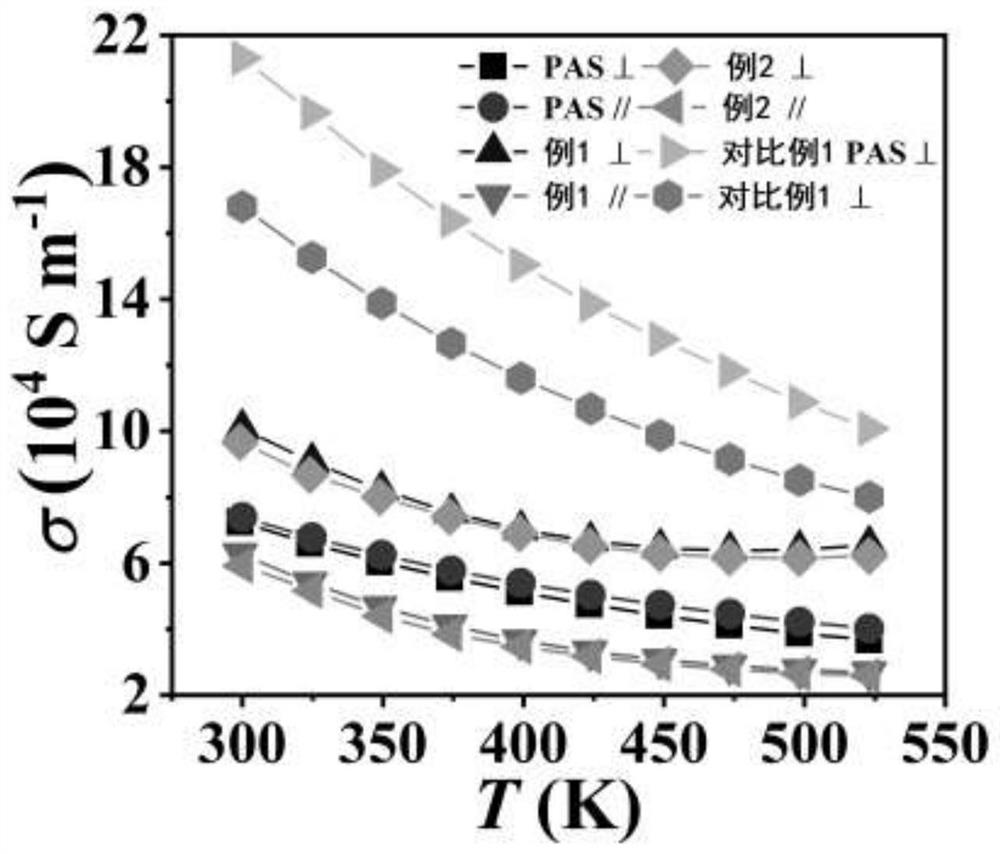

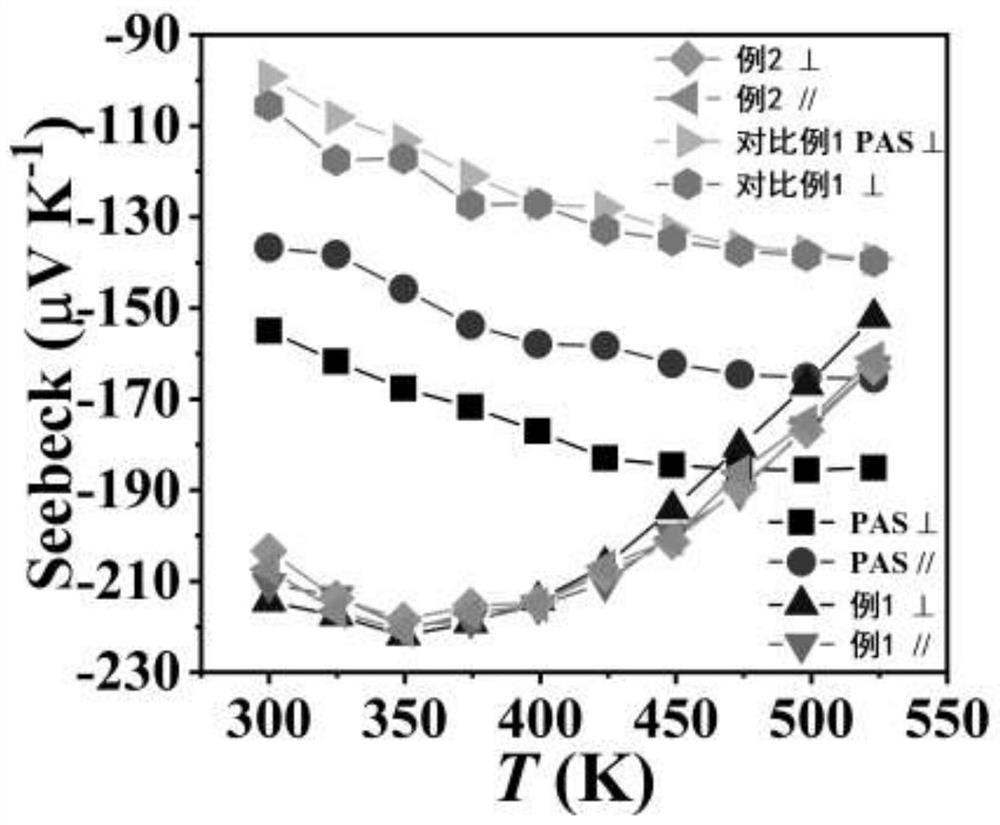

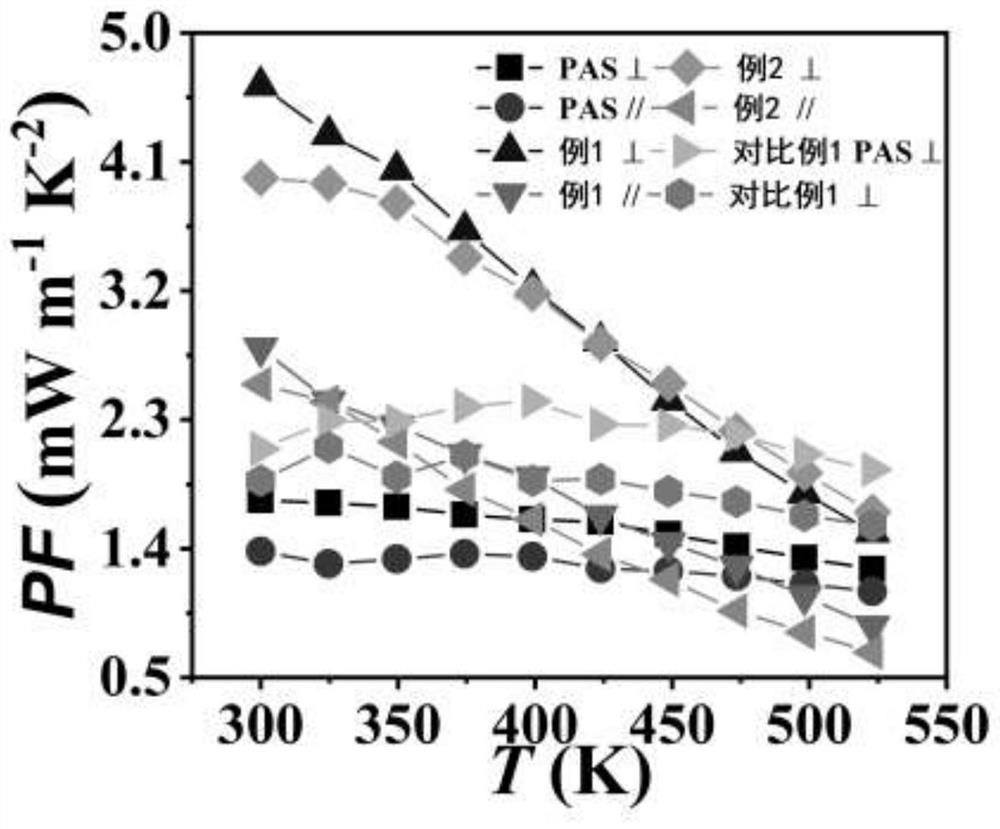

Preparation method of n-type bismuth telluride-based thermoelectric material

ActiveCN112201743AImprove machinabilityHigh electrical transport performance retentionThermoelectric device manufacture/treatmentThermoelectric device junction materialsBismuth tellurideBismuth

The invention discloses a preparation method of an n-type bismuth telluride-based thermoelectric material. The preparation method comprises the following steps: weighing bismuth powder, tellurium powder and selenium powder serving as raw materials according to the stoichiometric requirements of Bi2Te3-xSex, wherein x is more than or equal to 0.1 and less than or equal to 0.7; and then carrying outself-propagating reaction, reduction annealing, plasma activated sintering and hot forging treatment to obtain the compact n-type bismuth telluride-based thermoelectric material. The Bi2Te3-xSex powder is rapidly obtained by adopting a self-propagating combustion synthesis technology, reduction annealing is carried out on the Bi2Te3-xSex powder, and step-by-step hot forging is carried out to obtain the polycrystalline block thermoelectric material with high orientation, so that the thermoelectric performance of the obtained product can be remarkably improved; and the related preparation method is simple and convenient to operate, and a brand-new thought can be provided for expanded production of the high-performance n-type Bi2Te3-xSex-based thermoelectric material.

Owner:WUHAN UNIV OF TECH

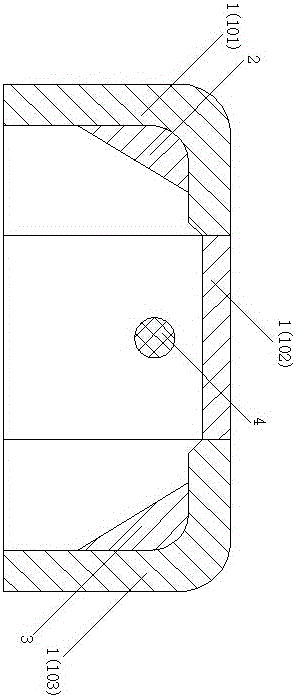

Forming method of zirconium oxide ceramic insertion needle for fibre-optic connector and its equipment

InactiveCN1477416AExcellent performance of sintered bodyWill not harmCoupling light guidesCross-linkIt equipment

The present invention relates to a zirconium oxide ceramic insertion needle forming method and its equipment. The zirconium oxide ceramic insertion needle can be used as optical fibre connector and is made up by adopting the following steps: using organic monomer, cross-linking agent and deionized water and making them into premixed material, then adding ceramic powder body, ball-grinding, addingcatalyst and initiator, injecting the above-mentioned mixed slurry material into mould cavity, forming to obtain blank body, drying and sintering so as to obtain the invented product.

