Porous Fe/C/N composite material and preparing method thereof

A composite material and mixture technology, applied in the field of materials, can solve the problems of secondary pollution pollutant adsorption capacity, low iron regeneration efficiency on catalyst, uneven distribution of catalytic sites, etc., to promote contact, eliminate the influence of effluent quality, The effect of evenly distributed metal centers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

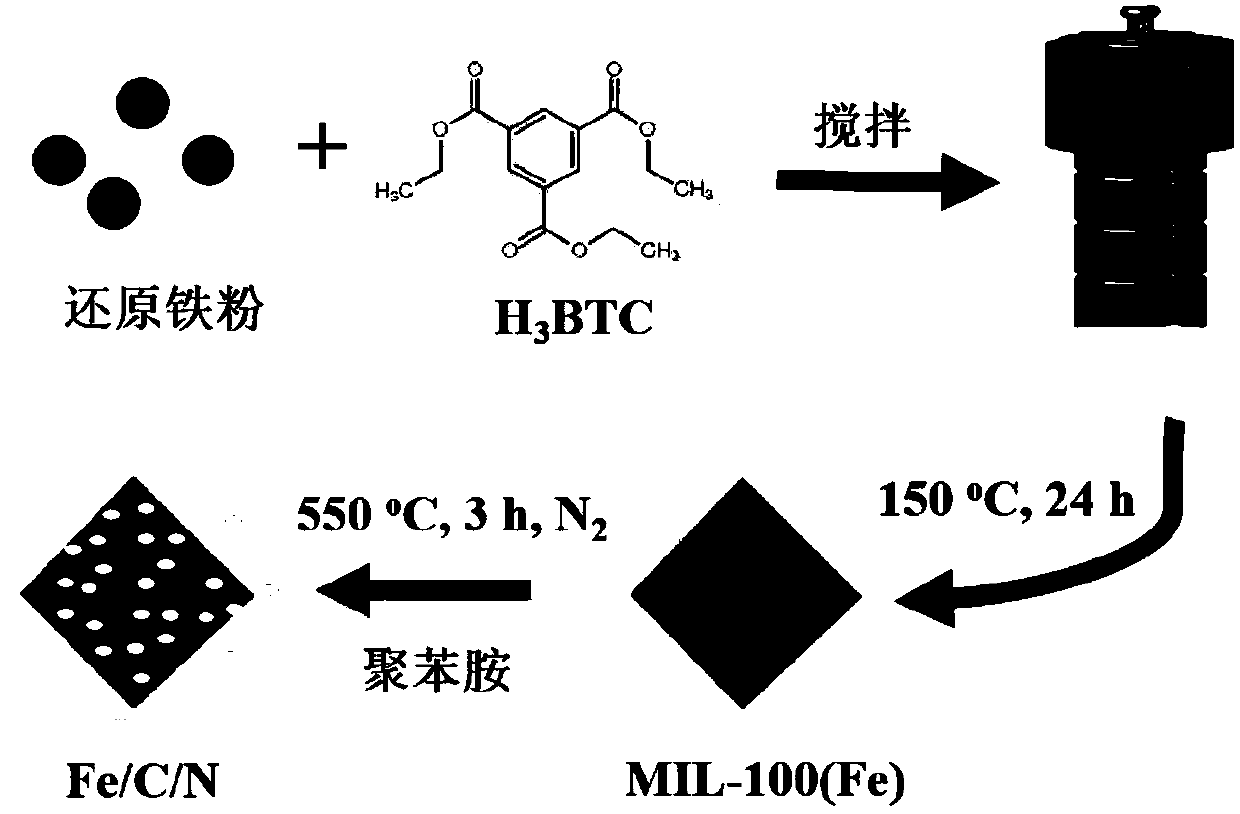

[0043] Preparation method of Fe / C / N porous composite material

[0044] (1) Synthesis of precursor MIL-100(Fe):

[0045] First, accurately weigh 277.5mg of reduced iron powder, 687.5mg of 1,3,5-trimellitic acid (H 3 BTC), mixed with 200 μL of hydrofluoric acid (40 wt%), 190 μL of nitric acid (65 wt%), and 20 mL of deionized water, and continuously stirred at a speed of 500 rpm for 30 min. The above mixed solution was transferred to a polytetrafluoroethylene reactor liner with a volume of 50mL, the cap was screwed on tightly, and the reaction was carried out by hydrothermal reaction at 150°C for 24h. Cool naturally to room temperature after the reaction is complete, centrifuge the reaction product, transfer the centrifuged product to a clean beaker, add about 250 mL of deionized water, and put it in an oil bath at 80°C for 3 hours to remove residual H 3 BTC. After the oil bath is completed, centrifuge, and wash the centrifuged product several times with deionized water and ab...

