Graphene-based antibacterial fabric and production process thereof

An antibacterial fabric, graphene technology, applied in the field of fabrics, can solve the problems of short service life, graphene wear or shedding, etc., to reduce wear, prevent excessive crosslinking, and improve flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

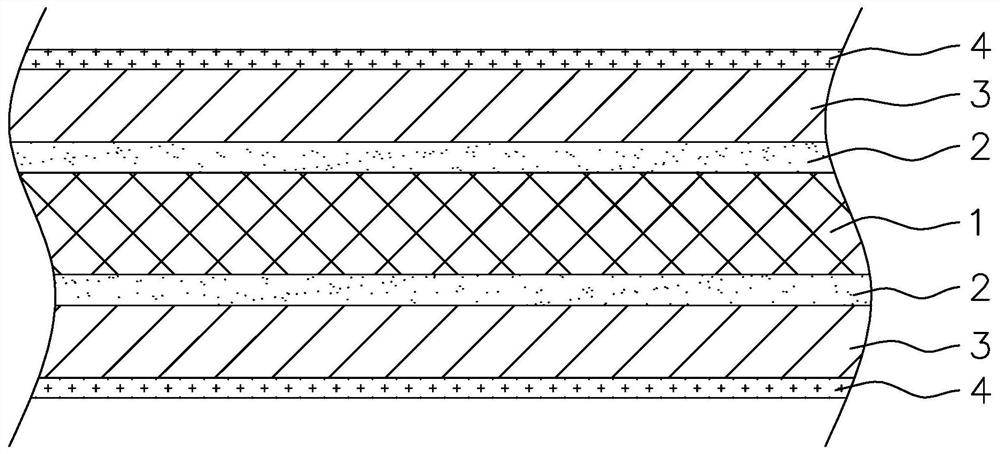

[0038] Embodiment 1: a kind of antibacterial fabric based on graphene, as attached figure 1As shown, it includes fabric layer 1, adhesive layer 2, graphene layer 3 and protective layer 4 sequentially from inside to outside;

[0039] The fabric layer 1 is woven from cotton fibers; the adhesive layer 2 is a structural layer formed after finishing the surface of the fabric layer with polyethyleneimine; the graphene layer 3 is graphene oxide on the surface of the adhesive layer The main antibacterial structural layer formed after hot pressing; protective layer 4 is the main protective structural layer formed by the cross-linking of epoxy resin glue on the surface of the bonding layer, and the epoxy resin glue is mainly composed of epoxy resin , Polyetheramine and benzyl alcohol mixed.

[0040] The production process is:

[0041] S1: use cotton fibers as warp and weft threads to weave to form a fabric layer to obtain a base fabric, the ratio of the warp density to the weft densit...

Embodiment 2

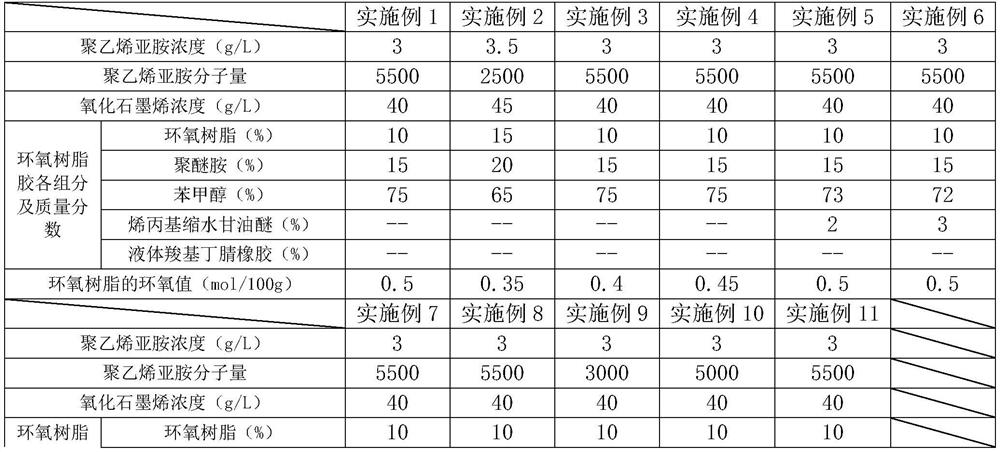

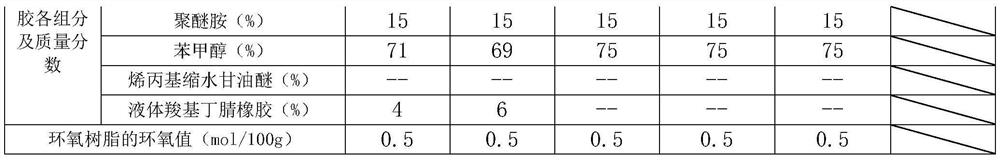

[0045] Embodiment 2: A graphene-based antibacterial fabric. The difference from Embodiment 1 is that various parameters in the process are different, as shown in Table 1 below.

[0046] The production process is:

[0047] S1: use cotton fibers as warp and weft threads to weave to form a fabric layer to obtain a base fabric, the ratio of the warp density to the weft density of the base fabric is 2:1, and the count of the cotton fibers used is 42s / 3;

[0048] S2: Soak the base fabric in a polyethyleneimine solution with a concentration of 3.5g / L and an average molecular weight of 2500 for 2.5 hours to form an adhesive layer. In the graphene oxide solution, stand at 35°C for 35 minutes to form a graphene layer, take it out, wash it with deionized water and dry it to get a graphene fabric;

[0049] S3: Mix epoxy resin, polyether amine and benzyl alcohol according to the amount to obtain epoxy resin glue. The mass fraction of each component is shown in Table 1. The epoxy value of ...

Embodiment 3-4

[0051] Embodiment 3-4: a kind of antibacterial fabric based on graphene,

[0052] The difference from Example 1 is that the epoxy value of the epoxy resin used is different, and the specific parameters are shown in Table 1 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com