Antibacterial, mildew-proof and flame-retardant silicate interior wall coating and preparation method thereof

An interior wall coating, anti-bacterial and anti-mildew technology, applied in alkali metal silicate coatings, fire-resistant coatings, anti-fouling/underwater coatings, etc., can solve waste of resources and energy, wall hollowing, environmental pollution, etc. problem, to achieve the effect of air permeability guarantee, long service life and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

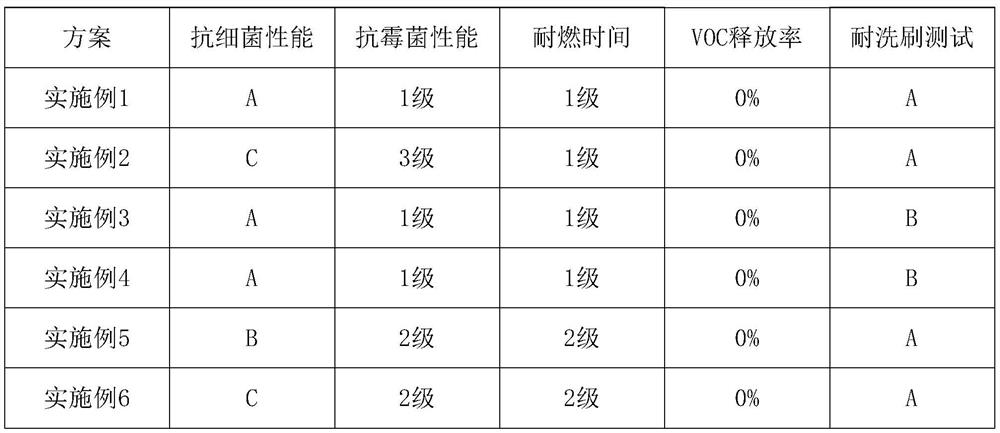

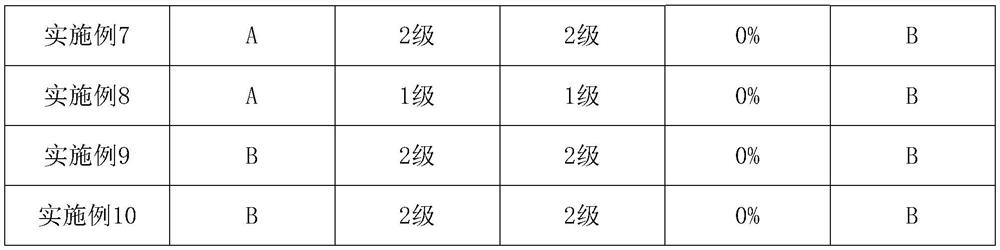

Examples

preparation example Construction

[0048] The present invention does not have special limitation to the preparation method of described carrier nano-silver, for example, 1-100g kaolin, 10-1000ml mass percent content is the dimethylsulfoxide (DOSO) solution of 1%-100% and stirs 24- After 72 hours, a kaolin / dimethyl sulfoxide complex was formed; after that, wash twice with pure water and once with an organic solvent to remove impurities and excess dimethyl sulfoxide, and the organic solvent can be one of methanol and ethanol species; then the washed kaolin / dimethyl sulfoxide complex is dried in an oven, the temperature in the oven is 40-90°C, and then the dried kaolin / dimethyl sulfoxide complex is combined with surface active The surfactant is mixed and stirred evenly with a mass ratio of 200:1-2:1, and the surfactant can be any one, two or more of cationic, anionic and nonionic surfactants; after that, each 1- Add 10-1000ml of silver ammonia solution with a concentration of 0.001-1mol / L to 100g of kaolin / dimethy...

Embodiment 1

[0077] This embodiment provides an antibacterial, mildew-proof and flame-retardant silicate interior wall coating, the coating includes 40 parts of slurry, 50 parts of filler, 40 parts of diluent A, 20 parts of diluent B, and 2 parts of auxiliary agent in parts by mass .

[0078] The slurry, in parts by mass, consists of 5 parts of hydroxyethyl cellulose, 0.6 parts of a wetting agent, 0.6 parts of a dispersant, 0.2 parts of a defoamer, and 0.3 parts of other additives;

[0079] The hydroxyethyl cellulose is Dow QP300; the wetting agent is composed of ethanol and ethylene glycol, and the mass ratio of ethanol and ethylene glycol is 2:1; the dispersant is sodium hexametaphosphate; defoaming The agent is Zhonglian B-313 organosilicon defoamer; the other additives include antifungal agent and antioxidant, the antifungal agent is salicylanilide, and the oxidizing agent is BASF antioxidant B215.

[0080]The filler, in parts by mass, consists of 20 parts of carrier nano-silver, 10 p...

Embodiment 2

[0090] This embodiment provides an antibacterial, mildew-proof and flame-retardant silicate interior wall coating, the coating includes 40 parts of slurry, 50 parts of filler, 40 parts of diluent A, 20 parts of diluent B, and 2 parts of auxiliary agent in parts by mass .

[0091] The slurry, in parts by mass, consists of 5 parts of hydroxyethyl cellulose, 0.6 parts of a wetting agent, 0.6 parts of a dispersant, 0.2 parts of a defoamer, and 0.3 parts of other additives;

[0092] The hydroxyethyl cellulose is Dow QP300; the wetting agent is composed of ethanol and ethylene glycol, and the mass ratio of the ethanol and ethylene glycol is 2:1; the dispersant is sodium hexametaphosphate; Described defoamer is Zhonglian B-313 organosilicon defoamer; Described other additives are antifungal agent, antioxidant, and antifungal agent is salicylanilide, and described oxidizing agent is BASF antioxidant B215 .

[0093] The filler, in parts by mass, consists of 20 parts of nano-silver po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com