Embodiment 2

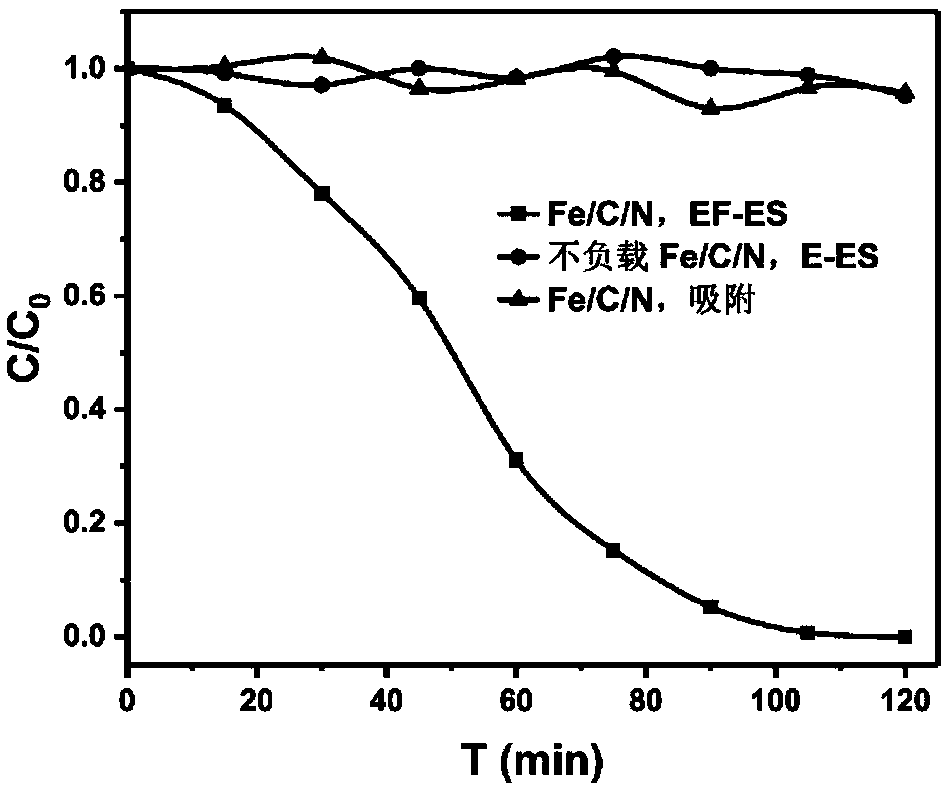

[0051] The catalytic performance test of embodiment 2.Fe / C / N composite material

[0052] Weigh 10 mg of Fe / C / N porous material, mix it with 2.45 mL of isopropanol and 50 μL of Nafion solution in a sealed glass weighing bottle, and ultrasonicate for 60 min to obtain a uniformly dispersed ink solution. Use a pipette gun to evenly drop the ink solution to an area of 6cm 2 Carbon paper electrodes were air-dried at room temperature to prepare carbon paper electrodes loaded with Fe / C / N porous materials.

[0053] The catalytic degradation experiment was carried out at room temperature, using platinum wire as the counter electrode, Ag / AgCl electrode as the reference electrode, and carbon paper electrode loaded with Fe / C / N porous material as the working electrode, connected to the electrochemical workstation to form a three-electrode system . 10mg·L -1 BPA solution was used as simulated wastewater, adding 0.05mol·L -1 Anhydrous Na 2 SO 4 Adjust its pH to 3.0 as a supporting ele...

PUM

| Property | Measurement | Unit |

|---|---|---|

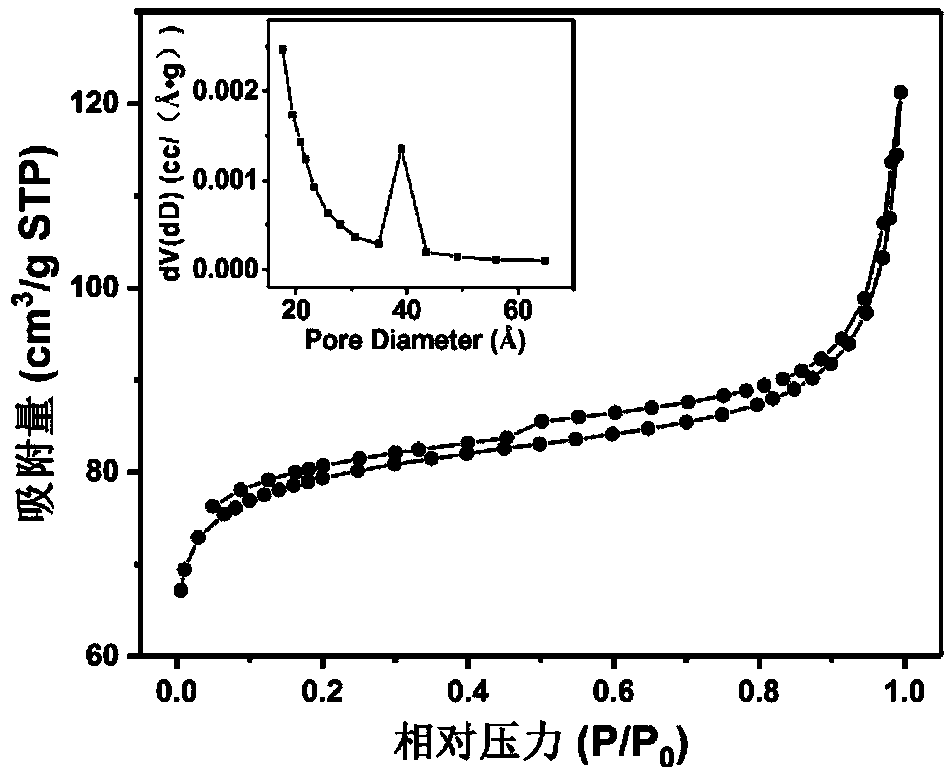

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com