Safety floor drain with floating cover

A safe, floating cover technology, used in waterway systems, indoor sanitary pipe installations, drainage structures, etc., can solve the problems of easy overflow of ground water, poor water inflow, blockage of floor drains and sewerage, etc., to enhance the resistance to turbidity Ability, smooth inflow of accumulated water, long-lasting effect of deodorant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

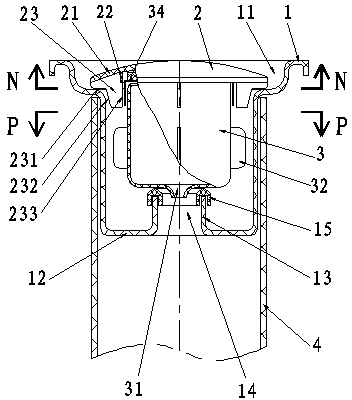

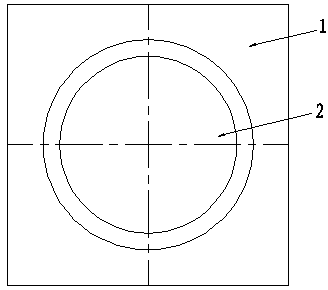

[0033] The floor drain of embodiment 1 of the present invention (structure sees figure 1 — Figure 4 ), including a floor drain seat 1 and a floor drain cover 2 located at its upper end, and at least three evenly distributed ribs 23 are arranged on the lower side of the floor drain cover 2, and the ribs 23 are movably supported on the bottom surface of the floor drain seat , make the rib 23 of the floor drain cover 2 contact the surrounding space of the bottom surface of the seat groove 11 to form a preset water inlet gap, so that the ground water can flow through the water inlet gap and be poured into the floor drain. The floor drain cover 2 of the present invention is preferably a non-orifice floor drain cover.

[0034]The upper end of the floor drain seat 1 is provided with a seat groove 11, so that the above-mentioned floor drain cover 2 is placed in the seat groove 11, and a predetermined water entry gap is provided between the floor drain cover 2 and the side wall of t...

Embodiment 2

[0052] The floor drain of embodiment 2 of the present invention (structure sees Figure 5-8 ), including a floor drain seat and a floor drain cover located at its upper end, the upper end of the above-mentioned floor drain seat is provided with a seat groove, so that the above-mentioned floor drain cover is placed in the seat groove, and the floor drain cover and the side wall of the seat groove of the floor drain seat There is a predetermined water inlet gap between them, and the lower side of the seat groove is close to the upper end of the floor drain pipe installed in the floor or the ground, so that the upper end of the floor drain seat is at the same level or slightly lower than the floor (or floor tile surface) above, so that the ground water flows over the floor drain cover and into the water inlet gap between the side of the seat tank and the floor drain cover, and passes through the preset water inlet gap formed by the surrounding space where the floor drain cover and...

Embodiment 3

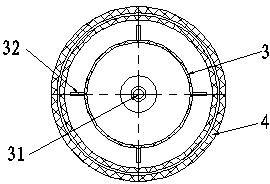

[0064] The floor drain of embodiment 3 of the present invention (structure sees Figure 9-13 ), including a floor drain seat 1 and a floor drain cover 2 located at its upper end, the floor drain seat 1 is indirectly provided with a drain hole 14, and a floating cup 3 is provided on the port of the drain hole 14 , The bottom surface of the floating cup 3 can be sealed on the port of the drain hole 14, the floor drain cover 2 is a hat-shaped cover plate 21 with a cap opening 24, and the upper end of the floating cup 3 is sleeved on the cap of the floor drain cover 2 In the mouth 24, a predetermined water inlet gap is provided between the floor drain cover 2 and the floor drain seat 1, so that the ground water flows through the gap and poured into the floor drain, so that the floating cup 3 floats, and the water in the floor drain The accumulated water is discharged into the sewer.

[0065] More specifically, the floor drain of Embodiment 3 of the present invention (see Figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com