Patents

Literature

165results about How to "Promote graphitization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

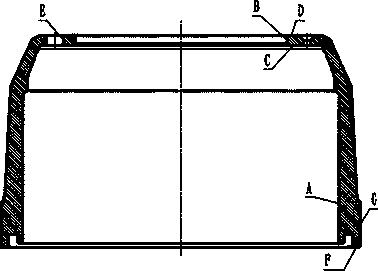

Sand-line iron mould casting process for grey cast iron flywheel housing of diesel engine

ActiveCN102728790AGood size consistencyPut an end to the phenomenon of sand swellingFoundry mouldsFoundry coresDieselingSurface roughness

The invention discloses a sand-line iron mould casting process for grey cast iron flywheel housings of diesel engines. In the invention, upper and lower sand-line iron mould processes are used, so that produced grey cast iron flywheel housing blanks have favorable geometric size precision which can be up to CT8 grade, favorable surface roughness which can be up to 12.5 microns and favorable mechanical properties, the blank processing has small allowance which can be controlled in 3mm, small flashing distortion which can be controlled in 0.5mm and small cleaning workload, so that the labor environment is improved, the environmental protection is improved, the yield is high and can be up to 95%, and the national policies of energy conservation, environmental protection and sustainable development are met.

Owner:JIANGSU SONGLIN AUTOMOBILE PARTS

Method for preparing isotropic graphite containing coal-based needle coke as aggregate

The invention discloses a method for preparing isotropic graphite containing coal-based needle coke as aggregate. The method comprises the following steps of: firstly, thoroughly mixing binders and aggregates at a weight ratio of (0.2 to 0.6):1 in the form of kneading under the condition of being higher than the softening point of the binder; performing cold isostatic pressing on the mixture and then charring to obtain a biscuit-firing product under such conditions that the cold isostatic pressing pressure is 100 to 200 Mpa and the charring temperature is 800 DEG C to 1000 DEG C; putting the product in a container, feeding an impregnant (i.e. asphalt), evacuating the impregnation system until the pressure is below 500 Pa, introducing molten asphalt, impregnating under 0.5 to 1.5 Mpa and maintaining for 1 hour, and calcining at 500 DEG C to 1000 DEG C; and putting the resulting product in a graphitizing furnace, performing graphitizing treatment at 2200 DEG C to 3000 DEG C and maintaining for 0.5 to 1 hour. The method has the advantages of easily-accessible raw material, high yield and low cost; and the product is advantageous in high graphitization degree, low volatile component and ash contents, high compression strength and good isotropic indexes.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Vanadium titanium cast iron brake drum and preparation method thereof

The invention relates to a manufacturing technique of an automotive vanadium titanium cast iron brake drum with high strength and high abrasive resistance, and particularly relates to a preparation method of a vanadium titanium cast iron brake drum. The preparation method comprises the following steps: melting base iron, namely b y taking vanadium titanium pig iron, steel scrap, foundry returns, a carburant, ferrosilicon, ferromanganese and ferrochrome as furnace charge, adding the carburant to the furnace bottom; smelting the furnace charges by using a medium-frequency induction furnace to prepare the base iron; heating and purifying molten iron in an overheating manner after the molten iron is molten down, and then carrying out heat preservation at 1520-1530 DEG C; and carrying out drossing, adding a slag conglomeration agent to the surface to carry out heat preservation after drossing, and then adding a little of furnace charge, and adjusting the ingredients and the like of the molten iron. A little of furnace charge is added at the later smelting stage to increase the heterogeneous core technology, so that the chilling tendency of the molten iron is relieved, the graphitization ability of the molten iron is improved, and the inoculation effect is improved. A secondary inoculation treatment process of a launder and a pouring cup is adopted, so that the inoculation effect is improved, the graphite form is improved, carbide and ferrite are removed, and the content of pearlite is improved.

Owner:陈国

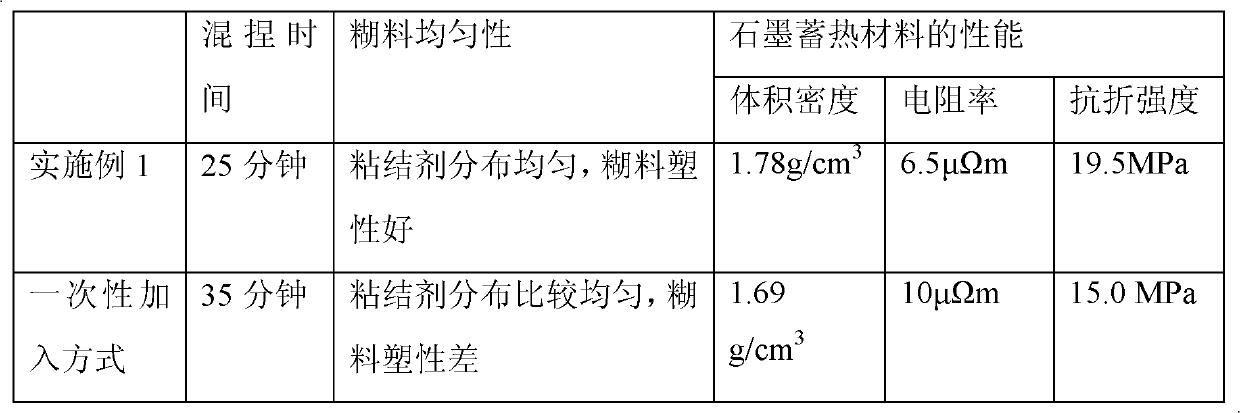

Heat accumulation and energy storage graphite material for solar thermal power generation and preparation method thereof

ActiveCN101948675AImprove thermal conductivityImprove heat storage capacityHeat-exchange elementsCooking & bakingThermal expansion

The invention relates to a heat accumulation and energy storage graphite material for solar thermal power generation and a preparation method thereof. The performance parameters of the graphite material meet the following requirements that: volume density is more than or equal to 1.75 g / cm<3>; electrical resistivity is less than or equal to 7.5 mu ohm m; ash content is less than or equal to 0.2 percent; rupture strength is more than or equal to 18.5 Mpa; elastic modulus is less than or equal to 8.8 Gpa; and thermal expansion coefficient is less than or equal to 2.0*10<-6> / DEG C<-1>. The graphite material of the invention has the advantages of high thermal capacity, high heat conductivity, long service life, low cost and the like. In the preparation method, the focusing solar thermal power generation and heat accumulating material is prepared from raw materials by the steps of sieving, burdening, kneading, airing, vibration molding, baking, soaking, secondary baking, graphitizing and machining.

Owner:DATONG XINCHENG NEW MATERIAL CO LTD

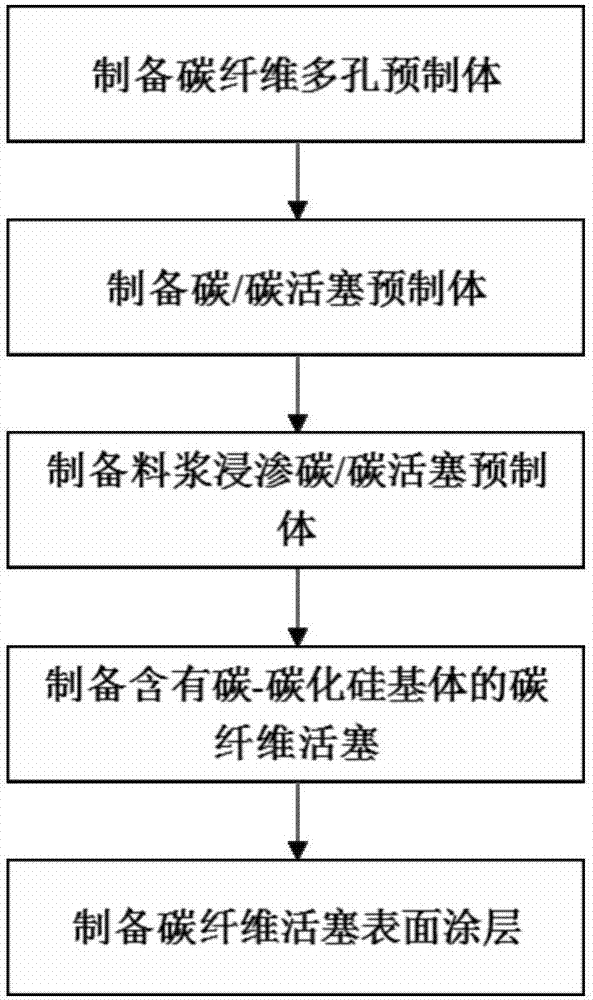

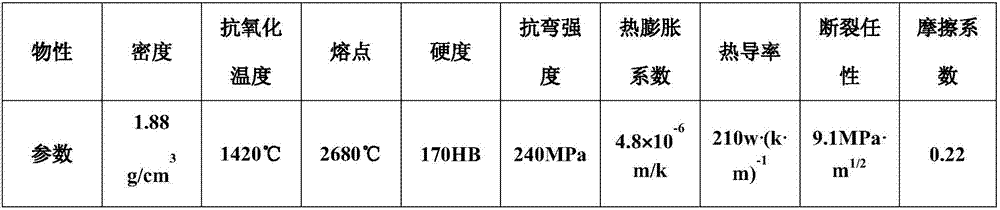

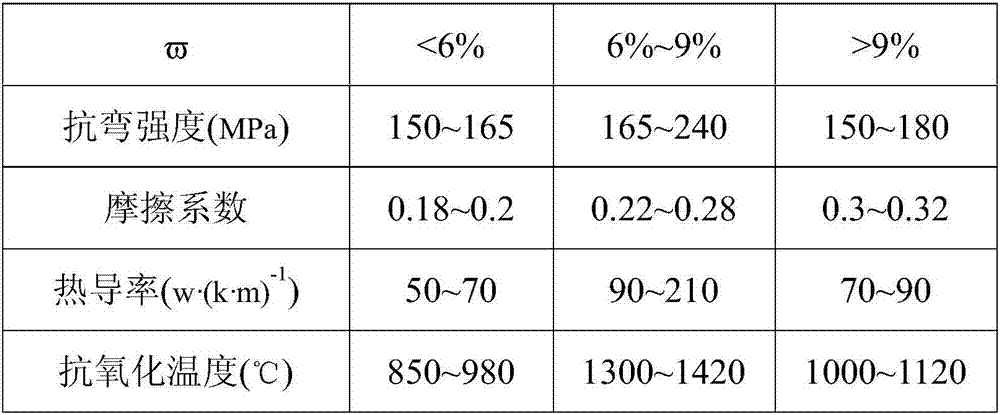

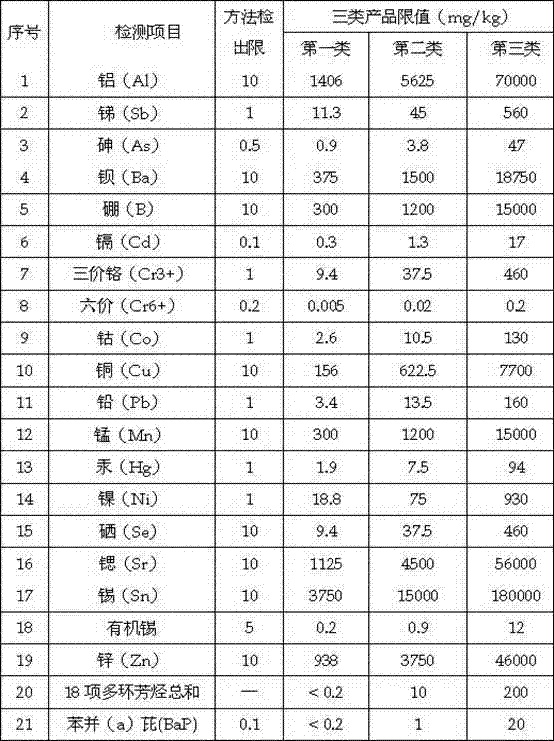

Cf/C-SiC composite material as well as preparation method and application thereof

The invention designs a composite material. The composite material comprises carbon-fiber perform, matrix carbon, filler and diamond-like carbon, wherein the matrix carbon is uniformly adhered on the carbon fiber of the perform to form the carbon-fiber perform with the matrix carbon; the filler fills the inside of the carbon-fiber perform with the matrix carbon and coats the outside of the carbon-fiber perform with the matrix carbon to form a semifinished product; the diamond-like carbon comprises a diamond-like carbon layer coated on the semifinished product; and the filler contains a Ti element, a Si element, a C element and a Mo element. The composite material has the advantages that a method of combining four processes of CVI, SI, RMI and PECVD to prepare a finished product with the advantages of high compactness, low thermal expansion coefficient and friction coefficient, high self-lubricating property, high thermal conductivity, oxidation resistance, thermal shock resistance, ablation resistance, wear resistance, high strength and toughness and the like; and simultaneously, the process is simple, the preparation period is short, the equipment requirement is low, the cost is low, net shaping can be realized and convenience is brought for large-scale industrial application.

Owner:XIANGTAN UNIV

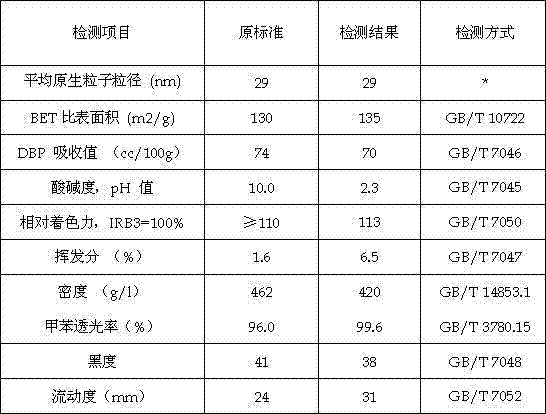

Production method of environment-friendly and safe furnace carbon black and carbon black product

ActiveCN104725899AExtended stayPromote graphitizationPigmenting treatmentExhaust fumesProcess engineering

The invention discloses a production method of environment-friendly and safe furnace carbon black and a carbon black product. The production method comprises the following steps: preheating raw material oil after fractioning treatment, then spraying the preheated raw material oil into a furnace carbon black reaction furnace with an ultra-long retention section from a throat pipe section, and strictly controlling the purity of the raw material entering the furnace to prepare carbon black smoke gas; collecting the carbon black in the carbon black smoke gas by a main bag filter; crushing the carbon black by a micron crushing machine, then sending the carbon black to a collection cyclone separator and an exhaust bag filter by a wind-sending fan, exhausting waste gas, collecting carbon black powder to a carbon black storage tank, and meanwhile, introducing one part of preheated hot air to a conveying pipeline from the wind-sending fan to the collection cyclone separator; sending the powdery carbon black in the carbon black storage tank to at least one oxidation-granulation unit for oxidation and granulation; sending the prepared oxidized carbon black into a roller rotary drying machine for drying; and drying and packaging a finished product. The process disclosed by the invention is safe and reliable, and the produced pigment carbon black can meet various international environment-friendly and safe requirements of the carbon black products.

