Patents

Literature

148results about How to "Long-acting antibacterial" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anti-bacterial water-based paint and preparation method thereof

InactiveCN102702889AImprove aging resistanceImprove the pulverization performanceBiocideAntifouling/underwater paintsWater basedEscherichia coli

The invention relates to anti-bacterial water-based paint and a preparation method thereof. The paint comprises the following components in parts by weight: 0.2-11 parts of anti-bacterial agent, 8-33 parts of nano material, 23-64 parts of water-based resin dispersoid and 0.75-18 parts of adhesive resin or plasticizer. The preparation method comprises the following steps: firstly preparing a nano silver anti-bacterial agent; mixing deionized water, the anti-bacterial agent, a wetting agent, a dispersing agent and a defoaming agent and uniformly mixing, adding the nano material, uniformly dispersing to obtain the water-based dispersoid; adding the obtained water-based dispersoid to the mixed emulsion or water-based resin dispersoid, then adding the adhesive resin or plasticizer and various conventional assistants, stirring and dispersing evenly; adding pigments or colorant; and supplementing water to obtain the anti-bacterial water-based paint. The long-acting broad-spectrum antibacterial water-based paint has high fungicidal efficiency (more than 99%) on escherichia coli, staphylococcus aureus, black varietas of bacillus subtilis and the like and can reduce the high concentrate of organic matters of formaldehyde to the range of specified concentration index.

Owner:ANHUI JINDUN PAINT

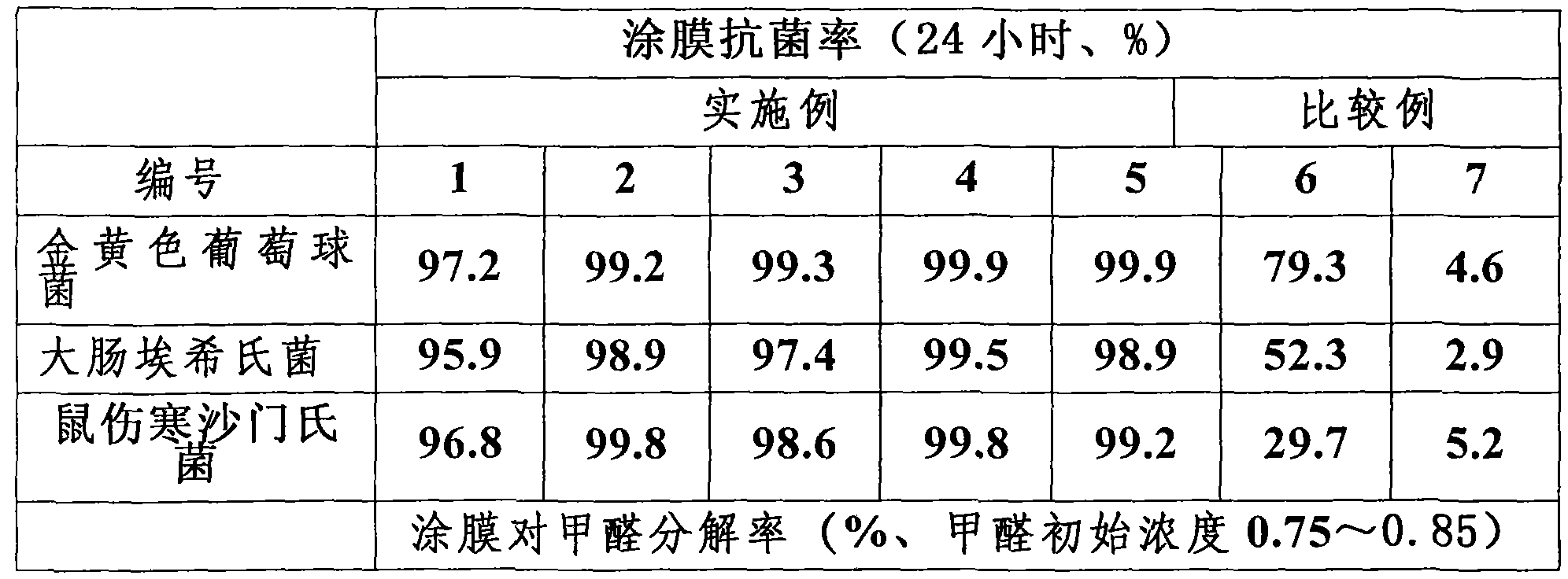

Coating composition with antimicrobial and air purification function

ActiveCN101245211AGood dispersionLong-acting antibacterialDeodrantsCoatingsEscherichia coliStaphylococcus aureus

The invention provides a coating composition with antibacterial and air purification function, which comprises 1 to 10 parts by weight of doping four acicular zinc oxide whisker, 1 to 10 parts by weight of mesoporous filler, 40 to 55 parts by weight of acrylate emulsion, 10 to 30 parts by weight of titanium dioxide, 10 to 25 parts by weight of filler talcum powder, and 0.5 to 10 parts by weight of addition agent, that are calculated according to part by weight; wherein, the doping ion is one or more than one elements among Fe<3+>, Cu<2+>, Ag<+> or V<5+>. The coating composition constructed by ordinary spraying or brushing has long-term antibacterial and air purification effects after curing and film forming; the antibacterial effect to staphylococcus aureus, escherichia coli, salmonella typhimurium and other ordinary bacteria in indoor air reaches more than 95 percent, and the degradation rate to formaldehyde with thickness of 0.75 to 0.85 in 12h, 24h, 48h and 72h reaches respectively to 50 percent, 70 percent, 82 percent and more than 85 percent. The coating composition with antibacterial and air purification function is mainly used as indoor coating.

Owner:CHINA PAINT MFG CO SHENZHEN

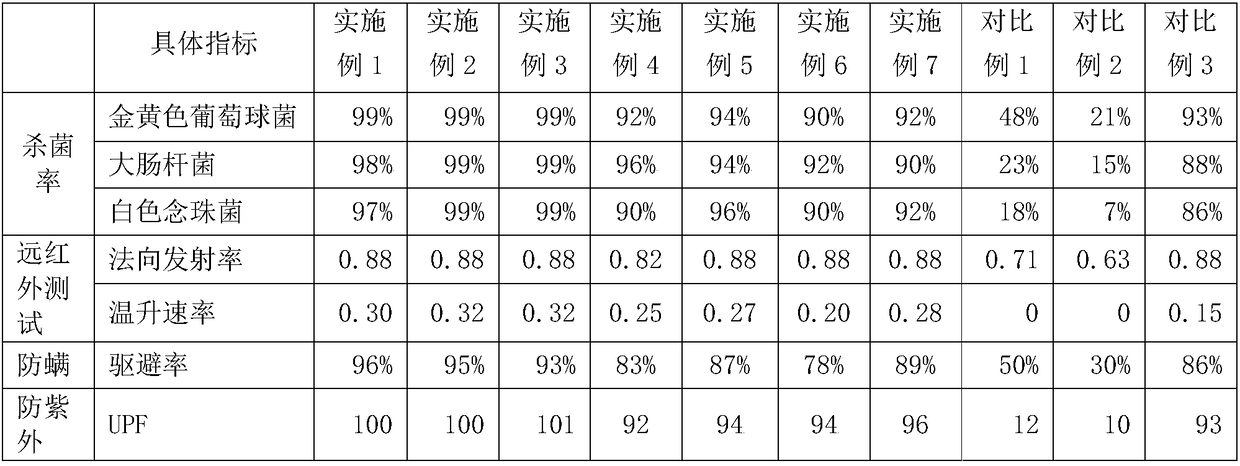

Preparation method of graphene composite nonwoven cloth

ActiveCN108301201ALong-lasting anti-miteWith far infrared effectBiochemical fibre treatmentLight resistant fibresGrapheneNonwoven fabric

The invention relates to a preparation method of graphene composite nonwoven cloth. The preparation method comprises the following steps: A1, preparing nonwoven cloth from common fiber; A2, mixing a graphene raw material with active carbon, water, an antioxidant, stearate and glue, and uniformly stirring the materials to form spraying liquid; A3, uniformly spraying the spraying liquid formed in Step A2 onto the nonwoven cloth prepared in Step A1, and drying and rolling the nonwoven cloth to prepare the graphene composite nonwoven cloth. The preparation method has the following beneficial effects: 1, the graphene-containing spraying liquid is sprayed onto the common nonwoven cloth, so that the long-acting anti-mite, antibacterial and antiultraviolet graphene composite nonwoven cloth havinga far infrared effect can be obtained; 2, the preparation method disclosed by the invention is simple and efficient, and can be widely applied to industrial production to prepare facial mask cloth, antibacterial costumes, antibacterial underwear, antibacterial socks, gauze masks, bedroom supplies and the like.

Owner:NANTONG QIANGSHENG GRAPHENE TECH CO LTD

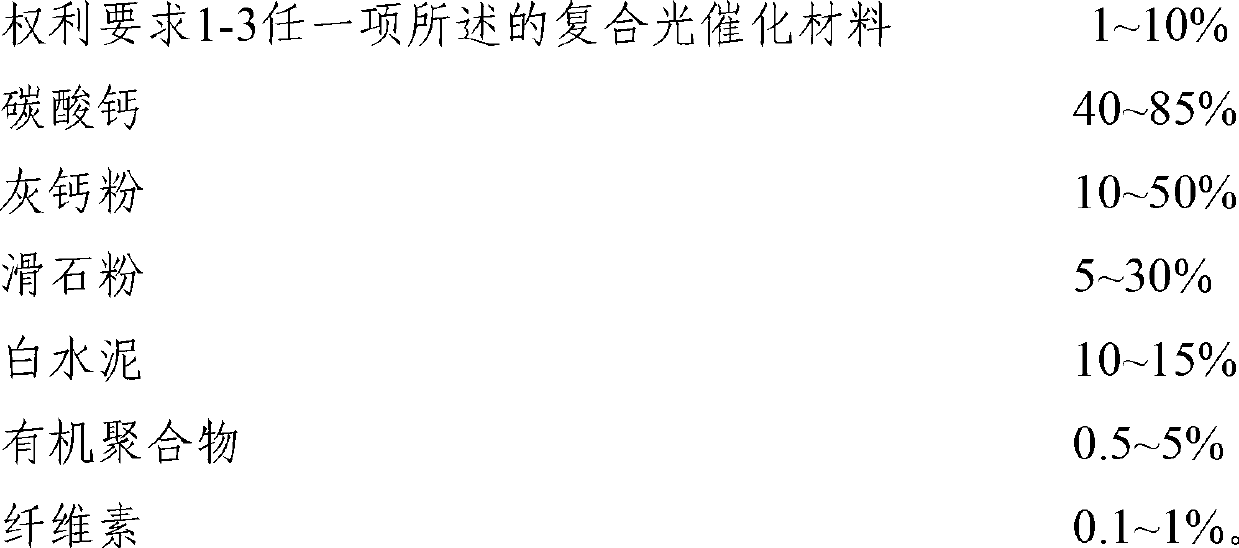

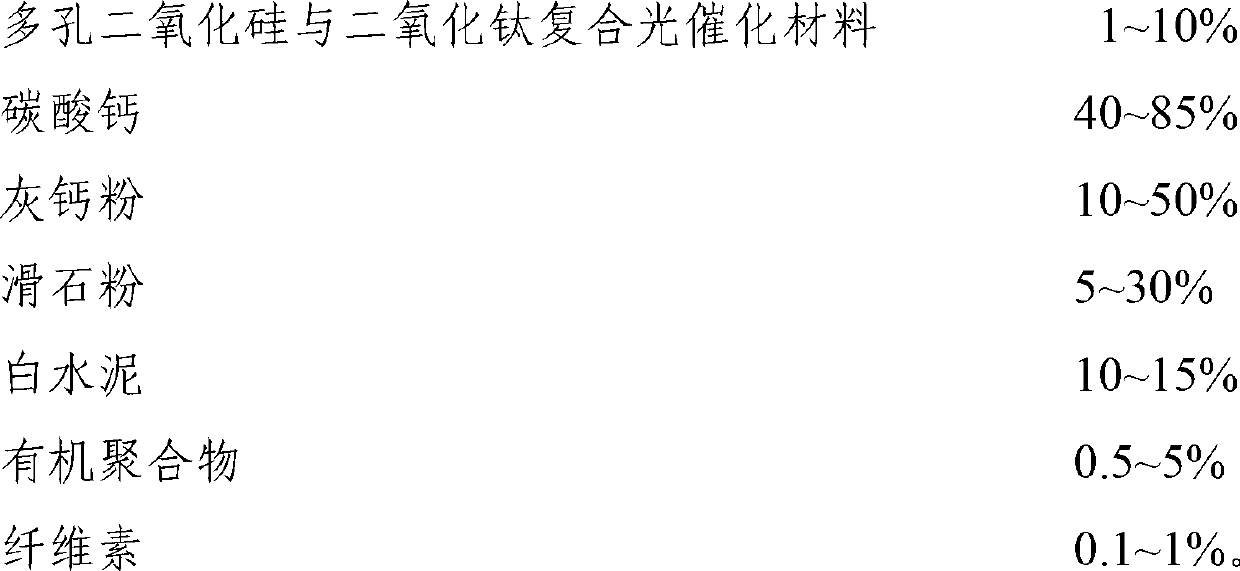

Coating with antibacterial and air-purifying functions

InactiveCN102989436ALong-acting antibacterialStrong ability to degrade formaldehyde/toluenePhysical/chemical process catalystsCelluloseEscherichia coli

The invention provides a coating with antibacterial and air-purifying functions. The coating is formed by the following component in percentage by mass: 1-10% of porous silicon dioxide and titanium dioxide compound photocatalytic material, 40-85% of calcium carbonate, 10-50% of ash calcium powder, 5-30% of talcum powder, 10-15% of white cement, 0.5-5% of organic polymer and 0.1-1% of cellulose. A dry powder coating and water are mixed according to a weight ratio of 1: (0.3-1) and then a mixture is subjected to common spraying or scraping construction to be cured into a film, so that the long-effect antibacterial and air-purifying effects are realized. The antibacterial effect on common bacteria in the indoor air, such as Escherichia coli, reaches to be more than 98%; more than 83% of formaldehyde can be decomposed and purified in 48 hours and more than 49% of toluene can be decomposed and purified; and compared with the similar products, the formaldehyde / toluene degradation capability of the coating is stronger, so that the coating can be used as an indoor coating.

