Water-based wood wax oil and its preparation method and application

A wood wax oil and water-based technology, applied in the field of coatings, can solve the problems of poor air permeability, easy deformation, and explosive tendons, etc., and achieve the effects of fast drying speed, easy operation, and enhanced coating film strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

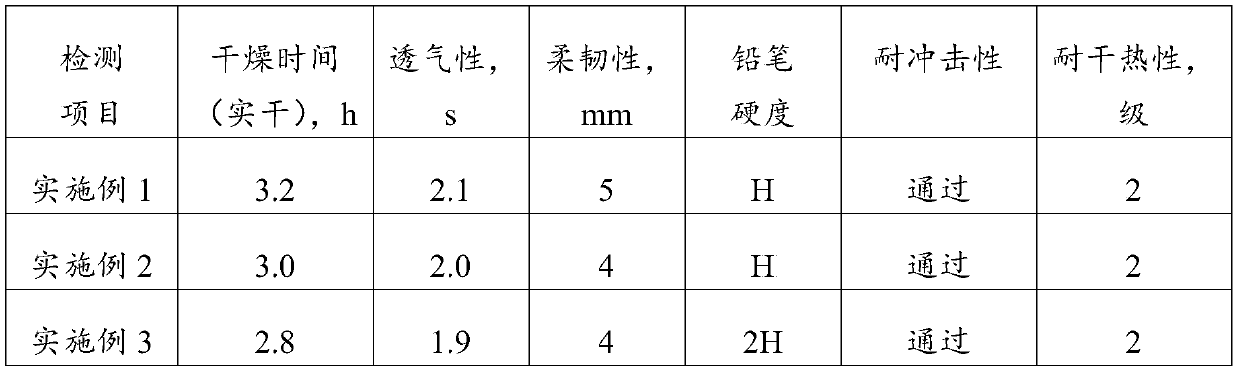

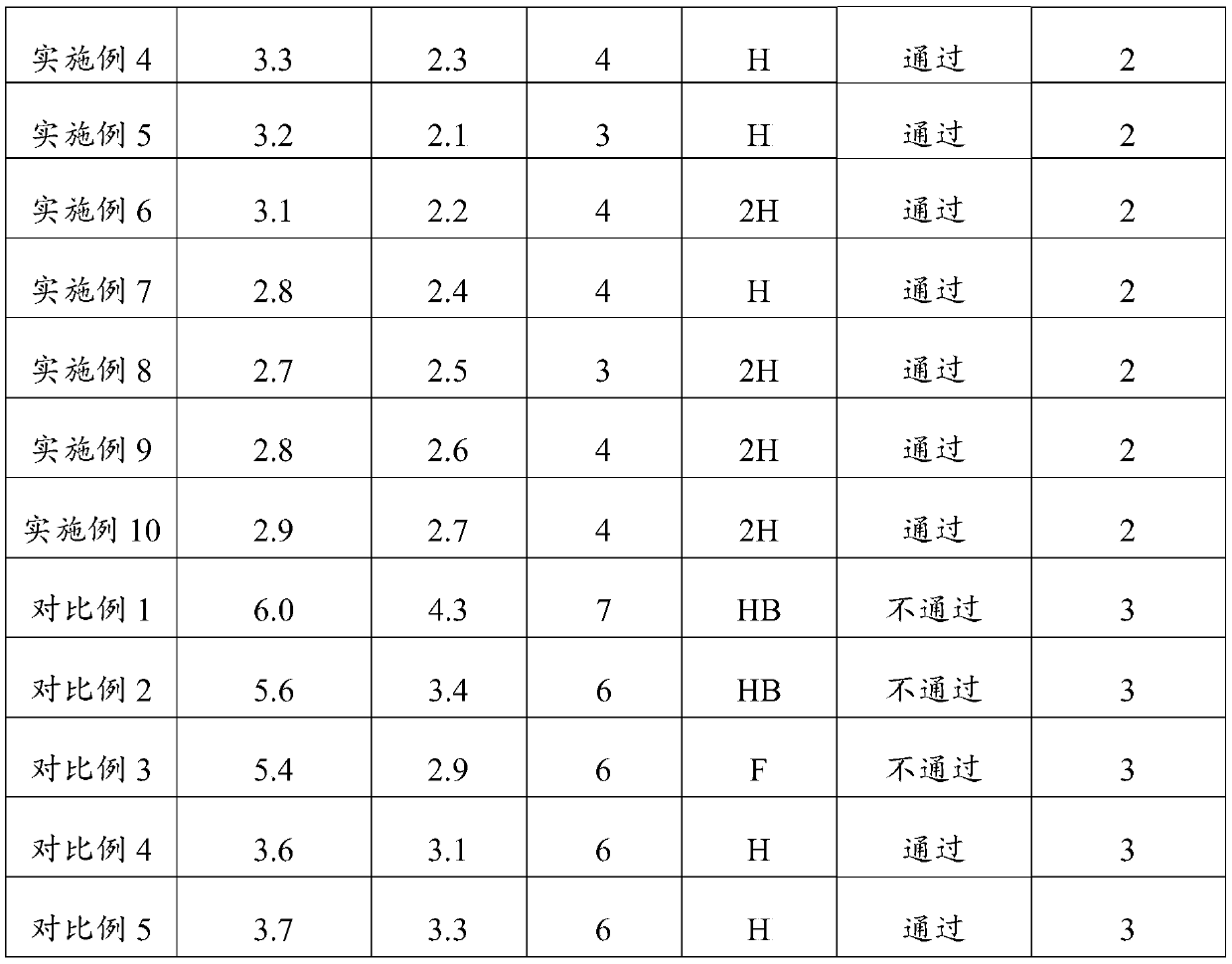

Examples

preparation example Construction

[0067] According to another aspect of the present invention, the present invention also provides a kind of preparation method of water-based wood wax oil, and this preparation method comprises the following steps:

[0068] Natural wood wax emulsion, polyurethane modified acrylic emulsion, nano-silica sol, lignocellulose, film-forming aid, glass powder, silane coupling agent and water in the formula amount, and optional polyethylene wax micropowder, polyethylene wax Emulsion, sepiolite, substrate wetting agent, defoamer and leveling agent are mixed evenly to obtain water-based wood wax oil.

[0069] The preparation method of the water-based wood wax oil provided by the invention has the advantages of simple process, easy operation and industrial production.

[0070] According to the third aspect of the present invention, the present invention also provides an application of water-based wood wax oil in wooden furniture. In view of the advantages of the above-mentioned water-bas...

