Antibacterial film-coated member and the preparation method thereof

An antibacterial coating and titanium dioxide technology is applied in the field of antibacterial coating parts and their preparation, which can solve the problems of reducing the antibacterial effect of metal antibacterial materials, and achieve the effect of prolonging the service life and strong antibacterial effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

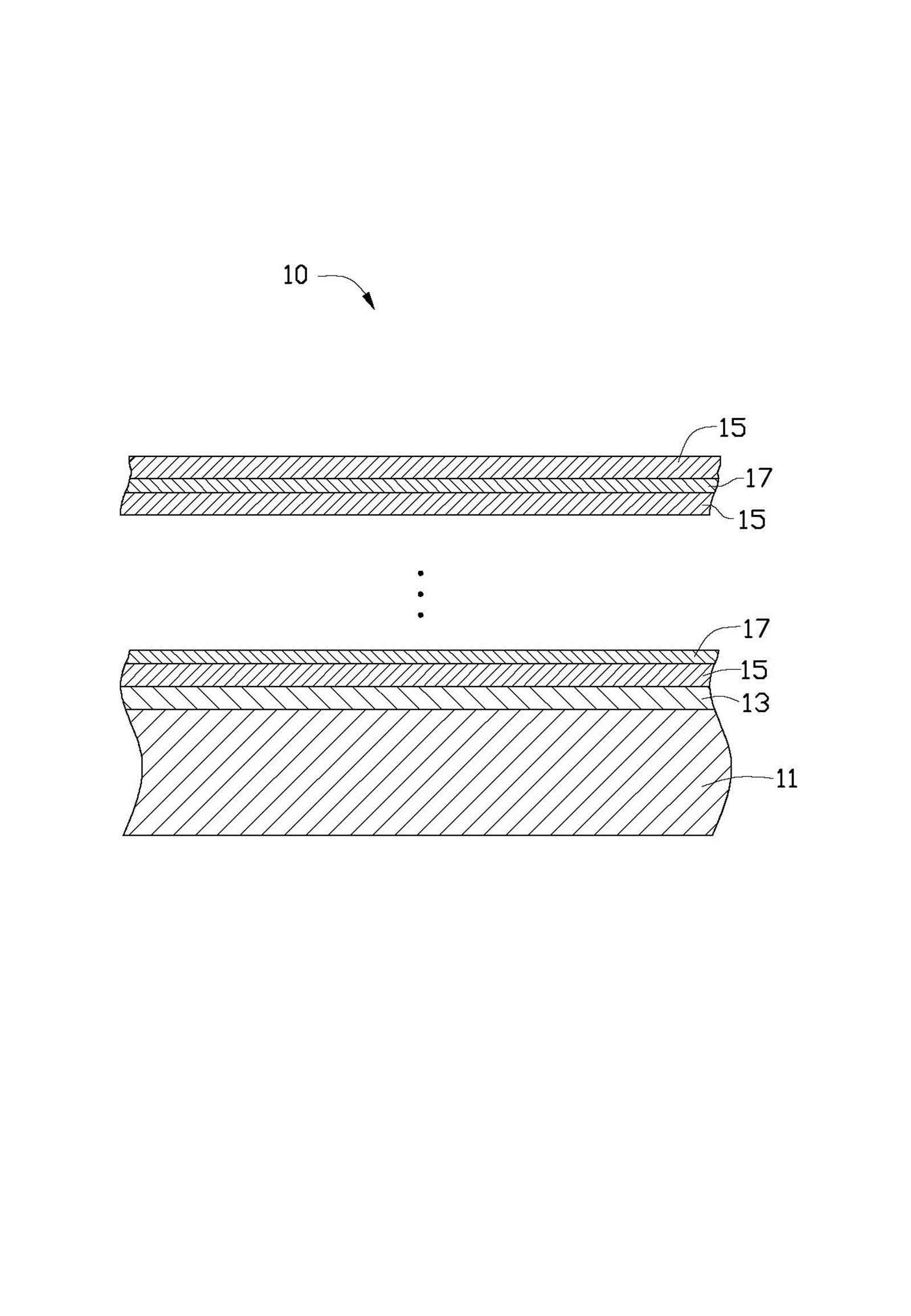

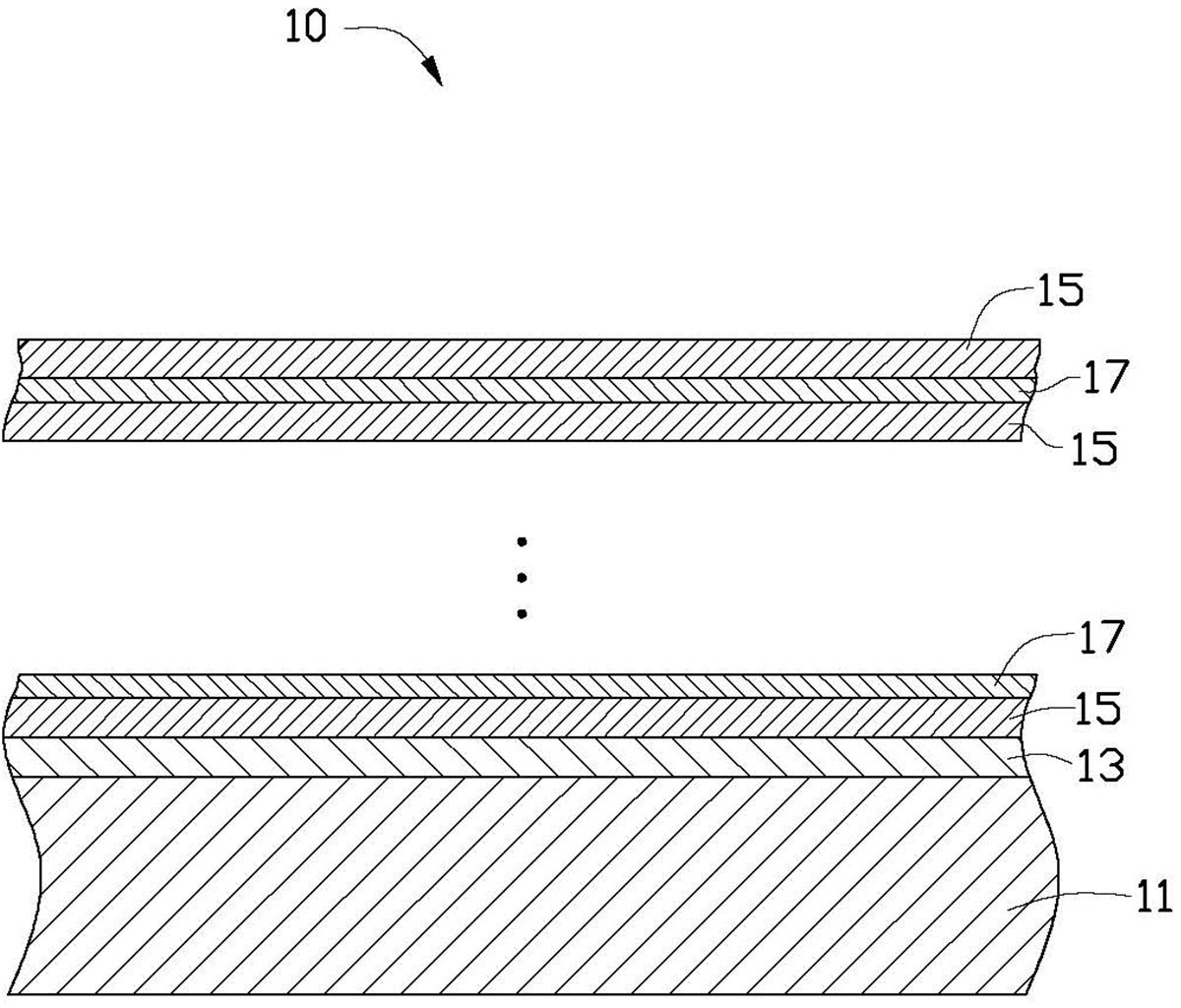

[0023] The preparation method of the antibacterial coating part 10 of a preferred embodiment of the present invention, it comprises the steps:

[0024] A substrate 11 is provided, and the material of the substrate 11 is preferably stainless steel, but not limited to stainless steel.

[0025] The substrate 11 is subjected to surface pretreatment. The surface pretreatment may include conventional steps such as ultrasonic cleaning and drying of the substrate 11 with absolute ethanol.