Owner:韦先飞

Antibacterial ceramic tile and preparation method thereof

ActiveCN110698227AGood antibacterial effectImprove bindingClaywaresAnti bacterialAntibacterial agent

The invention discloses an antibacterial ceramic tile. The antibacterial ceramic tile comprises an antibacterial glaze layer arranged on the upper surface of a ceramic tile; the antibacterial glaze layer is composed of a basic transparent glaze and a zirconium phosphate loaded composite antibacterial agent; the zirconium phosphate loaded composite antibacterial agent comprises a zirconium phosphate carrier and a composite antibacterial agent; the zirconium phosphate loaded composite antibacterial agent is accumulated at the upper part of the antibacterial glaze layer, and antibacterial effective components of the composite antibacterial agent are antibacterial oxides and antibacterial ions. According to a preparation method, zirconium phosphate is introduced into the antibacterial glaze layer on the surface of the ceramic tile; by utilizing the characteristic of low density of zirconium phosphate, zirconium phosphate is accumulated at the upper part of the glaze layer after being sintered at a high temperature to form a surface with a porous structure, so that the zirconium phosphate is used as a carrier to which the composite antibacterial agent is attached, the binding force of antibacterial materials and the ceramic tile is enhanced, the ceramic tile is endowed with long-acting and excellent antibacterial performance, and meanwhile, the surface appearance decoration effect of the ceramic tile is not influenced. The invention further discloses a preparation process of the antibacterial ceramic tile, and the preparation process is simple in step, high in controllability and beneficial to large-scale industrial production.

Owner:FOSHAN OCEANO CERAMICS

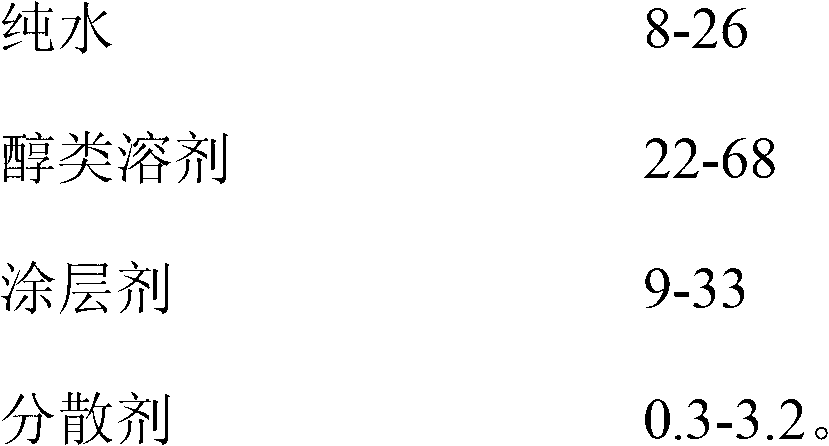

Thermal insulation coating and preparation method thereof

The invention relates to a thermal insulation coating and a preparation method thereof, and the preparation method comprises the following steps: adding hollow granular micro-bubbles made of special materials, hollow glass beads and an opaque polymer on the basis of a water base, a bonding agent base material and a filler, combining active hydroxyl genes thereof with a molecular chain of an emulsion polymer and forming a dense net layer structure in a coating, wherein the coating has the comprehensive thermal insulation function of reflecting, blocking and radiating solar heat and has the significant effects of thermal insulation and energy conservation. The coating has strong adhesion to the surface of a building, the thickness of a coating dry film is only 60 mu m-150 mu m, and the coating is not only thermal-insulating, but also water-proof. The coating has excellent air permeability and long-lasting antibacterial property, as well as the advantages of pollution prevention, self-cleaning, sound isolation, aging resistance, long service life, easy construction and manpower conservation; compared with the traditional thermal insulation material, the coating has excellent performance-price ratio.

Owner:刘志光

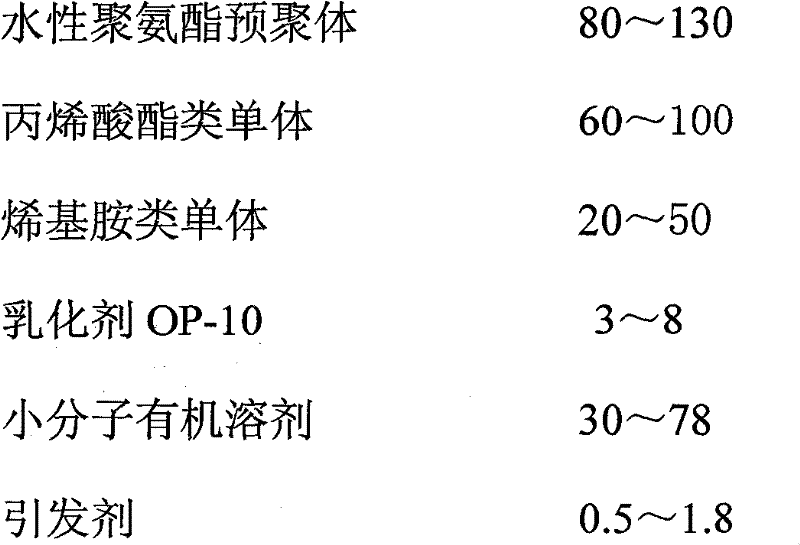

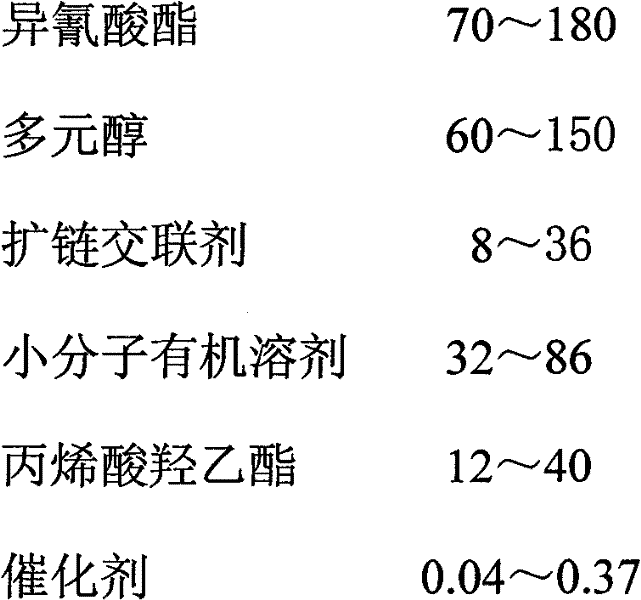

Silver-carried antibacterial finishing agent and preparation method thereof

The invention relates to a silver-carried antibacterial finishing agent and a preparation method thereof, which are mainly applied to a textile coating. The preparation method comprises the following steps of: reacting isocyanate and a polyalcohol compound to generate an isocyanate-terminal prepolymer, and reacting the isocyanate-terminal prepolymer and a hydroxyl-containing alkenyl monomer to form an alkenyl-containing polyurethane prepolymer; and copolymerizing the prepared polyurethane prepolymer, an acrylate monomer and an alkenyl amine monomer to generate amine-containing polyurethane-acrylate copolymer emulsion, and adding silver nitrate and amino group into the emulsion to form a complex and then generate the silver-carried long-lasting antibacterial finishing agent.

Owner:洪桂焕

Antibacterial powder coating

ActiveCN107603413ALong lasting effectSee high efficiencyAntifouling/underwater paintsPaints with biocidesEpoxyPolyester resin

The invention discloses an antibacterial powder coating, prepared from the following raw materials by weight: 25 to 35 percent of epoxy resin, 25 to 35 percent of polyester resin, 0.8 to 1.5 percent of flatting agent, 0.8 to 1.5 percent of smooth degasifier, 0.3 to 1.5 percent of antibacterial agent and 25.5 to 48.1 percent of pigment and filler. A coating film formed after the antibacterial powder coating material is sprayed and cured has excellent antibacterial performance, and takes effect quickly in antibacterial capability, and the effect is long-acting and lasting.

Owner:六安科瑞达新型材料有限公司

Antibacterial diatomite-based coating as well as preparation method and application thereof

ActiveCN103741545AImprove antibacterial propertiesEasy to operateDefoamers additionPaper coatingAdhesiveDefoaming Agents

The invention relates to an antibacterial diatomite-based coating as well as a preparation method and application thereof, and particularly relates to an antibacterial coating for wallpaper, belonging to the field of coatings. According to the antibacterial diatomite-based coating, an antibacterial agent is loaded on a special porous structure of diatomite, so that the diatomite is endowed with antibacterial performance, and then the antibacterial agent-loaded diatomite, a dispersing agent, a defoaming agent, a water retaining agent, water and an adhesive are mixed and stirred to prepare the diatomite coating. According to the method, the antibacterial agent with excellent performance is used for replacing existing widely-used nanometer titanium dioxide; during implementation of the method, the antibacterial agent is good in bactericidal activity, broad-spectrum, long-acting, small in usage amount and low in price. The method is convenient and feasible, simple to operate without using special instruments and equipment, and easily produced industrially.

Owner:DALIAN POLYTECHNIC UNIVERSITY

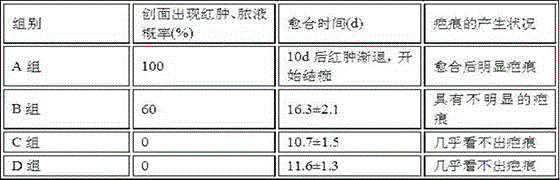

Chitosan quaternary ammonium salt porcine acellular dermal matrix dressing material and preparation method thereof

InactiveCN106421868ALow antigenicityReduce releasePharmaceutical delivery mechanismAbsorbent padsFiberAcellular Dermis

The invention belongs to the technical field of biomedical engineering, and particularly relates to a chitosan quaternary ammonium salt porcine acellular dermal matrix dressing material and a preparation method thereof. The preparation method of the chitosan quaternary ammonium salt porcine acellular dermal matrix dressing material specifically comprises the following steps: S1, preparing a chitosan quaternary ammonium salt; S2, processing a porcine acellular dermal matrix; and S3, preparing the chitosan quaternary ammonium salt porcine acellular dermal matrix dressing material. The chitosan quaternary ammonium salt porcine acellular dermal matrix dressing material disclosed by the invention completely reserves morphological structures and components of cells, has the characteristic of low antigenicity, and meanwhile can induce fiber-forming cells and vascular endothelial cells with regeneration capacity to grow therein.

Owner:GUANGDONG TAIBAO MEDICAL SCI TECH

Uvioresistant fleece fabric and preparation method thereof

ActiveCN103820939ALong-acting antibacterialImprove wash resistanceFibre typesWarp knittingFiberPolyester

The invention discloses an uvioresistant fleece fabric, which comprises the following raw materials in percentage by mass: 20% to 40% of bottom layer tissue and 80% to 60% of fleece yarn tissue, wherein at least one of the bottom layer tissue and the fleece yarn tissue is made of uvioresistant fiber, and the uvioresistant fiber is uvioresistant polyester fiber. The invention also discloses a preparation method of the uvioresistant fleece fabric, and the method comprises the following steps of selecting of raw materials, warping, weaving, slitting, thermal shaping, dying or printing and post arrangement. By adopting the method, the prepared uvioresistant fleece fabric has the uvioresistant function for a long time.

