Peony liqueur and production process thereof

A production process, the technology of peony, applied in the field of wine preparation, can solve the problems that have not been seen, and achieve the effects of cardiomyocyte protection, good taste, and immune system protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

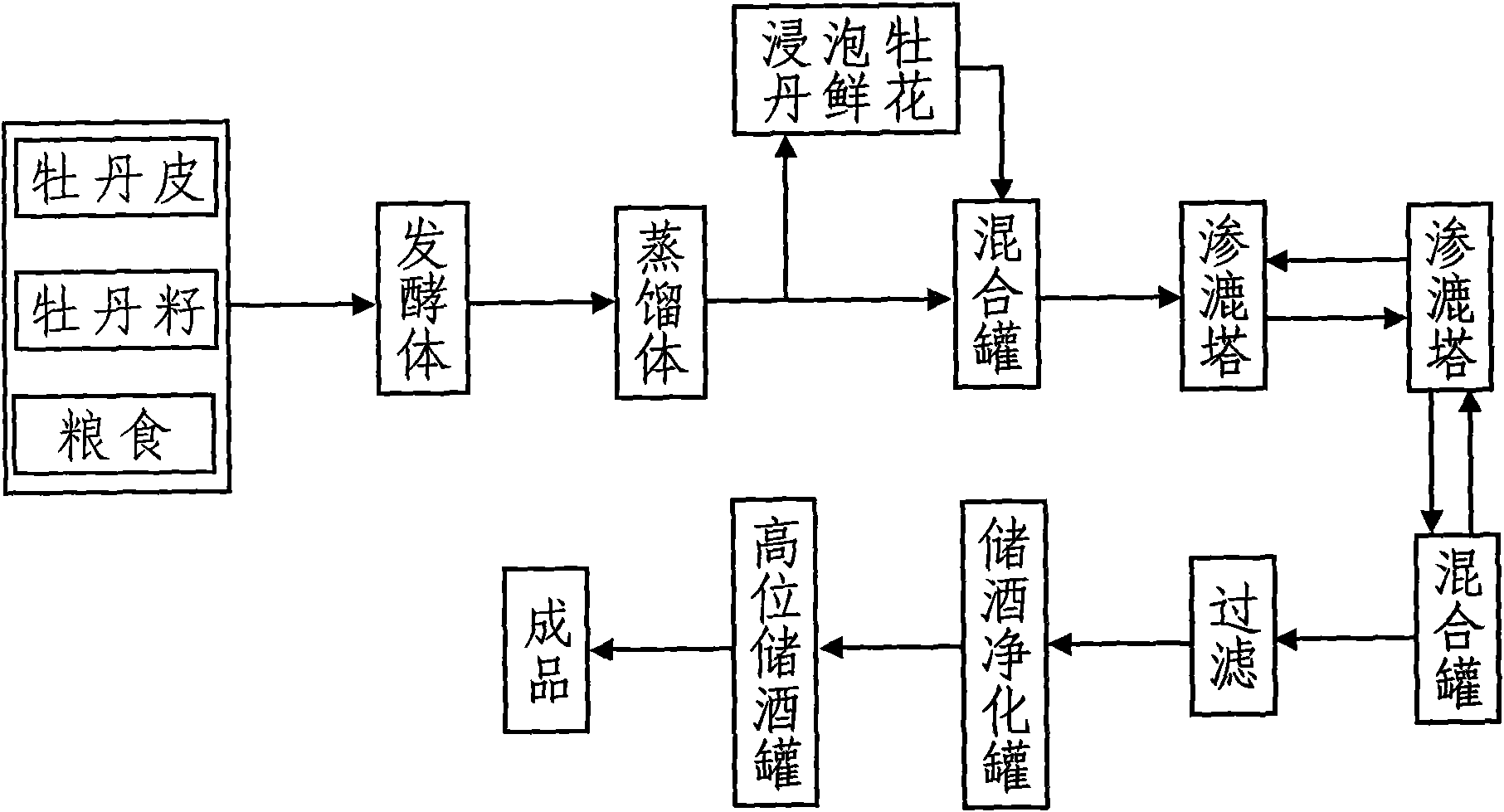

Image

Examples

Embodiment 1

[0010] 500 grams of sorghum, corn, wheat, rice, and peas; 3 grams of peony bark, 2 grams of peony seeds; 6 grams of peony flowers;

[0011] 1) Washing and drying the selected raw material tree peony bark and tree peony seeds, crushing the tree peony bark and crushing the tree peony seeds; fermenting with sorghum, corn, wheat, rice, and pea grains according to the fermentation method of Luzhou-flavor wine; 2) Distill after fermentation to make peony puree wine at 58°C; 3) Extract part of peony puree wine to soak peony flowers for 12-24 hours, and then mix with peony puree wine; 4) Then percolate: after mixing Add mineral water to the liquid, and throw it up and down in the percolation tank. There are many spikes in the percolation tank. During the process of throwing the liquid up and down, the peony flower liquid and the peony puree wine are fully mixed and fused; 5 ) The mixing tank is loaded with peony puree wine, soaked peony flower liquid, mineral water, edible spices and ...

Embodiment 2

[0013] 500 grams of sorghum, corn, wheat, rice, and peas; 6 grams of peony bark, 3 grams of peony seeds; 9 grams of peony flowers; edible spices: 3 grams of star anise, 3 grams of tangerine peel, 6 grams of fennel;

[0014] 1) Washing and drying the selected raw material tree peony bark and tree peony seeds, crushing the tree peony bark and crushing the tree peony seeds; fermenting with sorghum, corn, wheat, rice, and pea grains according to the fermentation method of Luzhou-flavor wine; 2) Distill after fermentation to make peony puree liquid at 58°C; 3) Extract part of peony puree wine to soak peony flowers and edible spices for 12-24 hours, and then mix with peony puree wine; 4) Follow by percolation: Add mineral water to the mixture, and throw it up and down in the percolation tank. There are many spikes in the percolation tank. During the process of throwing the liquid up and down, the peony flower liquid and peony puree wine are fully mixed and fused. ; 5) The mixing tan...

Embodiment 3

[0016] 500 grams of rice, sorghum or peas; 12 grams of peony bark, 9 grams of peony seeds; 15 grams of peony flowers; edible spices: 3 grams of star anise, 3 grams of tangerine peel, 9 grams of fennel, 3 grams of wolfberry;

[0017] Others are the same as in Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com