Owner:TSINGHUA UNIV

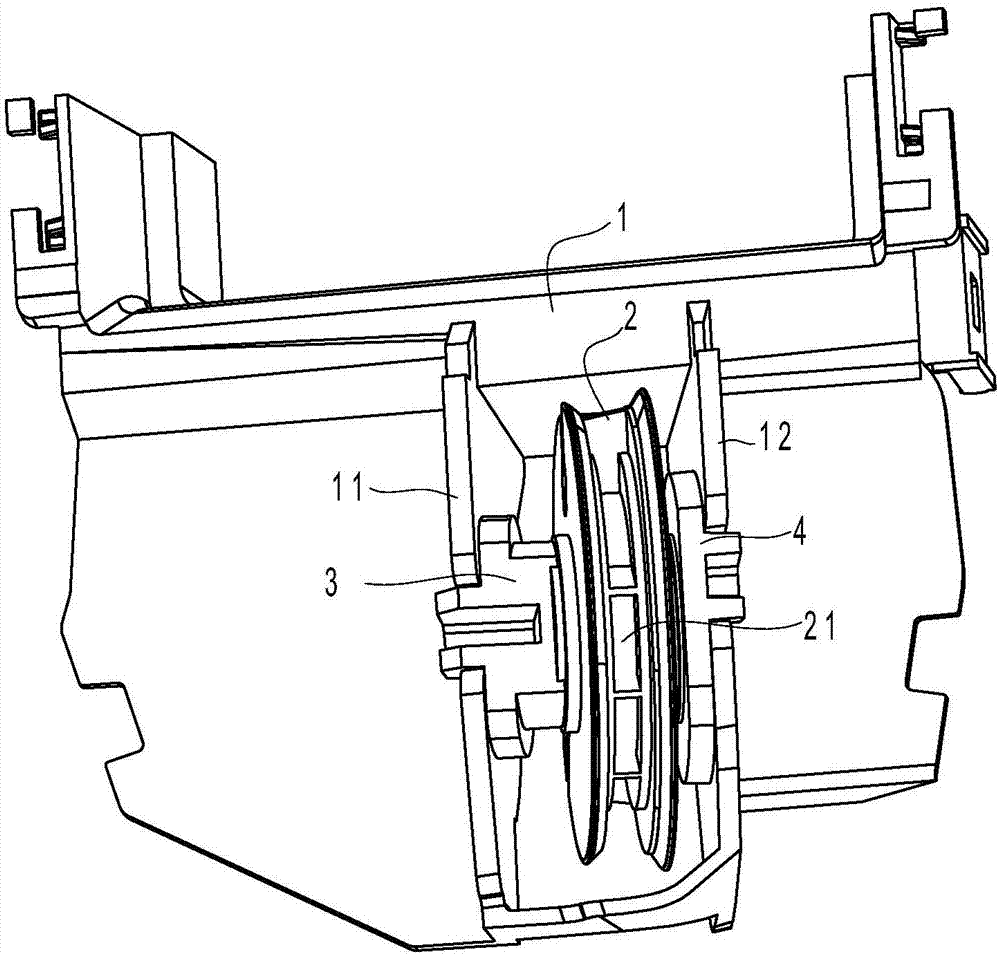

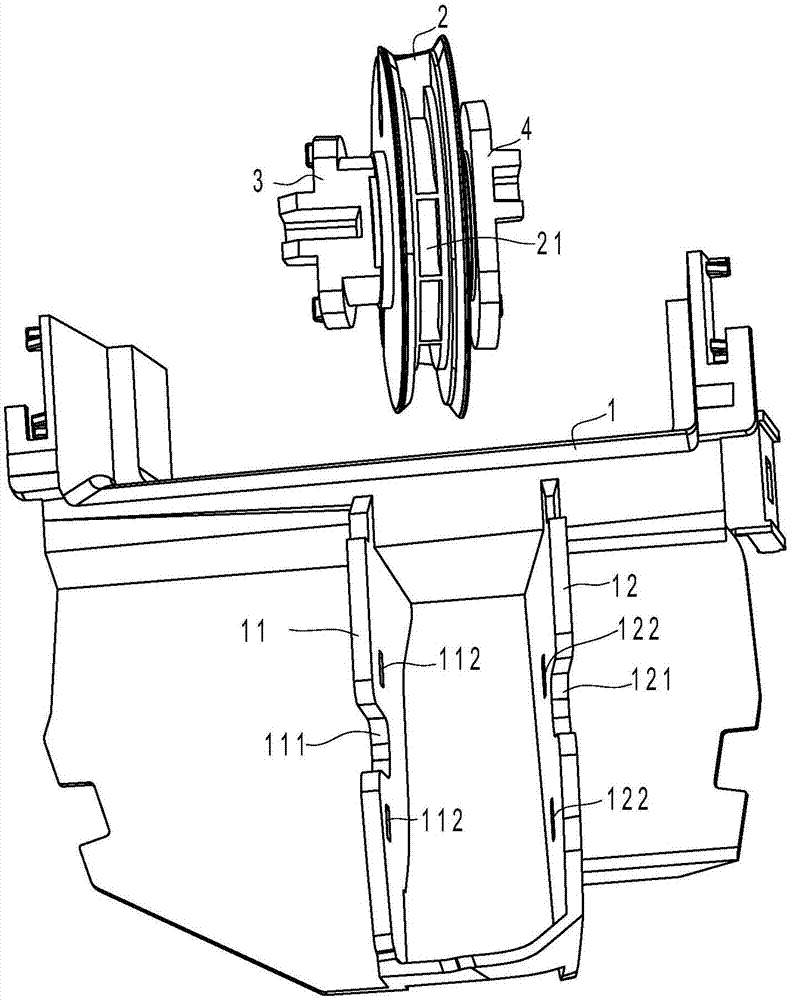

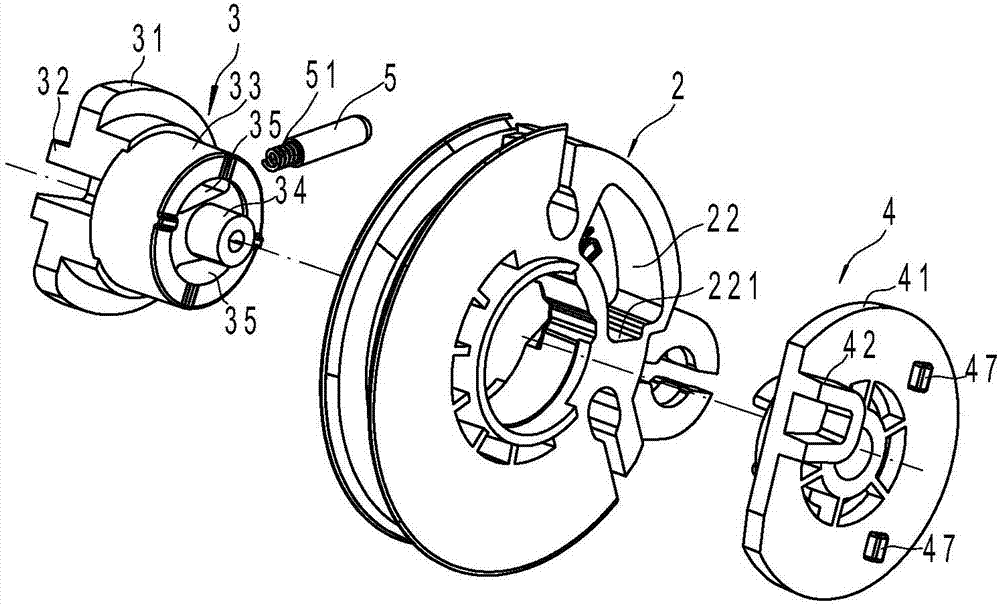

Air outlet thumbwheel structure for automobile air conditioner

ActiveCN107139688ALow mold requirementsReduce manufacturing costAir-treating devicesVehicle heating/cooling devicesEngineeringMechanical engineering

Provided is an air outlet thumbwheel structure for an automobile air conditioner. The thumbwheel structure comprises a shell and a thumbwheel which is rotatably arranged on the shell, and is characterized in that the outer side of the shell is convexly provided with a first extending piece and a second extending piece arranged at interval with the first extending piece, the first extending piece is provided with a first card slot, and the second extending piece is provided with a second card slot. The thumbwheel structure further comprises a bracket component, wherein the bracket component comprises a first bracket and a second bracket assembled in an integrated mode with the first bracket, the first bracket is connected in a clamped mode with the first card slot, the second bracket is connected in a clamped mode with the second card slot, and the thumbwheel is positioned in the gap between the first extending piece and the second extending piece. The thumbwheel is firstly arranged on the bracket component, and then the bracket component is connected in a clamped mode with the first extending and the second extending piece of the shell, so that the requirements for the shell mold are greatly reduced, thereby being favorable for the stability of the quality and the reduction of the production cost; meanwhile, the assembly is convenient and reliable, thereby being favorable for improving the production efficiency.

Owner:NINGBO FUERDA SMARTECH CO LTD

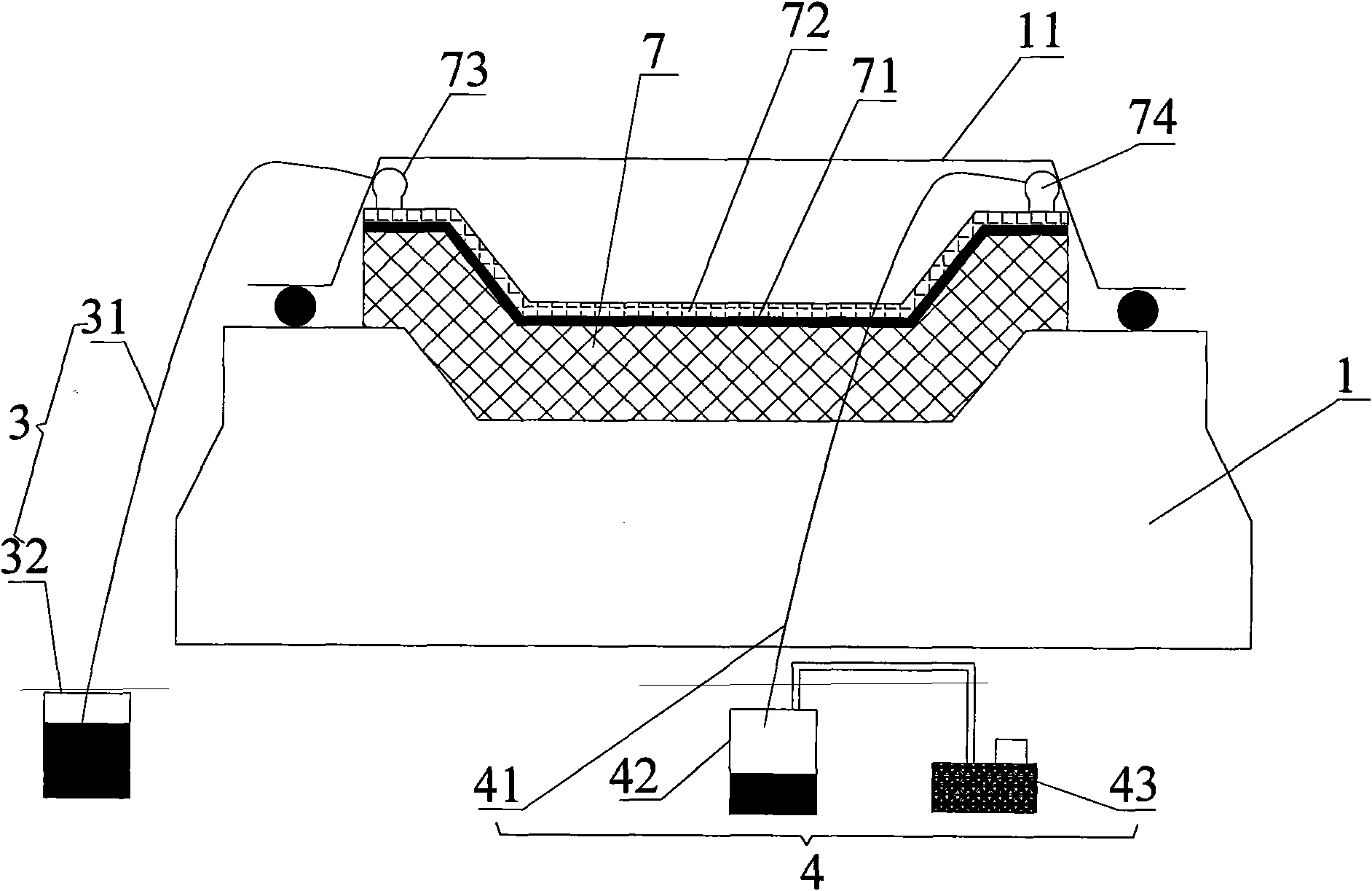

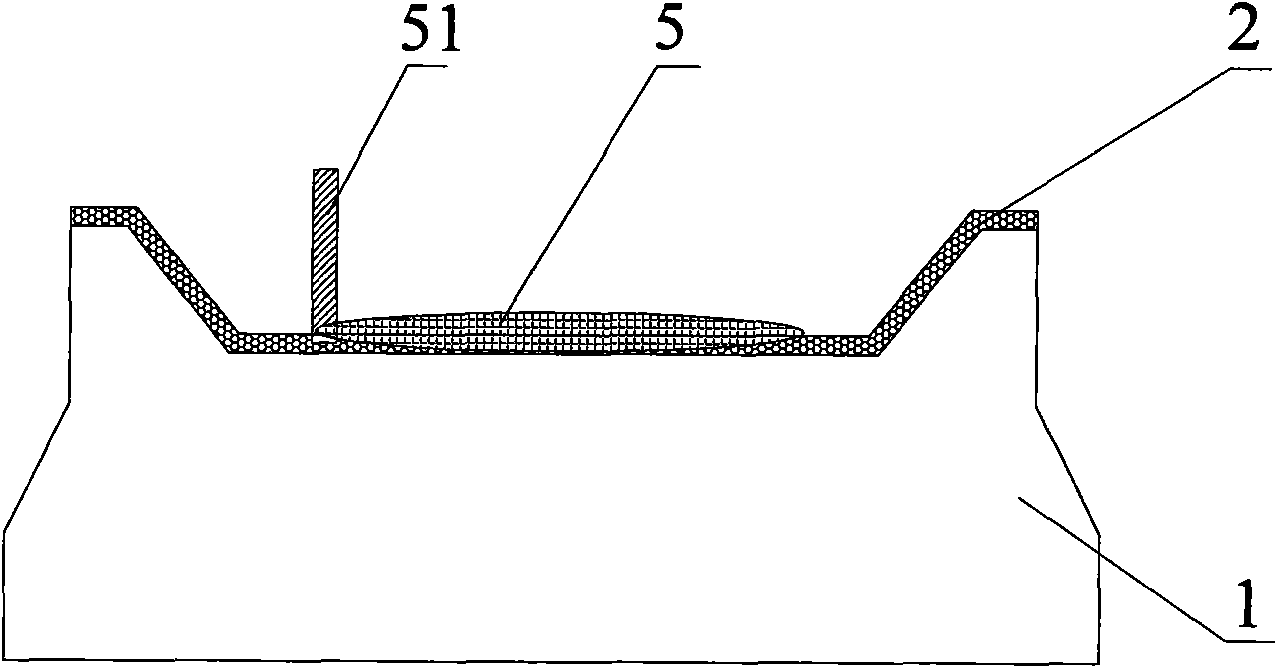

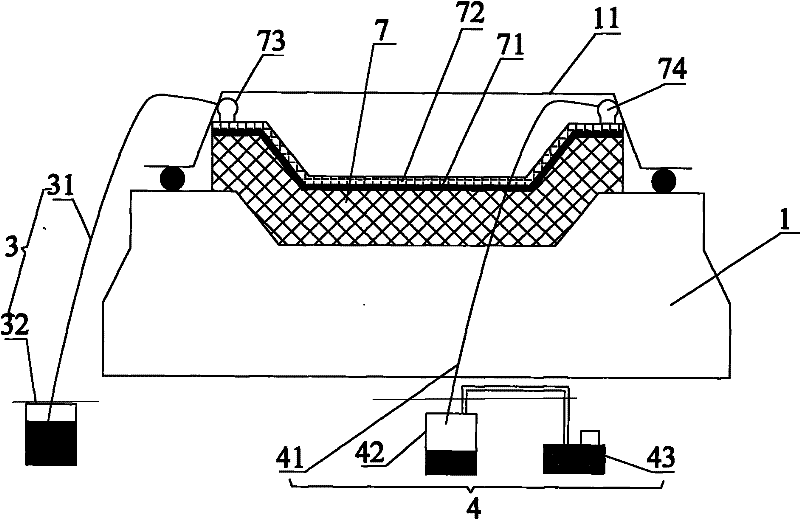

Vacuum formation preparation method for yacht

The invention discloses a vacuum formation preparation method for a yacht. The vacuum formation preparation method for the yacht includes the steps of cleaning, waxing, get coating spraying, lamination, vacuum laying-up, grinding and trimming and mold releasing. On the basis of traditional hand lay-up molding, formation of the yacht is carried out through a vacuum injection process. The vacuum formation preparation method not only has the advantages of traditional and lay-up molding that construction is easy, requirements for a mold are low, and maintenance is easy, but also reduces use of resin in the preparation process, reduces volatile components in the preparation process, is more environmentally friendly, and enables the resin to be distributed more evenly and produced products to be higher in mechanical property, better in waterproof performance and higher in quality.