Owner:CHANGSHU XINXIN WARP & KNITTING

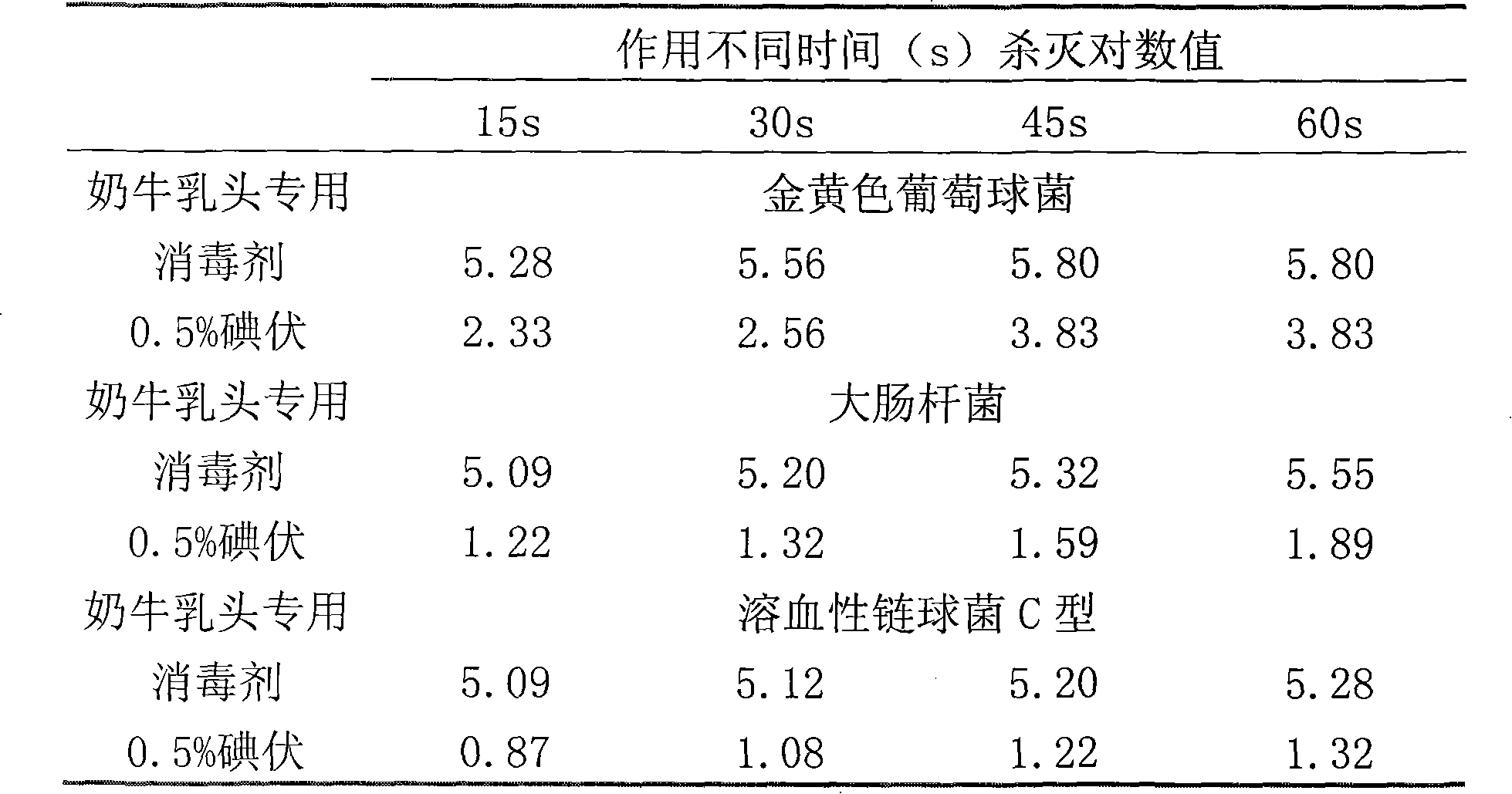

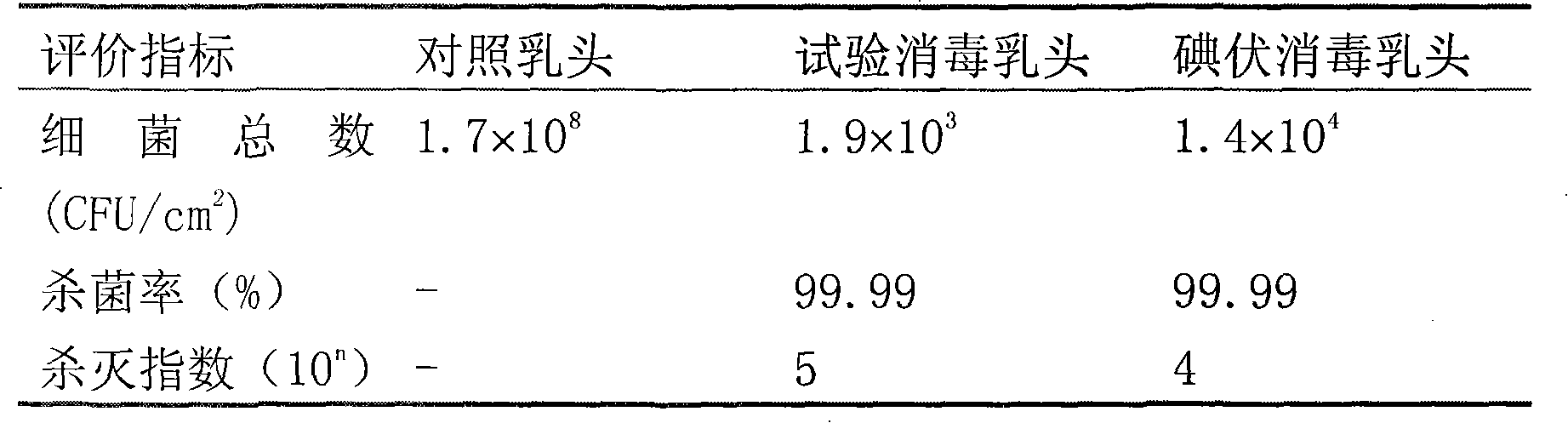

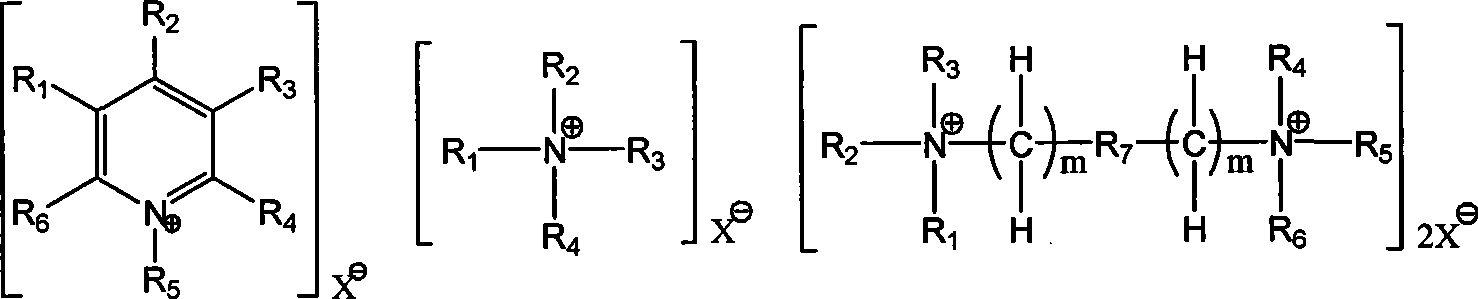

Composition for disinfecting nipple skins of dairy cows

ActiveCN101628006AImprove the bactericidal effectBroad spectrumBiocideOrganic active ingredientsBiology

The invention relates to a novel composition for disinfecting nipple skins of dairy cows, in particular to a composition for disinfecting the nipple skins of the dairy cows before and after milking.

Owner:烟台爱士津动物保健品有限公司

Sol-gel method-based sorting method for quaternary ammonium salt antibiotic textile

InactiveCN101545203AStable and long-lasting antibacterialFeel effectFibre treatmentQuaternary ammonium cationSilicon dioxide

The invention relates to a sol-gel method-based sorting method for quaternary ammonium salt antibiotic textile. The method adopts the sol-gel technology, takes an ammonium salt as a catalyst, and prepares a modified silica sol through the joint hydrolysis of water glass and a quaternary ammonium salt or a quaternary ammonium hydrate. An antibiotic gel coating is formed on the textile by an impregnation, padding or padding stacking method so as to endow the textile with stable and durable antibiotic performance. The method is widely applied to the antibiotic sorting of textile, and has simplicity, low cost and easy industrialization.

Owner:DONGHUA UNIV

Method for preparing nano-silver antibacterial melt-blown non-woven fabric

InactiveCN106436020AEvenly distributedSmall particle sizeNon-woven fabricsHigh concentrationPolymer science

The invention discloses a method for preparing an antibacterial non-woven fabric and particularly discloses a method for preparing an efficient and long-acting nano-silver antibacterial melt-blown non-woven fabric. Benzene, toluene, trichloromethane or carbon tetrachloride solution of an amphiphilic hyperbranched polymer is mixed with silver nitrate aqueous solution, and a high-concentration solution of the amphiphilic hyperbranched polymer is obtained through standing liquid separation and rotary evaporation. A spraying method is adopted to spray the high-concentration solution to raw material particles or slices of the melt-blown non-woven fabric, stirring is performed continuously, and after a processing process of the melt-blown non-woven fabric, the antibacterial non-woven fabric with fibers containing nano-silver particles can be obtained. The amphiphilic hyperbranched polymer is utilized to perform in-situ control in the melt-blown non-woven fabric fibers to generate nano-silver, the generated nano-silver has the advantages of being small in particle diameter, being dispersed evenly and being high in combining firmness, an existing melt-blown non-woven fabric production device does not need to be upgraded and rebuilt, and the method has simplicity and convenience in processing.

Owner:江西天滤新材料有限公司

Preparation method of long-acting and anti-bacterial polylactic acid fiber film

InactiveCN108914375AAvoid reunionImprove antibacterial effectNon-woven fabricsLong actingElectrospinning

Owner:FOSHAN SENANG BIO TECH CO LTD

Production technology of antibacterial blended cotton yarns

InactiveCN109610058AHas sweat-absorbing propertiesFeelMonocomponent cellulose artificial filamentWet spinning methodsYarnCotton fibre

The invention discloses a production technology of antibacterial blended cotton yarns. The production technology comprises the following steps: firstly, respectively preparing 10 to 16 parts of cottonfibers and 3 to 5 parts antibacterial fibers according to weight parts; secondly, respectively preparing the cotton fibers and the antibacterial fibers in the first step into a first lap and second lap in an opening and cleaning procedure; thirdly, respectively preparing the first lap and the second lap obtained in the second step into a first card sliver and a second card sliver in a cotton carding procedure; preparing the first card sliver and the second card sliver into a drawn sliver through a drawing procedure; fourthly, enabling the drawn sliver obtained in the third step to undergo a roving procedure and the spinning procedure to obtain the antibacterial blended cotton yarns. The antibacterial blended cotton yarns with an antibacterial effect, disclosed by the invention, are obtained by blending ordinary fibers with antibacterial fibers, and have sweat absorbing performance and hand feel of cotton and a certain antibacterial effect.

