Preform reinforcing plate universal vacuum mold closing mold

A reinforcement board and prefabricated body technology, applied in the field of positioning devices for prefabricated body reinforcement boards, can solve the problems of high surface smoothness, achieve the effects of improving production efficiency, solving difficult demoulding problems, and reducing scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

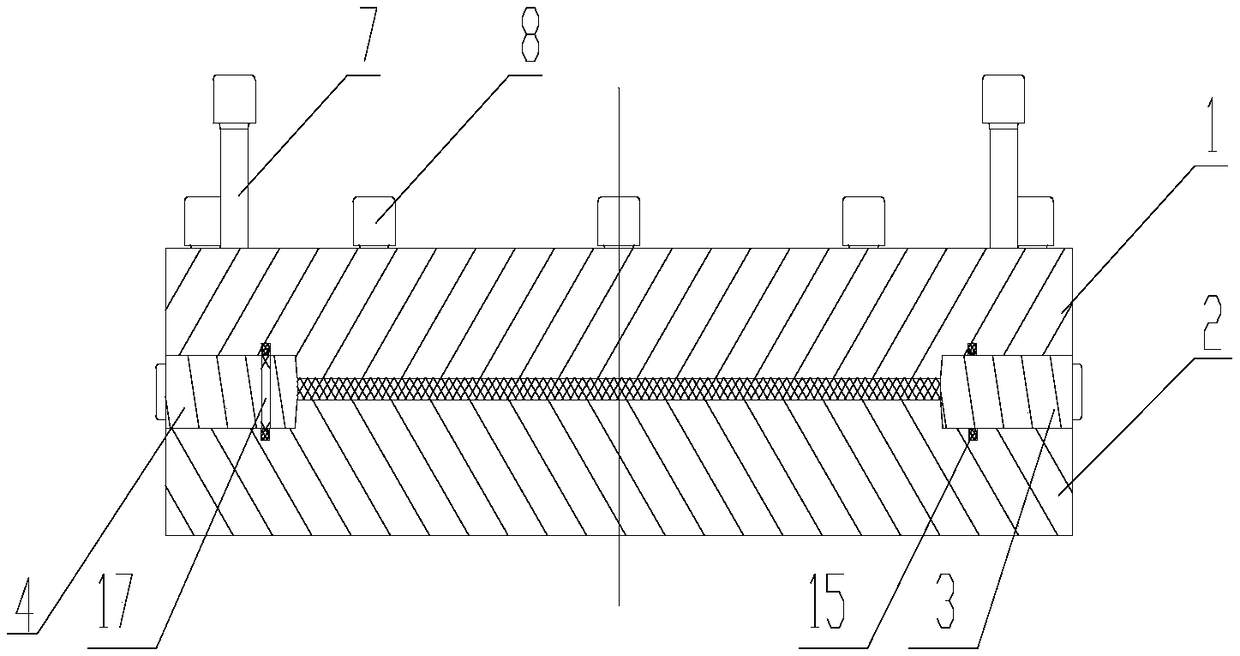

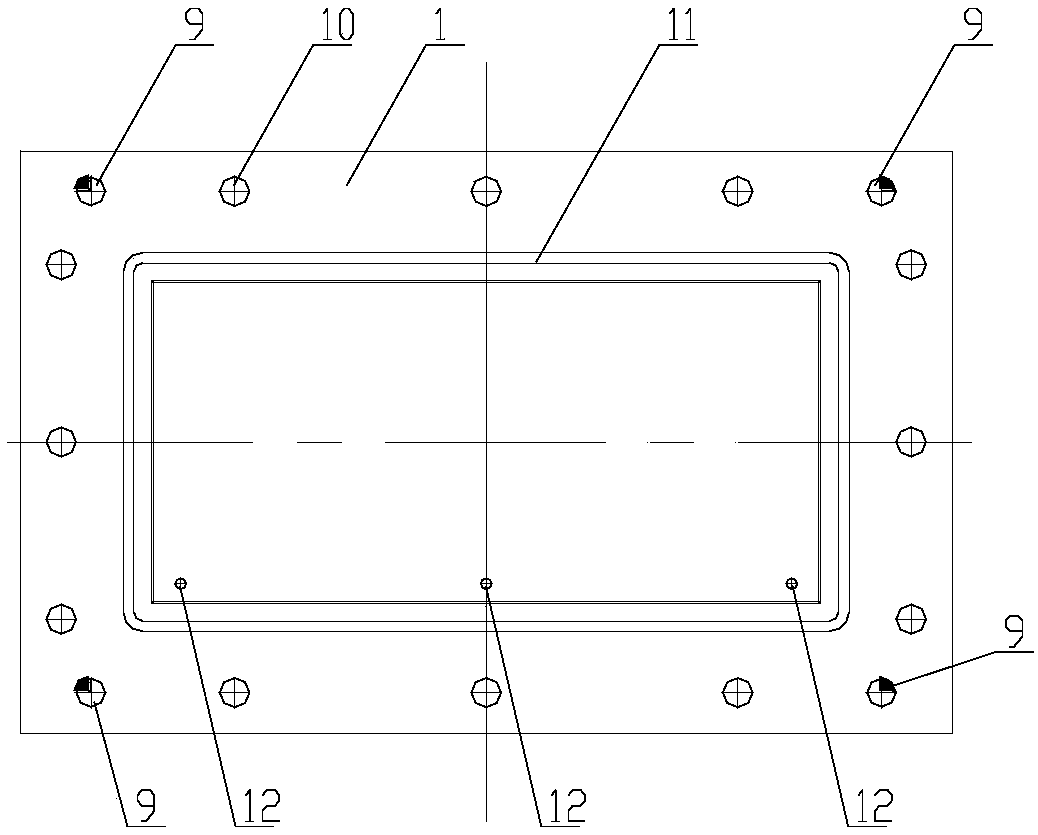

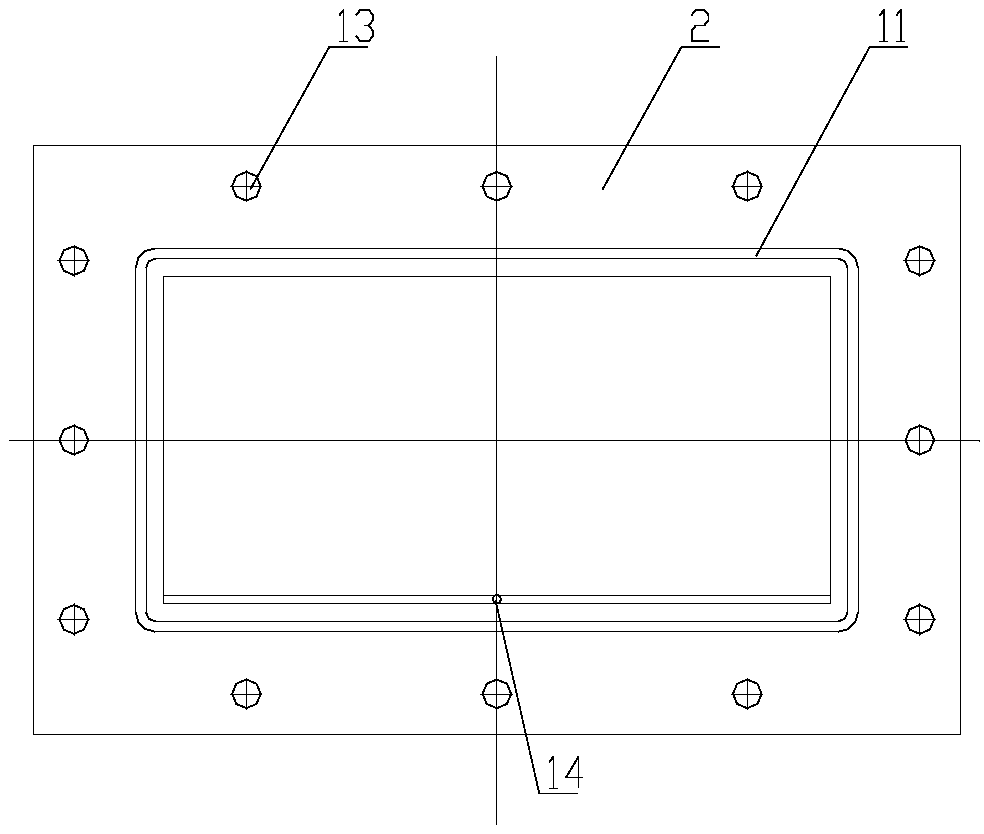

[0032] The present invention provides a prefabricated reinforced plate type vacuum closed mold positioning device, which includes an upper mold 1, a lower mold 2, a left partition 3, a right partition 4, a front partition 5, a rear partition 6, and demoulding screws 7 , positioning screw 8, demoulding hole 9, positioning hole 10, rectangular sealing groove a11, glue outlet 12, positioning screw hole 13, glue injection port 14, O-ring a15, rectangular sealing groove b16, O-ring b17 . This set of molds is used for forming 300x500x5mm prefabricated reinforced plate composite materials.

[0033] The upper mold 1 is a rectangular flat plate with a boss, and a rectangular sealing groove a11 is provided at a distance of 10 mm from the outer edge of the boss, and the cross section is rectangular and rectangular. The sealing groove a11 is located on the butt joint surface which is in contact with the left partition 3 , the right partition 4 , the front partition 5 and the rear partiti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com