Heat shaping fixture and heat shaping method in quenching process of metal material seal ring

A metal material and sealing ring technology, which is applied in the field of heat treatment, can solve the problems that the overall hardness of the metal material sealing ring cannot be improved, the opening size cannot be guaranteed, and waste products are prone to occur, and it can achieve high quenching hardness, uniform oil immersion, and fast cooling speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

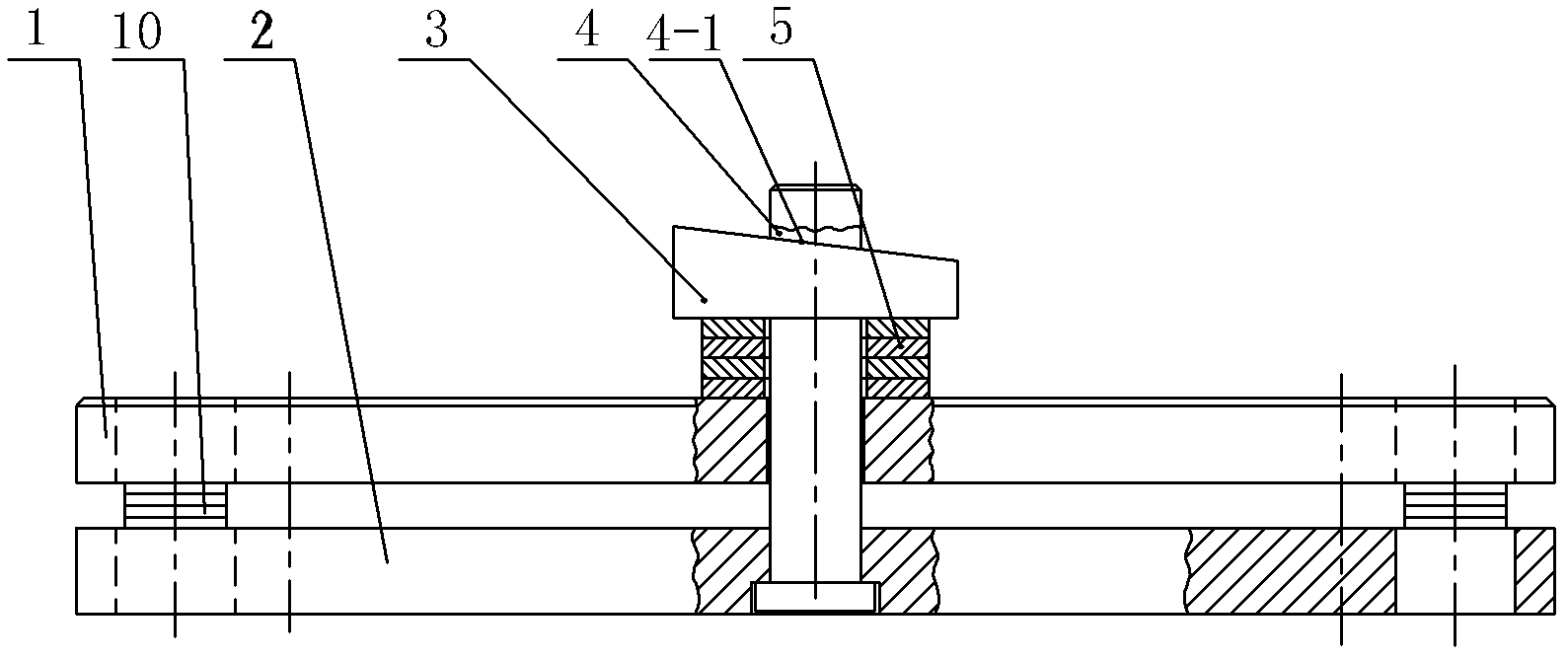

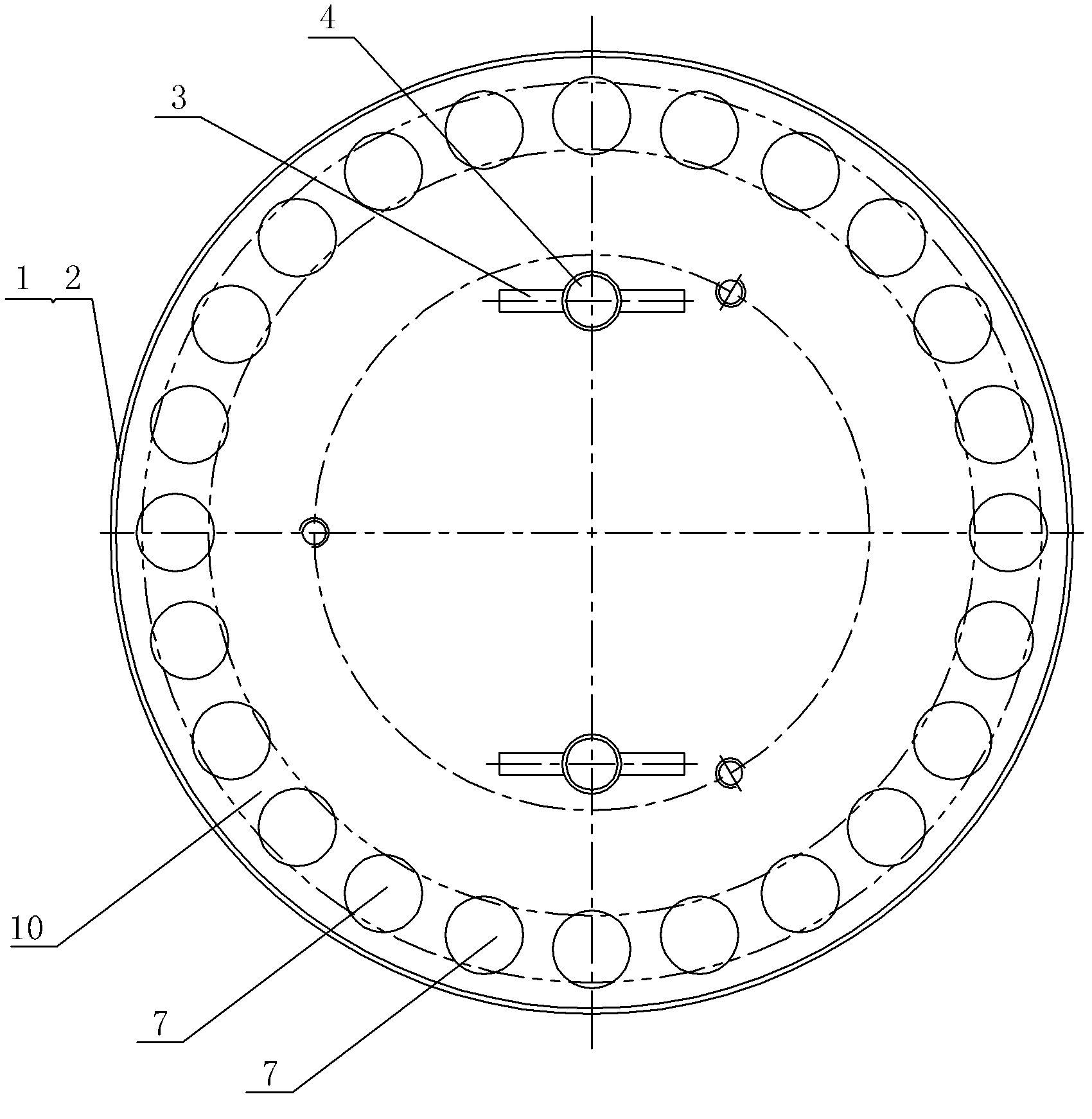

[0022] Specific implementation mode one: combine figure 1 and figure 2 To illustrate this embodiment, the heat setting fixture in the metal material seal ring quenching process of this embodiment includes an upper cover plate 1, a bottom plate 2, two wedges 3, two shafts 4 and a plurality of gaskets 5, the upper cover The plate 1 and the bottom plate 2 are aligned up and down, the upper cover plate 1 and the bottom plate 2 are connected together by two shafts 4, and the upper part of each shaft 4 passes through the upper cover plate 1, and the upper part of each shaft 4 is opened with Slanted holes 4-1, a wedge 3 is wedged in each slanted hole 4-1, a plurality of gaskets 5 are set on each shaft 4, the gaskets 5 are located between the wedges 3 and the upper cover plate 1, closed The metal material sealing ring 10 is arranged between the upper cover plate 1 and the bottom plate 2, and the upper cover plate 1 and the bottom plate 2 are provided with a plurality of oil immersio...

