Patents

Literature

149results about How to "Solve the difficulty of demoulding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

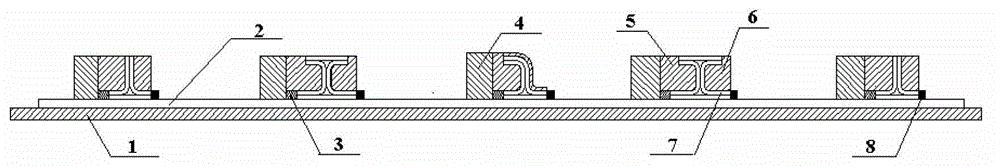

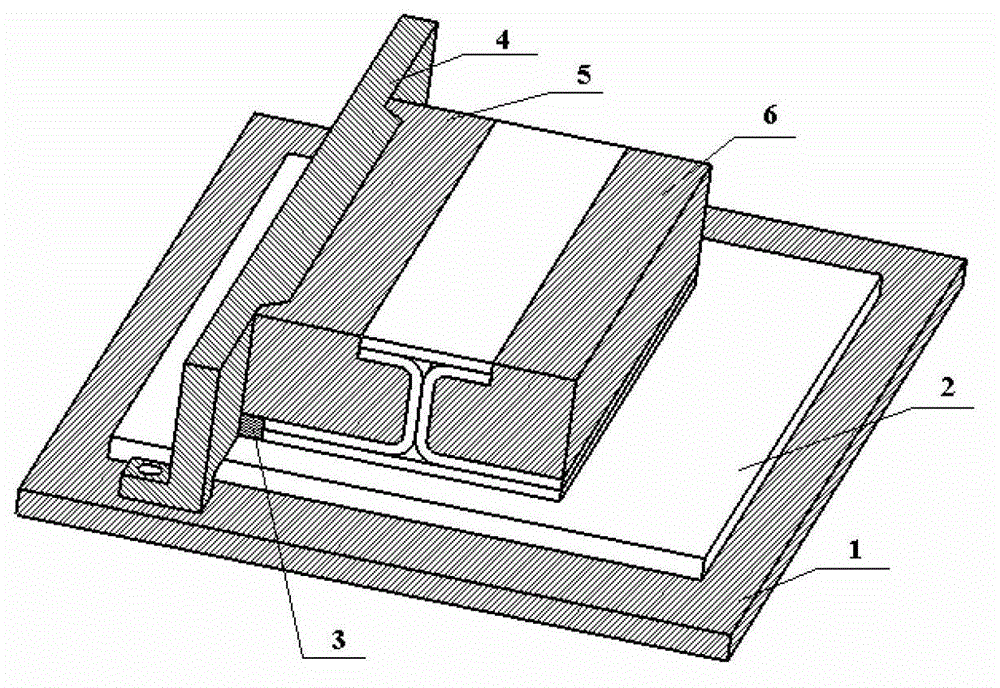

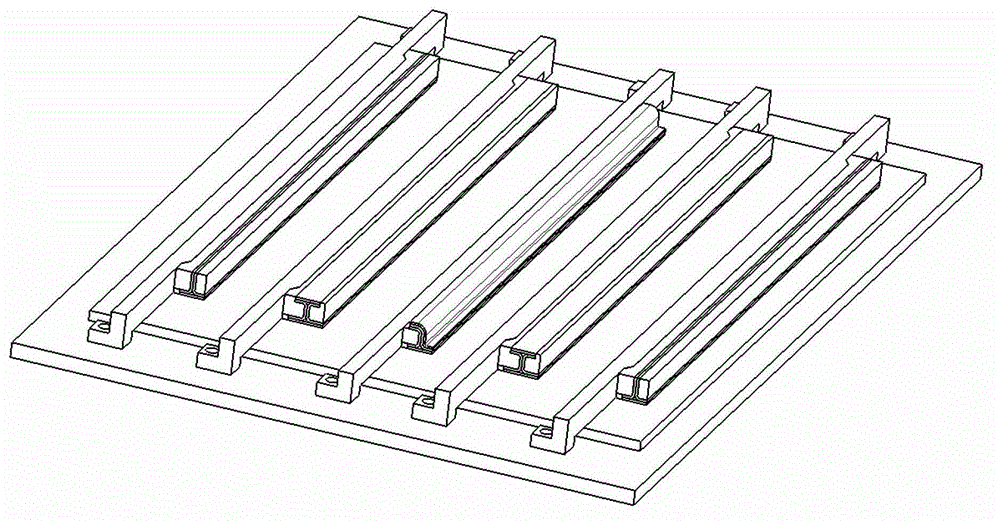

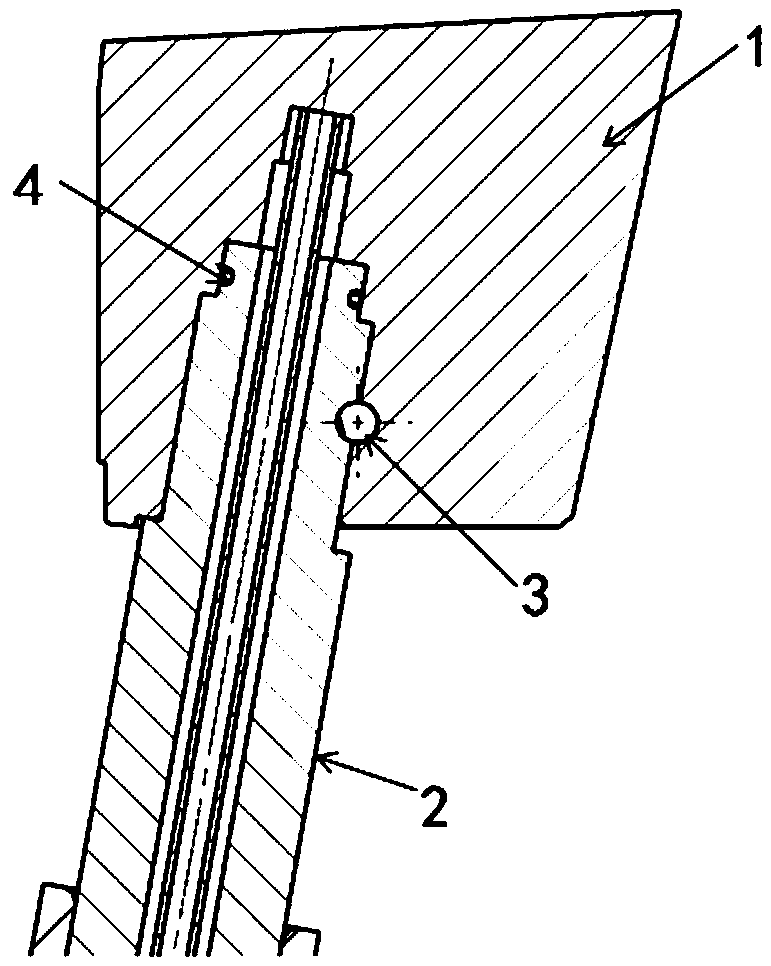

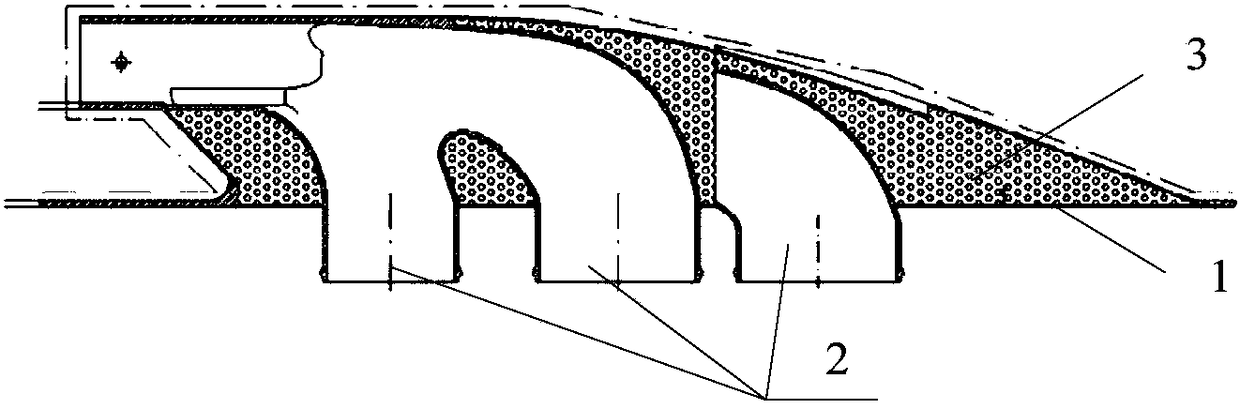

Method for forming control of long joist axial line of composite material stiffened wall panel

The invention belongs to technologies of composite material forming, and relates to a method for forming control of a long joist axial line of a composite material stiffened wall panel in an aviation aircraft. The method is a fixture method suitable for forming control of long joist axial lines of various types, such as a T shape, an I shape, a J shape and the like, of long joist composite material stiffened wall panels. A forming fixture mainly comprises a long joist forming mold A and a long joist forming mold B, a skinned curing mold, a cushion block and an axial line positioning mold. The two ends of the long joist forming mold A are designed to be dovetail-shaped and are closed matched with the axial line positioning mold to control the deviation of a long joist in the length direction of the axial line; and the axial line positioning mold is fixed on the skinned curing mold through positioning pins to control left and right deviations of the long joist axial line. By the forming fixture method, the molding surface quality and the position accuracy of a long joist product are effectively improved, and the long joist axial line is prevented from deviation.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

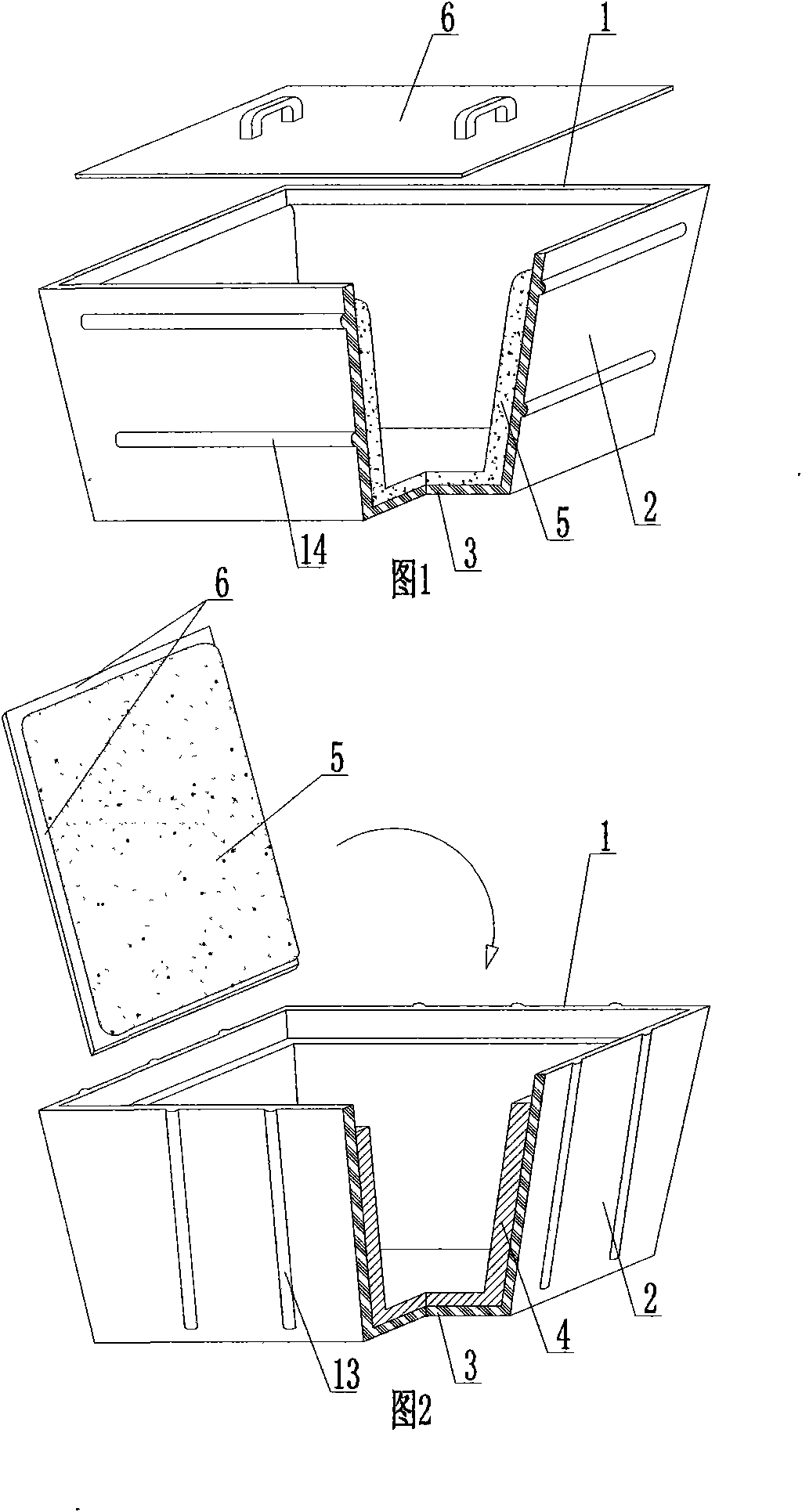

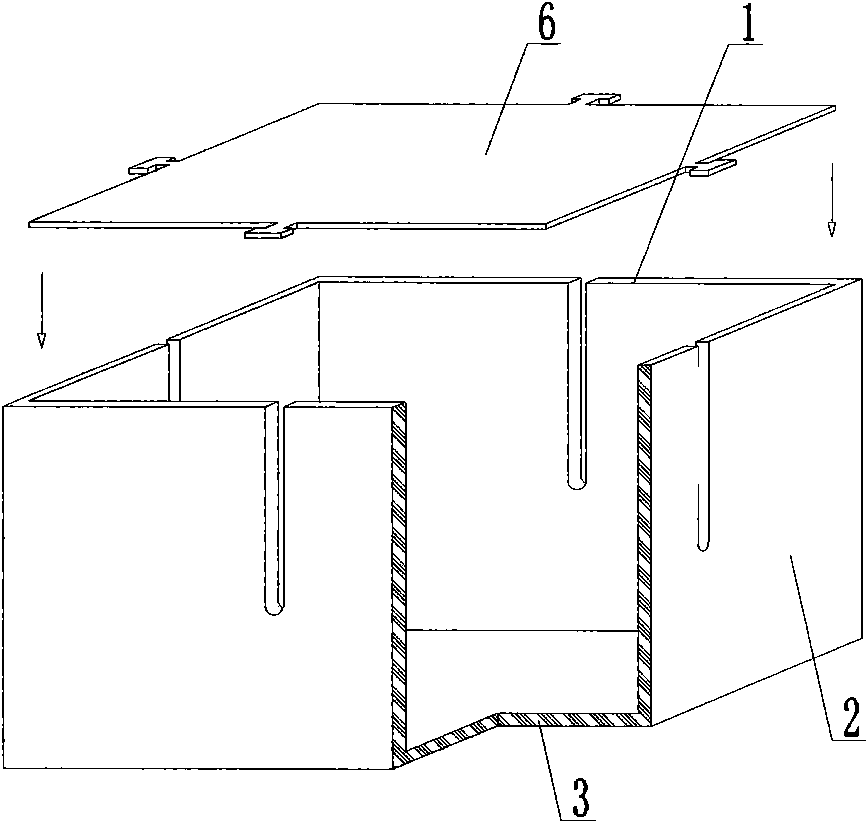

Forming die of thin-wall hollow member

The invention relates to a forming die of a thin-wall hollow member, comprising a basin-shaped female die (1). The basin-shaped female die (1) comprises surrounding basin side films (2) and a bottom film (3) and is characterized in that a slurry-covering template (6) is matched with a basin opening of the basin-shaped female die (1), a film surface at one side of the slurry-covering template (6) inwards plugs a hollow member (4) with an opening at one side or a hollow blank (5) with an opening at one side in the basin-shaped female die (1) from the basin opening, a male die is formed by splicing at least two templates, and a splicing device is arranged on the spliced templates so that the templates are extremely convenient to remove after loosening the splicing device. Meanwhile, at least one structure or device for drawing out and demolding the templates is arranged on the spliced templates so that the demolding of the die is more convenient. In addition, the die also has the advantages of simple structure, easy manufacture, high strength, low cost, and the like, is suitable for manufacturing thin-wall tubes or thin-wall boxes, and is particularly suitable for manufacturing thin-wall tubes with openings or thin-wall boxes with openings.

Owner:邱则有

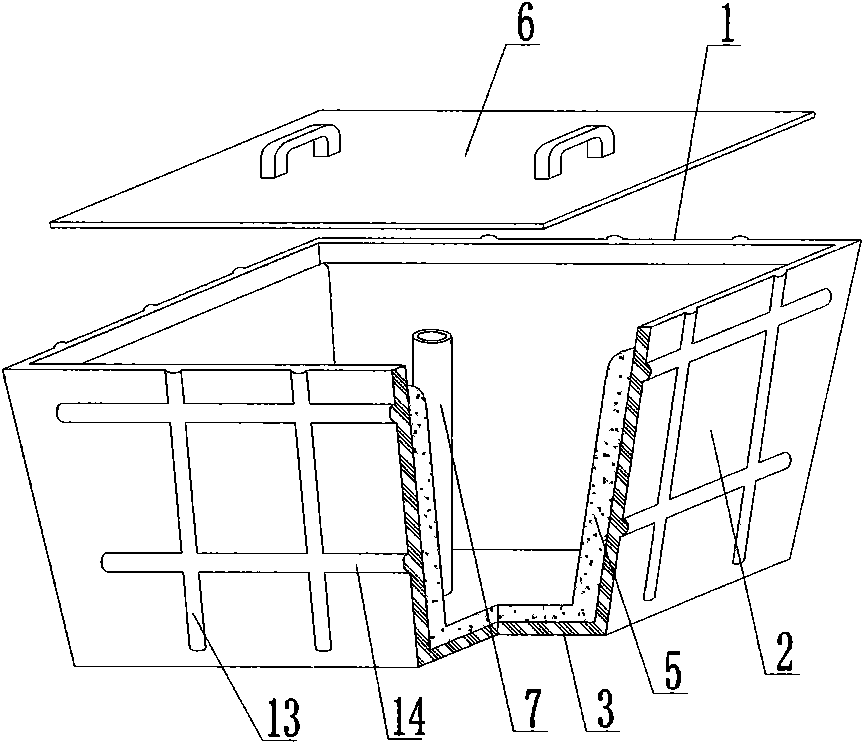

Ultra-high performance concrete column permanent formwork and preparation method thereof

The invention discloses an ultra-high performance concrete column permanent formwork which comprises a hollow columnar ultra-high performance concrete layer and a steel reinforcement cage arranged in the ultra-high performance concrete layer. Dents with the depth not lower than 5 mm are formed in the inner surface of the ultra-high performance concrete layer. The cross section of the ultra-high performance concrete layer is in the shape of a hollow column and a hollow square column. The dents are in strip, grid, dot and spiral shapes. The invention further discloses a preparation method of the ultra-high performance concrete column permanent formwork. By preparing the ultra-high performance concrete column permanent formwork with the dents with the depth not lower than 5 mm in the inner surface, the binding powder between ultra-high performance concrete and post-cast core concrete is enhanced, so that the column component bearing capacity is improved; the ultra-high performance concrete column permanent formwork is good in integrality, convenient to prepare, low in cost, remarkable in economic benefit and excellent in endurance quality.

Owner:广东利盈投资集团有限公司

Plant fiber particle-filling regeneration polyester composite material and preparation method thereof

The invention relates to a plant fiber particle-filling regeneration polyester composite material and a preparation method thereof. The plant fiber particle-filling regeneration polyester composite material is prepared by, by weight, 50-80% of regeneration polyester, 10-20% of polyolefin, 5-30% of plant fiber particles, 2-10% of compatilizer, 2-8% of chain extender, 0.2-1% of antioxygen and 0.2-2% of lubricating agents. The raw materials are fused and then particles are squeezed out and the plant fiber particle-filling regeneration polyester composite material is obtained. According to the plant fiber particle-filling regeneration polyester composite material and the preparation method thereof, the performances (tenacity, transparency and the like) are excellent, sources for raw materials are wide, cost is low, recycling and reusing are available, environment pollution is reduced, and resources are saved. Compared with various inorganic and synthetic fibers, the plant fiber particles have the advantages of being low in price, easy to obtain, low in density, high in tensile strength and modulus, and small in energy consumption for processing, renewable and compatible with the ecological environment, small in environment pollution, small in damage to human bodies, and capable of meeting requirements of the ecological environment, large in economic potential, and applicable to the fields such as automobile industries, interior decoration, and electric products.

