Patents

Literature

52results about How to "Improve quenching hardness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

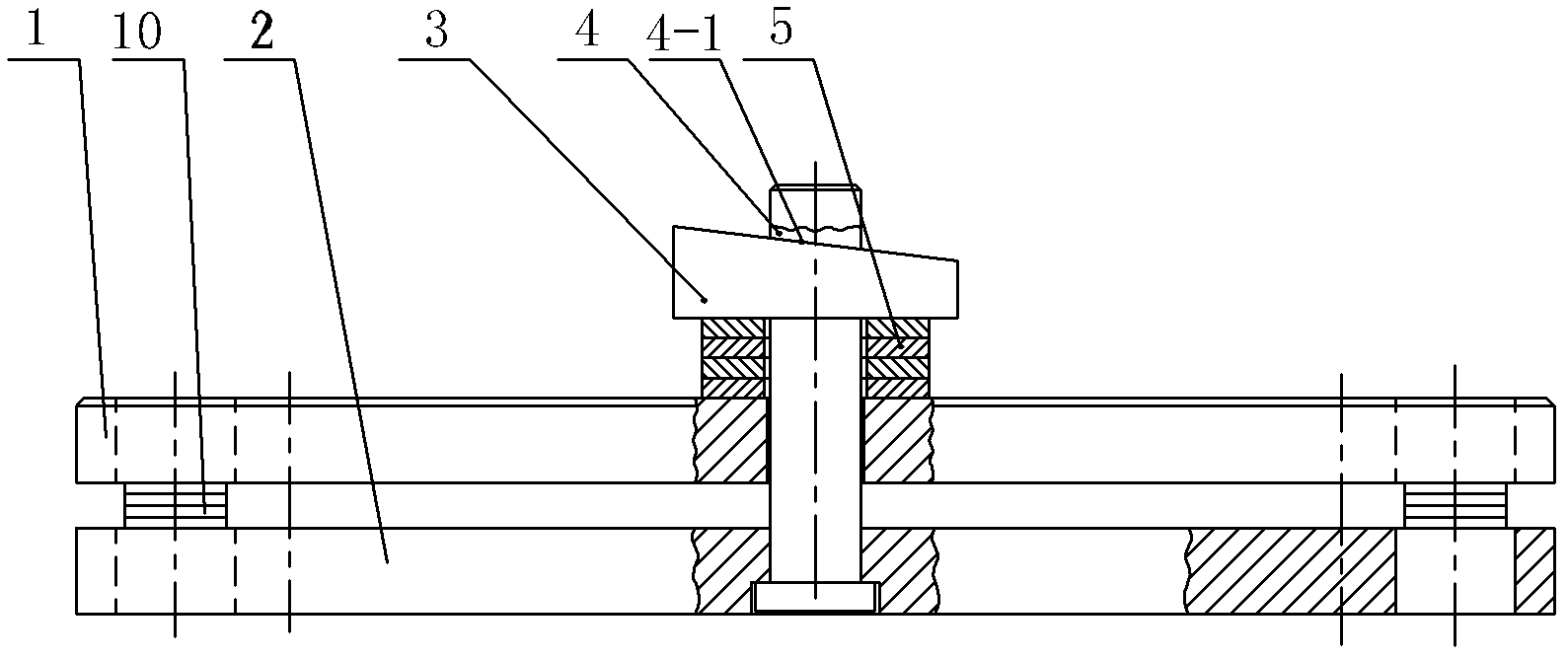

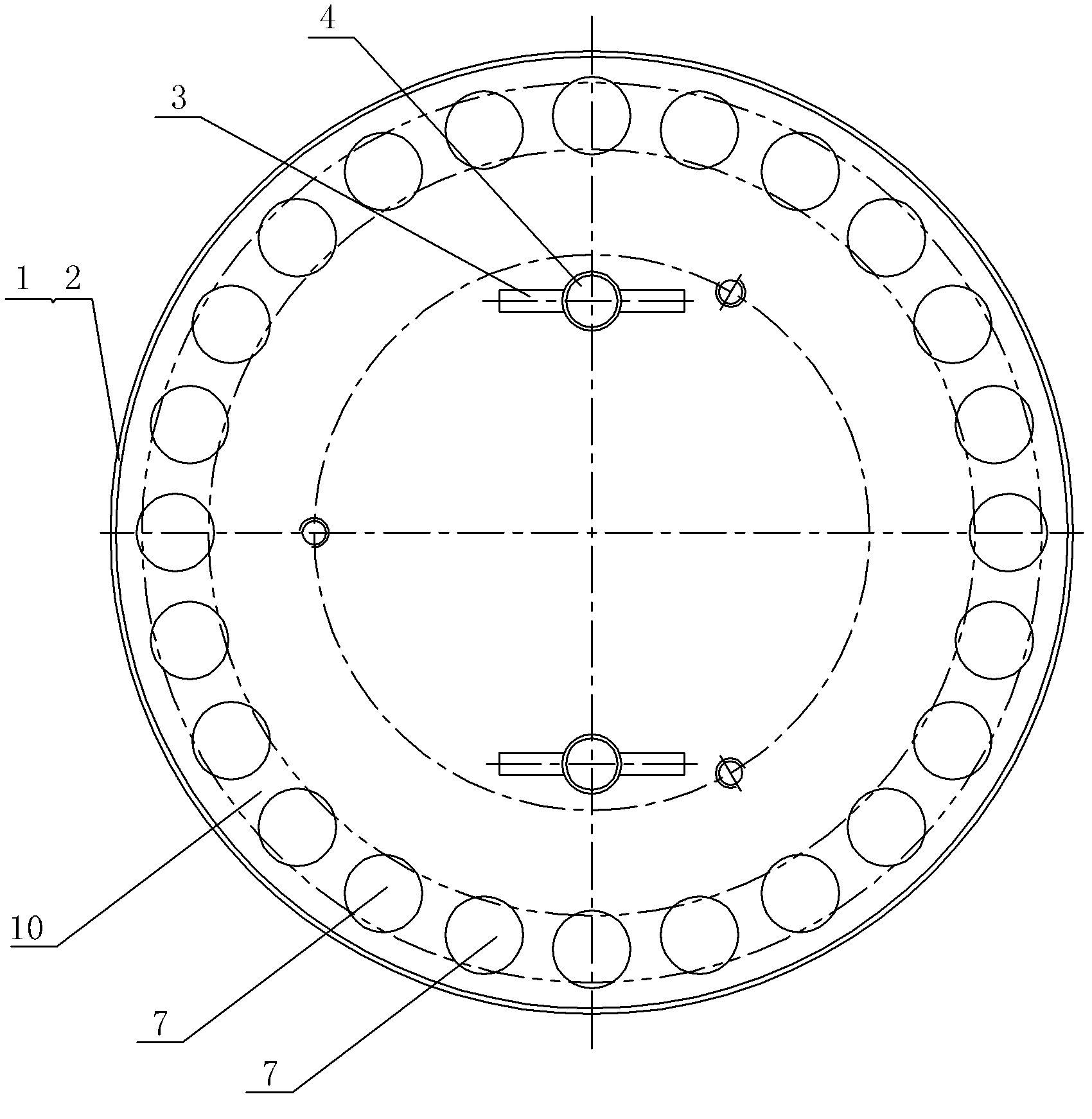

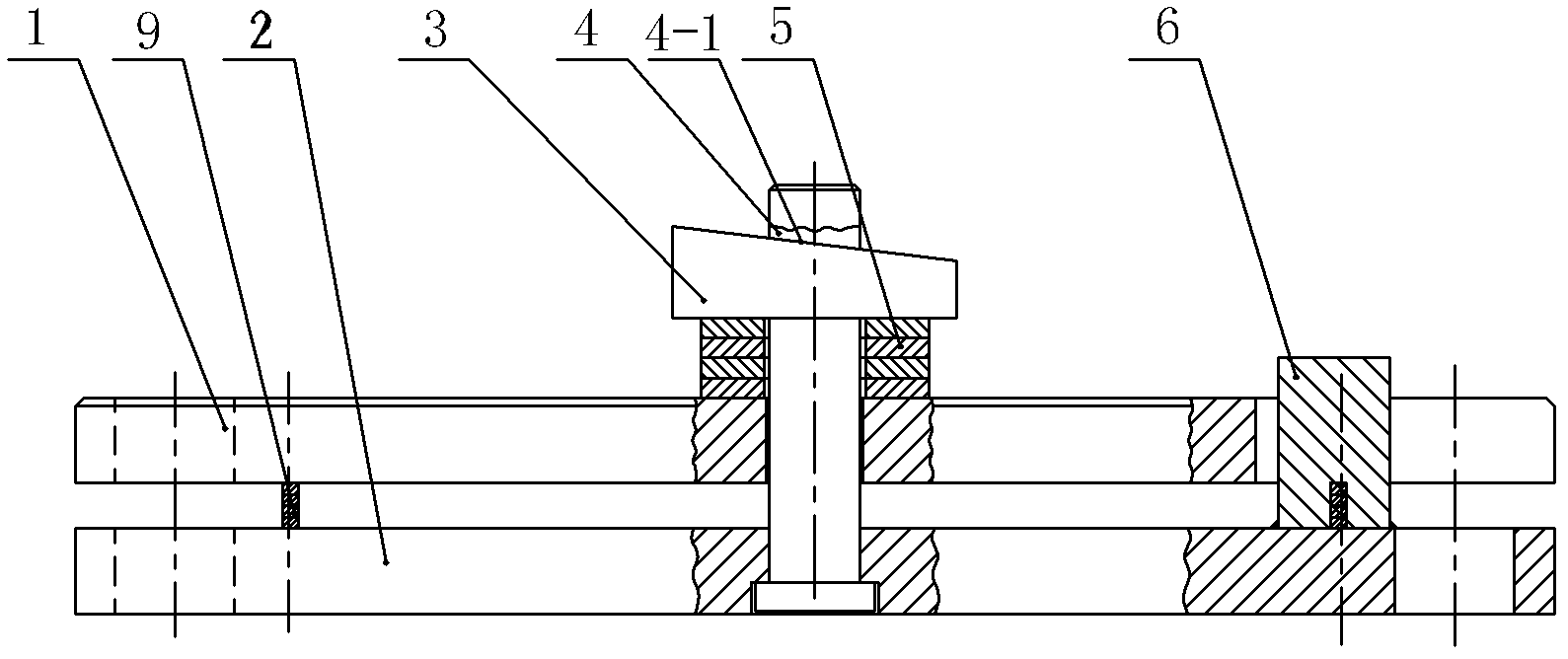

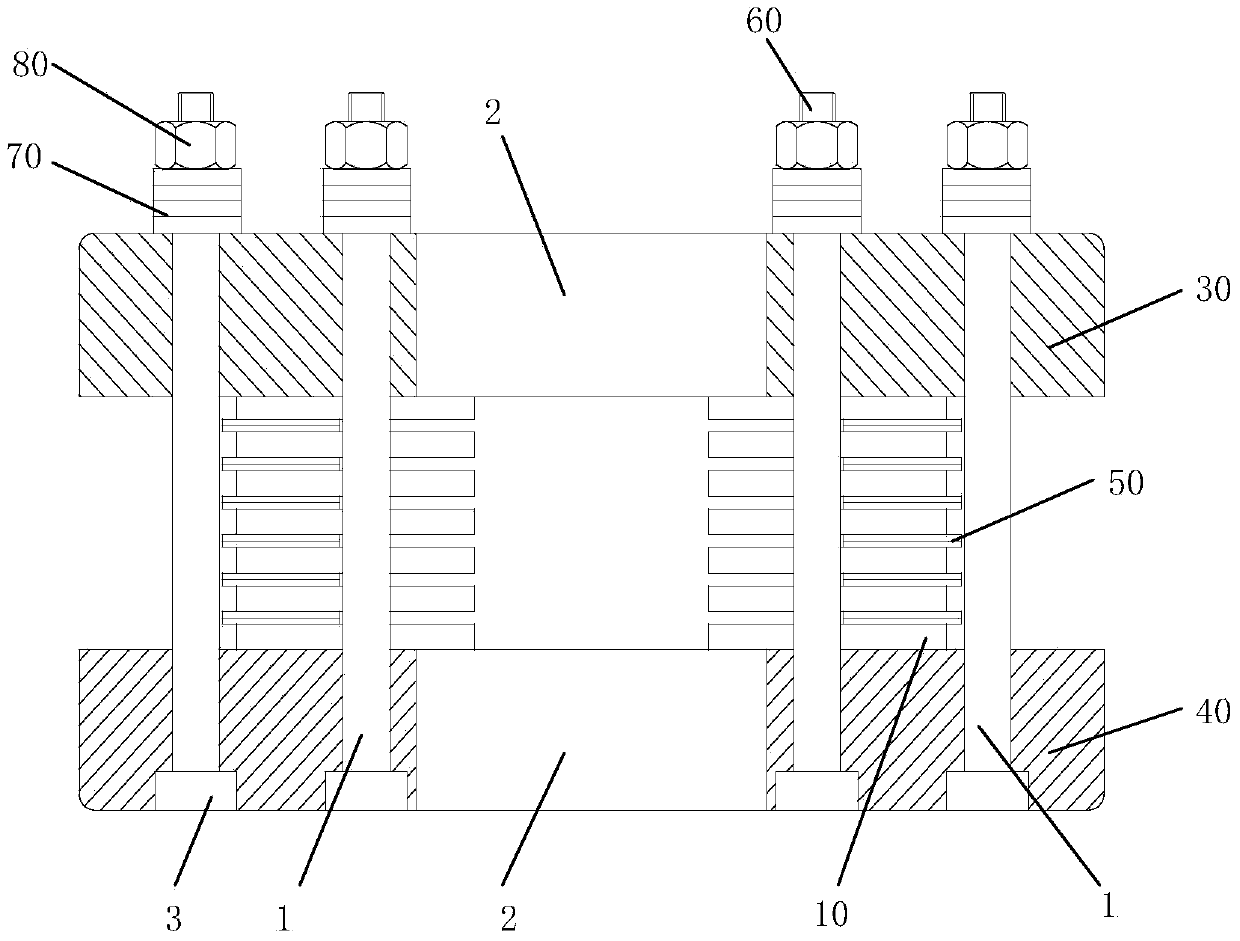

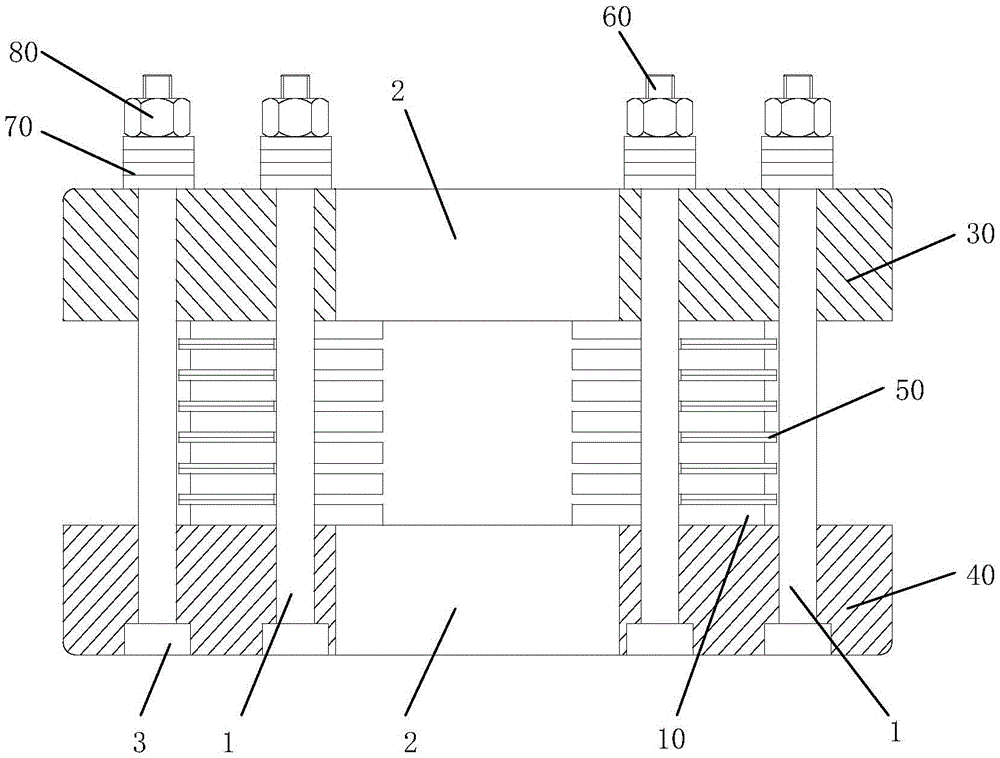

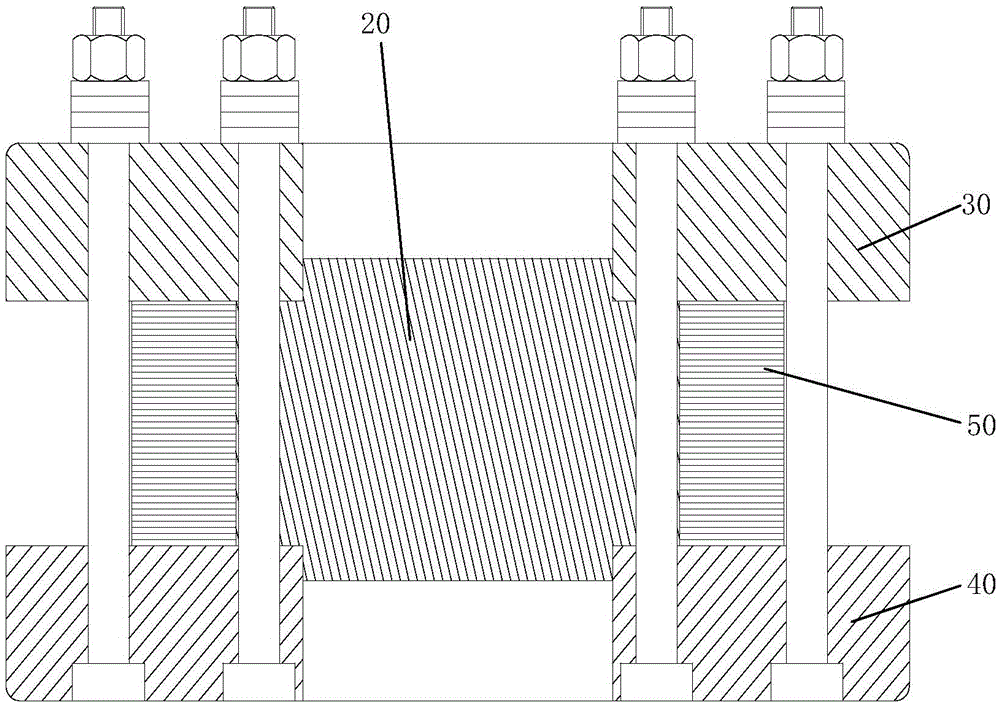

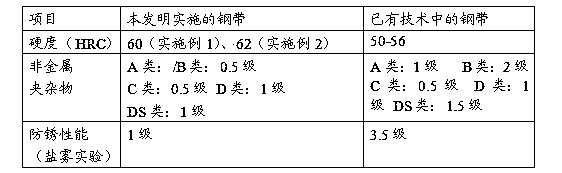

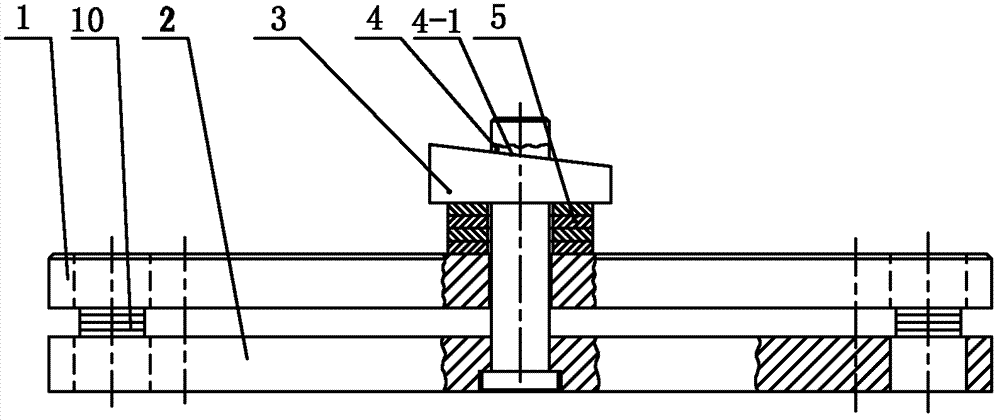

Heat shaping fixture and heat shaping method in quenching process of metal material seal ring

ActiveCN102321796AQuality assuranceEasy to operateFurnace typesHeat treatment furnacesMetallic materialsWaste product

The invention discloses a heat shaping fixture and a heat shaping method in the quenching process of a metal material seal ring, and relates to a heat shaping fixture and a heat shaping method in the quenching process of a seal ring. The invention solves the problems that the integral hardness of a seal ring cannot be improved, the opening size cannot be ensured and waste products are easily produced in the conventional quenching technology. The device comprises that: an upper cover plate and a bottom plate are vertically aligned; a wedge block is nailed in an inclined hole of each shaft; the shaft is sleeved with number adjustable gaskets; the metal material seal ring is arranged between the upper cover plate and the bottom plate; an oil immersion hole on the upper cover plate corresponds to the upper end face of the metal material seal ring; and an oil immersion hole of a lower cover plate corresponds to the lower end face of the metal material seal ring. The method comprises the following steps of: clamping the seal ring in the heat shaping fixture; putting the seal ring and the heat shaping fixture into a heat treatment furnace, and completing quenching and tempering procedures of the heat treatment, which meet the hardness requirement; and detaching the heat shaping fixture and taking the seal ring out. The invention is used for heat shaping in the quenching process of the metal material seal ring.