Owner:福建蓝海湾游艇发展有限公司

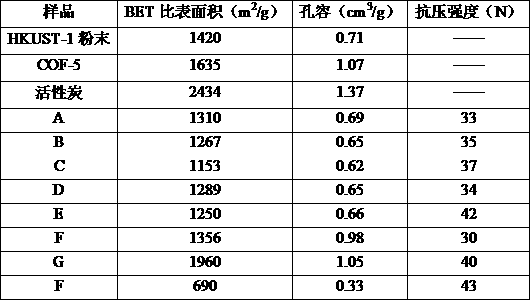

Core-shell type adsorbing material and preparation method thereof

ActiveCN111375384ALow mold requirementsPreserve the pore structureOther chemical processesAlkali metal oxides/hydroxidesSilica gelSilicon dioxide

The invention discloses a core-shell type adsorbing material and a preparation method thereof. A shell layer of the core-shell type adsorbing material is composed of silica gel, the interior of the core-shell type adsorbing material is coated with an adsorbing material and a binding agent, and the weight ratio of the adsorbing material to the binding agent to the silica gel based on silicon dioxide is 1: (0.05-0.2): (0.5-2). The core-shell type adsorbing material provided by the invention reserves the high specific surface area and high pore volume of an internal adsorbing material, has relatively high gas adsorption capacity and relatively high mechanical strength, is not easy to pulverize, and greatly prolongs the service life.

Owner:CHINA PETROLEUM & CHEM CORP +1

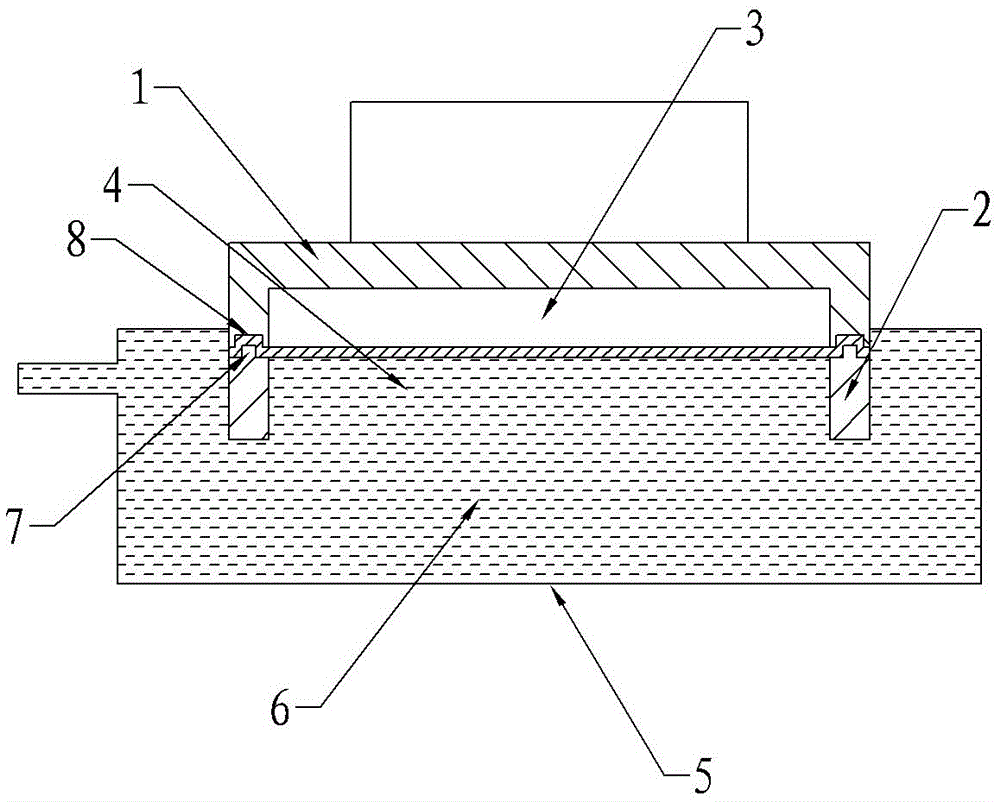

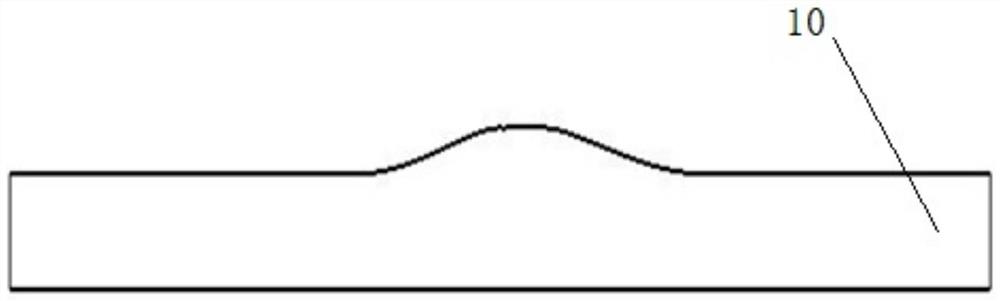

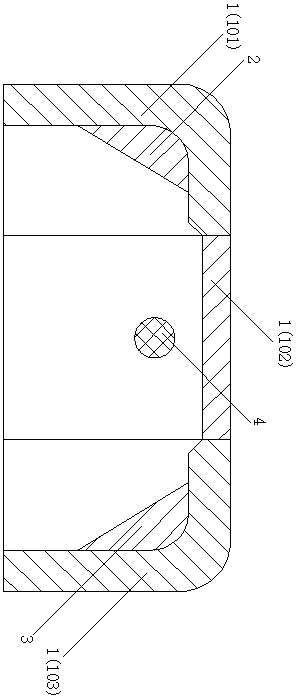

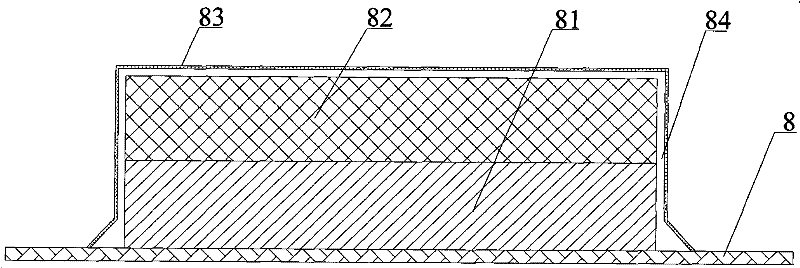

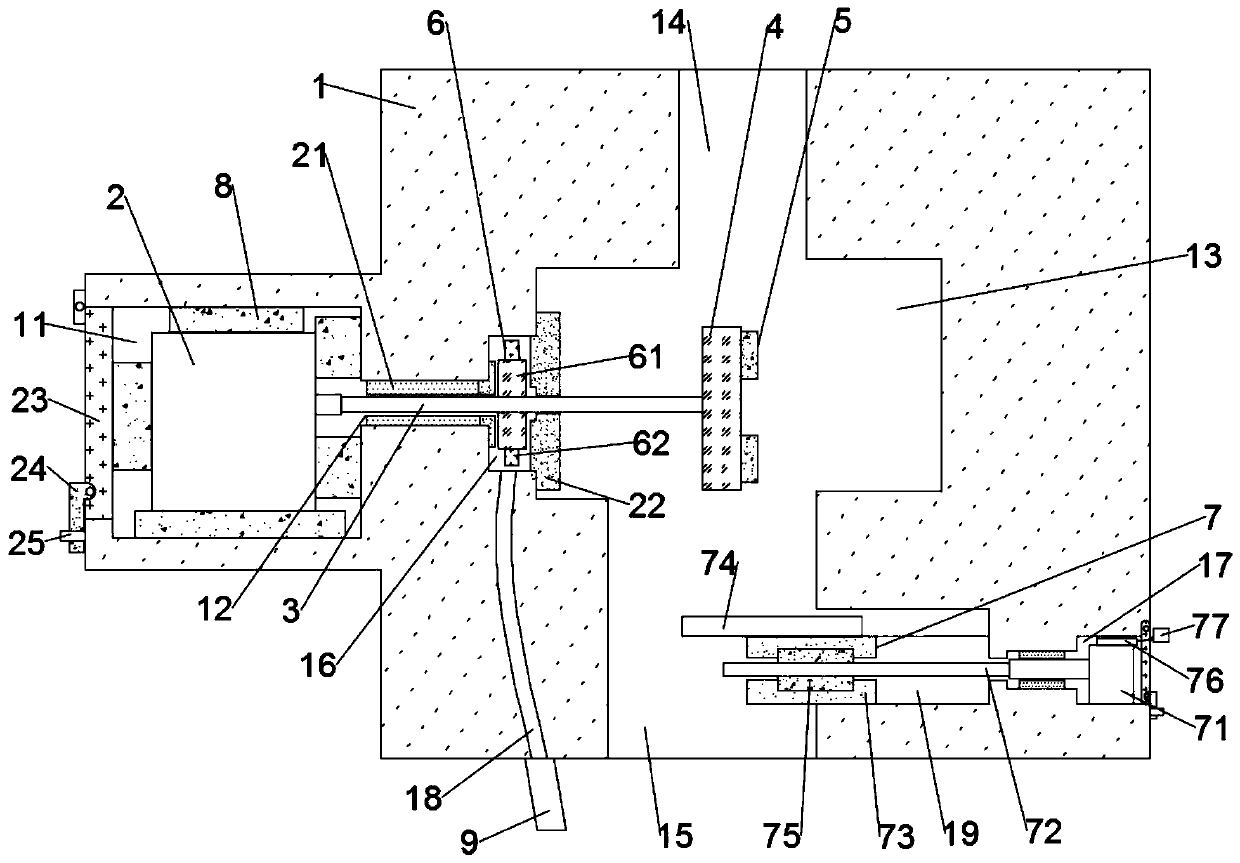

Novel liquid-expansion molding device and liquid-expansion molding process

The invention discloses a novel liquid-expansion molding device and a liquid-expansion molding process. The novel liquid-expansion molding device comprises an autofrettage pressure mould and a floating pressure mould. The autofrettage pressure mould is provided with a molding cavity; a through hole matched with the molding cavity is formed in the middle of the floating pressure mould which is mounted in a liquid-expansion pressure cavity; the edges of a plate to be molded are pressed by the adjoining plane of the floating pressure mould and the autofrettage pressure mould which is connected with a press machine; the liquid-expansion pressure cavity is connected with high-pressure liquid; in the molding process, the press machine is used for pressing and sealing the edges of the plate to be molded, and the high-pressure liquid is input into the liquid-expansion pressure cavity and acts on the plate to be molded, so that the plate to be molded deforms toward the molding cavity of the autofrettage pressure mould and is molded. The structures of the liquid-expansion molding moulds can achieve liquid-expansion molding of the plate, and the structure of the novel liquid-expansion molding device can also be conveniently used for liquid-expansion molding of the plate. The process is simple, requirements for the moulds are low, and the precision of molding can also be improved. Further, the structure can reduce the work load of the press machine, the work pressure of the press machine is reduced at the same time, and use requirements are lowered.