Owner:SHANGHAI SUNNY

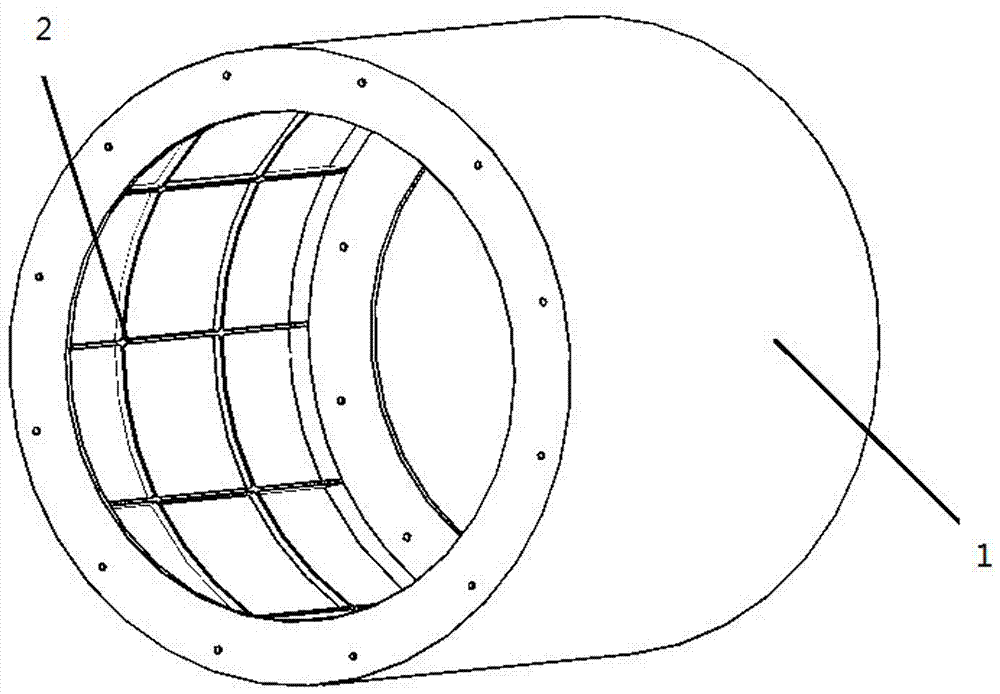

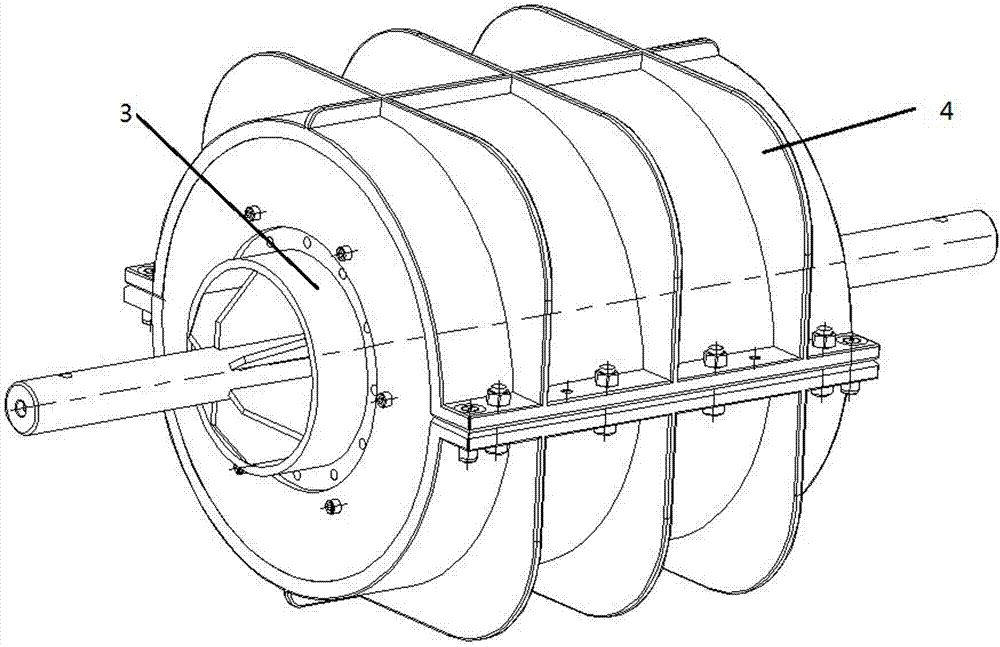

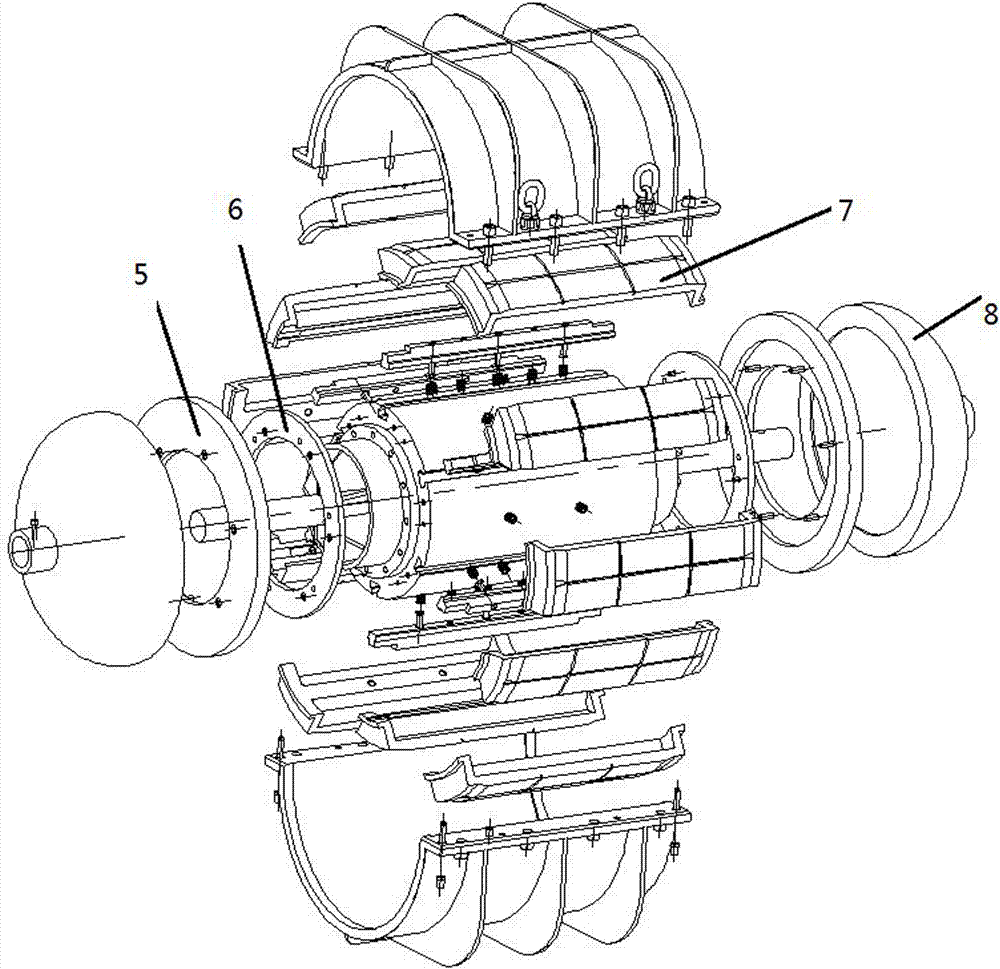

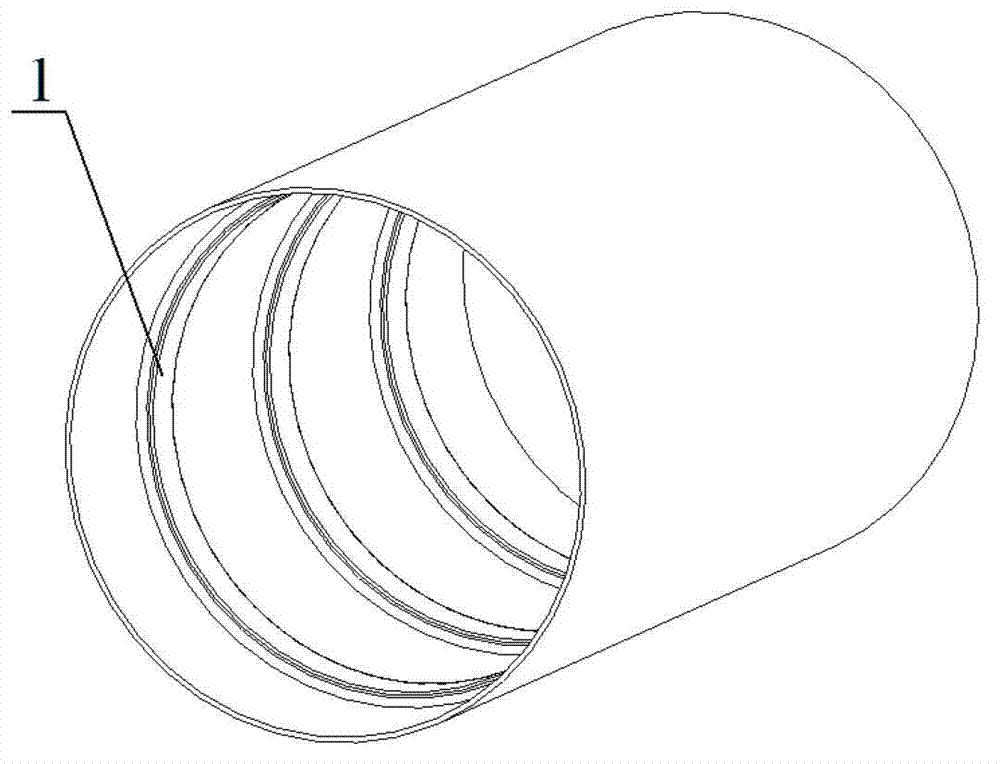

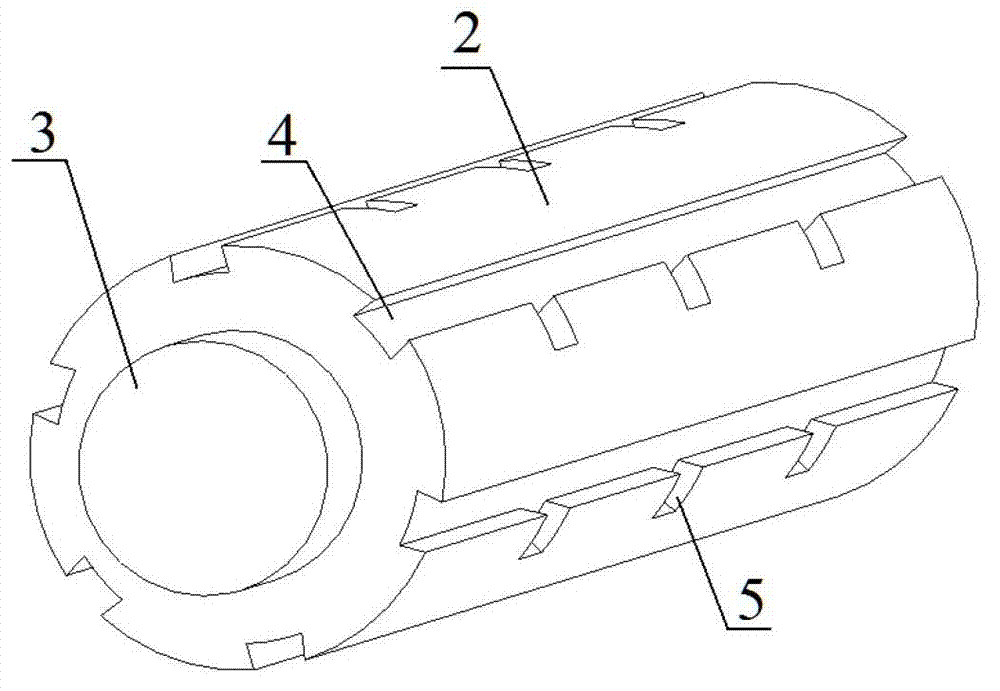

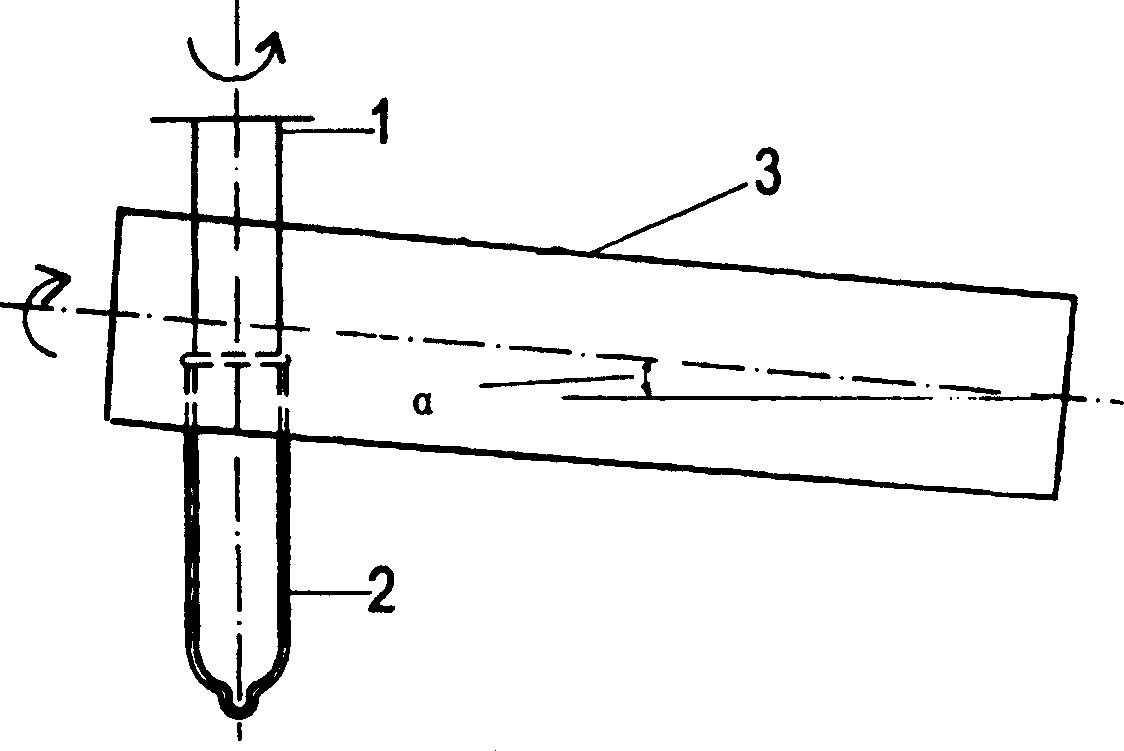

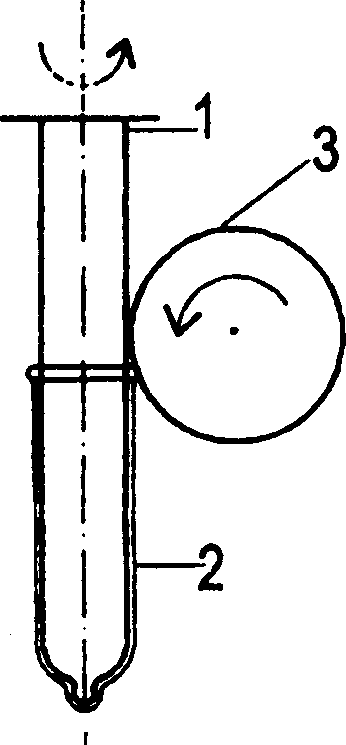

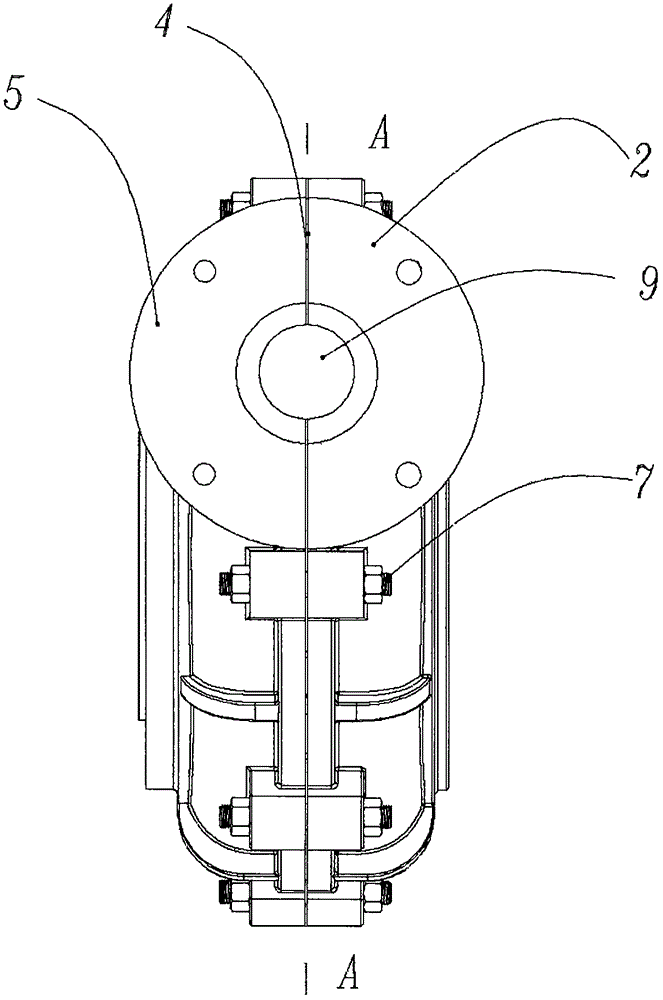

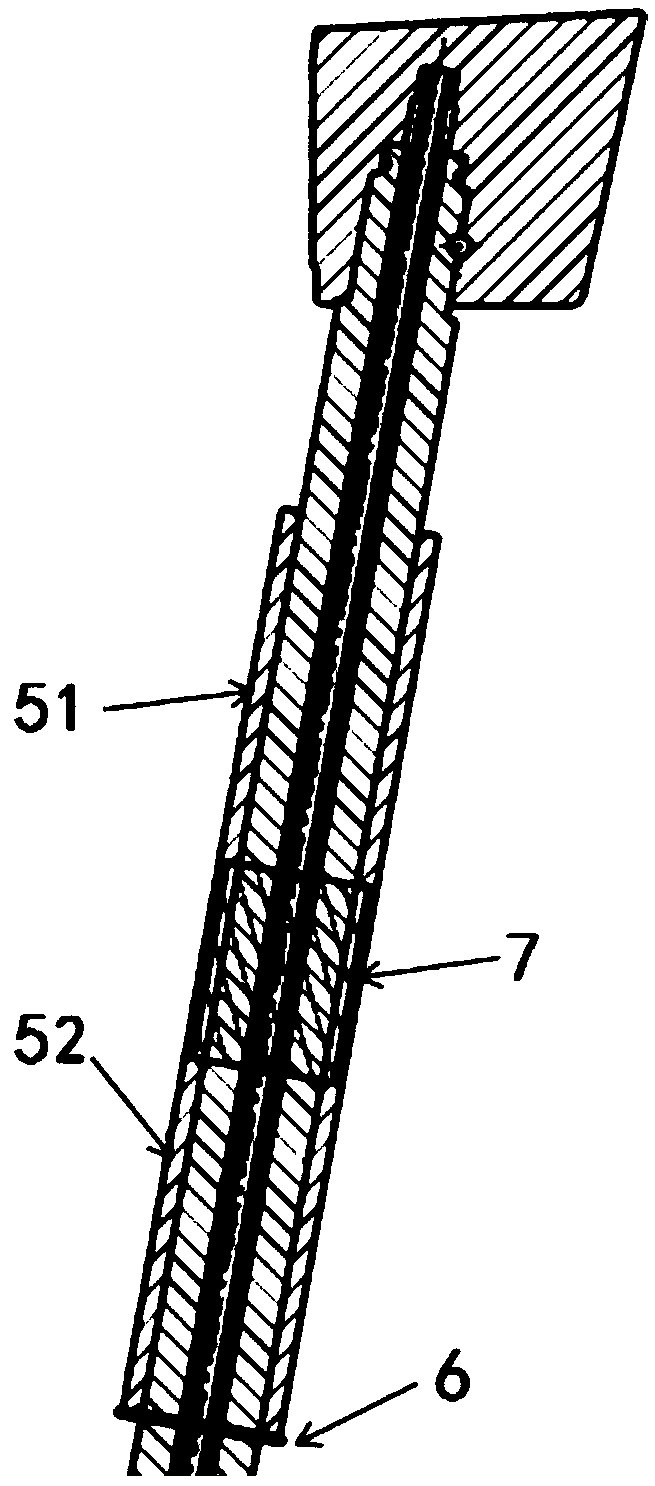

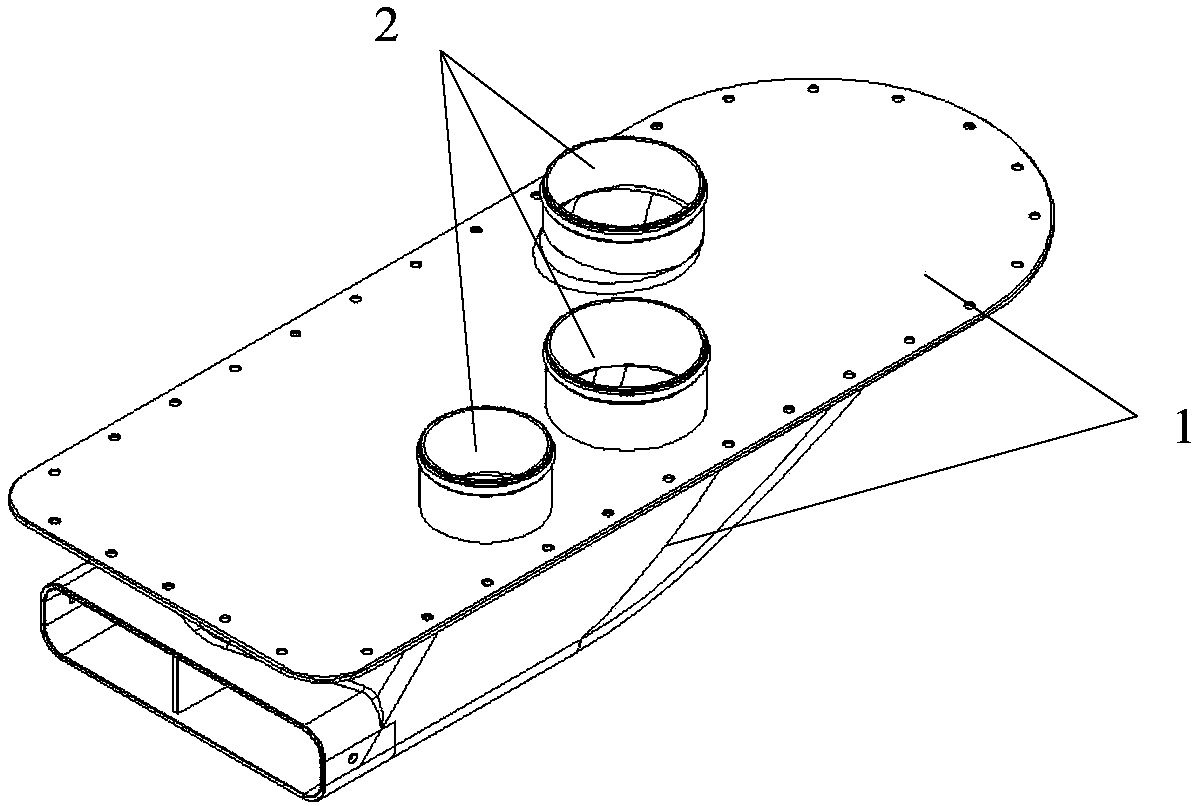

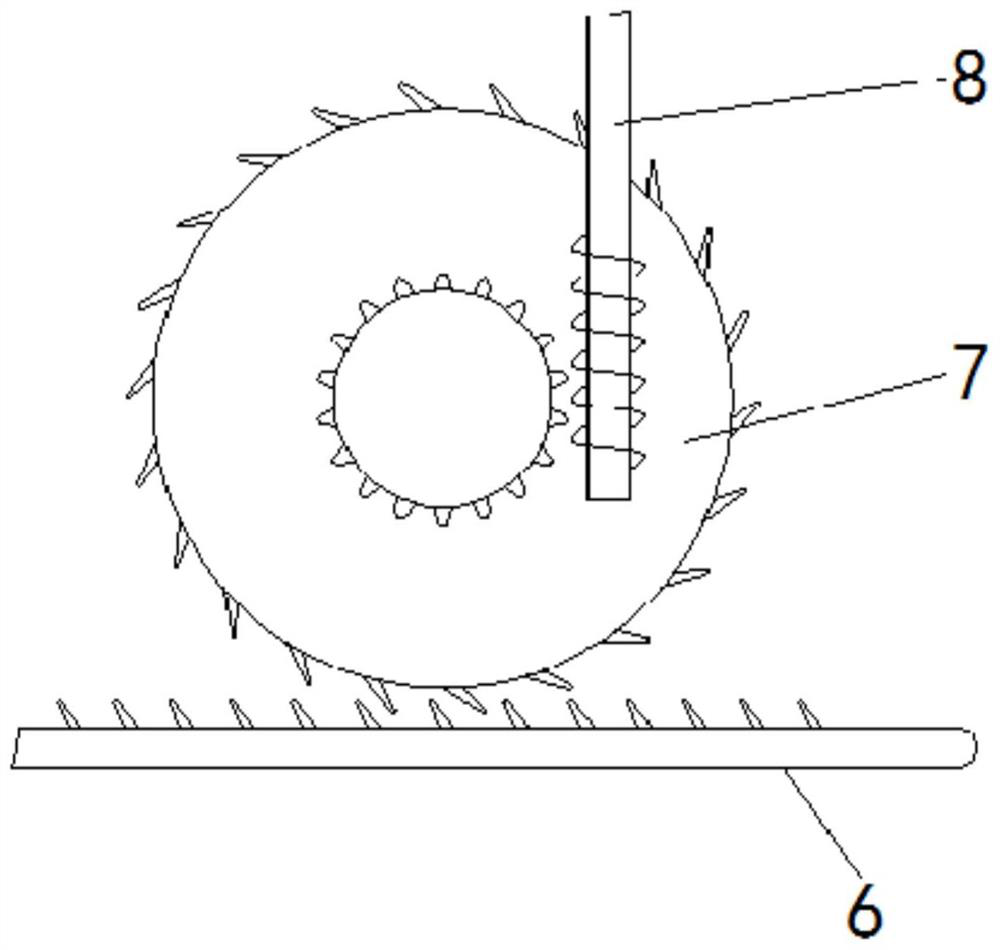

Winding die for molding interior grid stiffened cylindrical shell structure part and using step

InactiveCN106976250ASolve the difficulty of pressurization and demouldingImproved dimensional accuracy and positional accuracyDomestic articlesMesh gridEngineering

The invention relates to a winding die for molding an interior grid stiffened cylindrical shell structure part. The winding die comprises a body die, a core die and an outer die; evenly-arranged T-shaped grooves are formed in the two sides of the body die, the core die and the body die are assembled through T-shaped blocks, the outer die is arranged on the outer side of the core die and used for limiting the appearance of the molded part, end frame flanges facilitating turnup of the molded part are arranged at the two ends of the body die, and sealing heads are arranged on the outer side of the end frame flange. The using steps of the die comprises (1) cleaning and die assembling, (2) reinforcing rib winding, and vacuum bag hitting for pre-compaction; and (3) moving the die to a drying oven for curing, and demolding after curing is carried out. The winding die can be repeatedly used, grid reinforcing ribs of the molded product have the high size accuracy and position accuracy, the product quality consistency is good, and later period assembly of the product is facilitated.