Owner:安徽黑猫新材料有限公司

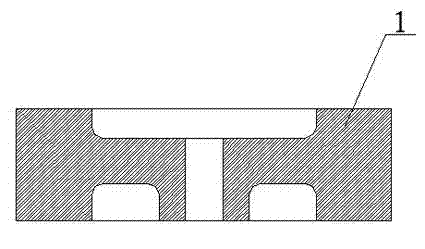

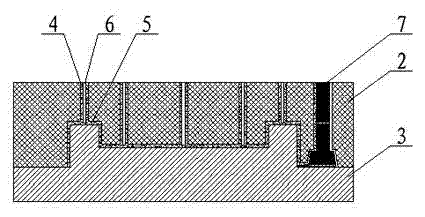

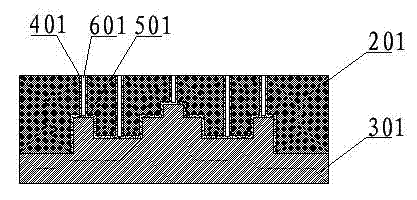

Hydraulic pump body casting process

InactiveCN104911458ANo shrinkage cavityHigh tensile strengthFoundry mouldsFoundry coresHydraulic pumpEngineering

The invention discloses a hydraulic pump body casting process, the process steps are as follows: moulding-casting material pretreatment-melting-spheroidizing treatment-pouring-heat treatment-stabilizing treatment-gas nitriding treatment-machining-inspection and storing-finished product; and the casting process is simple and practical, and low in cost, the casted hydraulic pump body is dense in tissue, free of shrinkage porosity and cavity, white cast and crack defects, good in tensile strength, and high in hardness.

Owner:SUZHOU JIN YUAN OIL MACHINERY

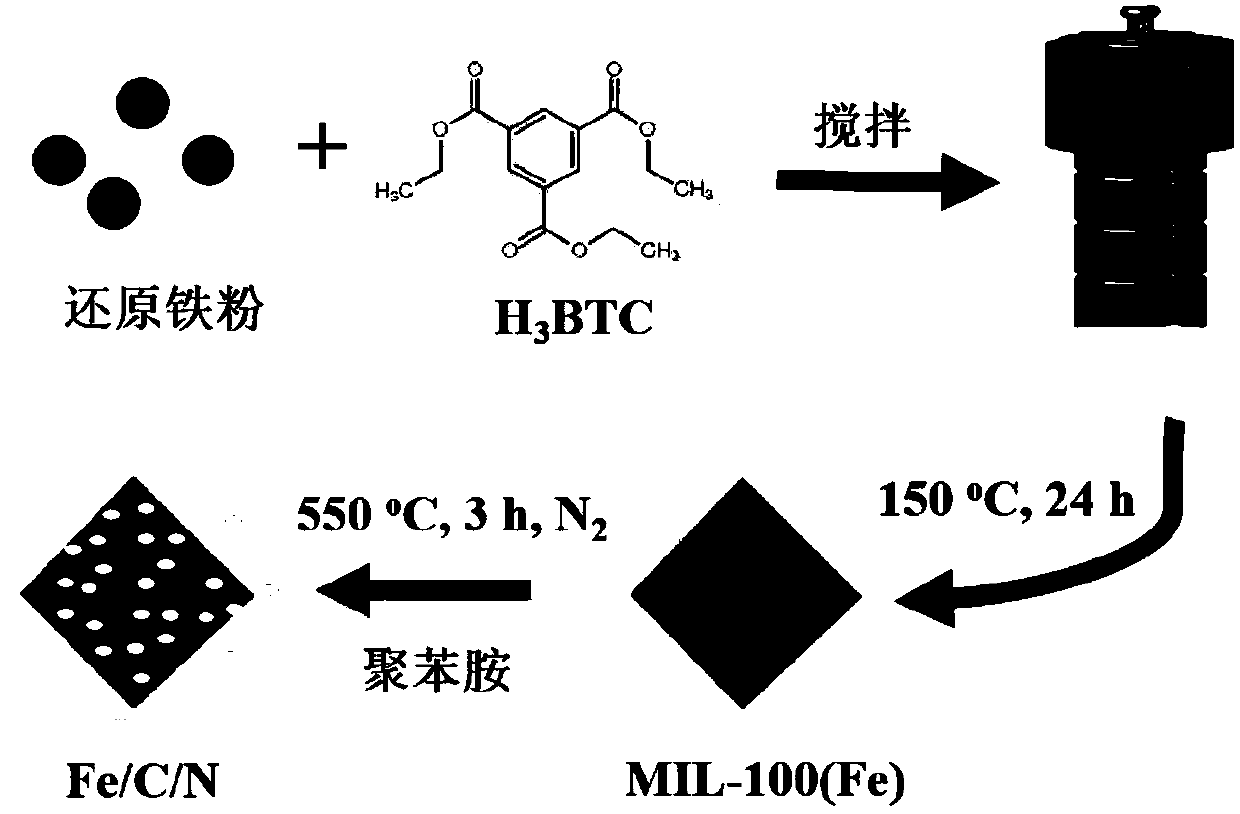

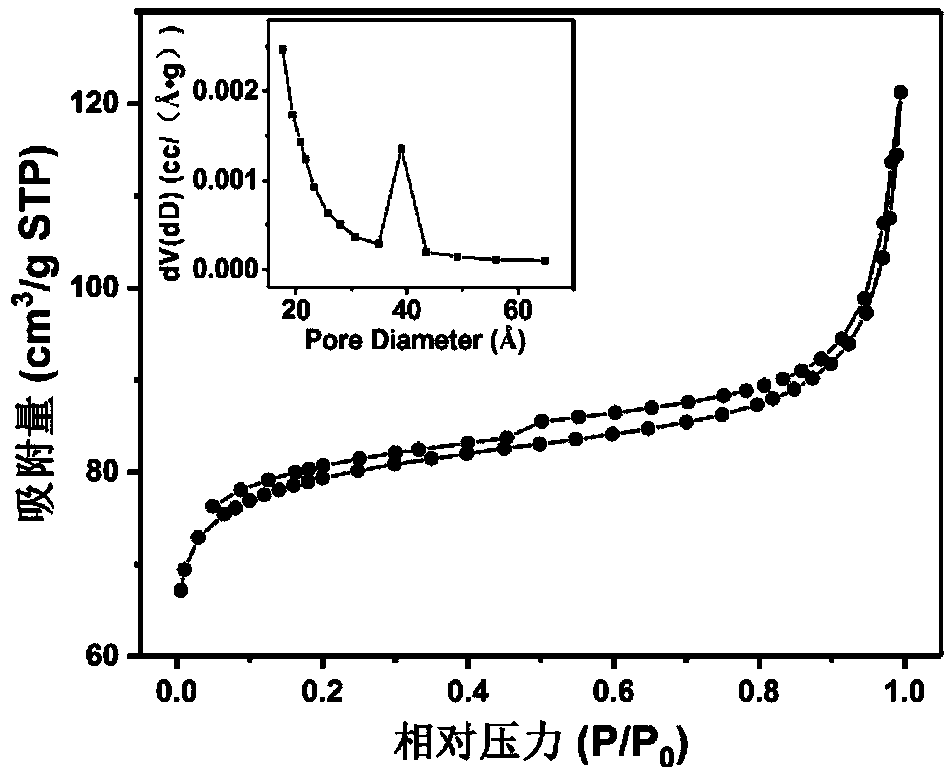

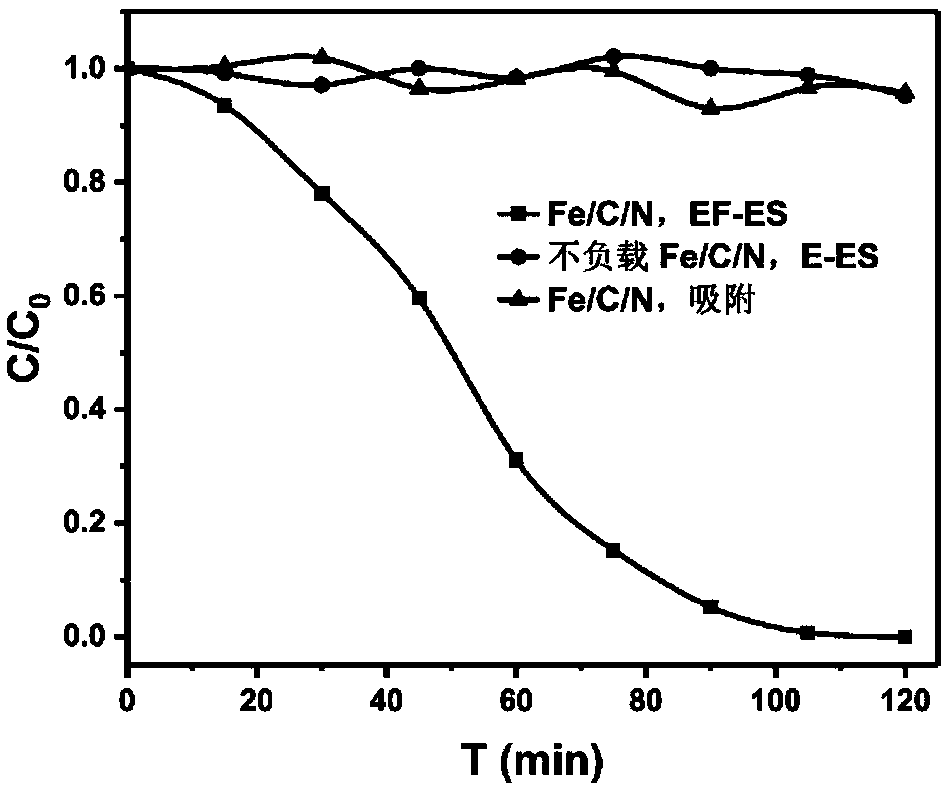

Porous Fe/C/N composite material and preparing method thereof

ActiveCN109626670AGood performance reproducibilityEvenly distributedWater treatment compoundsWater/sewage treatmentCarbon compositesCarbonization

The invention relates to the technical field of materials, and provides an efficient, stable, environment-friendly and porous iron carbon composite material. The porous iron carbon composite materialserves as an electro-Fenton cathode to improve the pollutant degradation efficiency and sustainability of an Electro-Fenton system. According to the porous Fe / C / N composite material, a ferrous metal skeleton organic compound MIL-(100)Fe serves as a precursor, polyaniline (PANI) serves as a carbon source and a nitrogen source, and after high temperature carbonization, the Fe / C / N porous composite material is obtained. The porous Fe / C / N composite material has efficient and stable heterogeneous electro-Fenton catalysis performance, has an oxidation-reduction effect and a Fenton catalysis effect during actual application and can ionize to produce H2O2 and catalyze H2O2 to produce OH at the same time, and no other reagents or catalysts need to be added.

Owner:SUZHOU INST FOR ADVANCED STUDY USTC

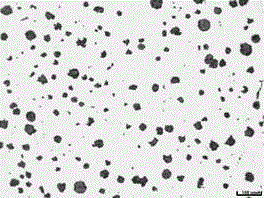

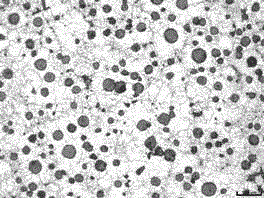

High-strength sulfur-oxygen nucleating agent

The invention provides a high-strength sulfur-oxygen nucleating agent. The high-strength sulfur-oxygen nucleating agent comprises the following elements in percentages by mass: 70-76% of Si, 0.2-1.0%of Ca, 0.3-0.5% of Ba, 1.5-2.0% of La, 0.5-1.5% of Al, 0.3-0.9% of S, 0.3-0.9% of O, 0.5-1.5% of Sb and the balance of iron. The sulfur-oxygen nucleating agent is prepared from the following raw materials in parts by weight: 2-4 parts of steel scrap, 130-140 parts of silicon iron, 1-1.4 parts of silicon barium, 1-1.8 parts of calcium silicon, 2-4 parts of pure lanthanum, 1.5-2.5 parts of stibonium, 1-2 parts of FeS and 1-1.4 parts of FeO. By the prepared high-strength sulfur-oxygen nucleating agent, the number of graphite nodules in nodular cast iron can be increased obviously, the strength and toughness of the nodular cast iron can be improved, the chilling tendency of the nodular cast iron is relieved obviously, the nodularity, the number of graphite nodules and the number of ferrites ofthe nodular cast iron are increased, shrinkage in a casting process is eliminated, and complicated castings with excellent quality can be formed.