Owner:HONY MACHINERY CO LTD

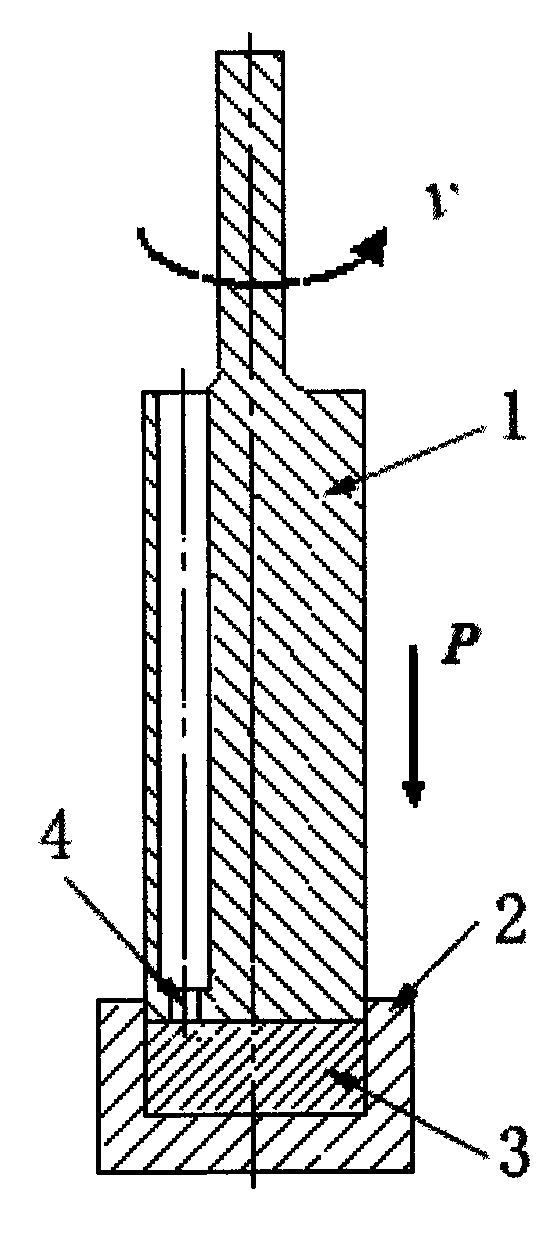

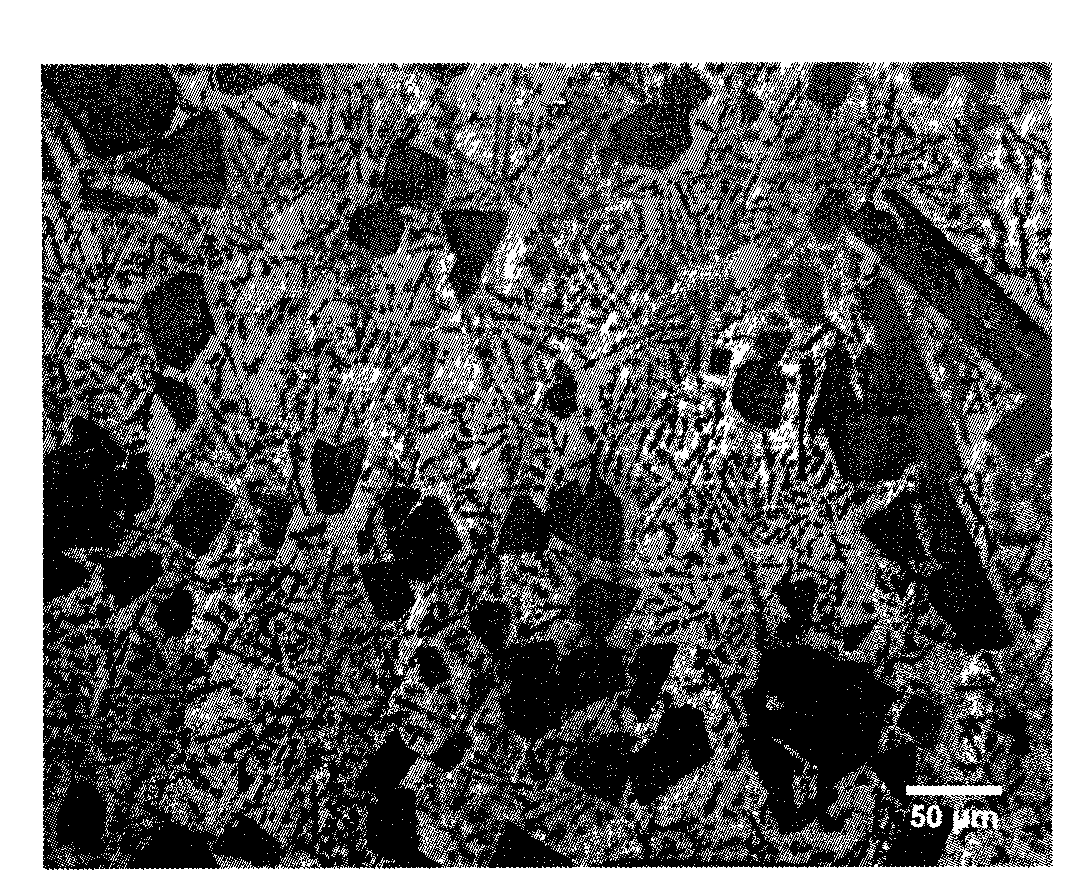

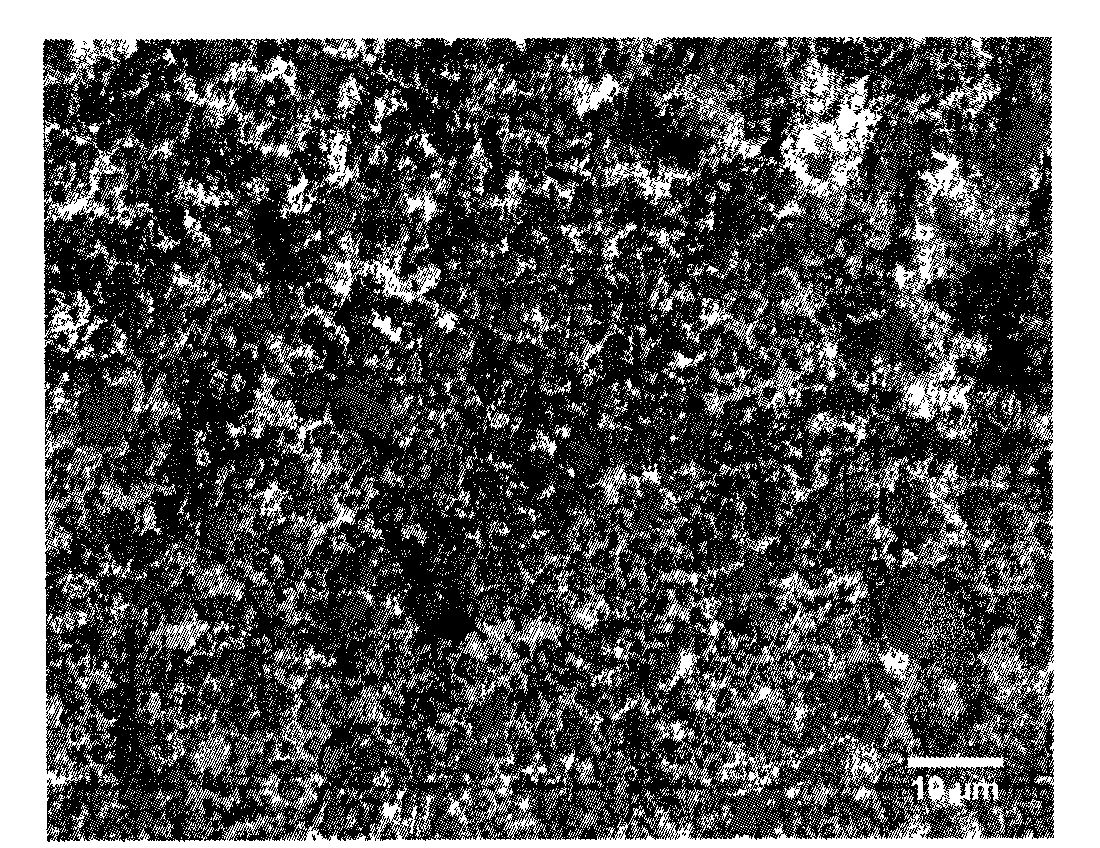

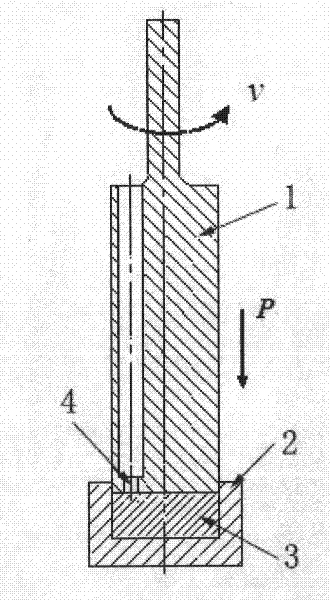

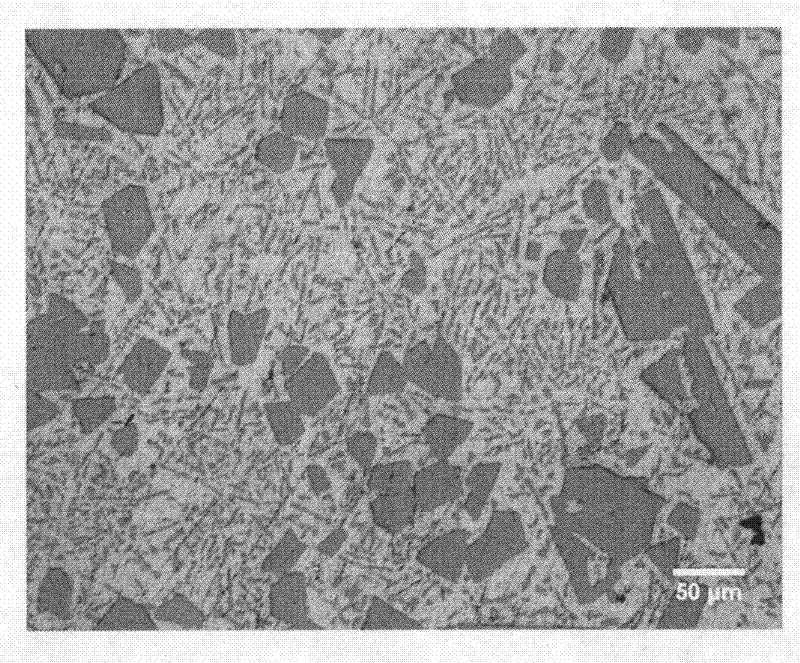

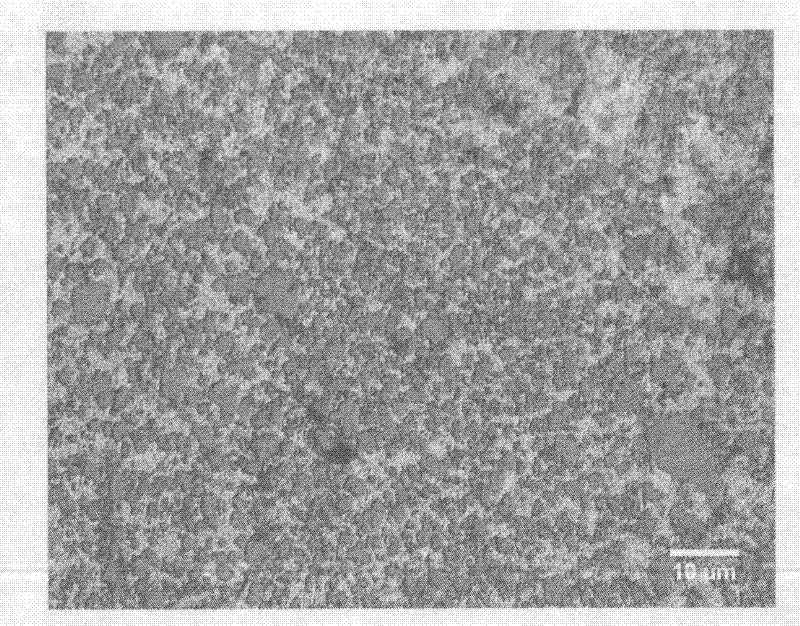

Friction extrusion method for preparing aluminium silicon alloy section bar

The invention relates to a method for preparing aluminium silicon alloy section bar, in particular to a friction extrusion method, belonging to the technical field of metal shaping and processing. The method adopts the following steps to shape: 1) an aluminium silicon alloy blank is filled in an aluminium silicon alloy blank jig with a concave cavity, and a friction extrusion head having an eccentric orifice deviating from the central line is arranged in the concave cavity; 2) the friction extrusion head rotates and applies pressure to the aluminium silicon alloy blank to cause the aluminium silicon alloy blank to rise temperature for plastification, and then, the aluminium silicon alloy blank is extruded out of the eccentric orifice of the friction extrusion head to form the section bar; 3) the temperature of the aluminium silicon alloy blank during friction extrusion does not exceed eutectic temperature thereof. The method can prepare aluminium silicon alloy section bar with average silicon-phase granule diameter being less than or equal to 10 micrometers, and the prepared aluminium silicon alloy section bar has no casting defects. In addition, the method has the advantages of simple technology, short flow, low requirement for equipment and the like, and has favourable application prospect.