Owner:HENGSHEN

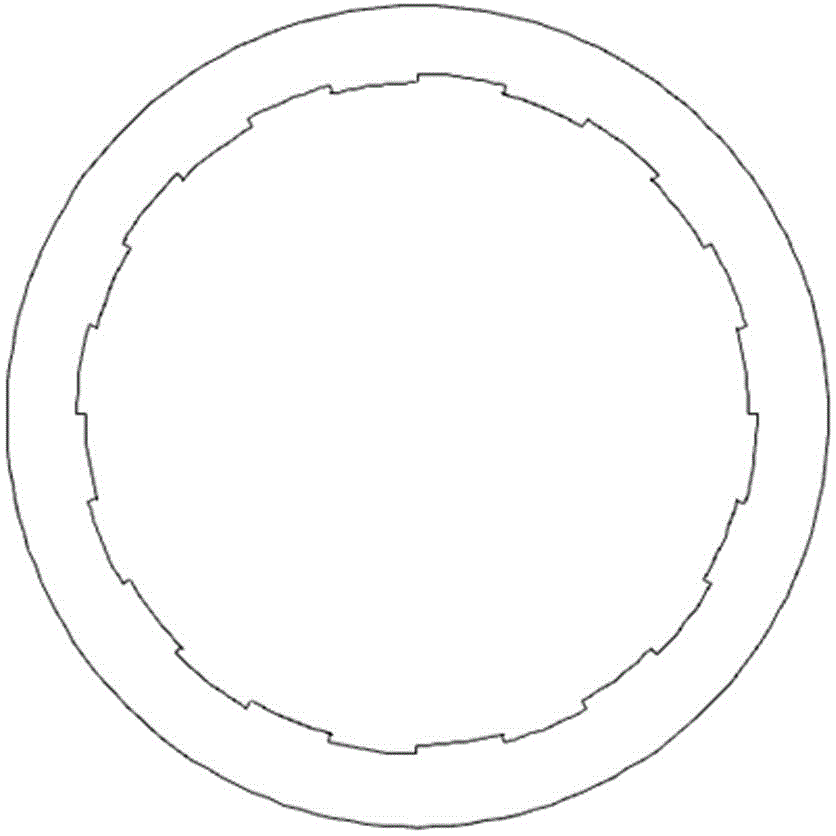

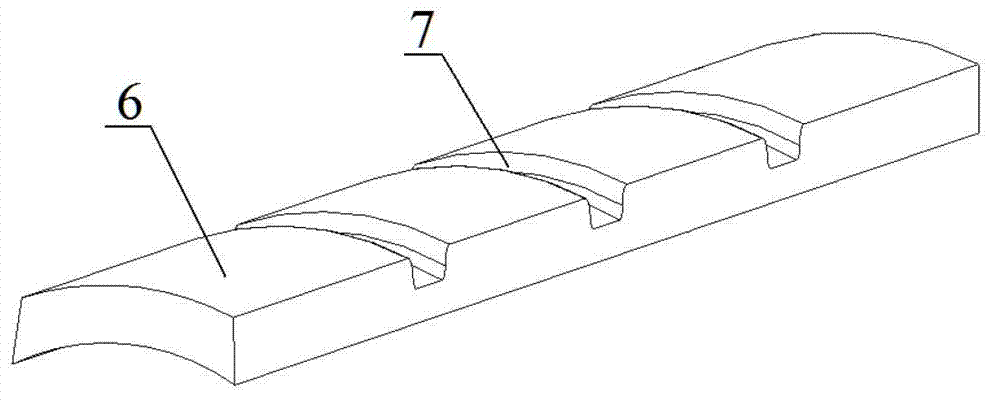

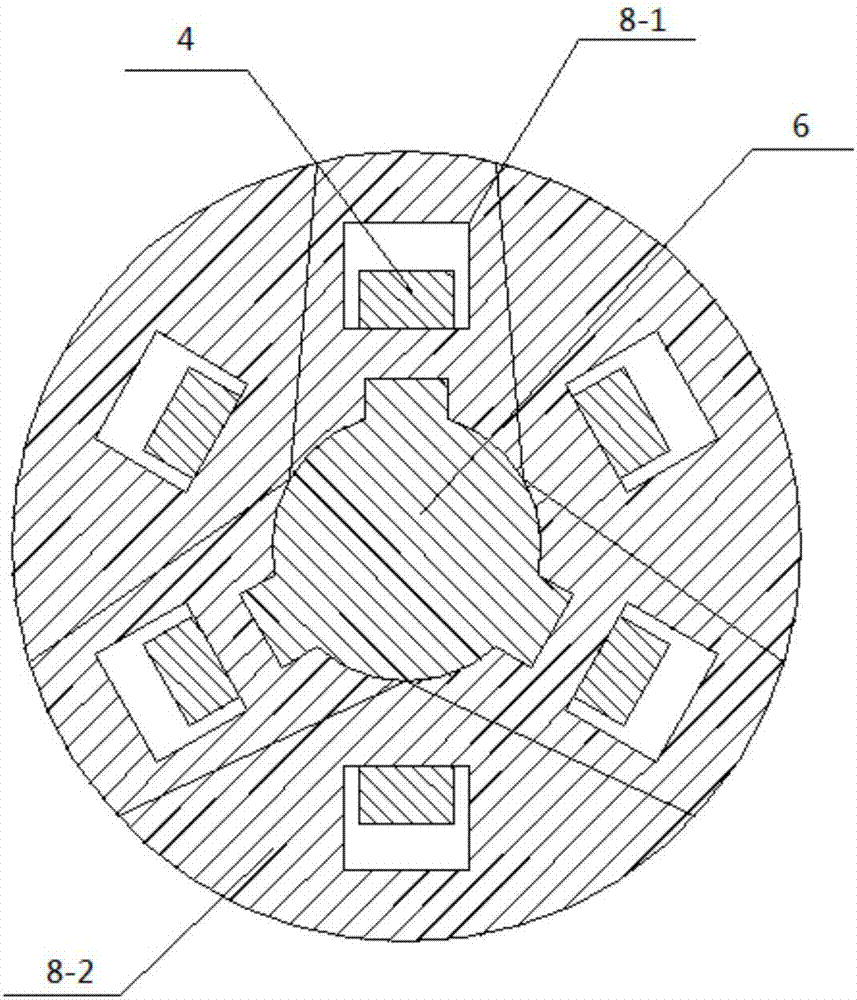

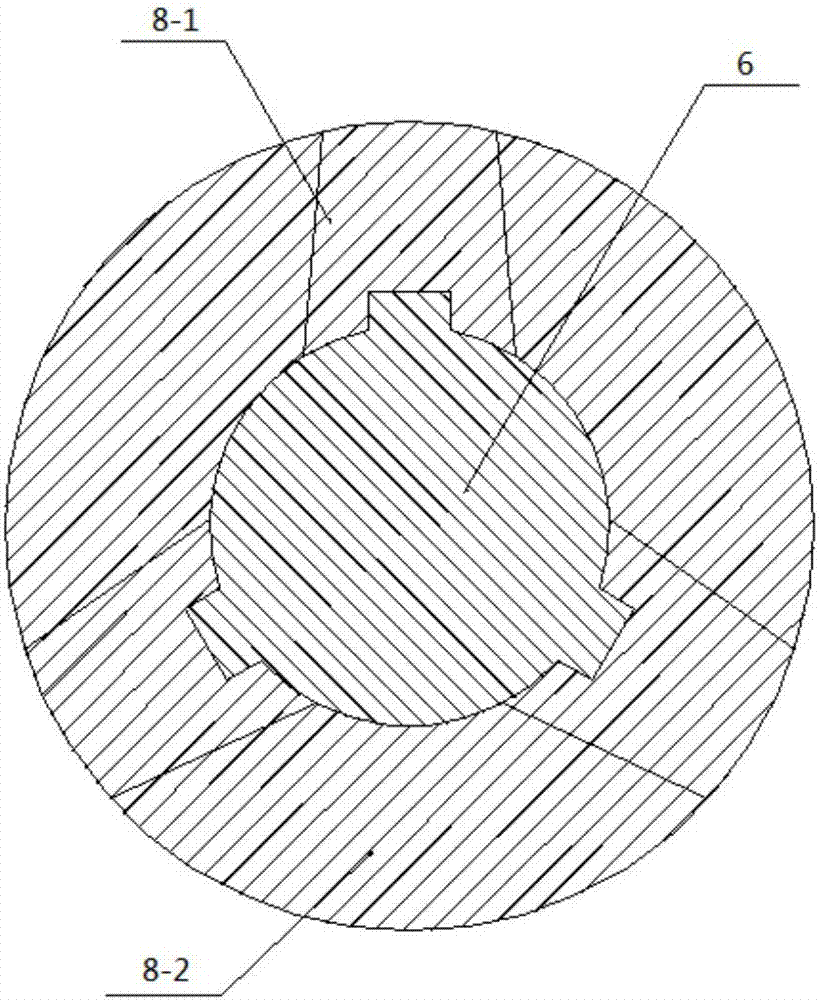

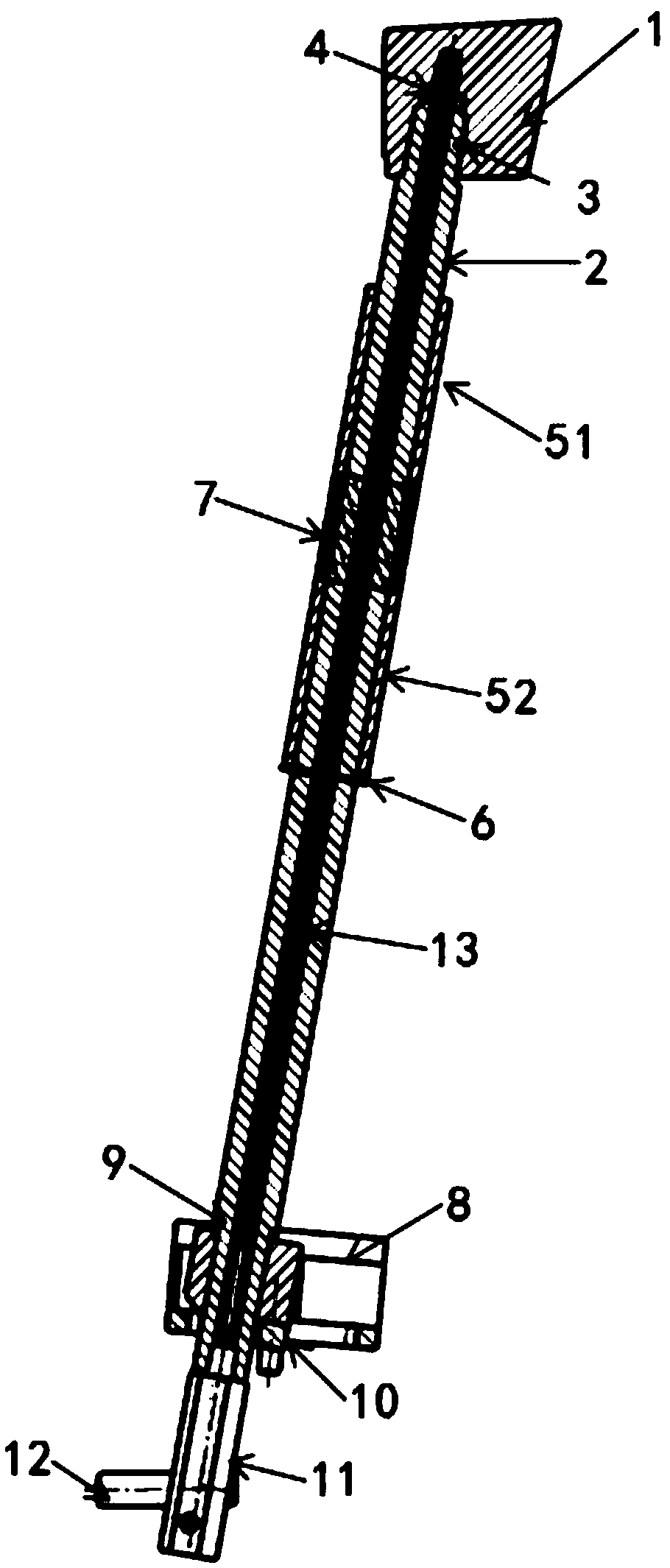

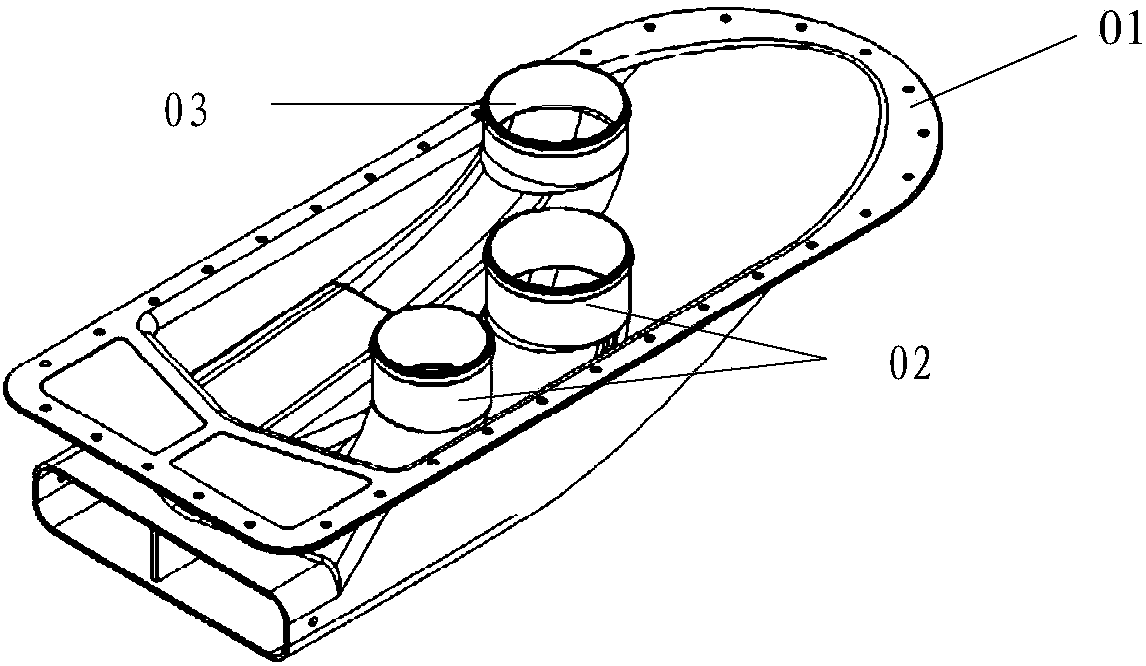

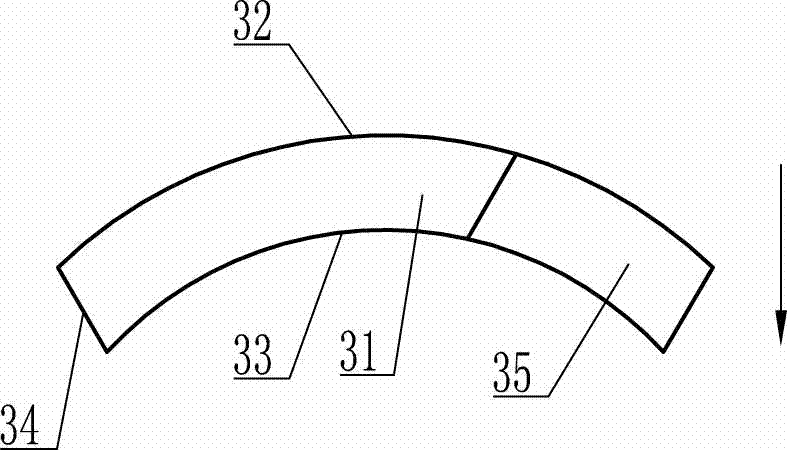

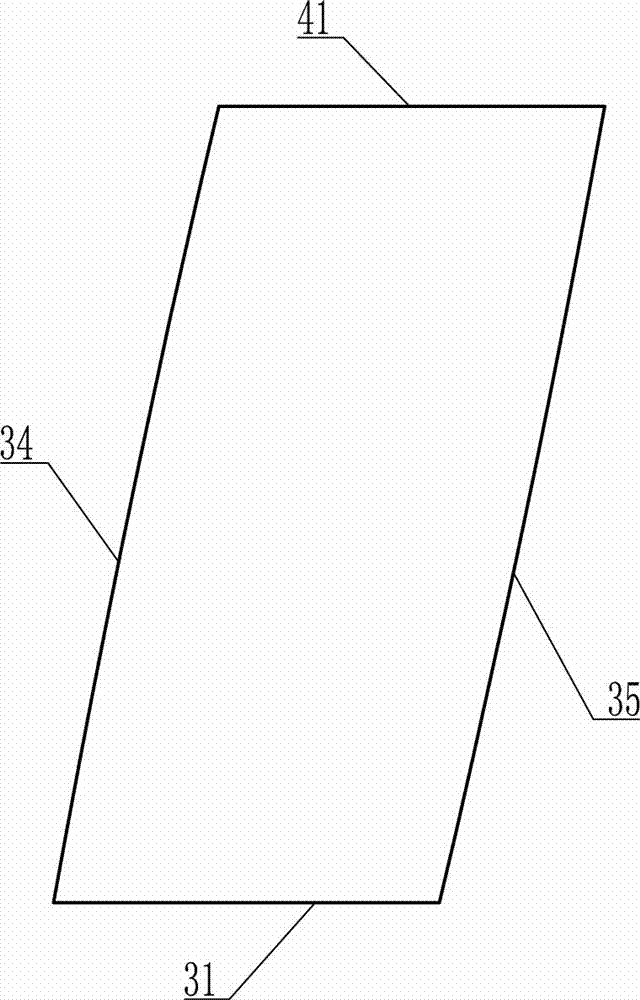

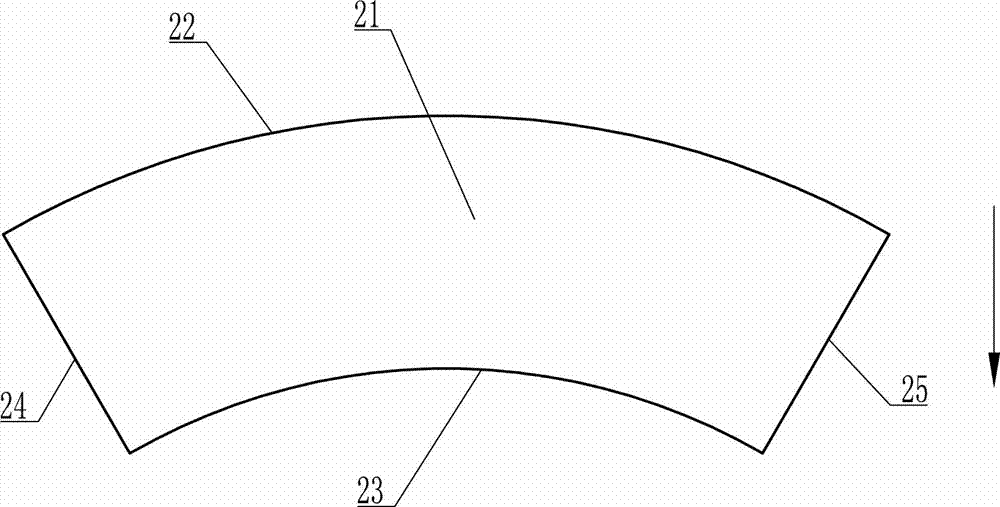

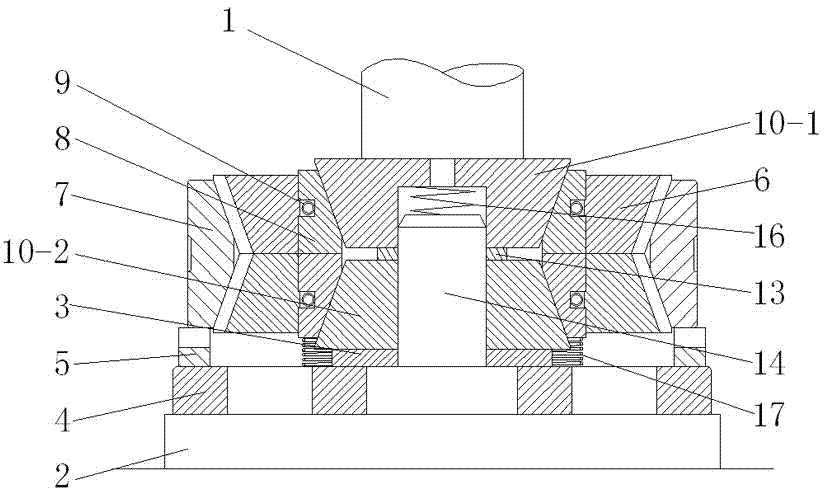

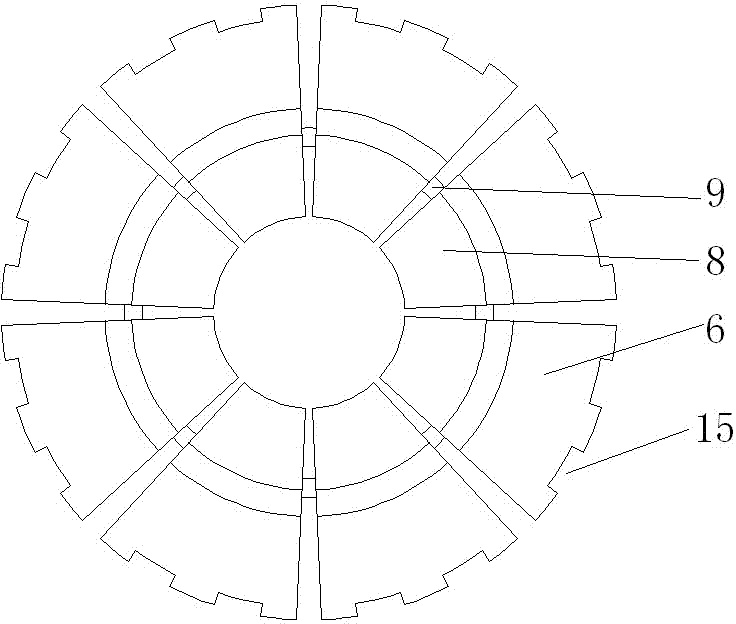

Core mold and shaping method for shaping strip annular internal reinforced rib rotary body thin-wall part

InactiveCN102764841APrevent movementHigh forming precisionForging/hammering/pressing machinesMetallic materialsUltimate tensile strength

The invention relates to a core mold and a shaping method for a shaping strip annular internal reinforced rib rotary body thin-wall part, wherein a base mold is composed of a base mold main body and a mold withdrawing end; a swallow tail groove and a positioning groove are formed on the base mold main body; a shape mold is wholly of an annular structure; the shape mold is uniformly divided into a plurality of split molds of same shapes; shaping arc grooves for annular internal reinforced ribs are formed on the shaping plane of the split molds; swallow tail tenons matched with the wallow tail groove and the positioning groove are formed on the inner surfaces of the split molds. By adopting the mode of combined core mold, the problem of hard demolding during the shaping process of the rotary body thin-wall part internal reinforced rib is solved. By virtue of the positioning on the base mold swallow tail groove, the movement of the shaping mold is prevented effectively; and the shaping precision of the rotary body thin-wall part internal reinforced rib is improved. The base mold, the shaping mold and the fixing pin of the core mold can be made of different metal materials according to respective strength requirements; only the mold needs to be replaced for rotary body thin-wall pieces of which the inner diameters are the same and the internal reinforcing ribs are different, so that the cost of the mold is reduced greatly.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Formula of chlorinated polythylene rubber pipe

The invention relates to a formulation of a haloflex hose. The components and the weight fraction are 100 parts of aloflex, 20-30 parts of fast extrusion carbon soot, 50-70 parts of pot clay, 25-35 parts of trioctyl trimellitate, 10-15 parts of magnesium oxide, 2-4 parts of fatty acid amide, 2-4 parts of dimercapto thiazole, and 1-3 parts of zinc fatty acid ester. Compared with the traditional products, the formulation has obviously effect of the maximum elongation of vulcanized rubber 450%; tearing strength 55KN / m, and 100 modulus 4.5Mpa. The formulation using thiadiazole vulcanizing system and high efficiency flow promotor is used for procuding the haloflex hose, has high maximum elongation and tearing strength, can solve the problem of difficult die-removing of the product; the product percent of pass is more than 95%.

