A kind of preparation method and application of hydrogen-containing polyborosiloxane modified white carbon black

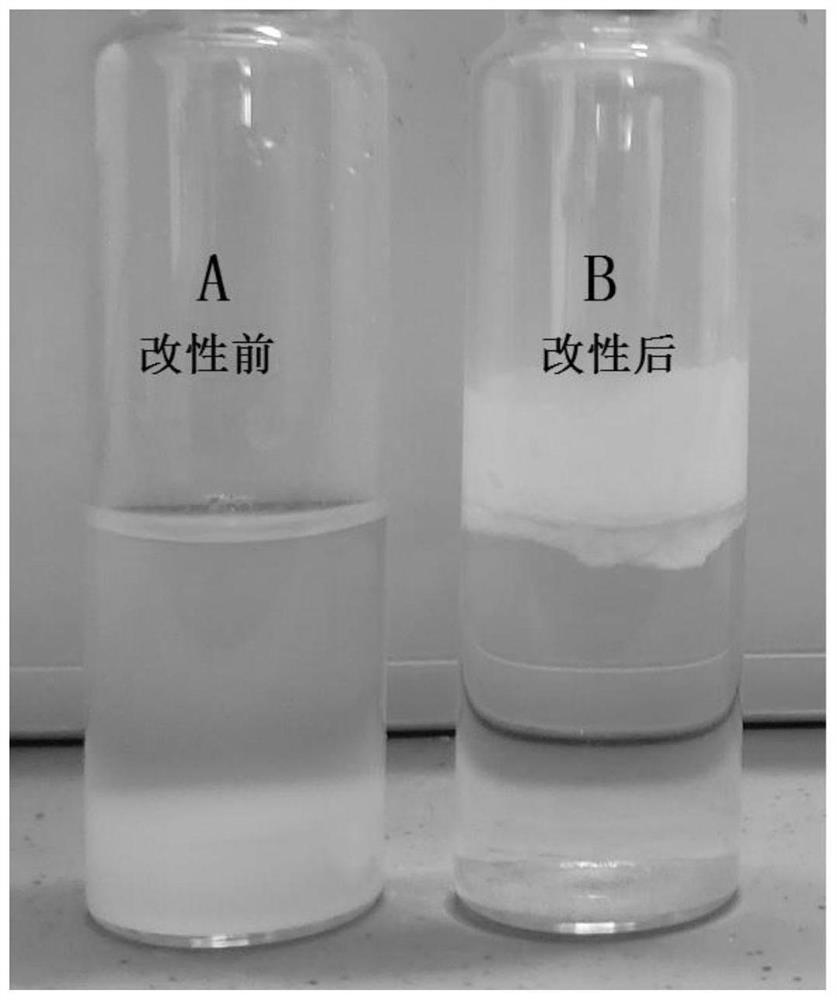

A technology of polyborosiloxane and white carbon black, applied in chemical instruments and methods, dyed organic silicon compound treatment, dyed low-molecular organic compound treatment, etc., can solve the problem of difficult control of polyborosiloxane structure and harsh preparation process , poor product reproducibility and other issues, to achieve excellent hydrophobic and lipophilic properties, uniform dispersion, and not easy to gel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

