Silver-carried antibacterial finishing agent and preparation method thereof

A silver-loaded antibacterial and finishing agent technology, used in fiber treatment, textiles and papermaking, etc., can solve the problems of high cost, mildew resistance, weak antifungal effect, easy discoloration, etc. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A silver-loaded antibacterial finishing agent, which is a complex formed by amino group-containing polyurethane and acrylate copolymer emulsion and silver salt, wherein 184 parts of amino group-containing polyurethane and acrylate copolymer emulsion, 8 parts of silver salt.

[0042] Wherein, the silver salt is silver nitrate.

[0043] The preparation method of the above-mentioned silver-loaded antibacterial finishing agent comprises the following steps:

[0044] Silver nitrate was added to the polyurethane and acrylate copolymer emulsion containing amine groups, and stirred at 18°C for 2 hours to fully complex the silver ions with the amine groups to obtain a silver-loaded antibacterial finishing agent.

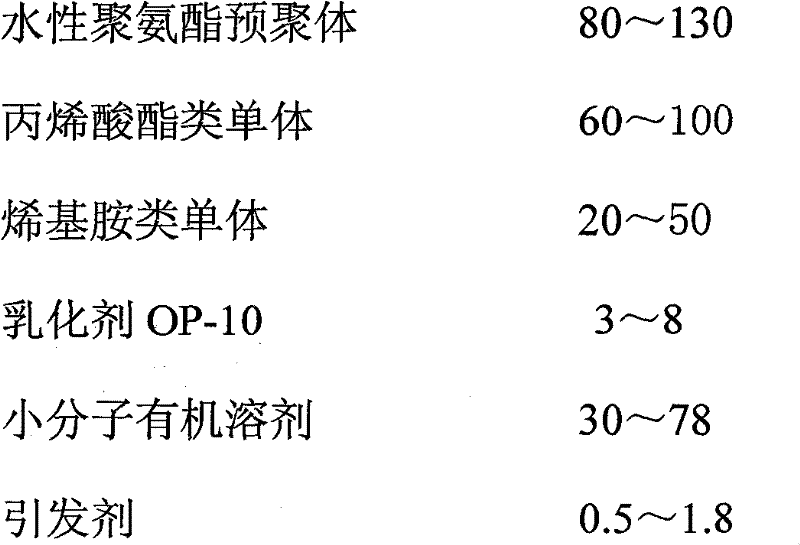

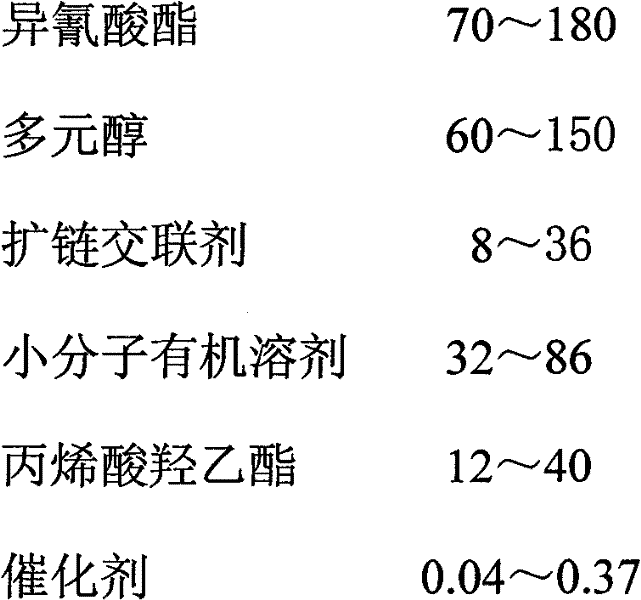

[0045] The concrete preparation steps of the polyurethane and acrylate copolymer emulsion containing amino group are as follows:

[0046] 1) A mixture of acrylate monomers and alkenylamine monomers, and an initiator dissolved in acetone to form an initiator solution. ...

Embodiment 2

[0053] A silver-loaded antibacterial finishing agent, which is a complex formed by amino group-containing polyurethane and acrylate copolymer emulsion and silver salt, wherein 212 parts of amino group-containing polyurethane and acrylate copolymer emulsion, and 11 parts of silver salt.

[0054] Wherein, the silver salt is silver nitrate.

[0055] The preparation method of the above-mentioned silver-loaded antibacterial finishing agent comprises the following steps:

[0056] Silver nitrate was added to the polyurethane and acrylate copolymer emulsion containing amine groups, and stirred at 19°C for 2 hours to fully complex the silver ions with the amine groups to obtain a silver-loaded antibacterial finishing agent.

[0057] The concrete preparation steps of the polyurethane and acrylate copolymer emulsion containing amino group are as follows:

[0058] 1) A mixture of acrylate monomers and alkenylamine monomers, and an initiator dissolved in acetone to form an initiator solut...

Embodiment 3

[0065] A silver-loaded antibacterial finishing agent, which is a complex formed by amino group-containing polyurethane and acrylate copolymer emulsion and silver salt, wherein 228 parts of amino group-containing polyurethane and acrylate copolymer emulsion, 16 parts of silver salt.

[0066] Wherein, the silver salt is silver nitrate.

[0067] The preparation method of the above-mentioned silver-loaded antibacterial finishing agent comprises the following steps:

[0068] Silver nitrate was added to the polyurethane and acrylate copolymer emulsion containing amine groups, and stirred at 20°C for 2 hours to fully complex the silver ions with amine groups to prepare a silver-loaded antibacterial finishing agent.

[0069] The concrete preparation steps of the polyurethane and acrylate copolymer emulsion containing amino group are as follows:

[0070] 1) A mixture of acrylate monomers and alkenylamine monomers, and an initiator dissolved in acetone to form an initiator solution. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com