Immersion oil quench cooling method adopting plurality of sections for bubble emission

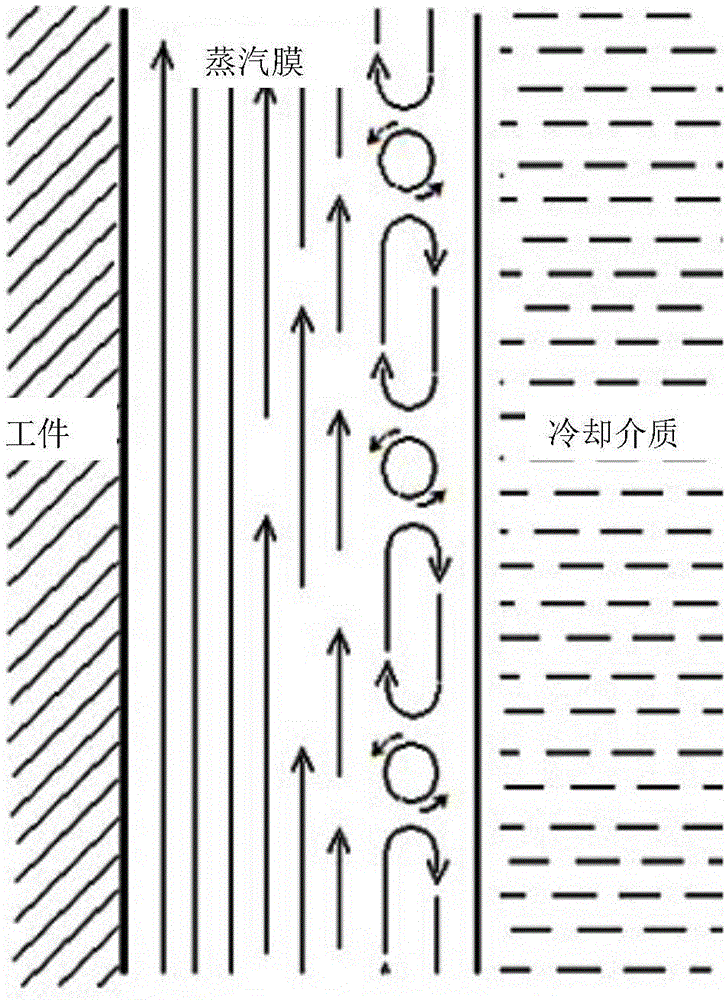

A cooling method and oil immersion technology, used in heat treatment equipment, furnaces, heat treatment furnaces, etc., can solve the problems of workpiece quenching deformation hardness, unqualified, etc., and achieve the effect of improving fatigue life, improving internal quality, and reducing quenching distortion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