Owner:HARBIN TURBINE

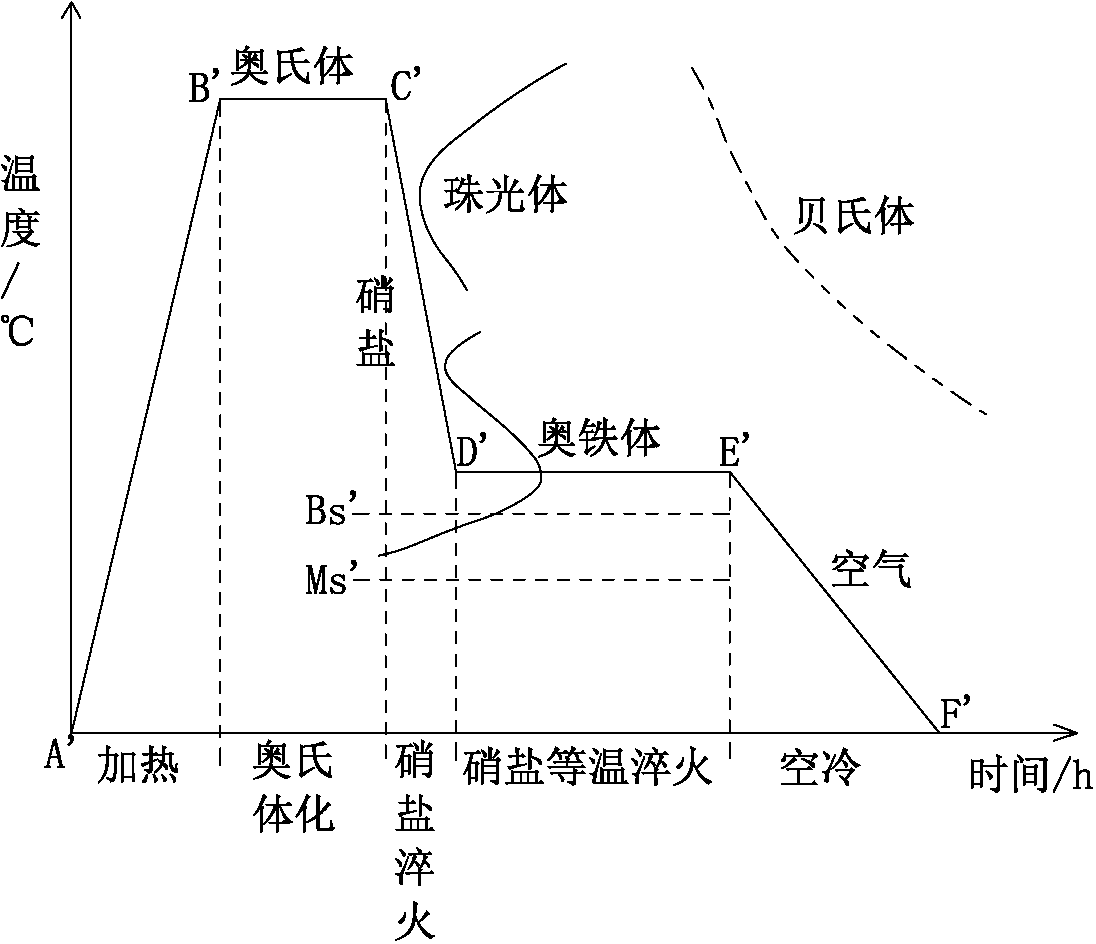

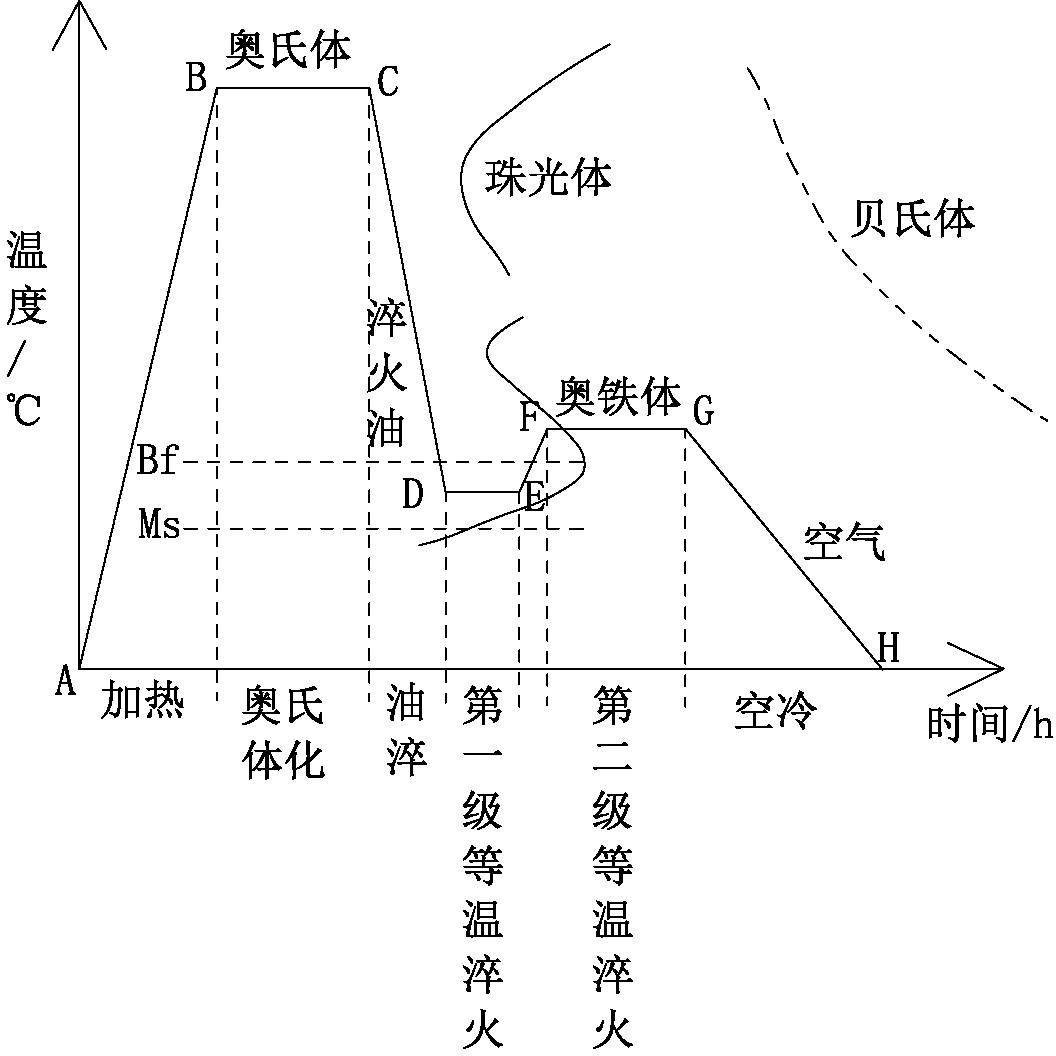

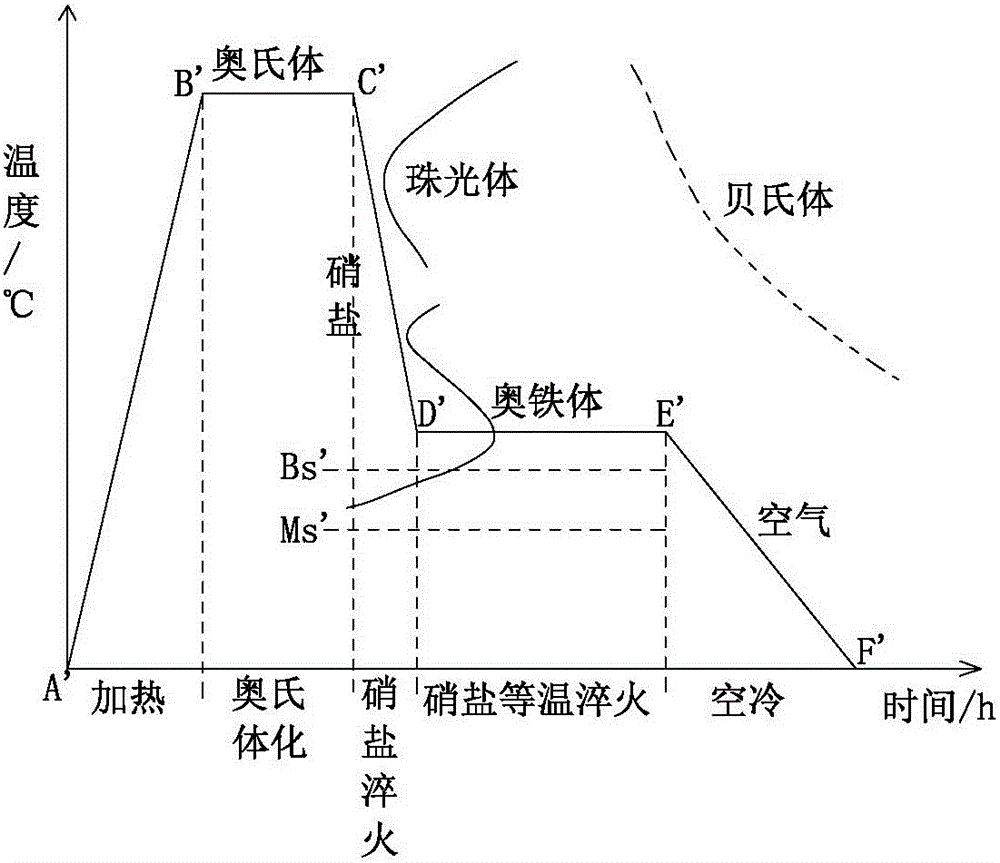

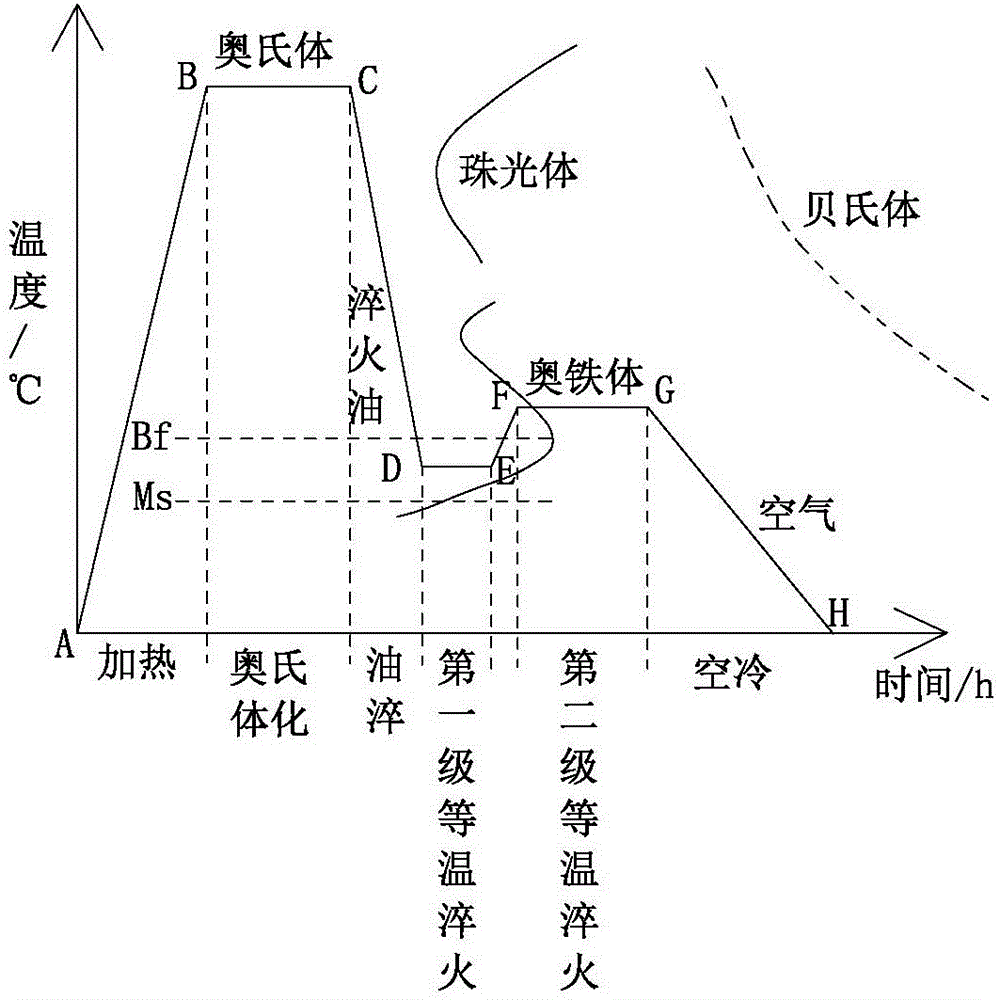

Austempered ductile iron and quenching technology thereof

The invention provides an austempered ductile iron adjusting chemical component. The chemical component uses Mn and Si as a base to substitute Mo and Ni, and contains a plurality of elements comprising Cu, B, Nb and Cr to realize low and micro alloying, so the respective effects of all elements are fully performed, the interactive effect promotion is realized, the hardenability is increased, the alloy consumption is reduced, and the cost is reduced. The invention also provides a new austempered ductile iron quenching technology matched with the austempered ductile iron. The technology is a step austempering technology using step quenching oil and an air isothermal furnace. The heat treatment of a workpiece through the technology realizes crystal grain refinement, good hardenability, high strength and toughness, low hardness (HB190-240) before the step austempering treatment, and good processing performances; and the obtained processed austempered ductile iron has a high hardness (HRC35-56) and extremely less oxidation and deformation, so the precision is guaranteed, and finishing treatments comprising grinding and the like are not needed. Compared with traditional nitrate bath austempering technologies, the austempered ductile iron quenching technology has the advantages of low cost, no generation of large amounts of harmful substances comprising nitrite or the like, low pollution and safety.