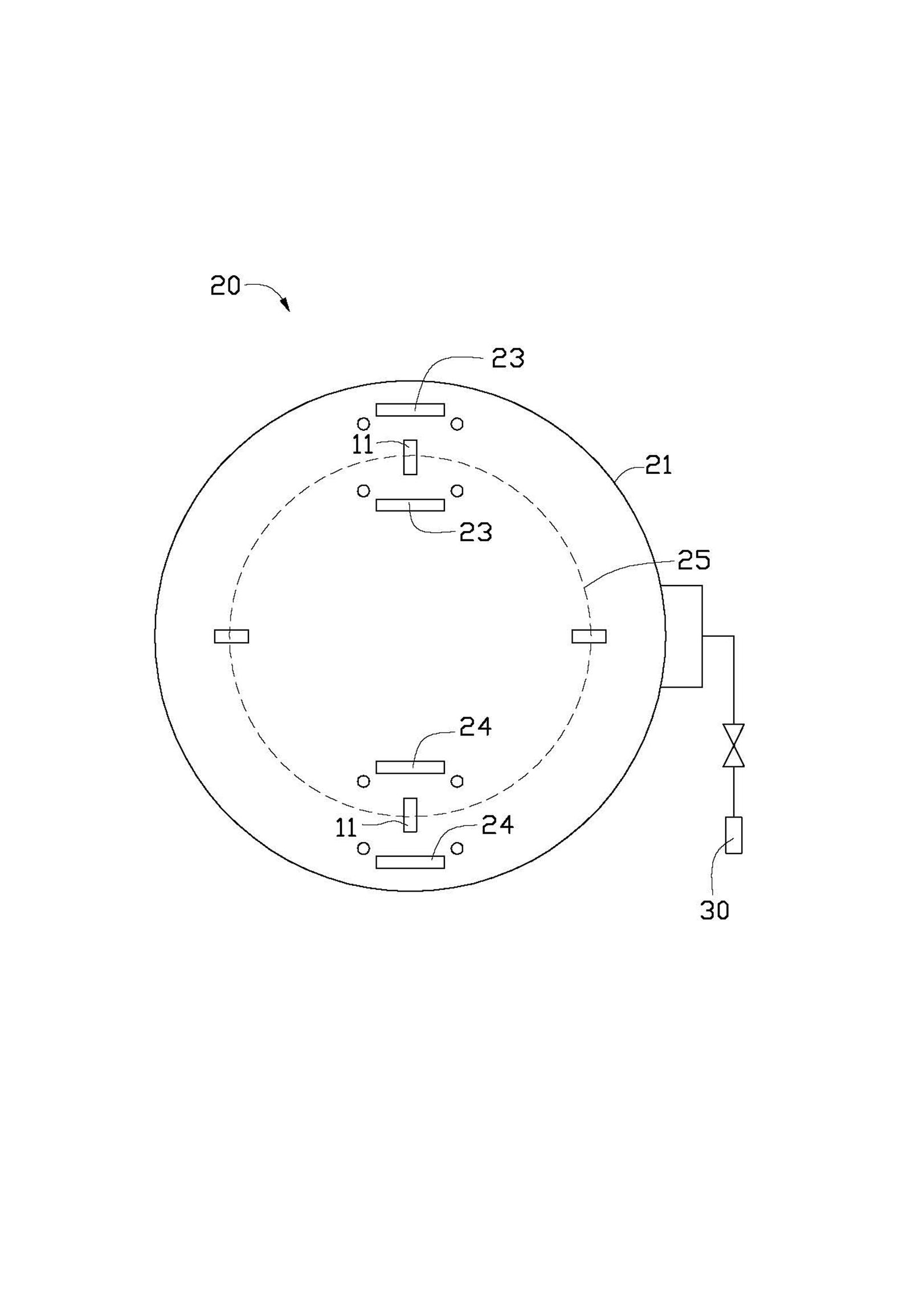

[0026] combined reference figure 2 , provide a vacuum coating machine 20, the vacuum coating machine 20 includes a coating chamber 21 and a vacuum pump 30 connected to the coating chamber 21, the vacuum pump 30 is used to evacuate the coating chamber 21. The coating chamber 21 is provided with a turntable (not shown), two titanium targets 23 and two copper targets 24 . The turntable drives the base material 11 to revolve along the circular track 25 , and the base material 11 also rotates when i...

Embodiment 1

[0033] The vacuum coating machine 20 used in this embodiment is a magnetron sputtering coating machine.

[0034] The material of the substrate 11 used in this embodiment is stainless steel.

[0035] Sputtering primer layer 13: the power of titanium target 23 is 8kw, the flow rate of argon gas is 150sccm, the bias voltage of substrate 11 is -100V, the coating temperature is 120°C, and the coating time is 10min; the thickness of the primer layer 13 is 100nm;

[0036] Sputtering titanium dioxide layer 15: the power of titanium target 23 is 8kw, the flow rate of argon gas is 150sccm, the flow rate of oxygen gas is 70sccm, the bias voltage of substrate 11 is -100V, the coating temperature is 120°C, and the coating time is 10min; the titanium dioxide layer The thickness is 50nm.

[0037] Sputtering metal copper layer 17: the power of copper target 24 is 5kw, the bias voltage of substrate 11 is -100V, the flow rate of argon gas is 150sccm, the coating temperature is 120°C, and the c...

Embodiment 2

[0040] The vacuum coating machine 20 and the substrate 11 used in this embodiment are the same as those in Embodiment 1.

[0041] Sputtering primer layer 13: the power of titanium target 23 is 8kw, the flow rate of argon gas is 150sccm, the bias voltage of substrate 11 is -100V, the coating temperature is 120°C, and the coating time is 5min; the thickness of the primer layer 13 is 50nm;

[0042] Sputtering titanium dioxide layer 15: the power of titanium target 23 is 10kw, the flow rate of argon gas is 150sccm, the flow rate of oxygen gas is 100sccm, the bias voltage of substrate 11 is -100V, the coating temperature is 120°C, and the coating time is 15min; the titanium dioxide layer The thickness is 90nm.

[0043] Sputtering metal copper layer 17: the power of copper target 24 is 5kw, the bias voltage of substrate 11 is -100V, the flow rate of argon gas is 150sccm, the coating temperature is 120°C, and the coating time is 5min; the thickness of the metal copper layer 17 is 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com