Owner:TIANJIN PENGYI GRP CO LTD

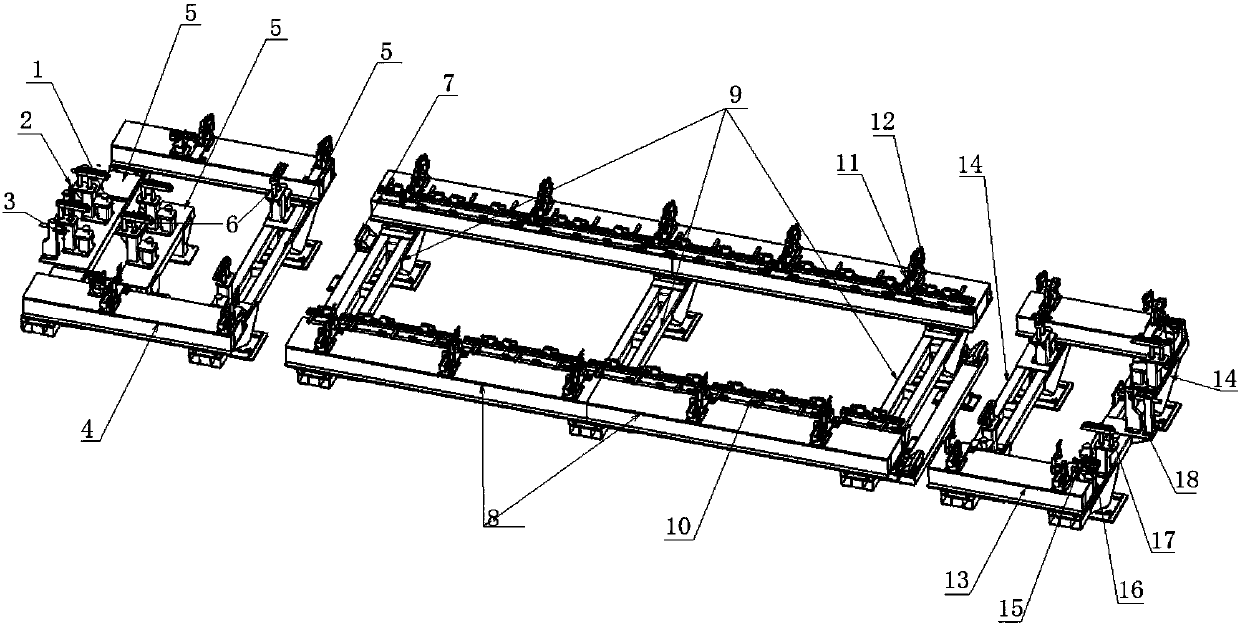

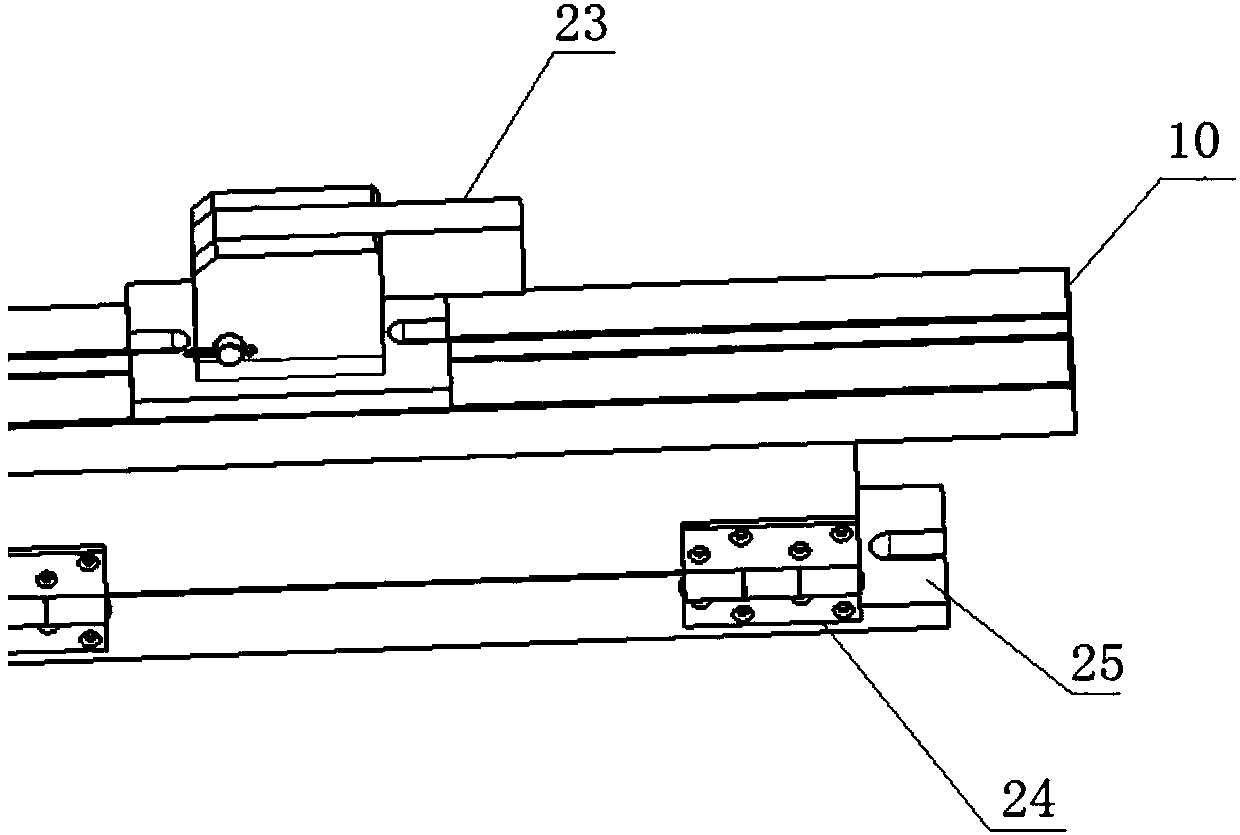

Welding tool for monorail vehicle chassis assembly

ActiveCN107790948AImprove general performanceStrong specificityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringChassis

The invention provides a welding tool for a monorail vehicle chassis assembly. The tool comprises a one-dimensional end welding frame, a middle portion welding frame and a two-dimensional end weldingframe. The one-dimensional end welding frame comprises a bottom surface supporting frame, a longitudinal beam, cross beams, a one-dimensional end limiting block and a center stay wire device, and theone-dimensional end limiting block and the center stay wire device are arranged on the cross beam at the forefront end. The middle portion welding frame comprises a bottom surface supporting frame, longitudinal beams, cross beams and a vehicle body side supporting limiting block, and the vehicle body side supporting limiting block is fixed to the bottom surface supporting frame and located on theside, close to the one-dimensional end welding frame, of the vehicle body side supporting limiting block; the longitudinal beams are provided with T-shaped groove guide rails, side beam limiting blocks and side beam pressing devices, and cross beam limiting blocks are arranged on the T-shaped groove guide rails. The two-dimensional end welding frame comprises a bottom surface supporting frame, a longitudinal beam, cross beams, a side beam side limiting block and a two-dimensional end limiting block, and the two-dimensional end limiting block is arranged on the cross beam at the tail end. The tool can be smoothly and easily demolded, and the requirements for forward installing positioning and reverse installing positioning can be simultaneously met.

Owner:南京雷尔伟新技术股份有限公司

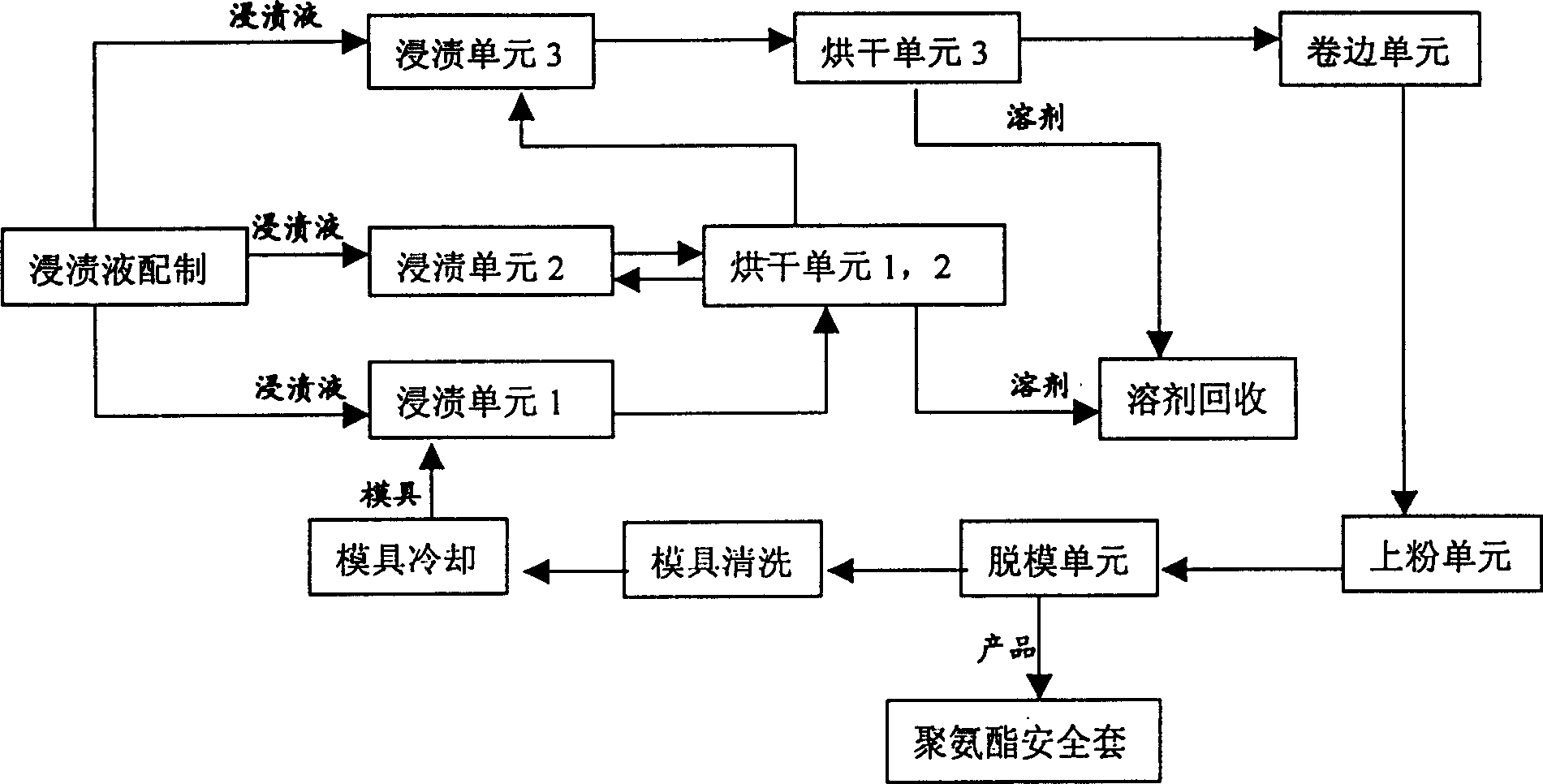

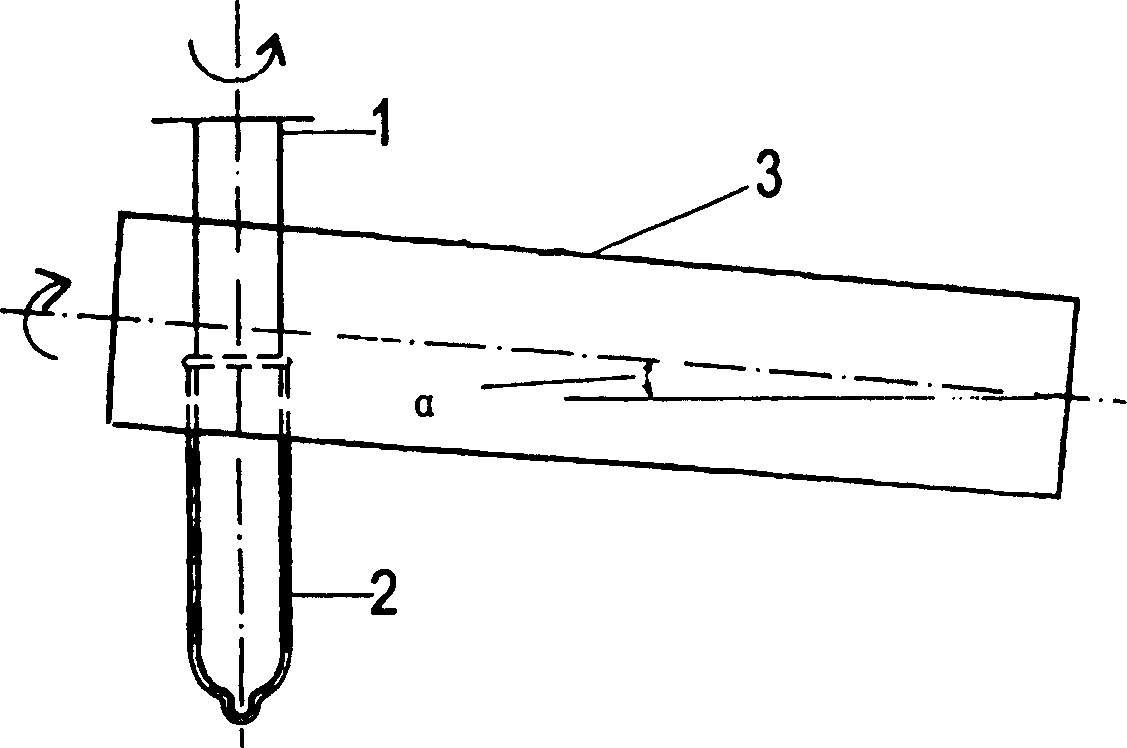

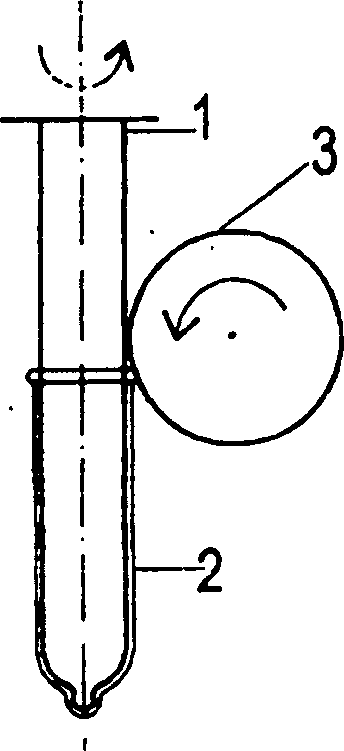

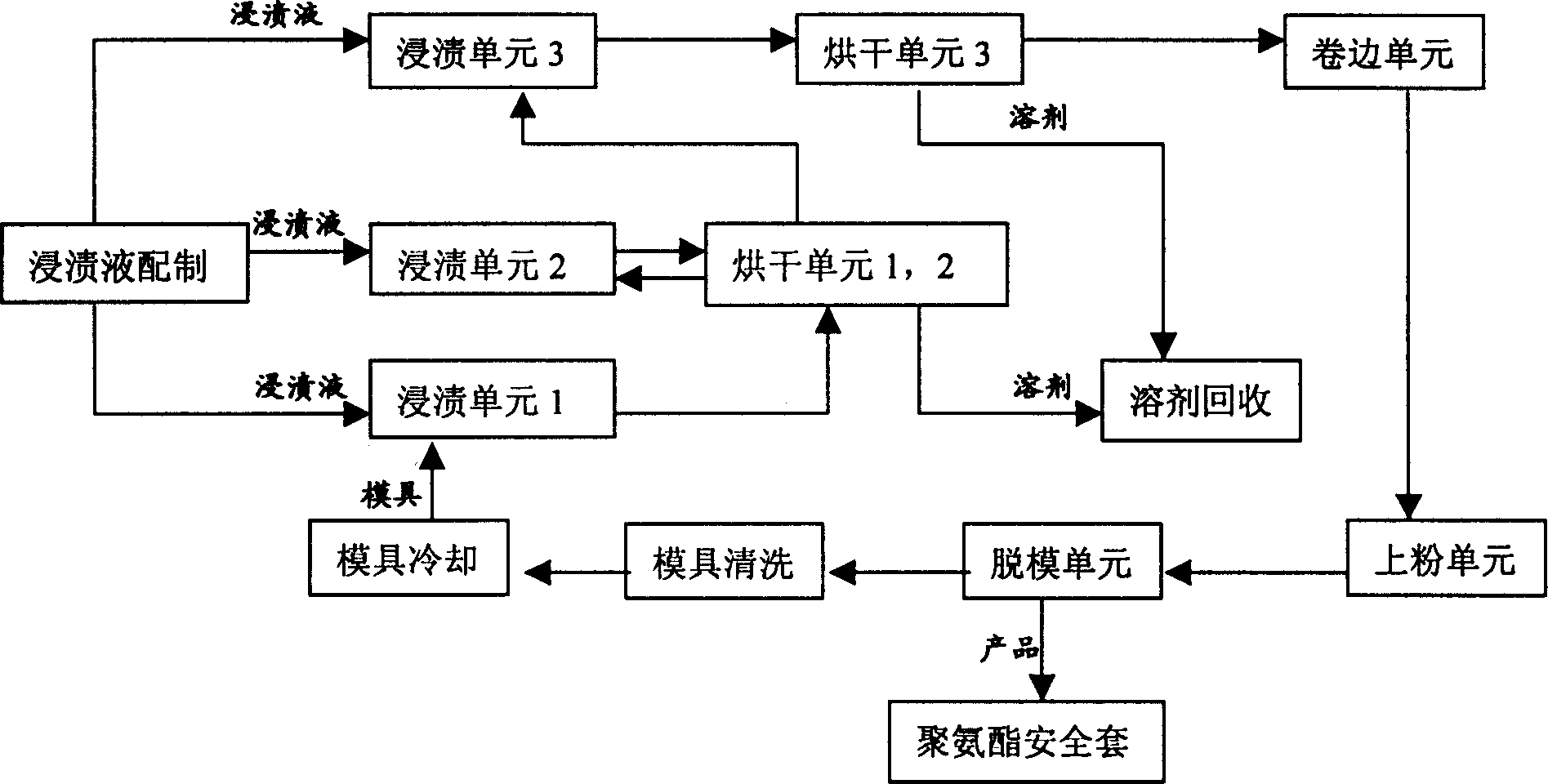

Polyurethane condom producing process

The polyurethane condom producing process includes dissolving polyurethane grains in organic solvent, filtering, soaking mold after being treated specially in the solution to form, drying, rolling hem, powdering, demolding and other steps. The polyurethane condom product has excellent performance and the process is complete, easy to roll hem and demold and high in production efficiency.

Owner:SICHUAN BOAO BIOLOGICAL MATERIAL

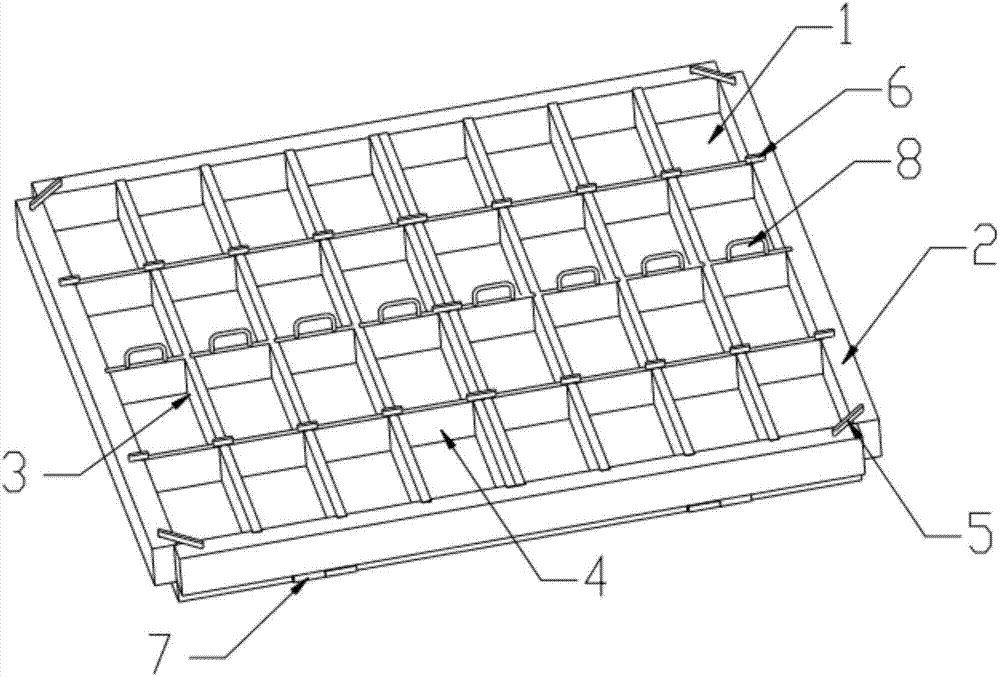

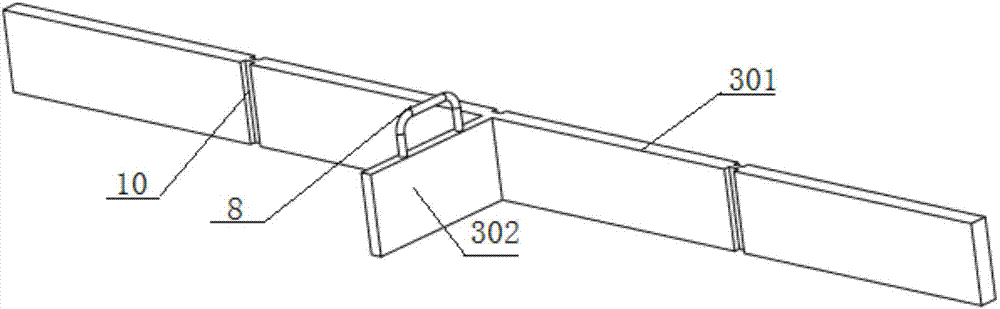

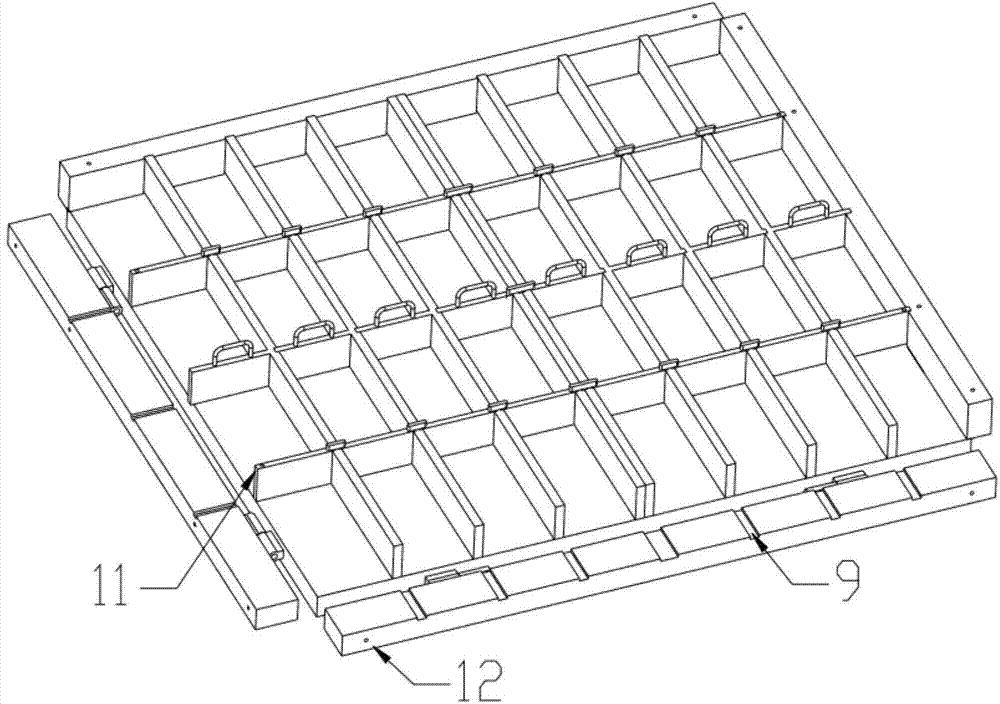

Combined multi-cavity forming die of expansion type foaming brick

InactiveCN104742230ASolve usabilitySolve the problem of difficult demouldingMould auxillary partsBrickVertical plane

The invention provides a combined multi-cavity forming die of an expansion type foaming brick. The combined multi-cavity forming die comprises a die bottom plate, a plurality of die side plates, a plurality of long partition die plates and a plurality of short partition die plates. The die side plates are connected with the side edges of the die bottom plate. The die side plates can rotate around the side edges of the die bottom plate in a vertical plane and can be fixed in a vertical state. The parallel long partition die plates are distributed on the die bottom plate and are perpendicular to the short partition die plates. A plurality of single die bodies are formed by the die bottom plate, the die side plates, the long partition die plates and the short partition die plates. By means of the combined design of the single die bodies formed by the die bottom plate, the die side plates, the long partition die plates and the short partition die plates and a mechanical structure, the problem that due to a release agent cannot be used, demoulding is difficult in the expansion type foaming brick demoulding process is solved, the single piece production period is shortened, and the production efficiency is improved.

Owner:JIANGSU UNIV

Aluminum alloy hub powerful spinning machining molding method and demolding mechanism

The invention discloses an aluminum alloy hub powerful spinning machining molding method and a demolding mechanism. The demolding mechanism comprises a core mold structure which comprises an inner core mold and an outer core mold connected to the exterior of the inner core mold in a sleeving manner, and the demolding mechanism further comprises a suppressing block and a limiting stretching mechanism, wherein the suppressing block and the outer core mold which is stressed to move in the radial direction are fixedly locked, and the limiting stretching mechanism is used for pushing the core mold structure to move and driving the outer core mold to separate from the suppressing block. The machining molding method comprises the steps that a plate is jacked to the core mold structure through a tail jacking part to be fixed, the inner core mold is extruded, and the outer core mold is stressed to move in the radial direction to be matched and locked with the suppressing block; the core mold structure is rotated to drive the tail jacking device and the plate to rotate; and hub molding is carried out through a multi-wheel spinning process. By means of the aluminum alloy hub powerful spinning machining molding method and the demolding mechanism, the problem that demolding is difficult after complex section hub spinning molding is solved, the demolding principle is simple, and universality is high.

