A kind of long-acting anti-mite, anti-mildew, antibacterial PP nonwoven fabric and preparation method thereof

A non-woven, long-lasting technology, used in non-woven fabrics, rayon manufacturing, textiles and paper making, etc., can solve the problems of anti-mite, poor antibacterial durability, anti-mite, reduced antibacterial effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0101] The preparation of embodiment 1 anti-mite, anti-mildew, antibacterial masterbatch

[0102] Using polypropylene as the carrier of the masterbatch, prepare the anti-mite, anti-mildew and antibacterial masterbatch according to the formula shown in Table 1:

[0103] Table 1 Anti-mite, anti-mildew, anti-bacterial masterbatch formula

[0104] sample

Embodiment 2

[0105] Embodiment 2 Preparation of long-acting anti-mite, anti-mildew, antibacterial PP spunbond non-woven fabric

[0106] The functional masterbatch sample obtained in embodiment 1 is made into non-woven fabric through the following (spun-bonding) steps:

[0107] Feeding→melting→filtering→spinning→cooling→drawing→laying→consolidation→winding

[0108] 1. Feeding:

[0109] Raw material: polypropylene, the addition amount is 95-99.9% (wt)

[0110] Masterbatch: the functional masterbatch obtained in Example 1, injection amount 0.1-5% (wt)

[0111] Equipment: suction system, injection machine

[0112] Process description: Through the suction system and the injection machine, according to the accurate metering ratio, the polypropylene raw material and the functional masterbatch obtained in Example 1 are sent to the screw extruder for preliminary mixing.

[0113] 2. Melting:

[0114] Equipment: screw extruder

[0115] The temperature control of each zone in zone 1-6 of the ext...

Embodiment 3

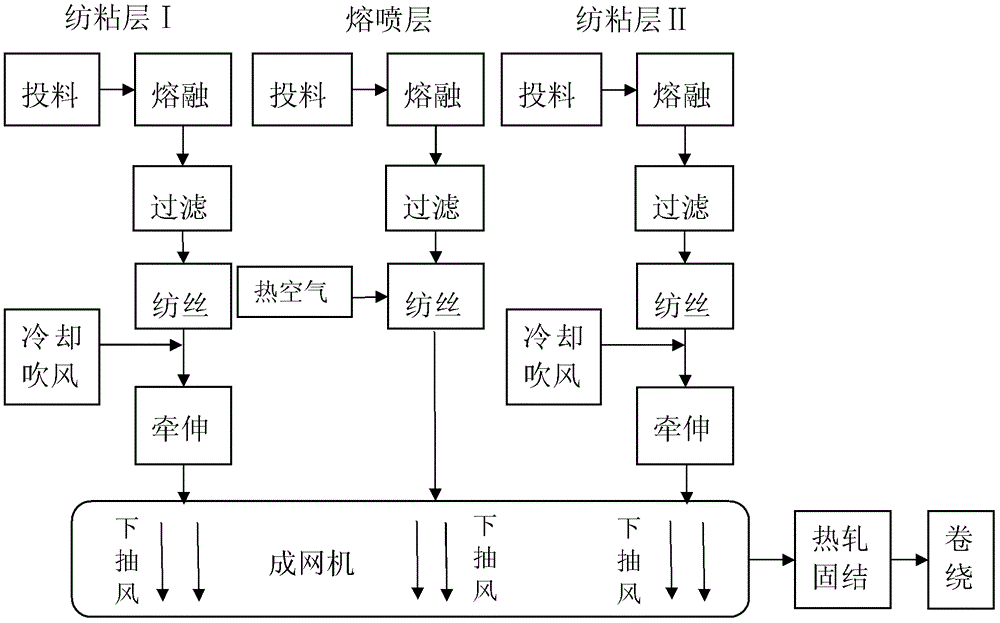

[0146] Example 3 Preparation of long-acting anti-mite, anti-mildew, antibacterial PP spunbond-meltblown-spunbond nonwoven fabric

[0147] The functional masterbatch sample obtained in embodiment 1 is made into a non-woven fabric through the following (spun-bonded-melt-blown-spun-bonded) steps:

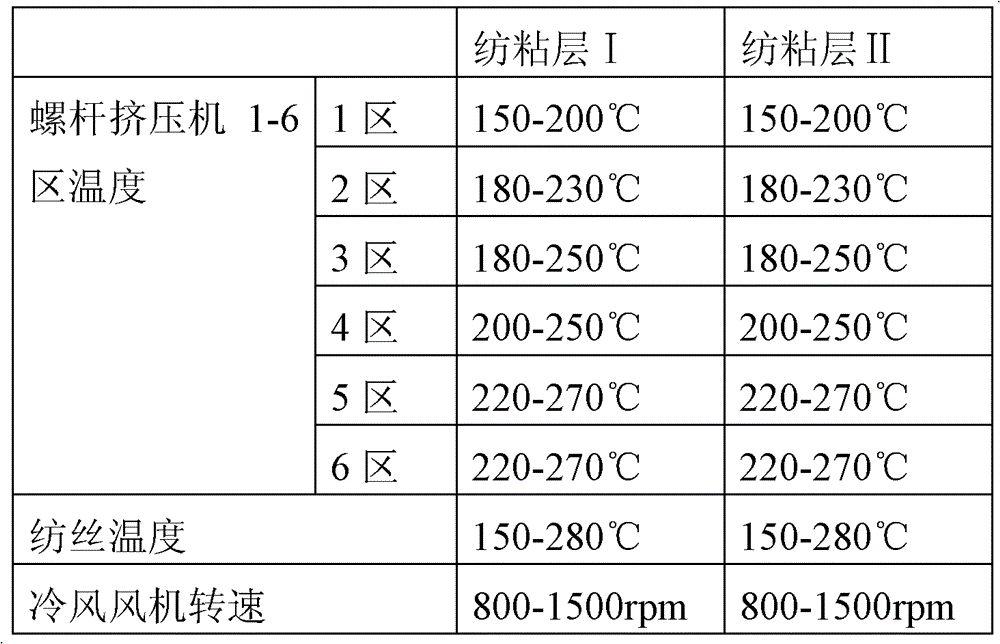

[0148] According to the spinning steps of the spunbond layer in Example 2: feeding→melting→filtering→spinning→cooling→drawing, the process parameters are as follows, see Table 2.

[0149] Table 2 process parameters

[0150]

[0151] Spinning steps of meltblown layer:

[0152] Feeding→melting→filtering→spinning

[0153] 1. Feeding:

[0154] Raw material: polypropylene, the addition amount is 95-99.9% (wt)

[0155] Masterbatch: the functional masterbatch obtained in Example 1, injection amount 0.1-5% (wt)

[0156] Equipment: suction system, injection machine

[0157] Process description: Through the suction system and the injection machine, according to the accurate metering rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com