Owner:YUZHOU HENGLILAI ALLOY CO LTD

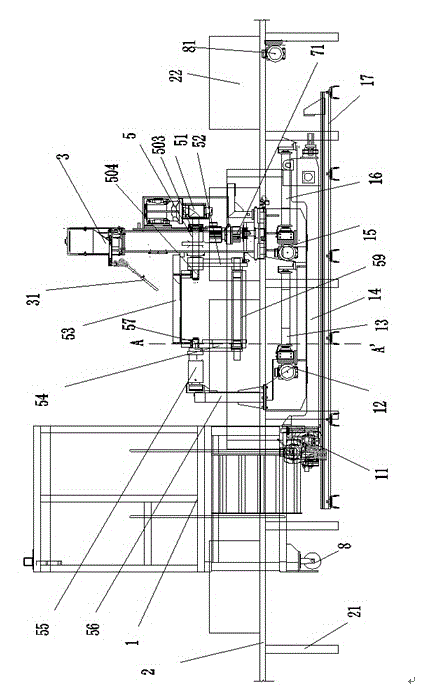

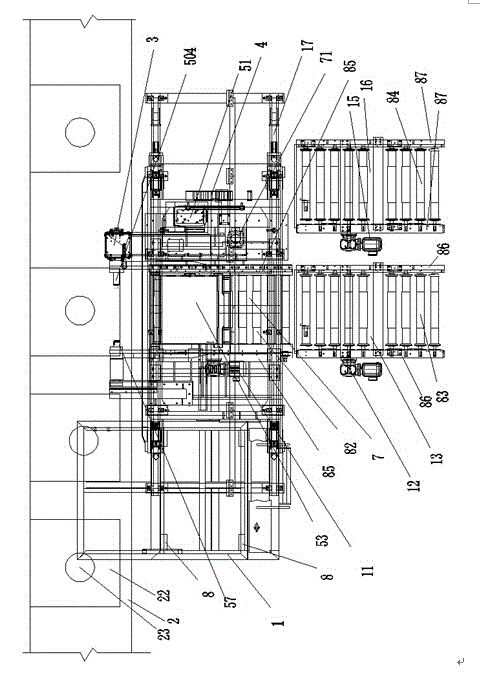

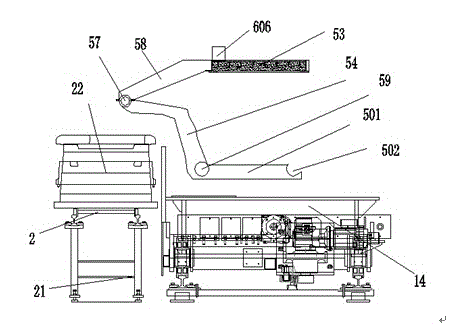

High-precision full-automatic casting machine

ActiveCN104439222AGuaranteed continuityImprove pouring qualityMolten metal supplying equipmentsMetallurgyThermal insulation

The invention discloses a high-precision full-automatic casting machine. The high-precision full-automatic casting machine comprises a casting ladle system, a casting ladle transverse moving and longitudinal moving system, a servo tilt-rotating mechanism, a detection unit and a control unit. The casting ladle system comprises a casting ladle made of thermal insulation materials and a casting ladle moving device. The casting ladle transverse moving and longitudinal moving system comprises a track system and a casting vehicle. The detection unit comprises a load sensor. The load sensor is used for detecting the weight of molten metal in the casting ladle of the casting machine and generating a signal representing the detected weight. The control unit is provided with a first arithmetic unit, a second arithmetic unit and a driving indication unit. The casting machine can effectively shorten the casting time and improve the casting stability.

Owner:山东时风(集团)有限责任公司

Vanadium-titanium ferrite ductile iron automobile hub and production process thereof

The invention relates to the field of cast iron alloys, and particularly relates to a vanadium-titanium ferrite ductile iron automobile hub and a preparation method thereof. The automobile hub is made of vanadium-titanium ferrite ductile iron, and the vanadium-titanium ferrite ductile iron comprises the following chemical compositions in percentage by mass: 3.3-3.6% of C, 3.0-3.4% of Si, 0.0-0.4% of Mn, less than or equal to 0.06% of P, less than or equal to 0.02% of S, 0.12-0.18% of V, 0.05-0.10% of Ti, 0.0-0.08% of Cr, 0.040-0.060% of RE, 0.040-0.060% of Mg, and the balance of Fe and other trace elements and impurities. The vanadium-titanium ferrite ductile iron automobile hub disclosed by the invention is 550-650 MPa in strength and 12-15% in elongation percentage. Comprehensive properties of the vanadium-titanium ferrite ductile iron automobile hub disclosed by the invention are significantly better than those of common ferrite ductile iron automobile hubs.

Owner:陈国

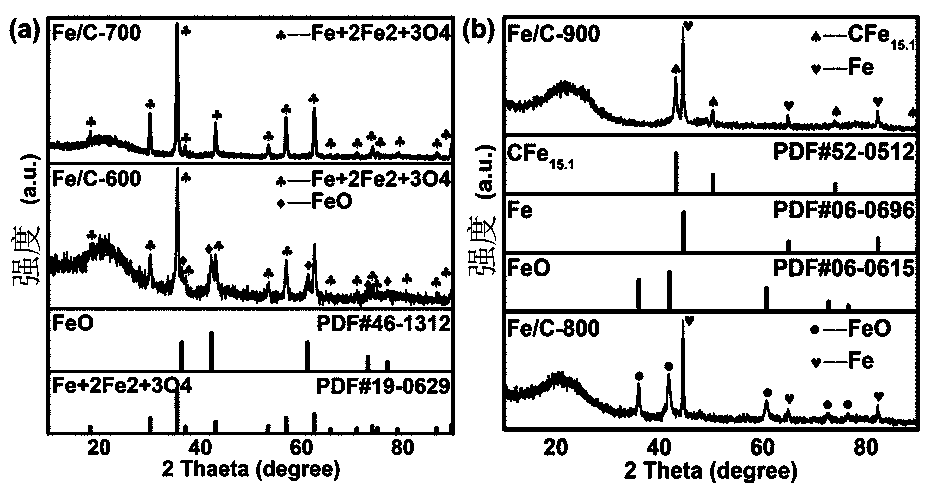

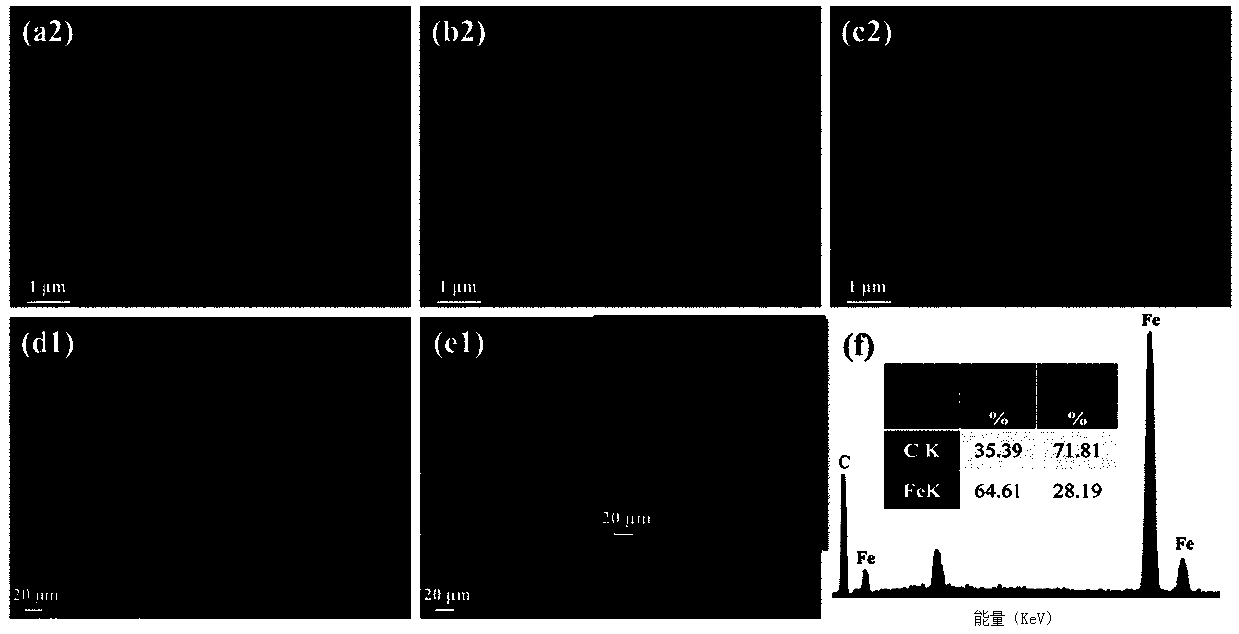

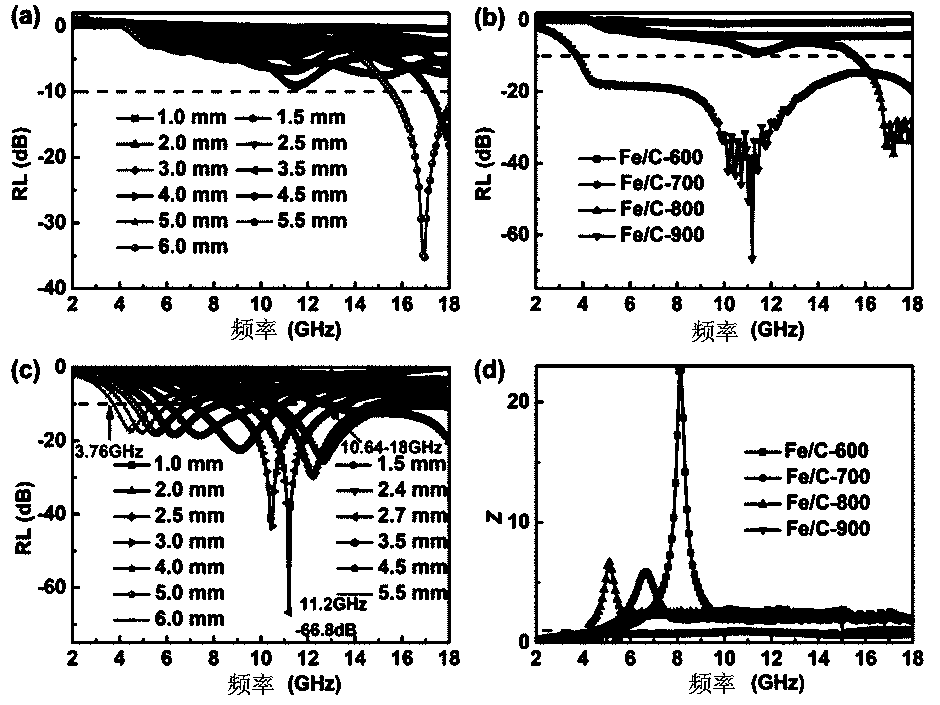

Preparation method of three-dimensional ordered carbon-based porous wave-absorbing material based on native wood

PendingCN110734048AChange the absorbing performancePromote graphitizationOther chemical processesCarbon preparation/purificationTube furnaceCarbonization

The invention provides a preparation method of a three-dimensional ordered carbon-based porous wave-absorbing material based on native wood. The preparation method comprises the following steps: S1, cutting the native wood into cuboids with preset sizes, soaking the formed wood blocks for 1-2 days, repeatedly washing the wood blocks with deionized water multiple times, and finally drying the woodblocks at 50-70 DEG C; S2, putting the wood blocks dried in the step S1 into a tubular furnace, carrying out heating to 350-450 DEG C, and keeping the wood blocks at the temperature for 0.5-1 hour toobtain pre-carbonized charcoal blocks; S3, mixing the pre-carbonized charcoal blocks with Fe (NO3) 3 having a concentration of 0.05 to 0.2 mol / L, and carrying out drying at a temperature of 50 and 70DEG C; and S4, putting a product obtained after drying in the S3 into the tubular furnace, carrying out heating to a preset temperature, keeping the product at the temperature for 0.5-1 hour, and taking out a sintered product when the temperature decreases to room temperature, thereby obtaining the three-dimensional ordered carbon-based porous wave-absorbing material. The three-dimensional orderedcarbon-based porous wave-absorbing material obtained by using the method can be used as an excellent wave-absorbing material with light weight, small thickness, wide absorption frequency band and strong absorption characteristics.

Owner:HARBIN INST OF TECH AT WEIHAI +1

Laminated Mo2CTx/nitrogen-doped carbon micron-nanometer hybridized compound wave-absorbing material and preparation method thereof

ActiveCN109181637AOvercoming the lack of absorbing abilityWide absorbing performanceOther chemical processesMagnetic/electric field screeningDielectric lossConductive polymer

The invention discloses a laminated Mo2CTx / nitrogen-doped carbon micron-nanometer hybridized compound wave-absorbing material and a preparation method thereof. According to the micron-nanometer hybridized compound wave-absorbing material, laminated Mo2CTx is taken as a carrier, and the surface of laminated Mo2CTx and the space among layers of laminated Mo2CTx are loaded with a nitrogen-doped carbon nanomaterial. Graphene-similar two-dimensional laminated Mo2CTx is taken as a carrier of the wave-absorbing material for the first time, and meanwhile, the nitrogen-doped carbon nanomaterial prepared through the pyrolysis of a conducting polymer is compounded with Mo2CTx for the first time so as to prepare the micron-nanometer hybridized compound wave-absorbing material, so that the deficiency that a single component is insufficient in wave-absorbing capacity is overcome, adjustable impedance matching and increased dielectric loss are realized, and the low-density, strong-absorptivity, low-thickness and wide-broadband wave-absorbing property is realized in a frequency range of 2GHz-18GHz.

