A powder metallurgy automobile engine sprocket lock pin hole laser quenching method

An automobile engine, laser quenching technology, applied in the direction of quenching device, furnace type, furnace, etc., can solve the problems of low quenching hardness, melting of quenching surface, etc., achieve high power density, accelerate quenching cooling speed, high hardness and wear resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

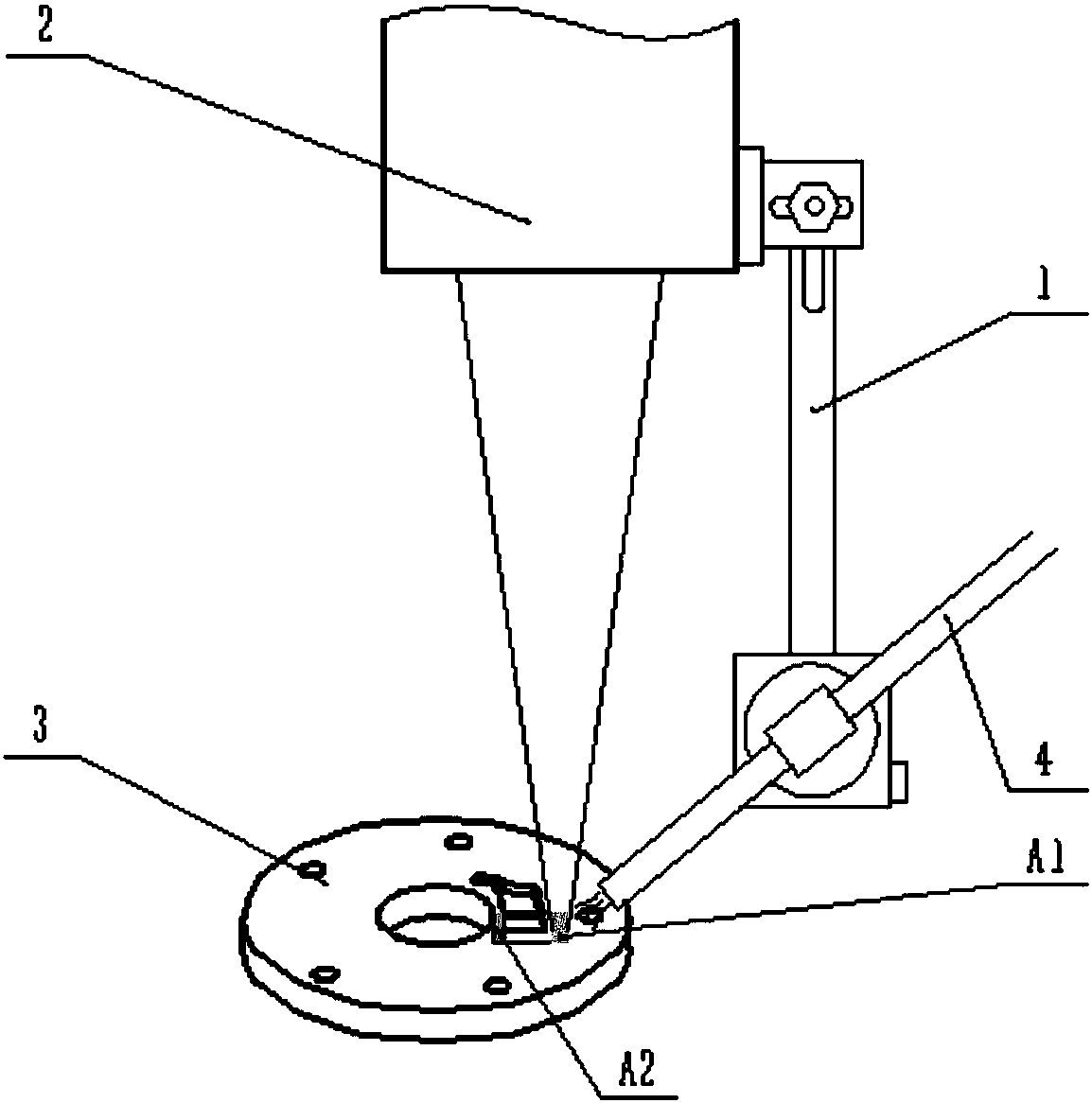

[0050] Example 1: Laser quenching of the lock pin hole of a powder metallurgy automobile VVT exhaust sprocket:

[0051] Automobile VVT exhaust sprocket is a powder metallurgy part, its chemical composition is: C 0.70%; Cu 1.50%; Ni1.74%; Mo 0.50%; Fe balance; density 7.0g / cm 3, The heat treatment requirements of the automobile VVT sprocket are: (1) the surface quenching hardness of the lock pin hole is 35-45HRC, (2), the depth of the hardened layer is ≥0.60mm.

[0052] Adjust the angle between the rigid gas delivery pipe and the sprocket plane to 53°, and the distance between the lowest point of the gas outlet and the center of the light spot to be 31mm. Quenching process parameters are: defocus amount +15mm, power 1600w, spot size 2×10mm, gas flow rate 15L / Min, first scan speed 7.0mm / s, second scan speed 10.0mm / s, between two scans pause for 2.5 seconds. After the second scan, the quenching is completed, the workpiece is removed, and the hardness, hardened layer depth...

example 2

[0053] Example 2: Laser quenching of the lock pin hole of a powder metallurgy automobile H02 intake sprocket:

[0054] Automobile H02 intake sprocket is a powder metallurgy part, its chemical composition is: C 0.75%; Cu 1.65%; Ni0.80%; Mo 0.30%; Fe balance; density 6.7g / cm 3 , The heat treatment requirements of the automobile H02 intake sprocket (1) the surface quenching hardness of the lock pin hole is 35 ~ 45HRC, (2), the depth of the hardened layer is ≥ 0.65mm.

[0055] The lock pin hole of the intake sprocket of automobile H02 adopts the laser quenching method of the present invention, the angle between the rigid gas delivery pipe and the sprocket plane is 51°, and the distance between the lowest point of the gas outlet end and the center point of the light spot is 29mm. Quenching process parameters are: defocus amount +10mm, power 1650w, spot size 2×10mm, gas flow rate 18L / Min, first scan speed 8.5mm / s, second scan speed 11.0mm / s, between two scans pause for 3.0 seconds....

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com