Embodiment 1

[0073] A water-based wood wax oil, made from the following raw materials in parts by weight: 25 parts of natural wood wax emulsion, 25 parts of polyurethane modified acrylic emulsion, 8 parts of nano-silica sol, 3 parts of lignocellulose, 2 parts of film-forming aid , 3 parts of glass powder, 0.3 parts of silane coupling agent and 4 parts of deionized water;

[0074] Among them, the average length of lignocellulose is 10 μm, the solid content of nano-silica sol is 30%, the average particle size of silicon dioxide is 25nm, the film-forming aid is dodecyl alcohol ester, and the silane coupling agent is γ-shrink Glyceryl ether oxypropyl trimethoxysilane.

Embodiment 2

[0076] A water-based wood wax oil, made from the following raw materials in parts by weight: 25 parts of natural wood wax emulsion, 25 parts of polyurethane modified acrylic emulsion, 8 parts of nano-silica sol, 3 parts of lignocellulose, 2 parts of film-forming aid , 3 parts of glass powder, 1 part of polyethylene wax micropowder, 0.2 part of substrate wetting agent, 1 part of defoamer, 0.3 part of silane coupling agent and 4 parts of deionized water;

[0077]Among them, the average length of lignocellulose is 10 μm, the solid content of nano-silica sol is 30%, the average particle size of silicon dioxide is 25nm, the film-forming aid is dodecyl alcohol ester, and the silane coupling agent is γ-shrink Glyceryl ether oxypropyl trimethoxysilane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com