Owner:SOUTHEAST UNIV

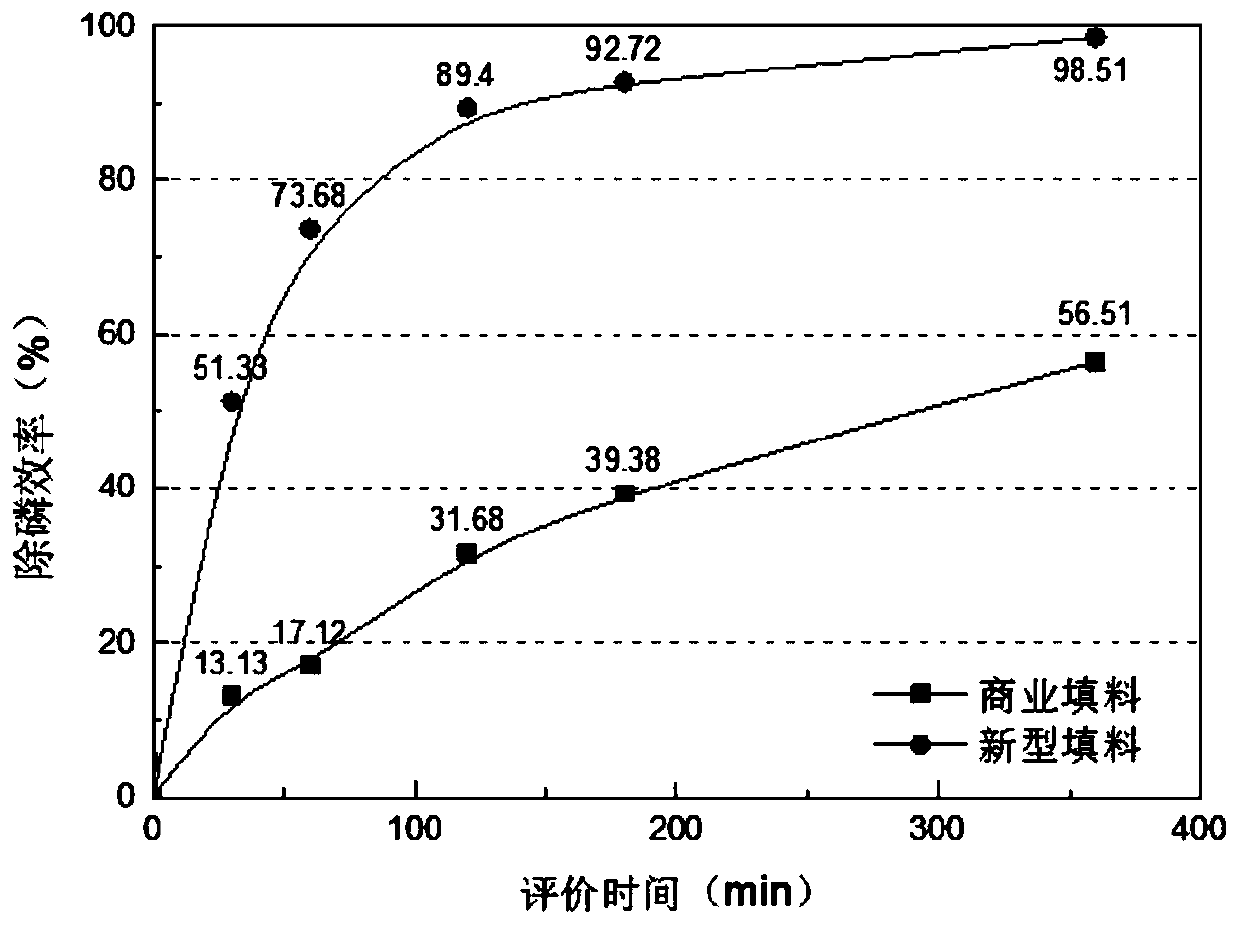

Preparation method of high-activity iron-carbon micro-electrolysis filler

ActiveCN109911990AHigh activityImprove removal efficiencyWater/sewage treatmentElectrolysisReaction rate

The invention relates to a preparation method of high-activity iron-carbon micro-electrolysis filler, belongs to the technical field of sewage treatment and is applicable to treatment of municipal sewage as well as industrial sewage such as pharmaceutical wastewater, heavy metal wastewater, printing and dyeing wastewater and the like. The filler is prepared from an iron-based material, a carbon-based material and a binder by homogenization treatment, carbonization treatment, mechanical forming treatment and high-temperature sintering treatment sequentially. The prepared iron-carbon micro-electrolysis filler can substantially increase the quantity of micro-primary batteries in unit volume, iron-carbon contact area, electron transfer efficiency and electrical conductivity of a material, hashigher reaction rate, can realize advanced purification treatment of sewage, effectively broadens the application range of micro-electrolysis, solves the problems of hardening and passivation, shows good stability and long effectiveness and has reduced operation cost and good application prospects.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

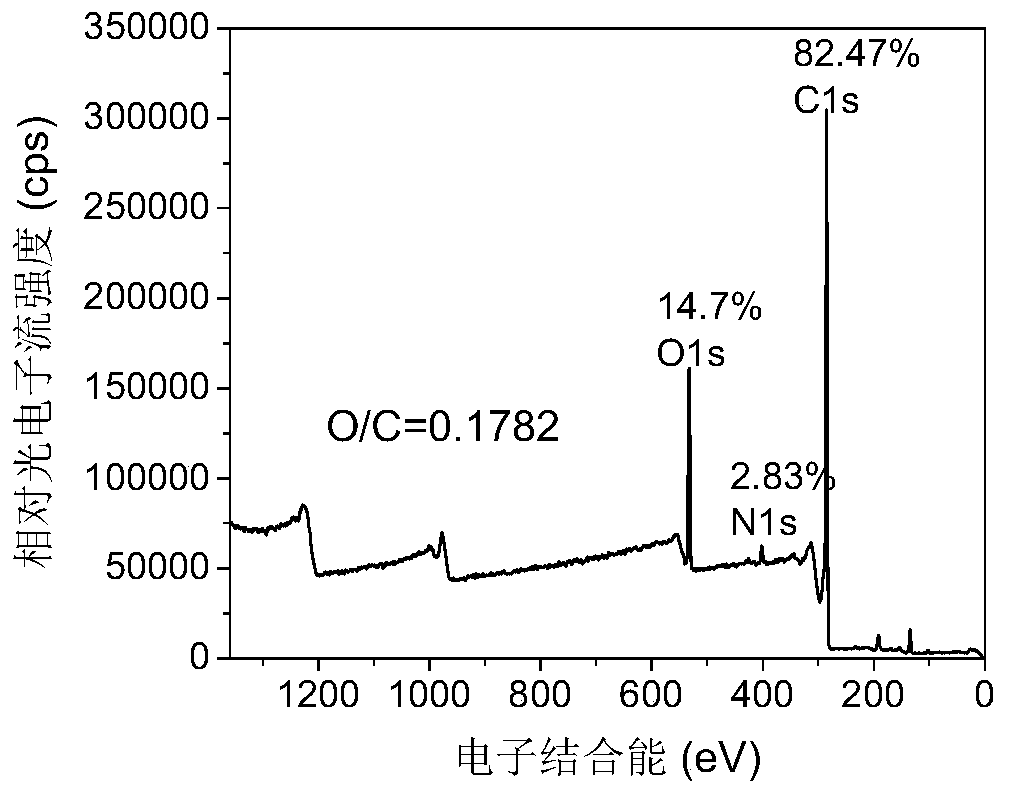

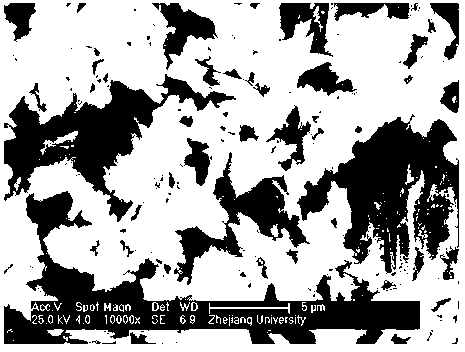

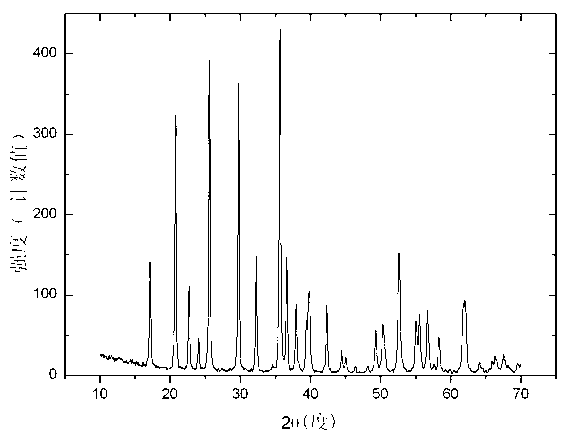

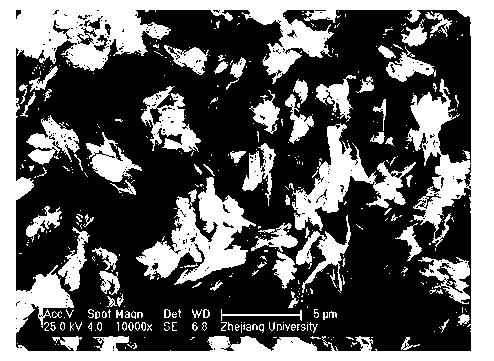

Graphitization processing method for soft coal and coal-rock compositions thereof

ActiveCN104016330AImprove the degree of graphitizationPromote graphitizationCarbon compoundsChemistrySoft Coals

A provided graphitization processing method for soft coal and coal-rock compositions thereof comprises the following steps: step 1, crushing soft coal into a coal powder; or firstly employing a manual peeling method to obtain coal-rock compositions from soft coal, and then crushing coal-rock compositions, so as to obtain a coal powder; step 2, performing de-ashing processing; step 3, uniformly mixing the coal powder with a catalyst to obtain a mixed powder; and step 4, performing graphitization processing, so as to obtain a graphitized product with the graphitization degree of 75% or more. According to the method, soft coal or coal-rock compositions peeled from soft coal are taken as the raw material, the influence of the catalyst iron chloride or boric acid on high-temperature graphitization of soft coal or coal-rock compositions thereof is investigated, graphitization of soft coal or coal-rock compositions thereof is realized, a new technology for employing soft coal to prepare ultrafine graphite powder is exploited, a new approach is developed for utilization of high added value of soft coal, and a new carbon raw-material source is developed for graphite materials.

Owner:XIAN UNIV OF SCI & TECH

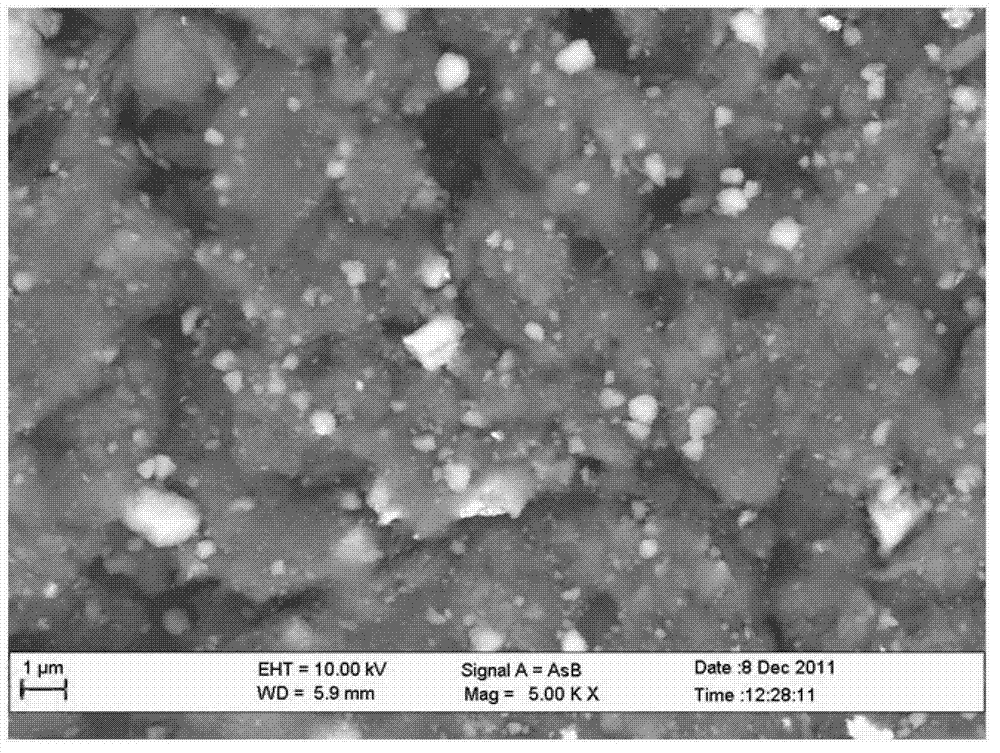

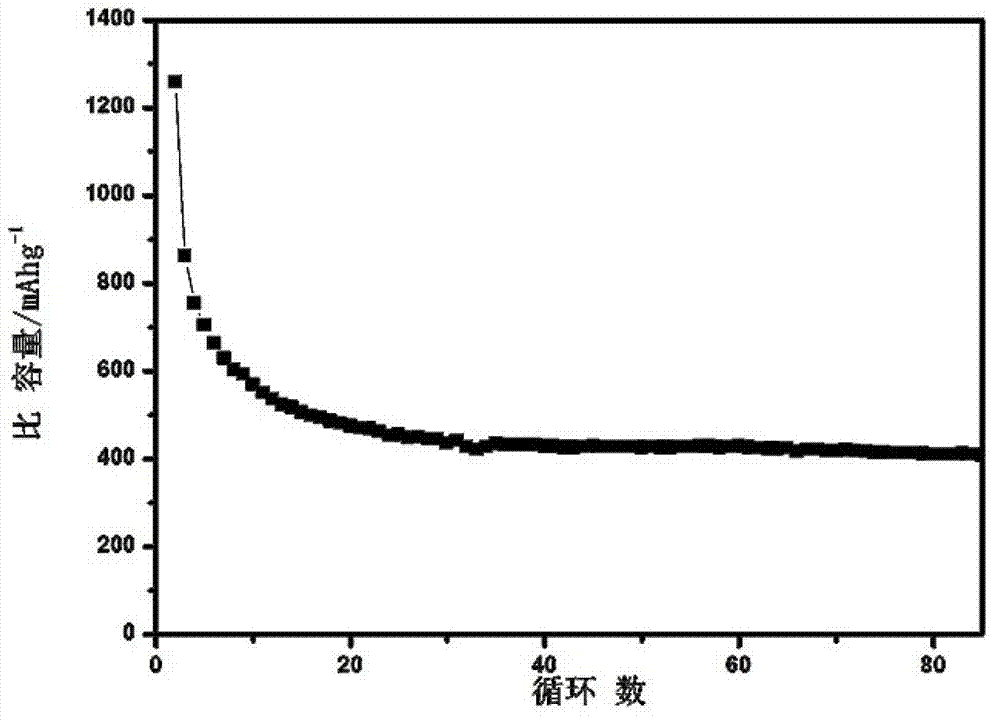

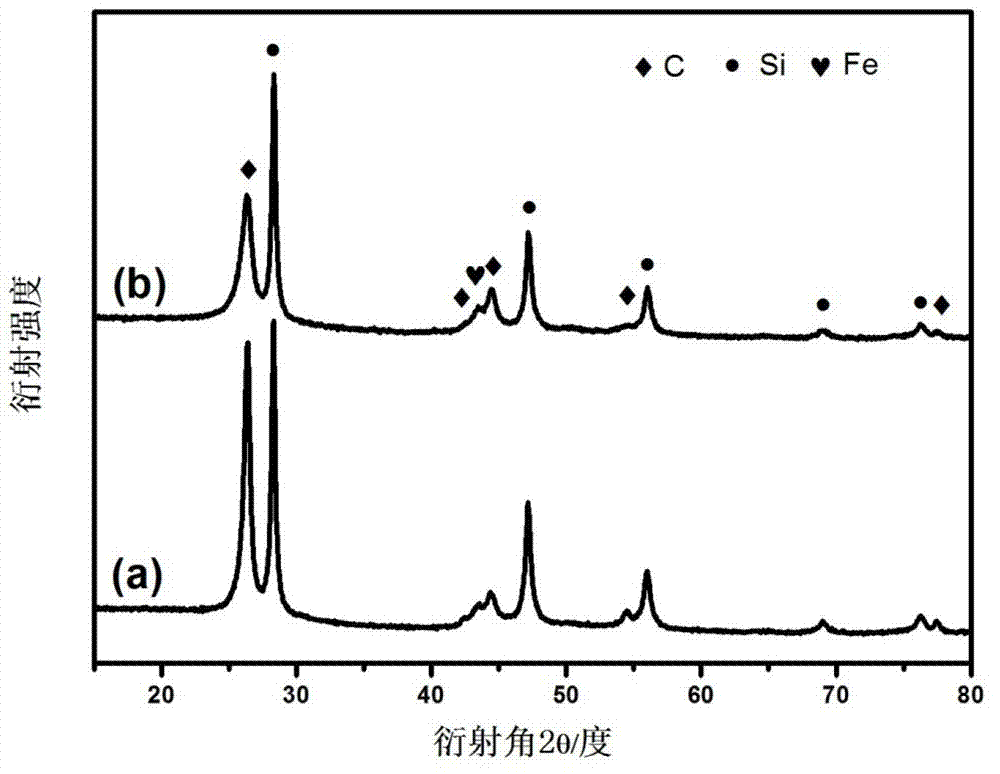

Preparation method for silicon carbon composite material for lithium ion battery negative electrode