Owner:KUNMING UNIV OF SCI & TECH

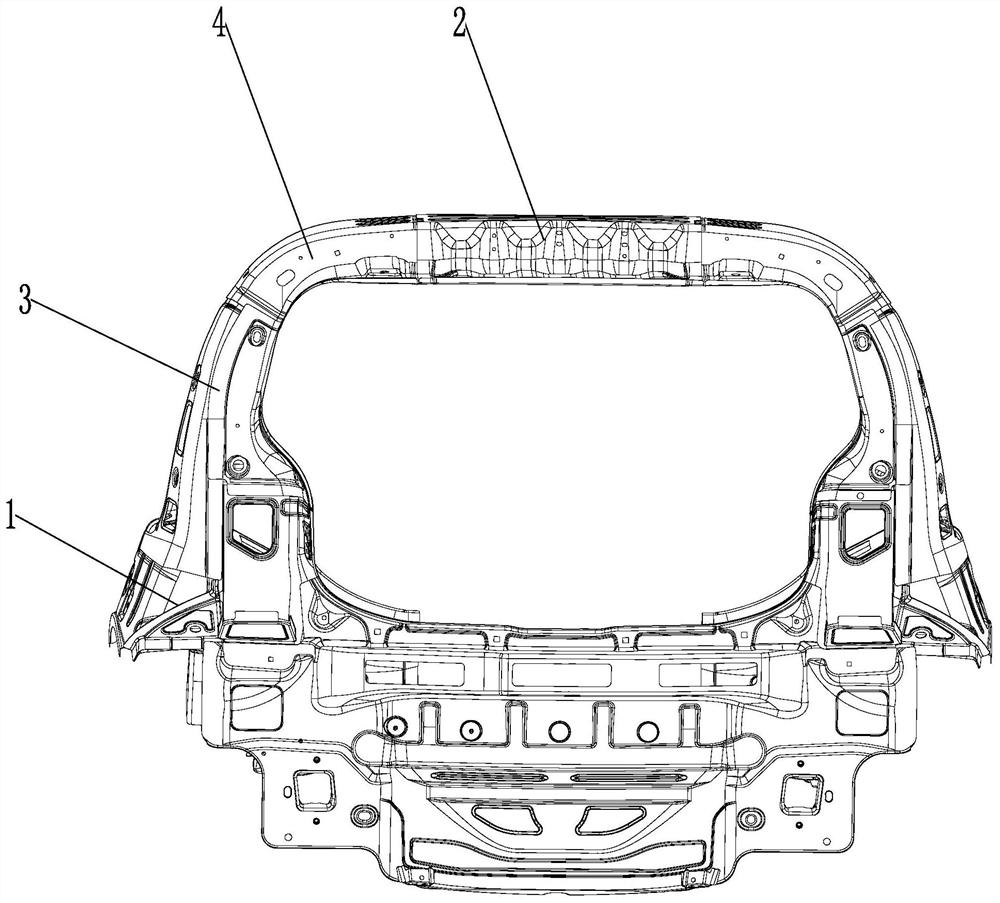

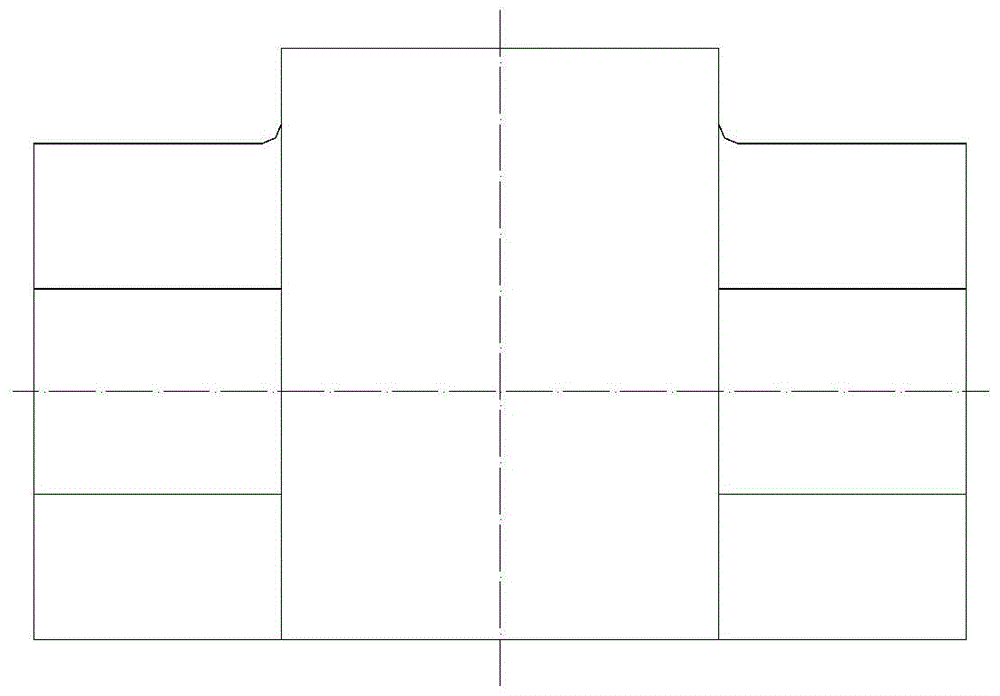

Split type SUV rear wheel cover based on weight reduction

ActiveCN106114647AImprove production efficiencyLow production costSuperstructure subunitsEngineeringMechanical engineering

Owner:JINGJIANG XINCHENG VEHICLE PARTS

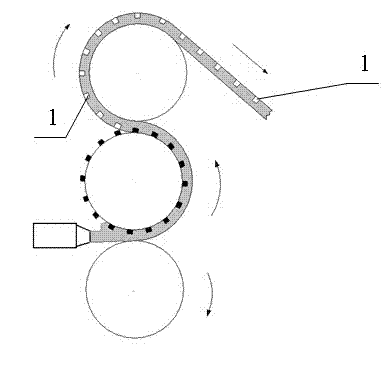

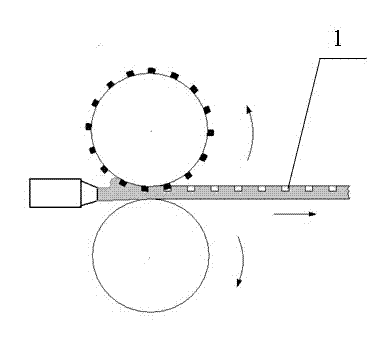

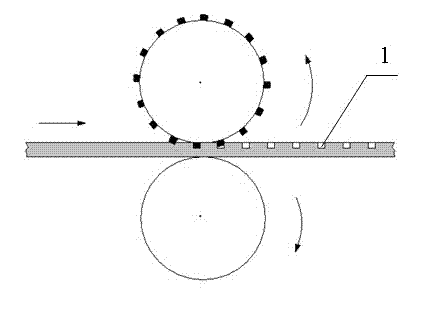

Manufacturing method of biaxial stretching thick node plastic geogrid

The invention relates to a manufacturing method of a biaxial stretching thick node plastic geogrid, and the method comprises the following steps: pressing thermoplastic plastic into an initial material tape, which is in set width and length and comprises pits, of the thick node plastic geogrid, punching through holes in the required shape in the pits of the initial material tape, and performing longitudinal and transverse stretching on the initial material tape after punching so as to prepare the thick node plastic geogrid. In the method, the corresponding but non-through pits are firstly pressed on the single side or double sides of a plastic flat tape, thereby reducing the punching thickness, having low requirements on a mold, enabling the size of a punching head to be smaller, preventing a thick plastic plate from restricting the size of the formed holes and greatly improving the node thickness and tensile strength of the biaxial stretching plastic geogrid. Polypropylene is used as a raw material, thereby enabling the node thickness of the biaxial stretching grid to achieve 10-26mm and enabling the comprehensive tensile strength to achieve 50kN / m-100kN / m; and polyester is used as a raw material, thereby enabling the comprehensive strength of the biaxial stretching grid to exceed 100kN / m.