Owner:湖北德永盛纺织有限公司

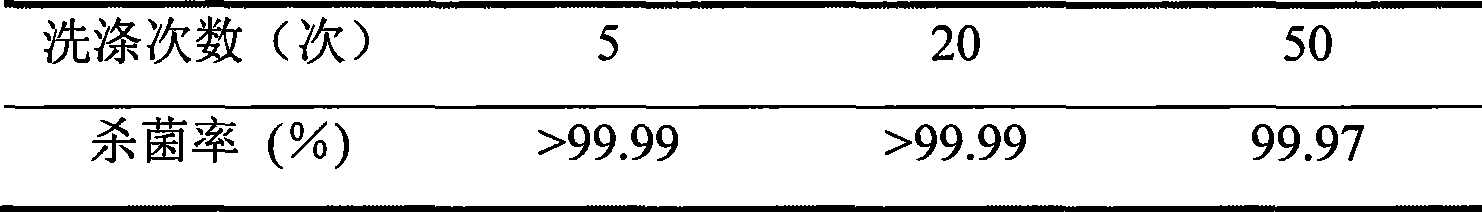

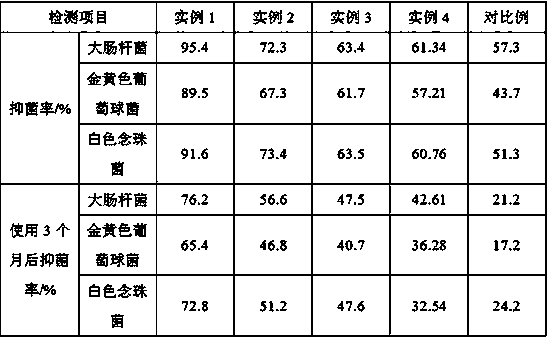

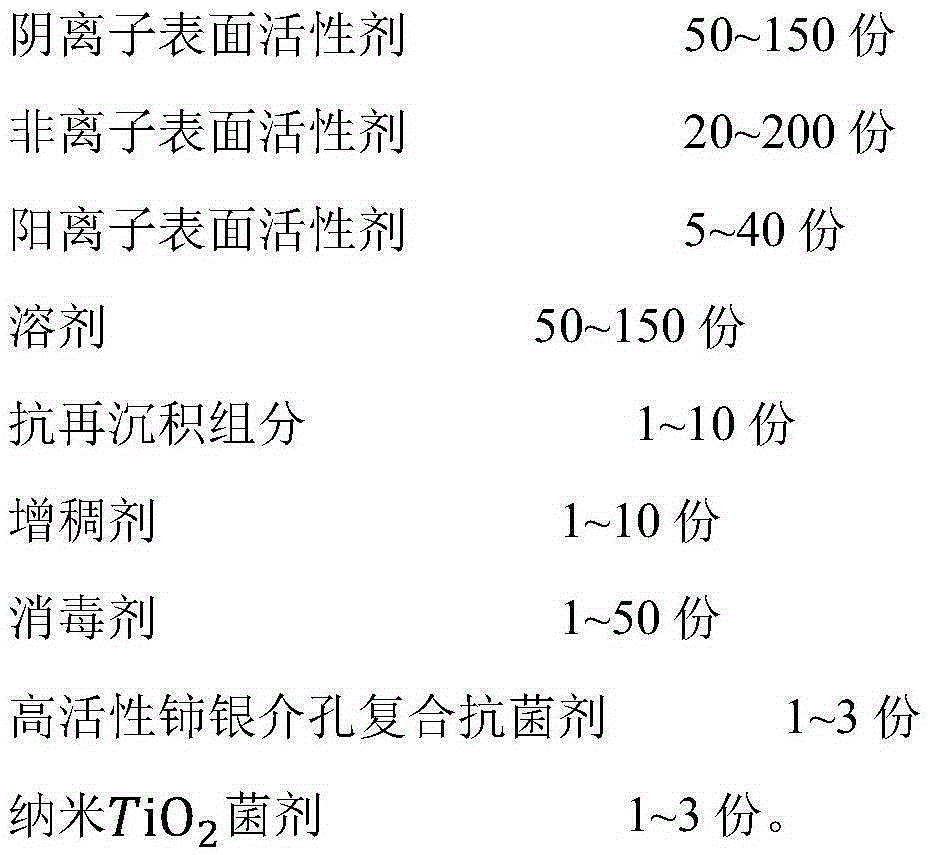

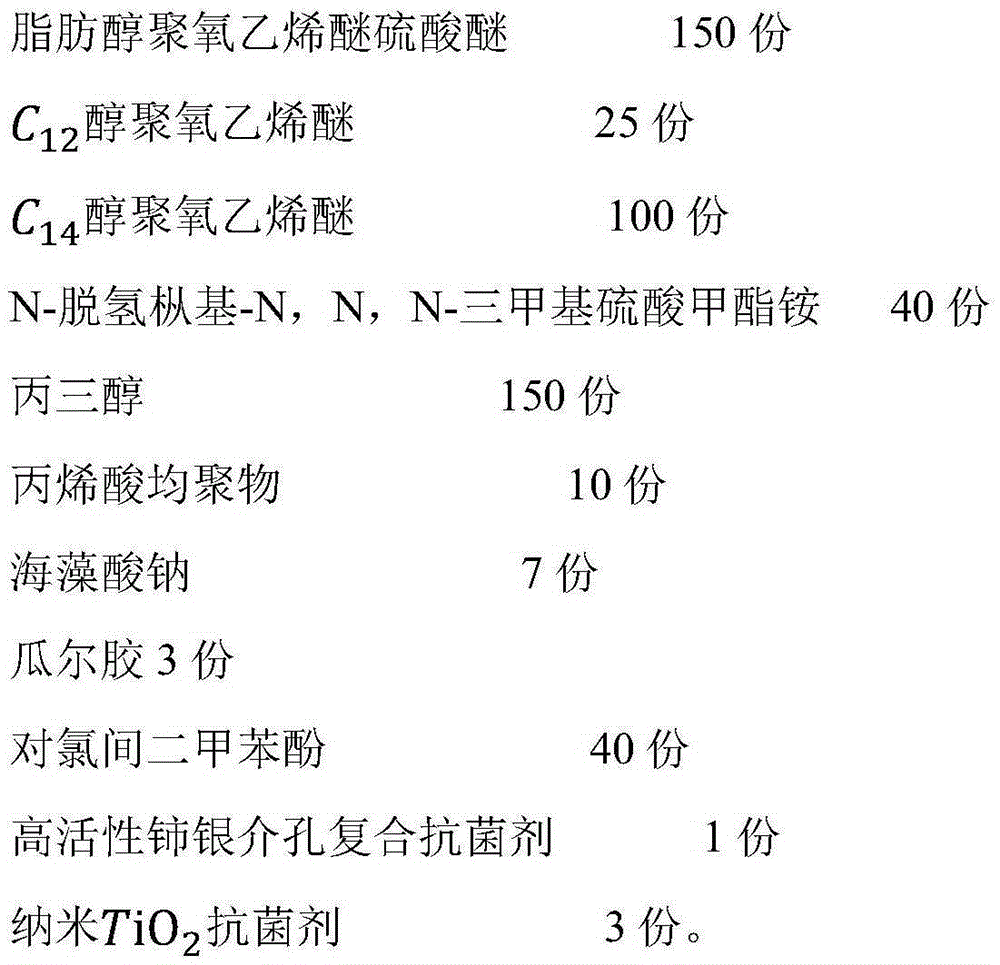

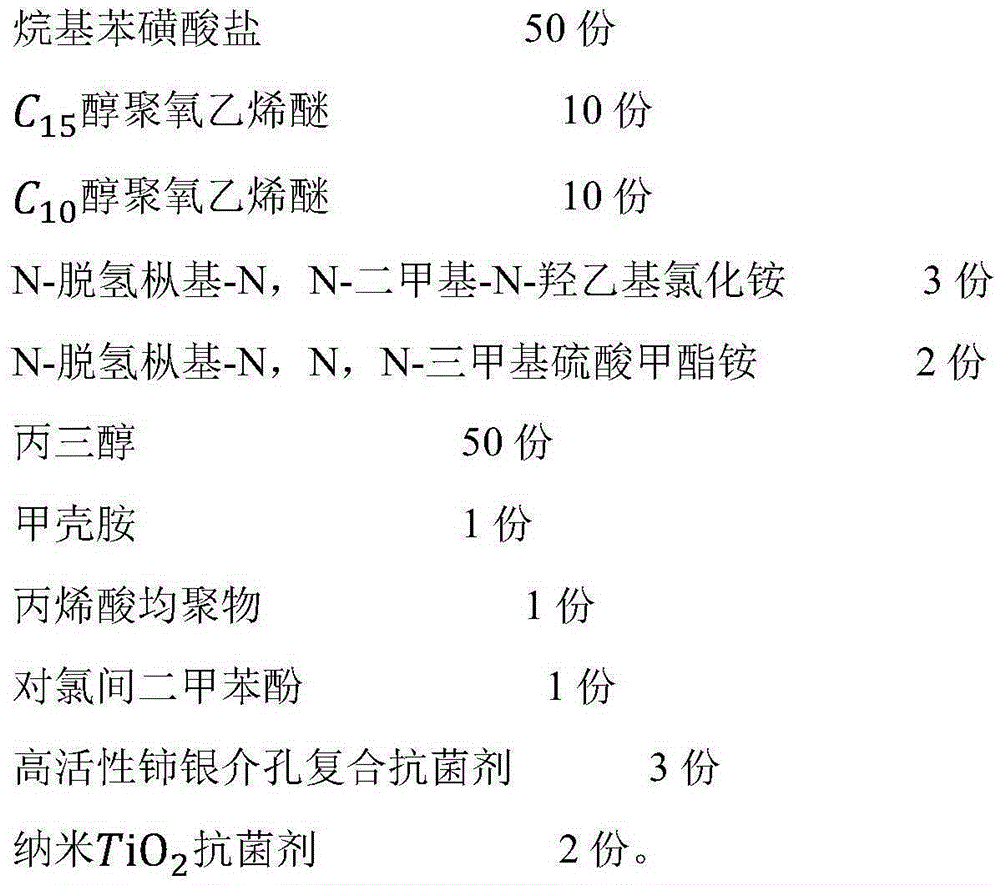

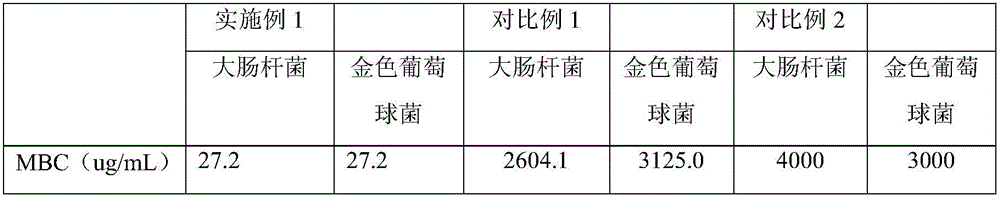

Antibacterial laundry detergent

InactiveCN105400608ALong-lasting antibacterial effectGood cleaning effectDetergent solventsAnionic-cationic-non-ionic surface-active compoundsSolventDisinfectant

The invention discloses an antibacterial laundry detergent. The technical scheme is mainly characterized in that the antibacterial laundry detergent comprises components in parts by weight as follows: 50-150 parts of an anionic surfactant, 20-200 parts of a nonionic surfactant, 5-40 parts of a cationic surfactant, 50-150 parts of a solvent, 1-10 parts of an anti-redeposition component, 1-10 parts of a thickener, 1-50 parts of a disinfectant, 1-3 parts of a high-activity cerium silver mesoporous composite antibacterial agent and 1-3 parts of nano-TiO2 antibacterial agent. The antibacterial laundry detergent is characterized in that the high-activity cerium silver mesoporous composite antibacterial agent is added to the antibacterial laundry detergent, and an antibacterial active material can be dispersed in a sterilization-requiring environment uniformly through combination of a mesoporous material and the antibacterial active material, so that bacteria on clothing can be killed effectively; the nano antibacterial agent is added to the antibacterial laundry detergent, after washing, the nano-TiO2 antibacterial agent can be partially attached to the clothing and has a lasting antibacterial function, and accordingly, a long-acting antibacterial effect is obtained.

Owner:BEIJING INNOVATION FINE CHEM LTD

Antibacterial metal ion/titanium-supporting hydroxyapatite nanometer photocatalyst and preparation method thereof

ActiveCN106560243AWith quick-acting sterilization functionLong-acting antibacterialBiocideDead animal preservationTitaniumMetal

The present invention discloses an antibacterial metal ion / titanium-supporting hydroxyapatite nanometer photocatalyst, which is a hydroxyapatite nanometer material, wherein partial Ca<2+> is substituted with antibacterial metal ions and Ti<4+>, the antibacterial metal ions comprise Cu<2+>, Zn<2+> and Ag<+>, and during the preparation, the original feeding molar ratio of various metal ions is that n(Ti+metal) / n(Ca+Ti+metal) is 0.1-0.5, and the "metal" refers to the antibacterial metal ions. According to the present invention, the nanometer material has functions of rapid sterilization, long-term sterilization function and high mildew ability, and can instantly play super-strong sterilization effect in the absence of illumination, wherein the sterilization rate within 1 min can achieve more than 96%, and the sterilization rate within 3-4 min can achieve more than 99%; and after visible light irradiation for 30 min, more than 80% of formaldehyde gas can be removed.