ActiveCN102832376AEvenly distributedImprove cycle performanceCell electrodesCarbon compositesHigh energy

The invention discloses a preparation method for a silicon carbon composite material for a lithium ion battery negative electrode. The method comprises the following steps: primary ball milling: a step of adding a grinding aid into elementary silicon for ball milling; and secondary ball milling: a step of mixing silicon powder obtained after primary ball milling with carbon powder and adding a grinding aid for ball milling again. The mass content of the carbon powder is 20 to 80%. A discharge gas medium employed in the dielectric barrier discharge plasma assisted high-energy ball milling method is inert gas. According to the invention, silicon in the composite material prepared in the invention can be finely and uniformly distributed on a carbon matrix, effective refining of silicon can be carried out on the basis that the integrity of graphite sheets is ensured, reversible capacity of a battery is improved, the problems of volume expansion and poor conductivity of a silicon-based electrode are alleviated, and comprehensive performance of the lithium ion battery is improved.

Owner:SOUTH CHINA UNIV OF TECH

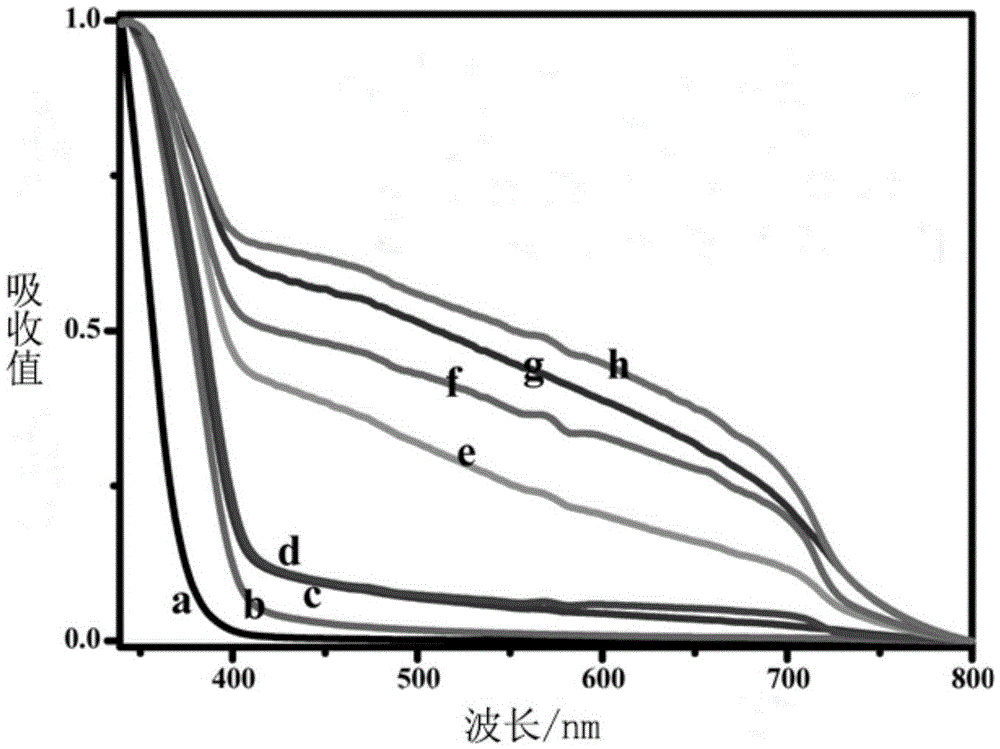

Carbon-modified TiO2/WO3 composite nanofiber photocatalyst, preparation method and application

ActiveCN105664922AImprove photocatalytic performancePromote orderMetal/metal-oxides/metal-hydroxide catalystsFiberCarbon layer

The invention discloses a carbon-modified TiO2 / WO3 composite nanofiber photocatalyst, a preparation method and application and belongs to the technical field of nano photocatalytic materials. The preparation method includes following steps: 1), adding polyvinyl pyrrolidone, ammonium tungstate and tetrabutyl titanate into mixed liquid of alcohol and acetic acid, and mixing well before electrostatic spinning to obtain nanofiber felt; 2), calcining the nanofiber felt to obtain TiO2 / WO3 nanofiber; 3), adding the TiO / WO3 nanofiber, glucose and water into a reaction kettle, allowing hydrothermal reaction, filtering, cleaning, and drying to obtain the photocatalyst. The TiO2 / WO3 composite nanofiber is modified through carbon, a carbon layer on the surface of TiO2 is used as an electron collector, and WO3 is used as an electron hole collector, so that photo-generated carriers can be separated effectively and photocatalytic performance of the photocatalyst can be improved. In addition, WO3 can promote ordering and graphitizing of the carbon layer, so that photocatalytic performance of the photocatalyst can be further improved.

Owner:ZHENGZHOU UNIV

Preparation method of high-strength thin-wall gray iron casting

ActiveCN109023034AReduce the amount addedReduce the proportionProcess efficiency improvementChemical compositionNational standard

The invention discloses a preparation method of a high-strength thin-wall gray iron casting. 3-8% of pig iron, 50-65% of waste steel and 27-42% of returns are adopted as raw materials of molten iron liquid, the process method of smelting, primary recarburization, primary inoculation, secondary recarburization, secondary inoculation, casting, in-mold inoculation and annealing is adopted, and the high-strength thin-wall gray iron casting is obtained. The high-strength thin-wall gray iron casting is prepared from chemical components in percent by mass: 2.9-3.5% of C, 1.4-2.1% of Si, 0.7-1.1% of Mn, smaller than or equal to 0.05% of P, smaller than or equal to 0.08% of S, smaller than or equal to 0.03% of Cu, 0.031-0.043% of Sn, 0.01-0.03% of RE and the balance Fe and inevitable impurities. Bymeans of the preparation method, the high-strength thin-wall gray iron casting can be prepared, the cost of the high-strength thin-wall gray iron casting is low, and the comprehensive performance issuperior to the national standard with the casting shop name being HT250.

Owner:慈溪市中环机械厂

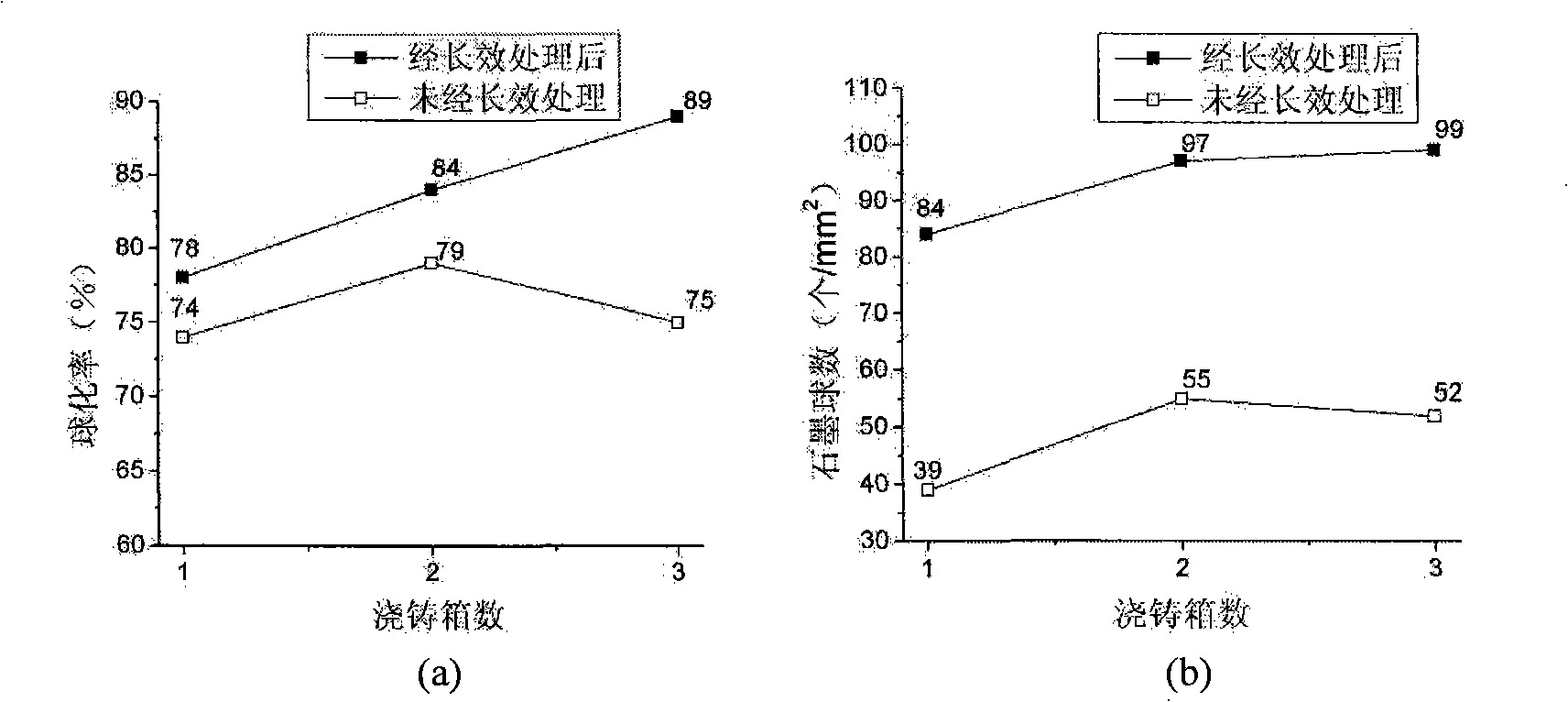

Long-acting synthesizing process of heavy sectioned ductile iron

InactiveCN101333618ARaise the eutectic temperatureLower eutectic temperatureMedium frequencyRare earth

The invention relates to a long-acting comprehensive treatment process of heavy wall ductile iron. The process comprises: placing ductile iron special pig iron materials and scrap steel in an appropriate amount in a medium frequency induction furnace, and smelting the materials at a temperature between 1350 and 1450DEG C according to the conventional method of: adding 0.1 to 2.0 percent of Cu; then adding 1 to 5 percent of nodulizer into a nodulizing ladle for nodulizing graphite, wherein the compositions of the nodulizer include: 10.0 to 12.0 percent of Mg, 2.0 to 3.0 percent of rare earth, 40.0 to 45.0 percent of Si, 2.5 to 3.0 percent of Ca, 2.5 to 2.9 percent of Ba, less than 1.5 percent of Al, balance Fe; and putting 0.1 to 1 percent of inoculant in a casting ladle in advance and pouring liquid iron into the casting ladle, the compositions of the inoculant have: 70.0 to 75.0 percent of Si, 0.5 to 0.6 percent of Ca, less than 1.5 percent of Al, 1.0 to 1.2 percent of Bi, balance Fe, and finally casting products. The process has the advantages of: improving the form of graphite, reducing degenerating graphite, and obviously improving the nodularity of heavy wall nodular iron and comprehensive mechanical properties of castings.

Owner:SHANGHAI UNIV

Austenite nodular cast iron containing carbide and preparing method for austenite nodular cast iron containing carbide

InactiveCN105838972APromote graphitizationImprove graphite morphologyProcess efficiency improvementCast ironHardness

The invention discloses austenite nodular cast iron containing carbide. The austenite nodular cast iron containing the carbide comprises, by percent, 3.0%-3.7% of C, 2.7%-3.2% of Si, 1.0%-1.5% of Mn, 0.2%-0.3% of Nb, 0.2%-0.4% of Ni, 0.2%-0.3% of V, 0.02%-0.04% of Mg, 0.02%-0.045% of RE and the balance Fe and inevitable impurities. The invention further discloses a preparing method for the austenite nodular cast iron containing the carbide. The preparing method comprises the steps of smelting, nodulizing inoculating, pouring, heat treatment and the like. A matrix structure with bainite as a main part, retained austenite and a small amount of martensite is obtained through the isothermal oil quenching treatment technology, the structure distribution is even, the mechanical performance of CADI is further improved, very good tenacity, hardness and abrasion resistance are achieved, and the producing and preparing technology is simple.