specific Embodiment approach 2

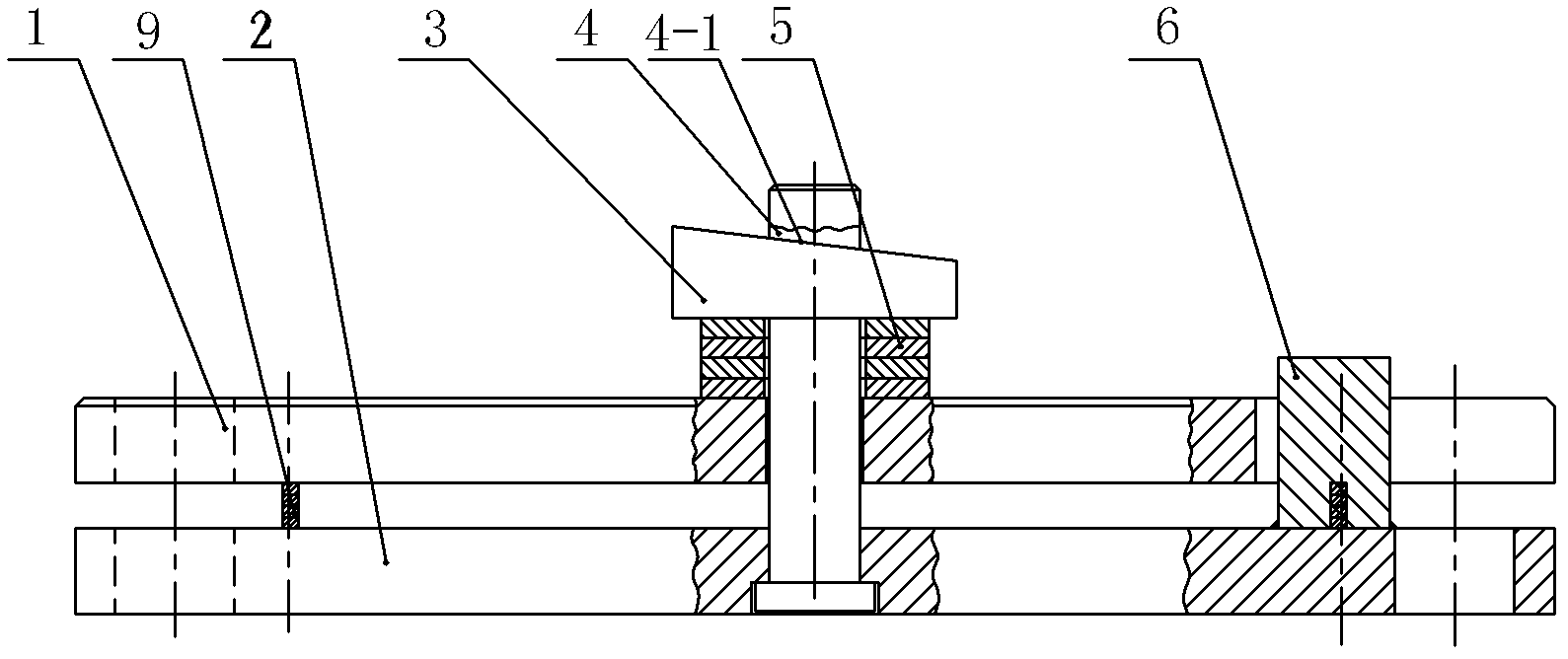

[0024] Specific implementation mode two: combination image 3 and Figure 4 To illustrate this embodiment, the heat setting fixture in the metal material seal ring quenching process of this embodiment includes an upper cover plate 1, a bottom plate 2, two wedges 3, two shafts 4 and a plurality of gaskets 5, the upper cover The plate 1 and the bottom plate 2 are aligned up and down, the upper cover plate 1 and the bottom plate 2 are connected together by two shafts 4, and the upper part of each shaft 4 passes through the upper cover plate 1, and the upper part of each shaft 4 is opened with Slanted holes 4-1, a wedge 3 is wedged in each slanted hole 4-1, and a plurality of gaskets 5 are set on each shaft 4, and the gaskets 5 are located between the wedges 3 and the upper cover plate 1, and the opening The metal material sealing ring 9 is arranged between the upper cover plate 1 and the bottom plate 2, and the upper cover plate 1 and the bottom plate 2 are provided with a plura...

specific Embodiment approach 3

[0026] Specific implementation mode three: combination Figure 7This embodiment will be described. The fixing block 6 of this embodiment is a two-stage bayonet fixing block. Such arrangement is suitable for sealing rings made of metal materials with different opening sizes. Other compositions and connections are the same as those in the second embodiment.

[0027] Specific implementation mode four: combination Figure 5 and Figure 6 To illustrate this embodiment, the heat setting fixture in the metal material seal ring quenching process of this embodiment includes an upper cover plate 1, a bottom plate 2, two wedges 3, two shafts 4 and a plurality of gaskets 5, the upper cover The plate 1 and the bottom plate 2 are aligned up and down, the upper cover plate 1 and the bottom plate 2 are connected together by two shafts 4, and the upper part of each shaft 4 passes through the upper cover plate 1, and the upper part of each shaft 4 is opened with Slanted holes 4-1, a wedge 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com