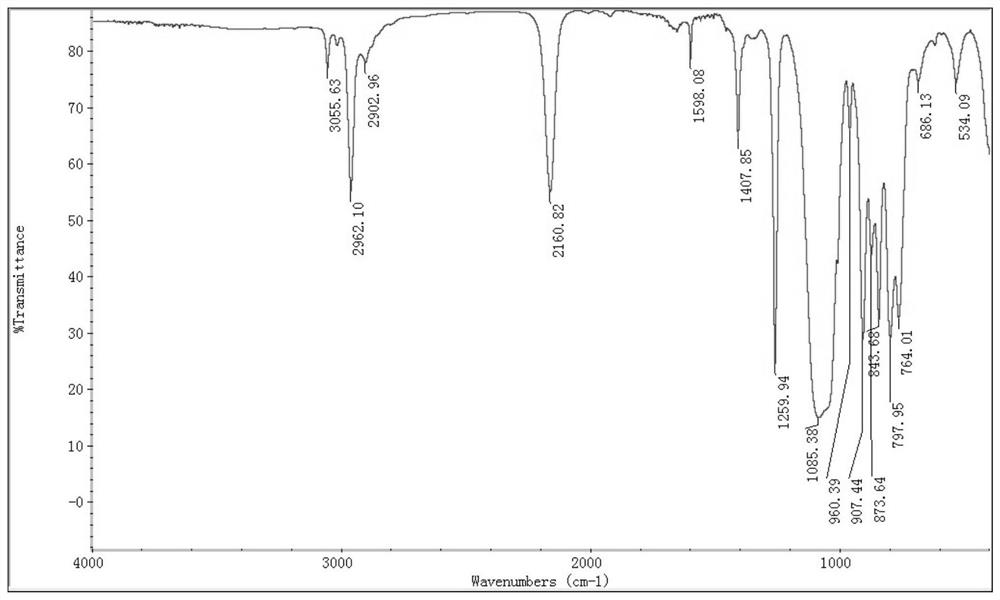

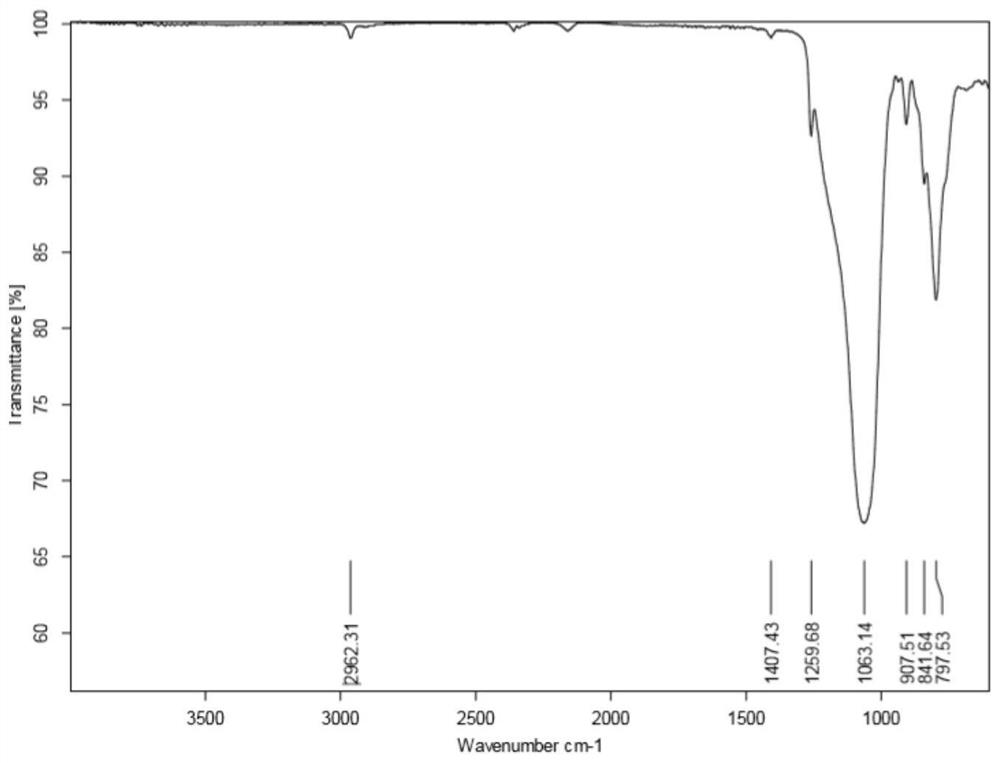

[0035] 1. Preparation of hydrogen-containing polyborosiloxane

[0036] Add 50g water, 10g Me 3 SiOMe, 30g MeHSi(OMe) 2 , 20gMeViSi(OMe) 2 , 15g B(OEt) 3 , 3g of concentrated sulfuric acid and 150g of petroleum ether, stir and mix evenly, heat to 50°C, and react for 6h. Cool to room temperature, separate the lower aqueous layer, and wash the organic layer until neutral. Add 3.5 g of anhydrous sodium sulfate, dry at room temperature for 24 hours, and filter off the desiccant to obtain 190 g of hydrogen-containing polyborosiloxane reaction liquid.

[0037] 2. Preparation of hydrogen-containing polyborosiloxane modified silica

[0038] Under stirring, add 190g of hydrogen-containing polyborosiloxane reaction solution prepared above, 0.01g of chloroplatinic acid-divinyltetramethyldisiloxane complex (platinum mass fraction is 0.02%) to 100g of hydrophilic Water vapor phase method silica (specific surface area is about 300m 2 / g), heat the system to the reflux temperature of p...

Embodiment 2

[0058] 1. Preparation of hydrogen-containing polyborosiloxane

[0059] Add 20g water, 10g Me 3 SiOEt, 10g MeHSi(OMe) 2 , 10gMe 2 Si(OEt) 2 , 10g B(OMe) 3 , 1g of concentrated hydrochloric acid and 100g of toluene, stirred and mixed evenly, heated to 30°C, and reacted for 8h. The lower aqueous layer was separated, and the organic layer was washed with water until neutral. Add 1.2 g of anhydrous magnesium sulfate, dry at room temperature for 12 hours, and filter off the desiccant to obtain 120 g of hydrogen-containing polyborosiloxane reaction liquid.

[0060] 2. Preparation of hydrogen-containing polyborosiloxane modified silica

[0061] Under stirring, 120g hydrogen-containing polyborosiloxane reaction solution, 0.02g chloroplatinic acid isopropanol complex (platinum mass fraction 0.02%) prepared above were added to 100g hydrophilic precipitation method silica (specific surface area about 170m 2 / g), heat the system to the reflux temperature of toluene, react for 5 hou...

Embodiment 3

[0068] 1. Preparation of hydrogen-containing polyborosiloxane

[0069]Add 60g water, 20g Me 3 SiOEt, 50g MeHSi(OEt) 2 , 50gMePhSi(OEt) 2 , 20g B(OBu) 3 , 5g of trifluoromethanesulfonic acid and 200g of xylene, stirred and mixed evenly, heated to 70°C, and reacted for 3h. The lower aqueous layer was separated, and the organic layer was washed with water until neutral. Add 13g of anhydrous calcium chloride, dry at room temperature for 24 hours, and filter off the desiccant to obtain 260g of hydrogen-containing polyborosiloxane reaction liquid.

[0070] 2. Preparation of hydrogen-containing polyborosiloxane modified silica

[0071] Under stirring, 260g of hydrogen-containing polyborosiloxane reaction solution prepared above, 0.05g of chloroplatinic acid tetrahydrofuran complex (platinum mass fraction is 0.02%) was added to 100g of hydrophilic fumed silica (specific surface area approx. 380m 2 / g), heating the system to the reflux temperature of xylene, reacting for 10 h, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com