Owner:高州创建铸造有限公司

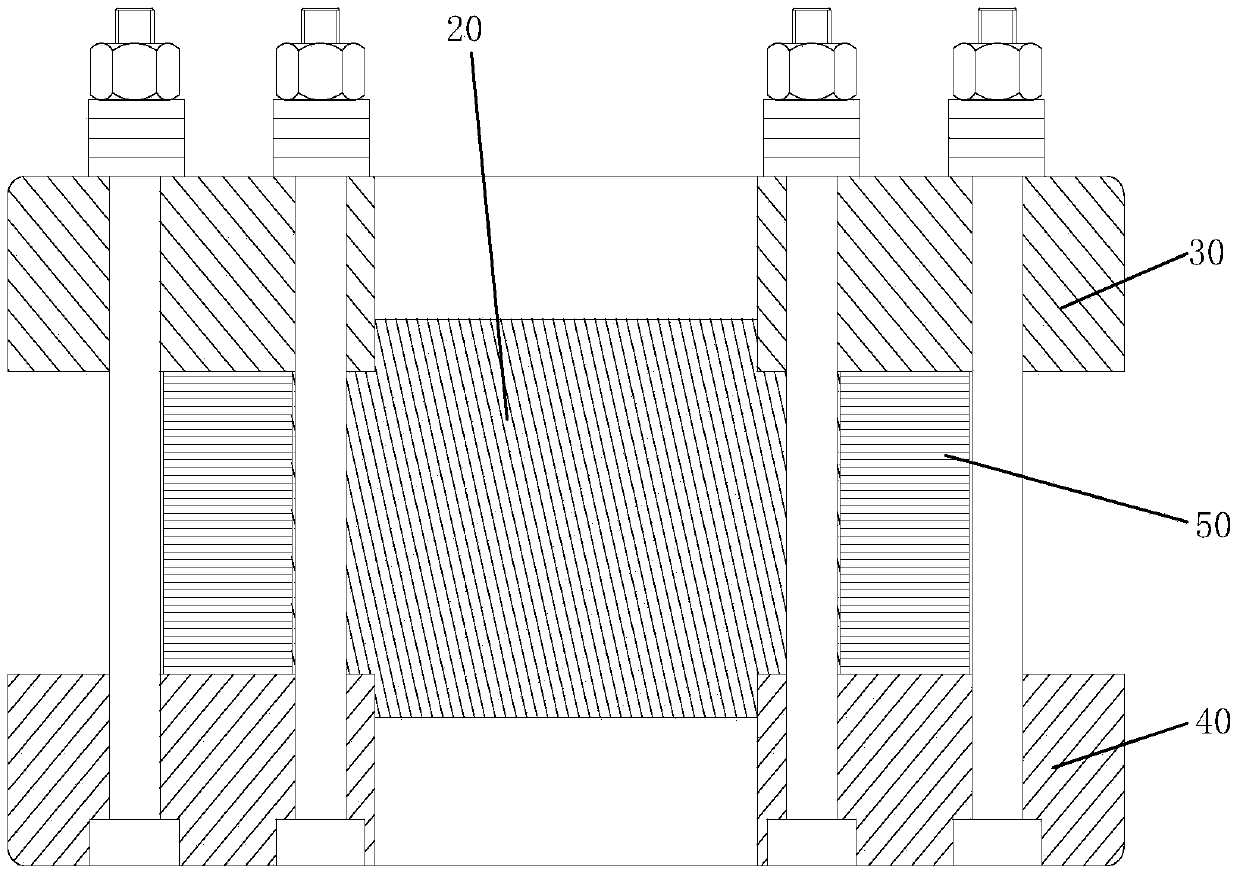

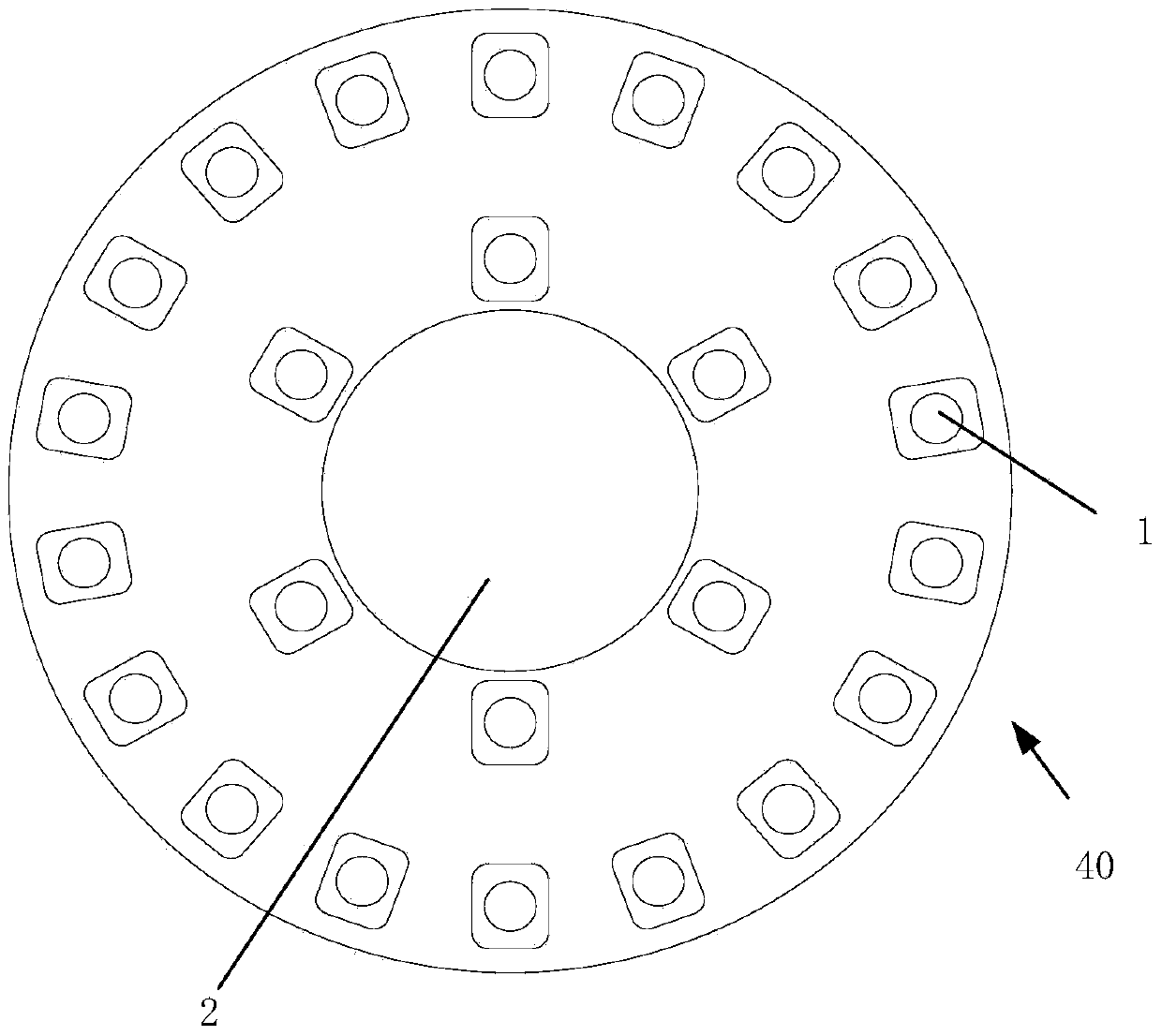

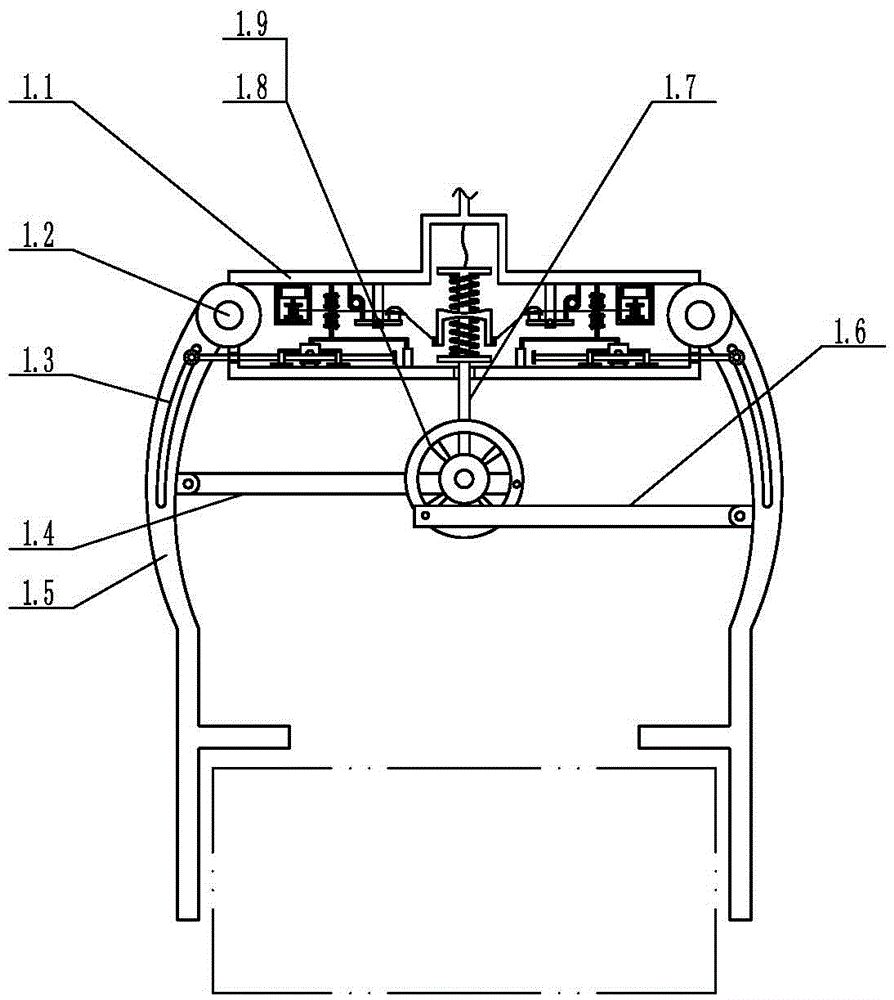

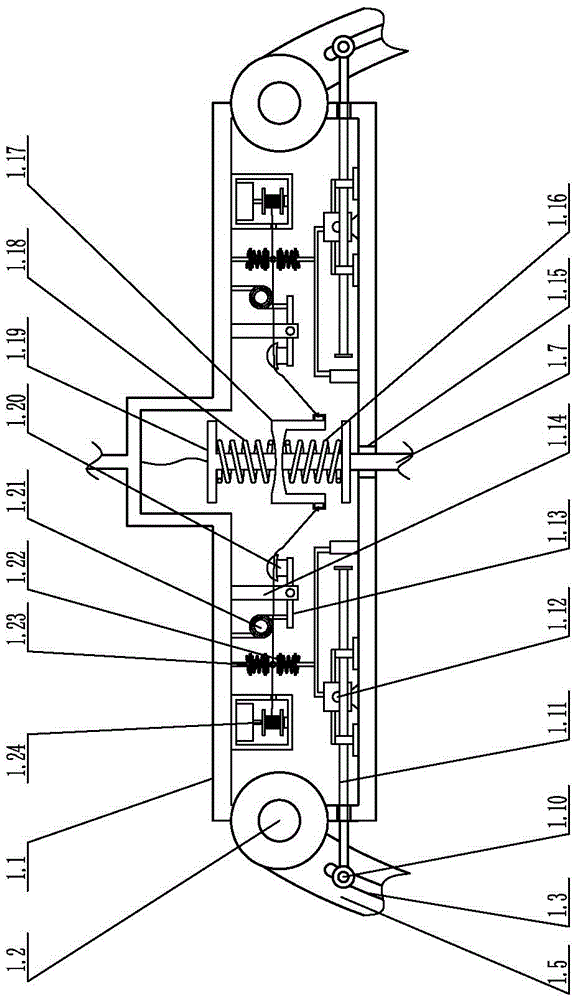

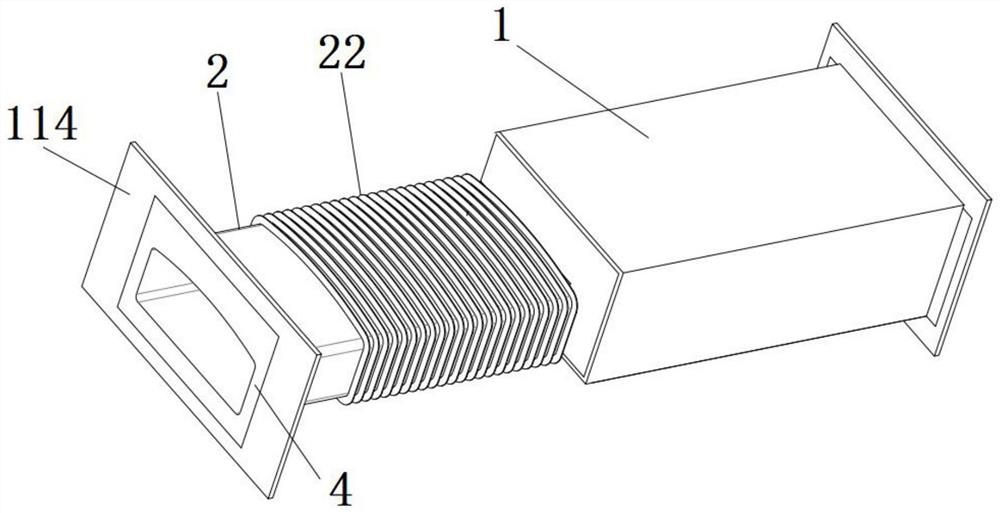

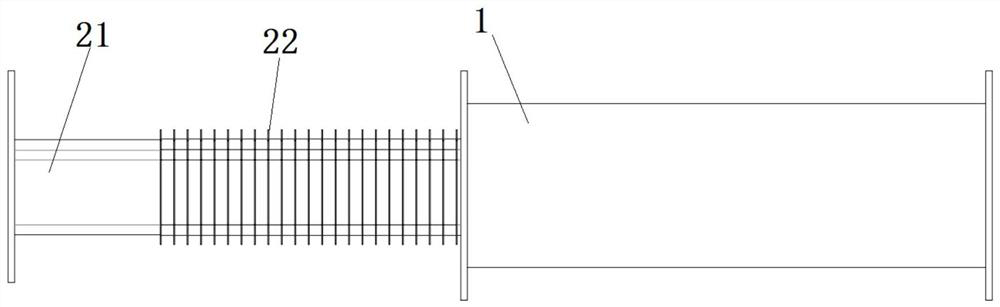

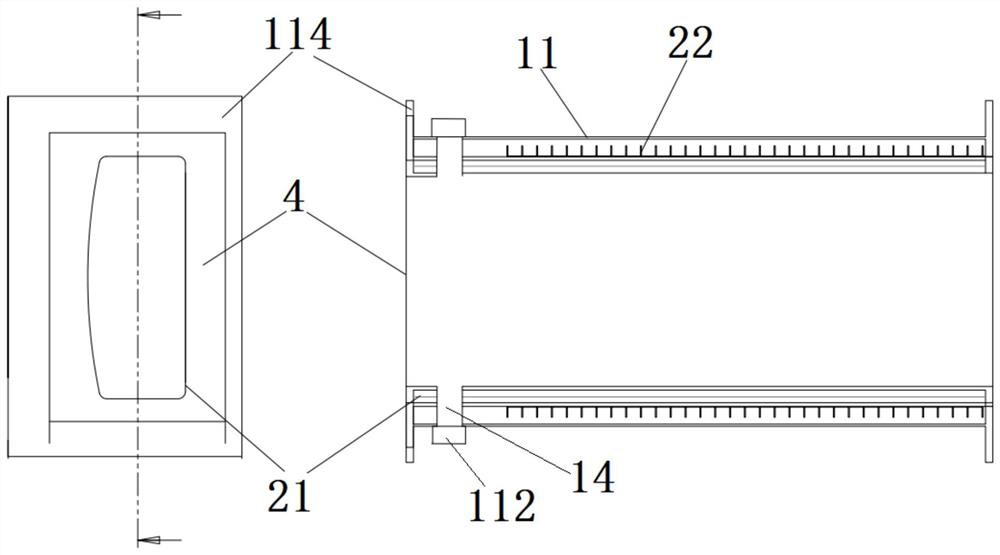

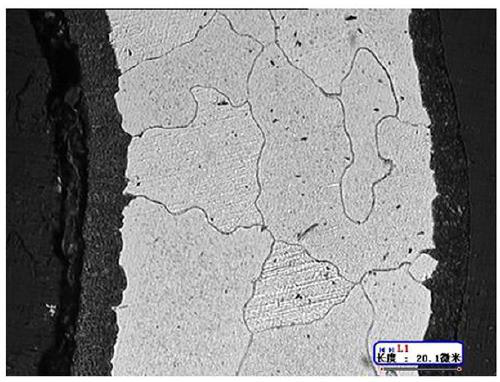

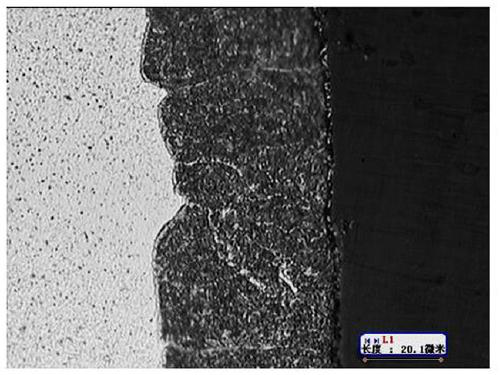

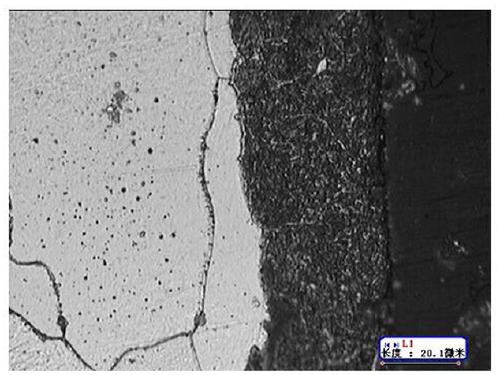

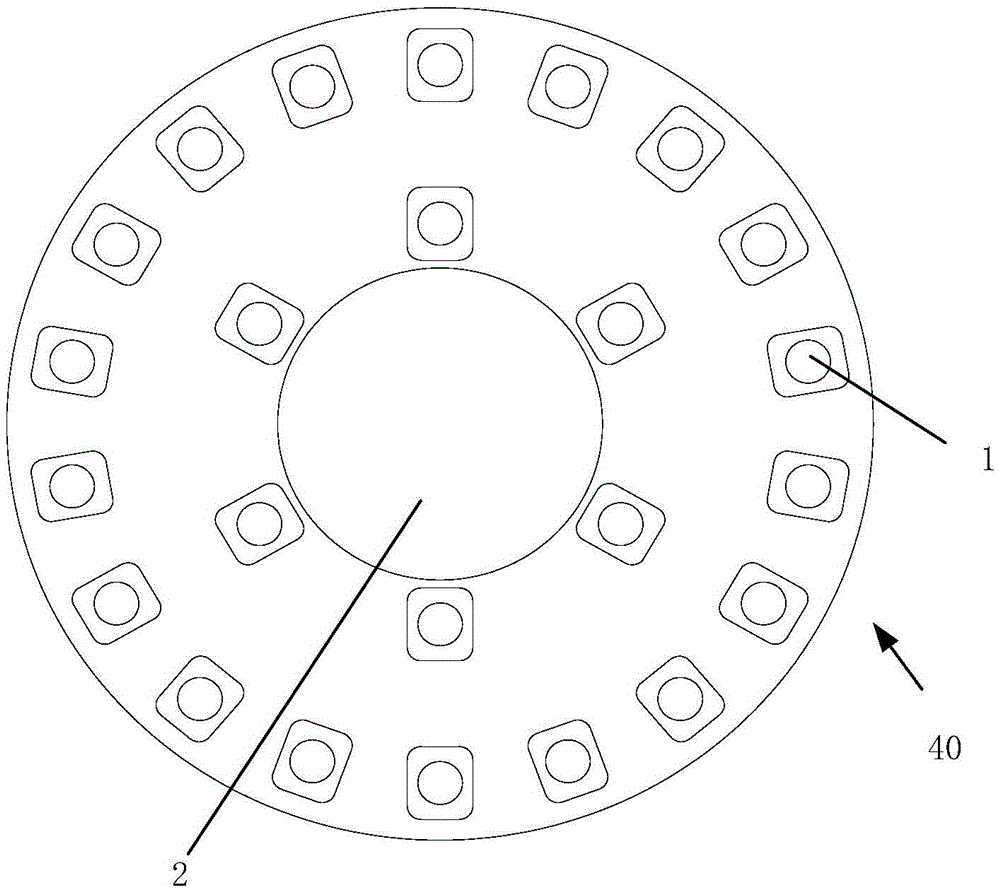

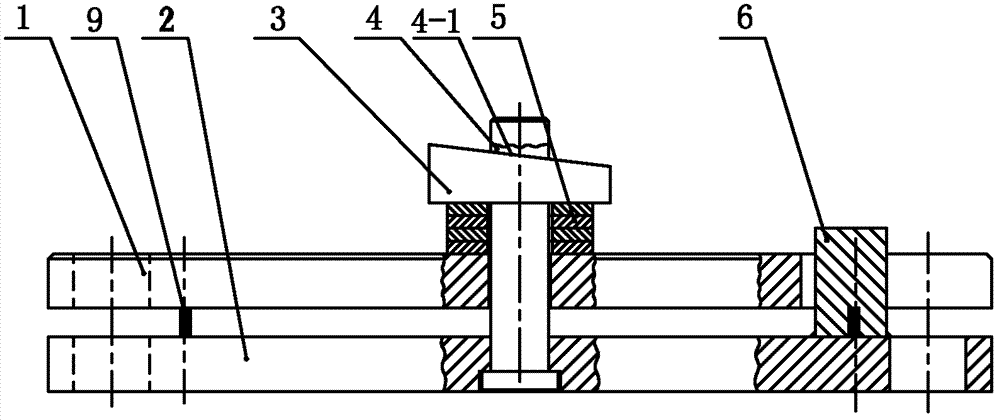

Thin ring part heat treatment fixture and processing method of thin spring steel tooth blade

ActiveCN104120240AImprove quenching hardnessAvoid soft spotsFurnace typesHeat treatment furnacesSpring steelFastener

The invention discloses a thin ring part heat treatment fixture which comprises a partition plate, a core rod, an upper mould plate and a lower mould plate, wherein the upper mould plate and the lower mould plate are oppositely arranged; a plurality of thin ring parts are stacked to form a plurality of thin ring part groups, and every two adjacent thin ring part groups are spaced by the partition plate; the partition plate is provided with a plurality of liquid holes, and the liquid holes are communicated with the annular end surfaces of the two adjacent thin ring part groups; the upper mould plate and the lower mould plate are both provided with first installation holes, and fasteners penetrate through the first installation holes of the upper mould plate and the lower mould plate and the liquid holes to clamp the partition plate and the plurality of thin ring parts between the upper mould plate and the lower mould plate. The invention also discloses a processing method of a thin spring steel tooth blade. The thin ring part heat treatment fixture disclosed by the invention can be used for improving the planeness of the thin ring parts subjected to quenching and tempering.

Owner:武汉华夏精冲技术有限公司

Alloy gray iron material for vehicle covering mould and its preparation method

InactiveCN1693525AEasy to processStrong self-hardening abilityIncreasing energy efficiencyHardnessWear resistance

An alloyed gray pig iron used for the die of the covering part of car contains C (2.8-3.2 wt.%), Si (1.8-2.2), Mn (0.6-0.9), P (0-0.08), S (0-0.03), Cr (0.1-0.5), Cu (0.2-1.0), Mo (0.1-0.5), Ni (0.3-0.5) and Fe (rest). Its preparing process includes such steps as proportionally mixing raw materials, smelting, casting, audio induction quenching, heating to 850-950 deg.C, and quenching in air. Its advantages are high hardness and high mechanical performance.

Owner:SHANGHAI UNIV

Machine tool guide rail broad band laser-quenching technique

The present invention provides a machine tool guide rail broad band laser quenching process, which includes: A. Gasoline or alcohol is used to remove oil stain or rust on the surface of a steel rail, then sand paper is used to polish the surface of the guide rail to remove the oil stain further, so that a light absorbing coat can be applied evenly; B. A spraying gun or a brush can be used to apply the SiO2 light absorbing dope well proportioned with adhering agent mixture on the surface of the guide rail evenly, to improve the absorbing rate of the SiO2 laser by the metal surface; the prescription of the dope and