Owner:姚 燕燕

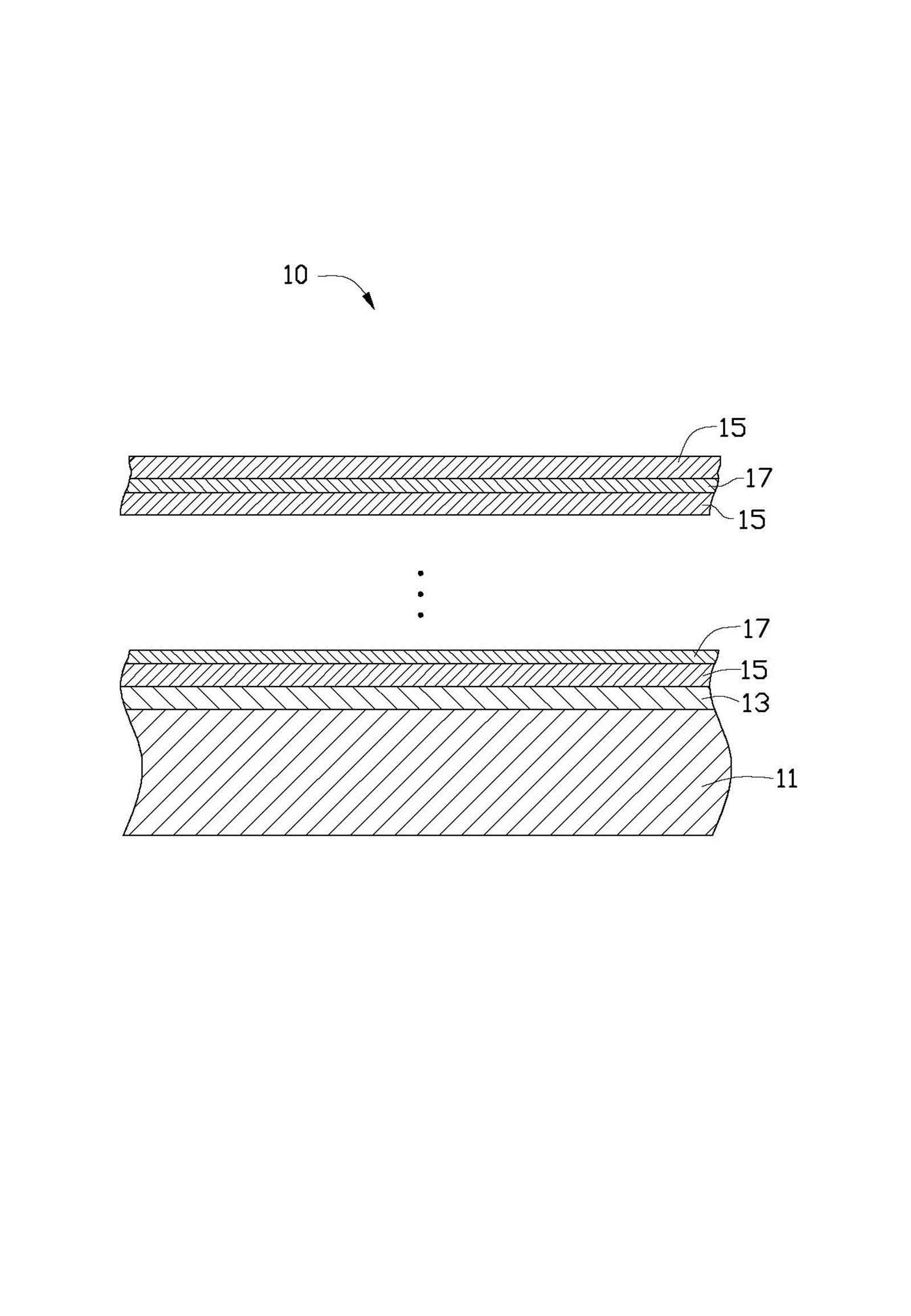

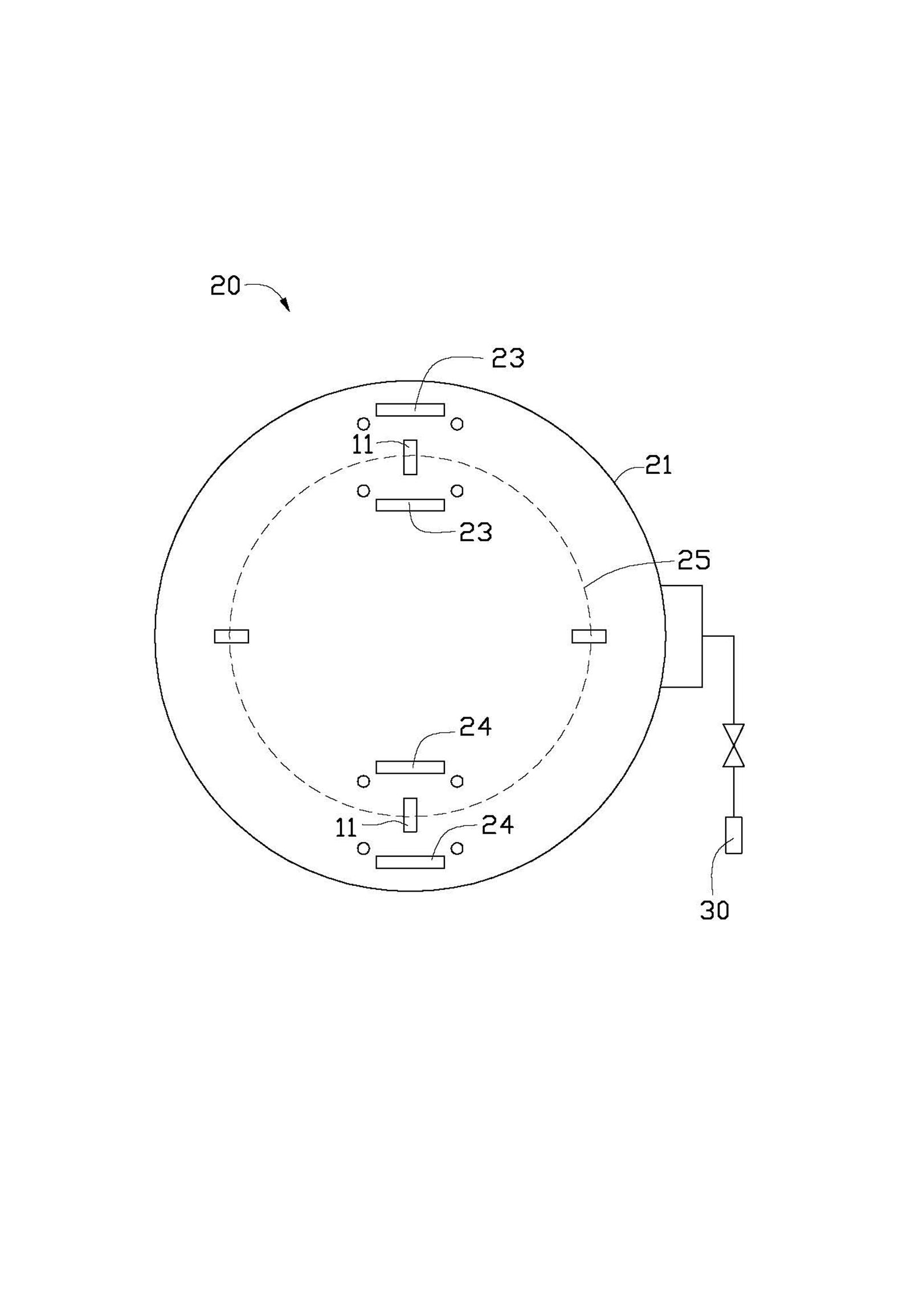

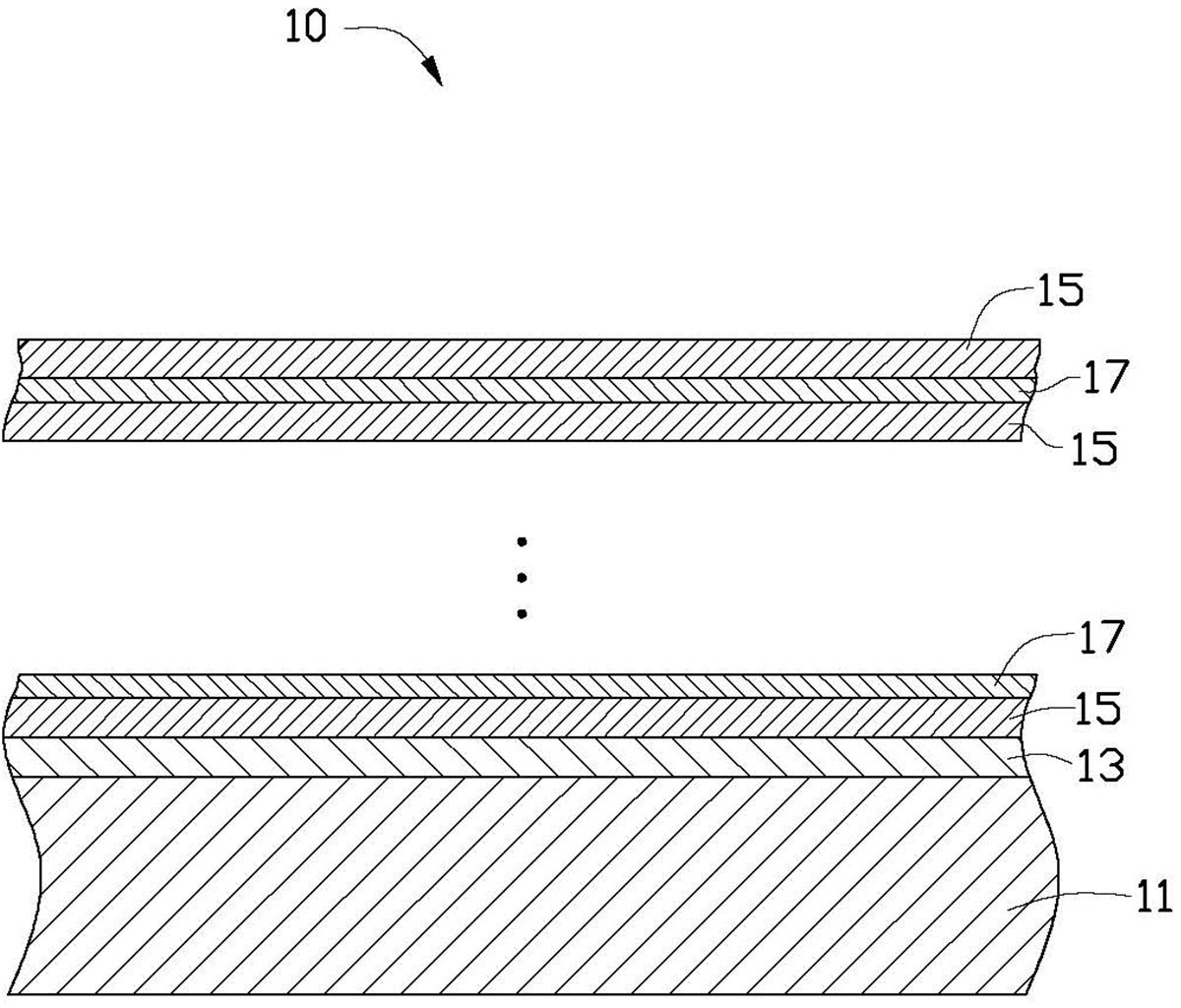

Antibacterial film-coated member and the preparation method thereof

InactiveCN102691046ALong-acting antibacterialImprove antibacterial propertiesVacuum evaporation coatingSputtering coatingDissolutionCopper

The invention provides an antibacterial film-coated member. The antibacterial film-coated member has lasting antibacterial effects, is suitable for a plurality of environments and comprises a base material, and multiple titanium dioxide layers and multiple copper layers formed on the surface of the base material, wherein the multiple titanium dioxide layers and the multiple copper layers are arranged alternately. The multiple titanium dioxide layers can inhibit the fast dissolution of copper ions of the multiple copper layers thereby delaying the dissolution of the copper ions and thus lasting antibacterial effects of the multiple copper layers are obtained. The antibacterial film-coated member is suitable for a plurality of environments. In the dark, the multiple copper layers of the antibacterial film-coated member perform main antibacterial effects and under lights, the multiple titanium dioxide layers perform antibacterial effects so that the antibacterial film-coated member has stronger antibacterial effects. In addition, the invention also provides a preparation method of the antibacterial film-coated member.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

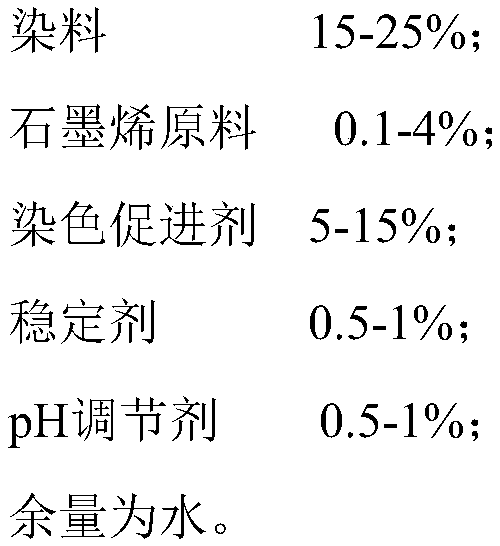

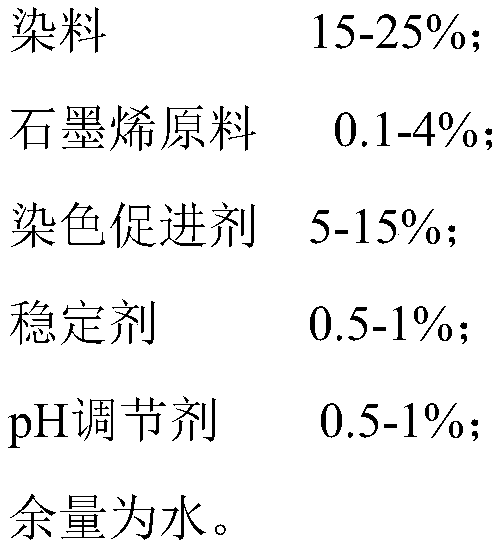

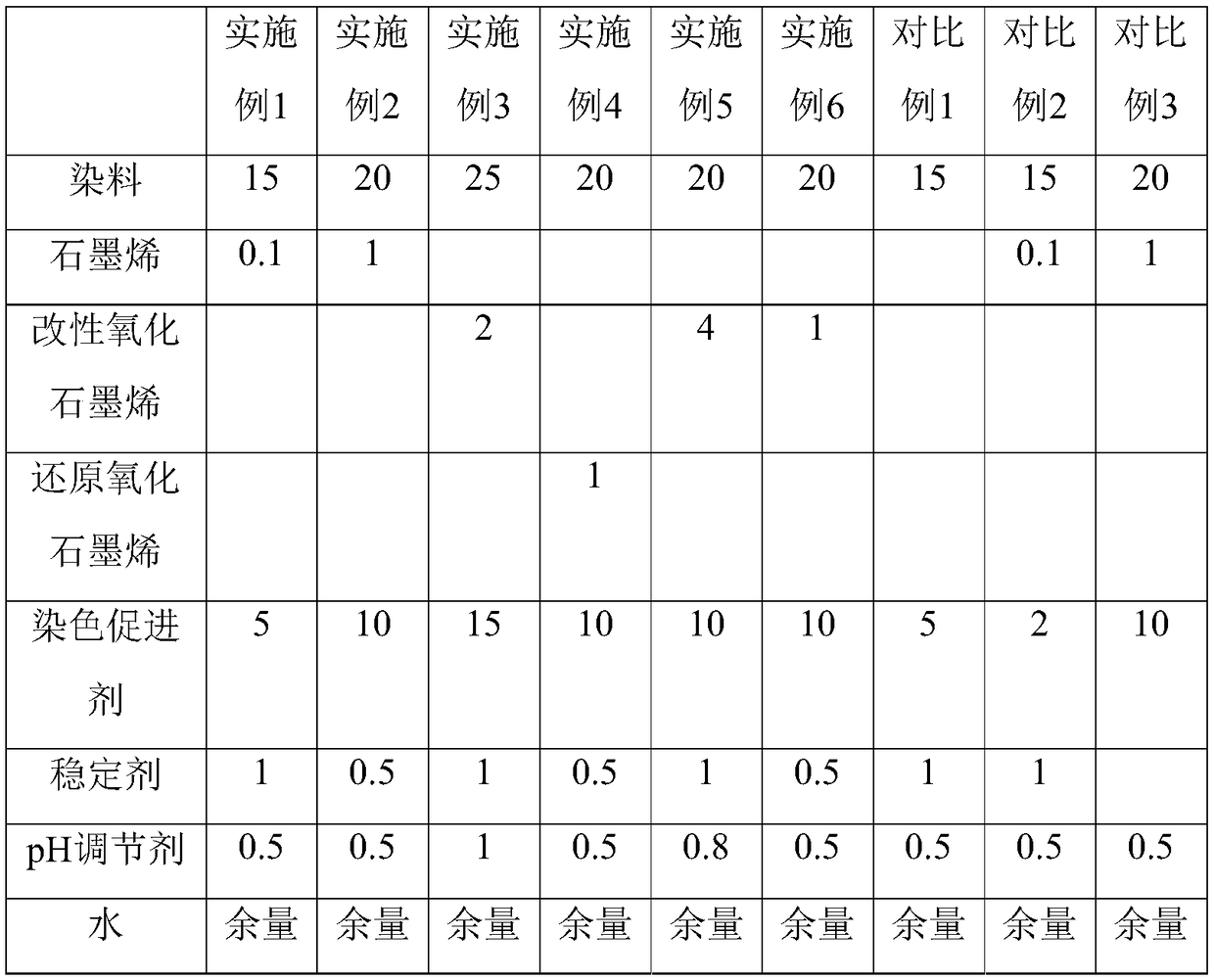

Multifunctional graphene printing and dyeing sizing agent and preparation method thereof

InactiveCN108842483ALong-lasting anti-miteLong-acting antibacterialDyeing processUltravioletGraphene

The invention provides a multifunctional graphene printing and dyeing sizing agent and a preparation method thereof. The multifunctional graphene printing and dyeing sizing agent comprises the following components in percentage by weight: 15% to 25% of dye, 0.1% to 4% of a graphene raw material, 5% to 15% of a dyeing accelerant, 0.5% to 1% of a stabilizer, 0.5% to 1% of a pH modifier and the balance of water. Graphene is added into the printing and dyeing sizing agent, and plants can be of long-acting mite prevention, bacteria resistance, ultraviolet prevention and far infrared heating functions after fabrics are dyed. Moreover, the preparation method is simple and efficient, and can be widely used for producing the graphene printing and dyeing sizing agent.