Owner:王奇伟

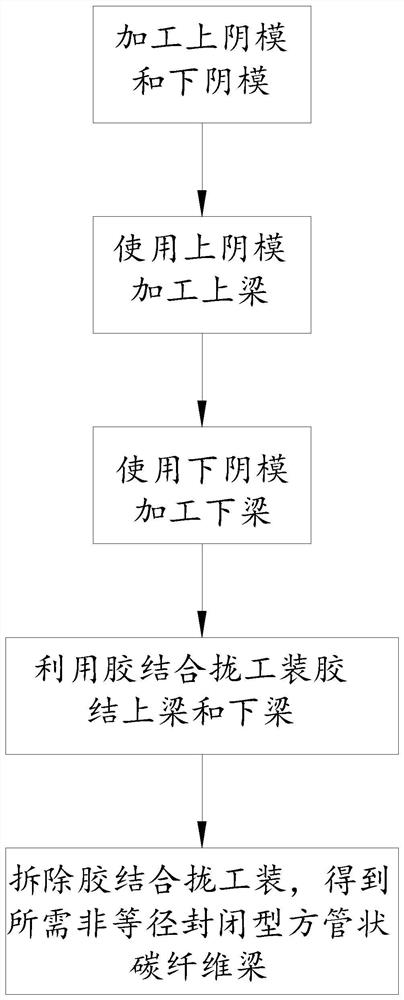

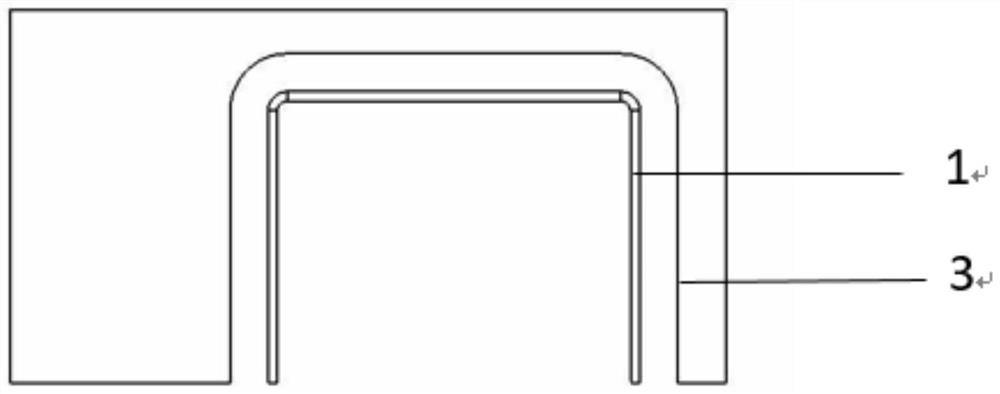

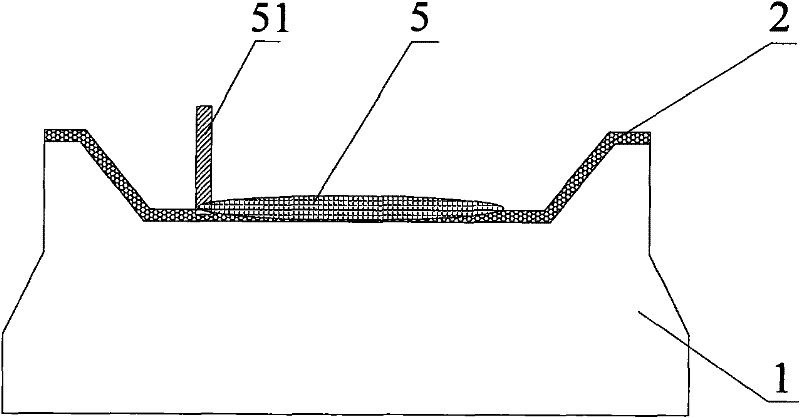

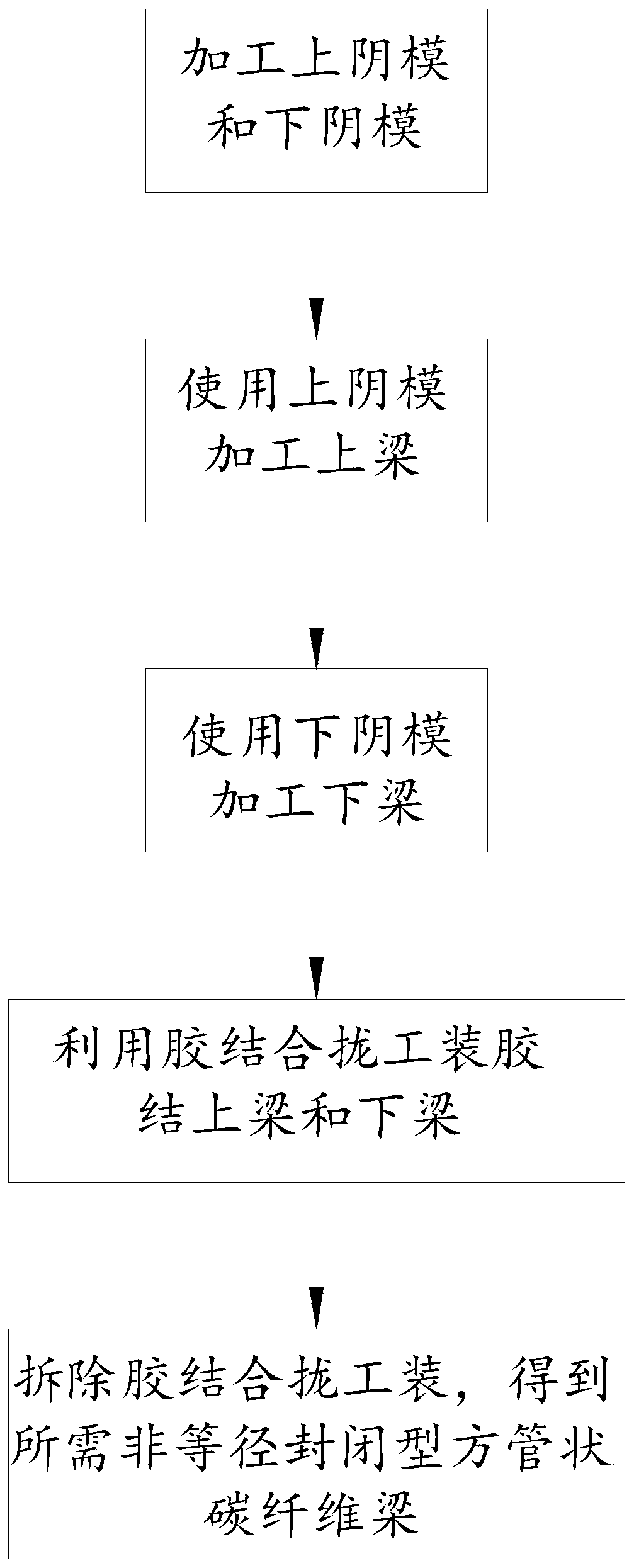

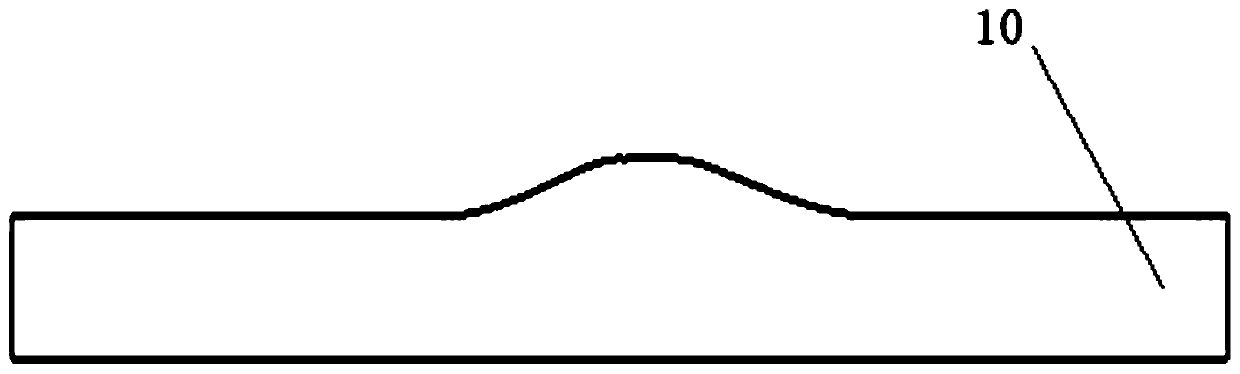

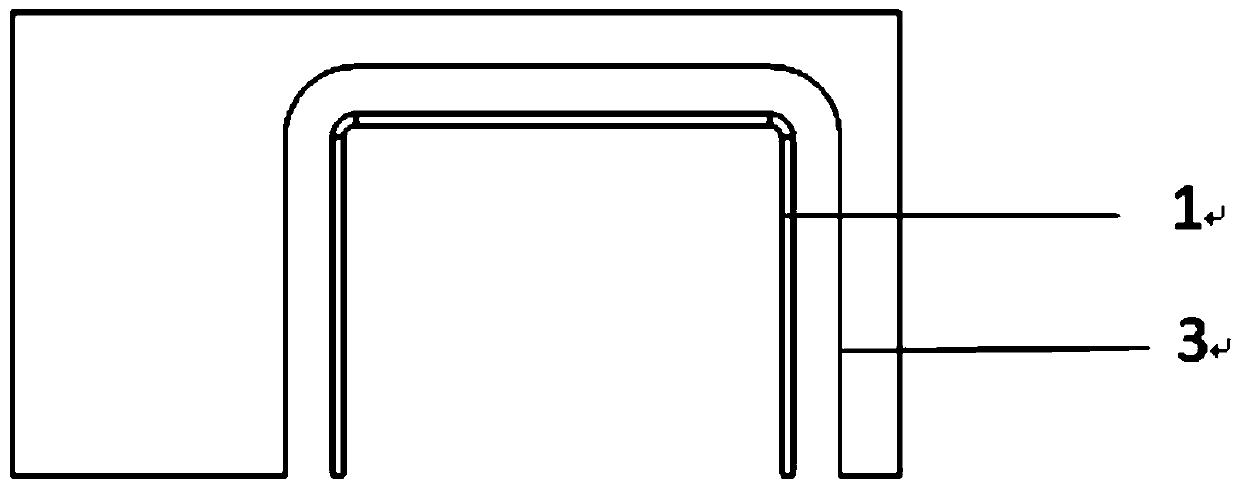

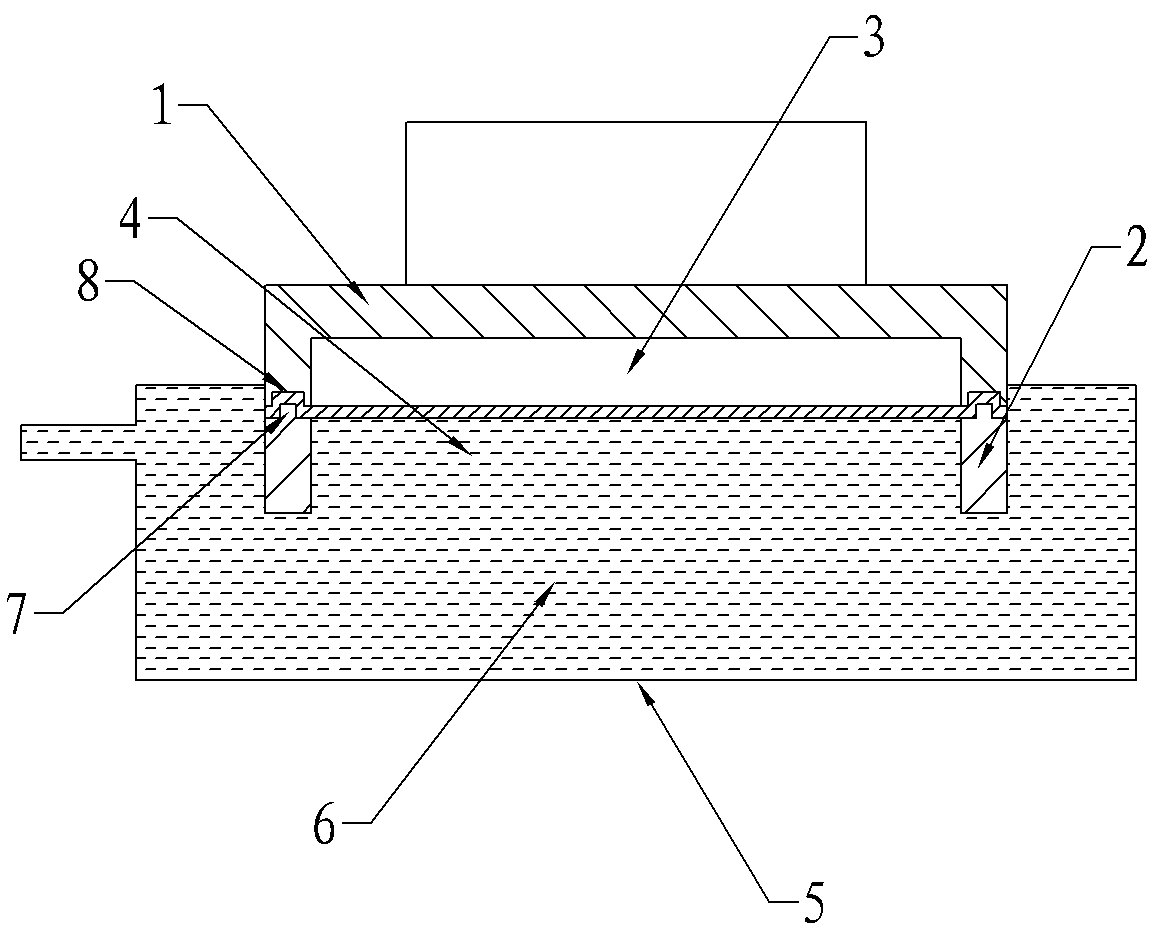

A method for manufacturing a non-equal-diameter closed square tubular carbon fiber beam for an unmanned aerial vehicle

ActiveCN110654039BSolve the difficulty of demouldingOvercome the defect of low yieldDomestic articlesFiberCarbon fibers

In order to effectively solve the technical problems of narrow application range, difficult demoulding, low yield of airbag core film, short service life, complicated process and high cost of the existing manufacturing method of non-equal-diameter closed square tubular carbon fiber beams of unmanned aerial vehicles, the present invention A method for manufacturing a UAV non-equal closed square tubular carbon fiber beam is proposed, including steps: 1) processing an upper die and a lower die; step 2) using the upper die to process an upper beam; step 3) Using the lower female mold to process the lower beam; step 4) gluing the upper beam and the lower beam with the gluing and joining tool; step 5) removing the gluing and joining tool to obtain the required non-equal diameter closed square tubular carbon fiber beam. The invention divides the integral component into two parts and forms them separately. Compared with integral forming, the requirements for forming process and forming tooling are lower, and the problem of difficult demoulding of non-equal-diameter closed square tube beams is solved.