the adhering agent is 80-100gSiO2 plus 500-600ml alcohol plus 15ml paint flake, and the pre-coating thickness is 0.02-0.05mm; C. An air-dry coat; D. A 3-6KW crosscurrent CO2 laser is used to scan the guide rail arranged on a laser numerical control machine at a speed of 250-800mm / min, to heat and cool the SO2 coat on the surface of the guide rail rapidly. The present invention has the advantages that the quenching rigidity is high, the workpiece distortion is small, the quenching medium is not needed, and the work efficiency is high, oxygenation and pollution cannot be produced.

Owner:SHENYANG DALU LASER COMPLETE EQUIP

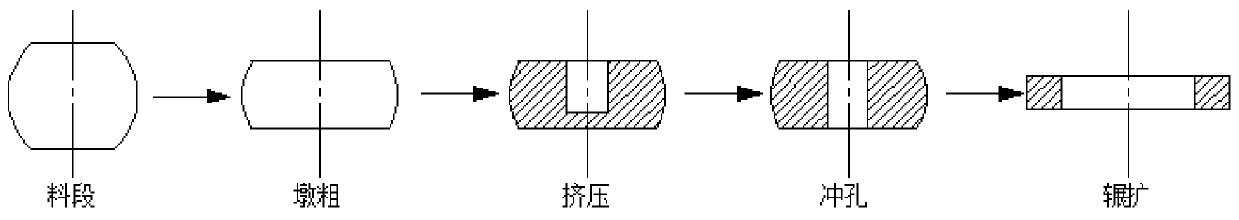

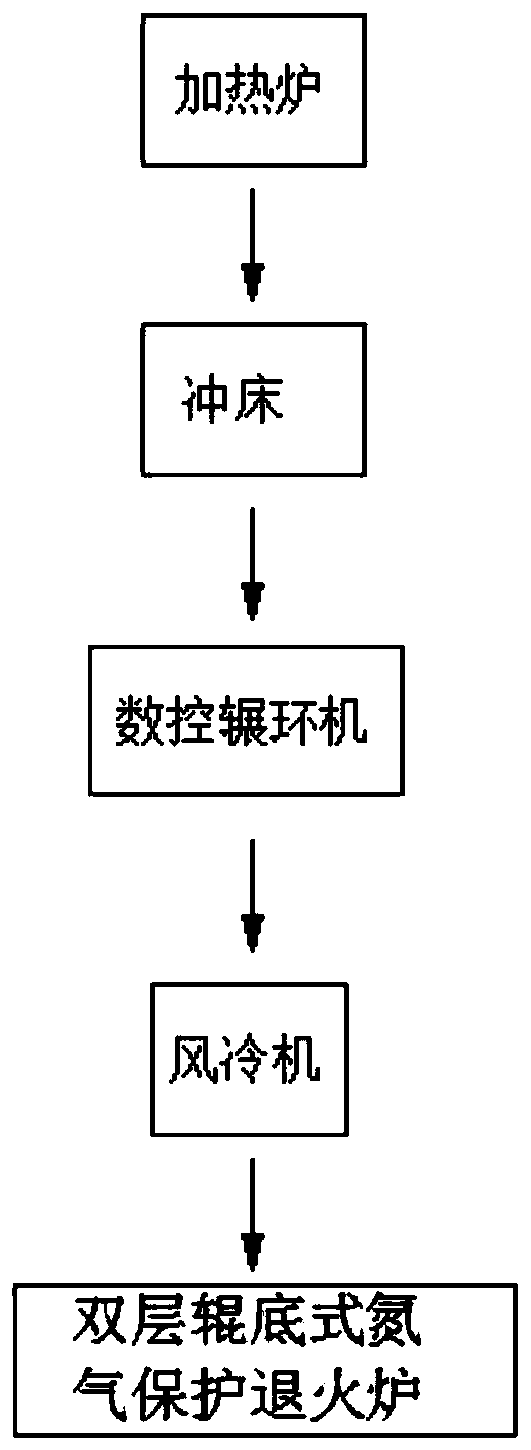

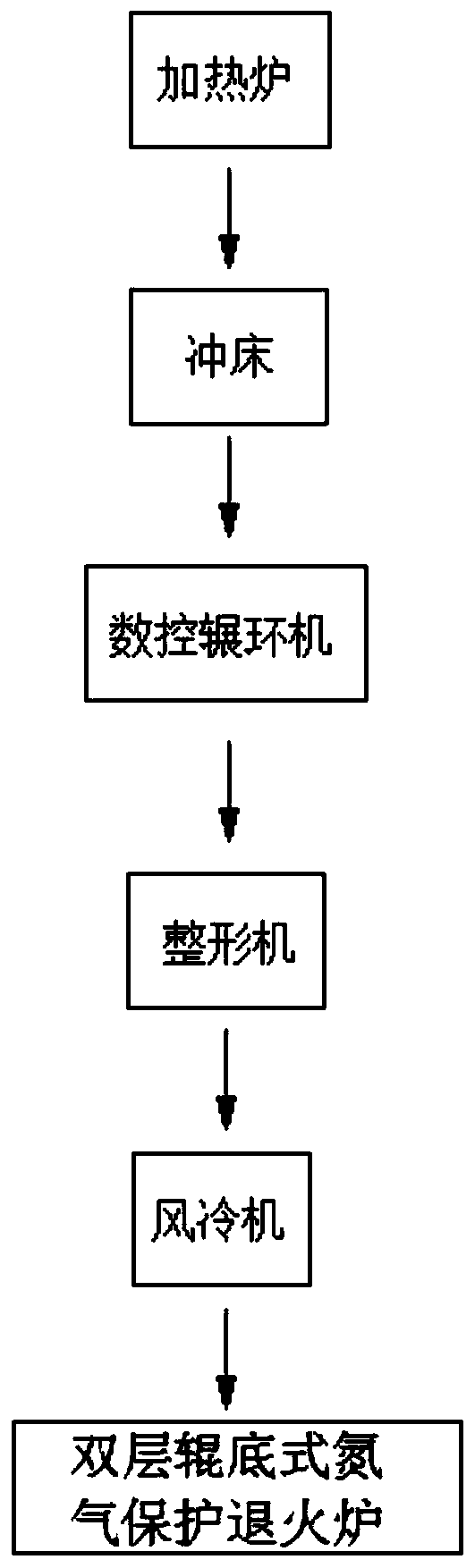

Bearing ring forging machining process and machining system

PendingCN109909437AHigh strengthHigh precisionMetal-working apparatusBearing componentsNumerical controlPunching

The invention discloses a bearing ring forging machining process and machining system, and relates to the technical field of bearing ring forging machining. The process includes the following steps that firstly, a steel material section of a high-carbon chromium bearing is heated to 1130 DEG C to 1180 DEG C; secondly, the heated material section is forged in the axial direction, and a material section subjected to upsetting is obtained; thirdly, the material section subjected to upsetting is extruded so that the middle portion of the material section subjected to upsetting can be indented, theindented portion of the middle portion of the material section is punched through, and a material section subjected to axial punching is obtained; fourthly, ring rolling is conducted on the materialsection, subjected to axial punching, through a numerical control ring rolling machine, and a ring is obtained; fifthly, the ring is air-cooled for 6 min to 8 min to 600 DEG C or below; and sixthly, spheroidizing annealing is conducted on the air-cooled ring through a double-layer roller hearth type nitrogen protection annealing furnace. The machining system comprises a heating furnace, a punchingmachine, the numerical control ring rolling machine, an air cooling machine and the double-layer roller hearth type nitrogen protection annealing furnace. By means of the bearing ring forging machining process and machining system, the surface roughness degree of the bearing ring can be decreased, no decarburized layers are generated after spheroidizing annealing, and therefore the cutting machining allowance is reduced, steel is saved, and the raw material utilization rate is increased.

Owner:临清市同兴轴承锻造有限公司

Hard hollow alloy ball iron mould material for vehicle mould and its making method

InactiveCN1693526AStrong processing technologyImprove quenching hardnessIncreasing energy efficiencyHardnessAlloy

An air-hardened alloyed nodular cast iron for the die of car contains C (3.5-3.8 wt.%), Si (2.1-2.5), Mn (0.5-0.8), Cr (0.1-0.3), Cu (0.8-1.0), Mo (0.4-0.6), Ni (0.2-0.4), P (0-0.02), S (0-0.02) and Fe (rest). Its preparing process includes such steps as proportionally mixing raw materials, smelting, casting, quenching in audio induction mode, heating to 850-950 deg.C, and quenching in air. Its advantages are high hardness and high mechanical performance.

