Antibacterial moisture-absorbing sweat-releasing type composite 14-needle stitch bonded cloth and preparation method thereof

A technology of moisture absorption and perspiration, Lixin cloth, applied in the direction of knitting, warp knitting, heating/cooling fabrics, etc. Close fit, improved effect, improved applicability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

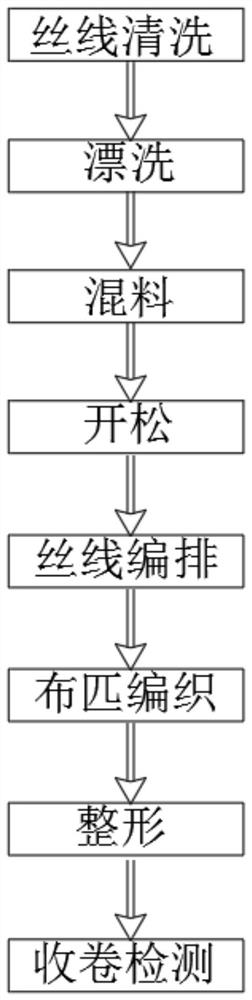

[0033] refer to figure 1 , an antibacterial, moisture-absorbing and sweat-wicking cloth conforming to 14 needles and a preparation method thereof, comprising the following steps:

[0034] S1: Silk thread cleaning, select 10-30 parts of copper fiber, 23-50 parts of polyester yarn, 10-23 parts of wood pulp yarn;

[0035] S2: rinsing, the selected yarns and polyester filaments are rinsed in clean water and then air-dried;

[0036] S3: Mixing, mixing the rinsed raw materials through a cotton blender;

[0037] S4: Opening, the raw materials are mixed and sent to the opening machine for full opening and carding, so that the fibers are fully opened and straightened, and the effect of subsequent work is improved;

[0038] S5: silk thread arrangement, select 0-13 g / m2 fiber web to pass through the reciprocating action of the cotton-feeding curtain and the reciprocating curtain, so that the web can reach 4-15 layers, and the thickness of the cotton web is 16-28cm for use in the next p...

Embodiment 2

[0045] refer to figure 1 , an antibacterial, moisture-absorbing and sweat-wicking cloth conforming to 14 needles and a preparation method thereof, comprising the following steps:

[0046] S1: Silk thread cleaning, select 12-28 parts of copper fiber, 24-45 parts of polyester yarn, 12-20 parts of wood pulp yarn;

[0047] S2: rinsing, the selected yarns and polyester filaments are rinsed in clean water and then air-dried;

[0048] S3: Mixing, mixing the rinsed raw materials through a cotton blender;

[0049] S4: Opening, the raw materials are mixed and sent to the opening machine for full opening and carding, so that the fibers are fully opened and straightened, and the effect of subsequent work is improved;

[0050] S5: Silk thread arrangement, select 0-12 g / m2 fiber web through the reciprocating action of the cotton-feeding curtain and the reciprocating curtain, so that the web can reach 4-16 layers, and the thickness of the cotton web is 16-26cm for use in the next process; ...

Embodiment 3

[0057] refer to figure 1 , an antibacterial, moisture-absorbing and sweat-wicking cloth conforming to 14 needles and a preparation method thereof, comprising the following steps:

[0058] S1: Silk thread cleaning, select 15-29 parts of copper fiber, 14-36 parts of polyester yarn, 11-22 parts of wood pulp yarn;

[0059] S2: rinsing, the selected yarns and polyester filaments are rinsed in clean water and then air-dried;

[0060] S3: Mixing, mixing the rinsed raw materials through a cotton blender;

[0061] S4: Opening, the raw materials are mixed and sent to the opening machine for full opening and carding, so that the fibers are fully opened and straightened, and the effect of subsequent work is improved;

[0062] S5: Silk thread arrangement, select 0-12 g / m2 fiber web through the reciprocating action of the cotton-feeding curtain and the reciprocating curtain, so that the web can reach 4-16 layers, and the thickness of the cotton web is 16-26cm for use in the next process; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com