Preparation method of graphene composite nonwoven cloth

A graphene composite, non-woven technology, applied in textiles and papermaking, biochemical fiber processing, fiber processing and other directions, can solve the problems of cumbersome steps, high cost, uneven distribution of graphene, etc., and achieves the effect of a simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

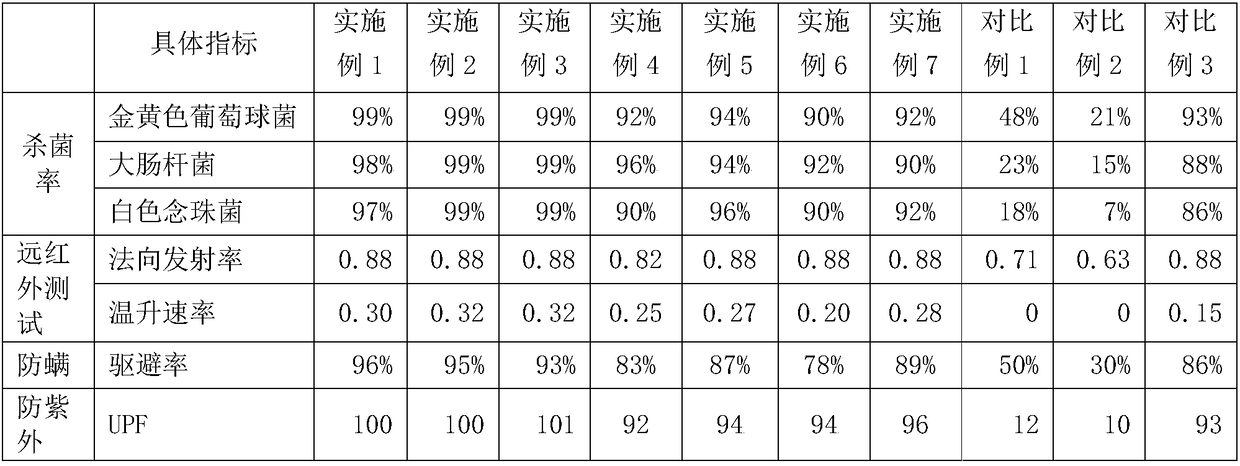

Examples

Embodiment 1

[0046] The present embodiment provides a preparation method of graphene composite non-woven fabric, comprising the following steps:

[0047] A1. Use polypropylene to prepare non-woven fabrics by spunlace technology;

[0048] A2. Mix the graphene raw material with activated carbon, water, antioxidant 1076, zinc stearate and glue, and stir evenly to form a spray solution;

[0049] A3, the spray liquid formed in step A2 is evenly sprayed on the non-woven fabric obtained in step A1 by an air compressor, and is dried and rolled to obtain a graphene composite non-woven fabric.

[0050] The spraying liquid includes the following components by mass percentage: graphene raw material 2.5%, activated carbon 15%, acrylate glue 40%, antioxidant 0.8%, zinc stearate 0.3%, and the balance is water. The spray amount of spray liquid is per 1m 2 Spray 30g on the non-woven fabric.

[0051] The graphene raw material is a mixture of carbon dioxide supercritical expansion exfoliation graphene and...

Embodiment 2

[0053] The present embodiment provides a preparation method of graphene composite non-woven fabric, comprising the following steps:

[0054] A1. Use polyester to prepare non-woven fabric by heat sealing technology;

[0055] A2. Mix the graphene raw material with activated carbon, water, antioxidant 1076, calcium stearate and glue, and stir evenly to form a spray solution;

[0056] A3, the spray liquid formed in step A2 is evenly sprayed on the non-woven fabric obtained in step A1 by an air compressor, and is dried and rolled to obtain a graphene composite non-woven fabric.

[0057] The spraying liquid includes the following components by mass percentage: graphene raw material 3%, activated carbon 25%, natural latex 30%, antioxidant 0.3%, calcium stearate 0.5%, and the balance is water. The spray amount of spray liquid is per 1m 2 Spray 50g on the non-woven fabric.

[0058] The graphene raw material is a mixture of carbon dioxide supercritical expansion exfoliation graphene ...

Embodiment 3

[0060] The present embodiment provides a preparation method of graphene composite non-woven fabric, comprising the following steps:

[0061] A1. The non-woven fabric is prepared by melt-blown technology using ethylene;

[0062] A2. Mix the graphene raw material with activated carbon, water, antioxidant 1076, calcium stearate and glue, and stir evenly to form a spray solution;

[0063] A3, the spray liquid formed in step A2 is evenly sprayed on the non-woven fabric obtained in step A1 by an air compressor, and is dried and rolled to obtain a graphene composite non-woven fabric.

[0064] The spraying liquid includes the following components by mass percentage: graphene raw material 4%, activated carbon 20%, natural latex 20%, antioxidant 0.5%, calcium stearate 1%, and the balance is water. The spray amount of spray liquid is per 1m 2 Spray 80g on the non-woven fabric.

[0065] The graphene raw material is a mixture of carbon dioxide supercritical expansion exfoliation graphen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com