Owner:西安爱生无人机技术有限公司

A kind of preparation method of yacht vacuum forming

Owner:福建蓝海湾游艇发展有限公司

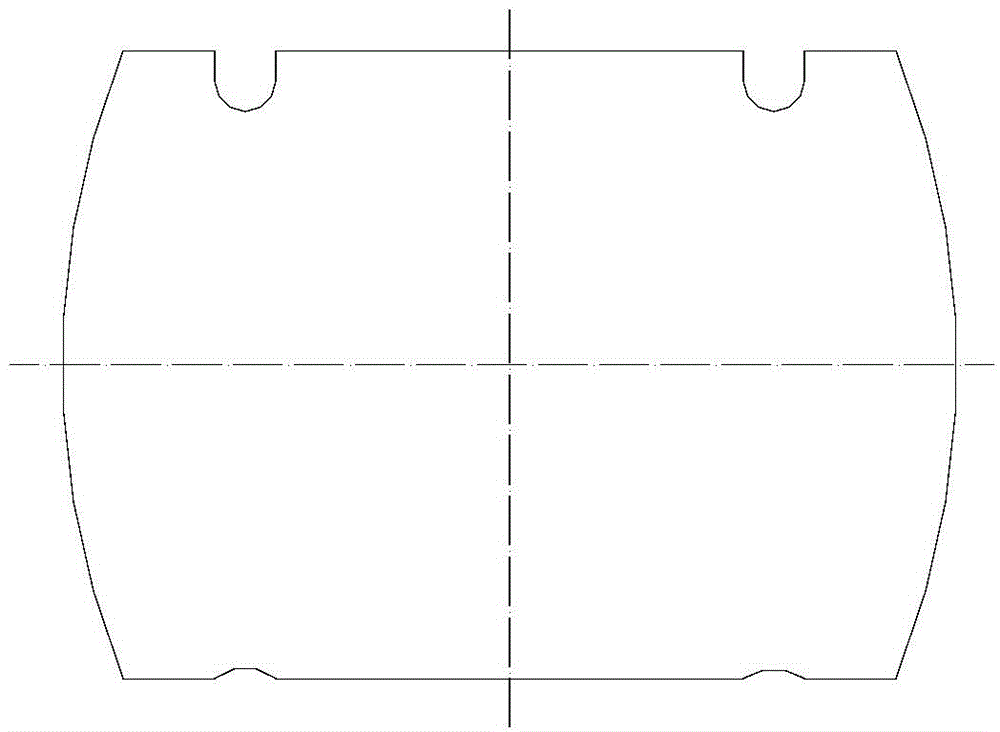

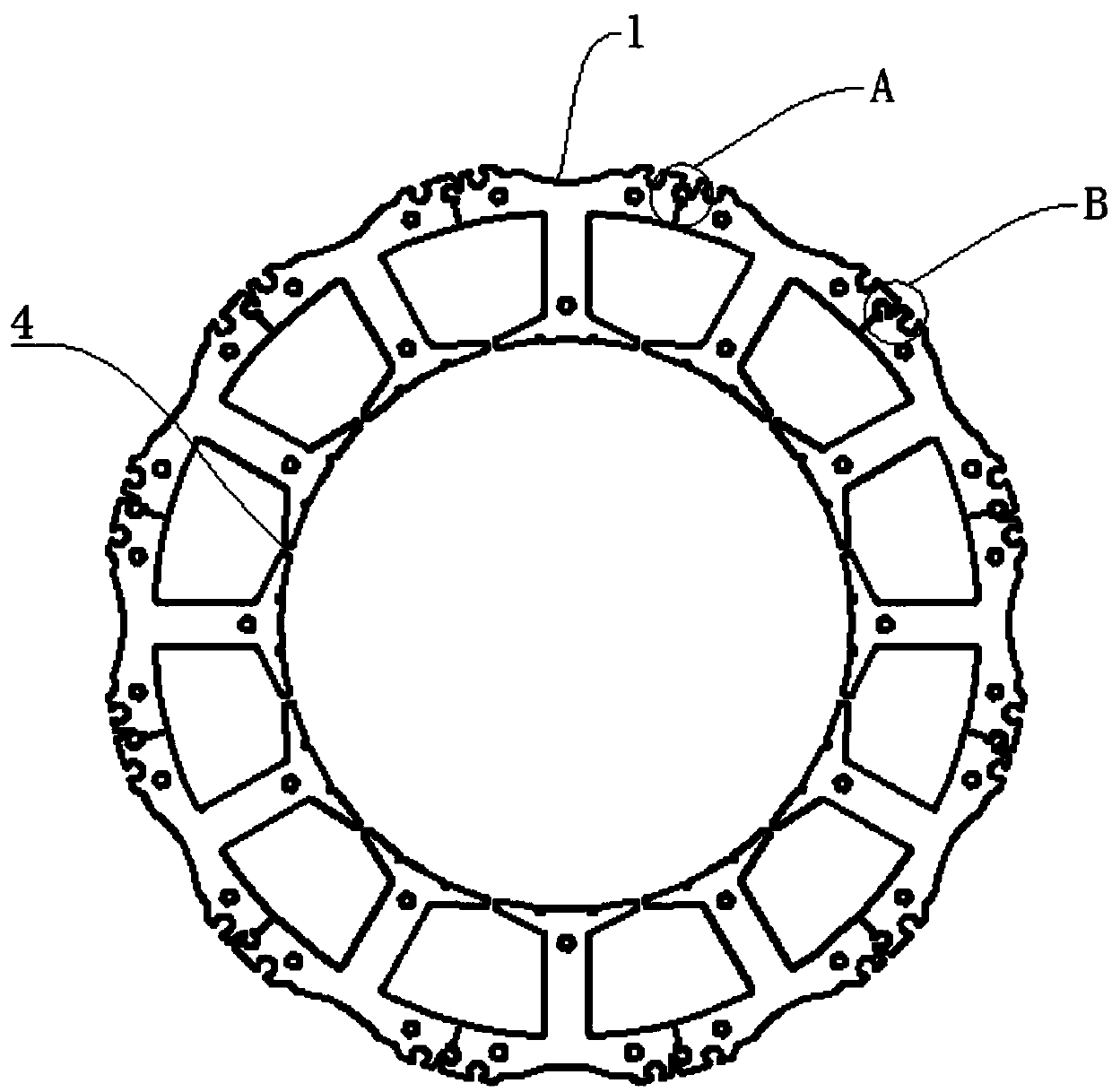

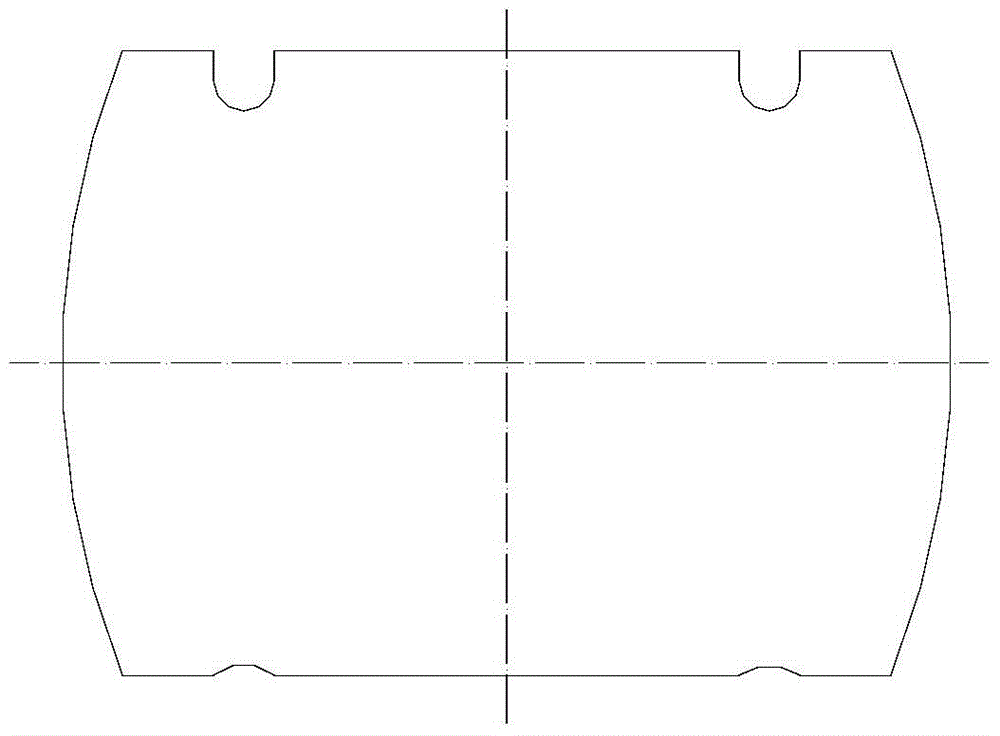

Blocking stator punching sheet, stator core and motor

InactiveCN107947399AIncrease profitLow costMagnetic circuit stationary partsSupports/enclosures/casingsWinding machinePunch press

The invention relates to the technical field of a motor, in particular to a blocking stator punching sheet, a stator core and a motor. The blocking stator punching sheet is formed by encircling tooth-shaped units independent to each other in an end-to-end way, a virtual groove is formed in the bottom of each tooth-shaped unit, the stator core is formed by laminating a plurality of blocking statorpunching sheets along an axial direction, and a motor comprises the stator core. The blocking stator punching sheet is low in requirement of a high punching machine and a high-punching die, the iron core can employ abutted high-punching dies in dual lines and in parallel, the silicon steel sheet material utilization ratio is high, a few waste is generated, the material cost is effectively reduced,and the blocking stator punching sheet is small in groove opening width; and with a tooth-top virtual groove structure, the working flux leakage is small, the electromagnetic noise is effectively reduced, the motor efficiency is improved, the blocking stator punching sheet is simple in winding and rapid in winding speed, various types of winding machines can be used in industry, and the manufacturing cost is effectively reduced.

Owner:合肥市通得力电气制造有限公司

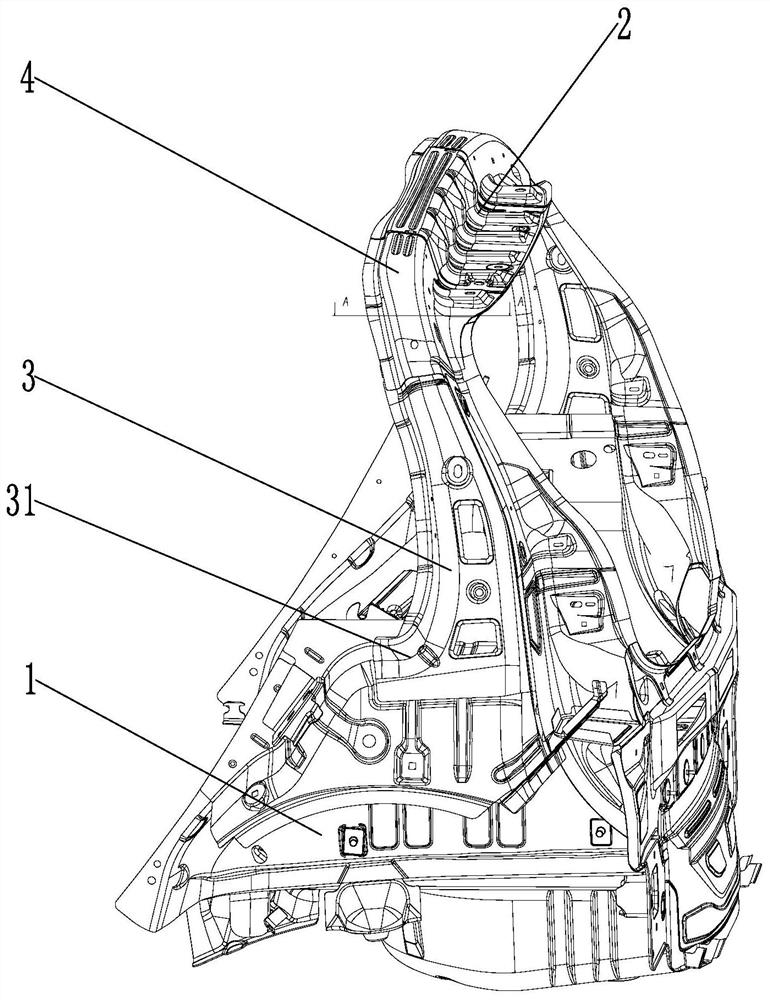

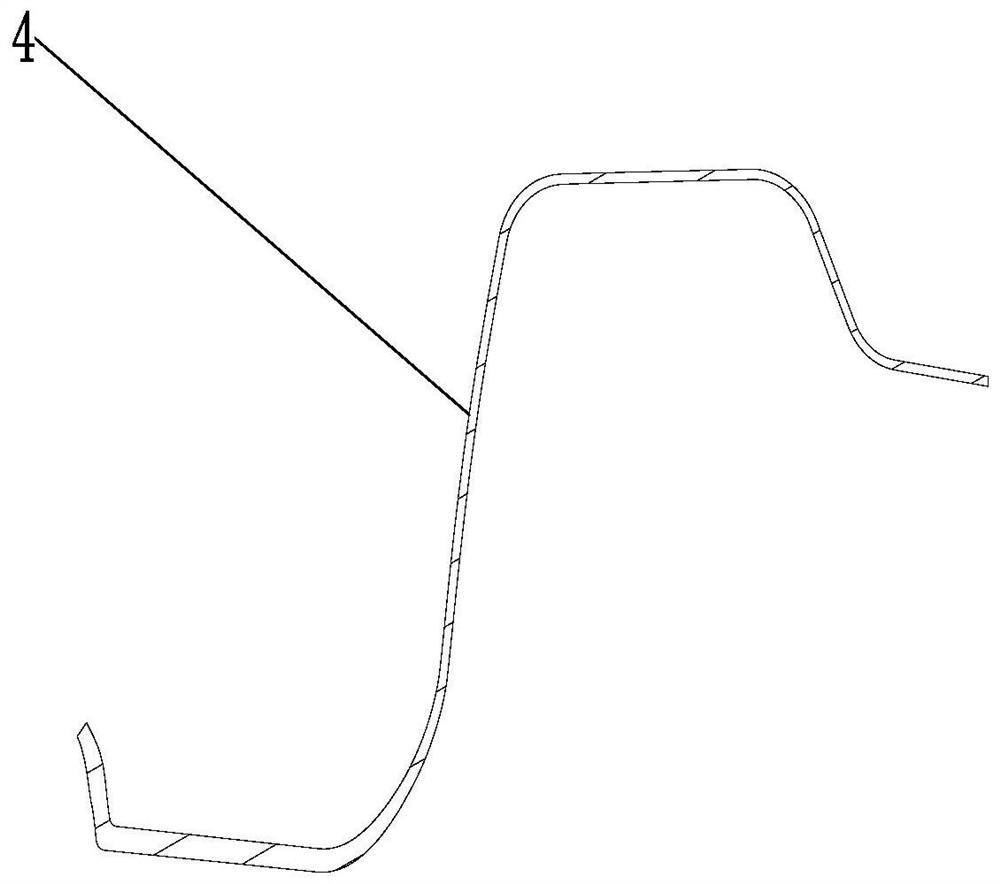

A joint structure on a d-pillar

ActiveCN111891222BStable structureImprove structural stabilitySuperstructure subunitsUpper jointStructural engineering

The invention relates to the field of vehicle structures, in particular to a joint structure on a D-pillar. It includes the outer wheel house, the rear roof beam and the D-pillar reinforcement plate on the D-pillar. The D-pillar reinforcement plate is located at the left and right ends of the rear roof beam. The upper and lower ends of the D-pillar reinforcement plate are respectively connected with the rear roof beam and the outer wheel house. , the upper end of the D-pillar reinforcement plate is connected to the rear roof beam through the D-pillar upper joint, and the D-pillar upper joint has two joints, one of which is connected to the rear roof beam, and the other joint is connected to the D-pillar reinforcement plate. The present invention improves the joint structure on the D-pillar, adopts the two-joint structure, and greatly reduces the difficulty of stamping compared with the three-joint structure, greatly improves the precision and reduces the stamping process, and the mold requirements are correspondingly reduced.

Owner:ZHEJIANG LEAPMOTOR TECH CO LTD

Valve body forging method

ActiveCN104439032BDense microstructureBeautiful appearanceValve arrangementsPressure grooveMaterials science

The invention relates to the field of valve body manufacturing, in particular to a valve body forging method. The valve body forging method saves materials and energy and reduces consumption on the condition of meeting the requirement of customers for product diversification. At first, blank forming is achieved by utilizing free forging for executing the following steps of A, selecting round steel with the weight being 1.15-1.25 times the weight of a finished valve body, riveting the two ends of the round steel, conducting indentation material separation, and forging the round steel into the preset size; B, enabling the two ends of the round steel to get off a table, forging eccentricity of the middle and the two ends, and forging the two ends into 260-degree octagons; C, then utilizing pressing blocks for making octagonal pressure grooves in the two ends into the preset size, and ensuring that flanges and grooves of a green body are within the design size range. Then, final forming is achieved by adopting semi-die forging for executing the following steps of a, forging the middle octagon of the green body in a vertical die buckling and pressing mode; b, after the middle octagon is formed, controlling the height of the flanges at the two ends through cushion blocks and forging the flanges to be rounded; c, finally, trimming the sizes of all parts of the forged piece into the designed sizes.

Owner:CHENGDU SHUANGLIU HENGSHENG FORGING

Rear wheel housing for split type suv based on lightweight

ActiveCN106114647BImprove production efficiencyLow production costSuperstructure subunitsEngineeringMechanical engineering

Owner:JINGJIANG XINCHENG VEHICLE PARTS

Composite member vimp preparation method with surface functional layer

InactiveCN101830095BIncrease stiffnessImprove surface qualitySynthetic resin layered productsFiberEpoxy

The invention belongs to the technical field of multi-layer composite material components and preparation methods thereof, and specifically discloses a VIMP preparation method of a composite material component with a surface functional layer. The composite material component includes an outer layer and a body layer. The layers are the first and second composite material systems; the first composite material system is based on epoxy resin, phenolic resin, etc., the second composite material system is based on unsaturated polyester resin, and each system is based on carbon fiber Or fiberglass cloth as reinforcement. The VIMP preparation method is to firstly adopt the resin film infiltration process to prepare a reinforced resin film on the surface of a vacuum dip molding process molding mold, and then use the molding mold covered with the reinforced resin film to prepare a composite product through a vacuum dip molding process. Material components. The VIMP process of the present invention combines the double advantages of the RFI process and the VIMP process, and the prepared composite material component has better surface quality, better integrity and excellent comprehensive performance.

Owner:NAT UNIV OF DEFENSE TECH

Manufacturing method for unmanned aerial vehicle non-equal-diameter closed square pipe shaped carbon fiber beam

ActiveCN110654039ASolve the difficulty of demouldingOvercome the defect of low yieldDomestic articlesFiberCarbon fibers

The invention provides a manufacturing method for an unmanned aerial vehicle non-equal-diameter closed square pipe shaped carbon fiber beam so as to effectively solve the technical problems that an existing manufacturing method for the unmanned aerial vehicle non-equal-diameter closed square pipe shaped carbon fiber beam is narrow in application range, demolding is difficult, the airbag core filmyield is low, the service life is short, the flow is complicated, and the cost is relatively high. The manufacturing method for the unmanned aerial vehicle non-equal-diameter closed square pipe shapedcarbon fiber beam comprises the following steps that 1) an upper female die and a lower female die are machined; 2) an upper beam is machined by using the upper female die; 3) a lower beam is machined by using the lower female die; 4) the upper beam and the lower beam are bonded by using a bonding combining tool; and 5) the bonding combining tool is removed to obtain the required non-equal-diameter closed square pipe shaped carbon fiber beam. According to the manufacturing method, an integral component is divided into two parts to be separately formed, compared with integral forming, the requirements on a forming process and a forming tool are relatively low, and the problem of difficult demolding of the non-equal-diameter closed square pipe beam is solved.

