Coating composition with antimicrobial and air purification function

A technology for air purification and composition, applied in the directions of coating, deodorization, disinfection, etc., can solve problems such as silver ion discoloration, and achieve the effect of reducing odor, long-term antibacterial and air purification effects, and avoiding dispersion difficulties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0008] Raw material ratio is as follows (each component is by weight):

[0009] Fe 3+ Doped tetraacicular zinc oxide whiskers 1 part

[0010] Molecular sieve 10 parts

[0011] Acrylate emulsion 40 parts

[0012] Titanium dioxide 20 parts

[0013] Filler talcum powder 25 parts

[0014] Sodium Dimetaphosphate 2 parts

[0015] 2 parts bentonite

[0016] Among them, Fe 3+ The preparation of doping tetraacicular zinc oxide whisker is, the FeCl of 10% (weight) 3 The aqueous solution is sprayed on the surface of the four needle-shaped zinc oxide whiskers, and the compounding amount is Fe in percent by weight. 3+ The content is 1% of the four needle-shaped zinc oxide whiskers, dried by air flow at 60°C, and then roasted at a constant temperature in a box-type resistance furnace at 800°C for 15 minutes to obtain Fe 3+ Doped with tetrapod ZnO whiskers.

[0017] In the mixing tank, sequentially add titanium dioxide, filler talc powder, molecular sieve, sodium dimetaphosphate, b...

Embodiment 2

[0019] Raw material ratio is as follows (each component is by weight):

[0020] V 5+ Doped tetraacicular zinc oxide whiskers 3.5 parts

[0021] Porous sodium silicate 1 part

[0022] Acrylate emulsion 55 parts

[0023] Titanium dioxide 30 parts

[0024] Filler talcum powder 10 parts

[0025] Sodium Dimetaphosphate 0.25 parts

[0026] Bentonite 0.25 parts

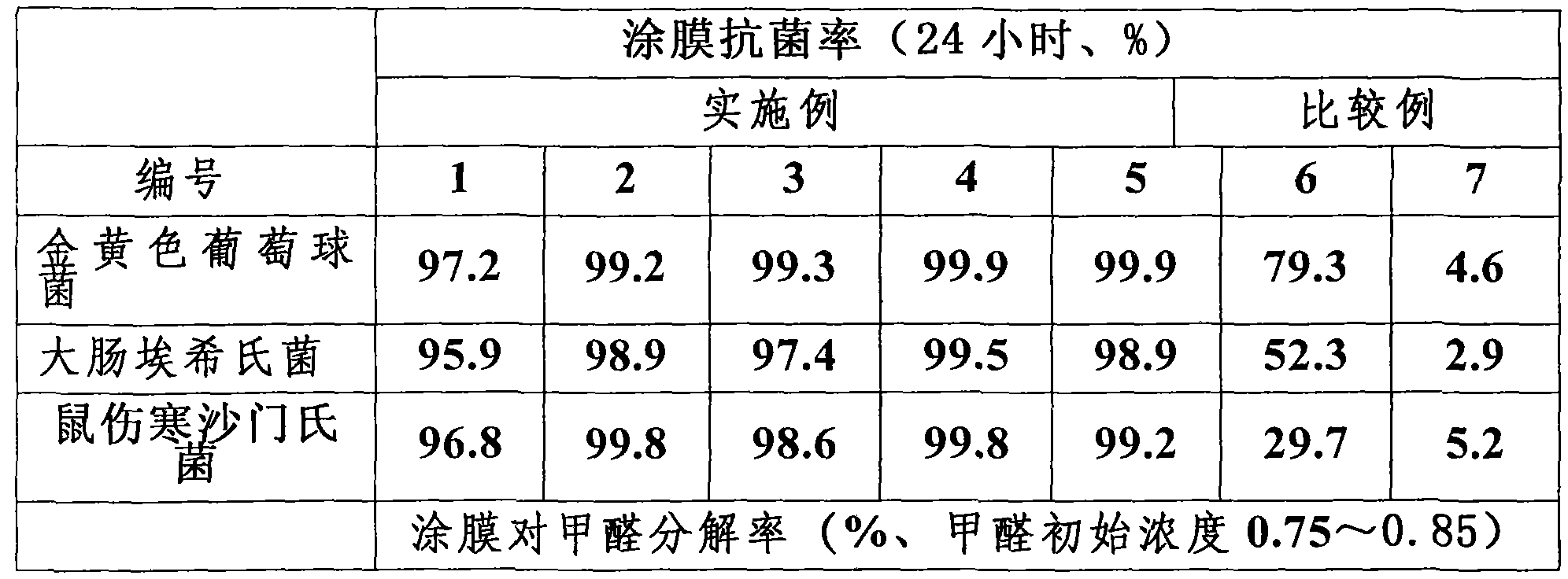

[0027] Among them, Fe 5+ The preparation of doping tetraacicular zinc oxide whisker is, the VCl of 10% (weight) 5 The aqueous solution is sprayed on the surface of the four-needle zinc oxide whisker, and the compounding amount is V in percent by weight. 5+ The content is 0.3% of the four needle-shaped zinc oxide whiskers, dried by air flow at 90°C, and then roasted at a constant temperature in a box-type resistance furnace at 500°C for 60 minutes to obtain V 5+ Doped with tetrapod ZnO whiskers. Operate later on with embodiment 1, obtain the coating composition with antibacterial and air cleaning function. Its anti...

Embodiment 3

[0029] Raw material ratio is as follows (each component is by weight):

[0030] Fe 3+ , V 5+ 、Cu 2+ Doped tetraacicular zinc oxide whiskers 5 parts

[0031] Molecular sieve 1 part

[0032] Activated carbon 1 part

[0033] Porous sodium silicate 1 part

[0034] Acrylate emulsion 45 parts

[0035] Titanium dioxide 25 parts

[0036] Filler talcum powder 20 parts

[0037] Sodium Dimetaphosphate 1 part

[0038] 1 part bentonite

[0039] Among them, Fe 3+ , V 5+ 、Cu 2+ The preparation of doping tetraacicular zinc oxide whisker is, the FeCl of 10% (weight) 3 , VCl 5 , CuCl 2 The aqueous solution is mixed and sprayed on the surface of the four-needle zinc oxide whisker, and the compounding amount is Fe 3+ , V 5+ 、Cu 2+ The contents are 0.3%, 0.5%, and 0.7% of the four-needle zinc oxide whiskers, dried by airflow at 80°C, and then roasted at a constant temperature in a box-type resistance furnace at 700°C for 50 minutes to obtain Fe 3+ , V 5+ 、Cu 2+Doped with tetra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com