Owner:DORCEN AUTO CO LTD

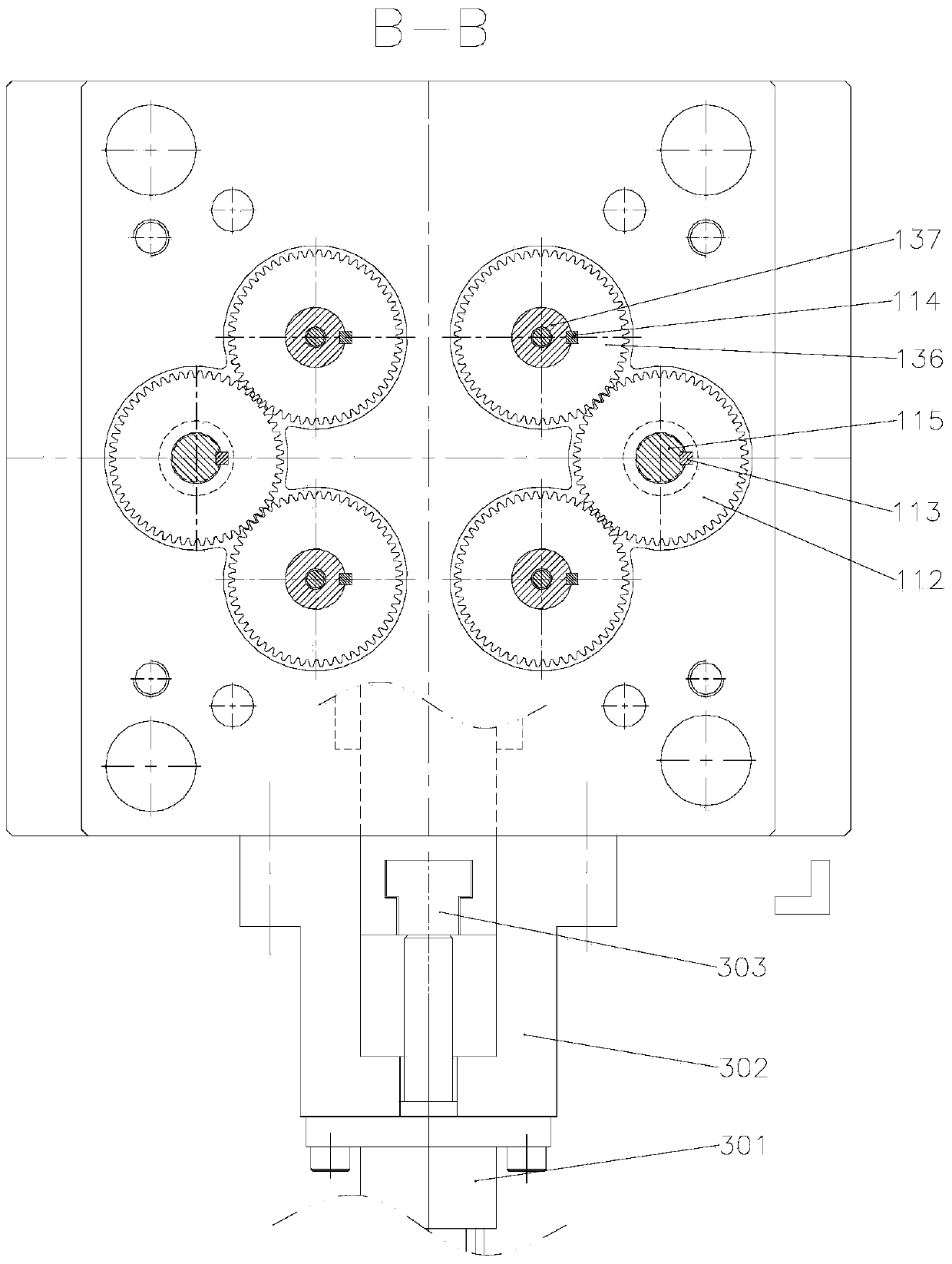

Plastic worm injection forming mold

InactiveCN103692619ASolve the difficulty of demouldingThe overall thickness is thinHot runnerManipulator

The invention provides a plastic worm injection forming mold. The worm injection forming mold comprises a stationary mold part and a movable mold part, wherein the stationary mold part comprises a demolding assembly consisting of a transmission mechanism and a sliding device; a stationary mold cavity of the stationary mold party, a worm cavity of the movable mold part, a movable mold cavity, and a movable mold insert are sequentially and tightly coupled to form a plastic worm cavity; an injection molding machine injects molten plastic in the worm cavity of the plastic worm mold through a hot runner system; the molten plastic is cooled and shaped to obtain the solid plastic worm. When demolding is performed, a hydraulic motor arranged in the injection molding machine and an oil cylinder arranged in the movable mold part drive the demolding assembly to separate the worm cavity and the molding insert from the plastic worm, and then the plastic worm can be taken down manually or by a manipulator. The mold is simple in structure, thin in the mold thickness, and capable of being mounted on a small precision injection molding machine to produce products. The product is excellent in various performances, high in precision, stable in size, short in production cycle and low in cost.

Owner:SHENZHEN HISYM IND

Polyurethane condom producing process

The polyurethane condom producing process includes dissolving polyurethane grains in organic solvent, filtering, soaking mold after being treated specially in the solution to form, drying, rolling hem, powdering, demolding and other steps. The polyurethane condom product has excellent performance and the process is complete, easy to roll hem and demold and high in production efficiency.

Owner:SICHUAN BOAO BIOLOGICAL MATERIAL

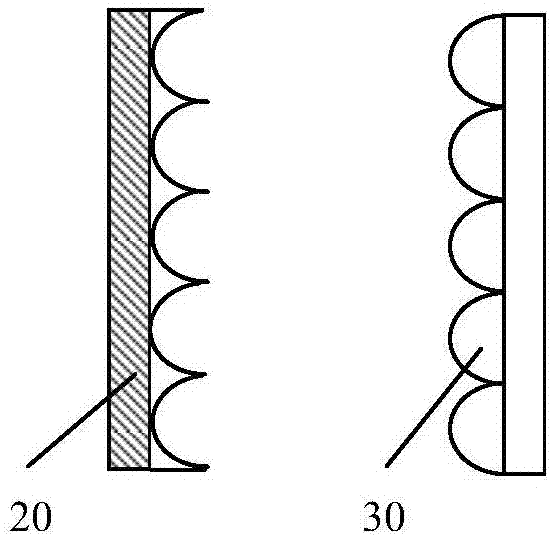

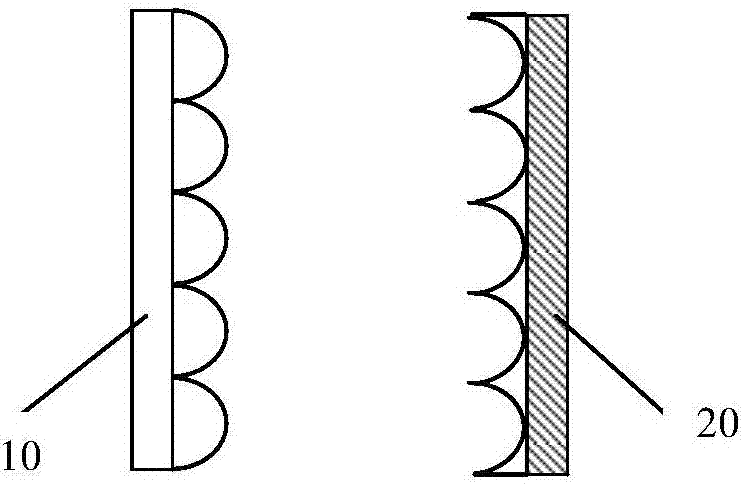

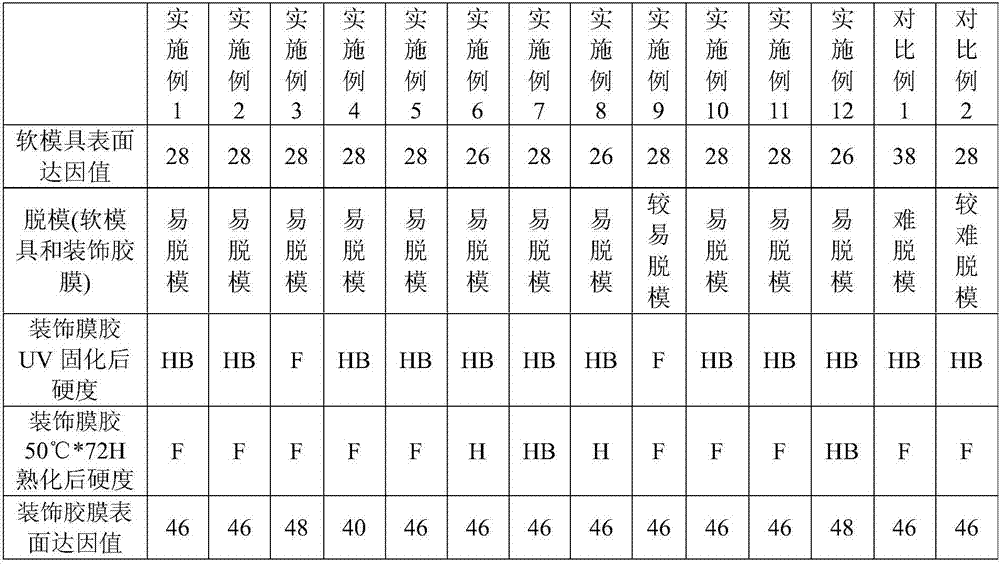

UV (Ultraviolet) cured glue composition, soft mold and transfer printing method

ActiveCN106867442ASolve the difficulty of demouldingEasy to break awayDuplicating/marking methodsPolyureas/polyurethane adhesivesOligomerUltraviolet

The invention provides a UV (Ultraviolet) cured glue composition, a soft mold and a transfer printing method. In parts by weight, the UV cured glue composition is prepared from 15 to 35 parts of polyurethane acrylate oligomer, 5 to 20 parts of silicon modified resin, 30 to 50 parts of first monomer and 2 to 8 parts of first photoinitiator. The UV cured glue composition contains the polyurethane acrylate oligomer and the silicon modified resin with the use levels, and therefore, is cured under UV irradiation, so that the surface dyne value of the UV cured glue composition is enabled to be controllable; when the UV cured glue composition is used as the soft mold, a difference between the surface dyne value of the UV cured glue composition and the surface dyne value of a decorative film formed through solidification is controlled to be larger; thus, the purpose that the UV cured glue composition and the decorative film are easily separated can be realized; further, the problem that the soft mold is difficultly demolded is solved.

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

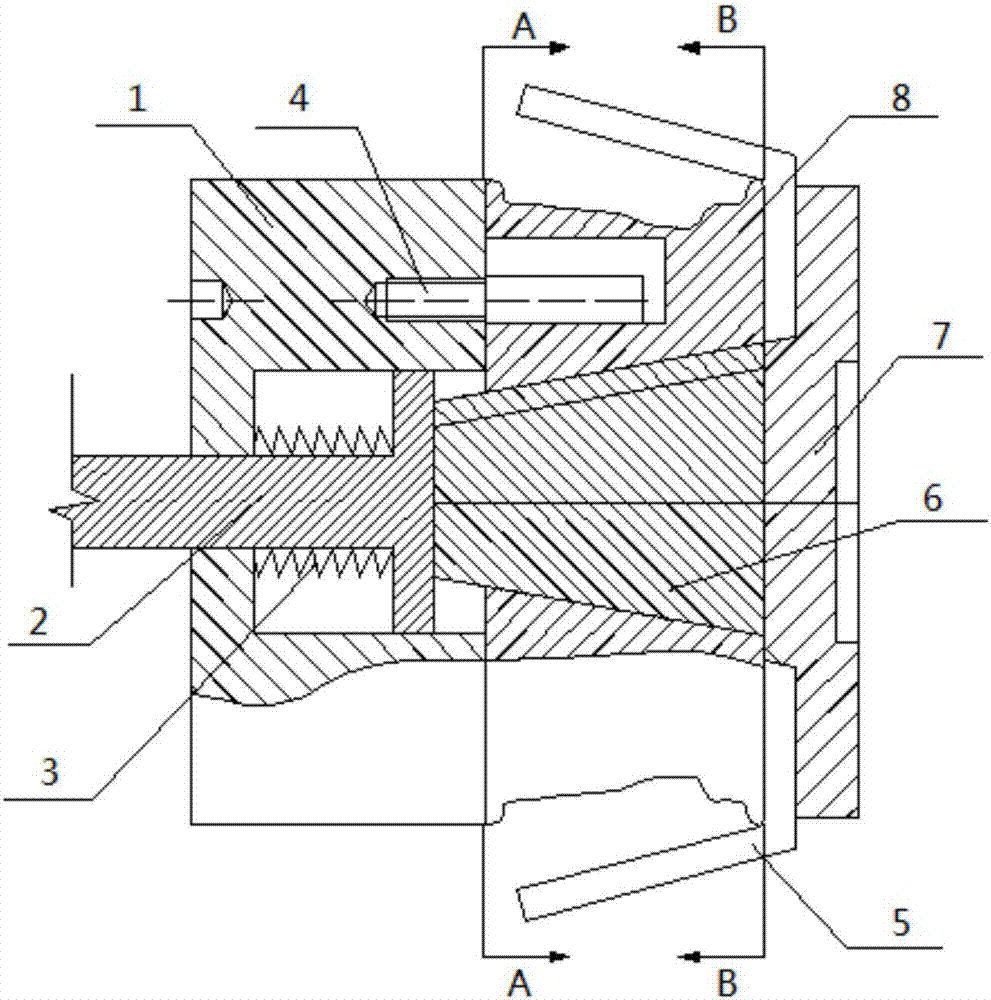

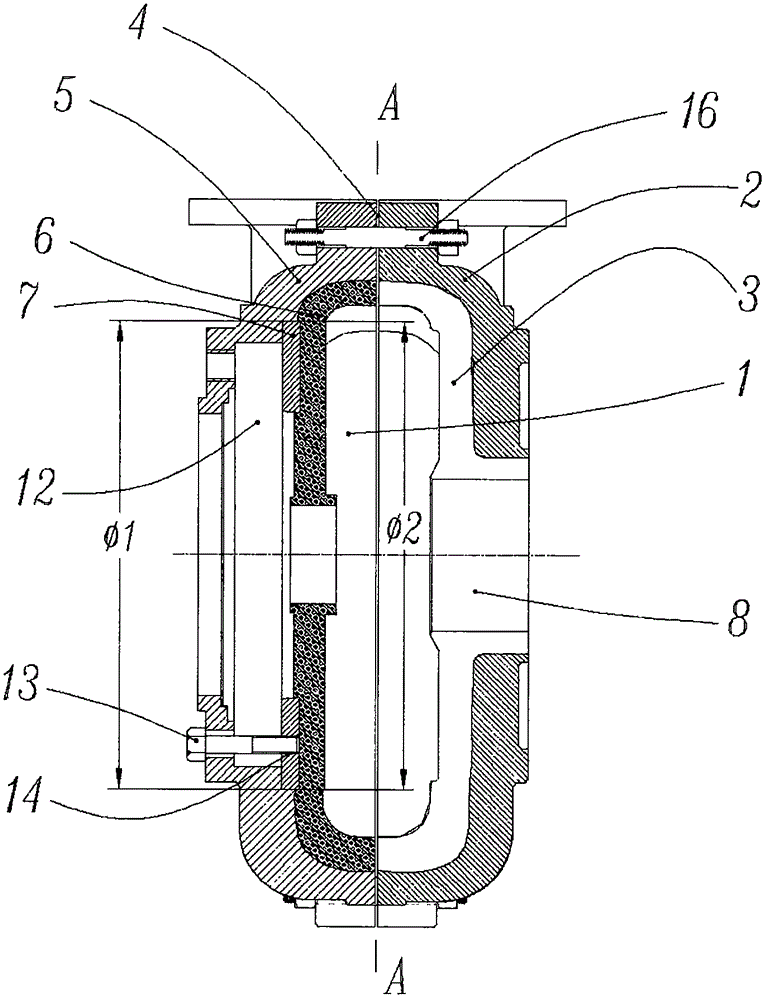

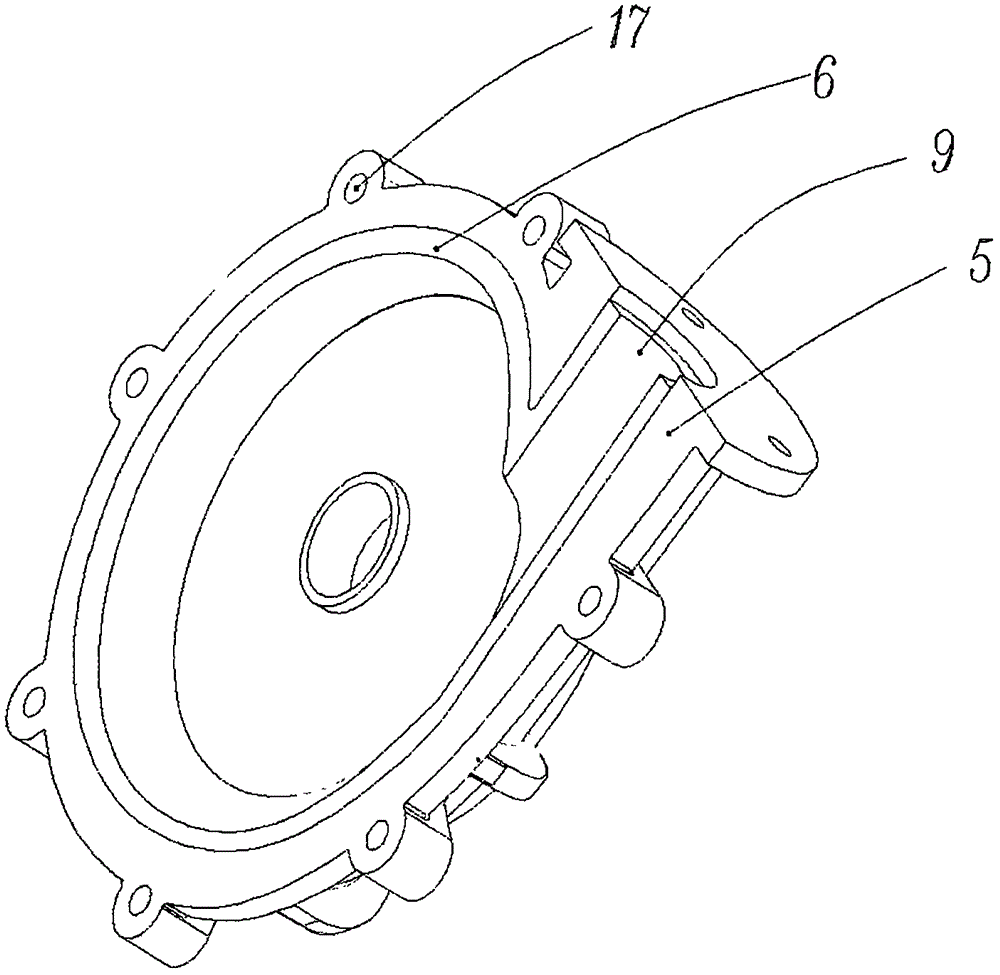

Wear pump

InactiveCN105201914AImprove wear resistanceSolve the difficulty of demouldingPump componentsPumpsWear resistantMechanical engineering

A wear pump comprises a pumping chamber, a suction inlet formed in the axis of a spindle, and a discharge opening led out from the pumping chamber. The wear pump is characterized in that a pump body is divided into two parts by an A-A plane which is perpendicular to the axis of the spindle and passes through the discharging opening the pumping chamber, the suction inlet, a front liner and a front shell are arranged at the same side of the A-A plane, and a rear liner and a rear shell are arranged at the other side of the A-A plane; the front liner and the rear liner are mainly made of a composite wear-resistant material, and the front shell and the rear shell are made of metal; a hole fai 1 coaxial with the spindle is formed in the rear shell, a shaft fai 2 coaxial with the spindle is arranged on the rear liner, and the fai 1 is matched with the fai 2.

Owner:肖琼

Mold angle ejector rod structure capable of adding cooling water

The invention discloses a mold angle ejector rod structure capable of adding cooling water, and belongs to the field of automobile injection molds. The mold angle ejector rod structure comprises an angle ejector block, an inclined ejector rod, an angle ejector sliding seat and an angle ejector change-over block, wherein the angle ejector block is connected with the head part of the hollow; the tail part of the inclined ejector rod is connected with the angle ejector sliding seat; the angle ejector sliding seat is capable of adjusting the relative height between the angle ejector sliding seat and the angle ejector rod through an O-shaped cushion block and is in clamping connection with the angle ejector rod through a U-shaped clamping block; the angle ejector rod is sequentially provided with a first self-lubricating copper guide sleeve, a hollow aluminum pipe and a second self-lubricating copper guide sleeve; an annular pipe is arranged in a cavity in the angle ejector rod along a longitudinal direction; the tail part of the angle ejector rod is connected with the angle ejector change-over block; the angle ejector change-over block is provided with a water pipe joint; the tail partof the annular pipe is communicated with the water pipe joint through the angle ejector change-over block; the head part of the annular pipe stretches out of the angle ejector rod. According to the mold angle ejector rod structure disclosed by the invention, addition of the cooling water to a single-rod angle ejector rod structure of a precision mold is realized, and meanwhile, an occlusion action process of an angle ejector rod can be avoided.

Owner:CHANGZHOU XINGYU AUTOMOTIVE LIGHTING SYST CO LTD

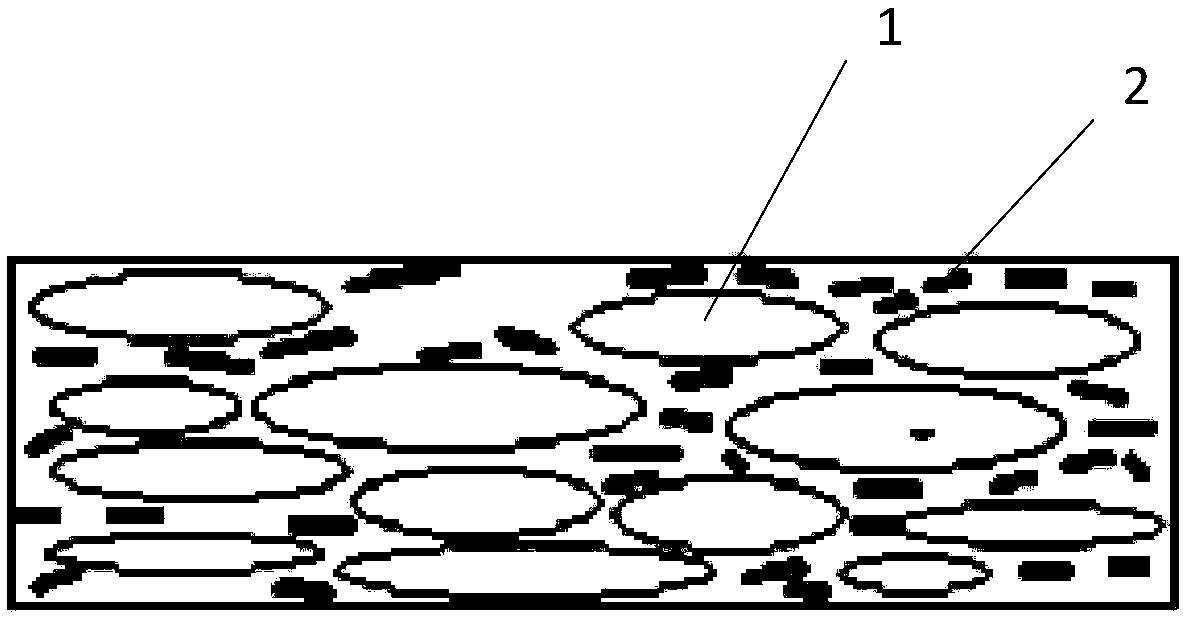

Method for preparing SiC3D/Al composite through vacuum pressure infiltration positive-pressure method

The invention discloses a method for preparing a SiC3D / Al composite through a vacuum pressure infiltration positive-pressure method for the first time. The method comprises the steps that soluble ceramic is adopted as a mold material to prepare a soluble ceramic mold, then, a three-dimensional continuous porous SiC perform is placed in the soluble ceramic mold, the soluble ceramic mold, to-be-infiltrated Al or an to-be-infiltrated alloy are placed in a crucible to be heated, subjected to heat preservation and cooled, in the preparation process, molten liquid Al is infiltrated into pores of theSiC preform under the action of external gas pressure and then subjected to cooling solidification at certain pressure, and finally the corresponding SiC3D / Al composite is formed. According to the method, the problems of difficult stripping of an existing graphite or alloy steel mold and excessively-high machining cost after the SiC3D / Al composite is prepared are solved, and thus the production cost of the SiC3D / Al composite is greatly lowered.