Owner:HANSHAN DONGSHAN DEYU SPHERULITIC GRAPHITE CASTING FACTORY

CF/PEEK composite material with chemical bond strong interface and preparation method thereof

The invention relates to a CF / PEEK composite material with a chemical bond strong interface and a preparation method thereof. The method comprises the following steps: (1) carrying out high-temperature decomposition on an original sizing agent on the surface of CF; (2) simultaneously carrying out microwave radiation and ultraviolet irradiation on CF in a saturated water vapor environment, and marking a product as ACF; (3) immersing ACF into the aminated PEEK / dimethylformamide / carbon nanotube suspension, performing heating to enable aminated PEEK to react with ACF, taking out, and drying, so asto obtain sized modified carbon fiber MCF; and (4) laminating and hot-pressing the MCF and the PEEK material, the CF / PEEK composite material with the chemical bond strong interface is obtained. The bending strength of the finally prepared CF / PEEK composite material with the chemical bond strength interface is 900-1100 MPa, the bending modulus of the finally prepared CF / PEEK composite material is57-65 GPa, the interface shear strength of the finally prepared CF / PEEK composite material is 100-120 MPa, and the residual compression strength of the finally prepared CF / PEEK composite material after impact is 210-250 MPa. The method disclosed by the invention has the characteristics of high efficiency, environmental friendliness and capability of realizing large-scale production, and the prepared CF / PEEK composite material can replace metal to be applied to the fields of aerospace, medical treatment, machinery, automobiles, rail transit and the like.

Owner:DONGHUA UNIV

Nodular cast iron for automobile braking disc and preparation method thereof

InactiveCN108441752AReduce hardenabilityImprove hardenabilityProcess efficiency improvementHigh intensityDuctile iron

The invention relates to the technical field of nodular cast iron, and particularly relates to nodular cast iron for an automobile braking disc and a preparation method thereof. The nodular cast ironis prepared from the following elements according to mass percent: 3.2 to 3.6% of C, 2.8 to 3.2% of Si, 0.4 to 0.8% of Cr, 0.2 to 0.6% of Mn, 0.2 to 0.8% of Al, 0.2 to 0.8% of Ni, 0.2 to 0.8% of Mg, 0.2 to 0.6% of Cu, 0.2 to 0.4% of Mo, 0.08 to 0.10% of Ta, 0.04 to 0.06% of Y, 0.02 to 0.03% of Sb, less than or equal to 0.02% of S, less than or equal to 0.04% of P and the balance of Fe and inevitable impurities. The invention provides the nodular cast iron for the automobile braking disc and the preparation method thereof. The elements and the content are reasonably optimized, so that the prepared nodular cast iron has the advantages of high strength, high toughness and wear resistance and high high-temperature resistance, and the service life of the automobile braking disc is prolonged during use.

Owner:HANSHAN COUNTY XINGDA DUCTILE IRON FACTORY

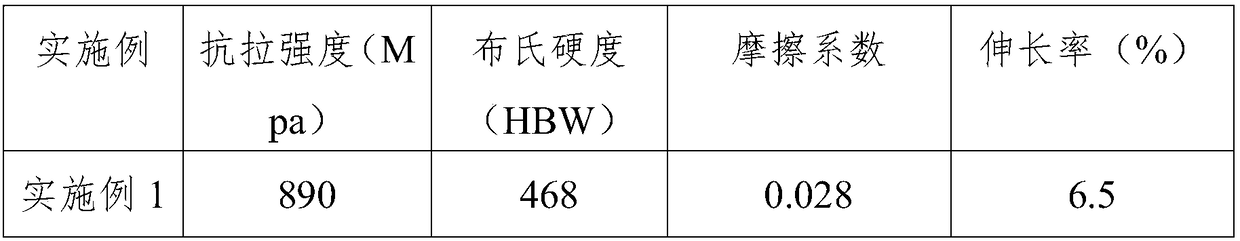

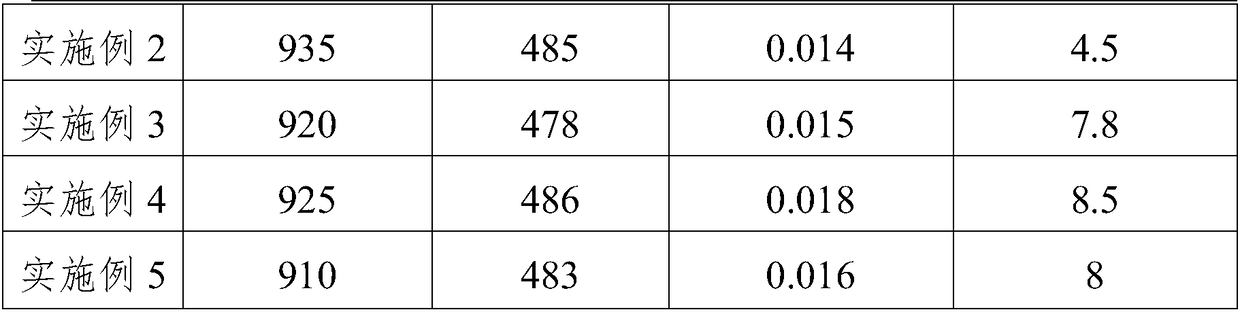

Pipe die powder for centrifugally casting nodular cast iron pipe and preparation process thereof

The invention discloses pipe die powder for centrifugally casting a nodular cast iron pipe and a preparation process thereof. The pipe die powder comprises the following components in percent by mass: 60-65 percent of Si, 1.5-2.0 percent of Ca, 2.0-3.0 percent of Ba, 1.4-1.6 percent of Mn, 1.0-1.5 percent of Mg, 1.0-2.0 percent of Zr, 0.7-1.5 percent of Al and the balance of Fe; and the granularities of pipe die powder comprise less than 1.5 percent of 80 mu, 25-30 percent of 100-120 mu, 40-50 percent of 140-180 mu, 25-30 percent of 200-300 mu and less than 2.5 percent of more than 300 mu. The preparation process comprises the following steps of: preparing, melting, pouring, cooling, crushing, milling, proportioning granularities and packaging in vacuum. The pipe die powder has the advantages of uniform components, consistent melting points and reasonable granulometric class, and is beneficial to the prolonging of the service life of a pipe die of the nodular cast iron pipe, the reduction of a series of casting defects of cockles, poor nodulizing, surface cracks and the like of the nodular cast iron pipe, the improvement of the quality of the nodular cast iron pipe and the yield, and the lowering of the production cost.

Owner:YUZHOU HENGLILAI ALLOY CO LTD

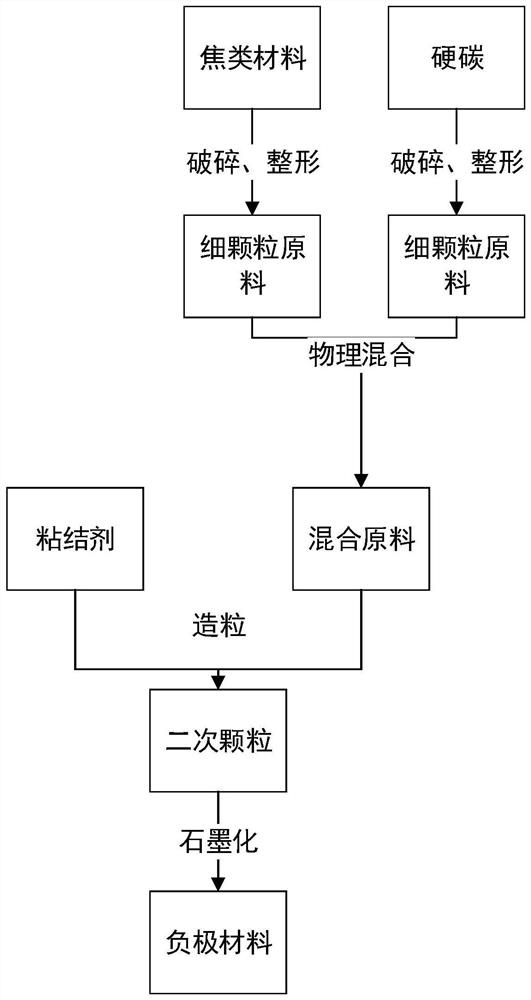

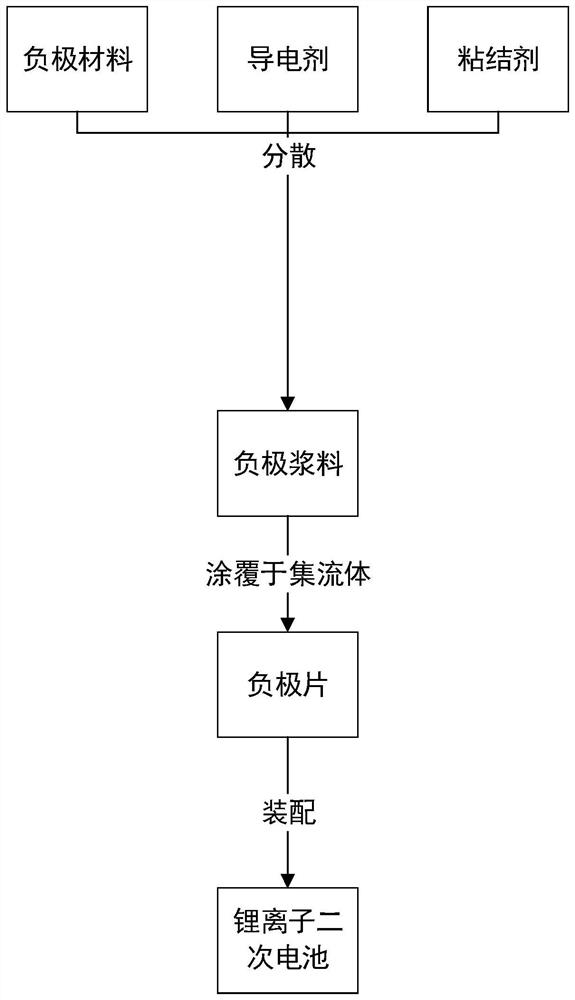

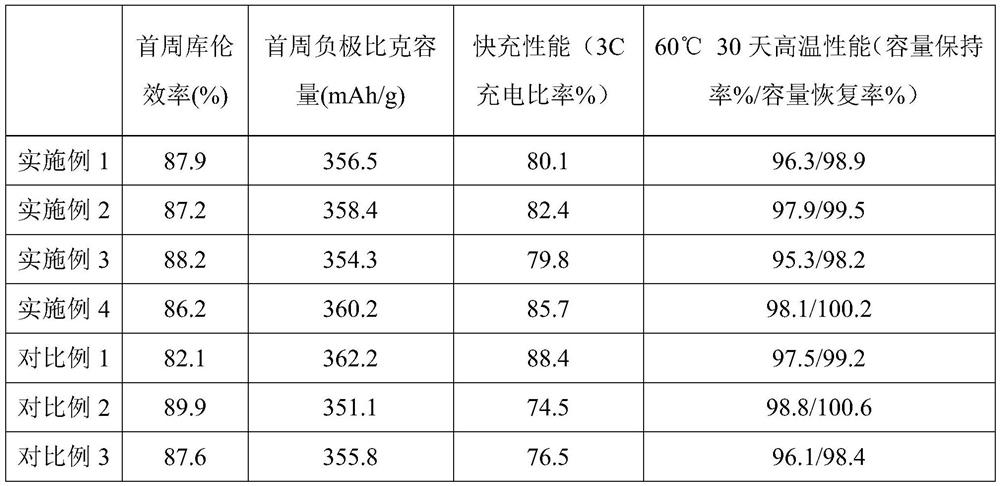

Negative electrode material and preparation method thereof, negative plate and lithium ion battery

PendingCN111620332AImprove high temperature performanceIncrease gram capacityCarbon compoundsNegative electrodesPhysical chemistryGraphite

The invention provides a negative electrode material and a preparation method thereof, a negative plate and a lithium ion battery. The method comprises the following steps: (1) mixing a coke materialand hard carbon, adding a carbon-containing binder, and granulating to obtain a granulated product; and (2) graphitizing the granulated product to obtain the negative electrode material. The negativeelectrode material obtained by the method disclosed by the invention is high in energy density and excellent in quick charging performance and high-temperature performance.