Owner:SHANGHAI UNIV

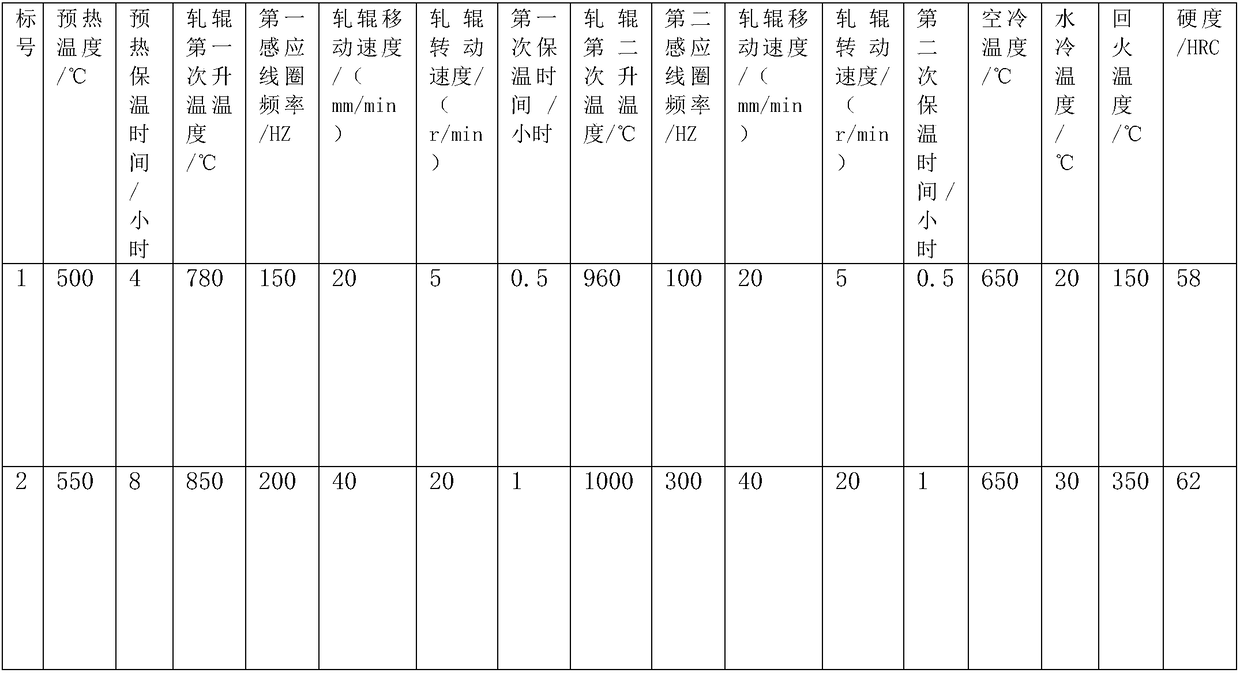

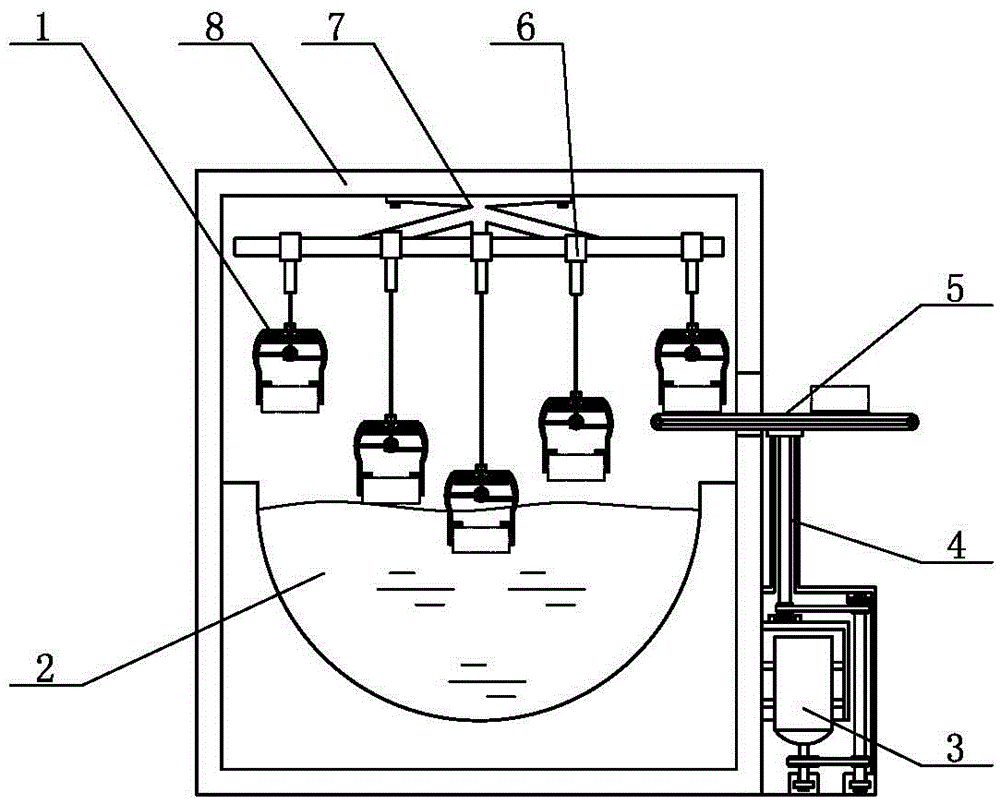

Improved roller double-frequently quenching process

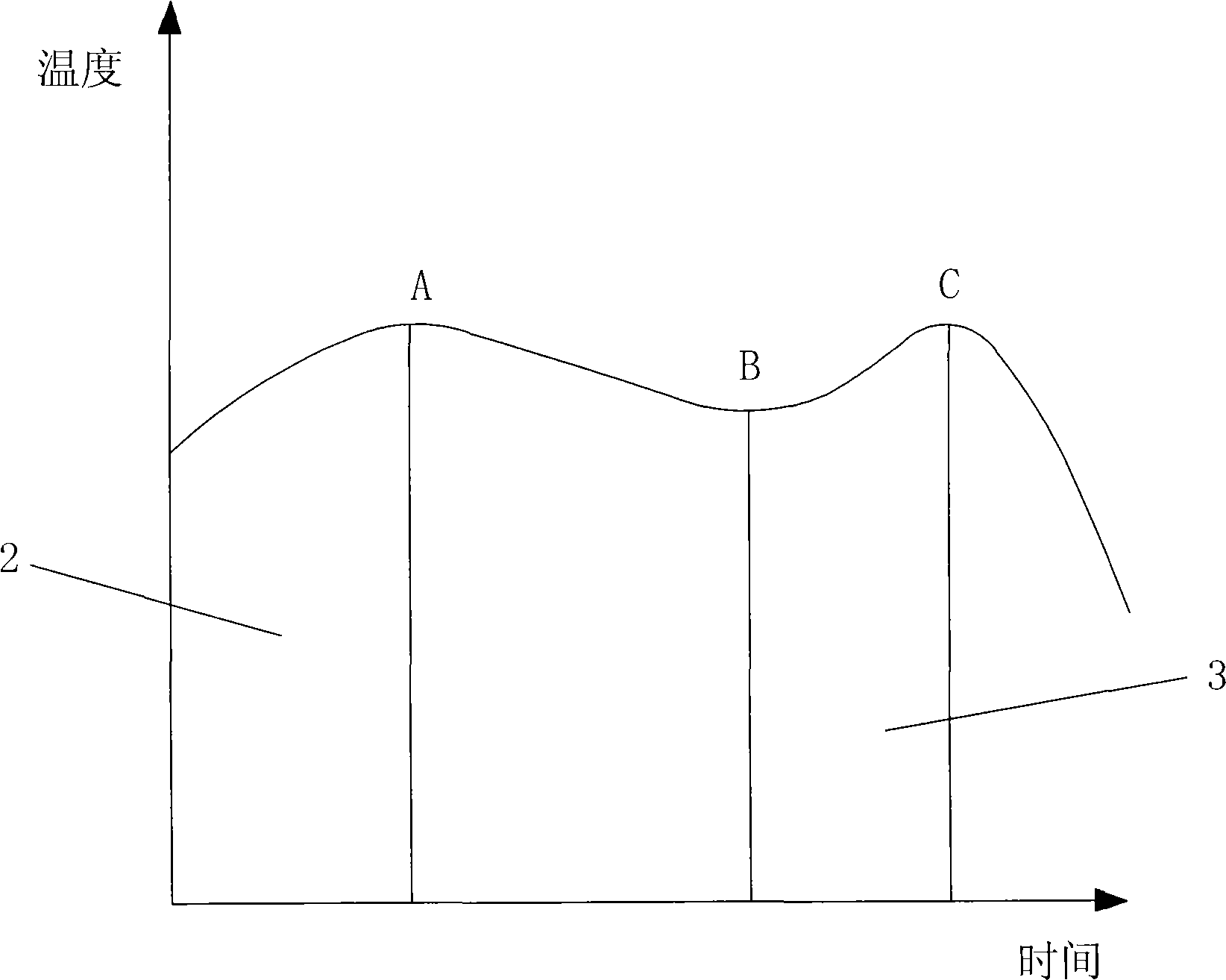

InactiveCN101509054AReasonable temperature distributionFully austenitizedFurnace typesIncreasing energy efficiencyDeep levelDouble frequency

The invention discloses an improved roller double frequency quenching technique. A roller which is vertically hung on a quench machining tool sequentially passes through an upper sensor and a lower sensor from top to bottom; then, a sprinkler positioned under the sensor is used for quenching and cooling the roller; the heating-up temperature (TA) of the upper sensor is slightly higher than the heating-up temperature (TC) of the lower sensor, so that the temperature distribution tend to be reasonable, and the distance between the upper sensor and the lower sensor can be enlarged, thus being beneficial to full austenization and deep level heat permeating.

Owner:JIANGSU RUNFU MECHANICAL ROLL MFG

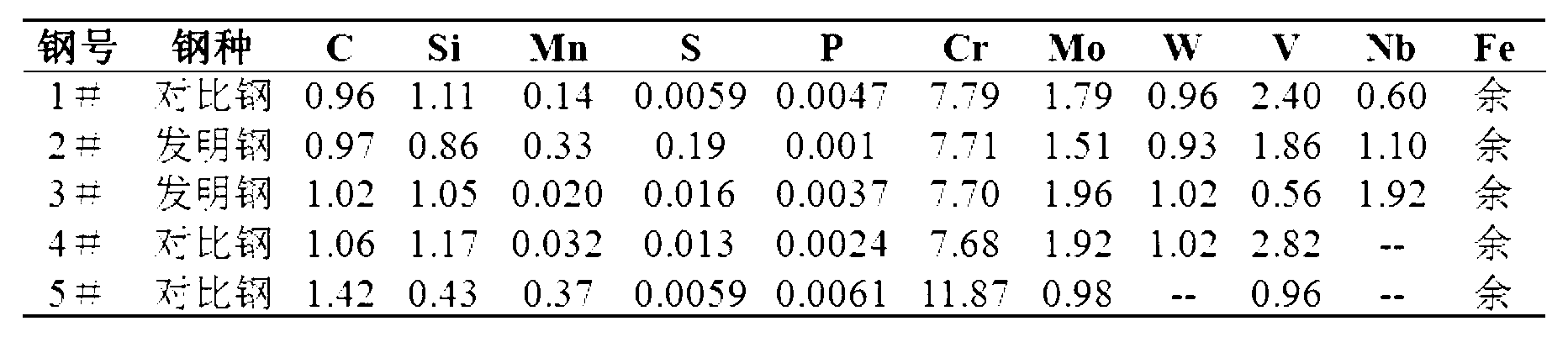

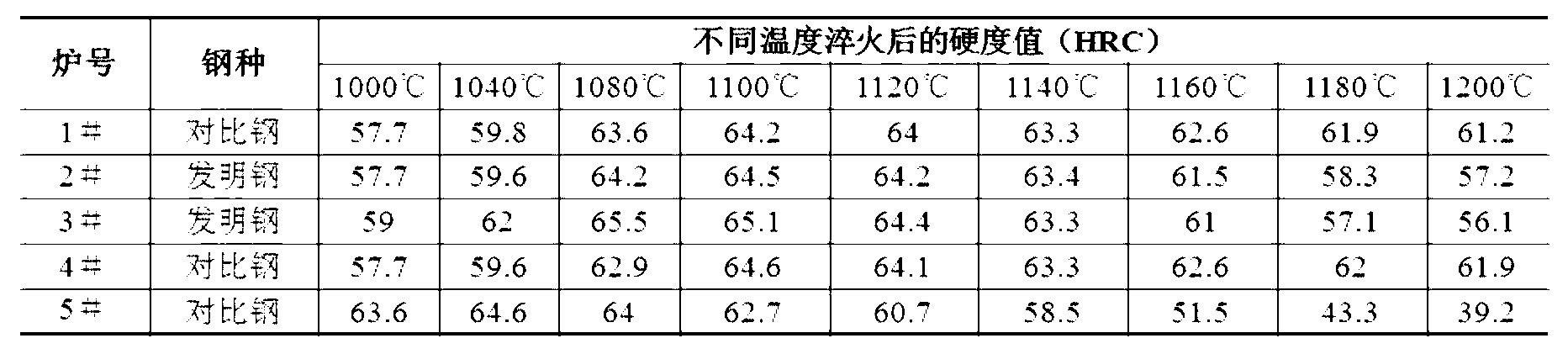

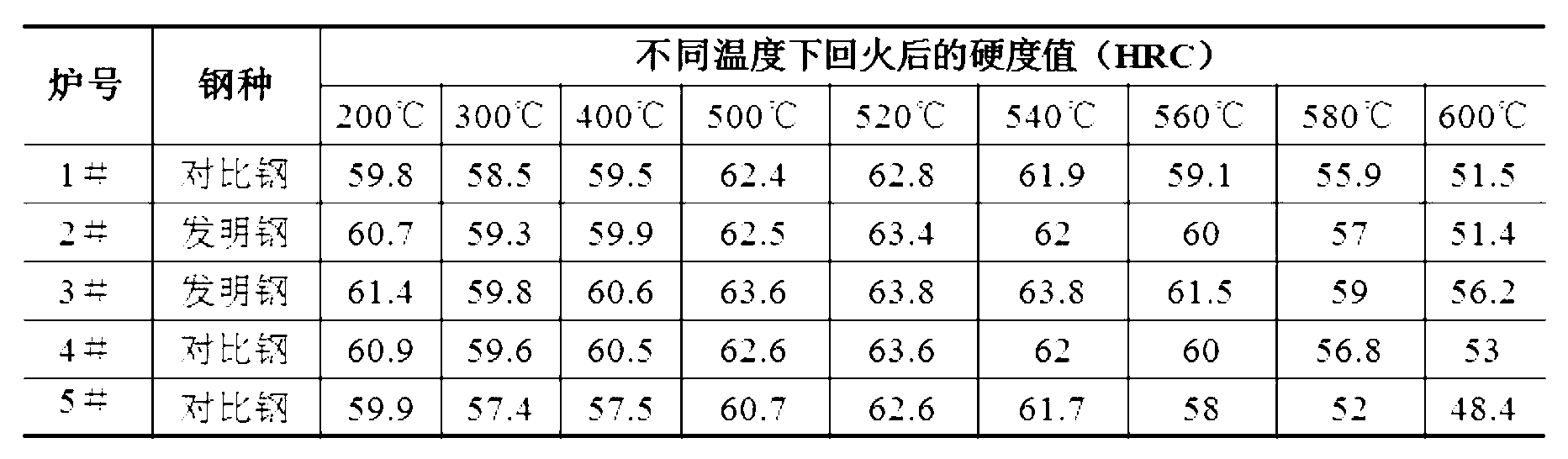

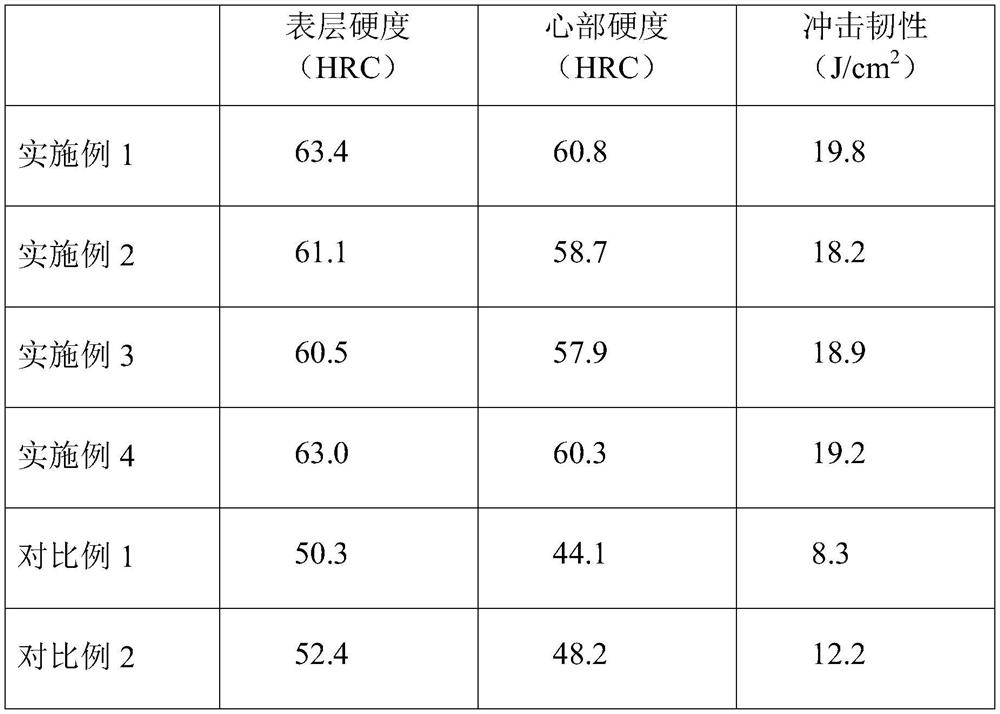

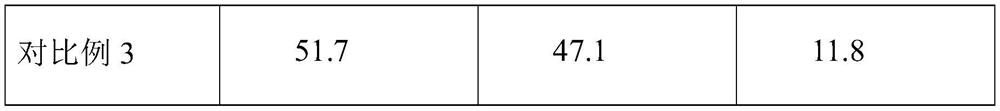

High-niobium, high-wear-resistance and high-toughness cold-work die steel

The invention discloses a kind of high-niobium, high-wear-resistance and high-toughness cold-work die steel, which belongs to the technical field of die steel. The die steel comprises the following chemical compositions in percentage by weight: 0.80-1.20% of C, 0.50-1.60% of Si, less than or equal to 0.030%, less than or equal to 0.030% of P, less than or equal to 0.40% of Mn, 0.80-1.20% of W, 1.50-2.20% of Mo, 7.80-8.20% of Cr, 0.50-1.90% of V, 1.10-2.00% of Nb, and the balance of Fe and unavoidable impurities. Compared with the prior art, the die steel disclosed by the invention has the advantages of high hardness, high wear resistance, high toughness and good comprehensive performance. The die steel disclosed by the invention is high in quenching peak hardness (65.5 HRC), high in secondary hardening hardness (63.8-64.5 HRC), and good in impact toughness (8-11J).