Owner:DONGGUAN UNIV OF TECH

Mutual-nested topology pipeline type structure and overall forming method

ActiveCN108481767AGuaranteed integritySolve molding problemsBranching pipesTubular articlesEngineeringUltimate tensile strength

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

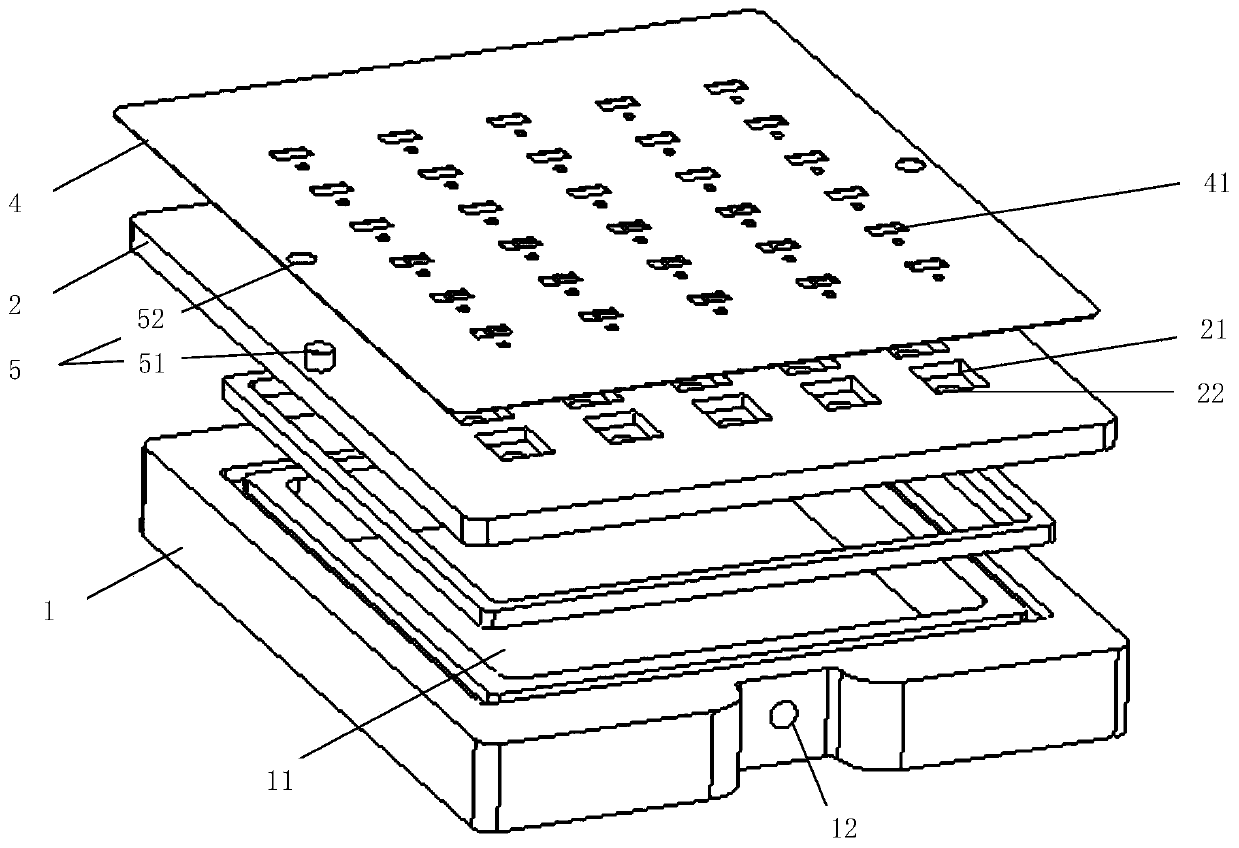

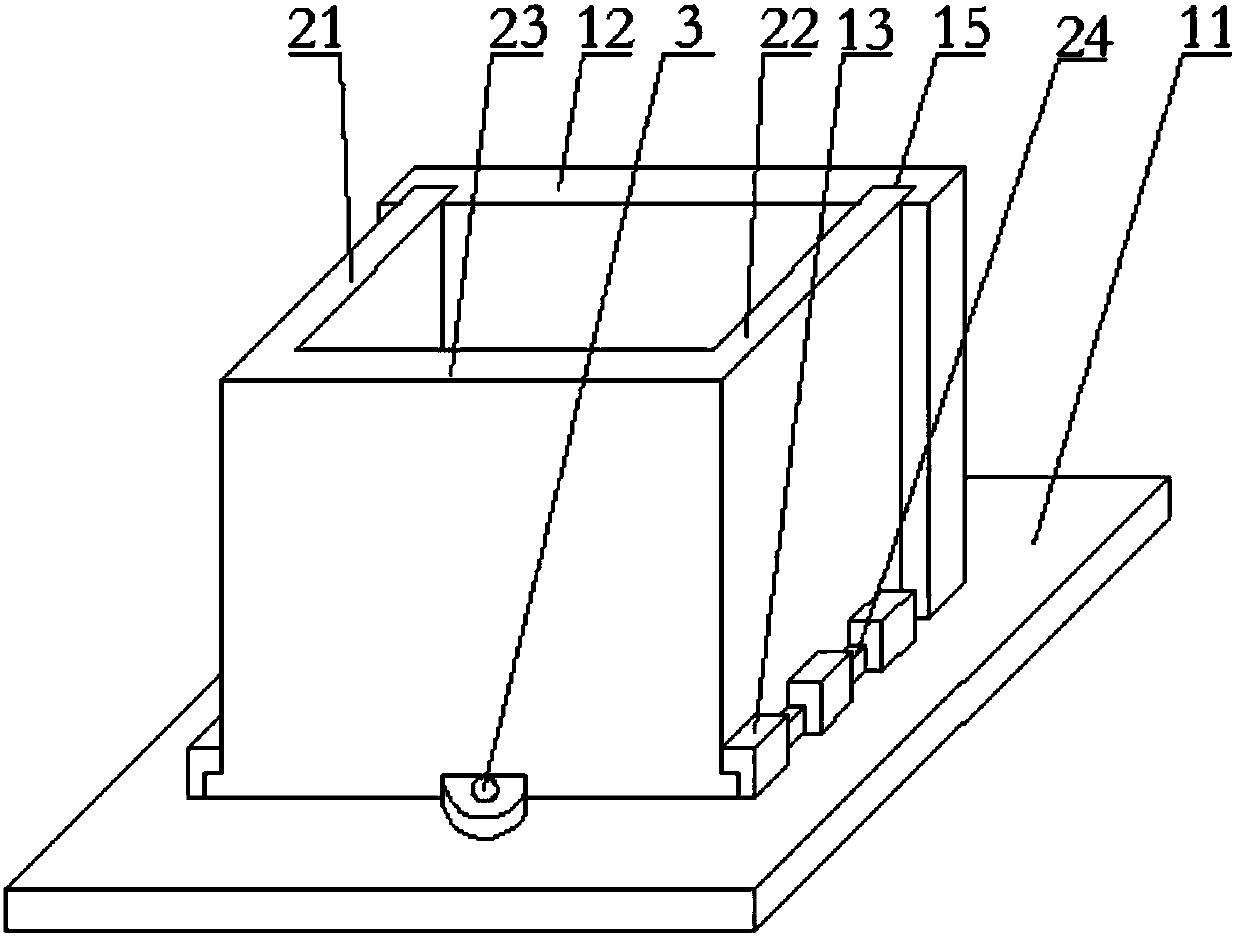

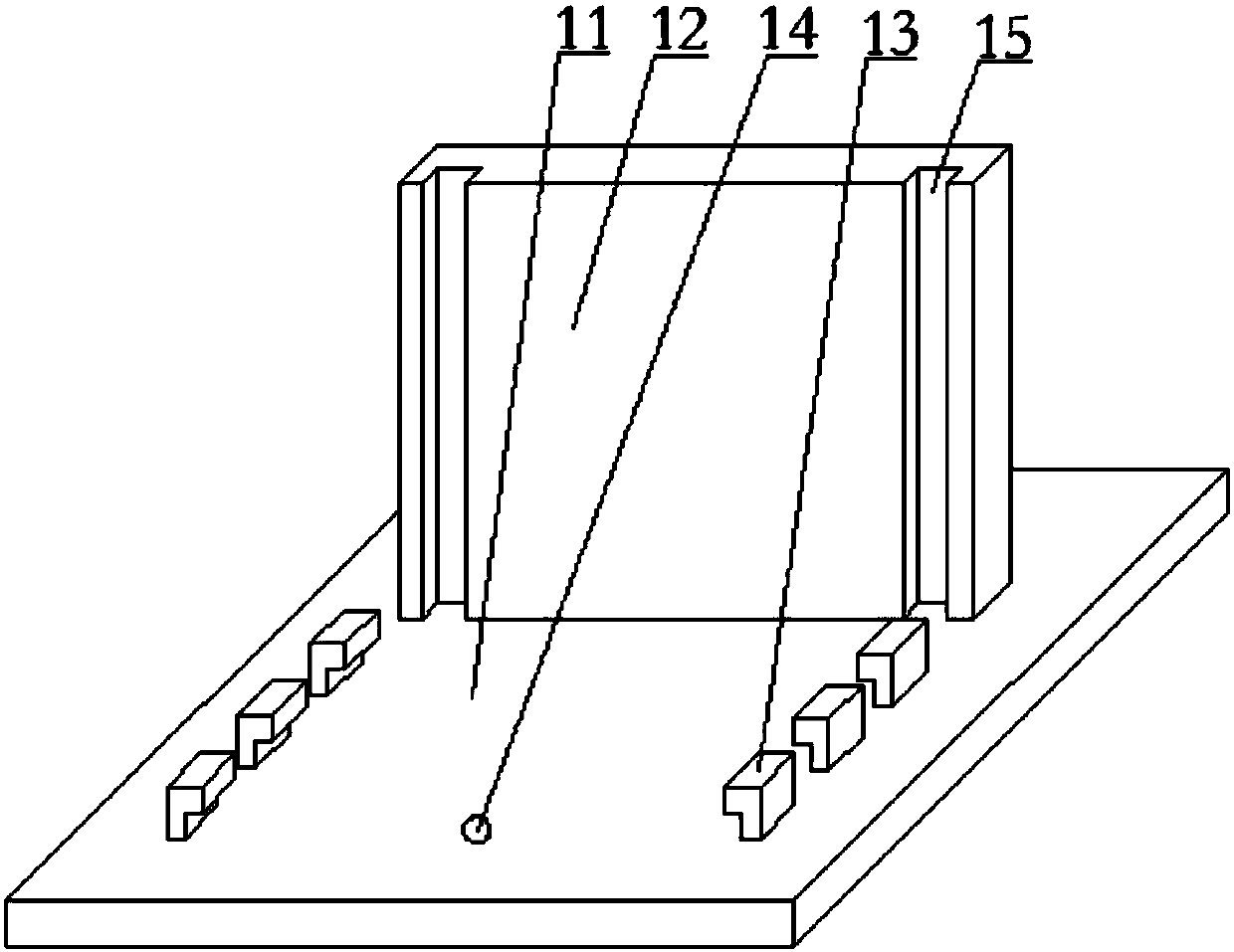

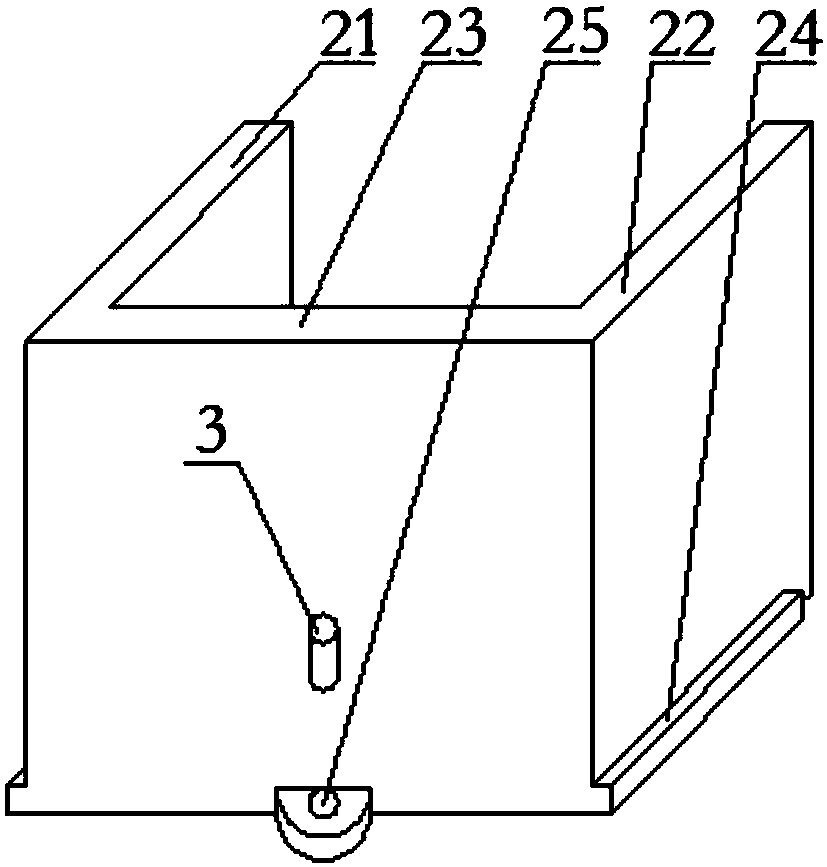

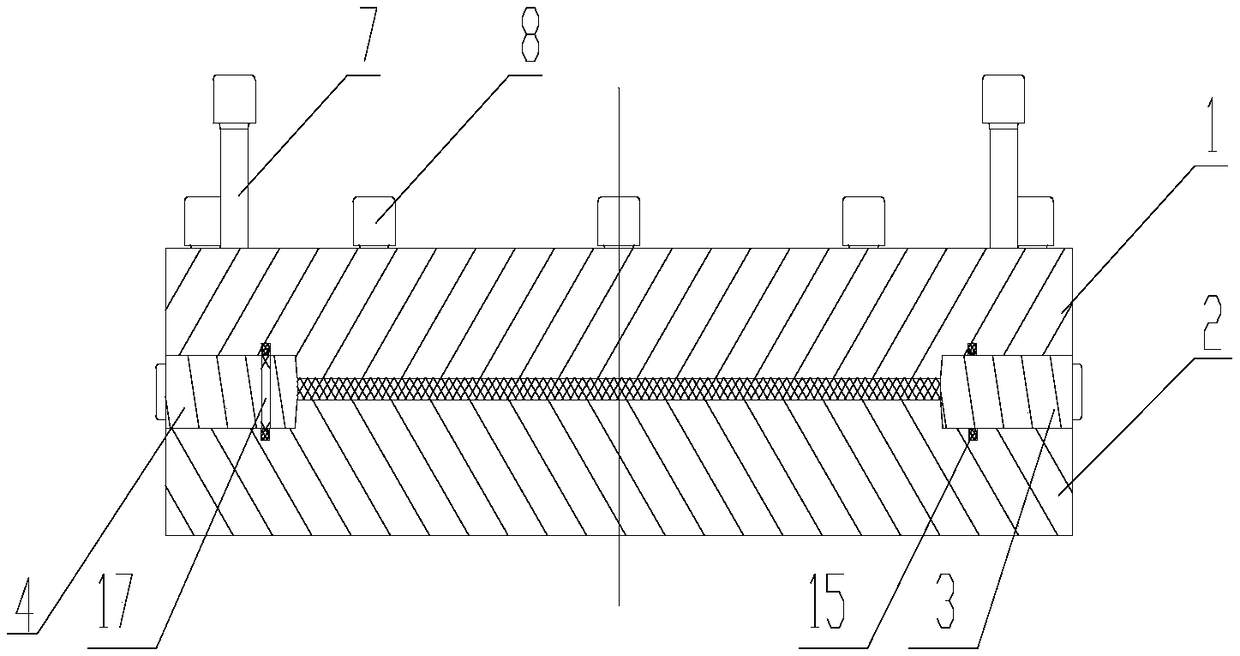

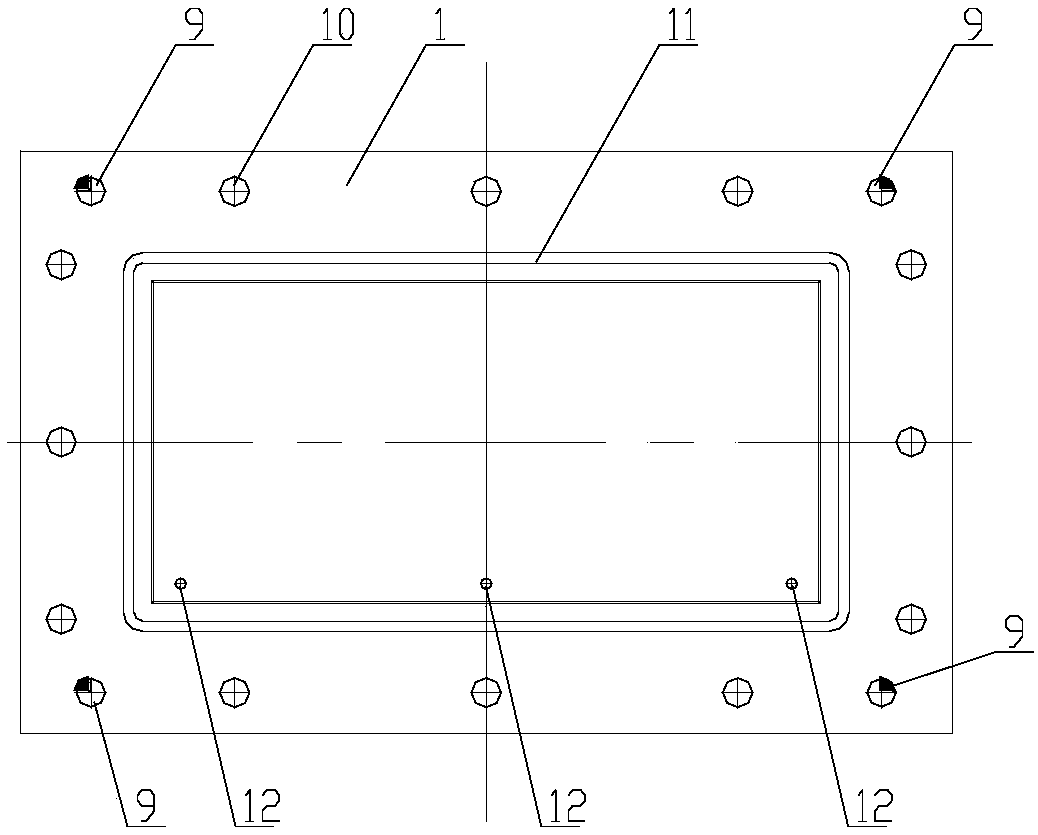

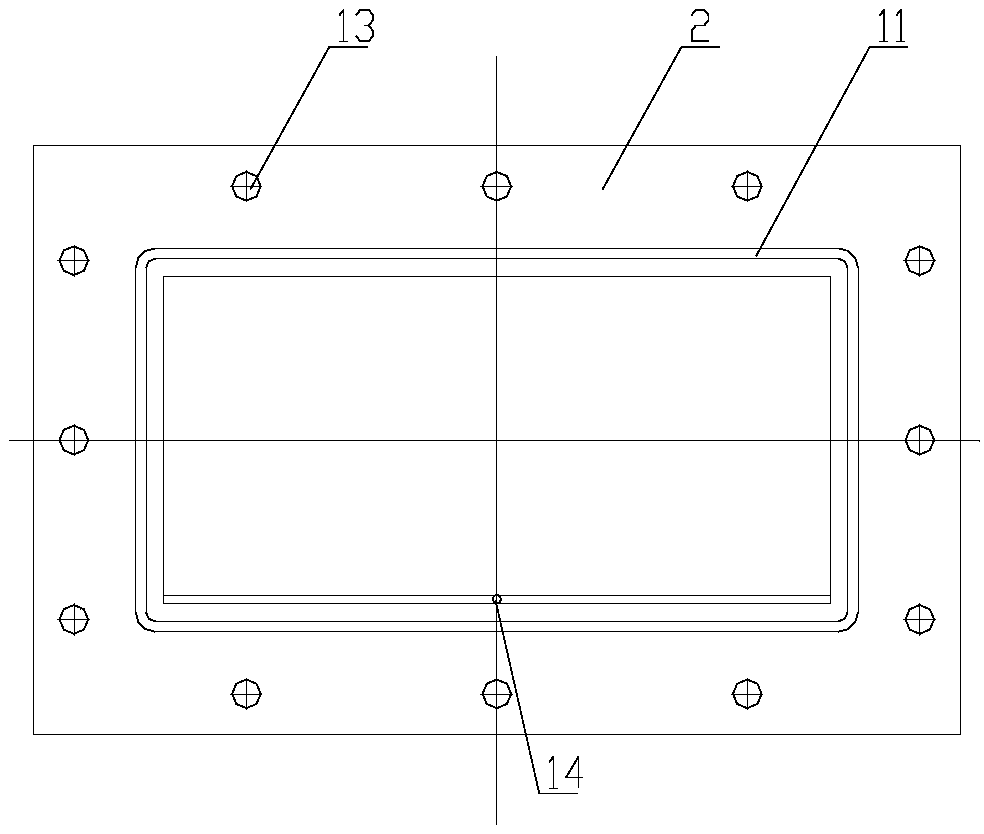

Printed board mounting die and method

InactiveCN111010819AHigh precisionAddress stressPrinted circuit assemblingConductive pattern formationEngineeringMechanical engineering

The invention discloses a printed board mounting die and method. The die comprises a base plate, a carrying plate, a template and a positioning plate. The base plate comprises a cavity with an upwardopening, and a space in the cavity is connected with the outside of the base plate through air holes in the base plate. The carrying plate covers the opening of the cavity and is in sealing contact with the base plate. A groove is formed in a surface of the carrying plate and used for placing a printed board, and a through hole is formed in a bottom of the groove and is connected with the cavity.The template comprises hollow points and is used for printing a soldering paste on the printed board. And the positioning plate comprises a mounting hole for mounting a component on the printed board.The invention further provides a printed board mounting method applying the device. According to the scheme, problems of low printed board mounting efficiency and reliability are solved.

Owner:BEIJING INST OF RADIO METROLOGY & MEASUREMENT

Graphene loudspeaker paper cone and production method thereof and loudspeaker

InactiveCN109024067AHigh strengthImprove toughnessNon-fibrous pulp additionPaper/cardboardPulp and paper industryGraphene

The invention discloses a graphene loudspeaker paper cone and a production method thereof and a loudspeaker. A paper pulp material is adopted for the paper cone, paper pulp and graphene powder which accounts for 0.5%-3% of the weight of the dry paper pulp material are mixed, and after the graphene powder is added, pores among paper pulp molecules are effectively filled with graphene particles, sothat the strength and the tenacity of the paper cone are greatly improved, and the reliability of the loudspeaker is improved. Meanwhile, due to the fact that graphene is smooth, and is not prone to adhere to a mould, after the paper cone is shaped on the mould, the paper cone can be taken off the mould very easily, the problem that traditional paper cone demoulding is hard can be effectively solved, and the production efficiency is improved. Moreover, due to the fact that the graphene powder is gray, when a black or gray paper cone needs to be produced, by adding a proper amount of graphene powder, the required color can be obtained, and the required color can be obtained without conducting color modulation on the paper pulp. According to the loudspeaker adopting the paper cone, the papercone is not prone to be damaged, the product quality of the loudspeaker is improved, and the service life of the loudspeaker is prolonged.