Owner:HUBEI JINQUAN NEW MATERIALS CO LTD

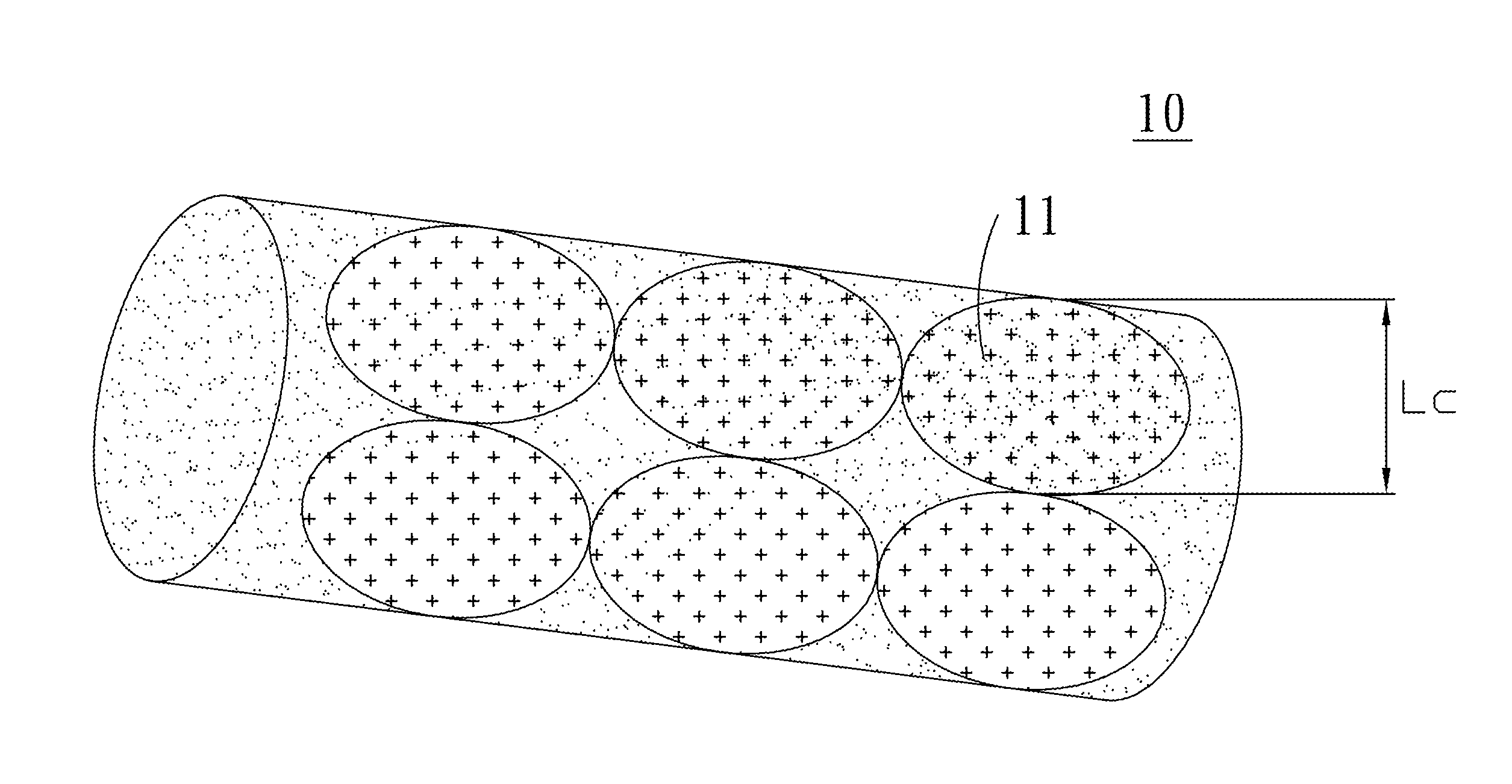

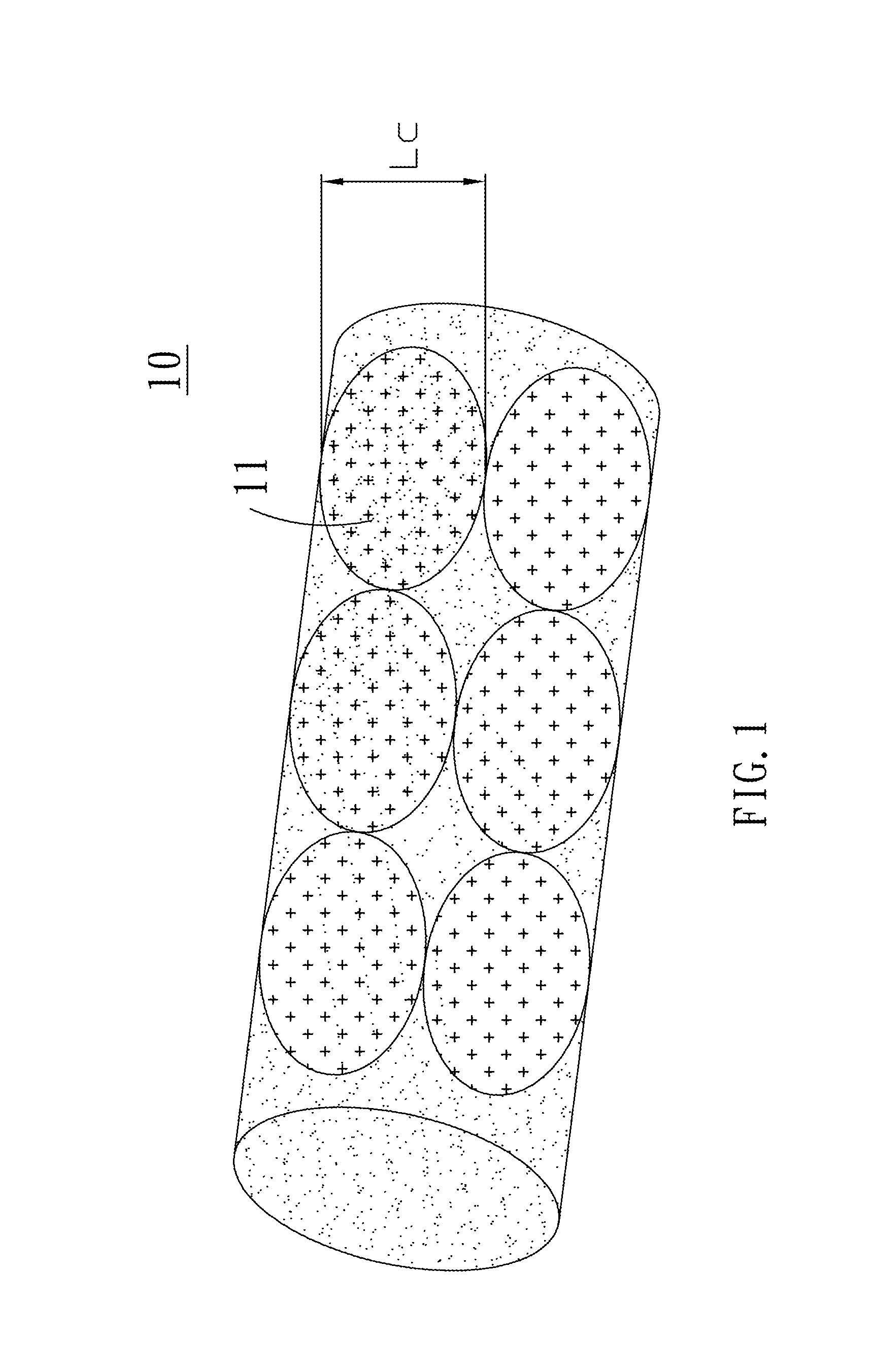

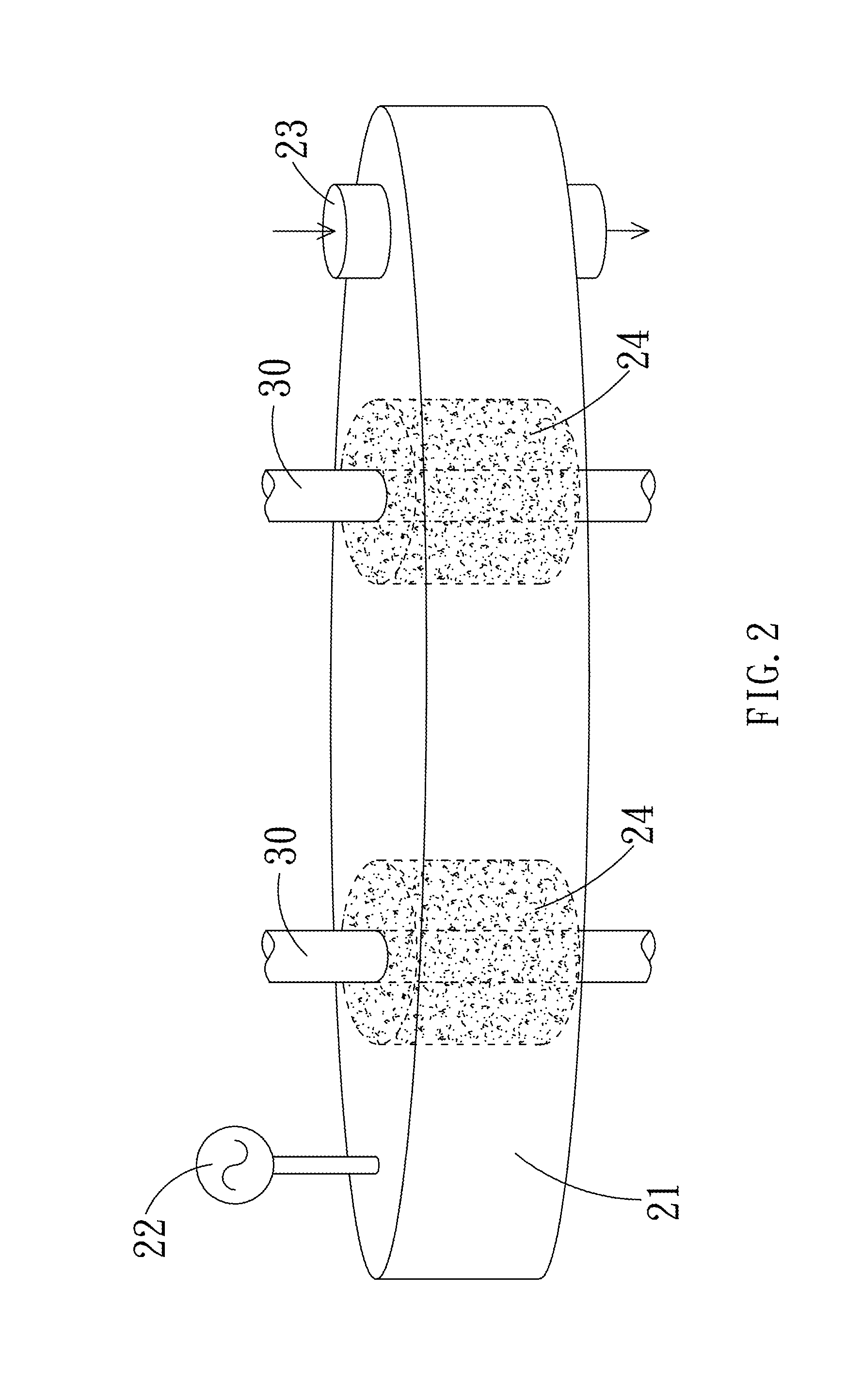

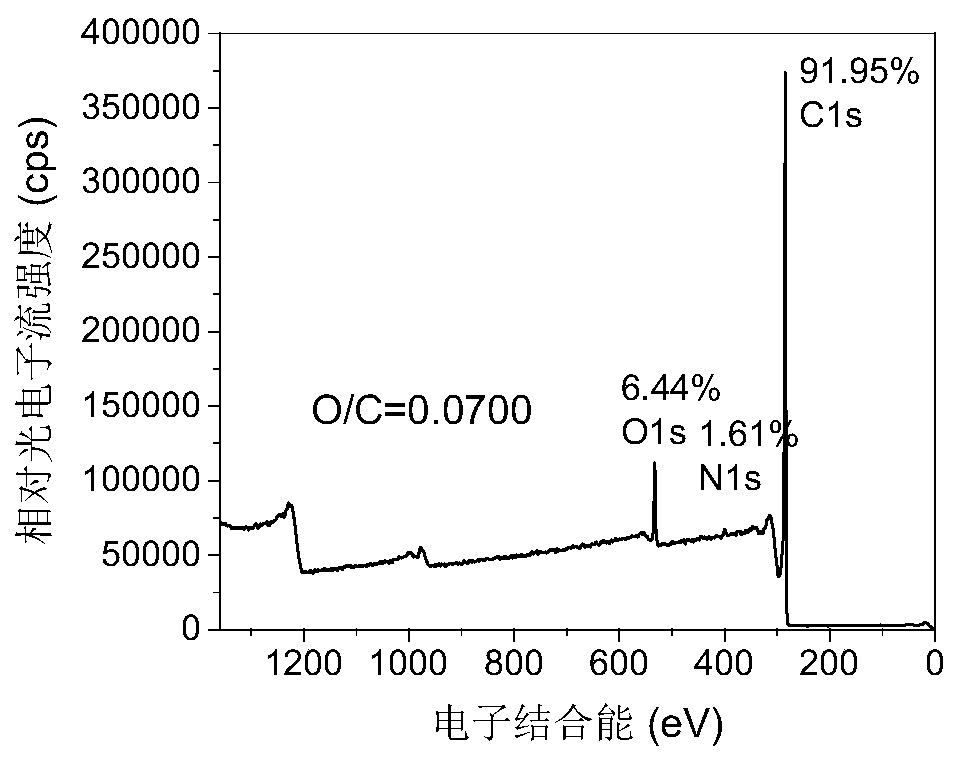

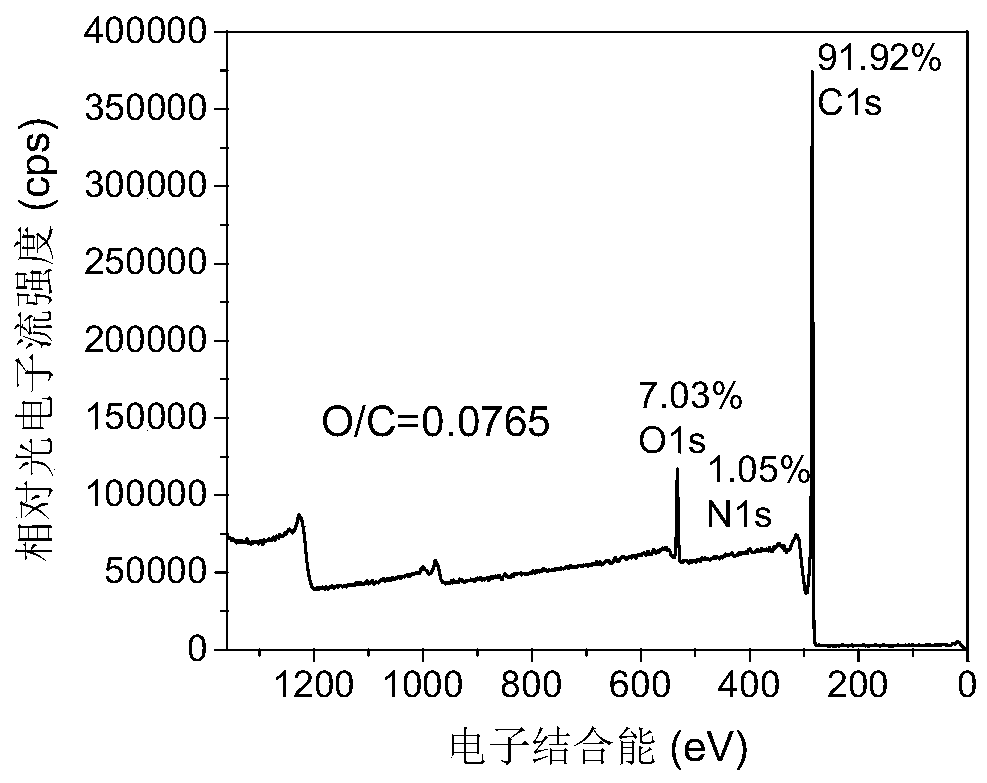

High modulus graphite fiber and manufacturing method thereof

ActiveUS20140037533A1Improving graphitization efficiencyReduce manufacturing costArtificial filament heat treatmentFibre chemical featuresFiberCarbon fibers

A high modulus graphite fiber with a tensile modulus of 270˜650 GPa and a plurality of crystal structures with a thickness (Lc) of 20˜70 angstroms is disclosed. Carbon fiber is used as a raw material, and a microwave focusing method is used to perform an ultra quick high temperature graphitization process to increase the temperature of the carbon fiber at a heating speed of 10˜100° C. per minute to a graphitization temperature of 1400˜3000° C., and then to perform a quick graphitization process for 0.5˜10 minutes to form the high modulus graphite fiber.