Owner:CENT IRON & STEEL RES INST

Quenching oil capable of enabling automobile plate spring to blacken automatically after quenched and quenching method thereof

ActiveCN105925768AWarranty Strength RequirementsGuaranteed stiffness requirementsFurnace typesMetallic material coating processesAntioxidantBase oil

The invention discloses quenching oil capable of enabling an automobile plate spring to blacken automatically after quenched and a quenching method thereof. The invention belongs to the field of metal heat treatment technology. The quenching oil comprises the following components, by weight, 35-40 parts of refined base oil, 7-10 parts of cooling catalyzed composite agent, 0.4-0.7 parts of blackening composite agent, 0.3-0.5 parts of brightening agent, 0.4-0.7 parts of surface activating agent and 0.02-0.03 parts of antioxidant. The effect is best when the maximum cooling speed of the quenching oil for the plate spring is about 110-120 DEG C / s and the using temperature is 65-70 DEG C. Under the above conditions, the strength and the stiffness of the quenched plate spring are greatly improved, at the same time the effect of the automatic surface blackening can be realized and a protective film formed on the surface is strong in adhesion and good in wear-resisting property. Once more surface coating and rust preventing treatment after the heat treatment can be reduced, so that the resources can be saved, the processes can be reduced and the efficiency can be improved.

Owner:马鞍山金泉工业介质科技有限公司

Heat treatment technology of martensite stainless steel workpiece

InactiveCN103627858AMeet the hardness requirements of heat treatmentGuaranteed heat treatment performanceMartensitic stainless steelHardness

The invention discloses a heat treatment technology of a martensite stainless steel workpiece. The technology comprises the steps of annealing, quenching, a primary tempering technology and a secondary tempering technology. By adopting the above mode, the heat treatment technology allows a forged piece to satisfy a heat treatment hardness requirement, guarantees the heat treatment performance, realizes a high quenching hardness, and also realizes alloy uniformization, crystal grain refinement and forging stress elimination.

Owner:SUZHOU BAOFORGING

Quenching phosphorated fluid for metal comprehensive processing

InactiveCN101671769ANo pollution in the processHigh degree of phosphatingMetallic material coating processesQuenching agentsPhosphateSurface-active agents

Owner:SHANDONG TENGDA STAINLESS STEEL PRODS

Preparing device and method for zero decarburization layer bearing steel wire rod

InactiveCN107322248AImprove wear resistanceImprove pitting resistanceOther manufacturing equipments/toolsWire rodAbutment

The invention discloses a preparing device and method for a zero decarburization layer bearing steel wire rod. The preparing device comprises a balling annealing furnace, a front cold drawing machine, a horizontal and vertical straightener, a centreless lathe, a rear cold drawing machine and a recrystallization annealing furnace. The outlet end of the front cold drawing machine is in butt joint with the inlet end of the horizontal and vertical straightener. The outlet end of the horizontal and vertical straightener is in butt joint with the inlet end of the centreless lathe. The outlet end of the centreless lathe is in butt joint with the inlet end of the rear cold drawing machine. The balling annealing furnace, the front cold drawing machine, the horizontal and vertical straightener, the centreless lathe, the rear cold drawing machine and the recrystallization annealing furnace are adopted in the preparing device and method for continuous machining of the bearing steel wire rod, a finished zero decarburization layer bearing steel wire rod high in strength and good in tenacity is obtained, and integral treatment of the large-specification bearing steel wire rod is achieved. The yield is high, the material utilization rate is high, the machining efficiency is improved, and the preparing device and method are suitable for industrial production.