Owner:湖北联庄科技有限公司

Durable anti-mildew aqueous wood wax oil, preparation method thereof and application technology thereof

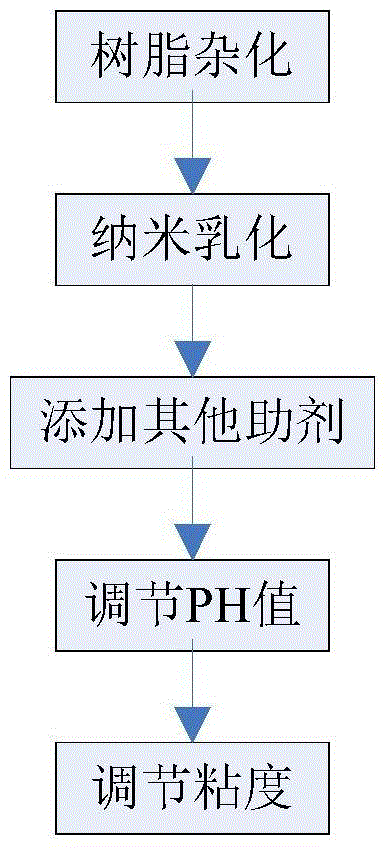

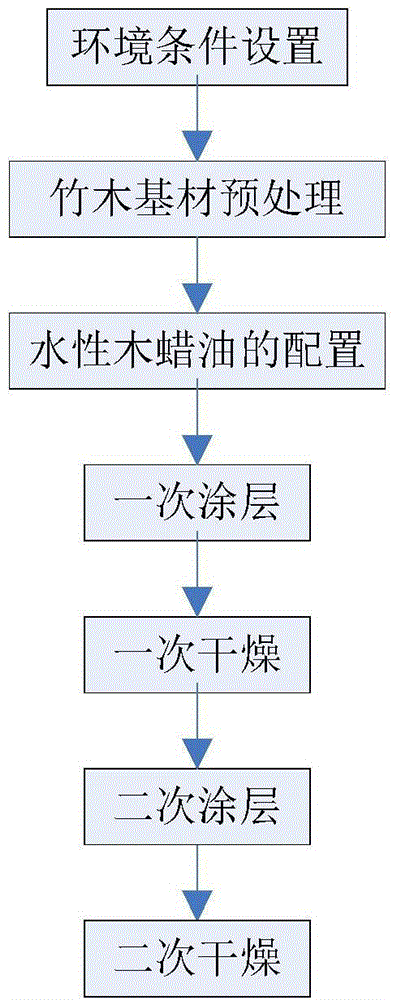

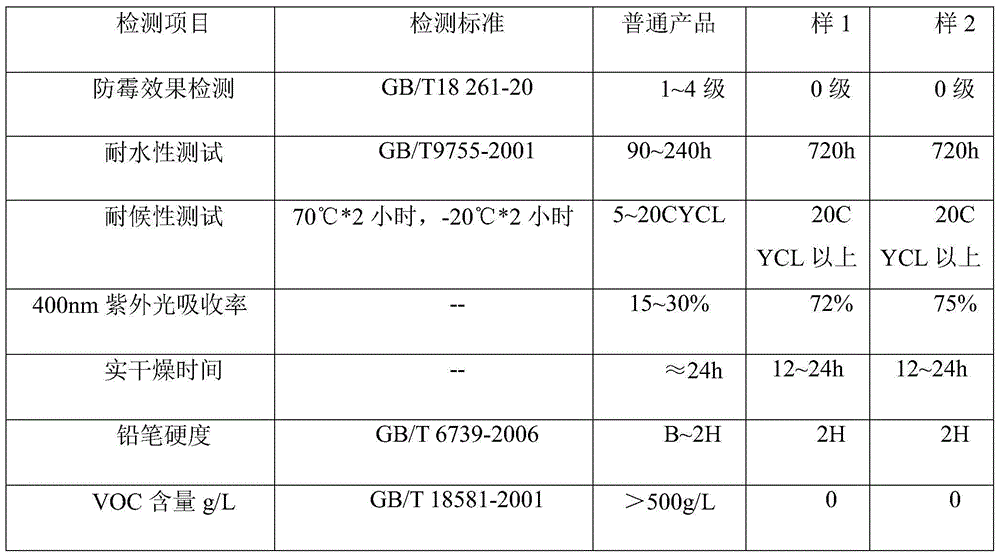

InactiveCN105860793ADoes not change natural propertiesBreathe freelyAntifouling/underwater paintsPretreated surfacesWaxFoaming agent

The invention discloses durable anti-mildew aqueous wood wax oil. The wood wax oil comprises the following components: 40-80% of aqueous urethane oil, 0.5-10% of a nano oxide, 0.2-5% of a silane coupling agent, 10-40% of water, 2-4% of a film-forming auxiliary agent, 0.05-5% of a dispersant, 0.05-5% of a levelling agent, 0.05-5% of an anti-foaming agent, 0.05-5% of a wetting agent, and 0.2-0.4% of a pH conditioning agent. The invention also provides a preparation method of the durable anti-mildew aqueous wood wax oil and an application technology thereof. The durable anti-mildew aqueous wood wax oil has good environmental protection performance, has deep and durable protection performance on bamboo and wood base materials, and has excellent moisture-resistance performance and is not easy to go moldy.

Owner:HUNAN BANFERT NEW MATERIALS TECH

Method for preparing efficient and durable antibacterial melt-blown non-woven fabric

InactiveCN106436015AAvoid reunionEvenly distributedNon-woven fabricsArtifical filament manufactureBenzeneControl mode

The invention discloses a method for preparing antibacterial non-woven fabric, and particularly relates to a method for preparing efficient and durable nano-silver antibacterial melt-blown non-woven fabric. The method includes the steps that a benzene or methylbenzene or trichloromethane or carbon tetrachloride solution of an amphipathy hyperbranched polymer and a silver nitrate aqueous solution are mixed and stirred, and a high-concentration solution of the amphipathy hyperbranched polymer is obtained through standing liquid separation and rotating evaporation; the high-concentration solution is sprayed into raw material particles or slices of melt-blown non-woven fabric with a spraying method, continuous stirring is carried out, then the processing working procedure of the melt-blown non-woven fabric is carried out, and the antibacterial non-woven fabric with fibers containing nano-silver particles can be obtained. According to the method, nano-silver is generated in melt-blown non-woven fabric fibers through the amphipathy hyperbranched polymer in an in-situ control mode, and the generated nano-silver has the advantages of being small in particle size, even in dispersing and high in combining firmness; meanwhile, existing melt-blown non-woven fabric production equipment does not need to be upgraded and transformed, and processing is easy and convenient.

Owner:江西天滤新材料有限公司

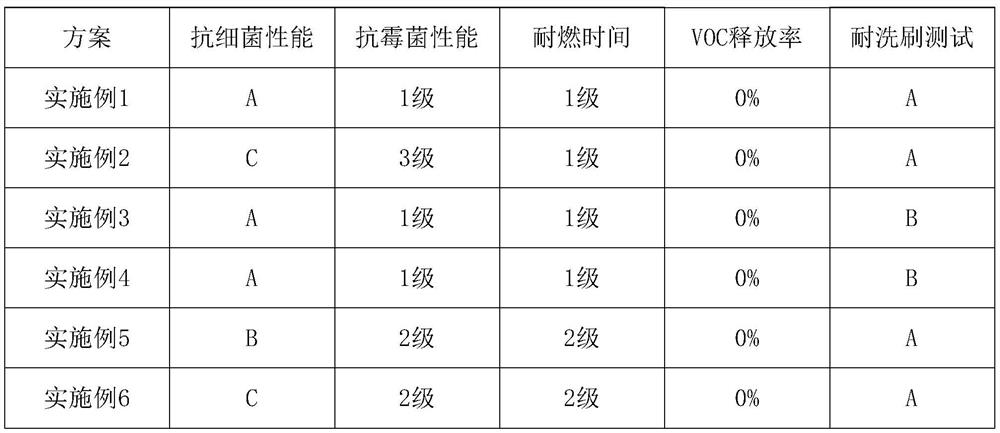

Antibacterial, mildew-proof and flame-retardant silicate interior wall coating and preparation method thereof

PendingCN113004733AImprove stabilityExtended service lifeFireproof paintsAntifouling/underwater paintsCelluloseHydroxyethyl cellulose

The invention relates to the field of building coatings, in particular to an antibacterial, mildew-proof and flame-retardant silicate interior wall coating and a preparation method thereof. The antibacterial, mildew-proof and flame-retardant silicate interior wall coating is prepared from, by mass, 30-60 parts of slurry, 45-55 parts of filler, 20-65 parts of diluent A, 10-25 parts of diluent B and 1-3 parts of auxiliaries; the slurry is prepared from the following components in parts by mass: 2 to 6 parts of hydroxyethyl cellulose, 0.3 to 1 part of a wetting agent, 0.1 to 1 part of a dispersing agent, 0.1 to 0.8 part of a de-foaming agent and 0.1 to 0.5 part of other auxiliary agents; the filler comprises the following components in parts by mass: 10-30 parts of carrier nano silver, 5-15 parts of titanium dioxide, 5-10 parts of kaolin, 10-15 parts of talcum powder and 10-30 parts of heavy calcium carbonate; the auxiliaries comprise the following components in parts by mass: 2-10 parts of propylene glycol, 0.1-3 parts of a defoaming agent, 0.1-1 part of a rheological modification auxiliary and 0.1-0.6 part of a polyurethane thickening agent. The antibacterial, mildew-proof and flame-retardant silicate interior wall coating disclosed by the invention is excellent in antibacterial, mildew-proof and flame-retardant properties, green, environment-friendly and long in service life.