Owner:UHT UNITECH

CF/PEEK composite material with excellent high-temperature mechanical properties and preparation method thereof

ActiveCN111410759APossibility of industrial scale productionGuaranteed normal windingMeth-Flexural modulus

The invention relates to a CF / PEEK composite material with excellent high-temperature mechanical properties and a preparation method of the CF / PEEK composite material. The preparation method comprisesthe following steps: (1) carrying out high-temperature decomposition on an original sizing agent on the surface of CF; (2) simultaneously carrying out microwave radiation and ultraviolet irradiationon CF in a saturated water vapor environment, and marking a product as ACF; (3) immersing ACF into the polyamic acid / N-methyl-2-pyrrolidone / carbon nanotube suspension, taking out, drying, and carryingout two-stage heat treatment to obtain sized modified carbon fiber MCF; (4) laminating and hot-pressing the MCF and the PEEK material; wherein the bending strength of the CF / PEEK composite material at 25 DEG C is 780-950 MPa, the bending modulus of the CF / PEEK composite material at 25 DEG C is 55-65 GPa, and the interlayer shear strength of the CF / PEEK composite material at 25 DEG C is 80-93 MPa;the bending strength at 200 DEG C is 550 to 650 MPa, the bending modulus is 40 to 50 GPa, and the interlaminar shear strength is 60 to 75 MPa. The method disclosed by the invention has the characteristics of high efficiency, environmental friendliness and capability of realizing large-scale production, and the prepared composite material can replace metal to be applied to the fields of aerospace,medical treatment, machinery, automobiles and the like.

Owner:常州君航高性能复合材料有限公司

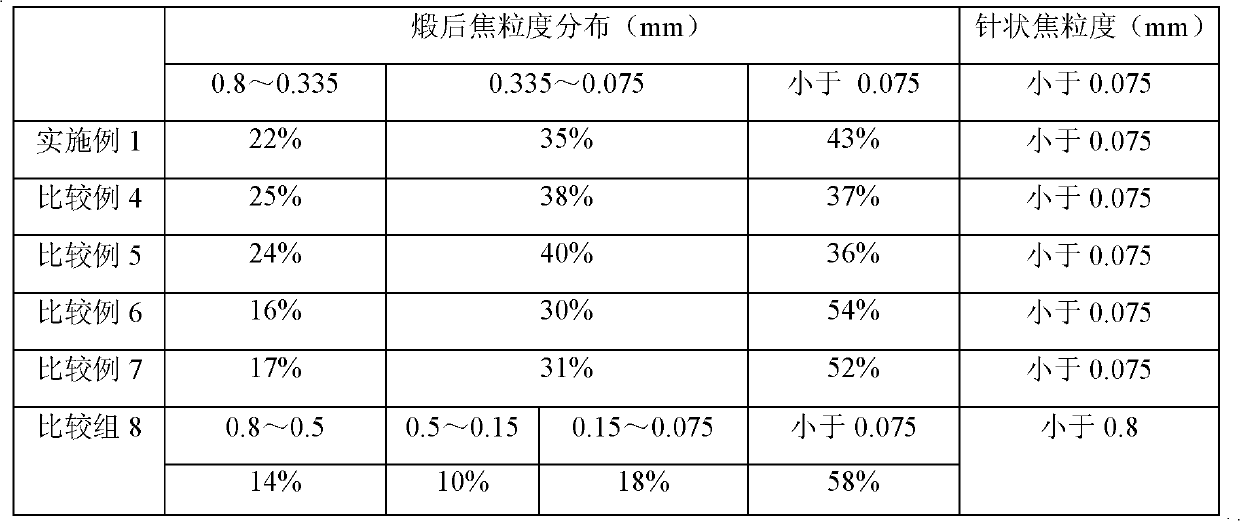

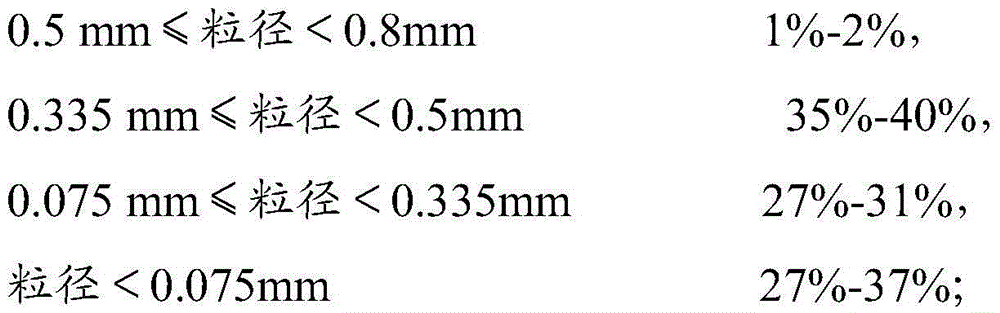

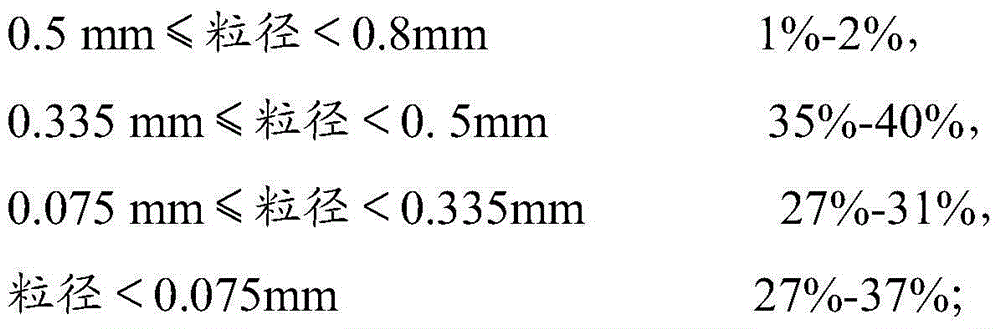

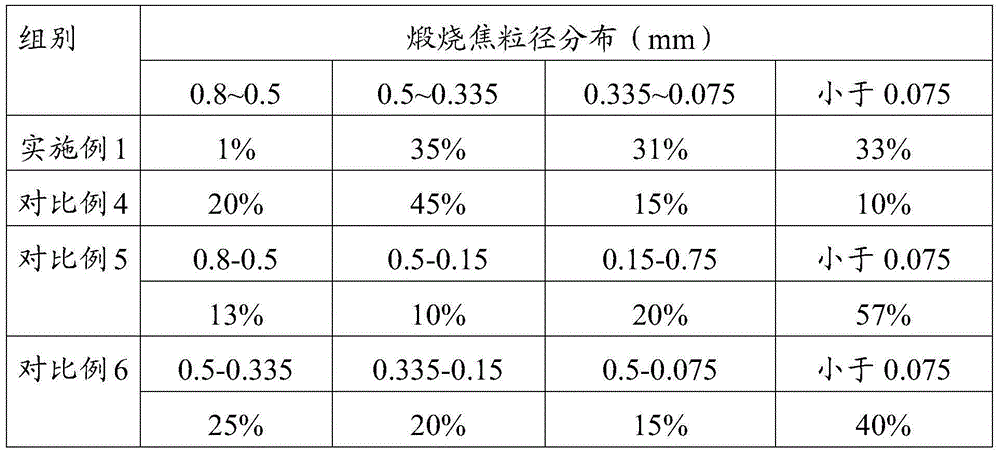

Graphite furnace lining used for high purity graphitization furnaces, and preparation method thereof

The invention discloses a graphite furnace lining used for high purity graphitization furnaces, and a preparation method thereof, and belongs to the technical field of graphite processing. The preparation method comprises steps of crushing, sieving, material preparing, dry blending, wet blending, moulding, primary roasting, primary dipping, secondary roasting, secondary dipping, tertiary roasting, and graphitization. In the raw materials of the graphite furnace lining, an aggregate is composed of calcined coke, pitch coke, and needle coke at a mass ratio of 80-82:10-15:5-8; wherein calcined coke is composed of particles with four following different particle size ranges: 0.5mm<=particle size<0.8mm, 0.335mm<=particle size <0.5mm, 0.075mm<=particle size<0.335mm, and particle size<0.075mm, and the weight amounts of the four particles account for 1 to 2%, 35 to 40%, 27 to 31%, and 27 to 37% respectively. Purity of the graphite furnace lining prepared via the preparation method is high; bulk density is large; porosity is low; ash content is low; oxidation resistance, compressive strength, and rupture strength are extremely excellent; and application requirements on high purity graphitization furnace linings are satisfied.

Owner:DATONG XINCHENG NEW MATERIAL CO LTD

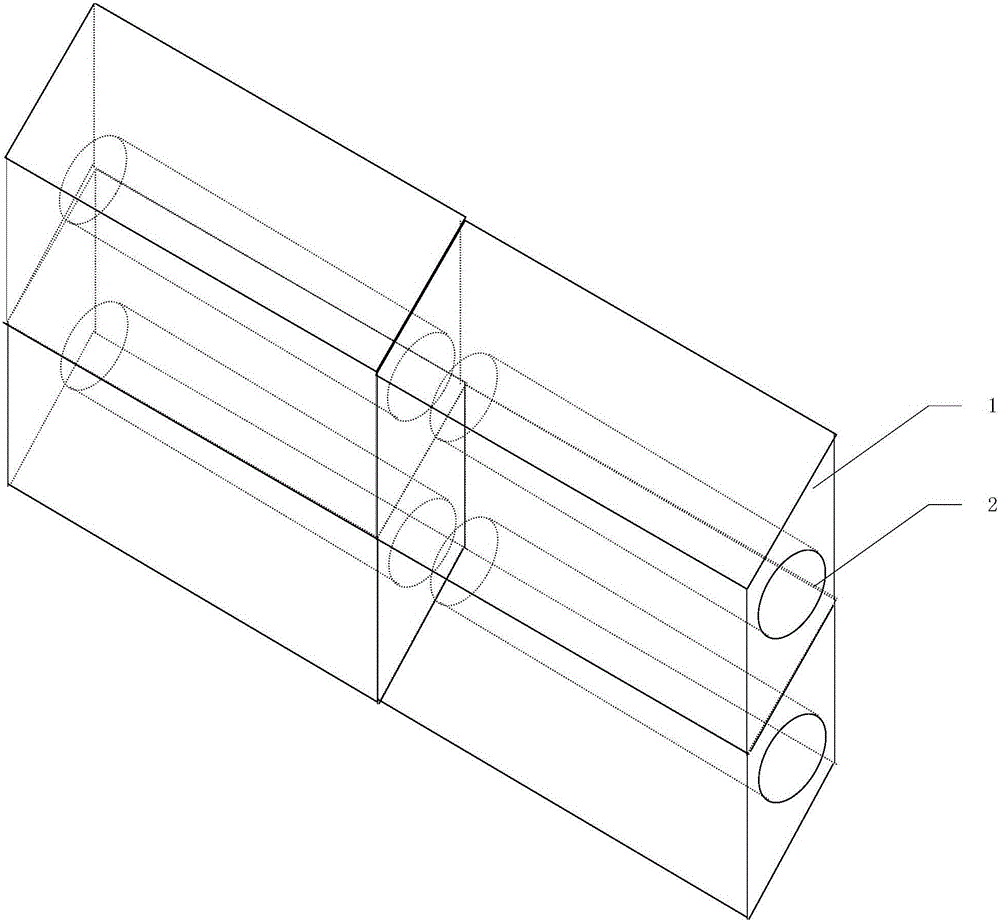

Heat conductive graphite film preparation method and graphite crucible

The invention discloses a heat conductive graphite film preparation method. A high-molecular thin film coiled material with metal salt attached to the surface is used as a raw material film and placed into a graphite crucible for carbonization and graphitization, and finally a heat conductive graphite film is obtained through pressing. The metal salt powder attached to the surface of the raw material film and graphite paper can promote graphitization of the raw material film, the crystallinity of the graphite film is improved, and the quality of graphite film products is improved. The invention further provides the graphite crucible. The graphite crucible is a cuboid graphite crucible. Compared with a barrel type crucible in the prior art, the contact area of the graphite crucible and a boiler is increased, heat can be transferred to raw materials better during thermal treatment, the cuboid graphite crucible can be better stacked, production yield of a single time of a graphitization furnace is greatly increased, and production efficiency is improved.

Owner:SUZHOU JINHE NEW MATERIAL

Preparation method of pipe mold powder for nodular cast iron and application thereof

Owner:成都宏源铸造材料有限公司

Method for preparing carbon-coated lithium iron phosphate from basic lithium iron phosphate

InactiveCN103265001AThe process is simpleGood controllabilityCell electrodesCarbon preparation/purificationIonChemistry

The invention discloses a method for preparing carbon-coated lithium iron phosphate from basic lithium iron phosphate. In conventional preparation processes for lithium iron phosphate, P, Fe and Li are originated from different raw materials, and in the process of mixing, inadequate batch mixing easily happens, which results in incomplete generation of lithium iron phosphate. The method provided by the invention comprises the following steps: mixing basic lithium iron phosphate, a carbon source and a catalyst and then carrying out sintering so as to obtain the carbon-coated lithium iron phosphate, wherein a mass ratio of the carbon source to basic lithium iron phosphate is 4-8: 100, and a mol ratio of metal ions in the catalyst to iron ions in basic lithium iron phosphate LiFePO4(OH) is 1-3: 100. According to the invention, P, Fe and Li are originated from the same raw material basic lithium iron phosphate, so the problem in homogeneity of batch mixing is overcome; the carbon source is decomposed at a high temperature to produce a gaseous organic matter which can reduce positive trivalent Fe in basic lithium iron phosphate into positive bivalent Fe and enables carbon to be deposited on the surface of lithium iron phosphate to form coating carbon. The method provided by the invention has the advantages of simple process, good controllability and stable product performance.

Owner:HANGZHOU DIANZI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com