Owner:西安爱生无人机技术有限公司

Liquid expansion forming device and liquid expansion forming process

The invention discloses a novel liquid-expansion molding device and a liquid-expansion molding process. The novel liquid-expansion molding device comprises an autofrettage pressure mould and a floating pressure mould. The autofrettage pressure mould is provided with a molding cavity; a through hole matched with the molding cavity is formed in the middle of the floating pressure mould which is mounted in a liquid-expansion pressure cavity; the edges of a plate to be molded are pressed by the adjoining plane of the floating pressure mould and the autofrettage pressure mould which is connected with a press machine; the liquid-expansion pressure cavity is connected with high-pressure liquid; in the molding process, the press machine is used for pressing and sealing the edges of the plate to be molded, and the high-pressure liquid is input into the liquid-expansion pressure cavity and acts on the plate to be molded, so that the plate to be molded deforms toward the molding cavity of the autofrettage pressure mould and is molded. The structures of the liquid-expansion molding moulds can achieve liquid-expansion molding of the plate, and the structure of the novel liquid-expansion molding device can also be conveniently used for liquid-expansion molding of the plate. The process is simple, requirements for the moulds are low, and the precision of molding can also be improved. Further, the structure can reduce the work load of the press machine, the work pressure of the press machine is reduced at the same time, and use requirements are lowered.

Owner:HONY MACHINERY CO LTD

Forming method of zirconium oxide ceramic insertion needle for fiber-optic connector and its equipment

InactiveCN1200297CExcellent performance of sintered bodyWill not harmCoupling light guidesFiberIt equipment

The invention discloses a molding method and device for a zirconia ceramic ferrule for an optical fiber connector, belonging to the field of preparation of ceramic devices. The method is to make a premixed liquid from an organic monomer, a cross-linking agent and deionized water, then add ceramic powder, add a catalyst and an initiator to the slurry after ball milling, inject it into a mold cavity through a molding device, and form a green body Sintered after drying. The deviation of the punch in the forming device involved in the present invention is less than 5 μm during the running process along the guide rail, so that the ceramic slurry can be filled and solidified at normal temperature and pressure, and the obtained ceramic green body is uniform and dense, and the sintered body has excellent performance . In particular, the viscosity of the slurry is very low (<1Pa·s), and there is no lateral force on the microneedles at the front end of the punch during filling and curing, and it will not damage the microneedles of the punch, nor will it cause deflection of the microneedles. shift. The method has low requirements on molds and equipment, and can form a zirconia ceramic ferrule body for an optical fiber connector that meets the requirements of dimensional accuracy in near-net dimensions.

Owner:TSINGHUA UNIV

Method for Gypsum Type Investment Precision Casting Using Copper Tube

ActiveCN103639360BAchieve castingSimple operation processFoundry mouldsFoundry coresWaxChemical reaction

The invention discloses a method for carrying out plaster mould precise investment casting by utilizing copper pipes. The method comprises the following steps: manufacturing a copper pipe with a predetermined structure, placing the formed copper pipe in a mound to manufacture a wax mould; embedding the formed copper pipe in the wax mould, precisely positioning the copper pipe so as to carry out processes of grouting, sintering, and casting; wherein after the casting process, the copper pipe is embedded in an aluminum casting; and soaking the aluminum casting in a nitric acid solution until the copper pipe completely finishes chemical reactions. The method has the advantages of simple operation technology, reliability, high precision, and low requirements on mould, reduces the cost, and can realize casting of complex and tiny pipelines at the same time. The qualified rate of special-shaped casting with a small diameter manufactured by the method can reach 90% or more.

Owner:成都新航工业科技股份有限公司

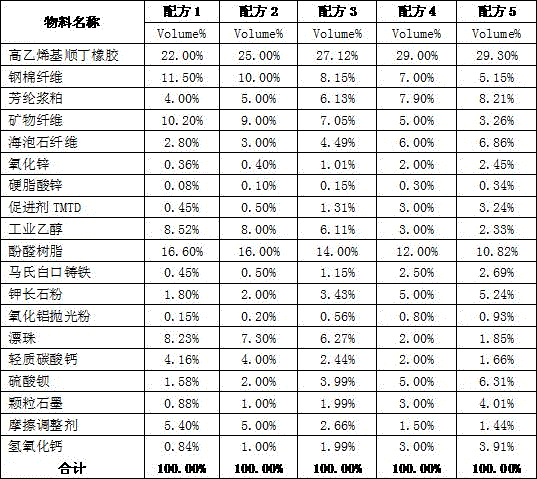

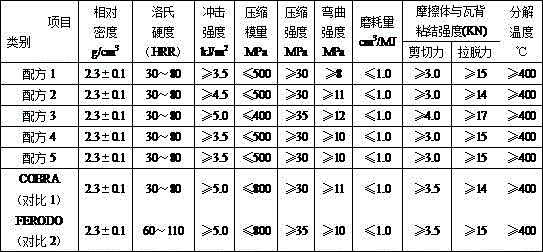

Synthetic brake shoe for high-power locomotive pressed at room temperature and preparation method thereof

The invention belongs to the technical field of brake pad materials, and in particular relates to a synthetic brake shoe for high-power locomotive pressed at room temperature and a preparation method thereof. The synthetic brake shoe friction body is synthesized from materials with the following volume ratio: high vinyl butadiene rubber 25 ~30, steel fiber 7~10, aramid pulp 5~7.9, mineral fiber 5~9, sepiolite fiber 3~6, zinc oxide 0.4~2, zinc stearate 0.1~0.3, rubber vulcanizing agent TMTD0. 5~3, industrial ethanol 3~8, phenolic resin 12~16, white cast iron 0.5~2.5, potassium feldspar powder 2~5, alumina polishing powder 0.2~0.8, floating beads 2~7.3, light calcium carbonate 2~ 4. Barium sulfate 2-5, granular graphite 1-3, friction modifier 1.5-5, calcium hydroxide 1-3. It is made by batching, banburying, crushing, pressing at room temperature and heat treatment. The synthetic brake shoe can be used in high-power locomotives with a maximum operating speed of 120km / h and an axle load of no more than 25t. It has stable friction performance and excellent wear resistance, and has little wear on wheels and low braking noise.

Owner:辽宁红德电碳制品有限公司

A kind of aluminum alloy automobile chassis casting metal type low-pressure casting forming method for rapid pressurization after holding pressure

Owner:北京航大新材科技有限公司

Friction Extrusion Method for Preparation of Al-Si Alloy Profiles

The invention relates to a method for preparing aluminum-silicon alloy profiles, in particular to a friction extrusion method, which belongs to the technical field of metal forming processing. The method adopts the following steps to form: ① put the aluminum-silicon alloy billet into the aluminum-silicon alloy blank fixture with a concave cavity, and then install a friction extrusion head with an eccentric hole off the center line into the concave cavity; ②The friction extrusion head rotates and exerts pressure on the aluminum-silicon alloy billet at the same time, so that the aluminum-silicon alloy billet is heated and plasticized, and extruded from the eccentric hole of the friction extrusion head to become a profile; ③The aluminum-silicon alloy is controlled during friction extrusion The temperature of the billet does not exceed its eutectic temperature. The method can prepare aluminum-silicon alloy profiles with an average diameter of silicon phase particles less than or equal to 10 microns and no casting defects. In addition, the method also has the advantages of simple process, short process, low equipment requirements, etc., and has good application prospects.

Owner:KUNMING UNIV OF SCI & TECH

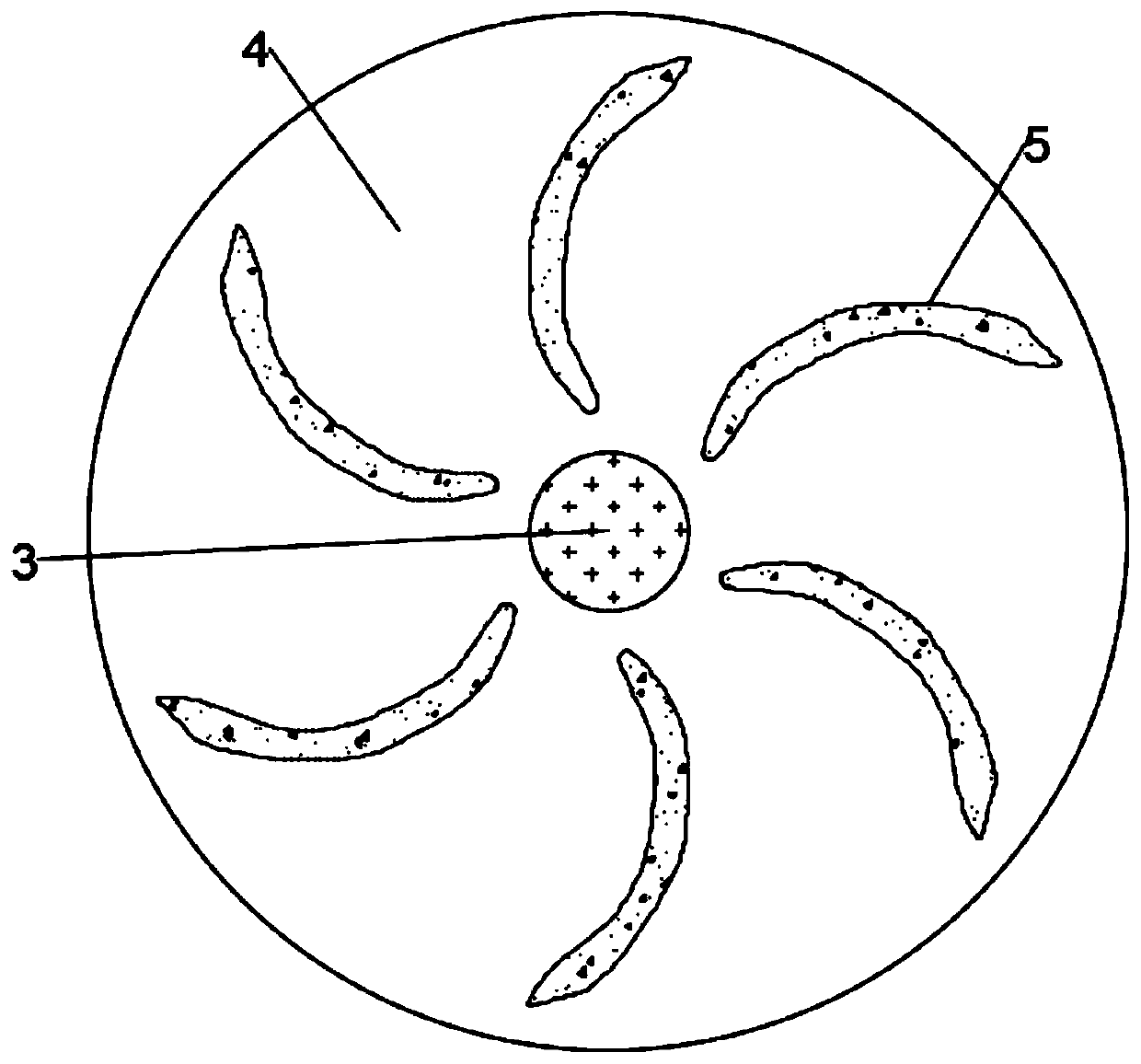

An automobile water pump structure and its production process

ActiveCN108661921BImprove sealing and waterproof performanceAvoid wastingCoolant flow controlPump componentsElectric machineryVehicle driving

The invention discloses a vehicle water pump structure and a production process thereof. The vehicle water pump structure comprises a pump body outer shell; a motor chamber, a rotating shaft groove and an impeller chamber are arranged in the pump body outer shell in sequence from left to right; a water outlet pipe groove and a water inlet pipe groove are connected to the top end and the bottom endof the impeller chamber separately; a motor, a rotating shaft and an impeller disc are inserted in the motor chamber, the rotating shaft groove and the impeller chamber separately; a shaft sealing device is mounted at the right end of the rotating shaft groove through a shaft sealing groove; a temperature measuring water control valve is mounted on one side of the water inlet pipe groove througha mounting groove; the shaft sealing device improves the tight waterproof performance of the motor, and can prevent the waste of water resources; such electric devices as the motor are convenient to install, maintain or replace by means of a maintenance mounting door; the temperature measuring water control valve controls the water pumping flow of a vehicle water pump according to the temperatureof a vehicle driving device, so that the vehicle driving device is always maintained in a better working state, and the water resources and the energy are saved; and the pump body outer shell is manufactured by using a lost-wax process, so that the water pump production difficulty and cost are reduced.

Owner:SICHUAN ANYUE YULIANG AUTOMOBILE WATER PUMP

A crystallization pressurization method for low-pressure casting molding of aluminum alloy automobile chassis casting metal mold

The invention discloses a crystallization pressurization method for metal mold low-pressure casting molding of an aluminum alloy vehicle chassis casting. The method continues a traditional low-pressure casting process of the aluminum alloy vehicle chassis casting in the phases of liquid rise, mold filling and crystallization pressurization; and the liquid rise pressure and the mold filling pressure are controlled within 18-21 kPa and 30-35 kPa. The crystallization pressurization is divided into two stages according to the condensation ending time of a characteristic part A: in the first stage: in the stage from the end of the mold filling phase to the condensation end of the characteristic part A, the crystallization pressurization pressure is increased to 80-150 kPa; and in the second stage: after the condensation of the characteristic part A is finished, the crystallization pressurization pressure is quickly increased to 160-1000 kPa, and the pressurization speed is 10-40 kPa / s. Then, the pressure keeping stage and the pressure relief are performed. The method prominently improves the condensation feeding effect and the casting mechanical performance, prevents such defects as molten aluminum splashing and casting flanges and burrs, and prominently reduces the requirements on the mold structure and the casting mold clamping force.

Owner:北京航大新材科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com