Owner:深圳市烽火宏声科技有限公司

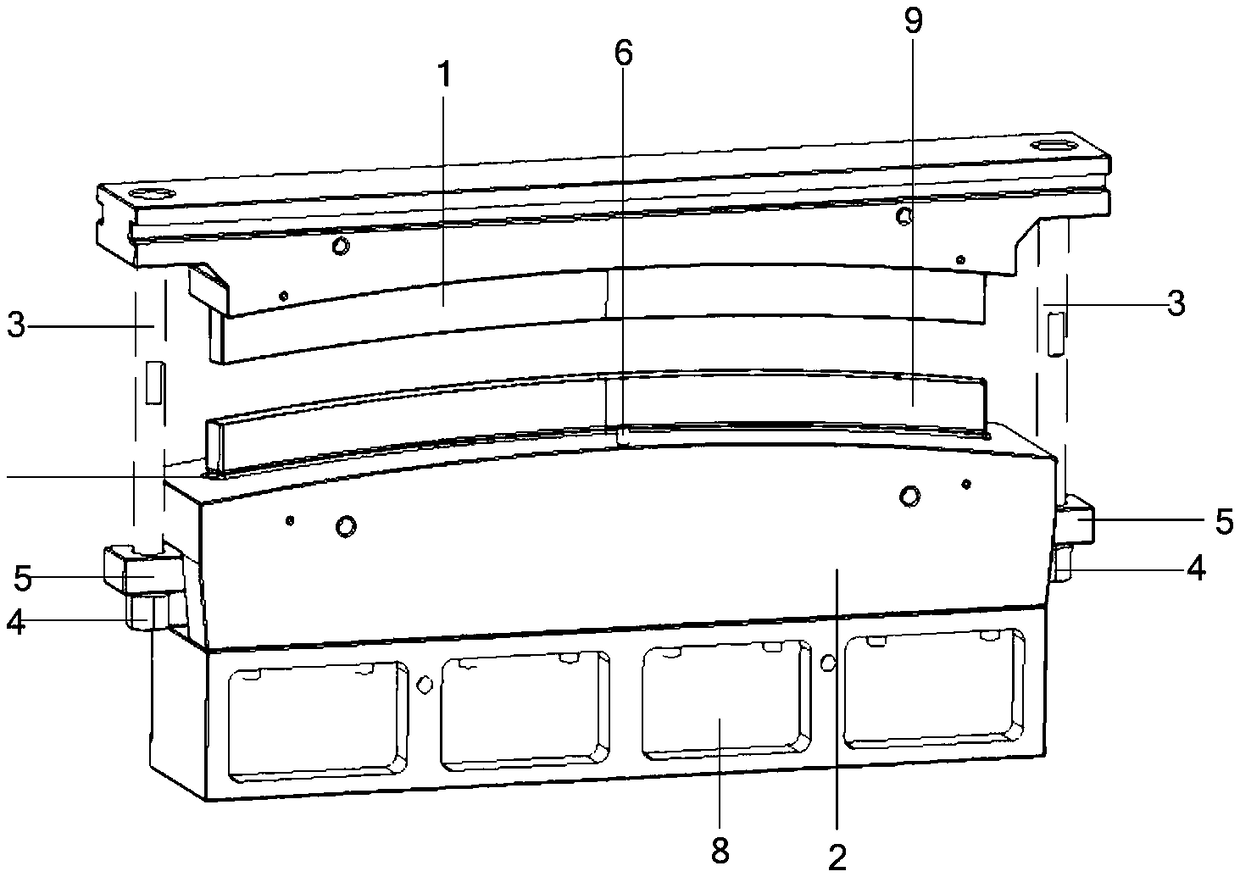

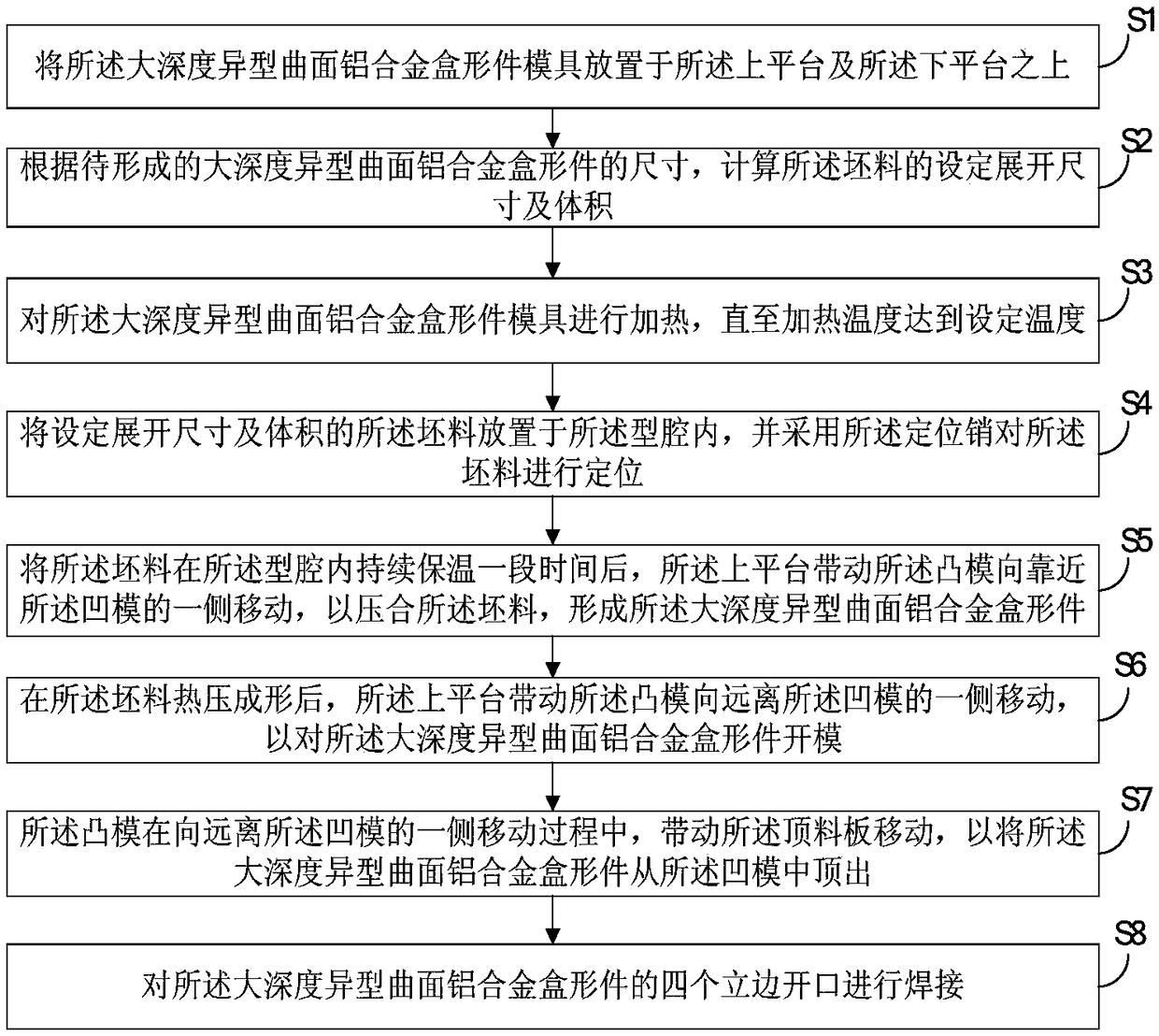

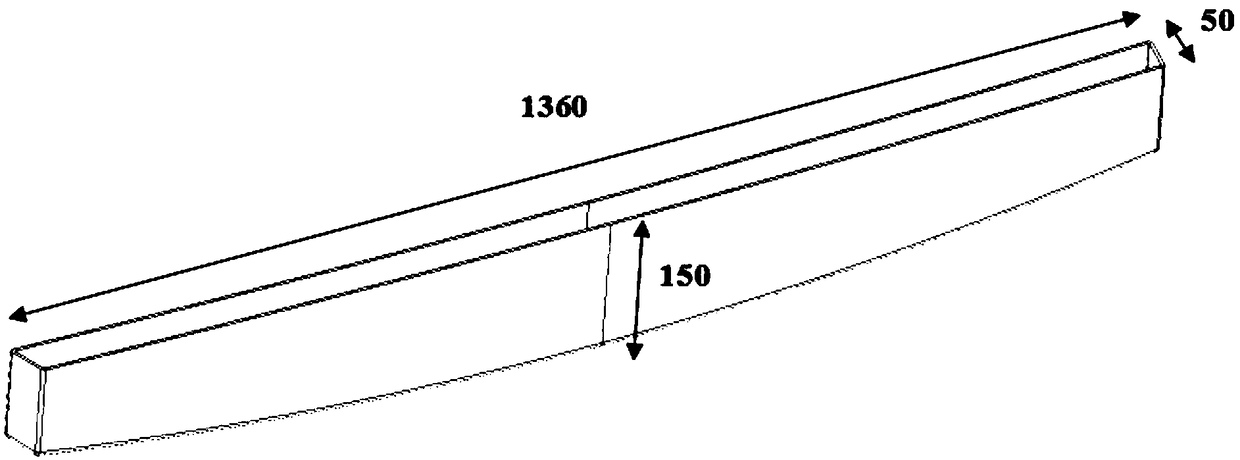

Preparation method of large-depth special-shaped curved-surface aluminum alloy box-like piece and mold of piece

ActiveCN109226509AHigh dimensional accuracyHigh profile precisionShaping toolsMetal-working feeding devicesVertical edgeAluminium alloy

The invention provides a preparation method of a large-depth special-shaped curved-surface aluminum alloy box-like piece and a mold of the piece. The method includes the steps of placing the mold of the large-depth special-shaped curved-surface aluminum alloy box-like piece on an upper platform and a lower platform; according to the size of the to-be-formed large-depth special-shaped curved-surface aluminum alloy box-like piece, calculating the set unfolding size and volume of a blank; heating the mold of the large-depth special-shaped curved-surface aluminum alloy box-like piece to a set temperature; placing the blank in a section cavity and adopting positioning pins for positioning the blank; after the blank is constantly subjected to heat preservation for a certain time period in the section cavity, using the upper platform for driving a protrusive die to move and press the blank; after hot compacting and forming of the blank, using the upper platform for driving the protrusive dieto move for mold opening of the large-depth special-shaped curved-surface aluminum alloy box-like piece; using the protrusive die to drive a material jacking plate to move to jack out the large-depthspecial-shaped curved-surface aluminum alloy box-like piece; conducting welding on openings in the four vertical edges of the large-depth special-shaped curved-surface aluminum alloy box-like piece. The problem that large-depth special-shaped curved-surface aluminum alloy box-like pieces cannot be demolded or are difficult to demold is solved.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

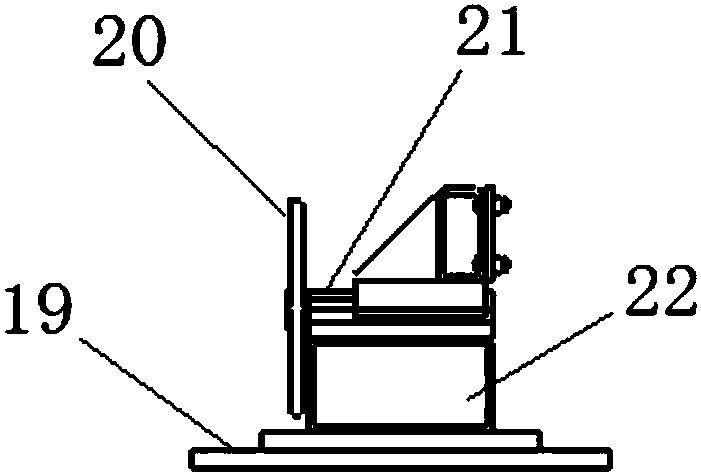

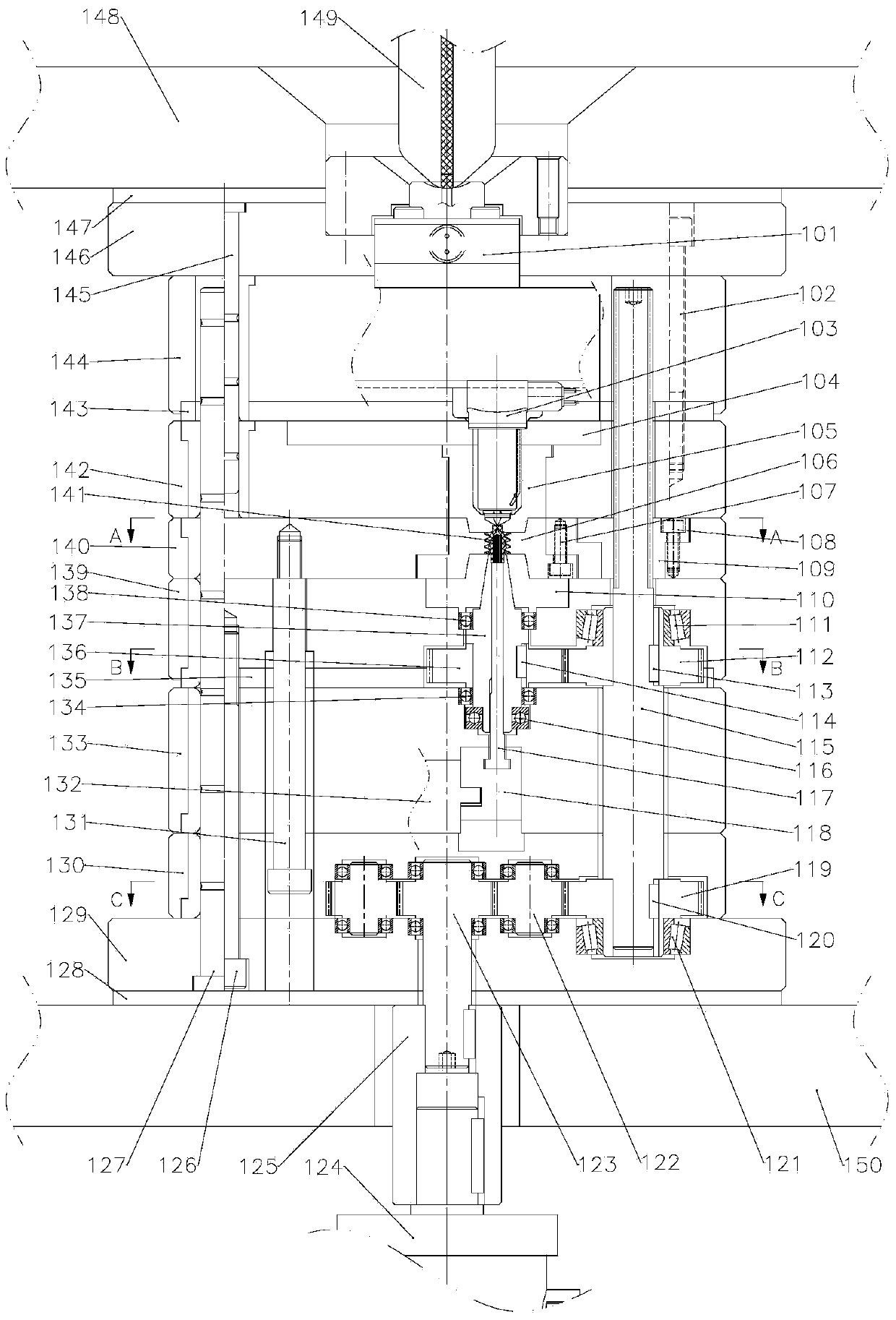

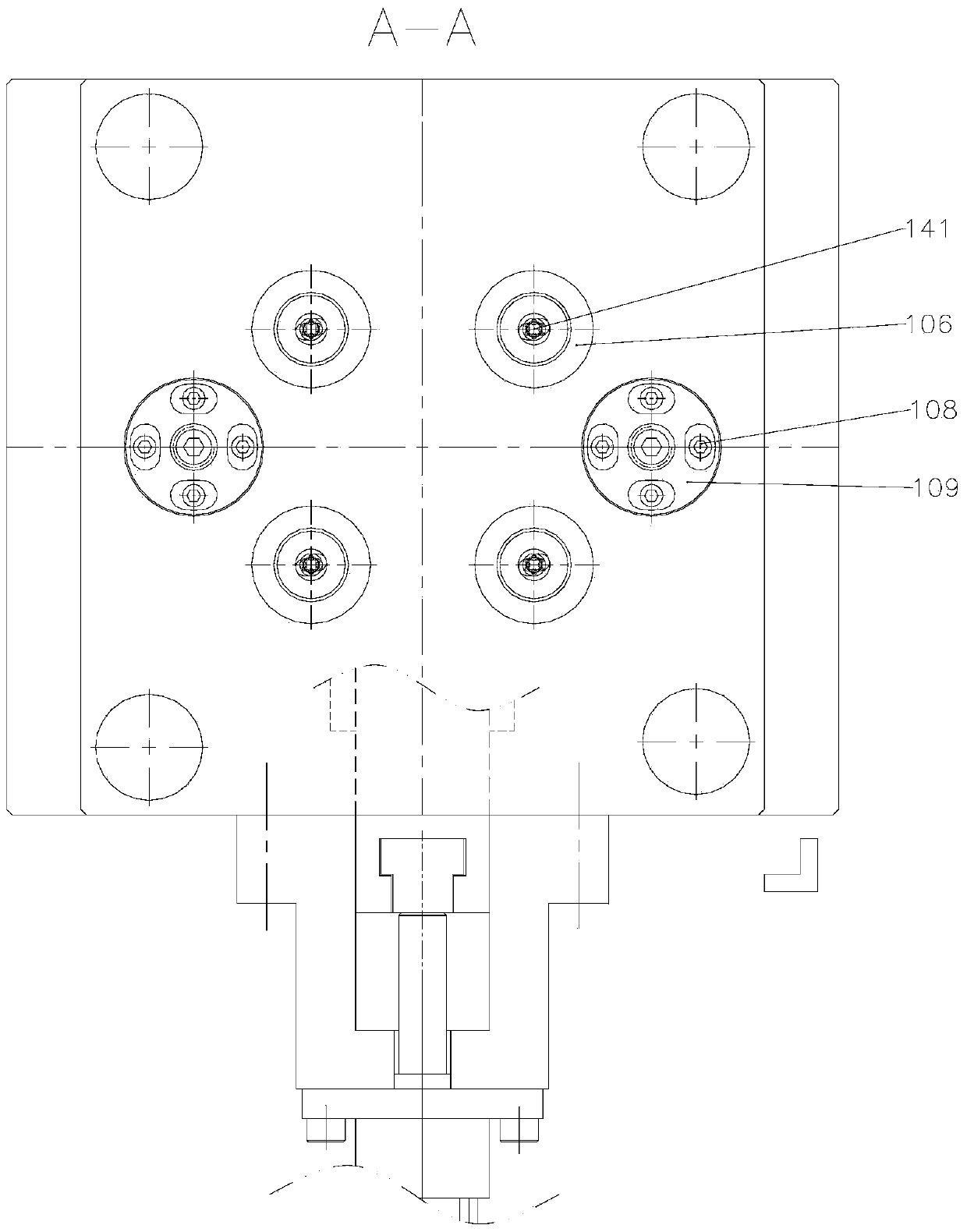

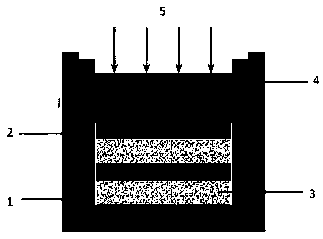

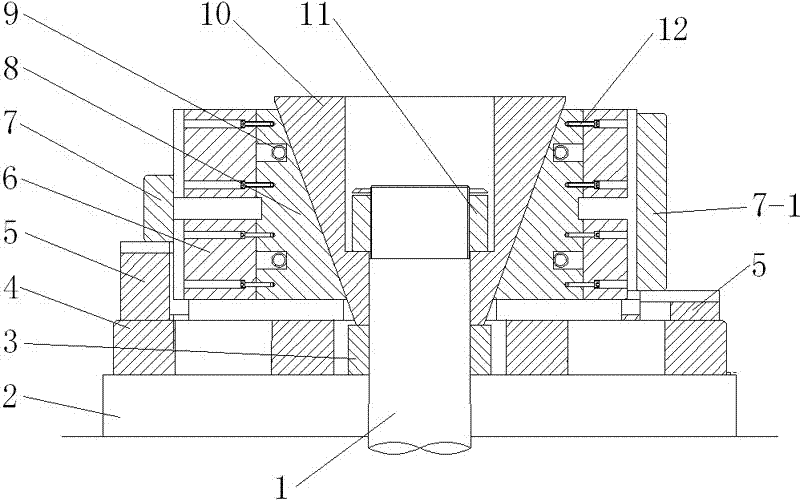

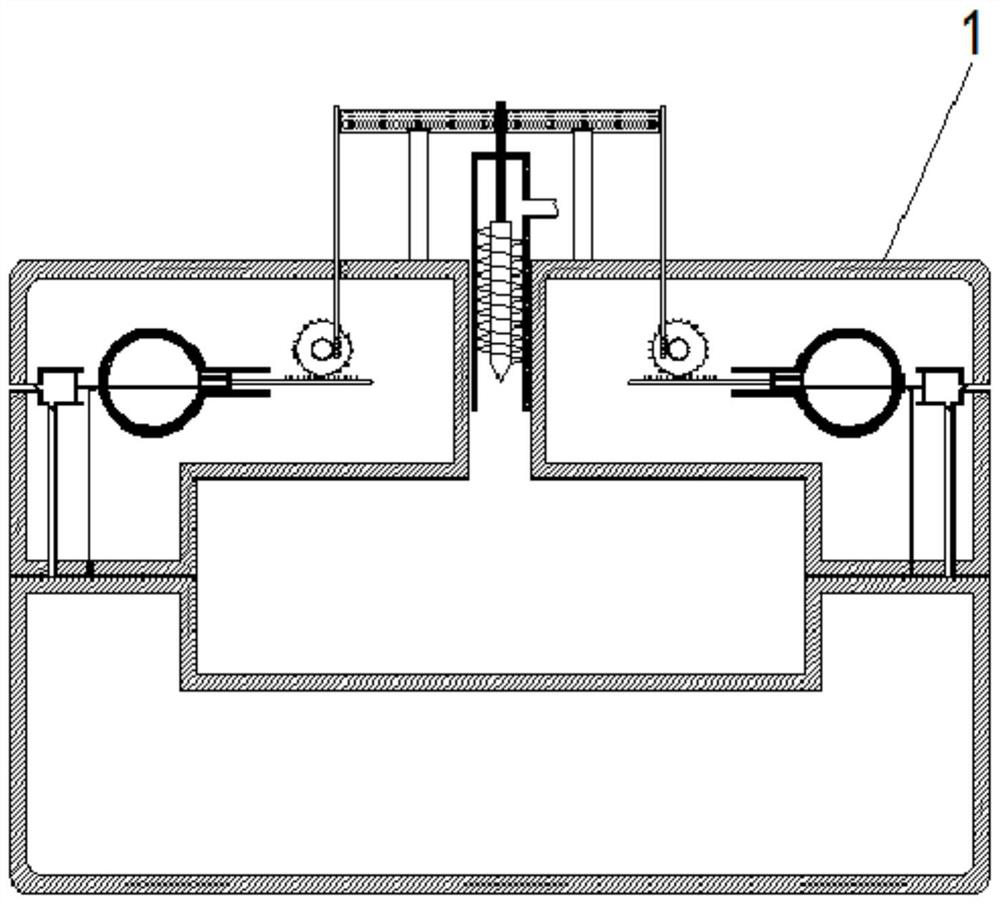

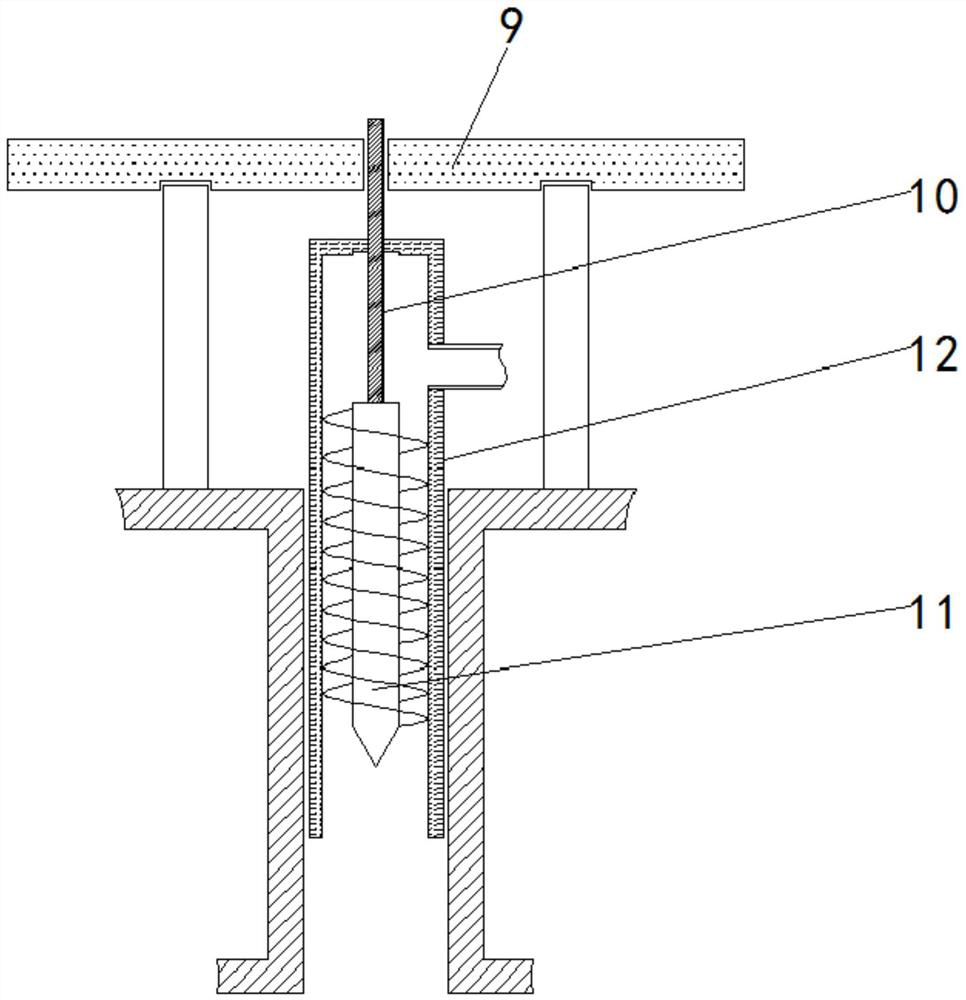

Magnetic material powder forming device and method

The invention belongs to the field of material forming and particularly relates to a magnetic material powder forming device and a forming method. The forming device consists of a forming press and a forming mold, wherein the forming press comprises a machine frame, an upper magnetic field coil, a lower magnetic field coil, an upper cover plate driving device, an ejector block driving device, a left pressing head driving device and a right pressing head driving device, the forming mold is surrounded into a mold cavity by a front side plate, a back side plate, an upper cover plate, an ejector block, a left pressing head, a right pressing head and a bottom plate, and the mold cavity is in a tile shape. According to the forming method, the forming press and the forming mold are adopted, and the magnetic material powder is pressed into tile-shaped blanks through step a to step f. When the forming device and the forming method are applied, the problems of demolding difficulty, too low magnetic steel performance, great blank processing quantity, low material utilization rate, blank crack and the like in the tradition tile-shaped blank pressing method are solved.