Owner:洛阳鼎辉特钢制品股份有限公司

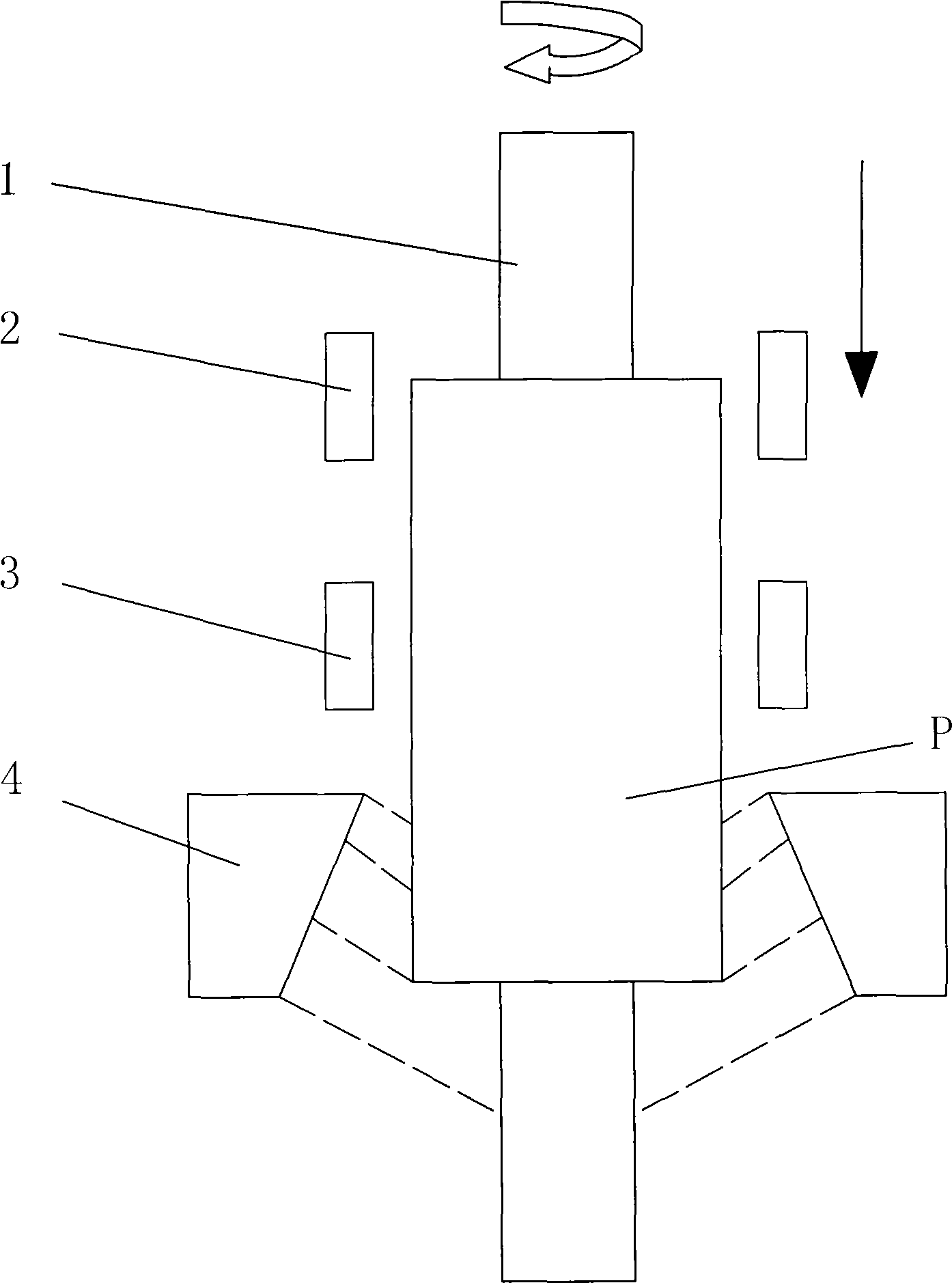

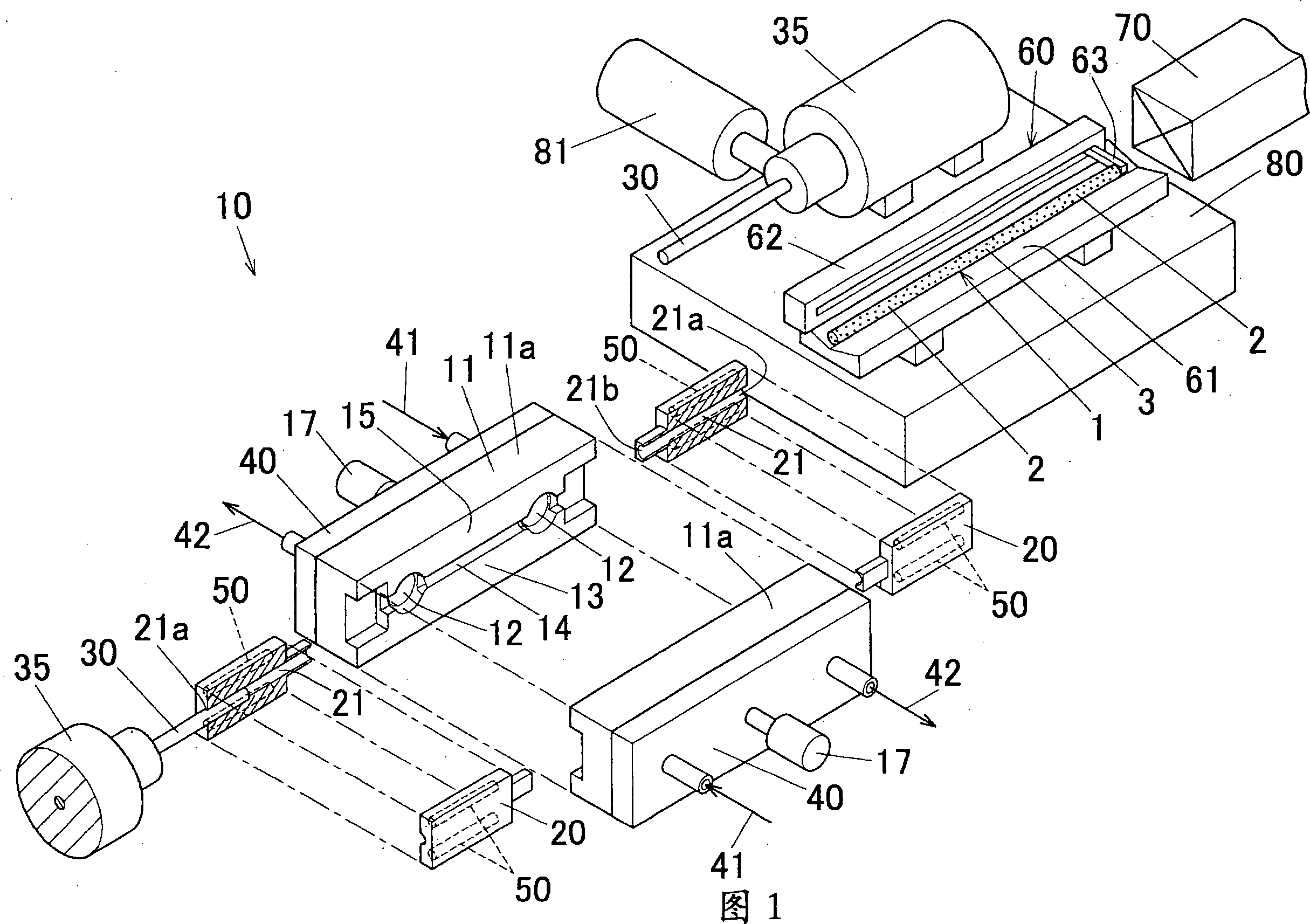

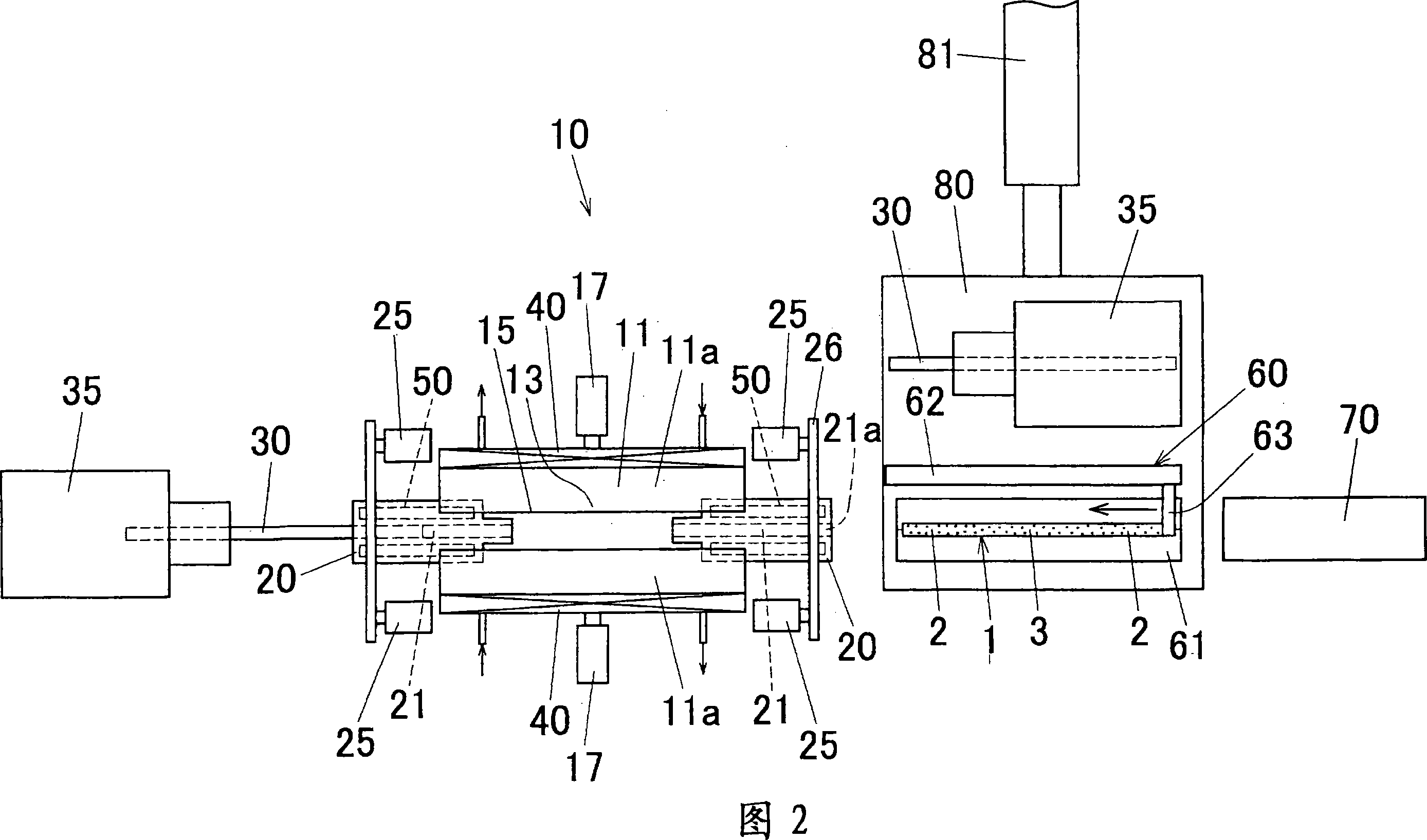

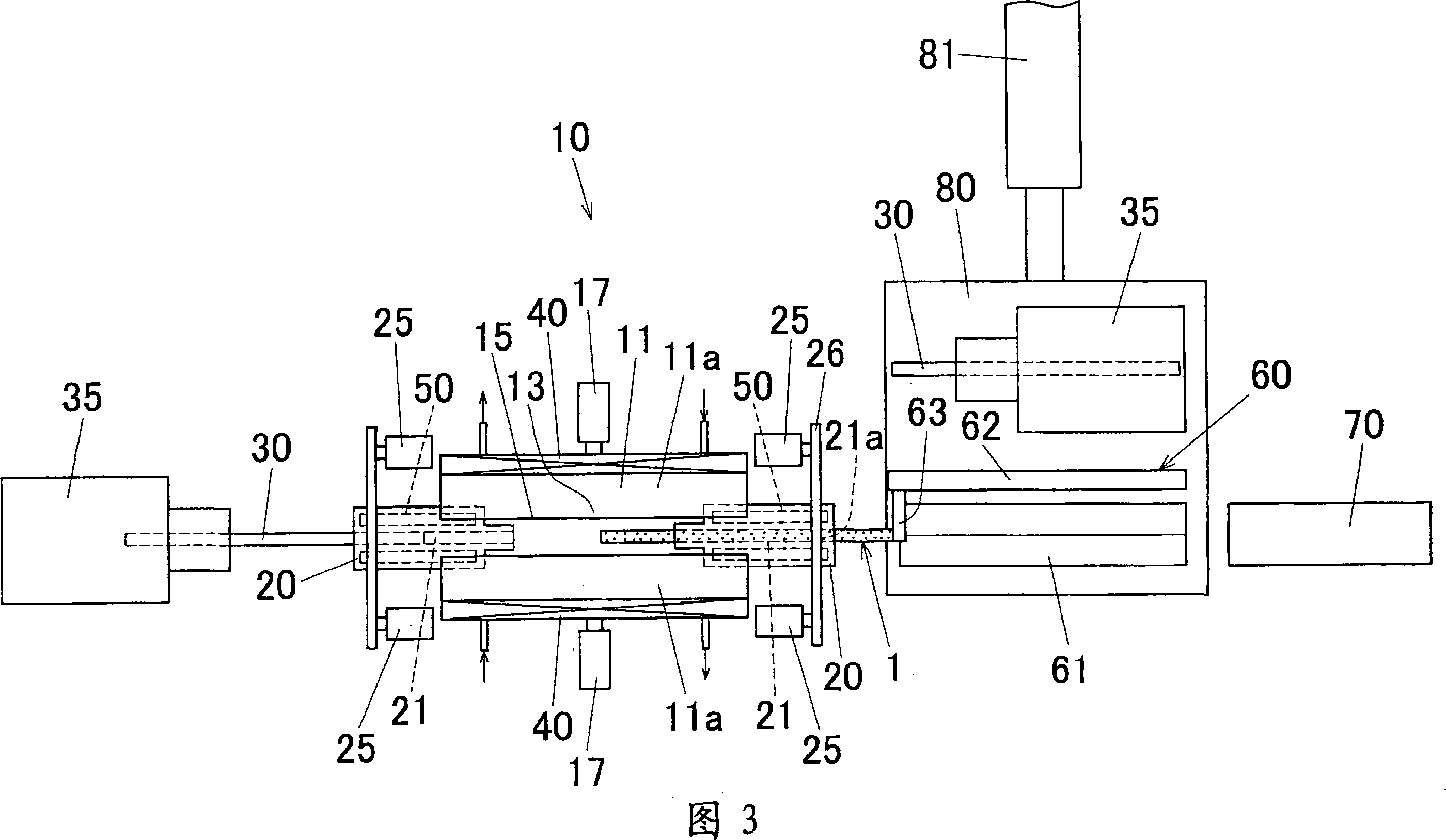

Method and apparatus for upsetting

InactiveCN101198424AEliminate corrective stepsPrevent quenching distortionForging/hammering/pressing machinesDistortionMaterials science

An upsetting method capable of eliminating a correction step by preventing occurrence of quench distortion is provided. The method includes the step of preparing an upsetting apparatus 10 equipped with a forming die 11 and a guide 20 having an insertion hole 21 for securing a diameter expansion scheduled portion 2 of the bar-shaped raw material 1 in a buckling preventing state and a punch 30. The diameter expansion scheduled portion 2 of the raw material 1 in a heated state is disposed in the insertion hole 21 of the guide 20 in a heated state, and the tip end portion of the guide 20 is disposed in the cavity 12 of the forming die 11 adjusted in temperature so as to be below a temperature of the raw material 1, and the raw material is secured to the securing portion 13 of the forming die 11. With this state, the guide 20 is moved in a direction opposite to a moving direction 37 of the punch 30 while axially pressurizing the diameter expansion scheduled portion 2 of the raw material 1 by moving the punch 30, to thereby expand the diameter expansion scheduled portion 2 of the raw material 1 exposed between a tip end portion of the guide 20 and the securing portion 13 of the forming die 11 within the cavity 12 of the forming die 11.

Owner:SHOWA DENKO KK

Induction quenching machining method of Cr12 roller

ActiveCN108130403AImprove quenching hardnessIncrease Hardening and ThickeningFurnace typesIncreasing energy efficiencyQuenchingPre cooling

The invention discloses an induction quenching machining method of a Cr12 roller, and belongs to a roller quenching process. The induction quenching machining method comprises the following steps: (1)putting a roller to be quenched into a resistance furnace and preheating the roller to be quenched to 500 DEG C to 600 DEG C and performing heat insulation for a period of time; (2) enabling the roller to penetrate through a first induction coil at a certain motion speed and a rotation speed, preheating the roller to 780 DEG C to 900 DEG C and performing heat insulation for a period of time; (3)enabling the roller to penetrate through a second induction coil at the certain motion speed and the rotation speed, heating the roller to 960 DEG C and 1080 DEG C and performing heat insulation for aperiod of time; (4) performing air-cooling and pre-cooling on the roller and then performing water-cooling quenching; and (5) putting the roller into an air-circulation tempering furnace and performing tempering at a tempering temperature of 150 DEG C to 500 DEG C. According to the induction quenching machining method disclosed by the invention, uniformity and fineness of metallurgical structuresof the roller can be ensured, the hardness is qualified, and the labor strength is reduced.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

Digital quenching process of leaf spring

ActiveCN106048189AImprove finished product qualityHigh hardened thicknessFurnace typesHeat treatment bathsSmall sampleQuenching

The invention discloses a digital quenching process of a leaf spring, and belongs to the technical field of a heat treatment and quenching process of a leaf spring. According to the present invention, the whole set of the quenching and cooling process is matched with the special equipment, the quenching cooling temperature is controlled by a digital terminal, the cooling curve close to the design process is achieved, the ideal material structure and the performance can be obtained, and the quality of the finished product leaf spring is substantially improved; the organic polymer water-soluble quenching liquid is used to replace the rapid oil or diesel oil to quench so as to save the rapid oil or the diesel oil, such that the production cost is reduced, and the production environment and the natural resources are protected; the quenching equipment achieves the whole-process automation during the operation implementation so as to reduce the labor consumption, and the workers only require the remote operation without close contact of the quenching environment so as to provide the high safety and health coefficient; and the production cost is reduced with the automatic equipment, and the process is suitable for small samples and can further achieve mass production.

Owner:山东雷帕得悬架系统检测有限公司

A kind of austempering ductile iron and its quenching process

The invention provides an austempered ductile iron adjusting chemical component. The chemical component uses Mn and Si as a base to substitute Mo and Ni, and contains a plurality of elements comprising Cu, B, Nb and Cr to realize low and micro alloying, so the respective effects of all elements are fully performed, the interactive effect promotion is realized, the hardenability is increased, the alloy consumption is reduced, and the cost is reduced. The invention also provides a new austempered ductile iron quenching technology matched with the austempered ductile iron. The technology is a step austempering technology using step quenching oil and an air isothermal furnace. The heat treatment of a workpiece through the technology realizes crystal grain refinement, good hardenability, high strength and toughness, low hardness (HB190-240) before the step austempering treatment, and good processing performances; and the obtained processed austempered ductile iron has a high hardness (HRC35-56) and extremely less oxidation and deformation, so the precision is guaranteed, and finishing treatments comprising grinding and the like are not needed. Compared with traditional nitrate bath austempering technologies, the austempered ductile iron quenching technology has the advantages of low cost, no generation of large amounts of harmful substances comprising nitrite or the like, low pollution and safety.

Owner:高州创建铸造有限公司

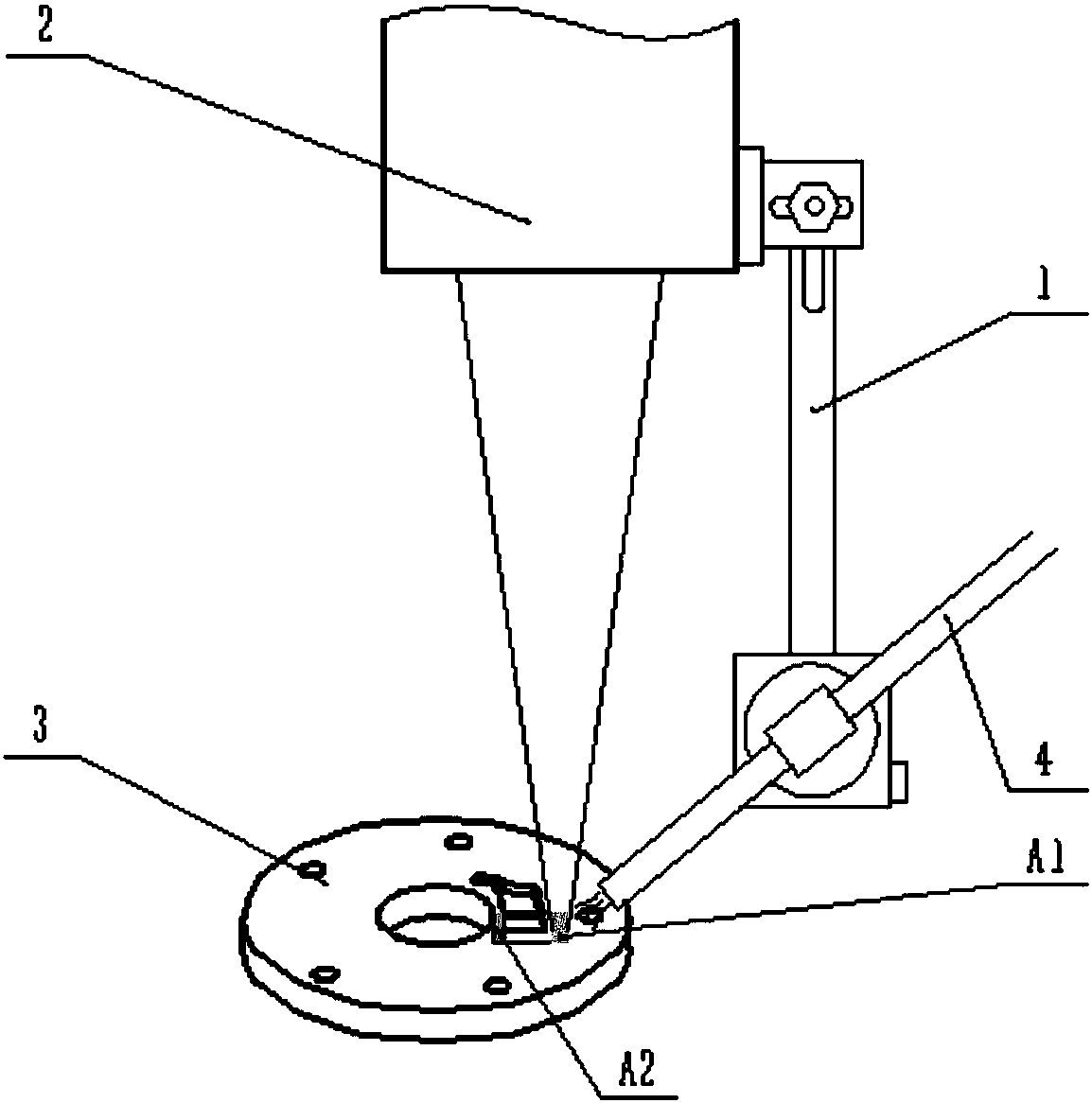

A powder metallurgy automobile engine sprocket lock pin hole laser quenching method

ActiveCN106755755BFine grainIncrease the dislocation densityFurnace typesHeat treatment furnacesLaser quenchingInduction hardening

Owner:XIAN BESAME LASER TECH CO LTD

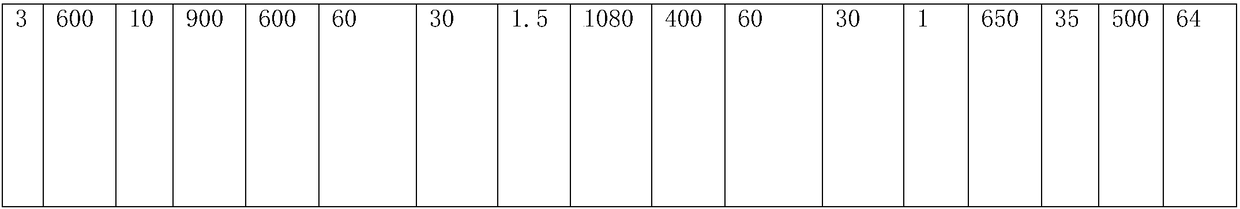

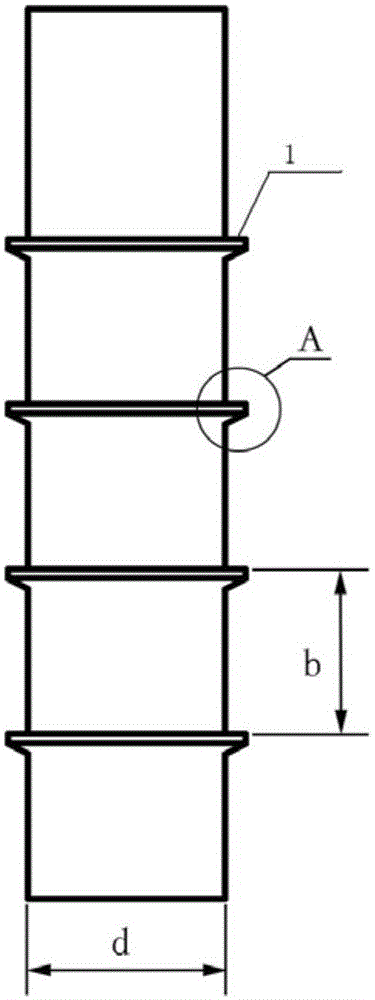

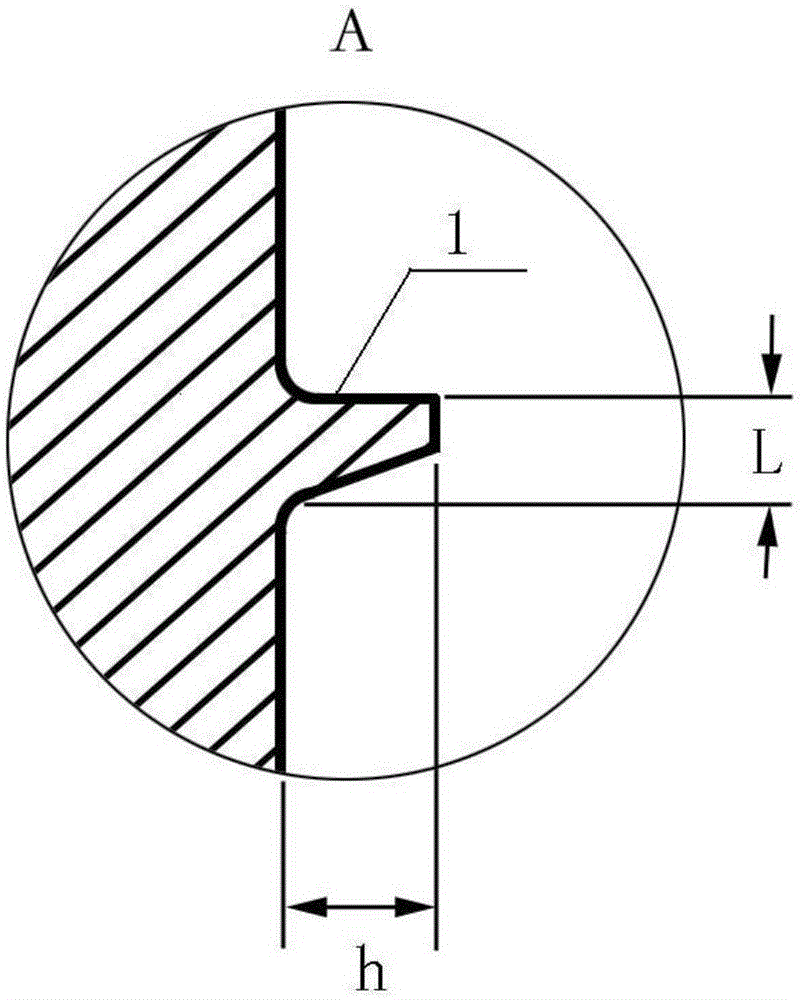

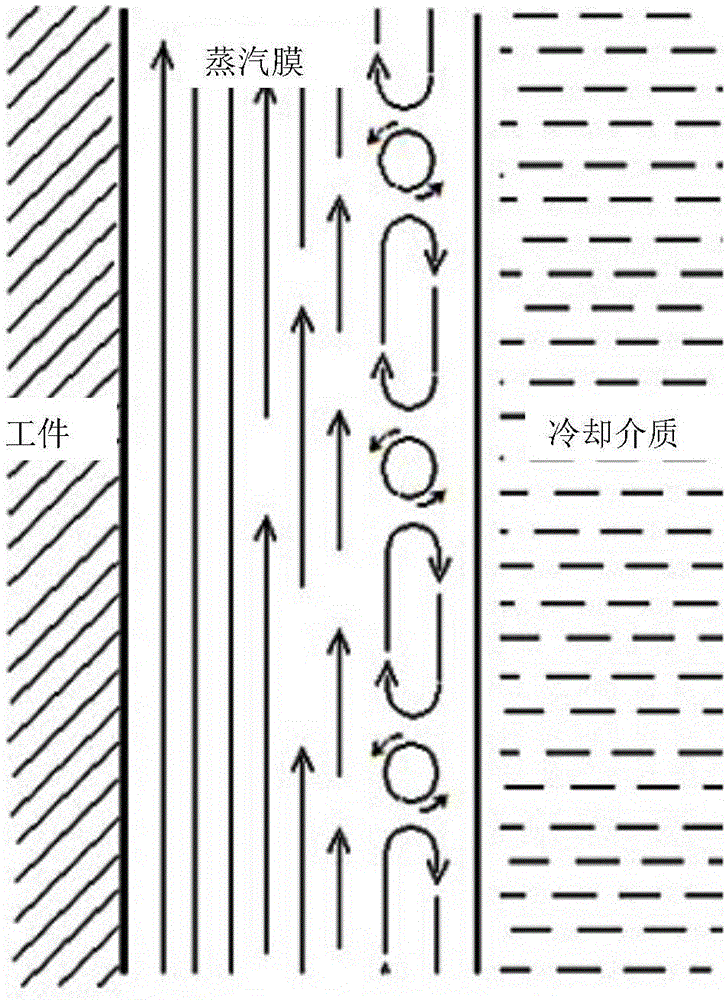

Immersion oil quench cooling method adopting plurality of sections for bubble emission

