Durable anti-mildew aqueous wood wax oil, preparation method thereof and application technology thereof

A wood wax oil, water-based urethane oil technology, applied in antifouling/underwater coatings, biocide-containing paints, coatings, etc., can solve the problem of poor smoothness and wear resistance of the coated surface and insufficient deep protection of the substrate , The substrate bonding degree is not high enough to achieve the effect of good compactness, strong anti-aging ability, and improved heat resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

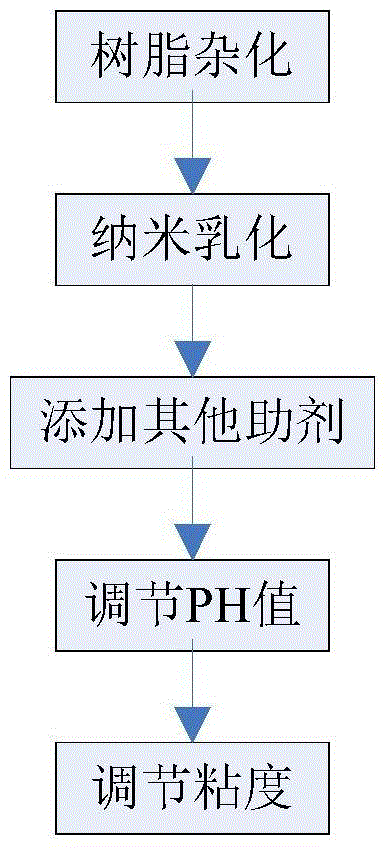

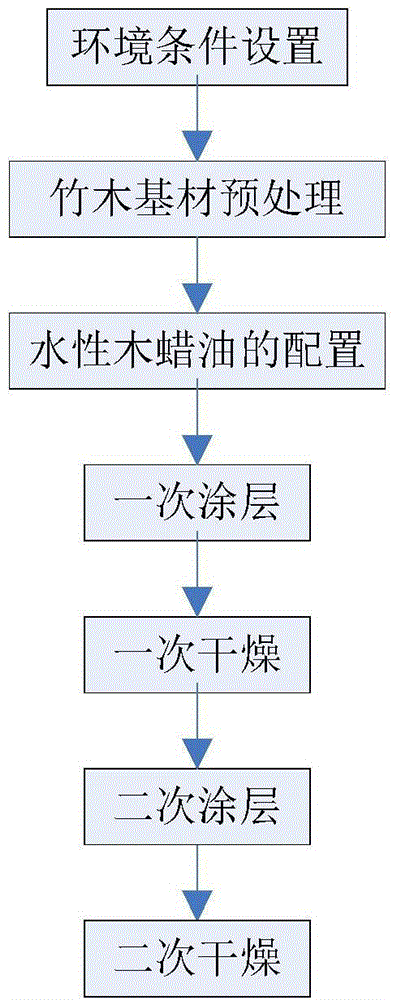

Method used

Image

Examples

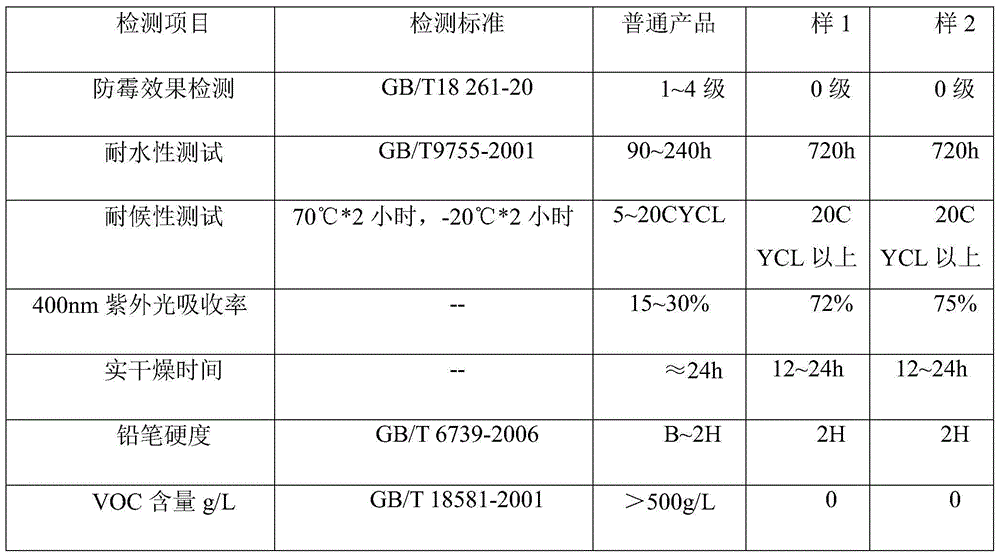

Embodiment 1

[0034] Example 1, the present invention includes 54% of water-based urethane oil, 5% of nano oxides, 3% of silane coupling agent, 10.7% of water, 3% of film-forming aids, 3% of dispersants, 3% of leveling agents, disinfectants 3% of foaming agent, 3% of wetting agent, and 0.3% of pH regulator. The invention utilizes the strong oxidative property produced by photocatalysis to inactivate microorganisms or microbial cell tissues. Since the nanoparticle itself does not participate in the reaction during the action process, there is no loss, so it has a long-term antibacterial effect. And the small nano-molecular structure can penetrate deep into the interior of the wood for a long-lasting bond without warping or peeling; inorganic nano-modification can resist strong ultraviolet rays, is more waterproof, moisture-proof and mildew-proof, does not change the natural characteristics of the wood, and the wood can breathe freely. It maintains elasticity and effectively prevents wood fro...

Embodiment 2

[0035] Example 2, the mass ratio of each component of the present invention is 80% of water-based urethane oil, 0.5% of nano-oxide, 0.2% of silane coupling agent, 16.9% of water, 2% of film-forming aid, 0.05% of dispersant, leveling Agent 0.05%, defoamer 0.05%, wetting agent 0.05%, PH regulator 0.2%.

Embodiment 3

[0036] Embodiment 3, the mass ratio of each component of the present invention is water-based urethane oil 40%, nano-oxide 10%, silane coupling agent 5%, water 20.6%, film-forming aid 4%, dispersant 5%, leveling Agent 5%, defoamer 5%, wetting agent 5%, PH regulator 0.4%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com