Coating with antibacterial and air-purifying functions

A paint and raw material technology, applied in the field of paint preparation and photocatalyst materials, can solve the problems of restricting industrialization, difficult recycling, easy aggregation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

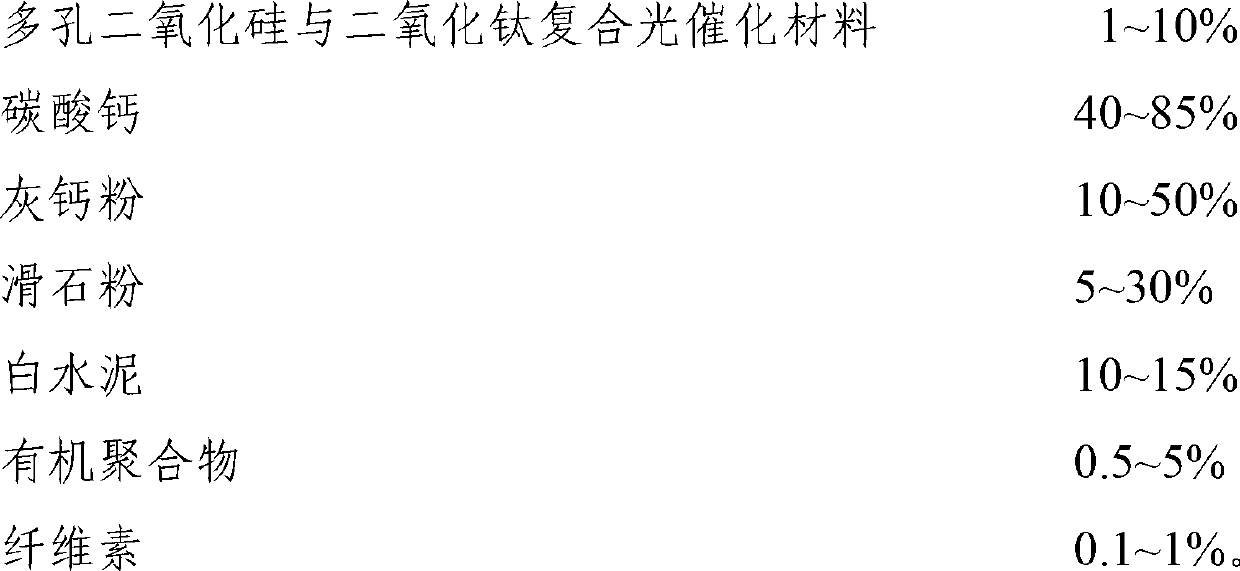

[0016] Embodiment 1 Preparation of porous silicon dioxide and titanium dioxide composite photocatalytic material

[0017] Take 50 grams of porous silicon dioxide, 187 grams of urea, add 15000 ml of water, stir evenly, and add 625 ml of 0.5 mol / L TiOSO 4 Add 15600ml of water to the solution, then mix and stir the two liquids, adjust the pH value to 1.5, stir at 75°C for 60mim, filter, wash, dry at 150°C for 2 hours, and calcinate at 500°C for 2 hours, then add 1 gram of tourmaline powder to mix and disperse , that is, porous silica and titania composite photocatalytic material.

[0018] Wherein, the preparation method of the porous silica is as follows: take 200 grams of diatomite raw earth, wash it with water, take 100 grams of washed diatomite and calcinate it at 550° C. for 1.5 hours, and add 1.3% diatomite after cooling. 120ml of sulfuric acid was stirred evenly, and calcined at 250°C for 2.5 hours, then washed with iron remover, and then washed with water until the pH val...

Embodiment 2

[0019] Embodiment 2 Preparation of porous silicon dioxide and titanium dioxide composite photocatalytic material

[0020] Take 100 grams of porous silicon dioxide, 375 grams of urea, add 30000 ml of water, stir evenly, and add 1250 ml of 0.5 mol / L TiOSO 4 Add 32000ml of water to the solution, then mix and stir the two liquids, adjust the pH value to 1.5, stir at 75°C for 90mim, filter, wash, dry at 150°C for 2.5 hours, and calcined at 650°C for 3 hours, then add 2 grams of tourmaline powder to mix and disperse , that is, porous silica and titania composite photocatalytic material.

[0021] Wherein, the preparation method of the porous silica is as follows: take 1000 grams of zeolite raw ore and pulverize it to 100 mesh, impregnate it with 3000 ml of hydrochloric acid or sulfuric acid with a concentration of 6-10%, filter it for 3 hours, and then wash it with distilled water until the pH value is 7. , The obtained zeolite precipitate is dried and calcined at 350-500°C to obtai...

Embodiment 3

[0022] The preparation of embodiment 3 porous silicon dioxide and titanium dioxide composite photocatalytic material

[0023] Take 50 grams of porous silicon dioxide and add 1500 ml of water and stir evenly, and another 2.9 mol / L of TiCl 4 100ml solution, then mix the two liquids evenly, add 230ml 1.49mol / L ammonium sulfate solution to it, make it react at 25-30°C for 2 hours, adjust the pH value to 4.5, filter, wash, and dry at 105°C for 2 hours, calcined at 650°C for 3 hours, and then added 1 gram of tourmaline powder to mix and disperse to obtain a composite photocatalytic material of porous silica and titania.

[0024] Wherein, the preparation method of the porous silica is as follows: take 1000 grams of kaolin or hard kaolin and pulverize to 80 meshes, then calcined at 500-600° C. for 2 hours, and then mix the calcined soil with 30% hydrochloric acid by 1 : Mixed at a weight ratio of 2.5, soaked in acid at 90°C for 7 hours, neutralized, filtered, and dried to obtain poro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com