ActiveCN105002331AImprove inner qualityReduce quenching distortionFurnace typesHeat treatment furnacesHardnessEngineering

The invention discloses an immersion oil quench cooling method adopting a plurality of sections for bubble emission. The method is adopted for perpendicular immersion oil quench cooling process of a workpiece. The workpiece is an axis workpiece or a workpiece with axis-shaped sections. The method comprises the following steps: reserving a plurality of axially distributed separation ring except the required size of the workpiece during the cutting process before the quench cooling process, so as to divide the workpiece into the sections axially; then, heating the axis workpiece with the separation rings or the axis-shaped sections, and carrying out cooling to fulfill quench cooling. The method provided by the invention has the advantages that the quench hardness, the hardness uniformity and the workpiece inner quality can be improved; the alloy element resource can be saved; the production cost can be reduced; the production efficiency can be improved.

Owner:BEIJING HUALI FINE CHEM CO LTD

Chain piece specific quenching oil and quenching method thereof

ActiveCN105925769ABeautify the appearanceSave resourcesFurnace typesMetallic material coating processesQuenchingAntioxidant

The invention discloses chain piece specific quenching oil and a quenching method thereof. The invention belongs to the field of metal heat treatment technology. The quenching oil comprises the following components, by weight, 35-40 parts of refined base oil, 7-10 parts of cooling catalyzed composite agent, 0.5-0.7 parts of blackening composite agent, 0.4-0.8 parts of brightening agent, 0.5-0.8 parts of surface activating agent and 0.02-0.04 parts of antioxidant. The effect of is best when the maximum cooling speed of the quenching oil for the chain piece is about 93-102 DEG C / s and the using temperature is 70-80 DEG C. Under the above conditions, the ideal quenching hardness can be obtained, the deformation rate is low, the effect of the automatic surface blackening can be realized, a protective film formed on the surface is strong in adhesion and not easy to fall off, and the effect of the appearance beautification and short-term rust prevention can be realized. Once more surface coating and rust preventing treatment after the heat treatment can be reduced, so that the resources can be saved, the processes can be reduced and the efficiency can be improved.

Owner:马鞍山金泉工业介质科技有限公司

Cooling water jacket for rapid-cooling quenching furnace and processing method of cooling water jacket

PendingCN113528772AIncrease contact areaImprove cooling effectFurnace typesHeat treatment furnacesWater flowHot work

The invention relates to the technical field of metal hot processing equipment, in particular to a cooling water jacket for a quick-cooling quenching furnace and a processing method of the cooling water jacket. The cooling water jacket comprises a water jacket assembly, a cooling inner container for storing workpieces and cooling fins annularly arranged on the outer surface of the cooling inner container. According to the cooling water jacket for the quick-cooling quenching furnace, the heat exchange area of the cooling water jacket is increased through the technologies of inserting objects in the jacket and the like, the heat exchange coefficient is increased through cooling fins, the quenching hardness of a workpiece is improved, when the quenching hardness required by the workpiece is low, the water flow is reduced, so that the quenching hardness is reduced, the production cost is also reduced, and the problems that an existing quenching furnace cannot meet the higher required quenching hardness of a workpiece, the hardness of the workpiece is insufficient, an additional electroplating process is needed in the later period, and the production cost is further increased are solved.

Owner:东莞市鑫迪机械设备有限公司

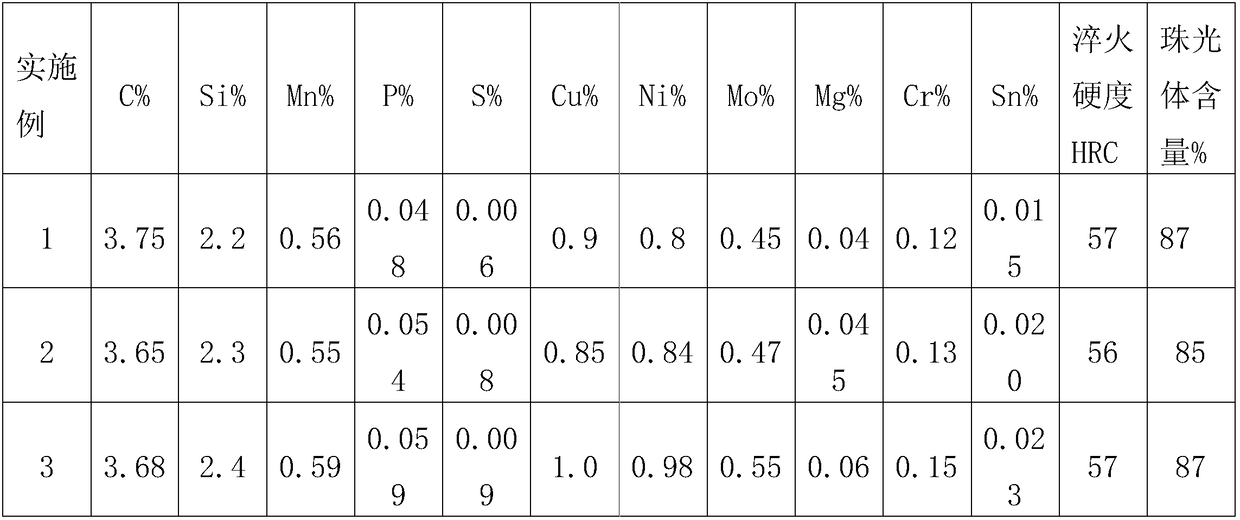

GGG70L nodular cast iron and preparation method thereof

The invention discloses GGG70L nodular cast iron and a preparation method thereof, and belongs to the technical field of cast iron production. The GGG70L nodular cast iron comprises the following chemical components of, by weight, 3.4-3.8% of C, 2.0-2.4% of Si, 0.5-0.6% of Mn, 0.06% of P or the less, 0.01% of S or the less, 0.45-0.55% of Mo, 0.9-1.0% of Cu, 0.9-1.0% of Ni, 0.04-0.06% of Mg, 0.015-0.025% of Sn, 0.1-0.15% of Cr and the balance Fe. The GGG70L nodular cast iron is added according to the existing alloy ratio, when a casting is more than 8 tons, the content of pearlite in the core can also reach 85% or more, and it is guaranteed that the hardness of the quenched casting is larger than 55 HRC.

Owner:HEBEI SHUOKAI CASTING

Vacuum cementation furnace 750 degrees centigrade low temperature cementation process of precision parts

ActiveCN109811295AImprove quenching hardnessThere is no breakageSolid state diffusion coatingFragilityCarbide

The invention provides a vacuum cementation furnace 750 degrees centigrade low temperature cementation process of precision parts. Cementation treatment can be carried out on metal parts at a temperature of 750 degrees centigrade; the metal parts treated by using the vacuum cementation furnace 750 degrees centigrade low temperature cementation process of the precision parts can realize uniform carburized layer, higher quenching hardness and steeper carburized layer gradient; the metal parts can realize lower fragility after annealing treatment and bending test; the bent surfaces of the metal parts have no phenomena of surface peeling, lifting and fracture; a vacuum cementation furnace using the vacuum cementation furnace 750 degrees centigrade low temperature cementation process of the precision parts does not generate intergranular oxidation in the carburizing process of the metal parts and can enhance the fatigue resistance of a workpiece material; and moreover, the surfaces of the carburized and quenched metal parts cannot generate black carbon deposit to be beneficial for follow-up electroplating processing; in addition, dotted or block-shaped carbide and residual austenite arealso not seen in the carburized layers of the produced parts; and the carburized layer and a matrix possess good bonding strength and good toughness; and the organization structure is excellent.

Owner:刘小阳

Heat treatment technology for die-casting die steel

InactiveCN104178602AImprove mechanical propertiesMore dissolvedProcess efficiency improvementCarbideDie casting

The invention relates to a heat treatment technology for die-casting die steel. The steps of heat treatment are as follows: 1. quenching: loading raw material into a furnace at 550 DEG C, preserving heat for 40 min; heating to 1,150 DEG C, preserving heat for 110-130 min, and then discharging the raw material and cooling the raw material with oil to room temperature; 2. tempering: tempering the raw material three times, with the heating temperature of 560-700 DEG C and the heat preservation time of 90 min in each tempering. according to the heat treatment technology, as the quenching temperature rises, the quenching hardness is improved, more carbide is dissolved, the austenite alloying extent is increased, and thus martensite is strengthened; tempering that is performed once in the traditional technology is performed three times, so that residual low-hardness austenite in the material is fully changed into high-hardness secondary martensite to improve the mechanical property of a die. The service life of the die treated according to the heat treatment technology can reach 4,500 times, the cost of the die is lowered and the production efficiency is increased.

Owner:TIANJIN JINGXIN METAL PROD

Processing method of heat treatment jig for thin ring piece and spring steel thin tooth piece

ActiveCN104120240BImprove quenching hardnessGuaranteed flatnessFurnace typesHeat treatment furnacesSpring steelHeat treated

The invention discloses a thin ring part heat treatment fixture which comprises a partition plate, a core rod, an upper mould plate and a lower mould plate, wherein the upper mould plate and the lower mould plate are oppositely arranged; a plurality of thin ring parts are stacked to form a plurality of thin ring part groups, and every two adjacent thin ring part groups are spaced by the partition plate; the partition plate is provided with a plurality of liquid holes, and the liquid holes are communicated with the annular end surfaces of the two adjacent thin ring part groups; the upper mould plate and the lower mould plate are both provided with first installation holes, and fasteners penetrate through the first installation holes of the upper mould plate and the lower mould plate and the liquid holes to clamp the partition plate and the plurality of thin ring parts between the upper mould plate and the lower mould plate. The invention also discloses a processing method of a thin spring steel tooth blade. The thin ring part heat treatment fixture disclosed by the invention can be used for improving the planeness of the thin ring parts subjected to quenching and tempering.

Owner:武汉华夏精冲技术有限公司

Nodular cast iron grinding ball and preparation method thereof

The invention provides a nodular cast iron grinding ball and a preparation method thereof. The grinding ball comprises the following chemical components in percentage by mass: 3.6%-3.7% of C, 2.5%-2.8% of Si, 1.6%-1.8% of Mn, 0.07%-0.1% of Sn, 0.03%-0.05% of Mg, 0.02%-0.03% of Re, less than or equal to 0.06% of S, less than or equal to 0.1% of P and the balance of Fe. According to the spheroidal graphite cast iron grinding ball and the preparation method thereof provided by the invention, the grinding ball overcomes the defects of high hardness and low toughness of a spheroidal graphite cast iron grinding ball in the prior art, and has certain hardness and high wear resistance while having high toughness.

Owner:宁国东方碾磨材料股份有限公司

Heat treatment induction quenching process for small hole

InactiveCN106011393AStrong stain resistanceAvoid crackingIncreasing energy efficiencyQuenching devicesEnvironmental resistanceInduction hardening

The invention discloses a heat treatment induction quenching process for a small hole. The process comprises the following steps of inspection, cleaning and drying, quenching, cleaning and drying, tempering, detection and rust prevention. The process is simple, the whole course is environmentally friendly and free of pollution, the hardness, strength and wear resistance of the small hole can be effectively improved, and the service life of the small hole is prolonged. In the quenching step, an HX-200 medium is adopted for cooling, so that quenching for the small hole is uniform, a uniform skin film is formed on the metal surface, a workpiece is effectively protected against cracking, the brought-out quantity is extremely small, the quenched workpiece is free of cleaning, the medium is free of discharge, the medium is applicable to various materials, the concentration does not need to be adjusted, the production cost is reduced, energy is saved, environmental pollution is reduced, and economic benefits are improved.

Owner:XINGHUA DONGHUA GEAR

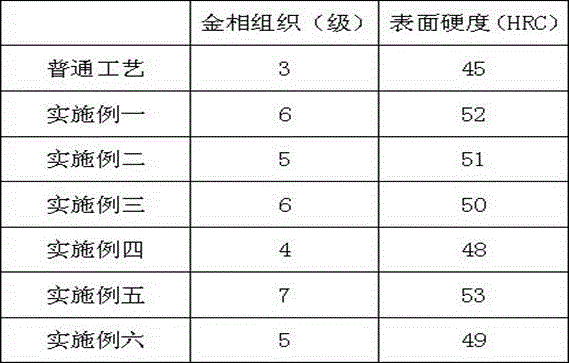

9Cr13MoVCo stainless steel strip steel and preparation method thereof

The invention relates to 9Cr13MoVCo stainless steel strip steel and a preparation method thereof. The steel comprises the chemical elements by the mass percentage: 0.88-0.95% of carbon, not more than 0.60% of silicon, not more than 0.60% of manganese, not more than 0.030% of phosphorus, not more than 0.030% of sulfur, 13.00-13.50% of chromium, 0.20-0.25% of molybdenum, 0.10-0.15% of vanadium, 0.20-0.30% of cobalt, and the balance iron. The gas contents in the steel comprise [N]=200-400 ppm, [H]<=2.5 ppm, and [O]=20-40 ppm. The steel has the advantages of high hardness, excellent wear resistance, good corrosion resistance and ideal toughness, has a biggest characteristic of scientific addition of an appropriate amount of cobalt, and can effectively improve the material quenching hardness for meeting special needs.

Owner:常熟市长江不锈钢材料有限公司

Easy-to-cut high-carbon steel annealing non-oxidation process

InactiveCN101476024APrevent decarbonizationImprove surface qualityFurnace typesHeat treatment furnacesHeating timeHigh carbon

The invention discloses a free-cutting high-carbon steel anneal non-oxidation technique. Workpieces are put into an annealing oven for annealing with the control of temperature and heating time, in the annealing process, carbon having a mass ratio of 1:200 with the workpieces is added into the annealing oven, the workpieces are heated under a temperature of 750 DEG C for five hours, and then are heated under a temperature of 694 DEG C for another five hours.According to the invention, decarburization in the anneal course of high-carbon steel can be prevented and quenching hardness can be improved, because carbon having a mass ratio of 1:200 with the workpieces is added into the annealing oven in the annealing process of high-carbon steels, subsequent acid washing process can be omitted, surface quality of the high-carbon steel can be improved and processing cost of the high-carbon steel can be reduced.

Owner:海南丰兴精密产业股份有限公司

Heat shaping fixture and heat shaping method in quenching process of metal material seal ring

ActiveCN102321796BQuality assuranceEasy to operateFurnace typesHeat treatment furnacesMetallic materialsWaste product

The invention discloses a heat shaping fixture and a heat shaping method in the quenching process of a metal material seal ring, and relates to a heat shaping fixture and a heat shaping method in the quenching process of a seal ring. The invention solves the problems that the integral hardness of a seal ring cannot be improved, the opening size cannot be ensured and waste products are easily produced in the conventional quenching technology. The device comprises that: an upper cover plate and a bottom plate are vertically aligned; a wedge block is nailed in an inclined hole of each shaft; the shaft is sleeved with number adjustable gaskets; the metal material seal ring is arranged between the upper cover plate and the bottom plate; an oil immersion hole on the upper cover plate corresponds to the upper end face of the metal material seal ring; and an oil immersion hole of a lower cover plate corresponds to the lower end face of the metal material seal ring. The method comprises the following steps of: clamping the seal ring in the heat shaping fixture; putting the seal ring and the heat shaping fixture into a heat treatment furnace, and completing quenching and tempering procedures of the heat treatment, which meet the hardness requirement; and detaching the heat shaping fixture and taking the seal ring out. The invention is used for heat shaping in the quenching process of the metal material seal ring.

Owner:HARBIN TURBINE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com