Preparation method of long-acting and anti-bacterial polylactic acid fiber film

A polylactic acid fiber, long-acting technology, applied in textiles, papermaking, non-woven fabrics, etc., can solve the problems of poor antibacterial performance and short antibacterial timeliness, achieve long-acting antibacterial performance, improve antibacterial effect, and increase adsorption capacity Effect

Inactive Publication Date: 2018-11-30

FOSHAN SENANG BIO TECH CO LTD

View PDF5 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] The technical problem mainly solved by the present invention is: Aiming at the shortcomings of traditional long-acting antibacterial polylactic acid fiber membran

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

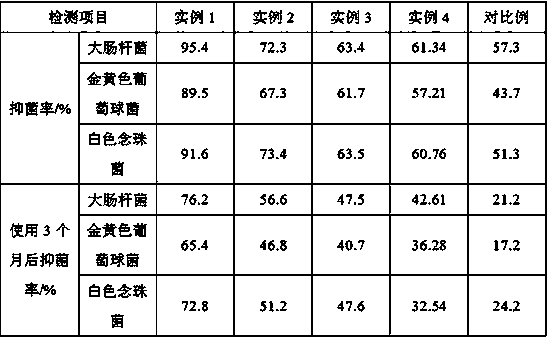

The invention discloses a preparation method of a long-acting and anti-bacterial polylactic acid fiber film, belonging to the technical field of eco-friendly material. The method comprises the following steps: mixing polyethylene glycol with dichloromethane according to the volume ratio ranging from 2:7 to 2:8 into a stirring machine, adding anti-bacterial additive which is 0.1 to 0.3 times the volume of the polyethylene glycol and polylactic acid which is 1.0-1.4 times the volume of the polyethylene glycol, mixing the above for 30-60 minutes and keeping stirring at temperature ranging from 40-50 DEG C and at rotary speed ranging from 380 to 500r/min and carrying out ultrasonic dispersion operation on the mixture at the frequency being 45 to 55 kHz in order to acquire spinning liquid; performing electrostatic spinning on the spinning liquid in order to obtain a film so that the long-acting and anti-bacterial polylactic acid fiber film is acquired. According to the technical scheme, thelong-acting and anti-bacterial polylactic acid fiber film enjoys excellent advantages such as anti-bacterial performance and long-acting and anti-bacterial performance so that a broad prospect in theindustry of eco-friendly material is acquired. A ceramic grinding aid prepared by the technical scheme has the feature of excellent grinding aiding efficiency and has a wide prospect in the development of the industry for ceramic processing agents.

Description

technical field [0001] The invention discloses a preparation method of a long-acting antibacterial polylactic acid fiber membrane, which belongs to the technical field of environmental protection materials. Background technique [0002] Polylactic acid fiber is made of corn, wheat, sugar beet and other starchy agricultural products, which are fermented to produce lactic acid, and then made by polycondensation and melt spinning. Polylactic acid fiber is a kind of raw material that can be planted and is easy to plant. Synthetic fibers that naturally degrade in nature. It can be decomposed into carbon dioxide and water by microorganisms in soil or seawater. When burned, it will not emit poisonous gas and cause pollution. It is a sustainable ecological fiber. The fabric has good handle and drapability, anti-ultraviolet radiation, low flammability and excellent processing performance. It is suitable for various fashion, casual wear, sporting goods and sanitary products, etc., an...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): D04H1/435D04H1/728D04H1/413

CPCD04H1/435D04H1/413D04H1/728

Inventor 胡次兵刘侠宋宇星

Owner FOSHAN SENANG BIO TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com