Owner:纽沃得复合建材(上海)有限公司

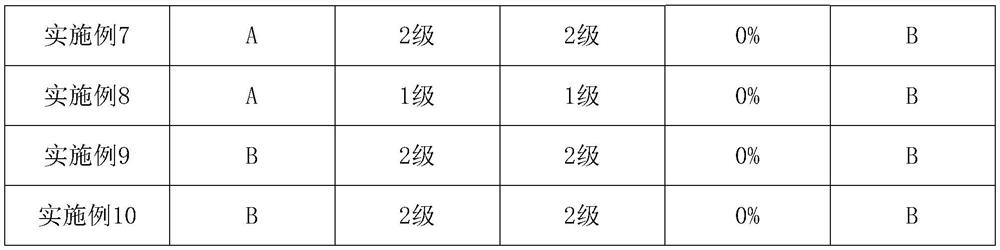

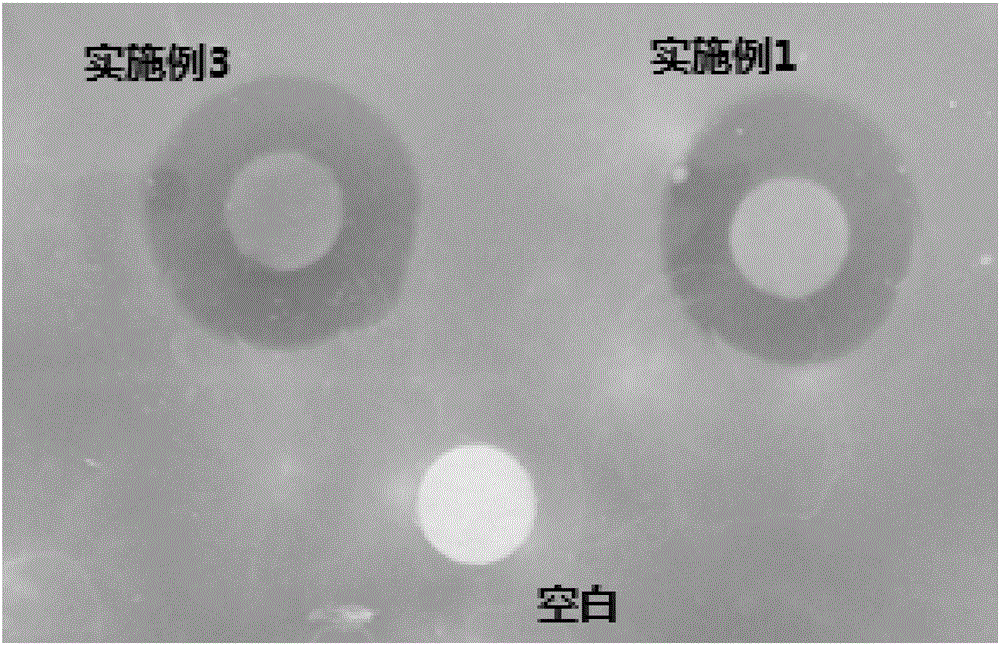

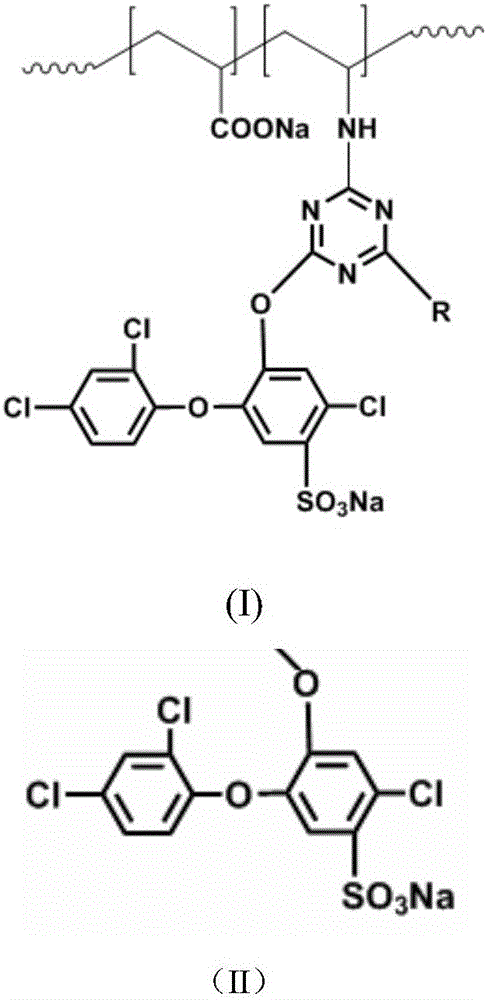

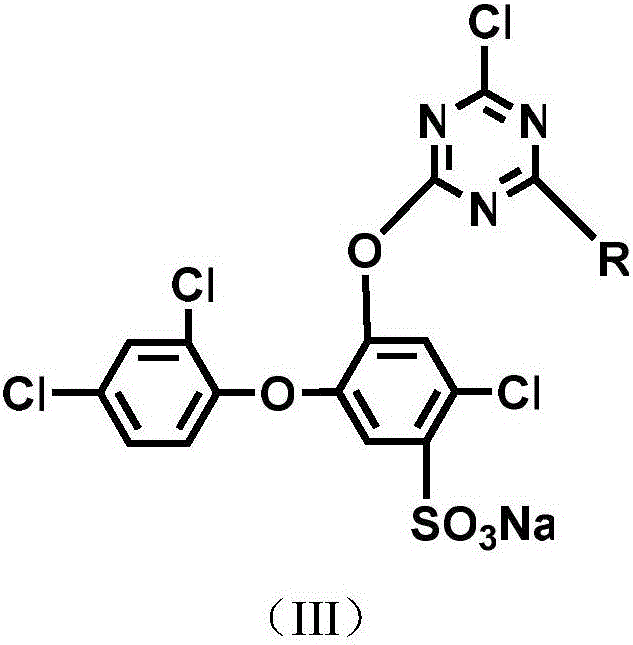

Antibacterial retanning agent and preparation method thereof

The invention relates to an antibacterial retanning agent and a preparation method thereof. The preparation method comprises the following steps: (1) adding poly(acrylic acid-vinylamine) copolymer in water to obtain a poly(acrylic acid-vinylamine) copolymer aqueous solution, and adjusting pH with an alkali solution; and (2) adding modified triclosan, and reacting to obtain the antibacterial retanning agent. The prepared antibacterial retanning agent is used in leather, and mildew-proof and antibacterial effects of the leather and products thereof can be improved. The obtained leather and fur are long in mildew-proof action time and is migration-resistant. The antibacterial retanning agent has long-acting antibacterial and bacteriostatic effects.

Owner:QI HE LI HOU CHEM CO LTD

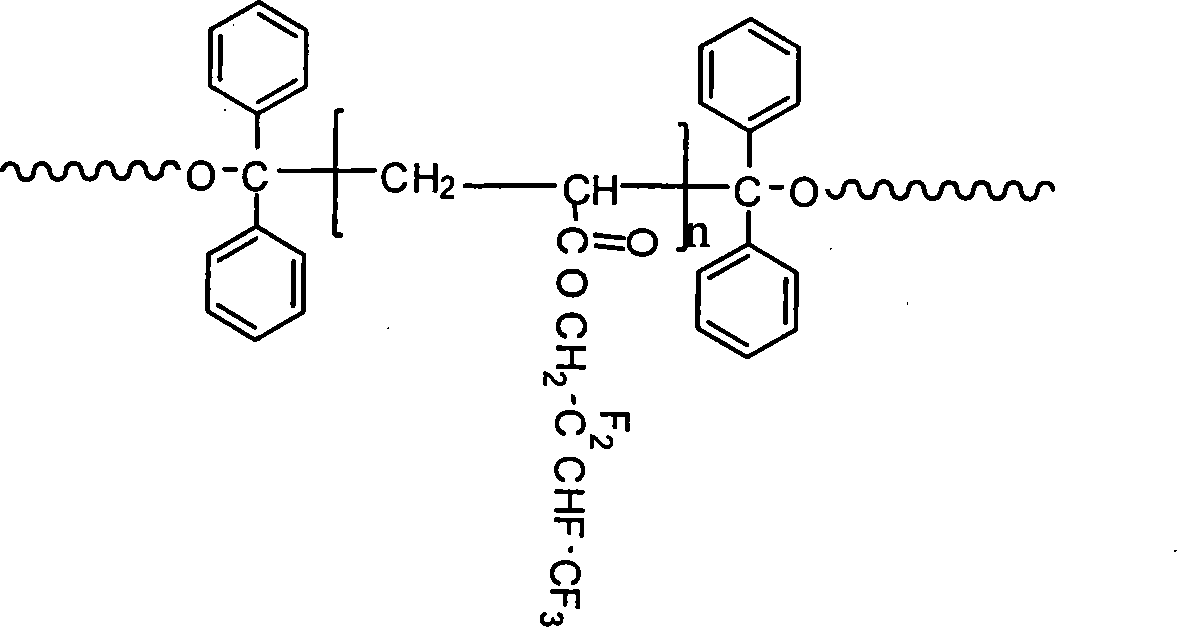

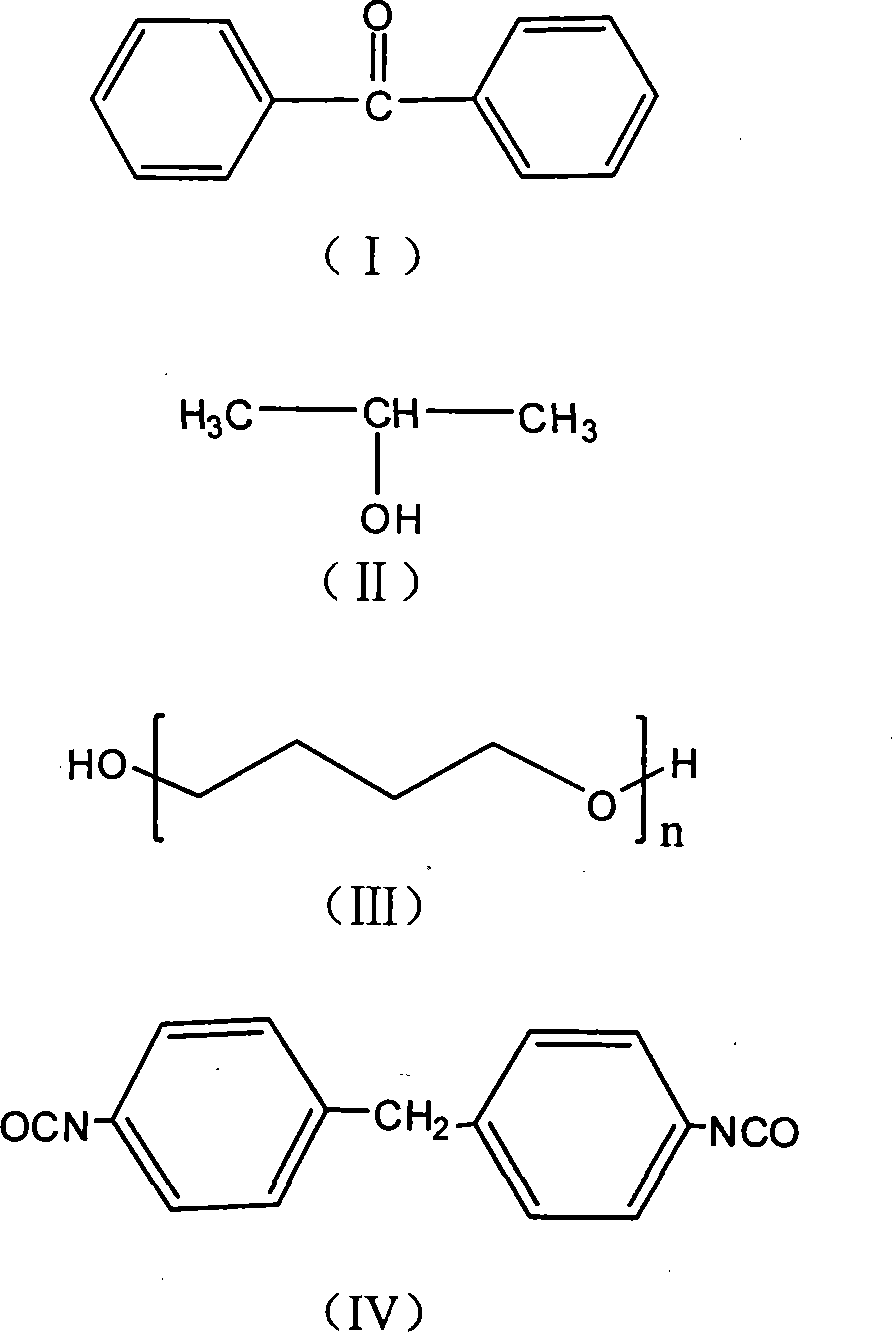

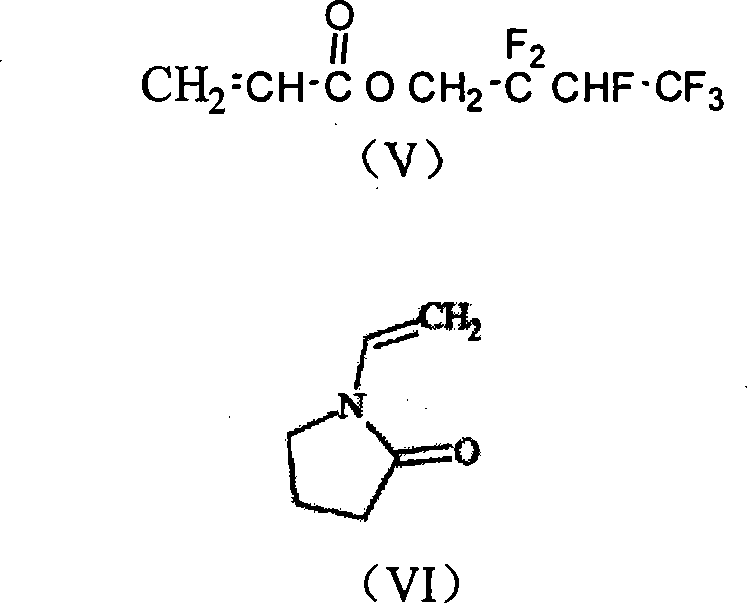

Antibiotic polyurethane material and preparation method thereof

InactiveCN101240053AHas antibacterial propertiesLong-acting antibacterialPolymer sciencePyrrolidinones

The invention relates anti-virus polyurethane material and a preparation method thereof, pertains to polymer material field. The material is polyurethane with monomer containing fluorin inserted into the main chain. The method uses materials including: benzophenone (I), isopropanol (II), polymeric diatomic alcohol (III), diisocyanate (IV), 2,2,3,4,4,4-Hexafluorobutyl acrylate (V) and vinylpyrrolidone;n-vinyl pyrrolidone (VI). The method including steps of: mixing material I and II, charging first catalyst, reacting under radiation of ultraviolet to obtain product of 1,1,2,2-tetraphenyl-1,2-ethanediol, recrystallizing and purifying by acetic acid, adding mixture of material III and IV into the solvent, stirring while reacting to obtain prepolymer; adding 1,1,2,2-tetraphenyl-1,2-ethanediol once more to get reactant, adding second catalyst, purifying to get polyurethane with 1,1,2,2-tetraphenyl-1,2-ethanediol, mixing it with material V and VI, and purifying to get fluorinated polyurethane. The invention has a long-term anti-virus effect.

Owner:TSINGHUA UNIV

Preparation method of nano-silver antibacterial plastic

The invention provides a preparation method of a nano-silver antibacterial plastic. The preparation method comprises following steps: firstly, ion substitution is adopted to load a microporous material nano zeolite carrier with antibacterial silver ions or other metallic oxides so as to obtain a nano silver zeolite composite antibacterial material; the nano silver zeolite composite antibacterial material is subjected to surface modification with a surfactant; the modified nano silver zeolite composite antibacterial material is mixed with a powdery polypropylene matrix at a mass ratio of 1:5, an accessory ingredient and a dispersing agent are added, and vibrating milling is adopted for dispersion treatment so as to obtain a nano silver zeolite composite antibacterial plastic masterbatch; and at last the nano silver zeolite composite antibacterial plastic masterbatch is uniformly mixed with polypropylene plastic at a mass ratio of 1:10, and an obtained mixture is delivered into an injection molding machine for injection molding so as to obtain the nano-silver antibacterial plastic. The nano-silver antibacterial plastic possesses broad spectrum, high efficiency, and long lasting antibacterial performance, and excellent slow release performance.