Owner:JIANGXI JLMAG RARE EARTH

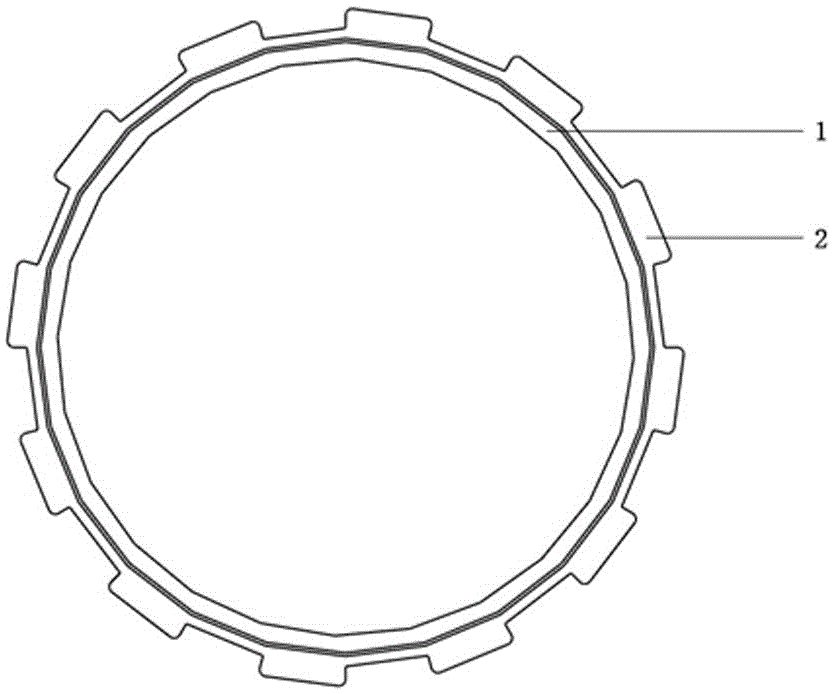

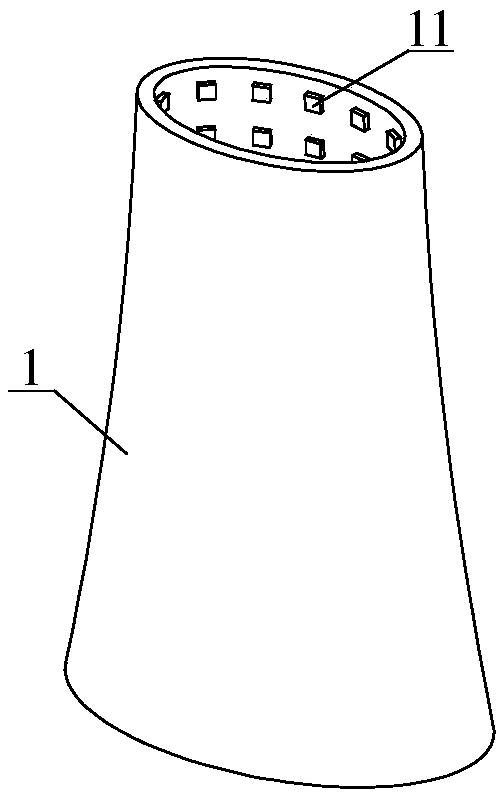

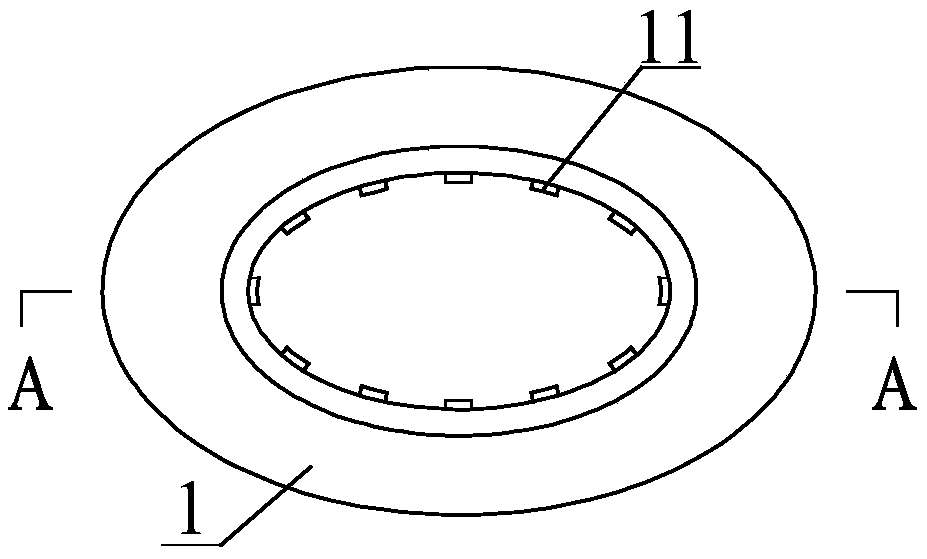

Hydraulic expansion assembled combination die for quenching ferrules

ActiveCN102776342ASolve the deformationSolve the difficulty of demouldingFurnace typesHeat treatment furnacesQuenchingMaterials science

The invention relates to a heat treatment quenching die, and in particular relates to a hydraulic expansion assembled combination die for quenching ferrules. The hydraulic expansion assembled combination die comprises a quenching working table, a quenching disc which is installed on the quenching working table, a die holder and a quenching die. The hydraulic expansion assembled combination die is characterized in that the quenching die consists of a central conical body and 4-12 quenching working blocks which are installed on the external conical surface of the central conical body, the quenching working blocks are wrapped on the external conical surface of the central conical body through annular tension springs, and a hydraulic rod of the quenching die is connected with the central conical body. The hydraulic expansion assembled combination die is used for solving the problems that a quenching workpiece deforms and is difficult to demould; the volume and the number of the die are greatly decreased, the problems of die processing difficulty and die storage space are solved, and the production period and the production cost of the die are also greatly reduced; one set of die can be suitable for quenching the workpieces within one dimension range; and a quenched workpiece has a stable size and small deformation, is easy to correct and has stable quenching quality.

Owner:NINGXIA MACHINERY RES INST

Basalt fiber grid reinforced concrete dismantling-free column formwork and preparation method thereof

InactiveCN108756065AReduce mold support difficulty and manufacturing cycleImprove manufacturing precision and qualityStrutsCeramic shaping apparatusHollow coreBasalt

The invention discloses a basalt fiber grid reinforced concrete dismantling-free column formwork and a preparation method thereof. The basalt fiber grid reinforced concrete dismantling-free column formwork comprises a hollow ultra-high performance concrete layer and basalt fiber grids, and shear-resistant convex blocks are arranged on the inner surface of the hollow ultra-high performance concretelayer. The preparation method of the basalt fiber grid reinforced concrete dismantling-free column formwork comprises the following steps that (1) according to column design information, shape parameters of the dismantling-free column formwork and parameters of the basalt fiber grids are determined; (2) according to design of the shape parameters of the dismantling-free formwork, geometric parameters of an inner turnover formwork and an outer turnover formwork are obtained; (3) the inner turnover formwork is manufactured through an additive manufacturing technology, and then the basalt fibergrids are fixed to the inner turnover formwork; (4) the outer turnover formwork is manufactured through the additive manufacturing technology and combined with the inner turnover formwork to form a whole; (5) ultra-high performance concrete is poured between the inner turnover formwork and the outer turnover formwork; and (6) curing and formwork dismantling are conducted, and the basalt fiber gridreinforced concrete dismantling-free column formwork is obtained. The basalt fiber grid reinforced concrete dismantling-free column formwork is suitable for manufacturing of personalized building curved columns, and is good in integrity, low in cost, excellent in durability and convenient to manufacture.

Owner:SOUTHEAST UNIV

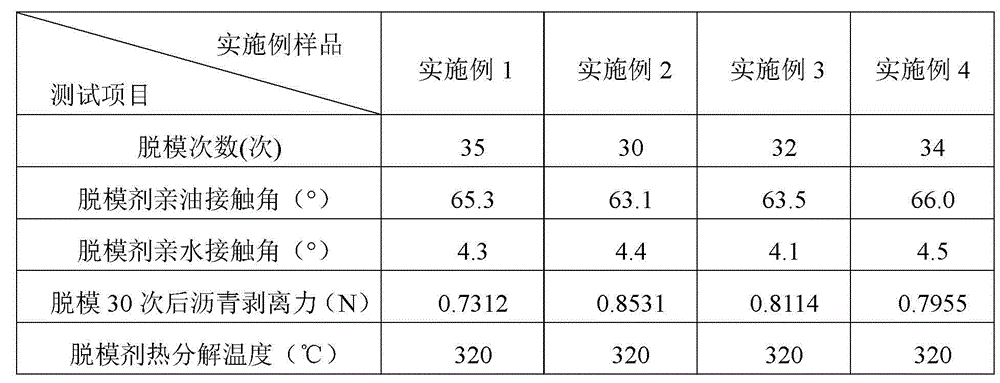

Preparation method of asphalt release agent

InactiveCN102942499ALong-lastingLow costOrganic compound preparationAmino-carboxyl compound preparationWater bathsSuberedamine B

The preparation method of an asphalt release agent of the present invention prepares a long-lasting environmental-friendly asphalt release agent through an ice water bath reaction of chloroacetic acid and ethylenediamine in an ethanol system under a certain process condition. The asphalt release agent is a associated liquid system of a Bola-type nitrogen-containing surface active agent of ethylenediamine diacetic acid and ethanol, can form a layer of non-migrating type micron grade film on a mold surface, and can play a corrosion preventive role on a metallic mold, and can naturally alienate the film surface through the interface interaction on encountering lyophobic asphalt, so as to achieve the effect of demolding. The asphalt release agent is not only able to solve the problems of asphalt demolding difficulties, asphalt use performance affected by the releasing agent, and high migration rate of the release agent after demolding, but has long-lasting and environment-friendly excellent performances. The asphalt release agent is innovative in the preparation method, simple in process and low in cost, and can be applied to the fields of processing, transportation, building materials, and water conservancy.

Owner:SHAANXI NORMAL UNIV

Energy-saving and environment-friendly plastic heat-insulating board forming device

ActiveCN112140424ACooling shrinkage size changeSolve the difficulty of demouldingFlat articlesEngineeringMechanical engineering

The invention relates to the technical field of plastic heat preserving boards and discloses an energy-saving and environment-friendly plastic heat-insulating board forming device which comprises a mold. A liquid drawing pipe is arranged on the top of the mold in a penetrating and inserting manner. A winching rod is connected into the liquid drawing pipe in a rotating manner. A liquid drawing pipeis arranged on the outer side of the winching rod. A middle shaft is fixedly connected to the top of the winching rod. A receiving wheel is connected to the side face of the middle shaft in an engaged manner. A screw rod is connected to one side, away from the middle shaft, of the receiving wheel in an engaged manner. A pushing rod is connected to the side face of an ejector rod in a sliding manner. A liquid drawing plate is fixedly connected to one side, away from a mercury plate, of the ejector rod. A transition box is connected to the side face of the liquid drawing plate in a sliding manner. A liquid input pipe is fixedly connected to the side face of the transition box. According to the energy-saving and environment-friendly plastic heat-insulating board forming device, by means of cooperative use of a mercury box and the receiving wheel, thus the effect that in the liquid plastic shrinkage process, liquid plastic in the mold is extruded continuously, and change of the size of plastic due to cooling shrinkage is prevented can be achieved.

Owner:瑞力恒生态科技(深圳)有限公司

Detachable concrete test block mold with convenient demolding function

PendingCN107901192ASolve the difficulty of demouldingAvoid damageMouldsEngineeringBuilding construction

Owner:JILIN UNIV

Rubber material for producing alkali-fast battery reservoir

InactiveCN101245161ASolve the difficulty of demouldingCell component detailsRubber materialVulcanization

The invention provides a formula for preparing the rubber material of a sac of alkali resistant batteries; the weight ratios are as follows: 65 portions of ethylene propylene rubber EP35, 35 portions of ethylene propylene rubber EP 4640, 5 portions of ZnO, 1.2 portions of stearic acid, 1 portion of Si-69, 1 portion of age inhibitor A, 7 portions of white carbon black, 45 portions of high-abrasion carbon black, 29 portions of naphthenoid oil, 1 portion of parting agent TM-80, 1.8 portions of promoter CZ, 1.2 portions of promoter DM, 0.4 portion of promoter DTDM, 1.1 portions of S and 1 portion of coumarone; the sac material for preparation have the following performances: tensile strength of not less than 8MPa, maximum elongation of not less than 250 percent, tearing strength of not less than 18kN / m, hardness (sauer A) of 60 to 65 degrees; alkali resistance: the product can resist 35 percent KOH and can be immersed for 72 hours at the temperature of 70 DEG C; the changing rate of the tensile strength is less than 15 percent; the changing rate of the tensile strength is less than 20 percent; the temperature of the using environment is minus 30 to 60 DEG C; the adoption of an inner-placed parting agent solves the parting difficulty after vulcanizing shaping.

Owner:天津市振海橡胶科技发展有限公司

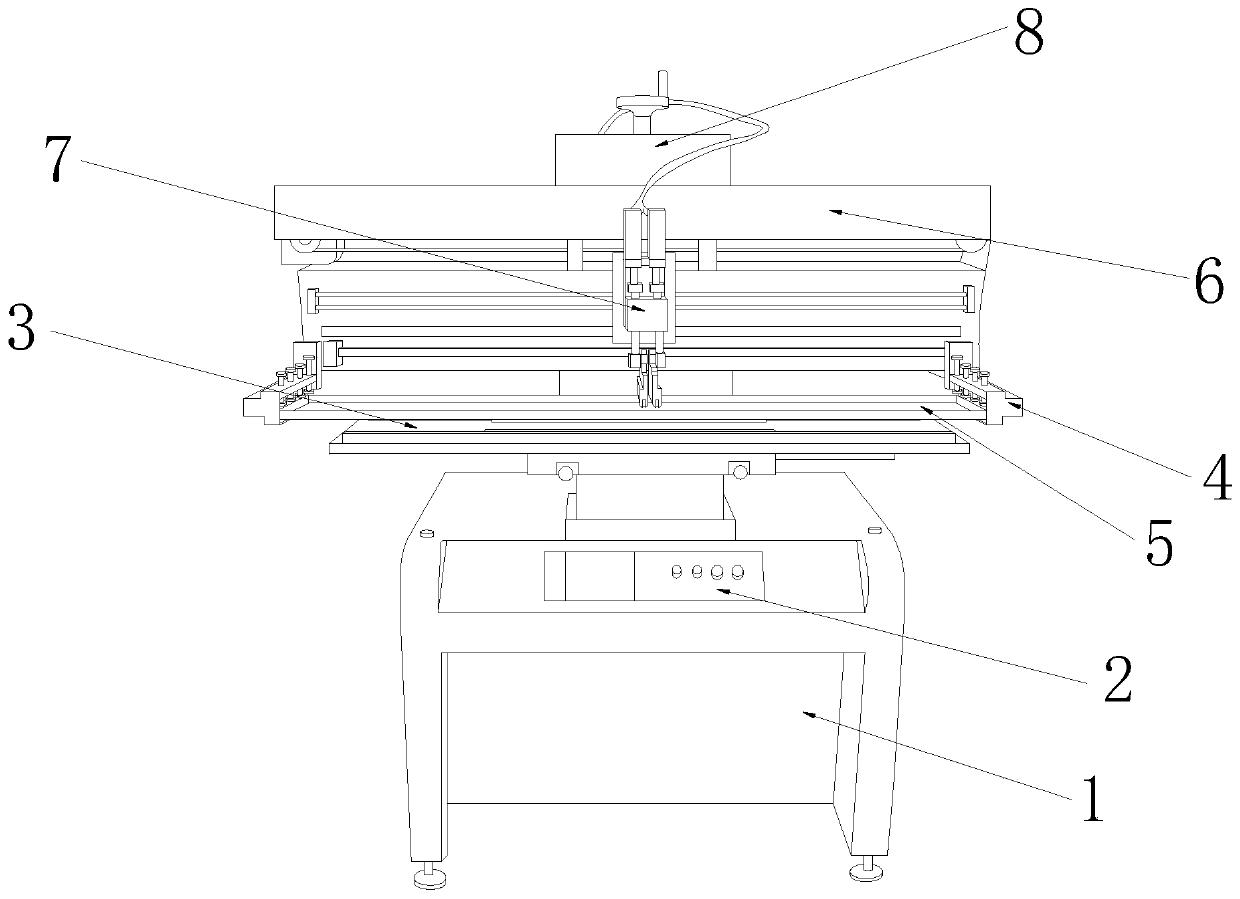

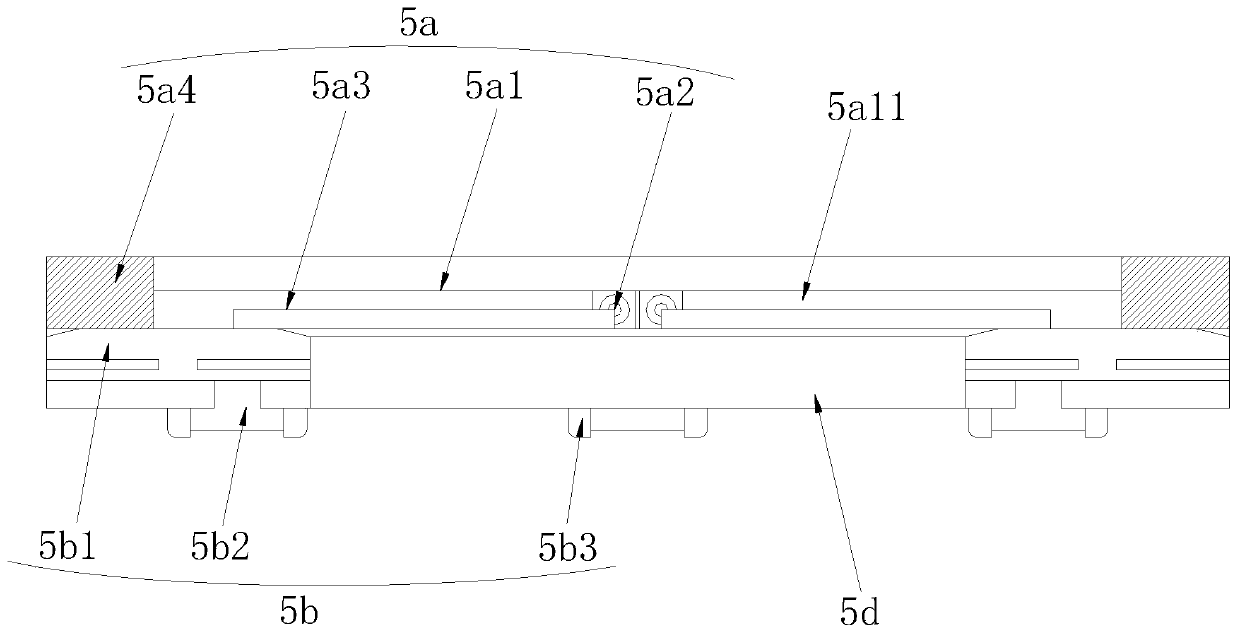

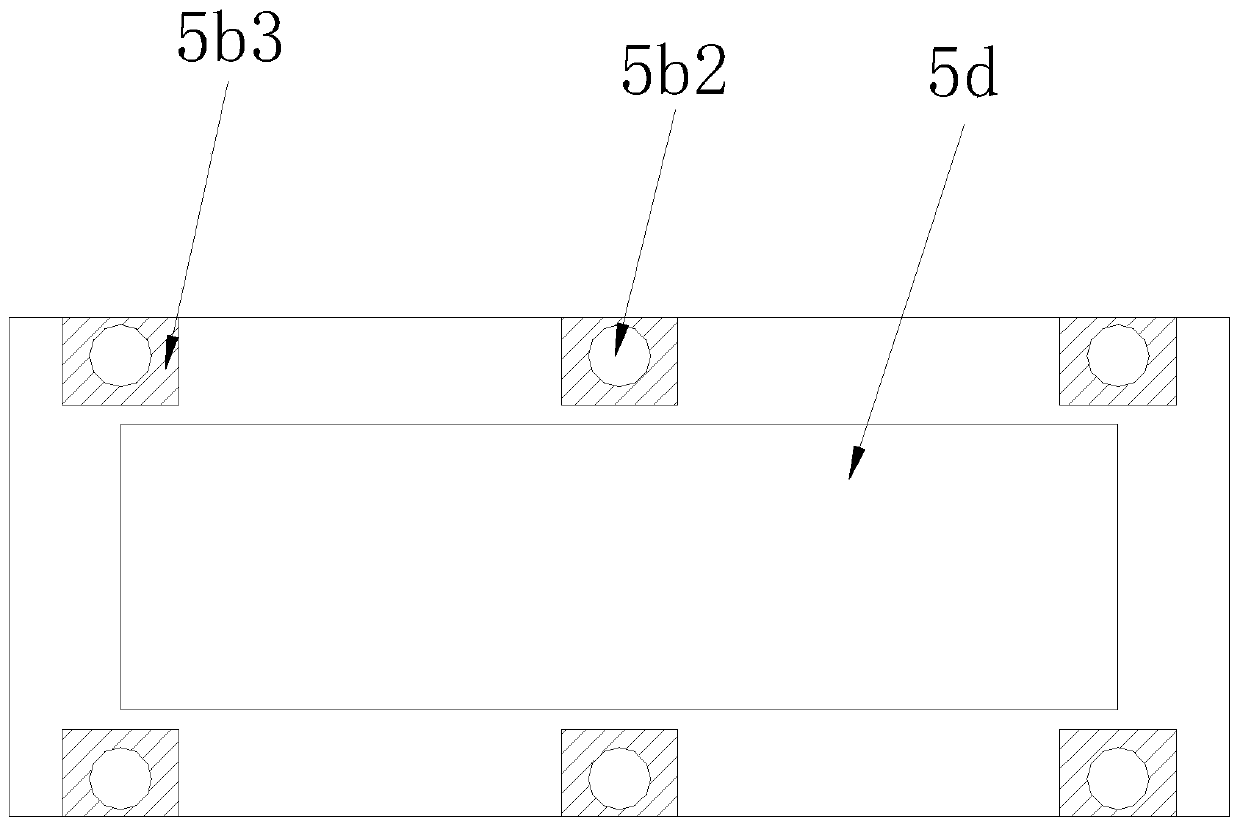

Automatic solder paste printing machine with printing material stacking prevention and easy demoulding functions

ActiveCN110103573AAvoid long-term accumulationAvoid the phenomenon of unclear printing and dyeingScreen printersConductive pattern formationEngineeringPrinting press

The invention discloses an automatic solder paste printing machine with printing material stacking prevention and easy demoulding functions. The machine structurally comprises an equipment main body,a control panel, a working panel, a steel net frame, a pneumatic stacking prevention device, a movable frame, a scraping plate and an electric cabinet. The beneficial effects are as follows: accordingto the machine, a pushing structure is utilized to assist the scraping plate to carry out ink return printing, and meanwhile, and the heating plate is utilized to avoid the phenomena of poor printingeffect, unclear printing and the like caused by the hardening of the solder paste due to the chemical action caused by long-term exposure to the air. According to the method, a stacking-free mechanism and a pneumatic anti-sticking film structure are mutually matched, so that when the solder paste is pushed to the outermost sides of the two sides, the solder paste is able to flow towards the inside of the frame under the interaction of an L plate and an arc-shaped air bag so as not to accumulate on the outermost sides for a long time and harden to result in mixing of new and old printing materials; and meanwhile, the printed template is subjected to air blowing type demolding under the pneumatic action of the pneumatic anti-sticking film structure, so that the difficulty in demolding is avoided, and the template and the printing material are printed again in the demolding process.

Owner:威海高新园区运营管理有限公司

Preform reinforcing plate universal vacuum mold closing mold

PendingCN108749033AGuaranteed thickness and dimensional accuracySolve the difficulty of demouldingFiberMaterials science

The invention provides a universal vacuum mold closing mold for forming a preform reinforcing plate. The universal vacuum mold closing mold comprises an upper mold, a lower mold, a left partition plate, a right partition plate, a front partition plate, a rear partition plate, positioning screws, demoulding screws and O-shaped sealing rings. By replacing the partition plates of different thicknesses, preform reinforcing plate composite materials of different thicknesses are formed. A parting surface adopts an upper, middle and lower halved structure, so that the sealing problem of a plurality of sections of a complicated structure is solved, the conjoint ratio of a preform reinforcement and the mold can be observed in the mold assembly process, it is ensured that a product does not deform after molding, no force is applied in the demolding process, the surface smoothness is high, and no defects such as poor gel and rich resin are achieved; and a plate mold is designed to be in a convexshape, on the one hand, the thickness of a plate is controlled, and on the other hand, the rigidity of the mold is increased; and more importantly, the compactness of impregnation of a preform is improved, and the percentage composition of fiber is increased.

Owner:BEIJING HANGTIAN XINFENG MECHANICAL EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com