[0048] Experimental example 1. Comparison of cooling time

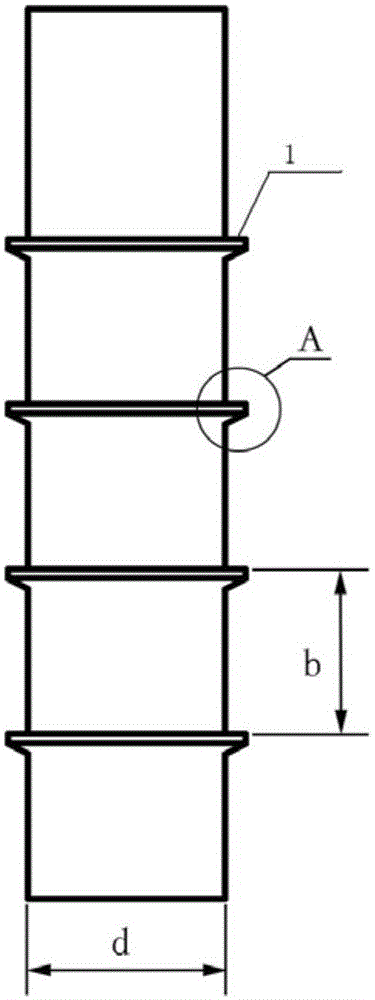

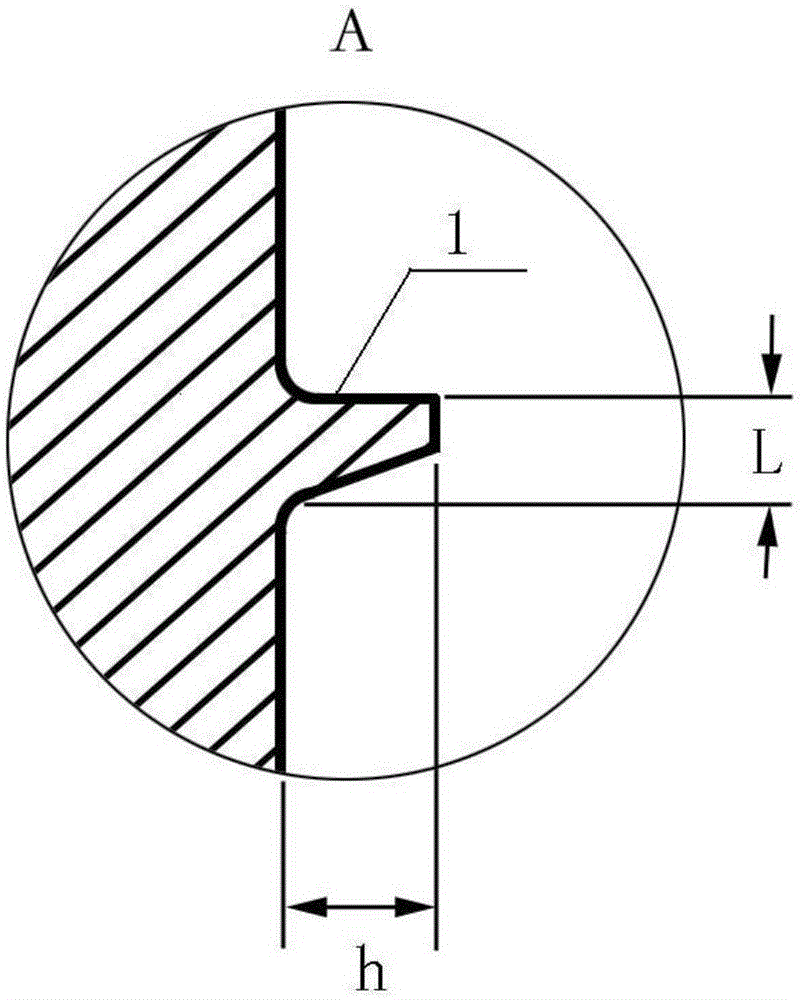

[0049] Take two samples, one is sample 1a without separator ring, the other is sample 1b with separator ring, the size is Φ30cm×135cm, the shape of the axial section of the separator ring is trapezoidal, the upper part is a horizontal plane, and the lower part is an inclined plane , the thickness of the base is 2mm, the thickness of the top is 1mm (the thickness of the top refers to the length of the farthest distance between the separator ring and the workpiece in the axial direction), the height is 3mm, and the distance between the separator rings is 25mm. Quenching cooling in the oil. Figure 7-Figure 9 The state change of these two samples 1a and 1b during quench cooling is shown. Figure 7 and Figure 8 They are four state diagrams of sample 1a without separator ring and sample 1b with separator ring at different moments during the cooling process, Figure 9 It is the extended diagram of the boundary line of t...

experiment example 2

[0050] Experimental example two, comparison of quenching hardness

[0051] Use the same 45# steel bar to process a sample 2b with a separator ring and a sample 2a without a separator ring. The base size of the sample is Ф20×135cm, except that there are four more spacer rings on the sample 2b with spacer rings, and the shape, size and spacing of the spacer rings are the same as those in Experimental Example 1. After being heated to 850°C under the same conditions, both are cooled vertically in the same rapid quenching oil. Figure 10 The left figure of the figure is the expanded boundary diagram of sample 2a without a separator ring, and the right figure is the expanded boundary diagram of sample 2b with a separator ring.

[0052]It can be seen from the figure that the lower end of the sample 2a without a partition ring cools faster, and its advanced expansion point appears at 5.5 seconds, while the upper end cools slowly, and its advanced expansion point appears later; and, t...

experiment example 3

[0057] Experimental example three, comparison of quenching oil

[0058] The two samples used in this experiment are taken from the same 42CrMo bar, and the basic dimensions of the samples are both Ф20×135mm. Among them, one is a sample 3a without a separator ring, and the other is a sample 3b with a separator ring, and the shape, size and spacing of the separator rings are the same as those in Experimental Example 1. After being heated to 850°C under the same conditions, sample 3b with a separator ring was cooled vertically in 60SN base oil, while sample 3a without a separator ring was cooled vertically in rapid quenching oil. In this experimental example, 60SN base oil is used to replace the original rapid quenching oil to quench the sample 3b with a partition ring, and compared with the sample 3a without a partition ring quenched with rapid quenching oil. Table 1 is the comparison of the cooling characteristics of the 60SN base oil and the rapid quenching oil used (the oil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com