Owner:TIANJIN BAOXINGWEI TECH

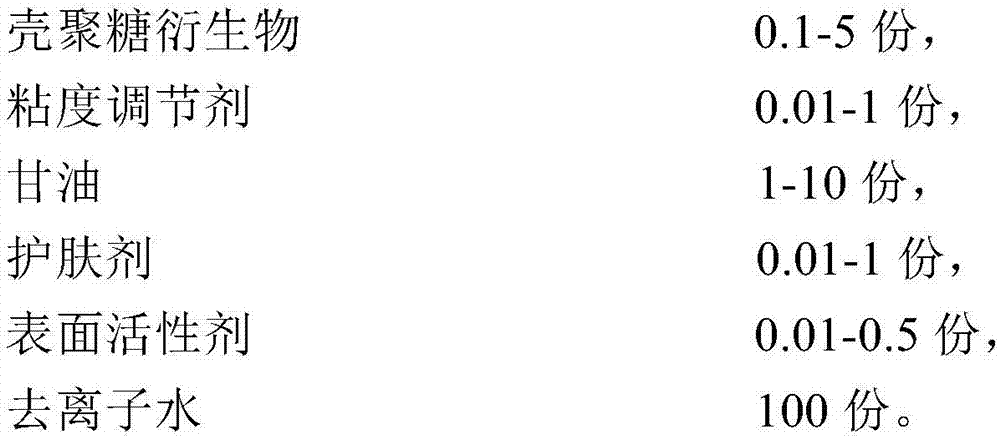

Special chitosan derivative-based water-free hand washing liquid for children, and preparation method thereof

PendingCN107496206AReasonable formulaPlay a killing effectCosmetic preparationsToilet preparationsEnvironmental resistanceFunction group

The invention discloses a special chitosan derivative-based water-free hand washing liquid for children, and a preparation method thereof, wherein the special chitosan derivative-based water-free hand washing liquid comprises the following raw materials by weight: 0.1-5 parts of a chitosan derivative, 0.01-1 part of a viscosity modifier, 1-10 parts of glycerin, 0.01-1 part of a skin-care agent, 0.01-0.5 part of a surfactant, and 100 parts of deionized water. According to the present invention, the water-free hand washing liquid with advantages of safety, no harm to human body, environmental protection and efficient antibacterial property is prepared by using the chitosan derivative macromolecule having the antibacterial function group as the active substance; and the water-free hand washing liquid designed for the children skin has the reasonable formula, can form the protective film on the child hand surface after the use, can kill a variety of pathogenic bacteria in children, and has characteristics of strong antibacterial ability, long acting time, no color, no odor, no toxicity, no irritating, smoothness and comfort after the use, no requirement of water rinsing, convenient use, and convenient carrying.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

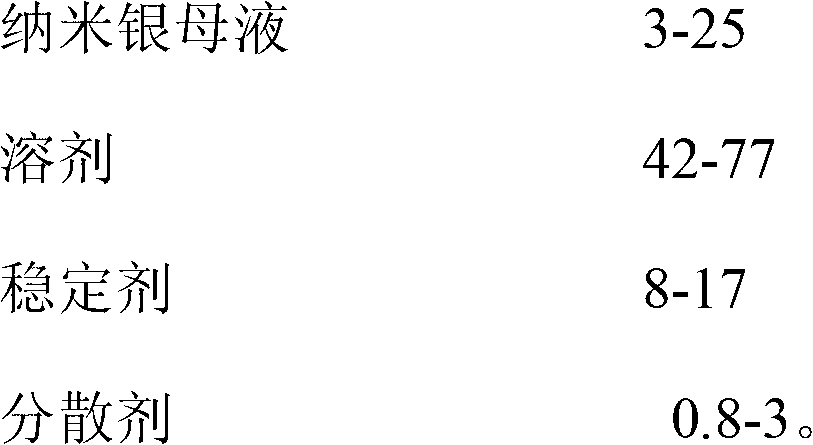

Environment-friendly high-efficiency nano antibacterial agent for leather, and preparation method and application thereof

ActiveCN110527756AImprove antibacterial propertiesLong-acting antibacterialTanning treatmentLeather surface finishingNanoparticleSolvent

The invention discloses an environment-friendly high-efficiency nanometer antibacterial agent for leather, and a preparation method and application thereof. The preparation method comprises the following steps: uniformly dispersing synthetic silicate nanoparticles in a certain mixed solvent, modifying the surfaces of the nanoparticles by using an amino silane coupling agent, and carrying out amidation reaction under specific conditions to obtain the nano antibacterial agent with phenolic hydroxyl and hydrophilic carboxyl. According to the preparation method, the adopted raw materials are environmentally friendly and easily avaiable, the prepared environment-friendly high-efficiency nanometer antibacterial agent for leather has long-acting antibacterial property, the antibacterial effect reaches 99% or above, and the nano antibacterial agent is uniformly dispersed and stably combined in a leather matrix and can be used for tanning, retanning, fat liquoring and other leather making procedures.

Owner:SHAANXI UNIV OF SCI & TECH

Method for producing antibacterial towels

InactiveCN105887484AGood antibacterial propertiesMaintain antimicrobial propertiesBiochemical fibre treatmentGrip property fibresLong actingEnvironmentally friendly

The invention discloses a method for producing antibacterial towels, and relates to the technical field of towel articles. The method includes steps of A, preparing raw materials including pure cotton yarns and bamboo fibers with a proportion of 3:2; B, carrying out antibacterial treatment on the raw materials, to be more specific, 1) washing and decontaminating the bamboo fibers by the aid of distilled water and drying the bamboo fibers by the aid of a loose dryer at a low baking temperature of 45-55 DEG C, 2) picking and decontaminating the pure cotton yarns, immersing the pure cotton yarns in antibacterial solution for 60-120 minutes and then drying the pure cotton yarns; C, weaving each group of warp yarns and each group of weft yarns in a staggered manner to obtain towels in required styles; D, carrying out finishing on the towels, to be more specific, cutting and trimming the towels woven at the step C and sewing the edges of the towels to completely produce the antibacterial towels. Each group of warp yarns comprises two corresponding pure cotton yarns and the single corresponding bamboo fiber, and each group of weft yarns comprises the single corresponding pure cotton yarn and the single corresponding bamboo fiber. Compared with the prior art, the method has the advantages that the antibacterial towels produced by the aid of the method are safe and are environmentally friendly, and long-acting antibacterial effects can be realized by the antibacterial towels.

Owner:SOUTHERN CHINA REGENERATED COTTON YARN WUZHOU CO LTD

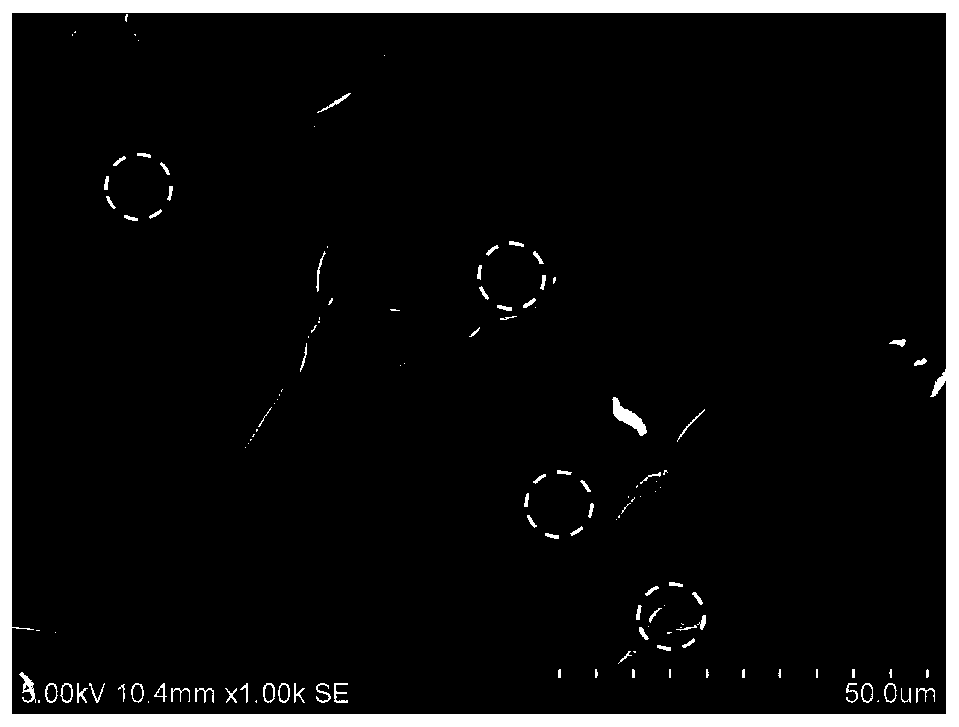

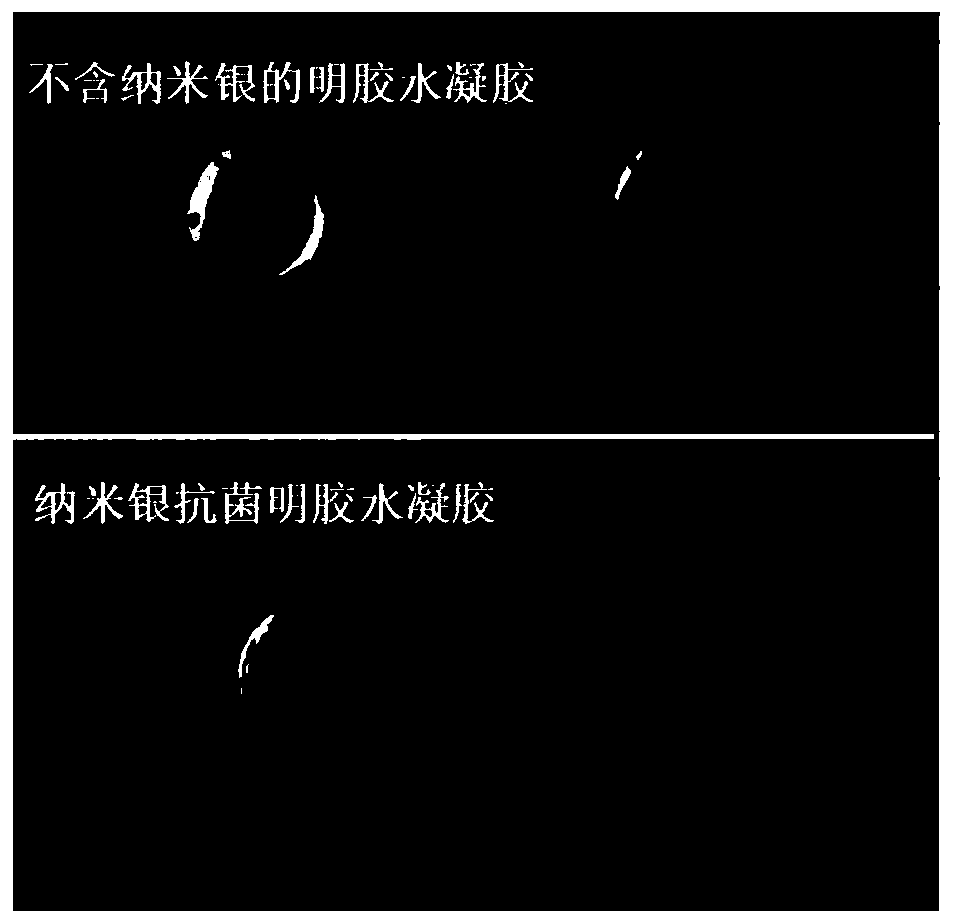

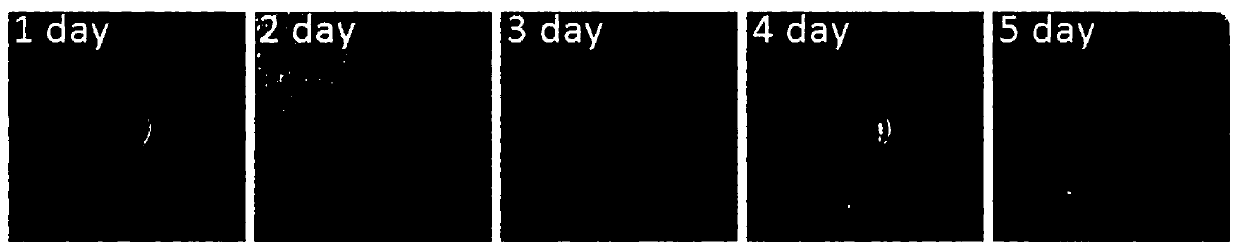

Antibacterial hydrogel with controllable released nano silver ions and preparation method thereof

The invention provides an antibacterial hydrogel with controllable released nano silver ions and a preparation method thereof. The preparation method comprises the following steps: 1, mixing modifiednano silver-loaded microspheres and a modified gelatin solution to form a prepolymer solution, adding a photoinitiator into the prepolymer solution, and uniformly mixing them; 2, putting the solutionobtained in the step 1 in a mold, carrying out photocrosslinking gelation under an ultraviolet light source to obtain the antibacterial hydrogel. The prepared hydrogel with controllable released nanosilver ions can effectively improve the toxic effect of the nano silver particles on tissue cells and achieve long-acting antibacterial and bacteriostatic functions, thereby promoting complete tissuerepair and regeneration.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com